Experimental study on bone grinding temperature and force under low temperature spray cooling

-

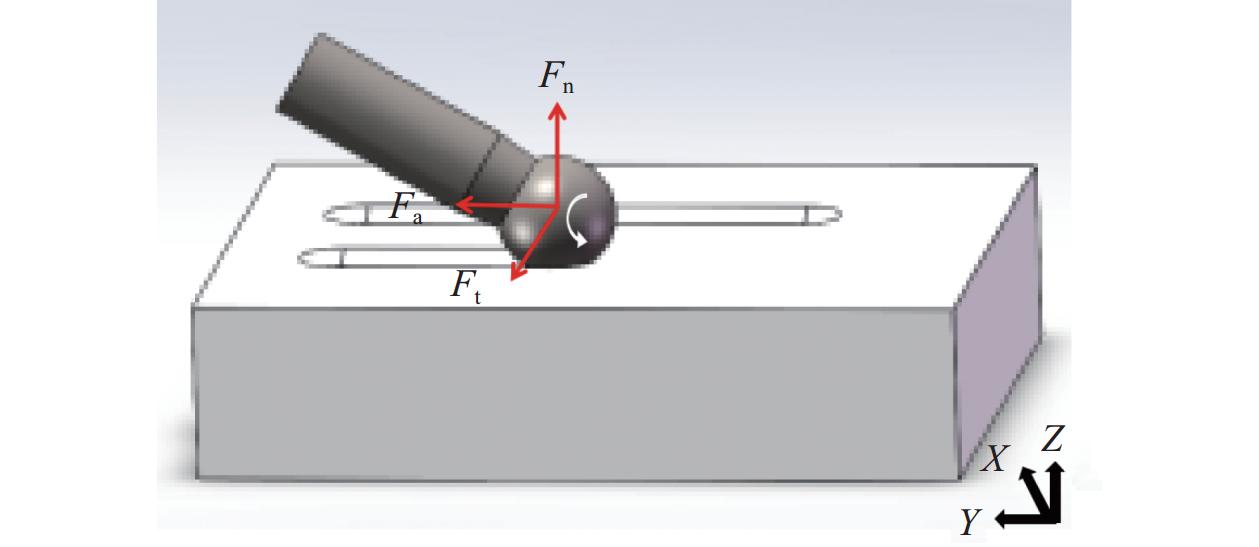

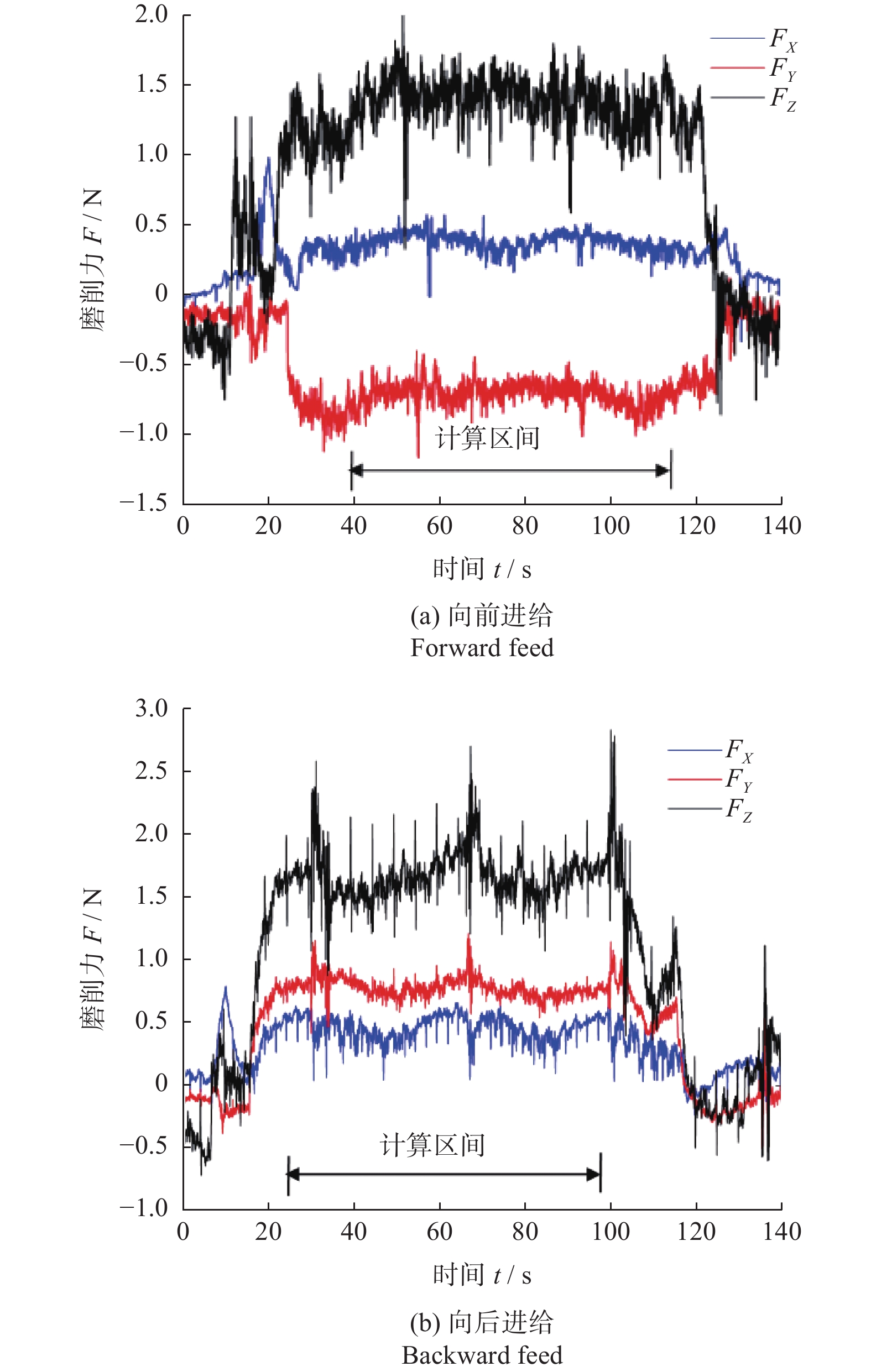

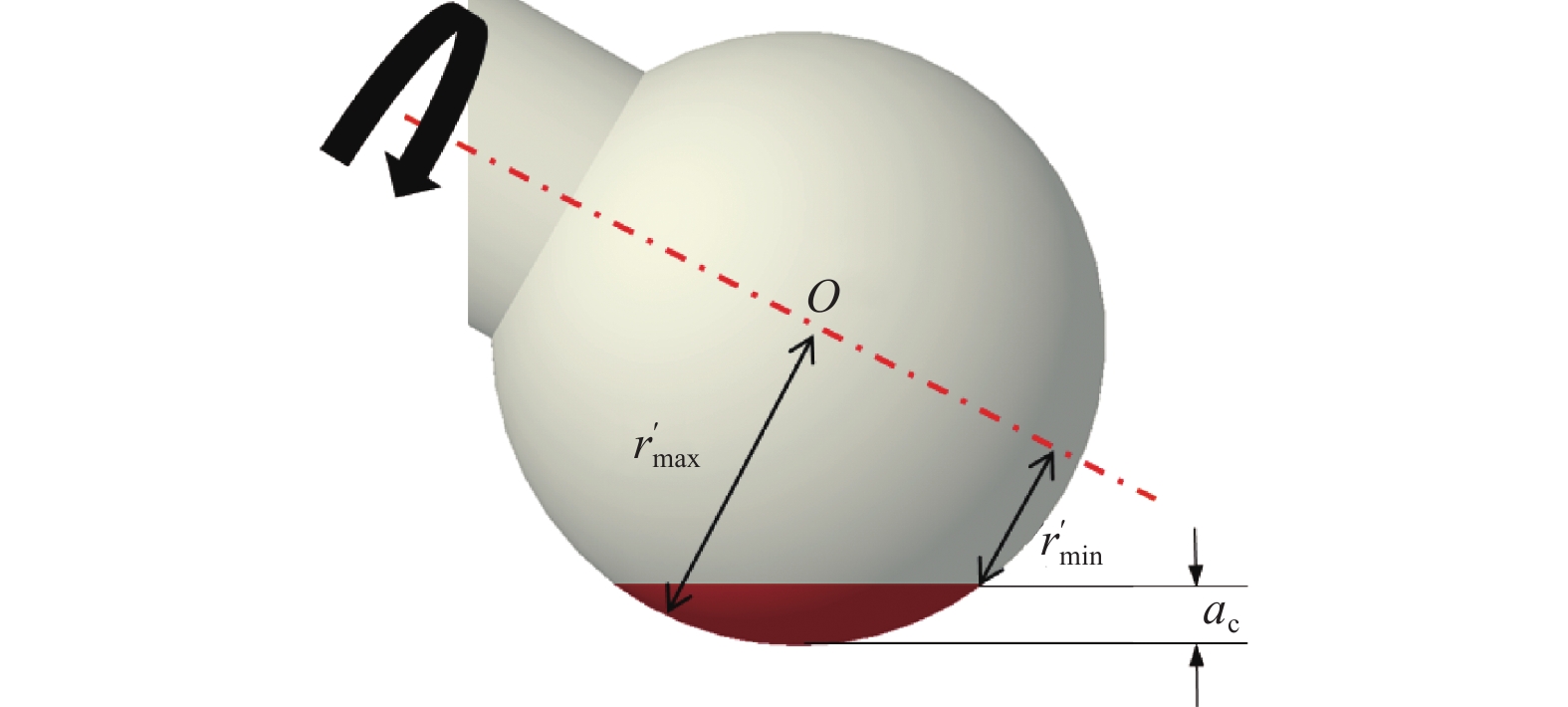

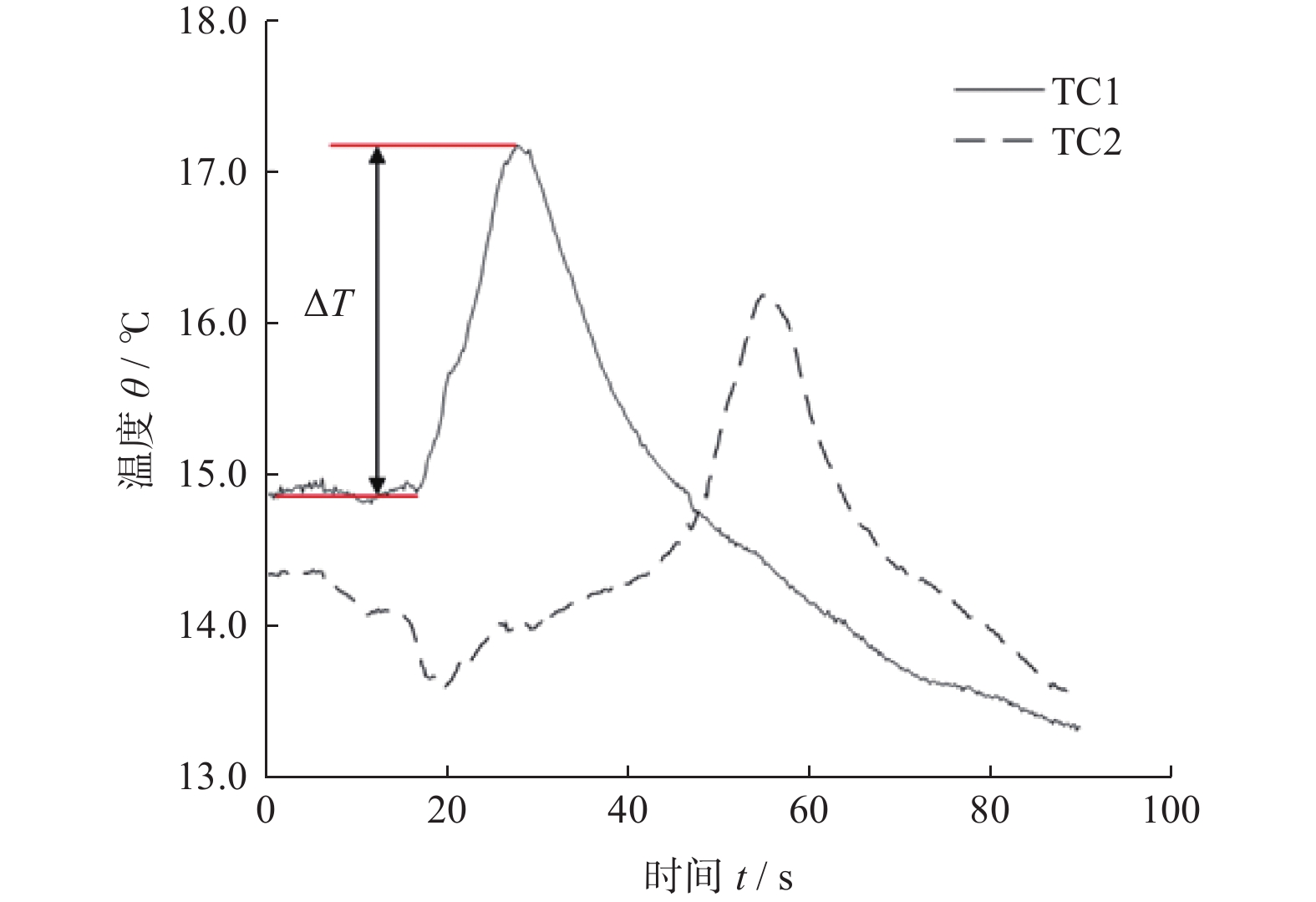

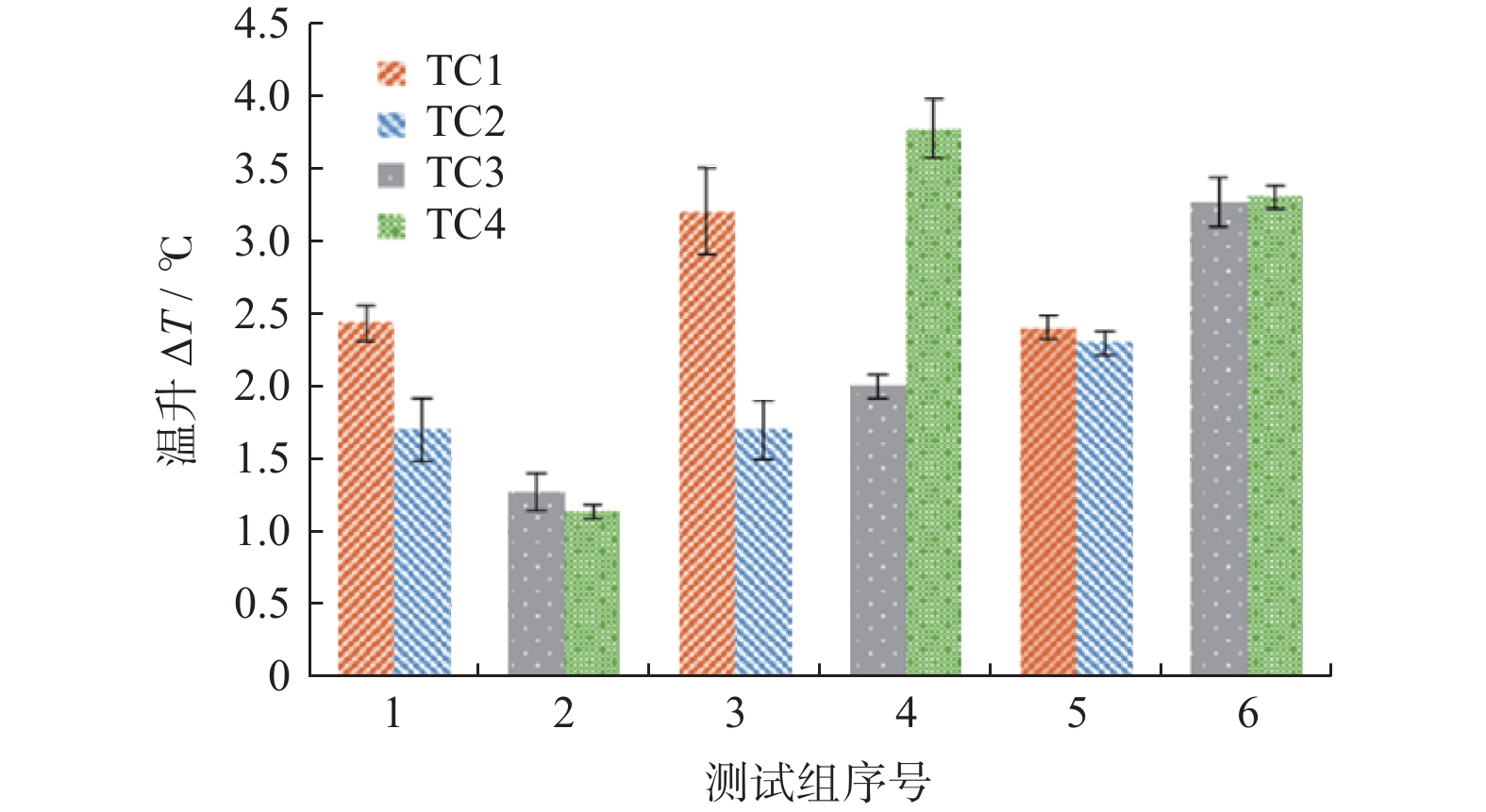

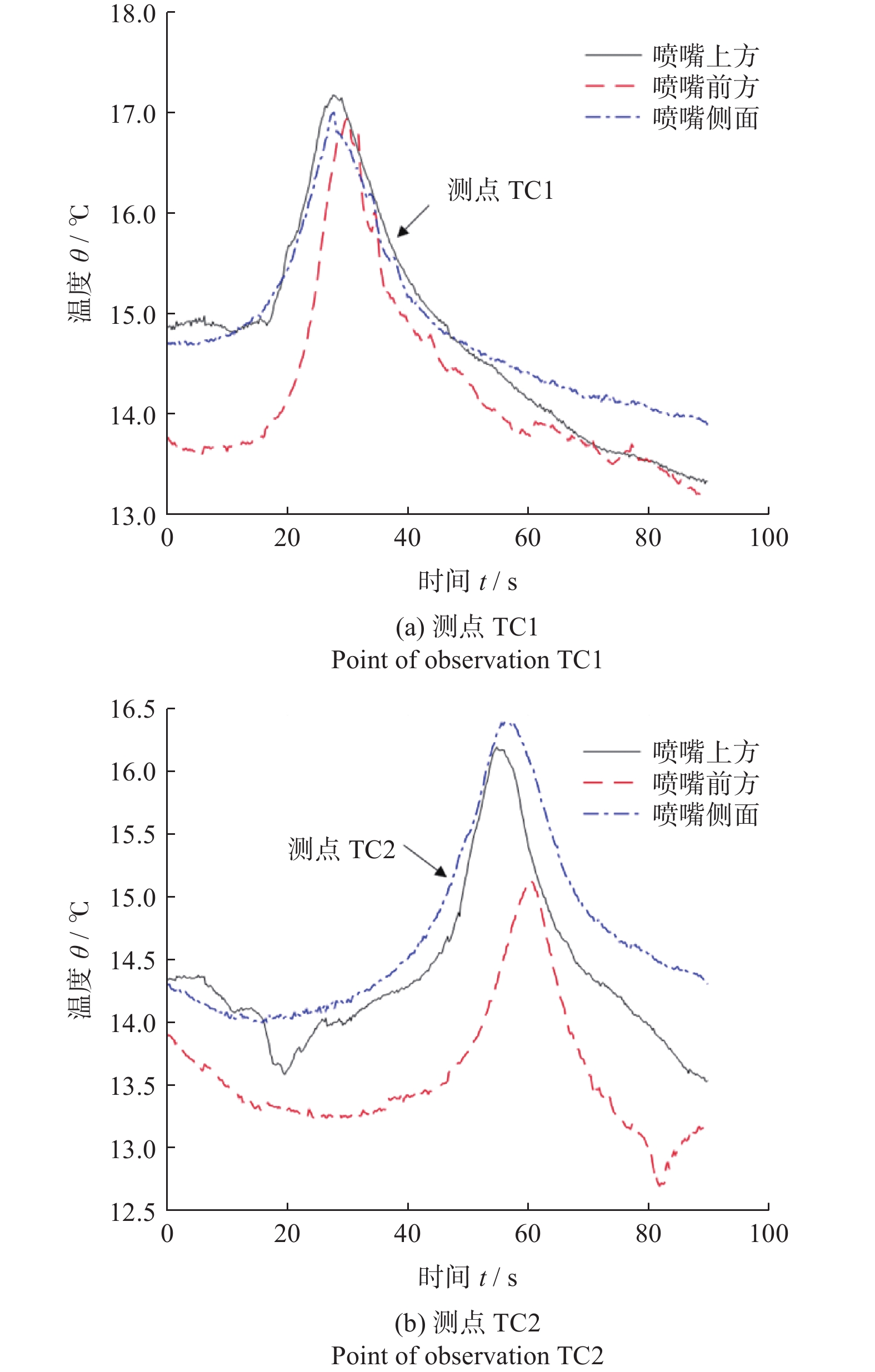

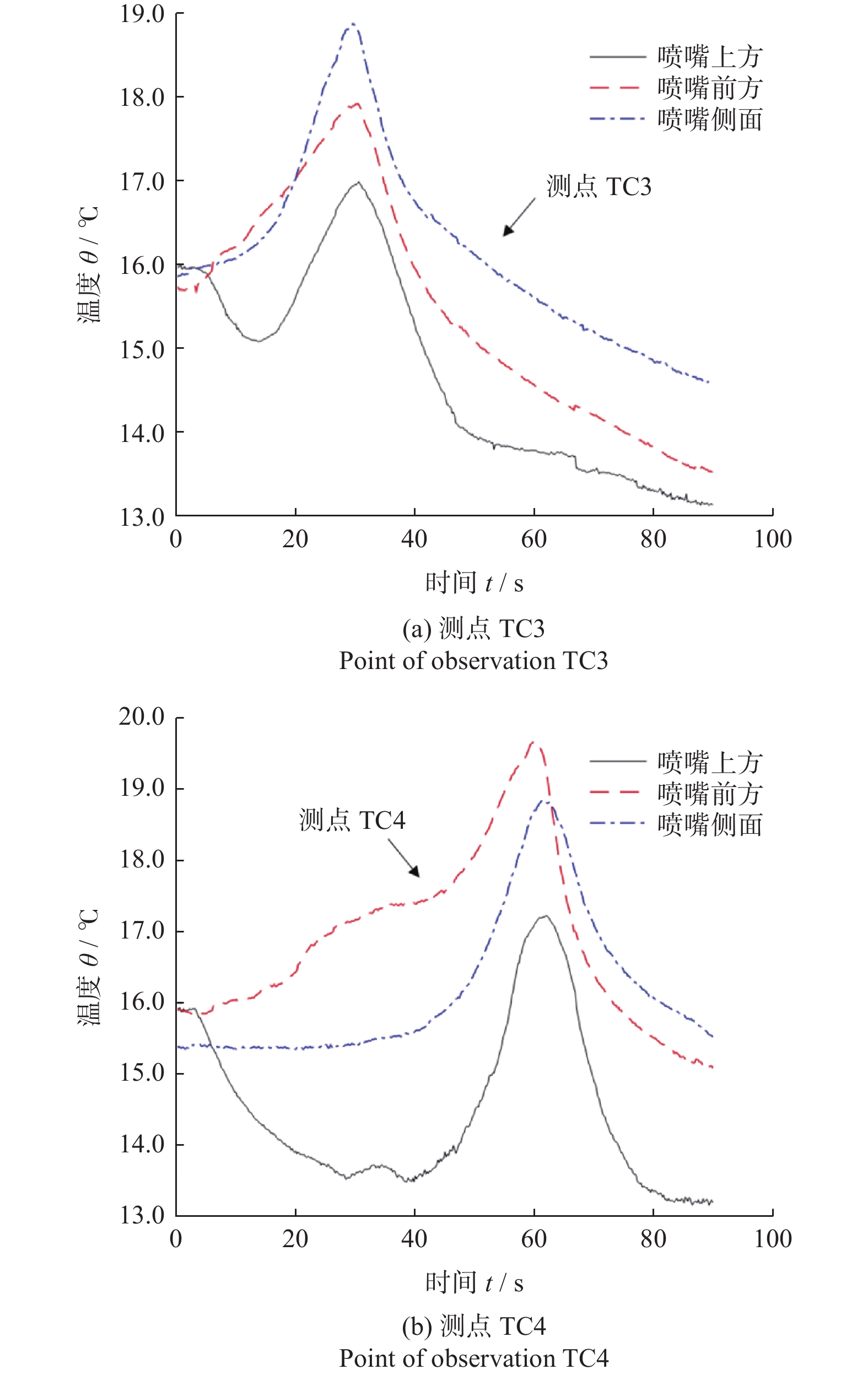

摘要: 为提高骨磨削手术的安全性,提出采用低温喷雾冷却对骨磨削过程进行热控制。搭建可三维运动的骨磨削实验平台,采用直径为4 mm的医用金刚石球状磨头以20 000 r/min高转速在骨表面磨削加工。 磨具前、后进给方式下磨削力值相近,当磨削深度为0.5 mm时磨削平均功率约为1.75 W。为降低磨削热引起的热损伤影响,将低温生理盐水喷雾(13 ℃,400 mL/h)输送到磨削区,并考察喷雾射流方向和磨头进给方向对磨削温度的共同影响。研究结果表明:低温喷雾冷却能使骨磨削温升低于4.0 ℃,低于神经组织热损伤温升阈值6.0 ℃,但喷雾的射流方向对温度场有较大的影响。当喷嘴位于磨具上方时,有利于向后进给;位于磨具前方时,有利于向前进给;位于磨具侧面时,对进给方向的影响较小。Abstract: Objectives: Bone tissue grinding is one of the common and basic applications in orthopedic surgery clinics. The grinding process is energy-intensive and generates a lot of grinding heat. The accumulation of this heat may cause thermal damage to biological tissues. This paper presents experimental research to investigate the bone-grinding heat and the cooling method. Methods: The combined influence of nozzle position and feed direction on the cooling effect of bone grinding under cryogenic spray cooling conditions is experimentally investigated. A bone grinding platform with three-dimensional motion, as well as a cryogenic spray generation device, is designed and constructed. A spherical diamond grinding head with a diameter of 4 mm and a grit size of #150 is utilized. Fresh bovine cortical bone is used as the processing sample. The temperature at the nozzle outlet is 13 ℃, and the flow rate valve regulates the coolant flow rate to 400 mL/h. A three-dimensional force transducer (DJSW-40, China) is connected to a data acquisition system, which captures the forces applied to the bone sample along the X, Y, and Z directions at a frequency of 100 Hz. Simultaneously, a 0.1 mm diameter type K thermocouple (Omega Inc., TT-K-36) is embedded inside the bone sample to measure the grinding temperature in real-time. Three different nozzle arrangements were designed: above, in front of, and to the side of the abrasive tool, with the nozzles 10 mm away from the spray surface. Six sets of experiments (3×2) were designed using three nozzle orientations and two feeding directions. Each set of experiments was repeated three times to study the cooling effect of the spray under the combined influence of nozzle orientation and feed direction. Results: (1) During bone grinding, the abrasive tool is subjected to three orthogonal directional forces, namely FX (the tangential grinding force used for removing material), FY (the axial grinding force, representing the resistance of the abrasive tool during its feed), and FZ (the normal grinding force, which serves as the support force of the workpiece on the abrasive tool). For forward feed, the average values of the individual forces are: FX = 0.37 N, FY = -0.72 N, FZ = 1.38 N. For backward feed, FX = 0.46 N, FY = 0.78 N, FZ = 1.67 N. Since the grinding tool remains in the same rotational direction, the tangential force FX is consistently positive. For forward/backward feed, the axial force FY is in the -Y and +Y directions respectively, thus the sign of the FY value changes. When feeding forward/backward, the tangential force (FX) is 0.37 N and 0.46 N, respectively, which are relatively similar to each other, in accordance with the grinding theory. The power consumed for grinding is approximately 1.6 W and 1.9 W for forward and backward feed, respectively. (2) The nerve tissue is more heat-sensitive than bone tissue. Taking the human body's 37 ℃ as the base temperature, the threshold for the occurrence of thermal injury is 43 ℃, so the temperature rise threshold for thermal injury of nerve tissue is 6 ℃. In our experiment, the maximum temperature rise of bone under low-temperature spray cooling was lower than 4 ℃, indicating that the cooling method is effective. The effect of the nozzle arrangement was investigated under a fixed forward or backward feeding direction. When the abrasive tool is fed forward, the cooling of the thermocouple under the front nozzle is obvious. This is because, in addition to the contact arc area between the abrasive tool and the bone sample, a portion of the coolant from the front nozzle is sprayed onto the bone sample surface, resulting in a pre-cooling effect within the bone. When the abrasive tool is fed backward, the grinding temperature is lowest when the nozzle is placed above. For the different nozzle orientations, the side nozzles are in a perpendicular plane to the feed direction (Y-direction) of the grinding tool, so the feed direction has the least influence on the grinding temperature. The upper and front nozzles are in the same plane as the feed direction of the abrasive tool, so the influence of the feed direction is more significant. Conclusions: (1) The average tangential grinding force is 0.42 N, axial grinding force is 0.75 N, normal grinding force is 1.53 N, and the average power consumed by grinding is approximately 1.75 W when bone grinding is performed at a depth of 0.5 mm using a spherical diamond abrasive tool with a diameter of 4 mm. (2) Under the cooling effect of the cryogenic spray, the maximum temperature rise of grinding is less than 4 ℃, which can effectively prevent the occurrence of thermal damage in biological tissues. The temperatures of the two thermocouples in the same set of experiments were more consistent when the nozzle was placed above or side, while there was a significant difference in the temperatures of the two thermocouples when the nozzle was placed in front. This indicates that the cooling effect is more uniform when the nozzle is placed above and to the side. (3) The coupling of the nozzle arrangement and the feeding mode has a greater impact on the grinding temperature. When the nozzle is placed on top, it is favorable to backward feeding; when the nozzle is placed in front, it is conducive to forward feeding; and when the nozzle is placed on the side, there is no significant difference in the temperature between forward and backward feeding.

-

Key words:

- bone grinding /

- spray cooling /

- injection direction /

- grinding temperature /

- grinding force

-

磨削作为一种精密加工方法,在零件加工方面有着广泛的运用。目前,骨组织磨削已是骨外科临床上常见和基本的应用之一,有关骨磨削特性的研究逐渐增多[1-2]。骨组织磨削通常采用表面有金刚石磨粒的微型球状磨头,由于磨削是能量密集型的加工方式,加工过程会产生很多磨削热[3],热量积聚会使得生物组织产生热损伤[4]。皮质骨为常见的骨磨削对象,其导热系数0.38~2.3 W/(m·K)远低于金刚石磨具的导热系数14~16.3 W/(m·K)[5],这使得大量的磨削热量很容易积聚在局部骨组织中,造成生物组织局部高温甚至热损伤。大量研究表明,热损伤程度与温度和暴露时间有关。当温度超过70 ℃时,骨组织立即坏死。随着暴露时间的延长,在较低的温度(55 和47 ℃)下分别暴露30 和60 s,骨组织也会出现不可逆的细胞死亡[5-8]。多数文献将47 ℃作为骨组织出现热损伤的阈值[9],而大脑组织、神经以及血管对温度更敏感,其热损伤临界温度为43 ℃[6,10,11]。考虑人体体温为37 ℃,则神经组织出现热损伤的温升阈值仅为6 ℃。骨磨削操作通常用于经鼻腔入路的颅底肿瘤摘除手术,骨磨削区旁分布有重要的视神经和三叉神经等,因此控制好骨磨削的温升十分重要。

骨加工冷却方法的研究主要集中在冷却剂的选择、冷却剂温度、冷却剂输送和喷射方式等方面[12-15]。在医学上,通常采用生理盐水作为冷却剂。在骨磨削中,骨组织逐层去除,切削深度较小,因此通常采用外部冷却法[16-18]。ENOMOTO 等[16]采用流量为180 mL/h、温度为20 ℃的水作为冷却液,对骨磨削过程进行外部滴管冷却来研究磨削冷却机理。SASAKI等[17]提出将喷雾冷却技术应用于骨磨削过程能提高冷却能力,同时有助于清理手术区域,提升手术视野。LI等[18]采用外部冷却法,对比了骨磨削过程中采用空气冷却、生理盐水浇注冷却和喷雾冷却时的冷却效果,最高磨削温度分别为43.8、52.6、70.1℃,证实了喷雾冷却的有效性。

有学者研究了低温生理盐水用于骨加工的可行性。TAKENAKA等[19]研究了骨钻孔时采用常温和低温生理盐水冲洗冷却对颈椎板成形术后上肢麻痹(upper-limb (C-5) palsy, ULP)发生率的影响。79例手术中采用室温生理盐水(平均温度为25.6℃),80例手术中采用低温生理盐水(平均温度为12.1℃)。研究结果表明,在钻孔过程中采用低温生理盐水可显著降低ULP的发生率,因此可推荐其作为预防ULP的简单方法。在先前的研究[20]中,初步探索了低温喷雾冷却技术用于骨磨削的可行性,发现喷嘴的喷射方向可能会对磨削温度有影响。

在实际临床过程中,医生手持磨具的运动方向是可变的。为考察喷雾的射流方位与磨具的进给方式对磨削温度的共同影响,设计了3种不同的喷嘴布置方式(磨具上方、前方和侧面),研究磨具沿不同方向进给时低温喷雾的冷却效果。

1. 骨磨削实验研究

通过实验研究了低温喷雾冷却条件下喷嘴位置和进给方向对骨磨削冷却效果的共同影响。以下为实验装置、实验设计和实验过程的详细阐述。

1.1 实验装置

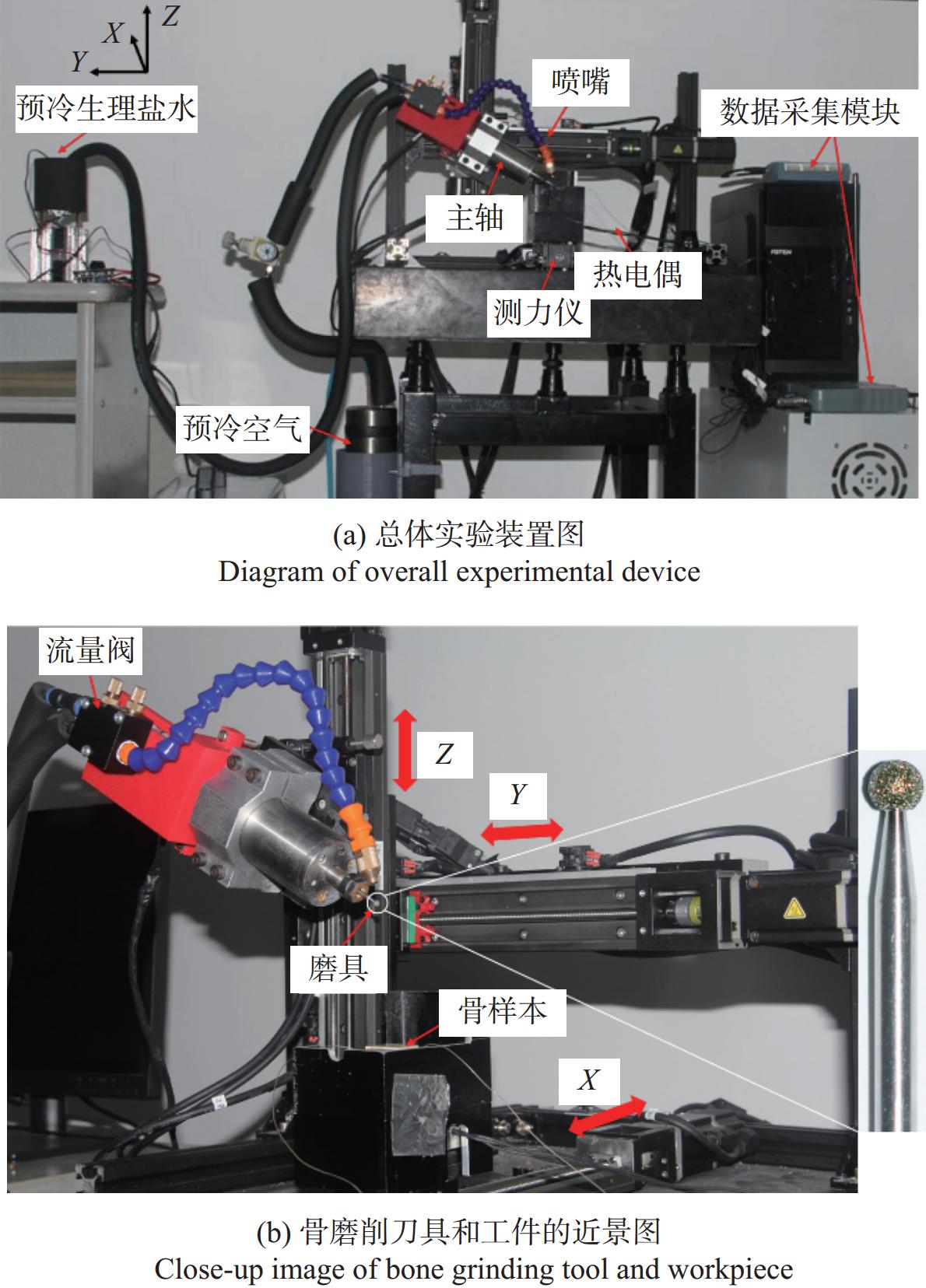

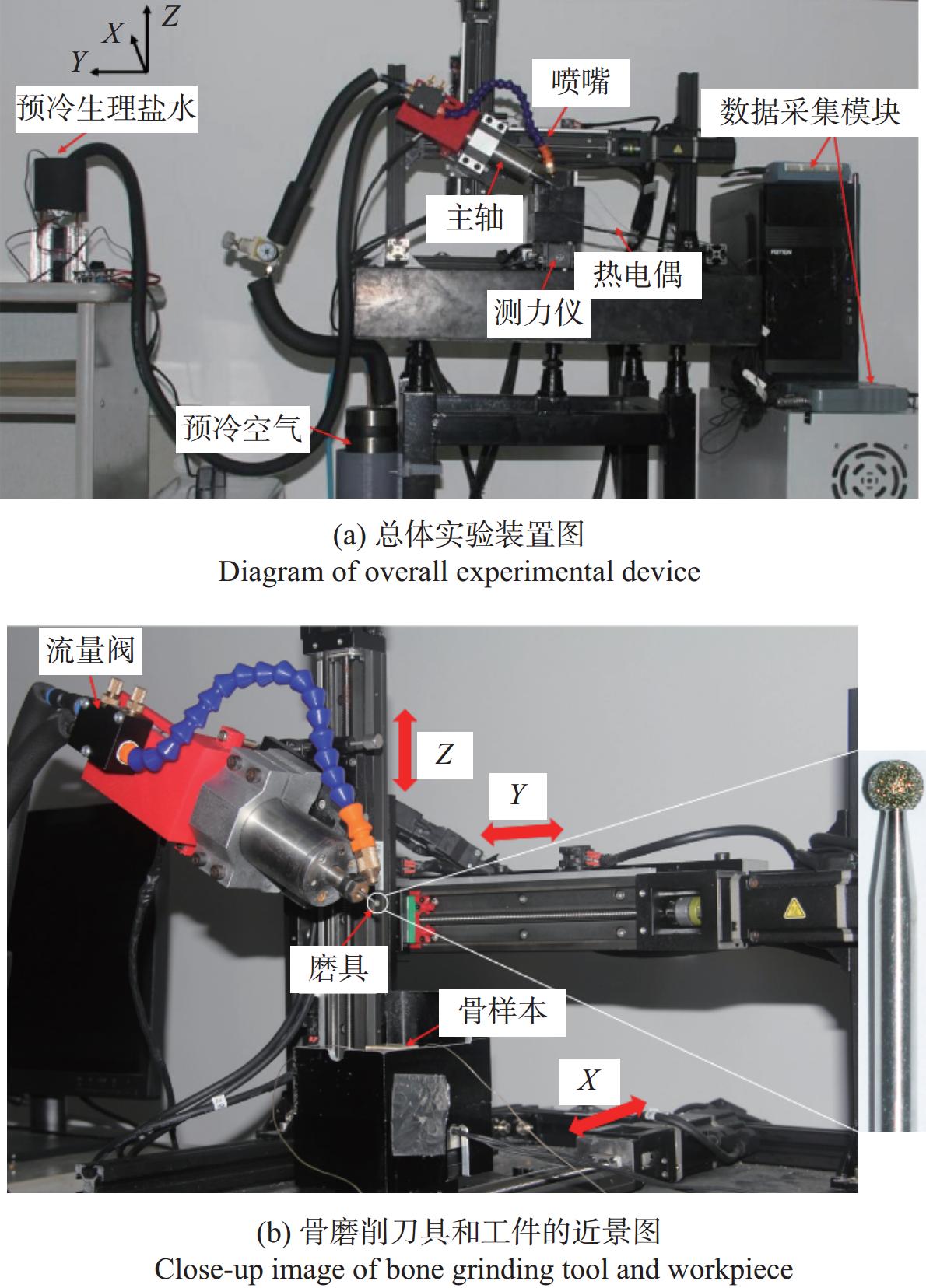

设计并搭建了三维运动的骨磨削平台以及低温喷雾的发生装置,如图1a所示。利用3个线性模块(型号:HIWINKK5002P-300A1-F2)驱动磨具在骨样本表面沿X、Y和Z轴方向移动,线性滑块的定位精度为0.02 mm,可满足加工深度的精度要求。实验过程中,采用直径为4 mm,粒度#150的球状金刚石磨头(广州阿奎拉精密工具有限公司,型号32120060),如图1b所示。

采用新鲜牛皮质骨为加工对象,其机械性能和热性能均与人体皮质骨相似[5]。骨样本加工成长方体形,尺寸约为25 mm × 15 mm × 6 mm。 进一步,利用高精度铣床对骨样本表面进行铣加工,使其上下表面的粗糙度Ra<0.6 μm。

低温喷雾冷却系统由预冷的生理盐水和加压空气混合而成,通过内径为2.1 mm的微喷嘴,实现磨削区低温射流冷却。生理盐水的温度由恒温器调节,保证其在喷嘴出口处的温度为13 ℃,流速阀调节冷却液流量为400 mL/h。

由于生理盐水出口温度低于环境温度,在本研究中将其定义为低温生理盐水。将三维力传感器 (DJSW-40,中国)连接到数据采集系统,该系统以100 Hz的频率采集施加在骨样本上沿X, Y和Z轴方向的力。同时,在骨样本内部埋入直径为0.1 mm的K型热电偶(Omega Inc.,TT-K-36) 实时测量磨削温度。

1.2 实验设计

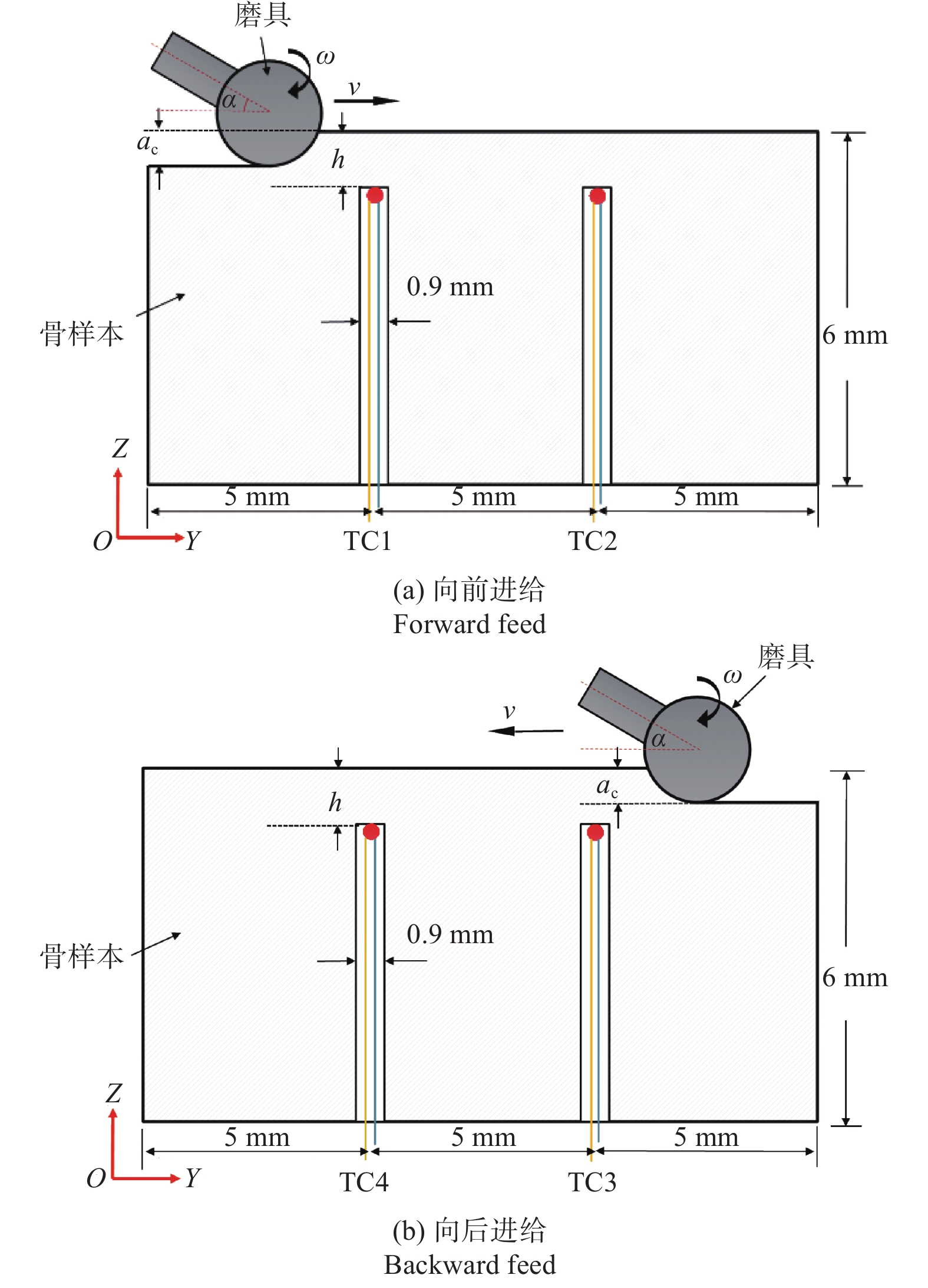

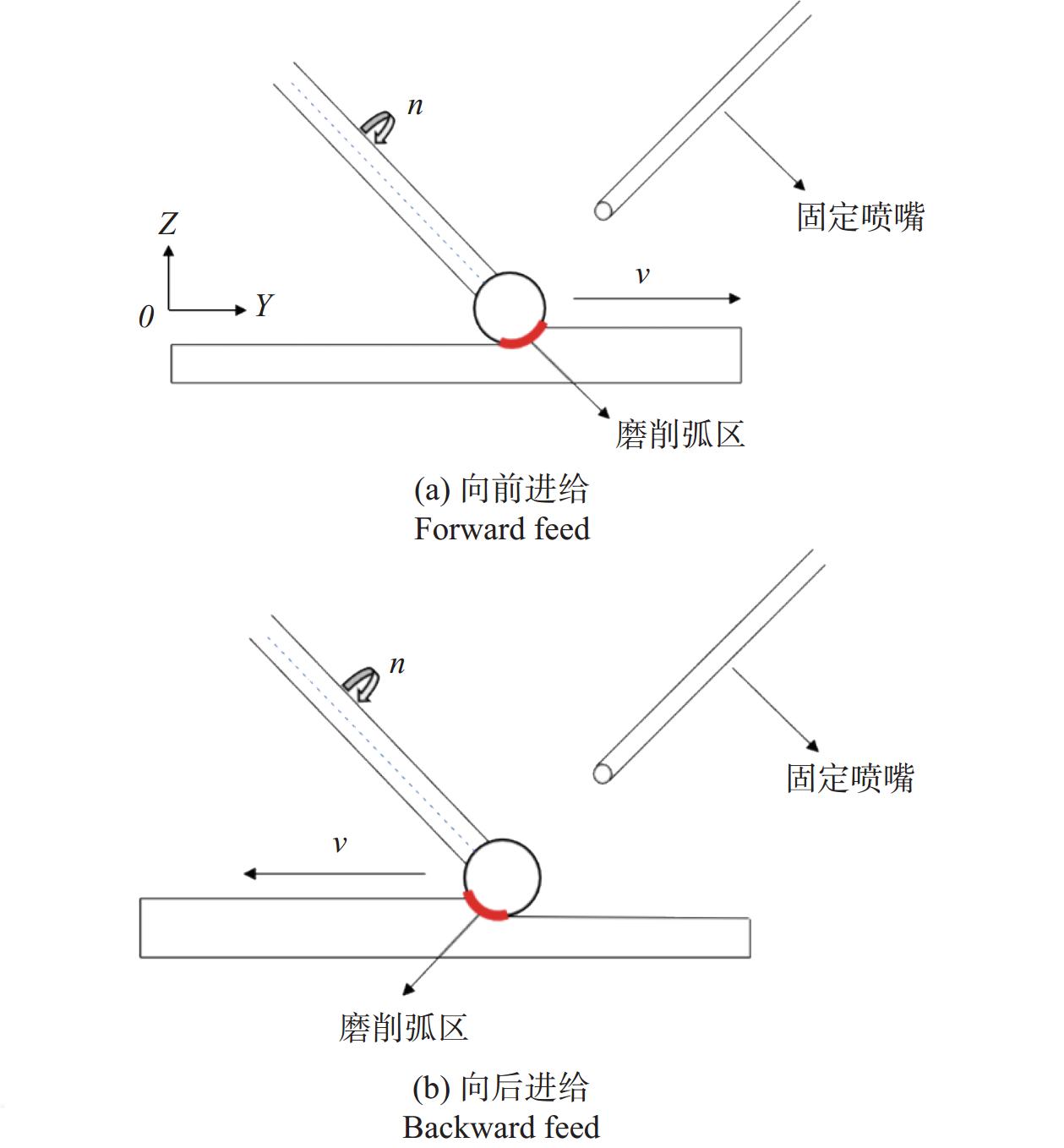

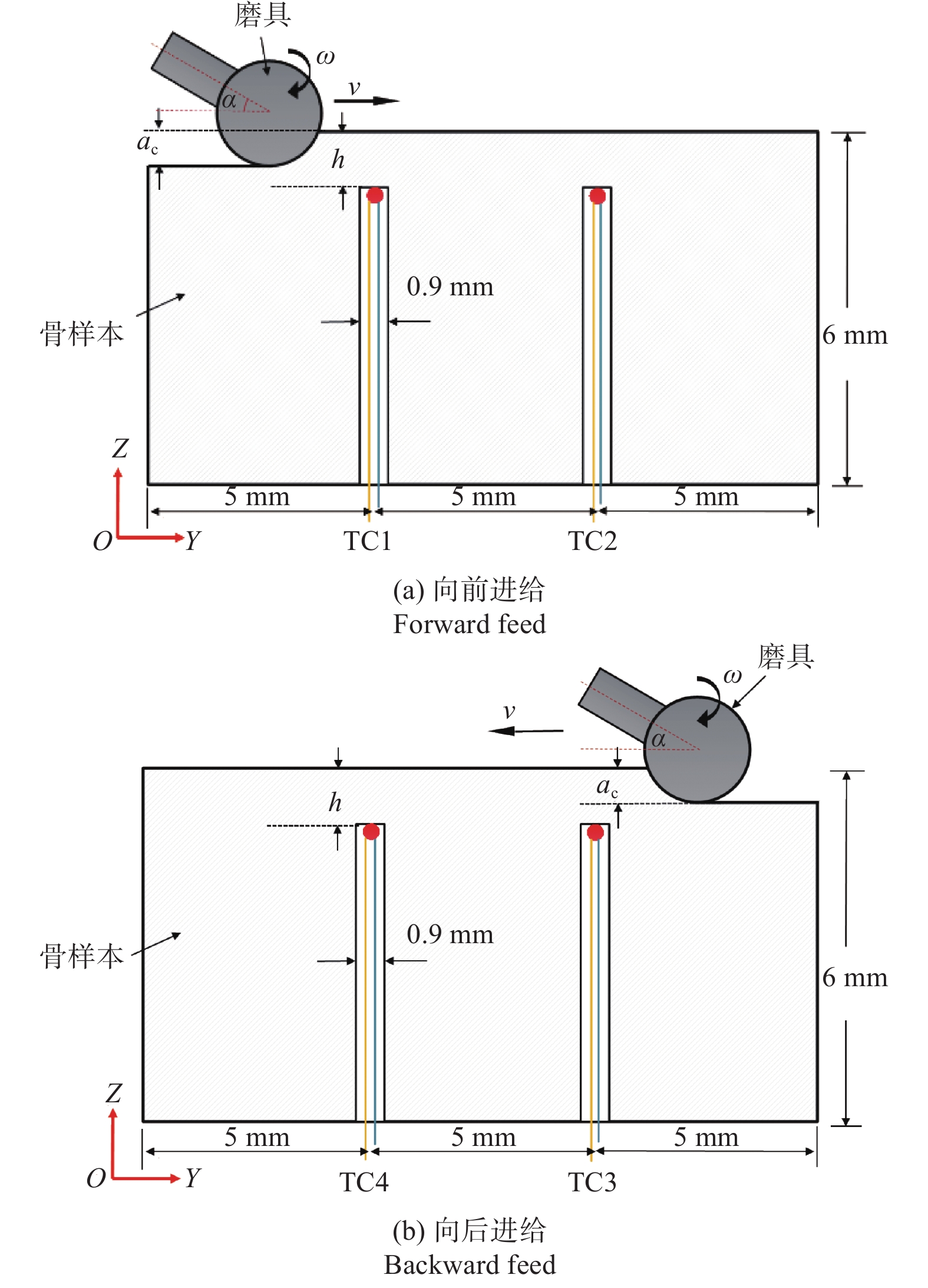

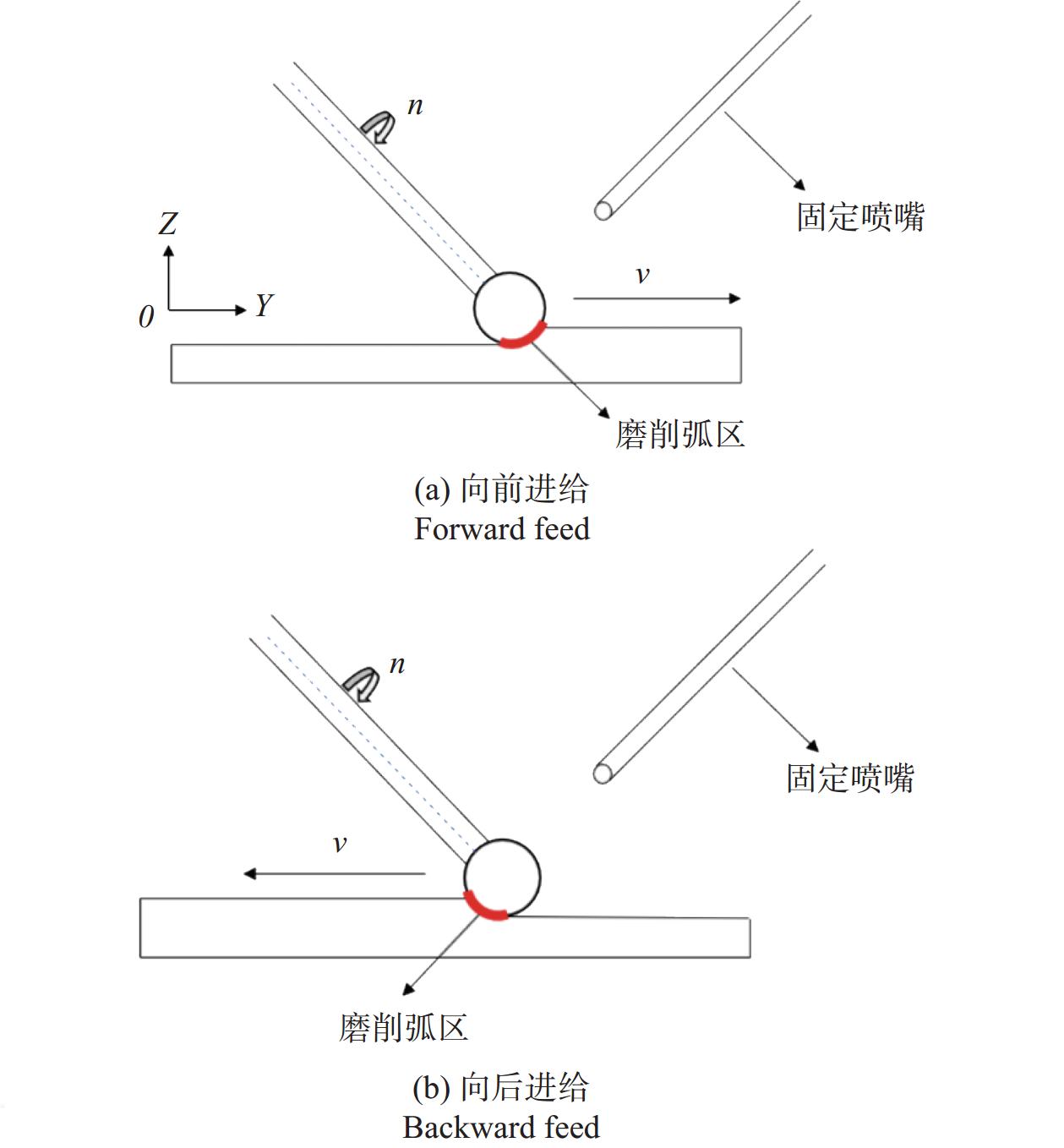

参考文献[20-21]设定磨削深度ac为0.5 mm,转速ω为20 000 r/min,进给速度v为10 mm/min。磨具沿Y轴方向进给,定义+Y方向为向前进给,−Y方向为向后进给,如图2所示。在外科手术中,由于磨削空间的限制,磨具与水平面的夹角α通常设定为30°(图2)。

当磨削表面有冷却液作用时,磨削槽正下方的温度往往最高,因此从骨样本底部分别埋入2个热电偶TC1和TC2、TC3和TC4,用于测量向前、向后进给时的磨削温度。热电偶顶端与磨削槽底面相距h(h=0.6 mm),h略大于磨削深度ac(ac=0.5 mm),以避免定位误差引起热电偶尖端被损伤。在所有实验中,h值保持一致,即所有的温度测量值均来自同一深度,温度测量结果接近最高温且具有可比性。

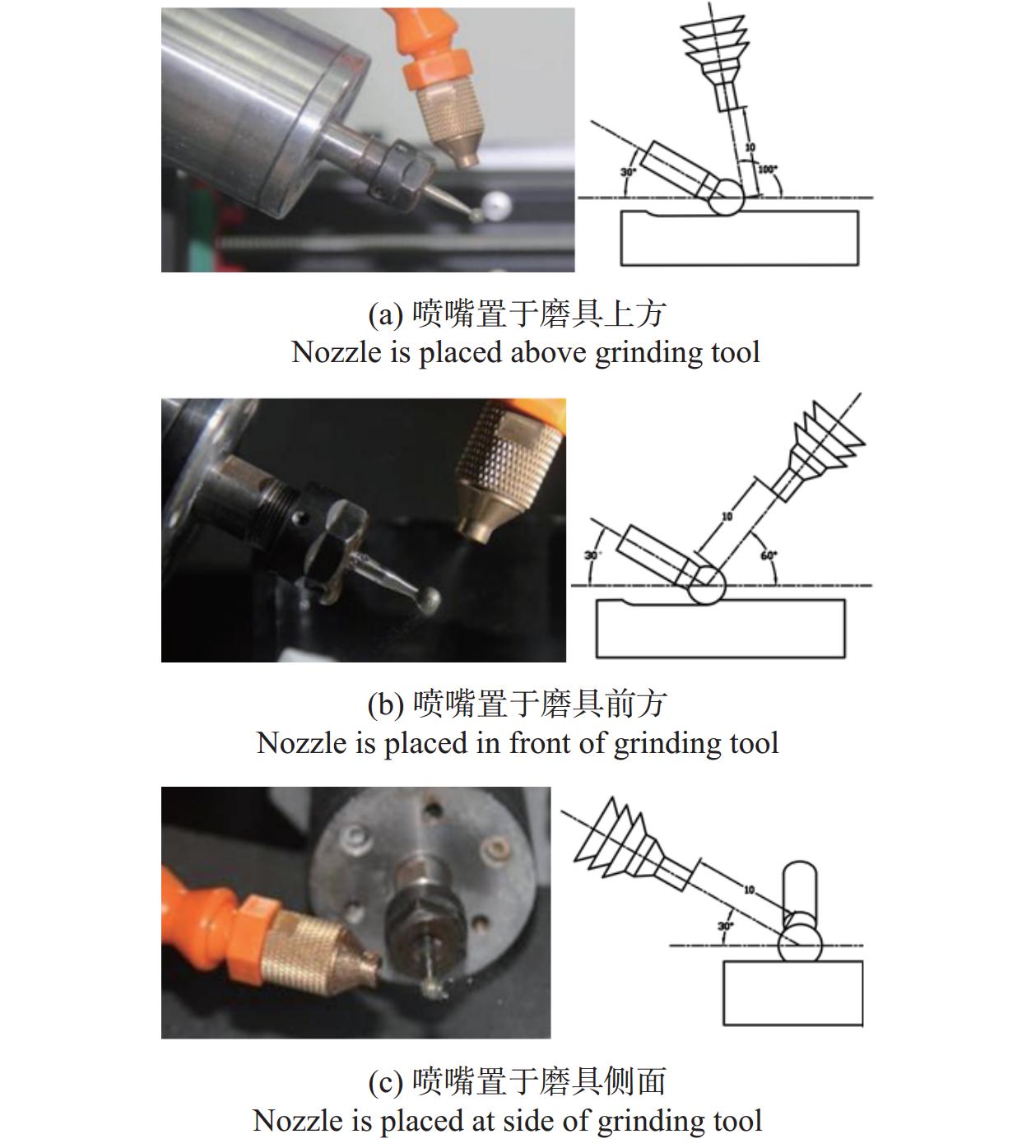

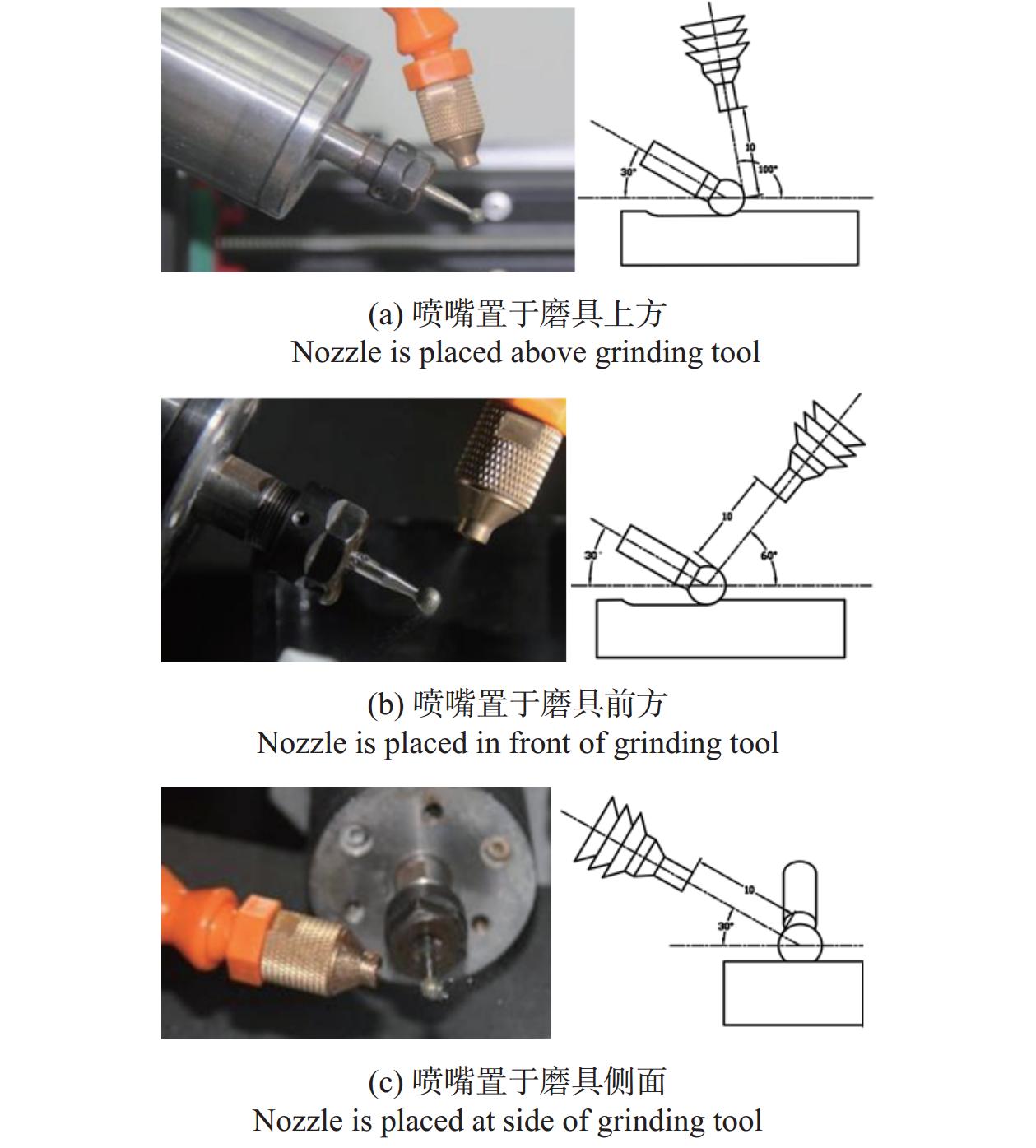

设计了3种不同的喷嘴布置方式,分别置于磨具的上方、前方和侧面,如图3所示。上方和前方的喷嘴布置于Y-Z平面,喷嘴与磨具轴线的夹角分别为50°和90°。侧面的喷嘴落于X-Z平面,喷嘴轴线与X轴的夹角为30°。喷嘴与喷射表面相距10 mm。采用3种喷嘴方位和2个进给方向,共设计了6组实验(3 × 2),每组实验重复3次,以研究喷嘴位置和进给方向共同影响下喷雾的冷却作用。表1列出了实验设计方案。

1.3 实验过程

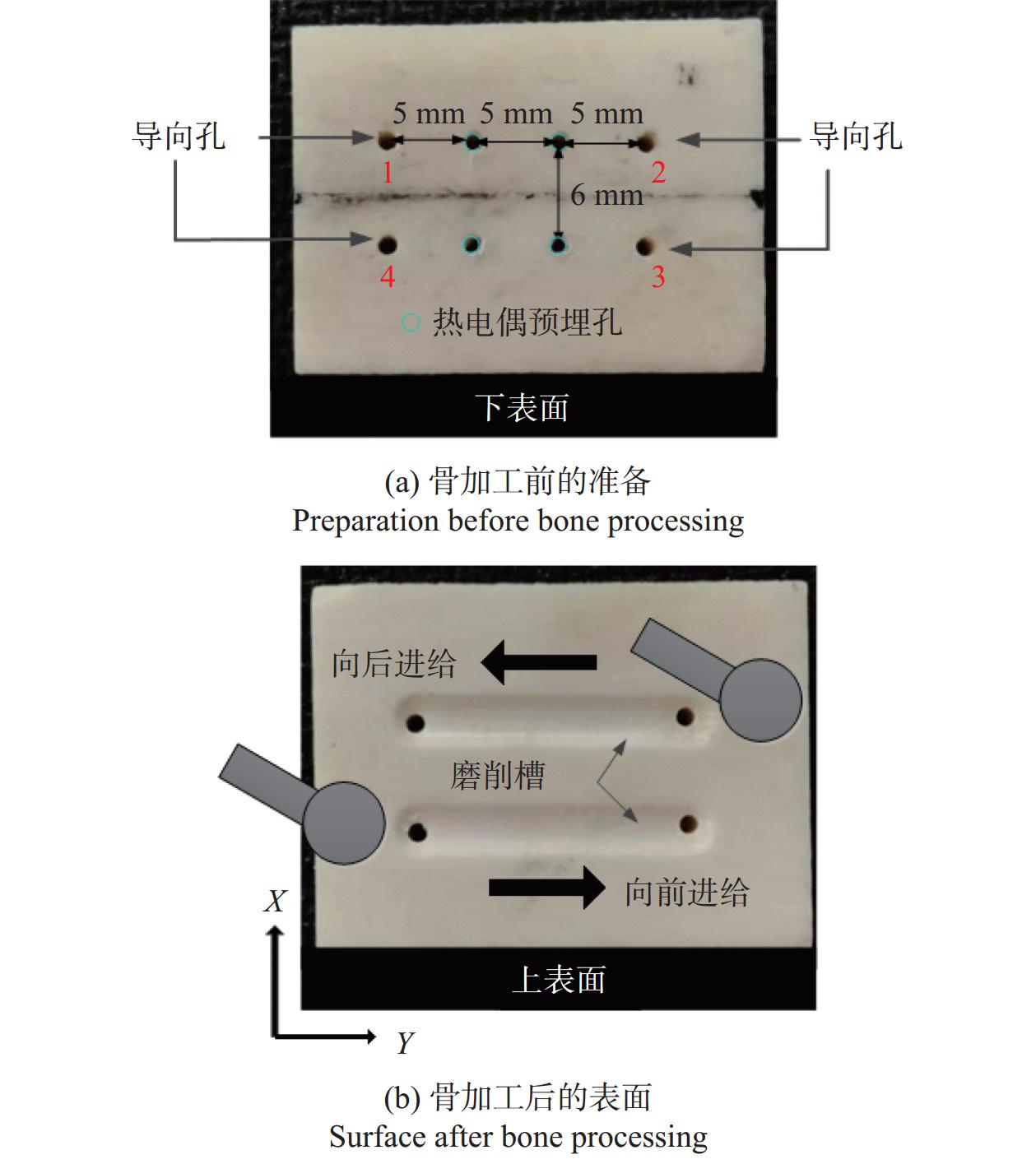

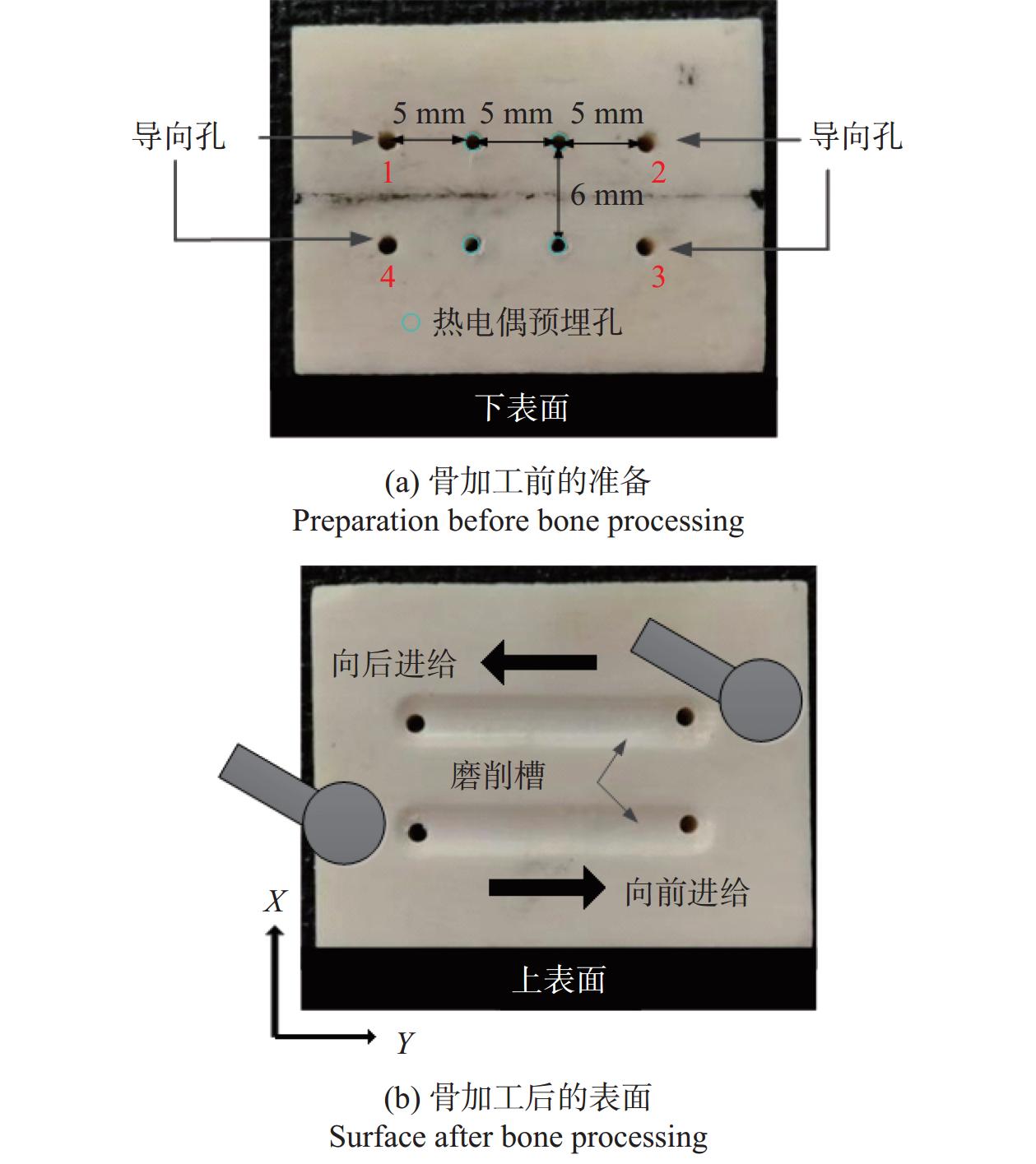

在相同的喷嘴方位下,同一骨样本上进行2次不同进给方向的磨削实验,如图4b所示。为保证磨削槽能处于热电偶的正上方,需要对磨削路径进行提前定位。实验前,采用直径为1 mm的钻头在骨样本上的两端打4个定位通孔1~4,沿X轴孔距为6 mm,沿Y轴孔距为15 mm,如图4a所示。此外,在孔1和孔2、孔3和孔4的连线上分别钻2个盲孔,用于埋入热电偶测量磨削温度。

表 1 实验设计方案Table 1. Experimental design编号 喷嘴位置 进给方向 其余加工参数 #1 上方 向前(+Y) 进给速度:10 mm/min

切削深度:0.5 mm

磨具转速:20 000 r/min

喷雾流量:400 mL/h

喷雾温度:13 ℃#2 上方 向后(−Y) #3 前方 向前(+Y) #4 前方 向后(−Y) #5 侧面 向前(+Y) #6 侧面 向后(−Y) 2. 结果与分析

2.1 磨削力

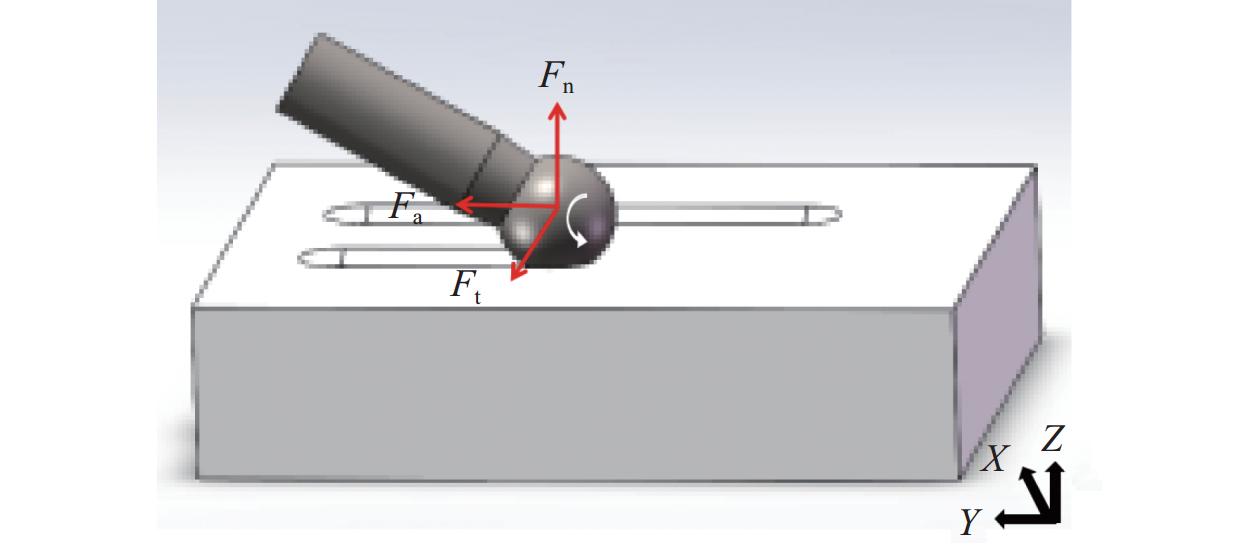

在骨磨削过程中,磨具会受到3个正交方向的力(如图5所示),分别为 Ft切向磨削力,用于去除材料;Fa轴向磨削力,磨具进给时受到的阻力; Fn法向磨削力,是工件对磨具的支撑力。磨削过程中能量消耗主要来源于切向力Ft产生的扭矩和轴向力Fa沿进给方向的做功,当磨削深度不变时,法向力Fn在Z轴方向不做功。通常,采用式(1)计算磨削过程消耗的功率[22]。

$$ {{P}\text={T}}_{\text{r}}{{ \omega }+{F}}_{\rm{a}}{v} $$ (1) 式中:Tr为扭矩(Tr= Ft r),ω为转速 (取20 000 r/min), Fa为轴向力,v为进给速度(取10 mm /min)。与钻削过程类似,扭矩项在功率消耗中占主导地位,因此可以通过测量扭矩和转速来简单地估计机械功率。

由于电机产生的振动与系统共振耦合,磨削力的原始曲线轮廓白噪声较多,为了求出平均磨削力,对原始数据进行了10 Hz低通滤波。图6给出了一组滤波后的典型测力数据。FX、FY和FZ分别为工件在X、Y和Z轴等3个方向的受力。根据坐标的对应关系,FX = Ft,FY = Fa,FZ = Fn。

选取磨削过程中的一段时间(70 s)作为计算区间求取磨削力的平均值。向前进给时,各个力的平均值FX = 0.37 N,FY = −0.72 N,FZ = 1.38 N。向后进给时,FX = 0.46 N,FY = 0.78 N,FZ = 1.67 N。值得注意的是,磨削力FX、FY和FZ的符号只体现了磨削力的方向。因磨具保持相同的旋转方向,切向力FX恒为正值。前、后进给时,轴向力FY分别沿−Y和 + Y方向,FY值符号发生变化。

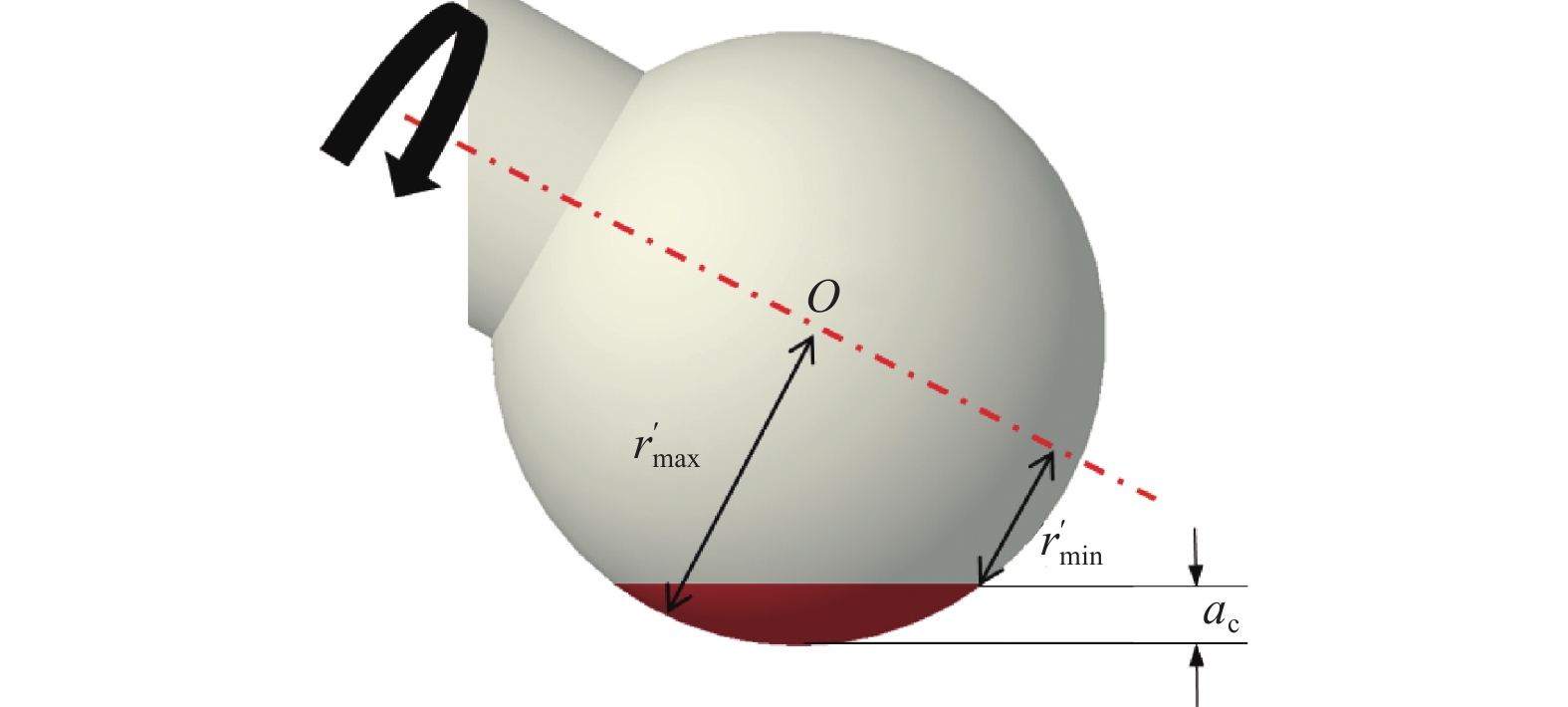

当磨具与水平面的夹角固定为30°,磨削深度为0.5 mm,只改变进给方向时,磨具与骨样本的接触面为同一曲面,如图7所示。对于球形磨具,磨粒的线速度(即切向速度)与其旋转半径 r'(磨粒绕磨具刀柄轴线旋转的半径)成正比,因此接触区的磨粒线速度$ v^{\prime} \in [r_{\min }^{\prime}\omega , r_{\max }^{\prime}\omega ] $。在磨削参数不变的情况下,理论上,前、后进给时接触面上参与磨削的磨粒线速度分布是接近的。在磨削加工中,磨削力与磨粒的切向速度有一定的对应关系,通常来讲,较大的切向速度对应较小的磨削力。考虑到骨组织具有非均质性,以及润滑液的影响,前、后进给时的磨削切向力应该是接近的。根据图6的测力结果,向前、向后进给时,切向力(FX)分别为 0.37和0.46 N,两者较相近,这与磨削理论是吻合的。根据式(1),磨具向前和向后进给时,磨削消耗的功率约为1.60和1.90 W。

2.2 磨削温度

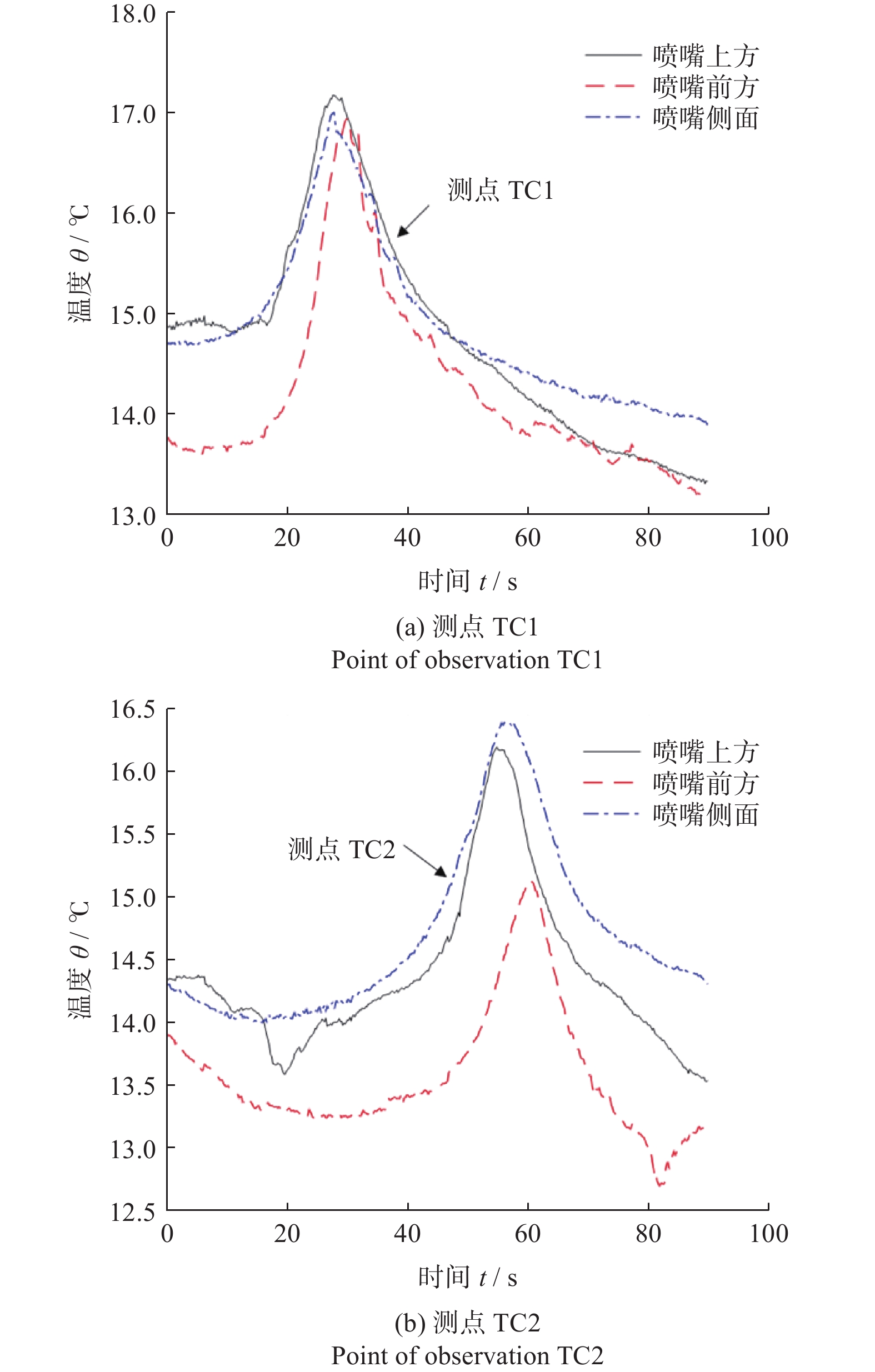

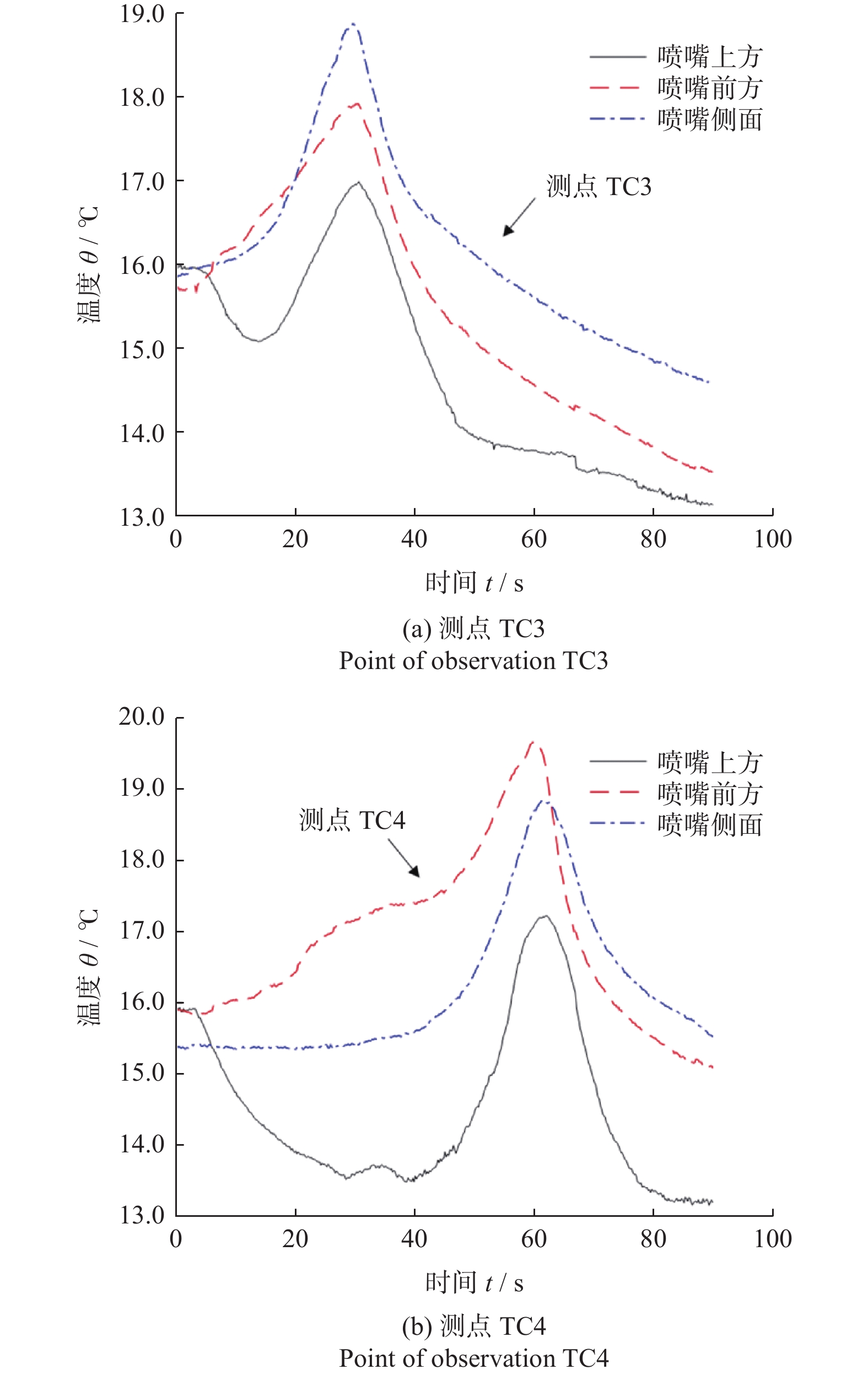

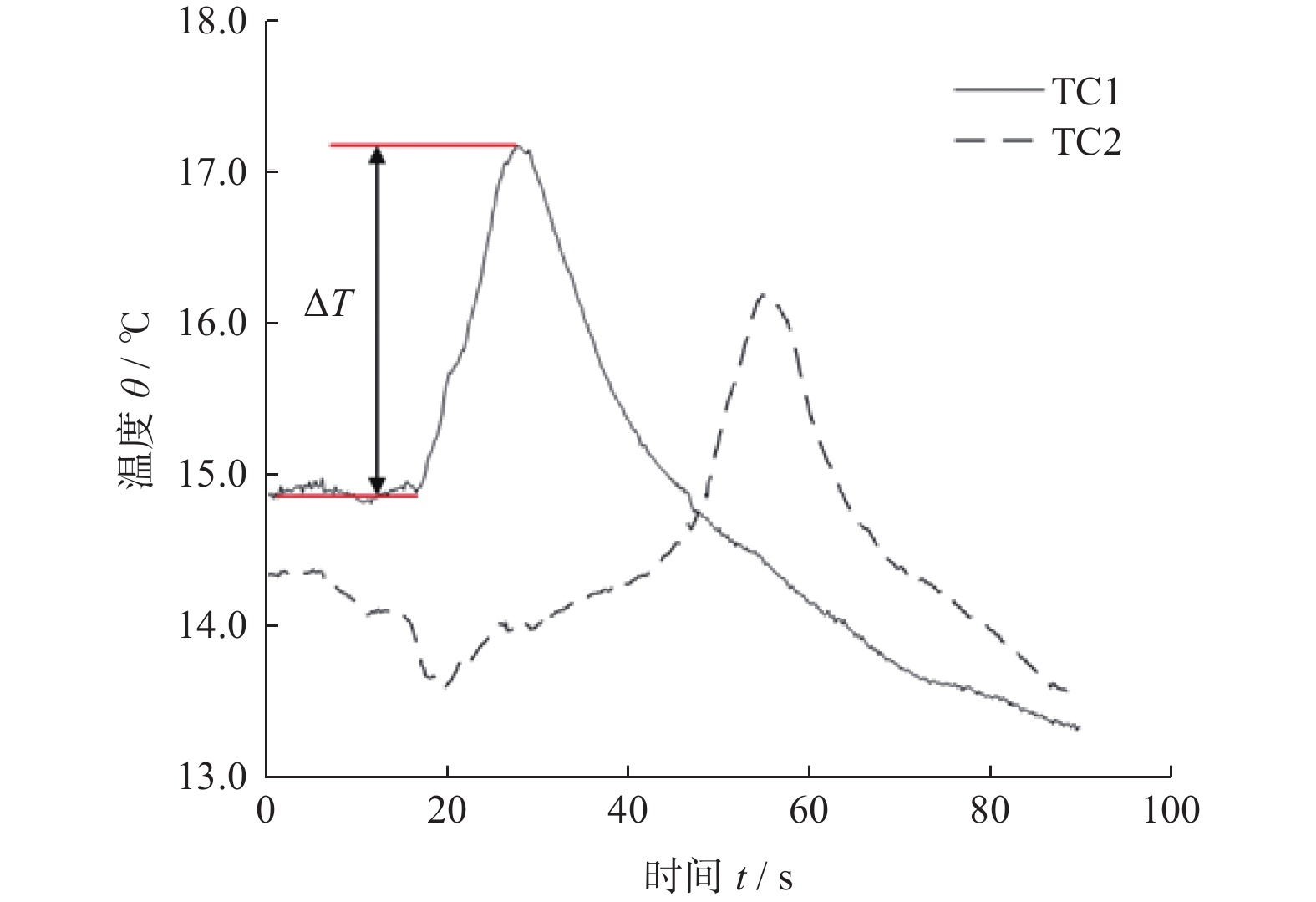

图8所示为一组典型的温度数据,磨具在骨样本表面进给,随着磨具与热电偶TC1和TC2的相对位置变化,瞬态温度分布均呈现先升后降的趋势。为比较不同工况下的冷却效果,以不同实验工况下热电偶的温升值(ΔT)作为比较对象,对温度测量结果进行了统计分析。

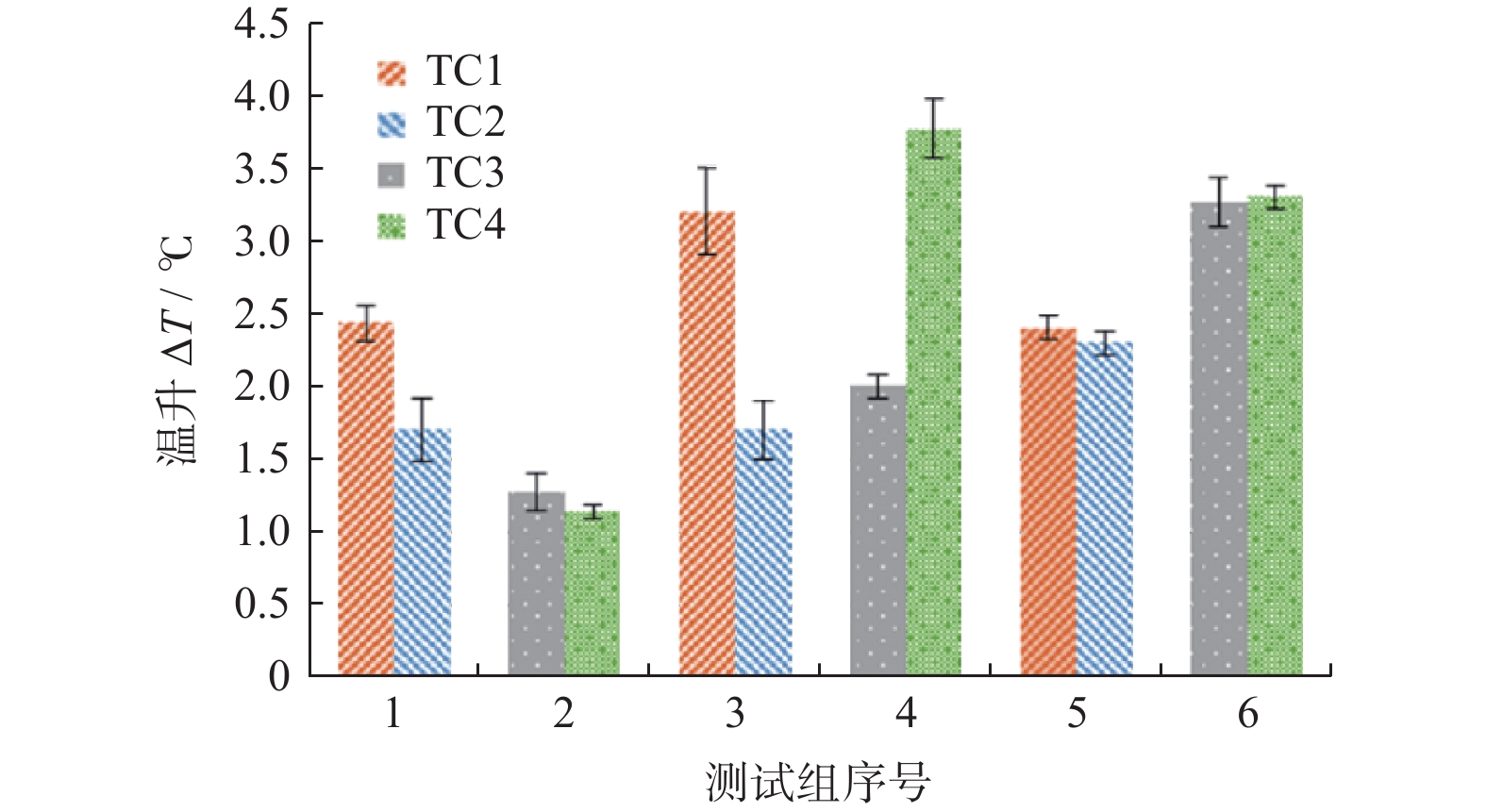

利用同一工况下3组重复实验的测温数据,计算#1~#6实验的平均温升值与标准偏差,结果如图9所示。由图9可知:在低温喷雾冷却下,本实验骨磨削的最大温升值<4.0 ℃,不超过神经热损伤的温升阈值6.0 ℃。

当喷嘴位于磨具上方(#1、#2)与侧面(#5、#6)时,同组实验的2个测点温度(TC1和TC2、TC3和TC4)温升较一致,当磨具向前进给时,#1和#5的温度值较接近,而当磨具向后进给时,#2的温度明显低于#6,这可能是因为磨具向后进给时,上方的冷却液更易进入磨削区,而从侧面靠磨具的旋转力进入磨削区的冷却液相对少些。

当喷嘴置于磨具前方(#3、#4)时,同组实验的2个测点温度表现出较大的差异。向前进给(#3)时,TC2的温度明显低于TC1,向后进给(#4)时,TC4的温度明显高于TC3。 这是由于喷嘴的喷射方向与磨具的进给方向比较接近,向前进给时磨削区在前方利于冷却,而向后进给时磨削区在后方冷却液难以进入。

2.3 喷嘴布置方式的影响

为考查喷嘴布置方式对温度的影响,在固定的进给方向下进行了温度分析。图10为磨具向前进给时,TC1和TC2的测温比较。

上方和侧面的喷嘴下温度分布较为相近,前方的喷嘴下TC2的降温明显,这是因为喷嘴的喷洒区域是一个面,除了磨具与骨样本的接触弧区,前方的喷嘴还有部分冷却液会喷在骨样本上,出现骨内部的预冷效果(图10b)。

图11为磨具向后进给时,TC3和TC4的测温比较。由图11可知:当喷嘴置于上方时,磨削温度最低。究其原因可能是两方面的:其一,与砂轮类似,高速旋转的磨头会产生气障效应,当喷嘴置于上方时,向后进给的方式有助于磨削液进入磨削区;其二,冷却液从上往下喷射,容易在磨削槽内积聚,这对于骨组织又有冷却作用。

所讨论的3种喷嘴布置方式中,上方与前方喷嘴处于Y-Z平面,侧面喷嘴处于X-Z平面。侧面喷嘴与磨具的进给方向(Y方向)处于垂直平面,因此进给方向对磨削温度差异影响最小。上方和前方喷嘴与磨具进给方向在同一平面,进给方向的影响大些,尤其是喷嘴置于前方时,前、后进给的磨削温度差异非常明显,这主要是因为喷嘴与磨削区域的相对位置关系,使得磨具向后移动时,喷雾难以进入磨削区,如图12所示。

3. 结论

采用低温喷雾冷却技术研究骨磨削过程中的磨削温度和磨削力的情况,得出以下结论:

(1)采用直径为4 mm的球状金刚石磨具进行骨磨削,当磨削深度为0.5 mm时,平均切向磨削力为0.42 N,轴向磨削力为0.75 N,法向磨削力为1.53 N,磨削消耗的平均功率约为1.75 W。

(2)在低温喷雾的冷却作用下,磨削的最高温升低于4.0 ℃,这能有效抑制生物组织出现热损伤。

当喷嘴置于上方和侧面时,同组实验的2个热电偶温度较一致,而当喷嘴置于前方时,2个热电偶的温度有较大的差异。这表明,当喷嘴置于上方和侧面时,冷却效果更为稳定。

(3)喷嘴的布置方式和进给方式耦合对磨削温度有较大的影响。当喷嘴置于上方时,有利于向后进给;当喷嘴置于前方时,有利于向前进给;当喷嘴置于侧面时,前、后进给的温度差异不大。

在一定的实验工况下,本研究着重考察了喷嘴方向与磨具沿 ± Y轴的进给方向耦合对冷却效果的影响。考虑到医生手持磨具进行骨磨削时进给方向具有一定的不确定性,后续需针对不同的进给方向展开研究。低温喷雾的冷却效果还与喷雾性能有很大关系,供气压力、冷却液流量以及喷嘴结构会对喷雾速度场和对流换热能力产生影响,后续可基于粒子图像测速技术(particle image velocimetry,PIV)对生理盐水喷雾射流的动力学特性进行研究。

-

表 1 实验设计方案

Table 1. Experimental design

编号 喷嘴位置 进给方向 其余加工参数 #1 上方 向前(+Y) 进给速度:10 mm/min

切削深度:0.5 mm

磨具转速:20 000 r/min

喷雾流量:400 mL/h

喷雾温度:13 ℃#2 上方 向后(−Y) #3 前方 向前(+Y) #4 前方 向后(−Y) #5 侧面 向前(+Y) #6 侧面 向后(−Y) -

[1] 吴茂忠, 王成勇, 郑李娟, 等. 生物组织磨削加工研究 [J]. 金刚石与磨料磨具工程,2022,42(2):137-149. doi: 10.13394/j.cnki.jgszz.2021.0123WU Maozhong, WANG Chengyong, ZHENG Lijuan, et al. Research on grinding of biological tissue [J]. Diamond & Abrasives Engineering,2022,42(2):137-149. doi: 10.13394/j.cnki.jgszz.2021.0123 [2] 王成勇, 陈志桦, 陈华伟, 等. 生物骨材料切除理论研究综述 [J]. 机械工程学报,2021,57(11):2-32. doi: 10.3901/JME.2021.11.002WANG Chengyong, CHEN Zhihua, CHEN Huawei, et al. A review on cutting mechanism for bone material [J]. Journal of Mechanical Engineering,2021,57(11):2-32. doi: 10.3901/JME.2021.11.002 [3] 朱欢欢, 李厚佳, 张利华, 等. 切入式磨削烧伤仿真预测与控制方法研究 [J]. 金刚石与磨料磨具工程,2019,39(5):44-49. doi: 10.13394/j.cnki.jgszz.2019.5.0009ZHU Huanhuan, LI Houjia, ZHANG Lihua, et al. Study on simulation prediction and control method of burns in plunge grinding [J]. Diamond & Abrasives Engineering,2019,39(5):44-49. doi: 10.13394/j.cnki.jgszz.2019.5.0009 [4] ZHANG L H, TAI B L, ZHANG K B, et al. Thermal model to investigate the temperature in bone grinding for skull base neurosurgery [J]. Medical Engineering & Physics,2012,35(10):1391-1398. doi: 10.1016/j.medengphy.2013.03.023 [5] MURAT C, SERDAR K, ERKAN B, et al. Investigation of thermal damage in bone drilling: Hybrid processing method and pathological evaluation of existing methods [J]. Journal of the Mechanical Behavior of Biomedical Materials,2022,126:105030. doi: 10.1016/j.jmbbm.2021.105030 [6] YANG Y Y, YANG M, LI C H, et al. Machinability of ultrasonic vibration-assisted micro-grinding in biological bone using nanolubricant [J]. Frontiers of Mechanical Engineering,2023,18(1):1-16. doi: 10.1007/s11465-022-0717-z [7] LIU Y, BELMONT B, WANG Y W, et al. Notched K-wire for low thermal damage bone drilling [J]. Medical Engineering & Physics,2017,45:25-33. doi: 10.1016/j.medengphy.2017.04.001 [8] PALMISANO A C, TAI B L, BELMONT B, et al. Heat accumulation during sequential cortical bone drilling [J]. Journal of Orthopaedic Research,2016,34:463-470. doi: 10.1002/jor.23044 [9] PANDEY R K, PANDA S S. Drilling of bone: A comprehensive review [J]. Journal of Orthopaedic Trauma,2013,4(1):15-30 . doi: 10.1016/j.jcot.2013.01.002 [10] GHOLAMPOUR S, DROESSLER J, FRIM D. The role of operating variables in improving the performance of skull base grinding [J]. Neurosurgical Review,2022,45:2431-2440. doi: 10.1007/s10143-022-01736-0 [11] GHOLAMPOUR S, HASSANALIDEH HH, GHOLAMPOUR M, et al. Thermal and physical damage in skull base drilling using gas cooling modes: FEM simulation and experimental evaluation [J]. Computer Methods and Programs in Biomedicine,2021(212): 106463. doi: 10.1016/j.cmpb.2021.106463 [12] YANG M, LI C H, ZHANG Y B, et al. Research on microscale skull grinding temperature field under different cooling conditions [J]. Applied Thermal Engineering,2017,126:525-537. doi: 10.1016/j.applthermaleng.2017.07.183 [13] YANG M, LI C H, ZHANG Y B, et al. Experimental research on microscale grinding temperature under different nanoparticle jet minimum quantity cooling [J]. Materials and Manufacturing Process,2017,32(6):589-597. doi: 10.1080/10426914.2016.1176198 [14] YANG M, LI C H, LUO L, et al. Predictive model of convective heat transfer coefficient in bone micro-grinding using nanofluid aerosol cooling [J]. International Communications in Heat and Mass Transfer,2021,125:105317. doi: 10.1016/j.icheatmasstransfer.2021.105317 [15] 孙建, 钱炜, 丁子珊. 基于FLUENT的微量润滑磨削流场仿真研究 [J]. 机电工程,2021,38(7):865-872. doi: 10.3969/j.issn.1001-4551.2021.07.009SUN Jian, QIAN Wei, DING Zishan. Minimal quantities lubricant grinding based on FLUENT flow field simulation [J]. Journal of Mechanical & Electrical Engineering,2021,38(7):865-872. doi: 10.3969/j.issn.1001-4551.2021.07.009 [16] ENOMOTO T, SHIGETA H, SUGIHARA T, et al. A new surgical grinding wheel for suppressing grinding heat generation in bone resection [J]. CIRP Annals-ManufacturingTechnology,2014,63(1):305-308. doi: 10.1016/j.cirp.2014.03.026 [17] SASAKI M, MORRIS S, GOTO T, et al. Spray-irrigation system attached to high-speed drills for simultaneous prevention of local heating and preservation of a clear operative field in spinal surgery [J]. Neurologia Medico-chirurgica,2010,50(10):900-904. doi: 10.2176/nmc.50.900 [18] LI C H, ZHAO H Y, MA H L, et al. Simulation study on effect of cutting parameters and cooling mode on bone-drilling temperature field of superhard drill [J]. International Journal of Advanced Manufacturing Technology,2015,81(9/10/11/12):2027-2038. doi: 10.1007/s00170-015-7259-z [19] TAKENAKA S, HOSONO N, MUKAI Y, et al. The use of cooled saline during bone drilling to reduce the incidence of upper-limb palsy after cervical laminoplasty: Clinical article [J]. Journal of Neurosurgery-spine,2013,19(4):420-427. doi: 10.3171/2013.7.SPINE13144 [20] ZHANG L H, TAI B L, WANG A C, et al . Mist cooling in neurosurgical bone grinding [J]. CIRP Annals- Manufacturing Technology,2013,62(1):367-370. doi: 10.1016/j.cirp.2013.03.125 [21] DANDA A, KUTTOLAMADOM M A, TAI B L. A mechanistic force model for simulating haptics of hand-held bone burring operations [J]. Medical Engineering and Physics,2017,49: 7-13. doi: 10.1016/j.medengphy.2017.06.041 [22] SHIH A J, TAI B L, ZHANG L H, et al. Prediction of bone grinding temperature in skull base neurosurgery [J]. CIRP Annals- Manufacturing Technology,2012,61(1):307-310. doi: 10.1016/j.cirp.2012.03.078 -

下载:

下载:

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS