Effect of WC on microstructure and properties of induction brazing diamond coating

-

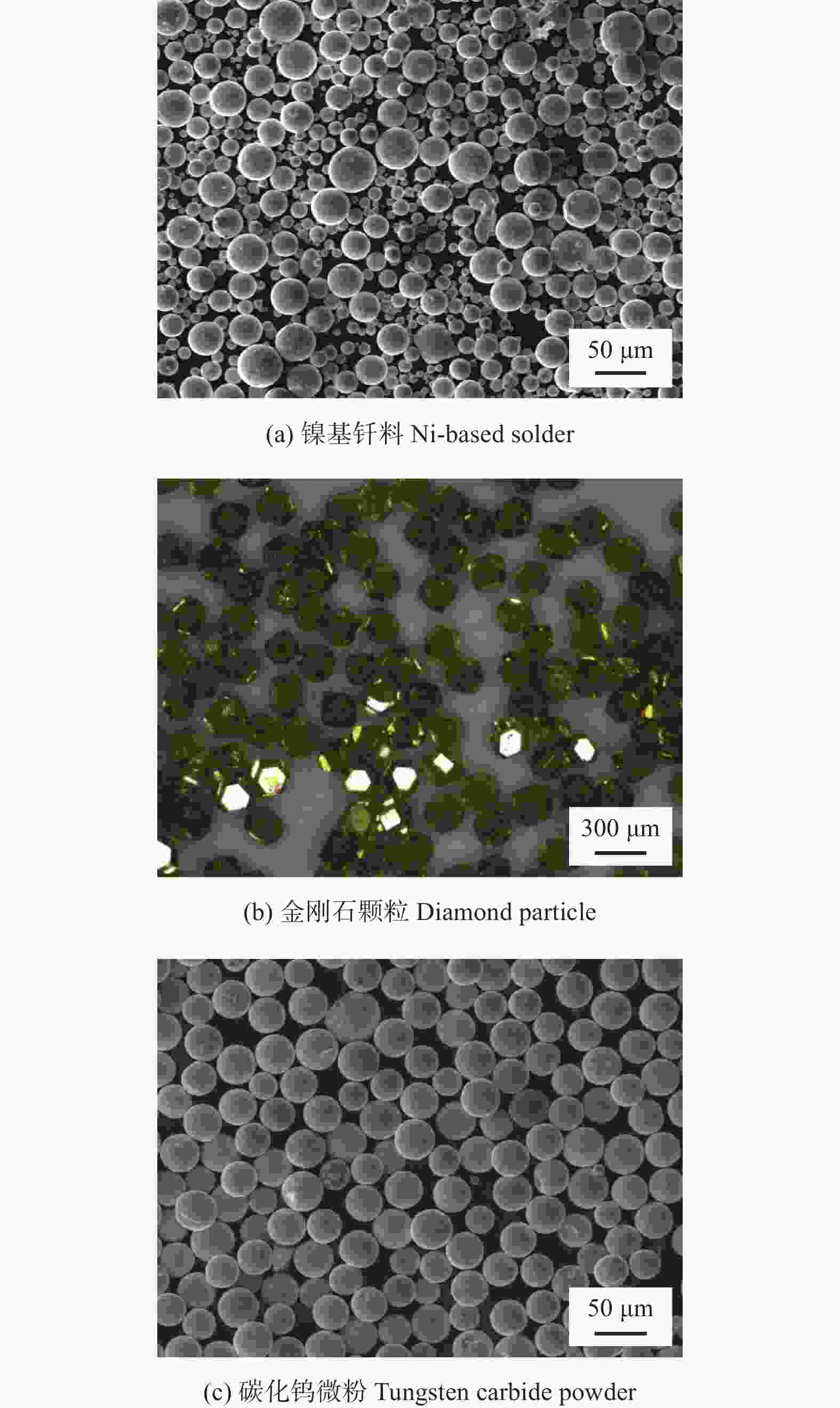

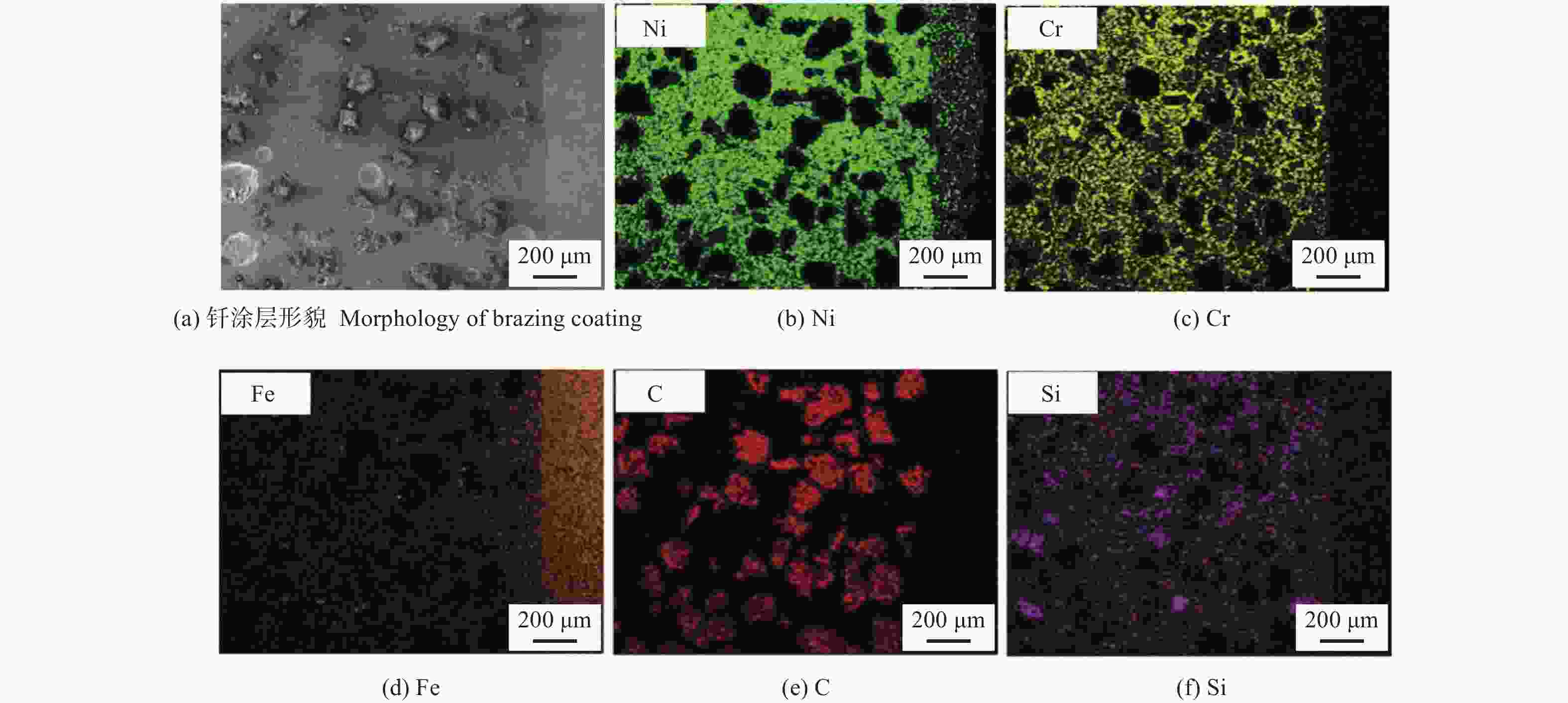

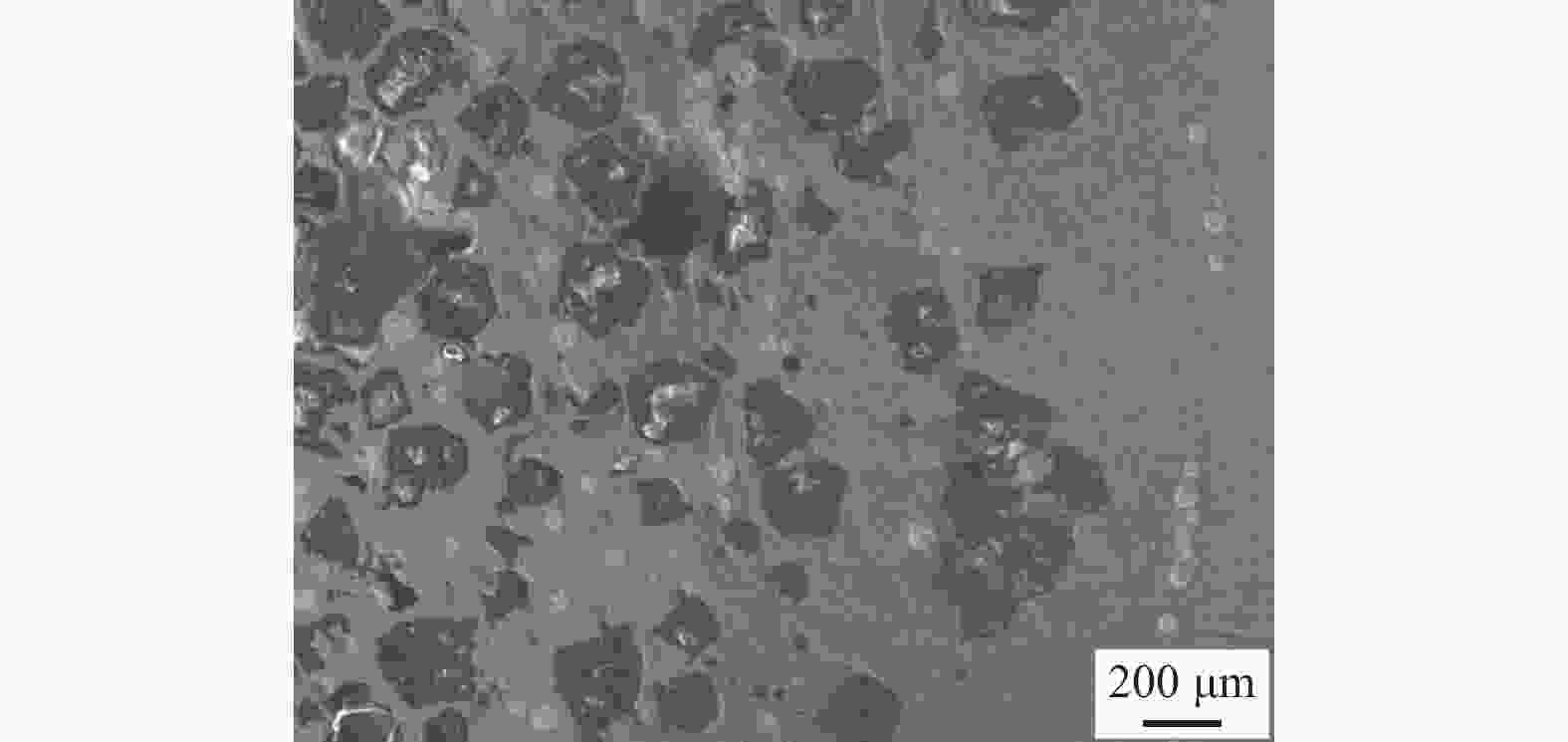

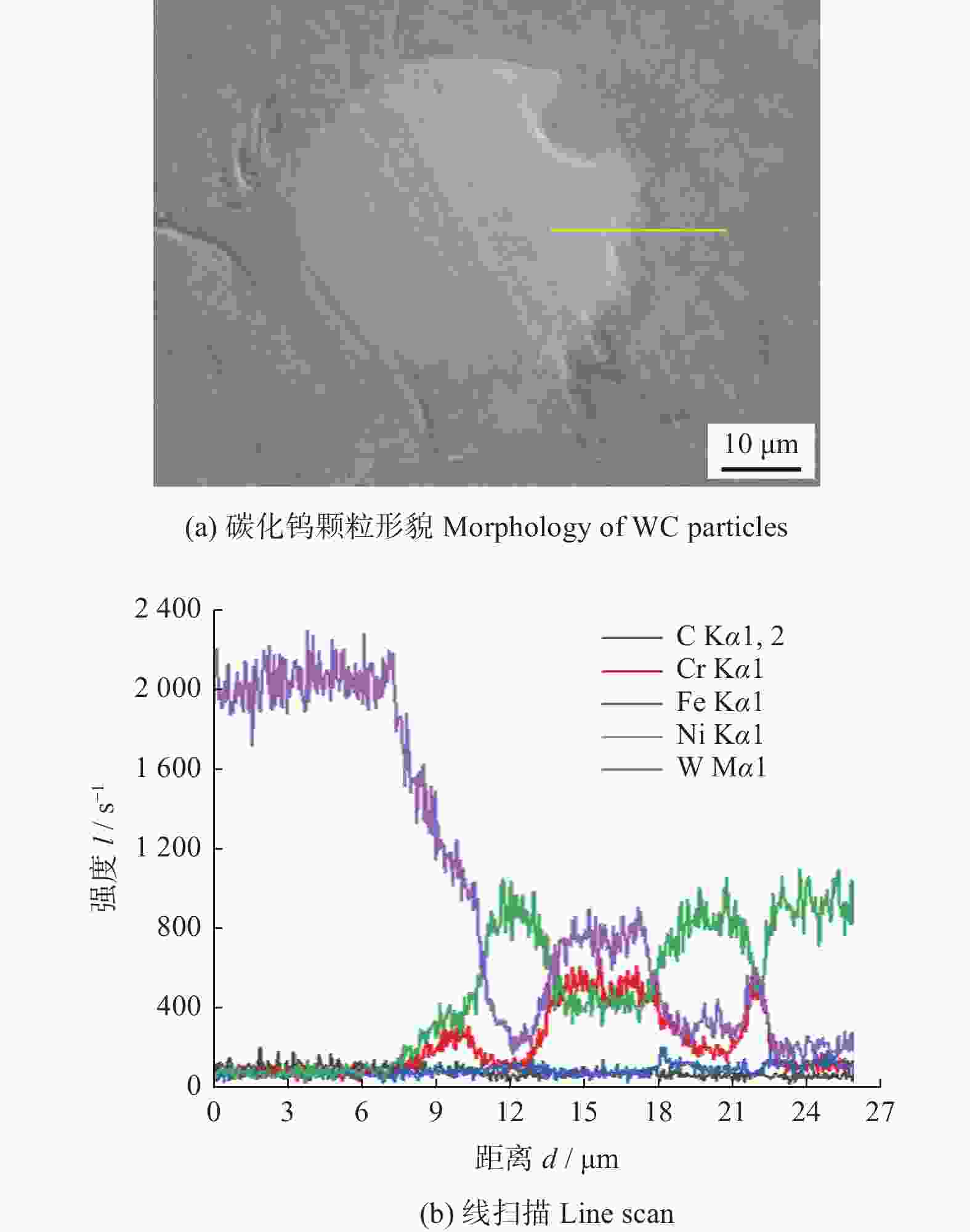

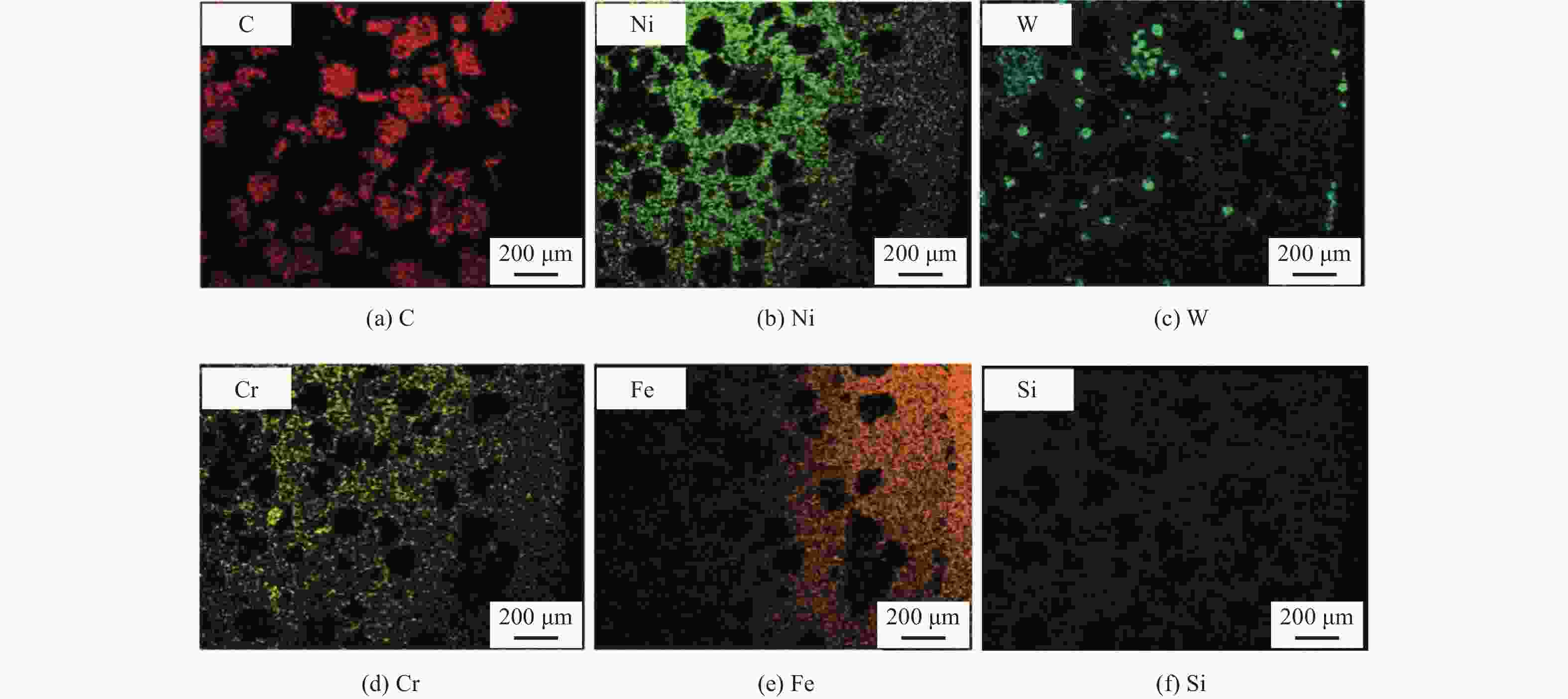

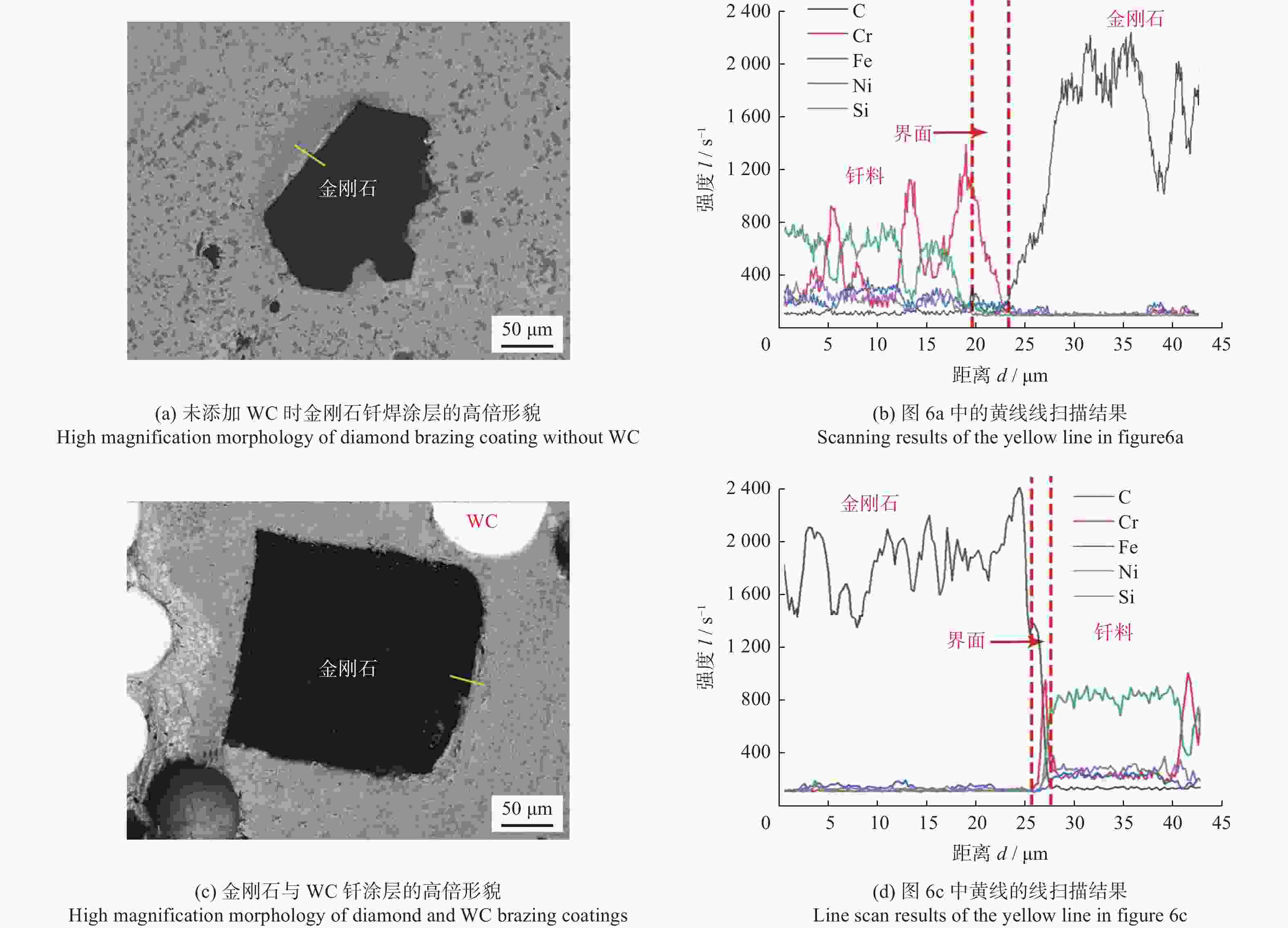

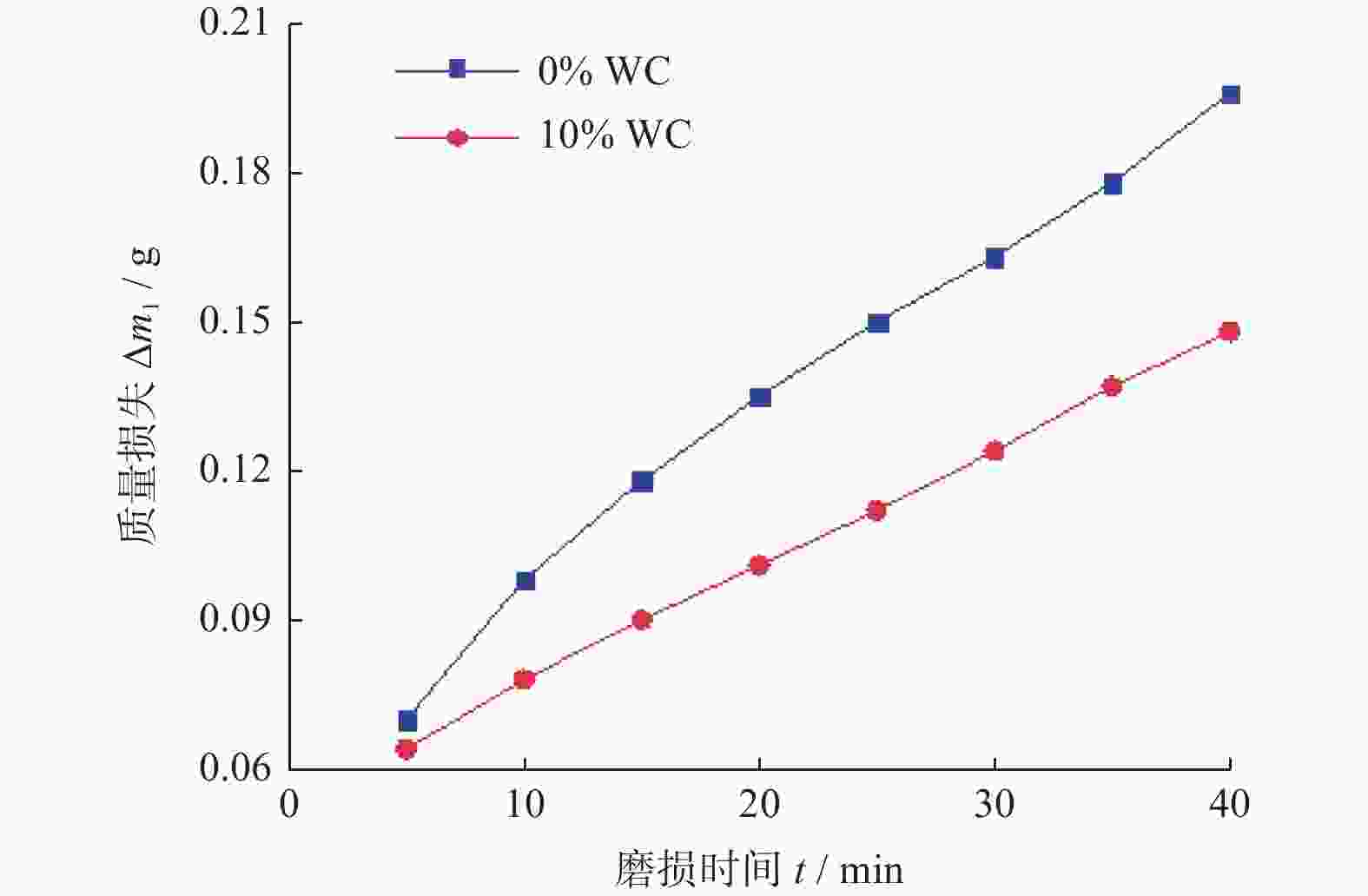

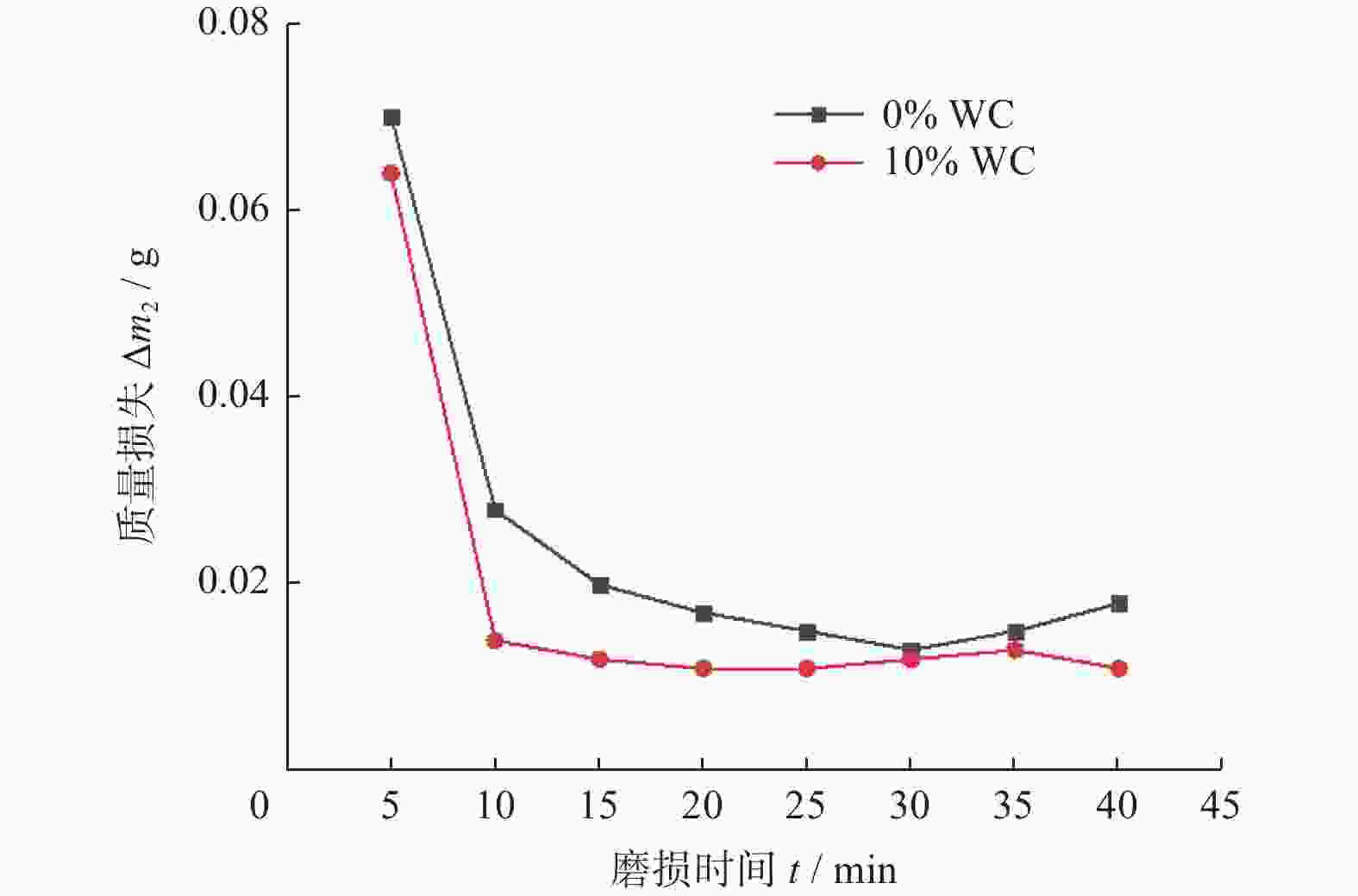

摘要: 在镍基钎料中加入WC微粉,采用钎涂的方法在Q235钢上制备金刚石涂层,研究WC微粉对金刚石涂层组织及耐磨性的影响,并通过扫描电镜、能谱分析、显微硬度和磨损失重测试表征金刚石钎焊涂层的组织和耐磨性能。结果表明:在钎涂过程中,金刚石、WC微粉与镍基钎料合金发生冶金结合,WC颗粒在镍基基体中具有弥散强化与细晶强化作用,添加质量分数为10%WC的钎料合金的洛氏硬度与未添加WC时的比较提高了7.5%;且在相同的磨损实验条件下,未添加WC微粉的钎涂金刚石涂层质量损失为0.196 g,而添加WC微粉后的涂层质量损失为0.148 g,后者的耐磨性能提高了24.5%。Abstract: The diamond coating was prepared on Q235 steel by adding WC micro-powder to a nickel-based filler metal during induction brazing. The effects of WC powder on the microstructure and wear resistance of the diamond coating were studied. The microstructure and wear resistance of the diamond coating were characterized by scanning electron microscopy, energy spectrum, microhardness and wear loss tests. The results show that during the brazing process, diamond and WC micro-powder form metallurgical bonds with the nickel-based brazing alloy. The WC particles contribute to dispersion strengthening and fine-grain strengthening effects in the nickel-based matrix. The Rockwell hardness of the brazing alloy with a mass fraction of 10% WC increases by 7.5% compared to that without WC. Under identical wear experimental conditions, the mass loss of the diamond coating without added WC micro-powder was 0.196 g, while the mass loss of the coating with WC micro-powder added was 0.148 g. The wear resistance of the latter increased by 24.5%.

-

Key words:

- WC /

- diamond /

- induction brazing coating /

- wear resistant

-

表 1 镍基钎料化学成分

Table 1. Chemical compositions of Ni-based solder

元素 质量分数 ω / % Cr 7.10 B 3.00 Si 4.40 Fe 3.10 C 0.02 Ni 余量 -

[1] 龙伟民, 秦建, 路全彬, 等. 旋耕刀感应钎涂层热处理工艺研究 [J]. 材料导报,2022,36(7):98-102.LONG Weimin, QIN Jian, LU Quanbin, et al. Heat treatment process of induction braze coating of rotary blades [J]. Material Reports,2022,36(7):98-102. [2] 李宇佳, 孙志鹏, 张雷, 等. 金刚石钎涂技术在过流部件上的应用研究 [J]. 电焊机,2021,51(10):19-23,152. doi: 10.7512/j.issn.1001-2303.2021.10.04LI Yujia, SUN Zhipeng, ZHANG Lei, et al. Application research of diamond brazecoating technology in flow passage components [J]. Electric Welding Machine,2021,51(10):19-23,152. doi: 10.7512/j.issn.1001-2303.2021.10.04 [3] 秦建, 杨骄, 龙伟民, 等. 金刚石及其复合材料增材技术研究进展 [J]. 焊接学报,2022,43(8):102-112,120. doi: 10.12073/j.hjxb.20220508002QIN Jian, YANG Jiao, LONG Weimin, et al. Research progress of additive technology of diamond and its composite materials [J]. Transactions of the China Welding Institution,2022,43(8):102-112,120. doi: 10.12073/j.hjxb.20220508002 [4] 王星星, 武胜金, 李帅, 等. 功能性钎涂技术的研究进展与应用现状 [J]. 中国有色金属学报,2021,31(1):72-83. doi: 10.11817/j.ysxb.1004.0609.2021-37711WANG Xingxing, WU Shengjin, LI Shuai, et al. Research progress and application status of functional brazed coating technology [J]. The Chinese Joural of Nonferrous Metals,2021,31(1):72-83. doi: 10.11817/j.ysxb.1004.0609.2021-37711 [5] 王文琴, 王昭漫, 王德, 等. 单晶高温合金真空钎涂MCrAl-YCr3C2涂层的研究 [J]. 焊接,2017(12):41-43,47.WANG Wenqin, WANG Zhaoman, WANG De, et al. Research on vacuum brazing MCrAl-YCr3C2 coating on single crystal superalloy [J]. Welding & Joining,2017(12):41-43,47. [6] 张启运, 庄鸿寿. 钎焊手册 [M]. 北京: 机械工业出版社, 2018, 582-584.ZHANG Qiyun, ZHUANG Hongshou. Handbook of brazing and soldering [M]. Beijing: China Machine Press, 2018, 582-584. [7] LIU D, LONG W, WU M, et al. Microstructure evolution and life time extension mechanism of Sn-added Fe based pre-alloy brazing coating in diamond tools [J]. Coatings,2019,9(6):364. doi: 10.3390/coatings9060364 [8] 朱晨颖, 孙志鹏, 王宇. 感应钎涂金刚石/镍基合金复合涂层的性能 [J]. 焊接学报,2022,43(2):106-112,120. doi: 10.12073/j.hjxb.20210521003ZHU Chenying, SUN Zhipeng, WANG Yu. Properties of induction brazing diamond/Ni-based alloy composite coating [J]. Transactions of the China Welding Institution,2022,43(2):106-112,120. doi: 10.12073/j.hjxb.20210521003 [9] ZHANG L, LONG W, DU D, et al. The microstructure and wear properties of diamond composite coatings on TC4 made by induction brazing [J]. Diamond & Related Materials,2022,125:109032. [10] 秦建, 龙伟民, 路全彬, 等. 金刚石/NiCrBSi钎涂接头组织与耐磨性能分析 [J]. 材料导报,2020,34(S2):1457-1461.QIN Jian, LONG Weimin, LI Quanbin, et al. Microstructure and wear properties of diamond/NiCrBSi composite brazing coating [J]. Material Reports,2020,34(S2):1457-1461. [11] 龙伟民, 刘大双, 王博, 等. 铝微粉对大气环境感应钎涂金刚石涂层性能影响 [J]. 焊接学报,2021,42(12):67-71. doi: 10.12073/j.hjxb.20210917002LONG Weimin, LIU Dashuang, WANG Bo, et al. Effect of aluminum powder on properties of induction braze coated diamond layers in atmospheric environment [J]. Transactions of the China Welding Institution,2021,42(12):67-71. doi: 10.12073/j.hjxb.20210917002 [12] 龙伟民, 郝庆乐, 傅玉灿, 等. 金刚石工具钎焊用连接材料研究进展 [J]. 材料导报,2020,34(12):23138-23144. doi: 10.11896/cldb.20100102LONG Weimin, HAO Qingle, FU Yucan, et al. Research progress of filler metals for brazing diamond tools [J]. Materials Reports,2020,34(12):23138-23144. doi: 10.11896/cldb.20100102 [13] LONG W, LU Q, ZHONG S, et al. Research on interface structure and performance of diamond brazed coating [J]. Welding in the World,2022,66(5):1043-1052. doi: 10.1007/s40194-022-01259-8 [14] LONG W, LIU D, DONG X, et al. Laser power effects on properties of laser brazing diamond coating [J]. Surface Engineering,2020,36(12):1315-1326. doi: 10.1080/02670844.2020.1758292 [15] LONG W, LIU D, WU A, et al. Influence of laser scanning speed on the formation property of laser brazing diamond coating [J]. Diamond and Related Materials,2020,110:108085. doi: 10.1016/j.diamond.2020.108085 [16] 路世盛, 周健松, 王凌倩, 等. 球墨铸铁表面激光熔覆Ni-Co复合涂层的耐腐蚀及高温摩擦学性能 [J]. 中国表面工程,2022,35(3):122-131.LU Shisheng, ZHOU Jiansong, WANG Lingqian, et al. Corrosion resistance and elevated-temperature wear properties of laser cladding Ni-Co composite coating on ductile cast iron [J]. China Surface Engineering,2022,35(3):122-131. [17] 龙伟民, 刘大双, 张冠星, 等. 感应钎涂粉末熔融及传热机制 [J]. 焊接学报,2021,42(11):29-34. doi: 10.12073/j.hjxb.20210916001LONG Weimin, LIU Dashuang, ZHANG Guanxing, et al. Melting and heat transfer mechanism of powder by induction brazing coating [J]. Transactions of the China Welding Institution,2021,42(11):29-34. doi: 10.12073/j.hjxb.20210916001 [18] XIAO H, XIAO B, WU H. Interfacial characteristics and mechanical properties of the vacuum brazing diamond grains segment with Ni-Cr composite active filler and tungsten carbide reinforcement [J]. Journal of Alloys and Compounds,2019,781:226-234. doi: 10.1016/j.jallcom.2018.12.106 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS