Polishing process of titanium alloy blade edges using bonded-resin diamond tools

-

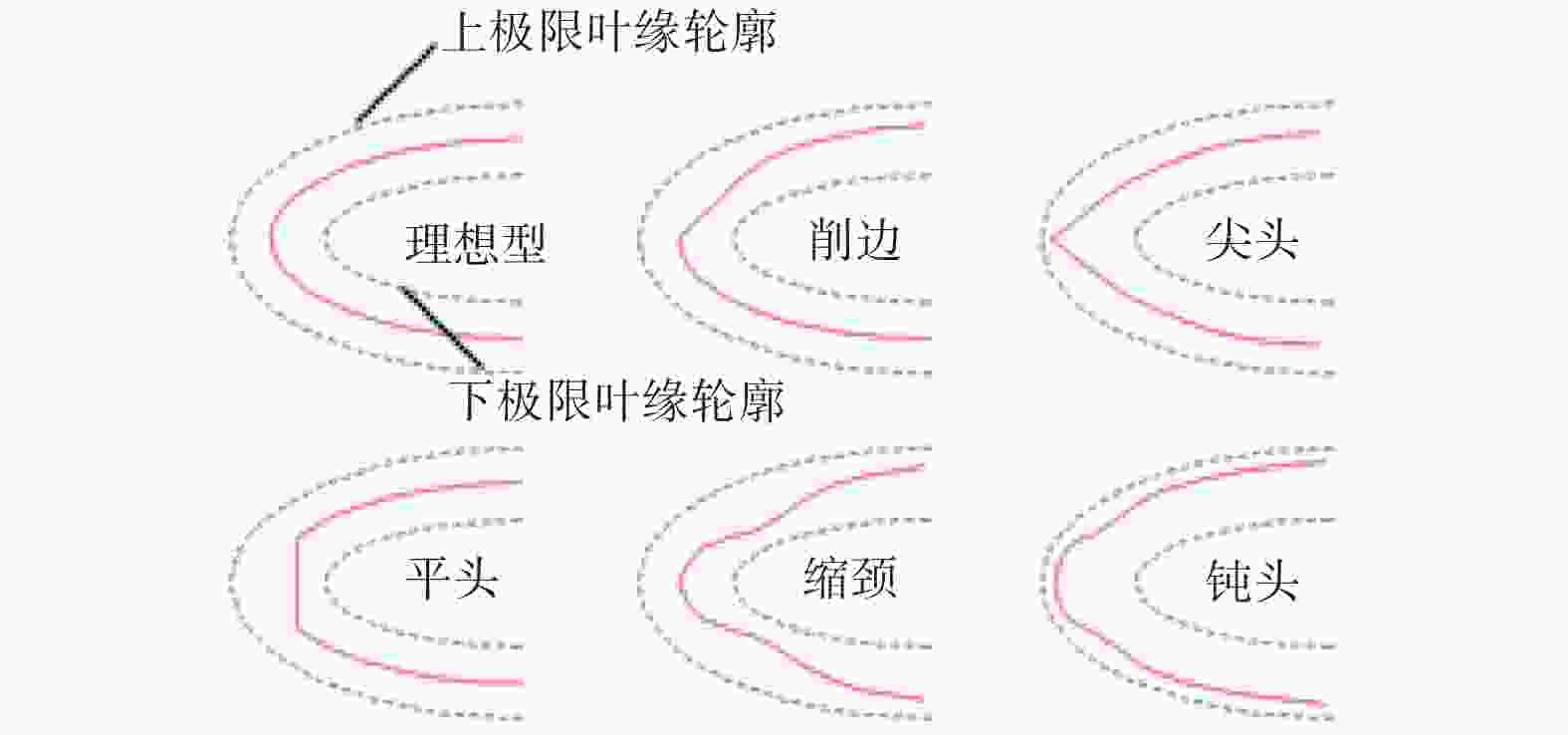

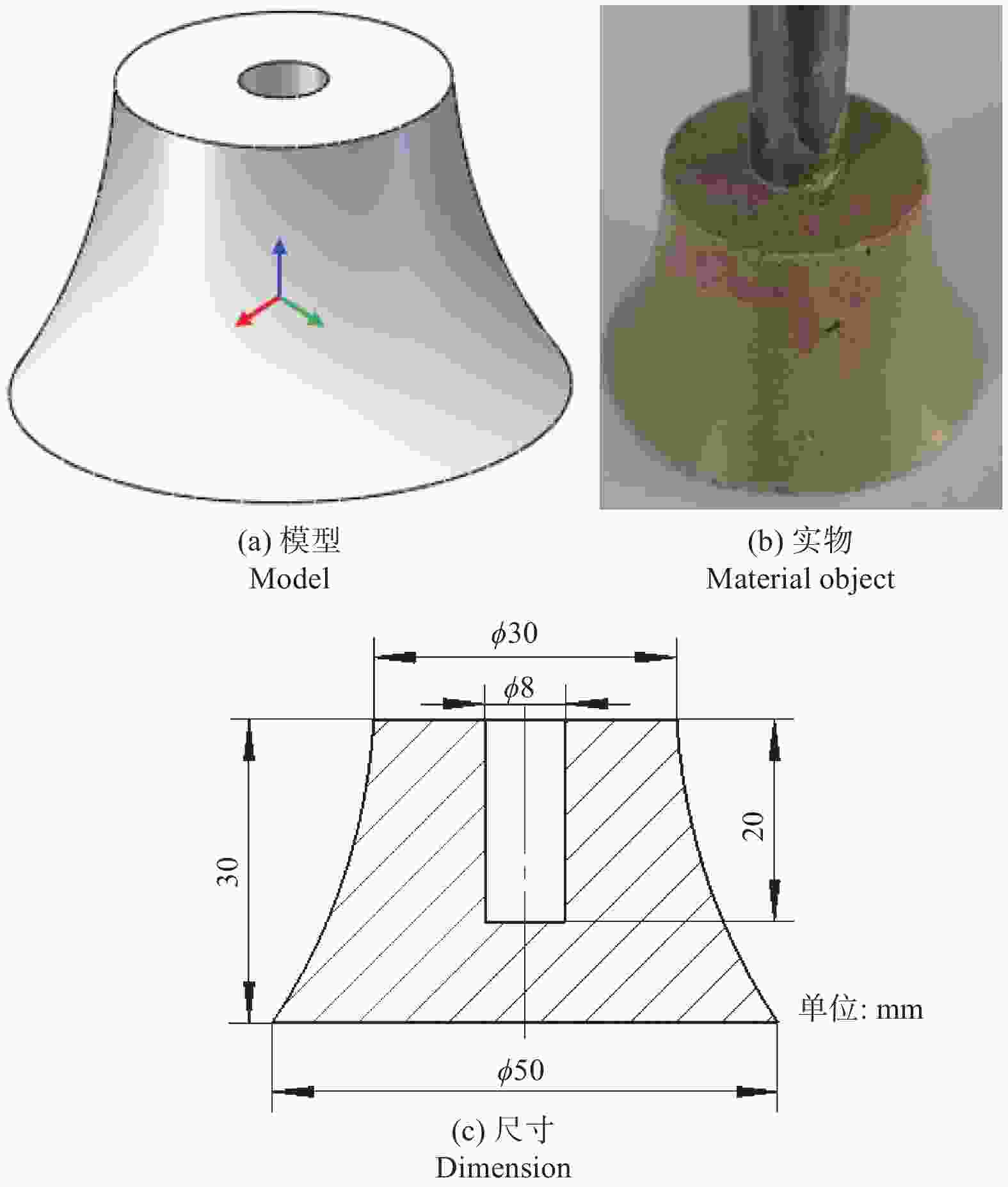

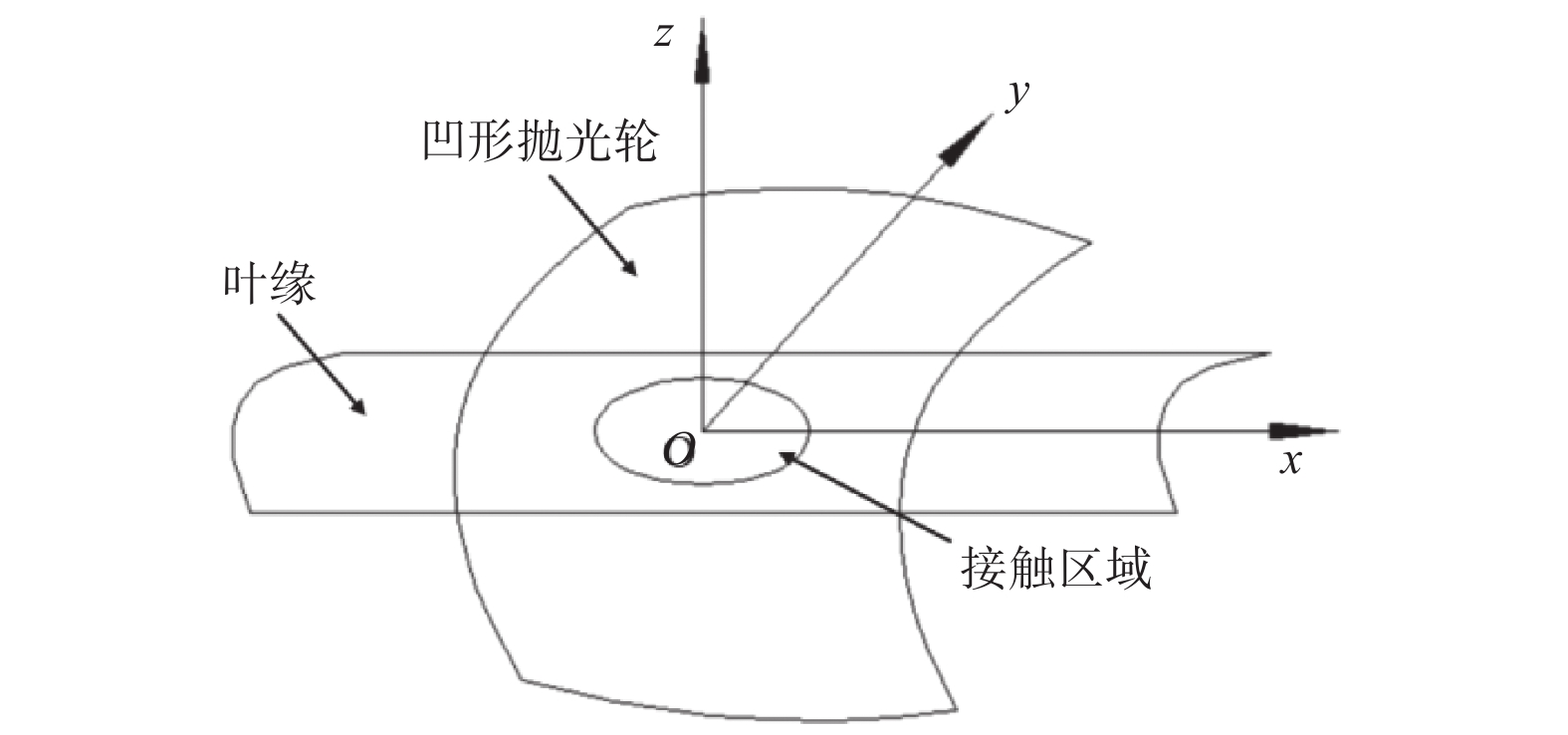

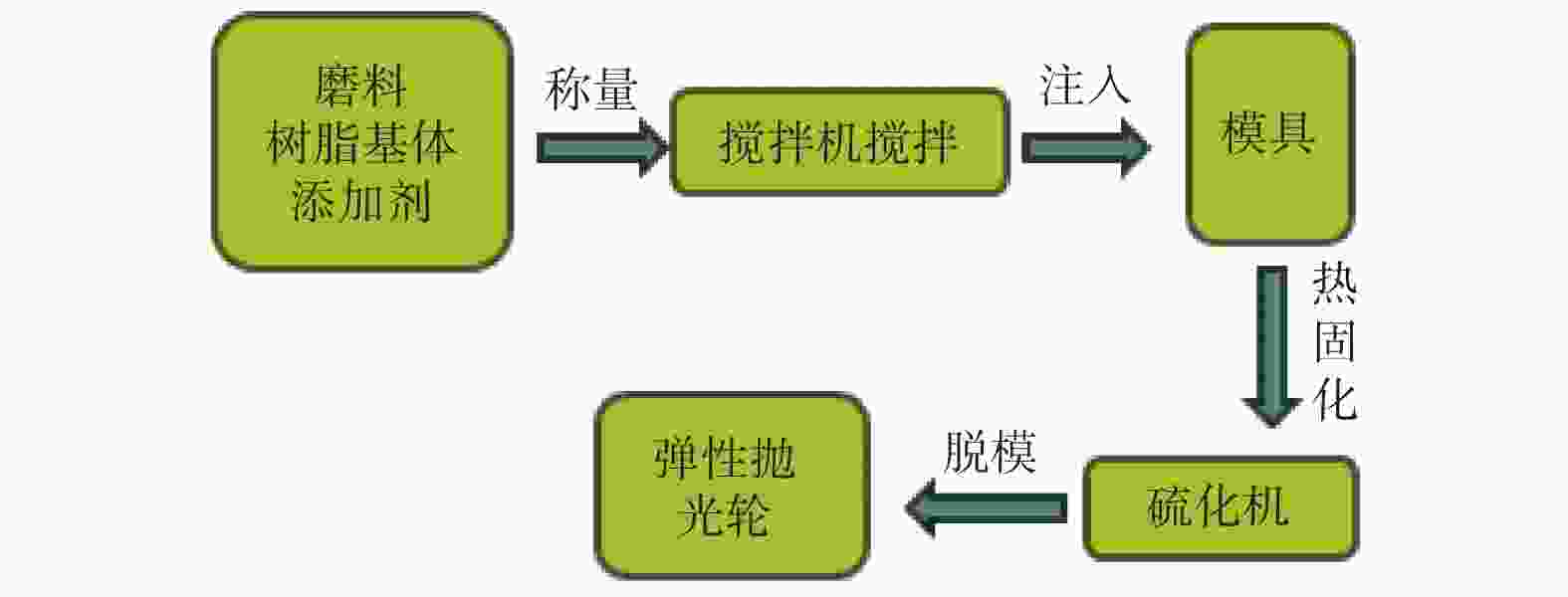

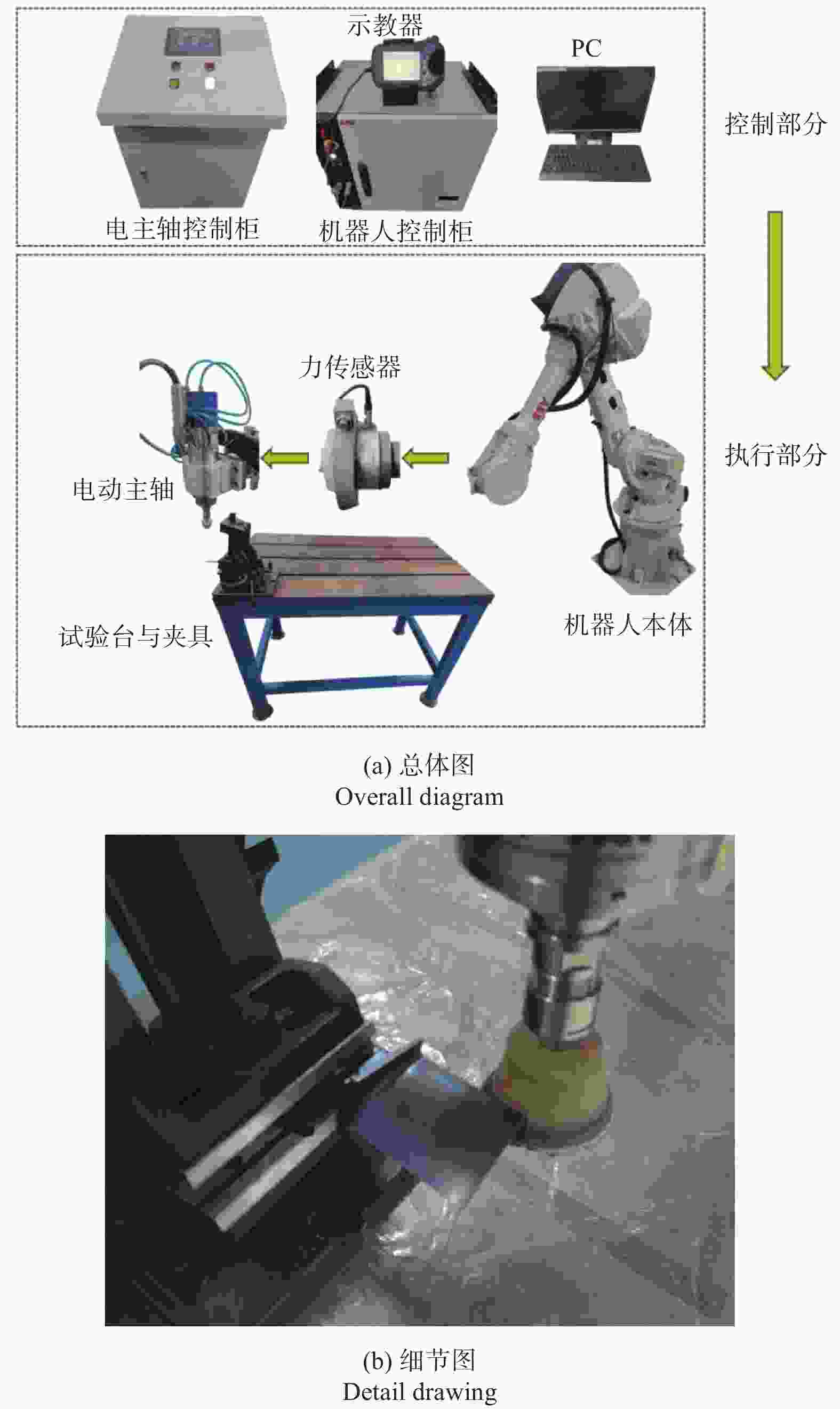

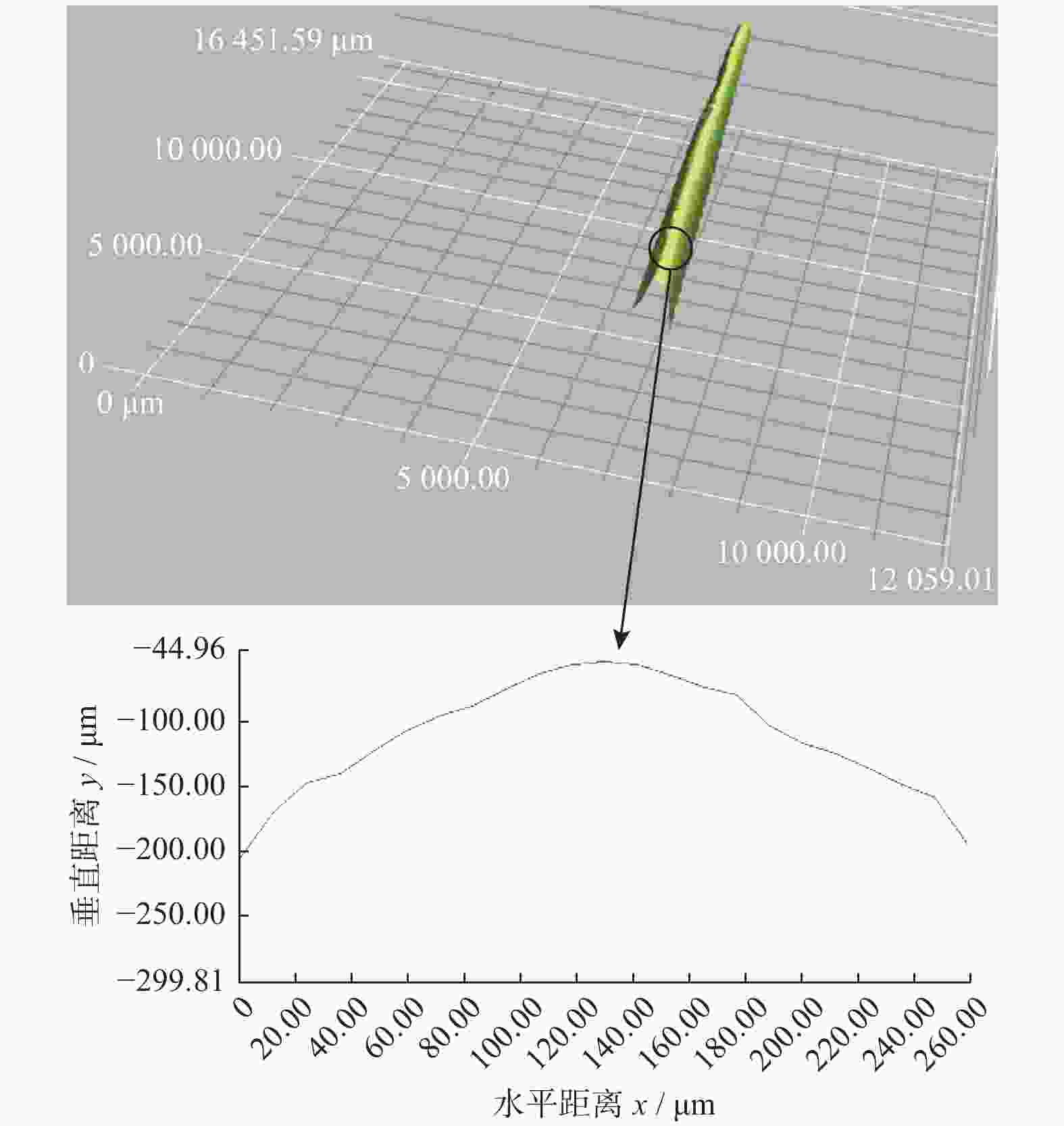

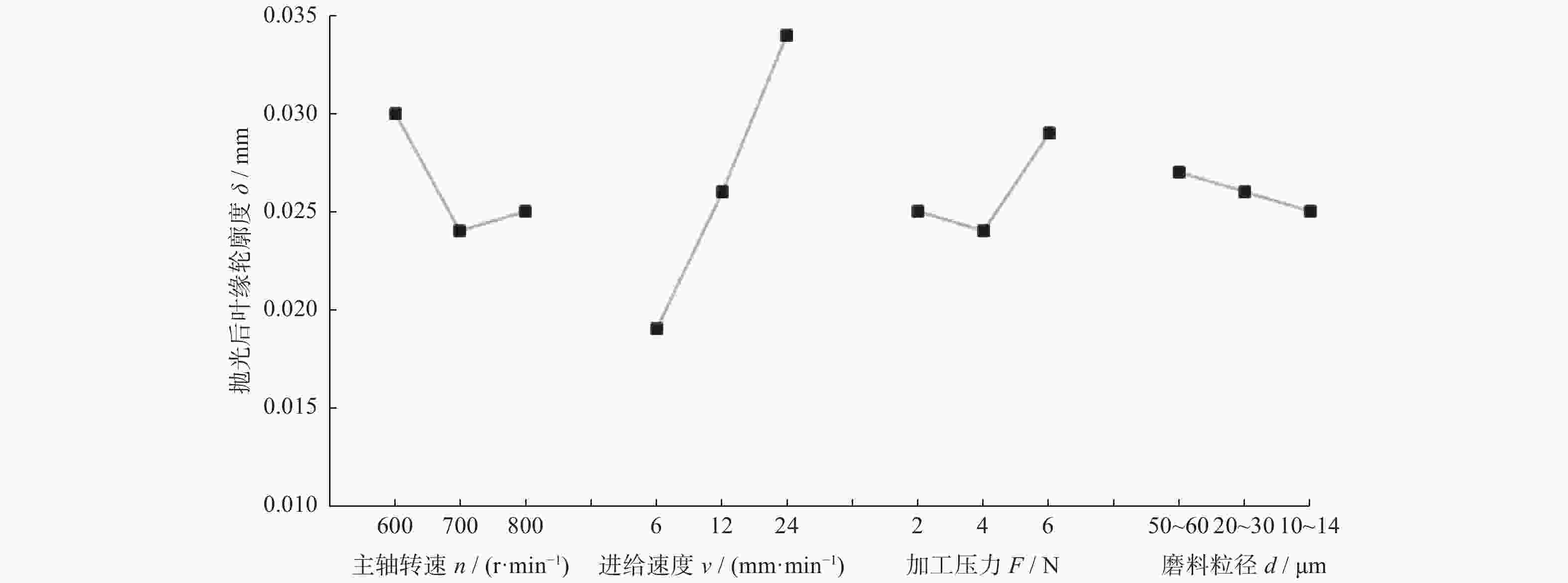

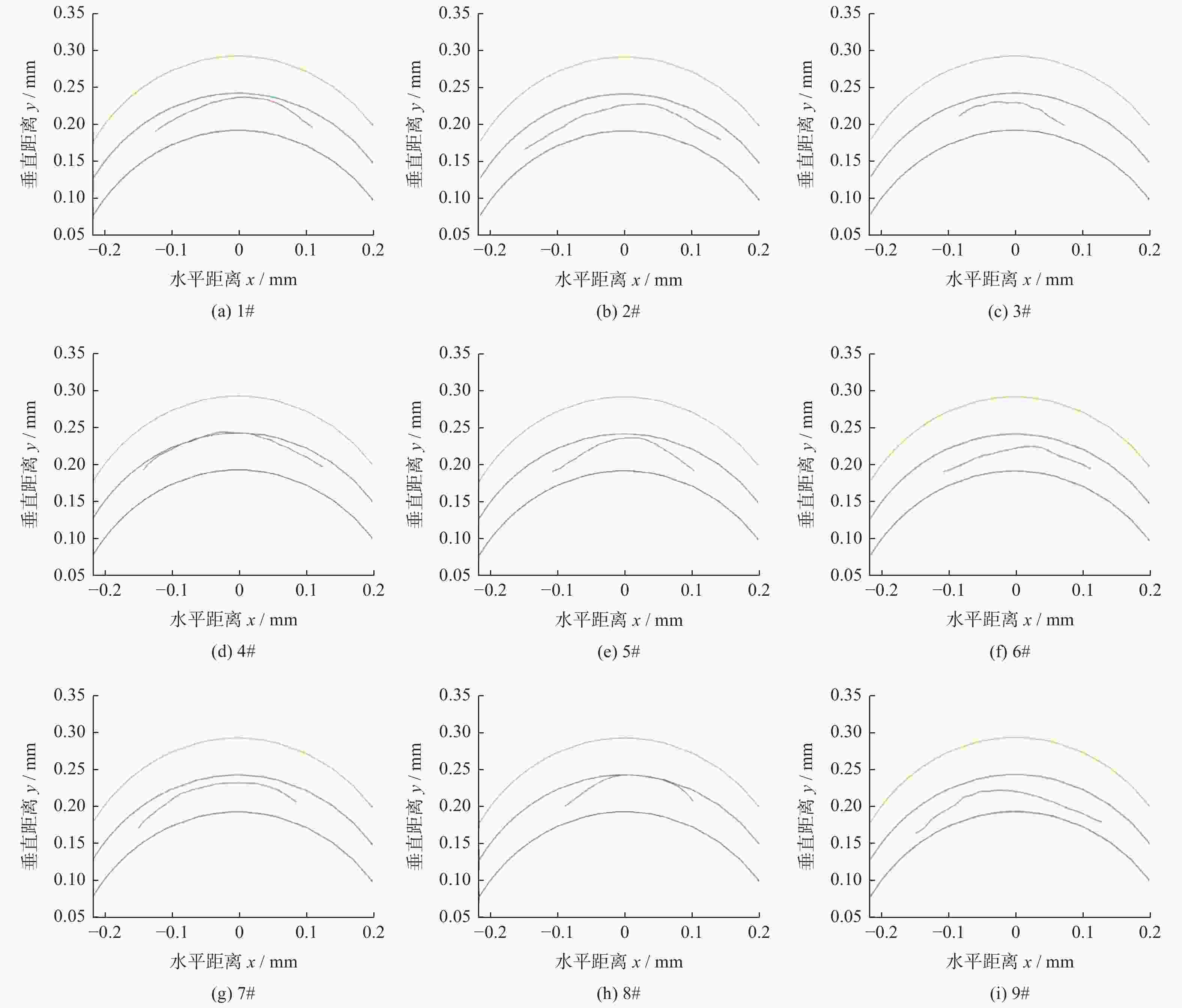

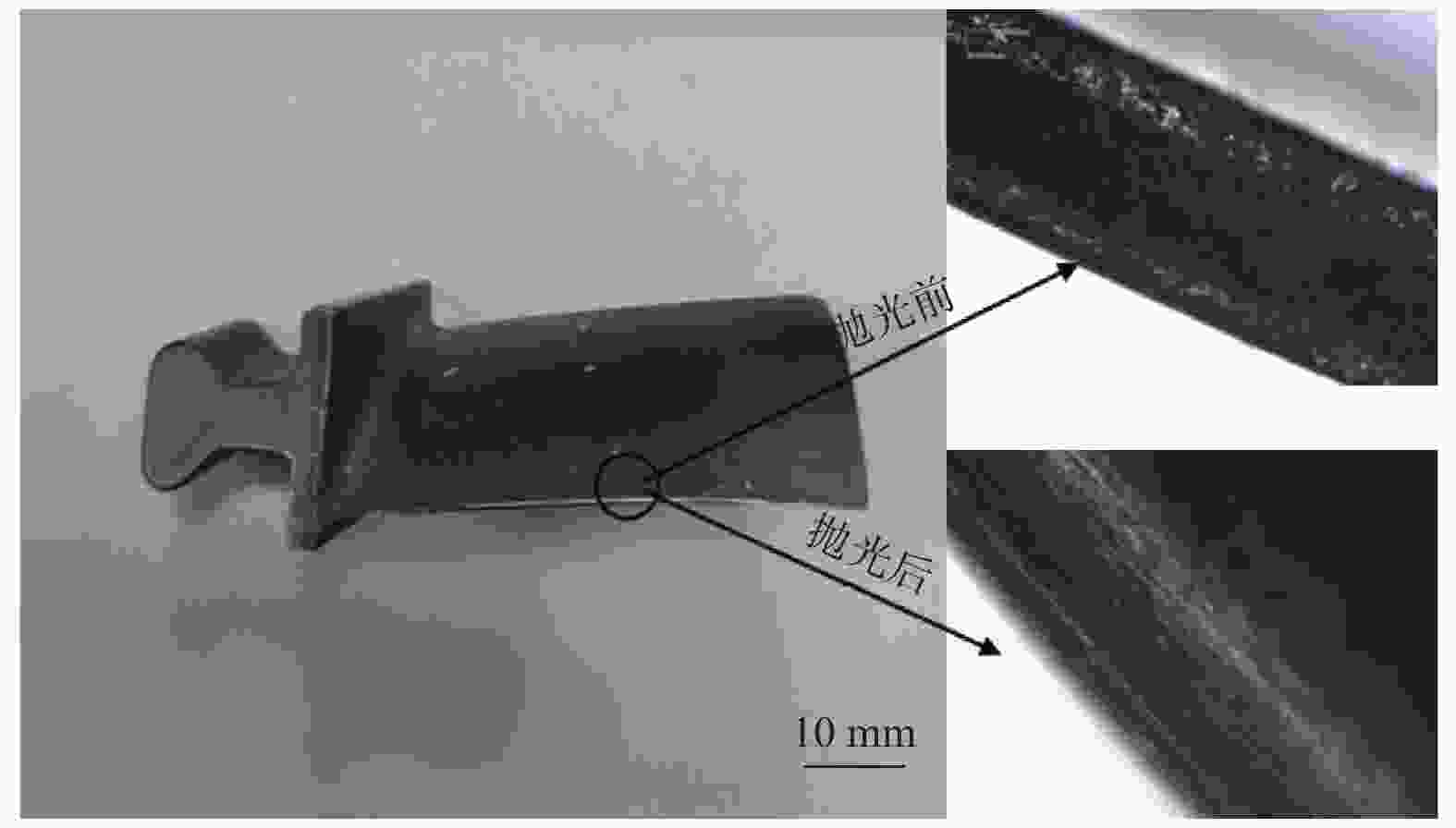

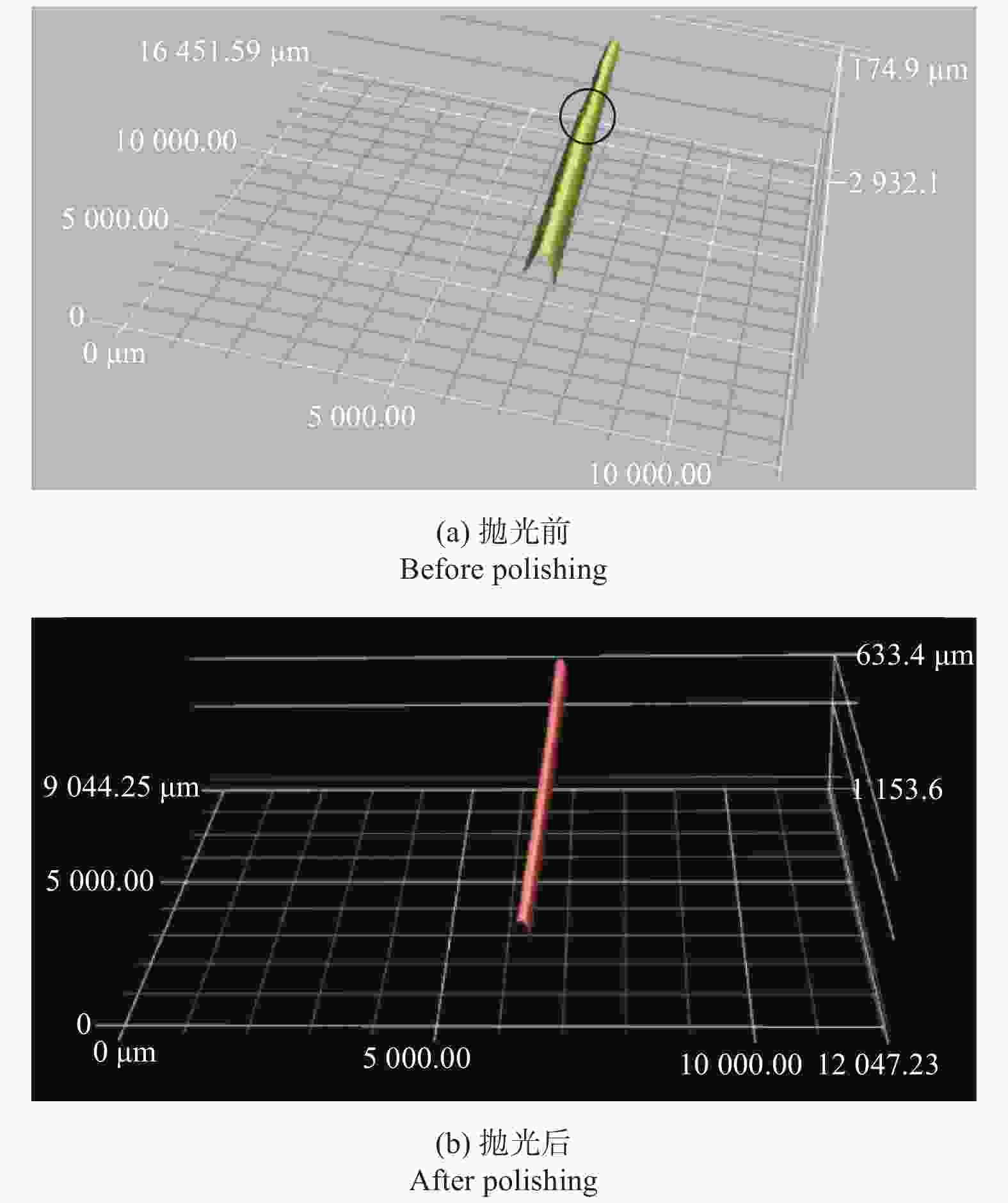

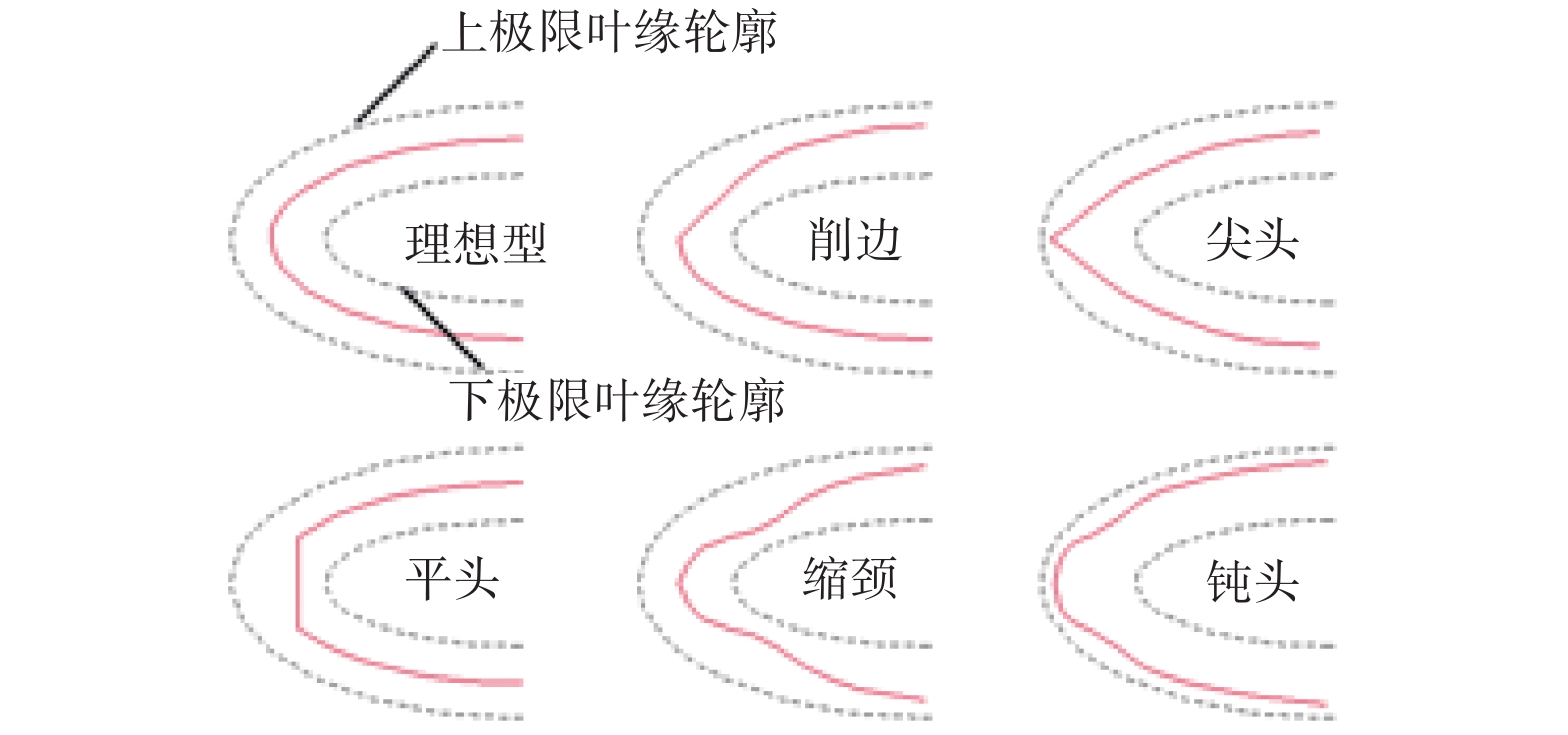

摘要: 叶缘作为航空发动机叶片的关键部位,其加工精度直接影响叶片的气动性能,降低叶缘表面粗糙度和轮廓度对延长发动机服役寿命至关重要。为此,设计并开发了固结树脂金刚石弹性抛光轮,基于机器人平台研究钛合金叶片叶缘的抛光工艺。采用正交试验法探索主轴转速、进给速度、加工压力、磨料粒径4个主要工艺参数对叶缘表面粗糙度及轮廓度的影响规律。试验确定的最佳工艺参数组合是:主轴转速为800 r/min,进给速度为6 mm/min,加工压力为4 N,磨料粒径为10~14 μm。在此最佳参数组合下,钛合金叶片叶缘抛光的综合效果较好,其表面形貌得到改善,面型精度提高,表面粗糙度由初始的1.165 μm降为0.213 μm ,轮廓度由初始的0.048 mm降为0.016 mm,可满足使用要求。Abstract: Objectives: Aero engine blades are important components in engines, and the machining accuracy of the blade edge directly affects the aerodynamic performance of the blade. Improving the surface roughness and the profile accuracy of the blade edge are crucial to improving the service life and the performance of the engine. However, the curvature radius of the blade edge surface varies greatly to even less than 0.05 mm, which puts higher requirements on processing equipment and technology. Therefore, the polishing process of blade edges is studied and a fixed resin diamond elastic polishing wheel adapting to the shape of the blade edge is developed to explore its feasibility on a 6R robot polishing platform when polishing blade edges. Methods: The fixed resin diamond elastic polishing wheel is developed based on the characteristics of small curvature radius and complex surface shape of the blade edge, and a robot polishing platform is built to study the polishing process of Ti alloy blade edges. Firstly, by combining UG secondary development with robot kinematics, the polishing path of the wheel based on the robot platform for polishing blade edges is planned. Secondly, the orthogonal experimental method is used to explore the influences of four main process parameters, namely spindle speed (A), feed rate (B), machining pressure (C), and abrasive particle size (D), on the surface roughness and contour of the blade edge. The optimal combination of process parameters is then obtained. Finally, the titanium alloy blade edge workpiece is polished using the optimal parameter combination, and the surface roughness and the contour of the workpiece after polishing are measured to determine whether the polishing quality of the workpiece meets the requirements for use. Results: The orthogonal experiments are conducted on titanium alloy blade edge polishing using the fixed resin diamond elastic polishing wheel on the 6R robot polishing platform. The experimental data show that: (1) Among the four process parameters A, B, C and D, B has the greatest impact on the blade edge profile with a range R1 of 0.015. The second greatest influences are from A and C, and the least influence is from D. The optimal combination of process parameters is A2B1C2D3, that is, the spindle speed is 700 r/min, the feed speed is 6 mm/min, the processing pressure is 4 N, and the abrasive particle size is 10~14 μm. (2) B has the greatest effect on the surface roughness of the blade edge, with its range R2 being 0.136, which is much higher than that of other parameters. The second greatest influences are from D and A, and the least influence is from C. The optimal combination of process parameters is A3B1C2D3, that is, the spindle speed is 800 r/min, the feed speed is 6 mm/min, the processing pressure is 4 N, and the abrasive particle size is 10~14 μm. Conclusions: A new type of resin diamond elastic polishing wheel is innovatively designed by combining fixed abrasive technology and elastic polishing technology, which is suitable for the characteristics of large curvature changes and complex surfaces of the blade edge. It is used for orthogonal experiments of blade edge polishing on the 6R robot polishing platform. The experimental results show that the designed and developed elastic polishing wheel is suitable for polishing the edges of titanium alloy blades, and the surface roughness and profile accuracy of the processed edges can meet the requirements for use. At the same time, the optimized process parameter combination for polishing the edge of titanium alloy blades is A3B1C2D3, which includes a spindle speed of 800 r/min, a feed rate of 6 mm/min, a processing pressure of 4 N, and an abrasive particle size of 10~14 μm. Under these parameters, the overall effect of blade edge polishing is the best, with the surface roughness Ra decreasing from the initial 1.165 μm to 0.213 μm, and the profile decreasing from the initial 0.048 mm to 0.016 mm.

-

表 1 固结树脂金刚石抛光轮组分

Table 1. Components of resin-bonded diamond polishing wheel

成分 质量分数 ω / % 树脂 60.0 金刚石 27.5 固化剂 1.0 成孔剂 10.0 加速剂 0.5 偶联剂 1.0 表 2 固结树脂金刚石抛光轮制备参数

Table 2. Preparation parameters for resin-bonded diamond polishing wheels

参数 取值 压强 p / MPa 0.5~1.0 固化温度 θ / ℃ 65 固化时间 t / s 1500 表 3 弹性抛光轮抛光叶缘正交试验因素与水平表

Table 3. Factors and levels table for orthogonal experiment of elastic polishing wheel polishing blade edge

水平 主轴转速

n / (r · min−1)进给速度

v / (mm · min−1)加工压力

F / N磨料粒径

d / μmA B C D 1 600 6 2 50~60 2 700 12 4 20~30 3 800 24 6 10~14 表 4 钛合金叶片叶缘正交试验轮廓度及极差分析结果

Table 4. Results of orthogonal test on profile and range analysis of titanium alloy blade edges

实验序号 A B C D 轮廓度

δ / mm1# 600 6 2 50~60 0.022 2# 600 12 4 20~30 0.027 3# 600 24 6 10~14 0.040 4# 700 6 4 10~14 0.014 5# 700 12 6 50~60 0.028 6# 700 24 2 20~30 0.031 7# 800 6 6 20~30 0.020 8# 800 12 2 10~14 0.022 9# 800 24 4 50~60 0.032 k1 0.030 0.019 0.025 0.027 k2 0.024 0.026 0.024 0.026 k3 0.025 0.034 0.029 0.025 极差 R 0.006 0.015 0.005 0.002 因素主次 B>A>C>D 表 5 钛合金叶片叶缘正交试验表面粗糙度及极差分析结果

Table 5. Surface roughness and range analysis results of orthogonal test on titanium alloy blade edges

实验序号 A B C D 表面粗糙度

Ra / μm1# 600 6 2 50~60 0.279 2# 600 12 4 20~30 0.316 3# 600 24 6 10~14 0.379 4# 700 6 4 10~14 0.221 5# 700 12 6 50~60 0.358 6# 700 24 2 20~30 0.380 7# 800 6 6 20~30 0.241 8# 800 12 2 10~14 0.263 9# 800 24 4 50~60 0.382 k1 0.325 0.247 0.310 0.340 k2 0.322 0.312 0.306 0.315 k3 0.295 0.383 0.326 0.288 极差 R 0.030 0.136 0.020 0.052 因素主次 B>D>A>C -

[1] 乔志杰. 工业机器人辅助抛磨叶片工艺规划及实验研究 [D]. 太原: 太原理工大学, 2022.QIAO Zhijie. Industrial robot-assisted blade polishing process planning and experimental research [D]. Taiyuan: Taiyuan University of Technology, 2022. [2] 陈雷, 李大力, 王婧雯, 等. 航空发动机叶片进排气边缘形状自动评价方法 [J]. 航空动力学报,2023,38(4):986-993.CHEN Lei, LI Dali, WANG Jingwen, et al. Automatic shape evaluation method of aeroengine blade inlet and exhaust edges [J]. Journal of Aerospace Power,2023,38(4):986-993. [3] 张军锋. 整体叶盘叶片前后缘柔性拋光工艺及参数优化 [D]. 西安: 西北工业大学, 2018.ZHANG Junfeng. Flexible polishing technology and parameters optimization for the leading and trailing edges of blisk blade [D]. Xi′an: Northwestern Polytechnical University, 2018. [4] 琚春, 刘佳, 杨胜强, 等. 叶片前后缘识别及百叶轮抛磨工艺研究 [J]. 中国机械工程,2023,34(22):2674-2683, 2692. doi: 10.3969/j.issn.1004-132X.2023.22.004JU Chun, LIU Jia, YANG Shengqiang, et al. Identification of blade leading edge and trailing edge and study on polishing process by flag wheel [J]. China Mechanical Engineering,2023,34(22):2674-2683, 2692. doi: 10.3969/j.issn.1004-132X.2023.22.004 [5] 赵欢, 姜宗民, 丁汉. 航空发动机叶片叶缘随形磨抛刀路规划 [J]. 航空学报,2021,42(10):256-266. doi: 10.7527/S1000-6893.2020.24318ZHAO Huan, JIANG Zongmin, DING Han. Tool path planning for profiling grinding of aero-engine blade edge [J]. Acta Aeronautica et Astronautica Sinica,2021,42(10):256-266. doi: 10.7527/S1000-6893.2020.24318 [6] 任泽, 朱永伟, 董彦辉, 等. 弹性磁极磨头磁力研磨TC4钛合金的工艺优化 [J]. 金刚石与磨料磨具工程,2023,43(2):257-264. doi: 10.13394/j.cnki.jgszz.2022.0101REN Ze, ZHU Yongwei, DONG Yanhui, et al. Process optimization of magnetic grinding TC4 titanium alloy with elastic magnetic pole grinding head [J]. Diamond & Abrasives Engineering,2023,43(2):257-264. doi: 10.13394/j.cnki.jgszz.2022.0101 [7] 刘明佳. 镍基合金叶片叶尖精密磨削实验及其振动特性影响研究 [D]. 长沙: 湖南大学, 2020.LIU Mingjia. Study on precision grinding experiment of nickel-based superalloy blade tip and its effect of vibration characteristics [D]. Changsha: Hunan University, 2020. [8] 王洋. 叶片自适应磨抛工具系统研制及实验研究 [D]. 长春: 吉林大学, 2023.WANG Yang. Development and experimental study of blade adaptive grinding and polishing tool system [D]. Changchun: Jilin University, 2023. [9] 邱阳. TC4钛合金曲面固结磨料抛光研究 [D]. 南京: 南京航空航天大学, 2023.QIU Yang. Research on fixed abrasive polishing for TC4 titanium alloy curved surface [D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2023. [10] 王健杰. 固结磨料研磨TC4钛合金的材料去除机理研究 [D]. 南京: 南京航空航天大学, 2020.WANG Jianjie. Material removal mechanism of lapping TC4 titanium alloy by fixed abrasive [D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2020. [11] 刘纪东. 机器人固结磨料工具抛光叶片轨迹规划 [D]. 南京: 南京航空航天大学, 2021.LIU Jidong. Robotic trajectory planning of polishing blade with fixed abrasive tool [D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2021. [12] 盛鑫, 朱永伟, 任闯, 等. 固结硅基聚集体金刚石磨料垫的研磨性能 [J]. 光学精密工程,2023,31(6):839-848. doi: 10.37188/OPE.20233106.0839SHENG Xin, ZHU Yongwei, REN Chuang, et al. Lapping performance of fixed silicon-based agglomerated diamond abrasive pad [J]. Optics and Precision Engineering,2023,31(6):839-848. doi: 10.37188/OPE.20233106.0839 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS