Elastic performance prediction and 3D drilling simulation of PW-CFRP

-

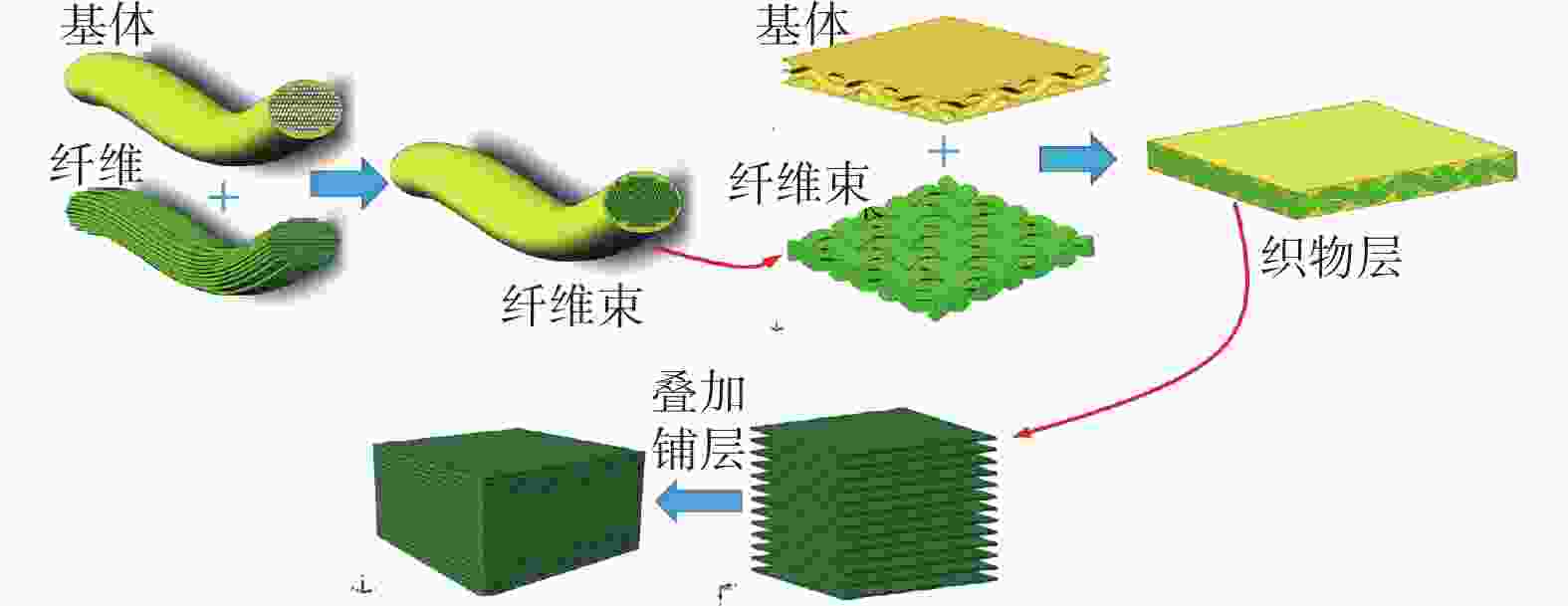

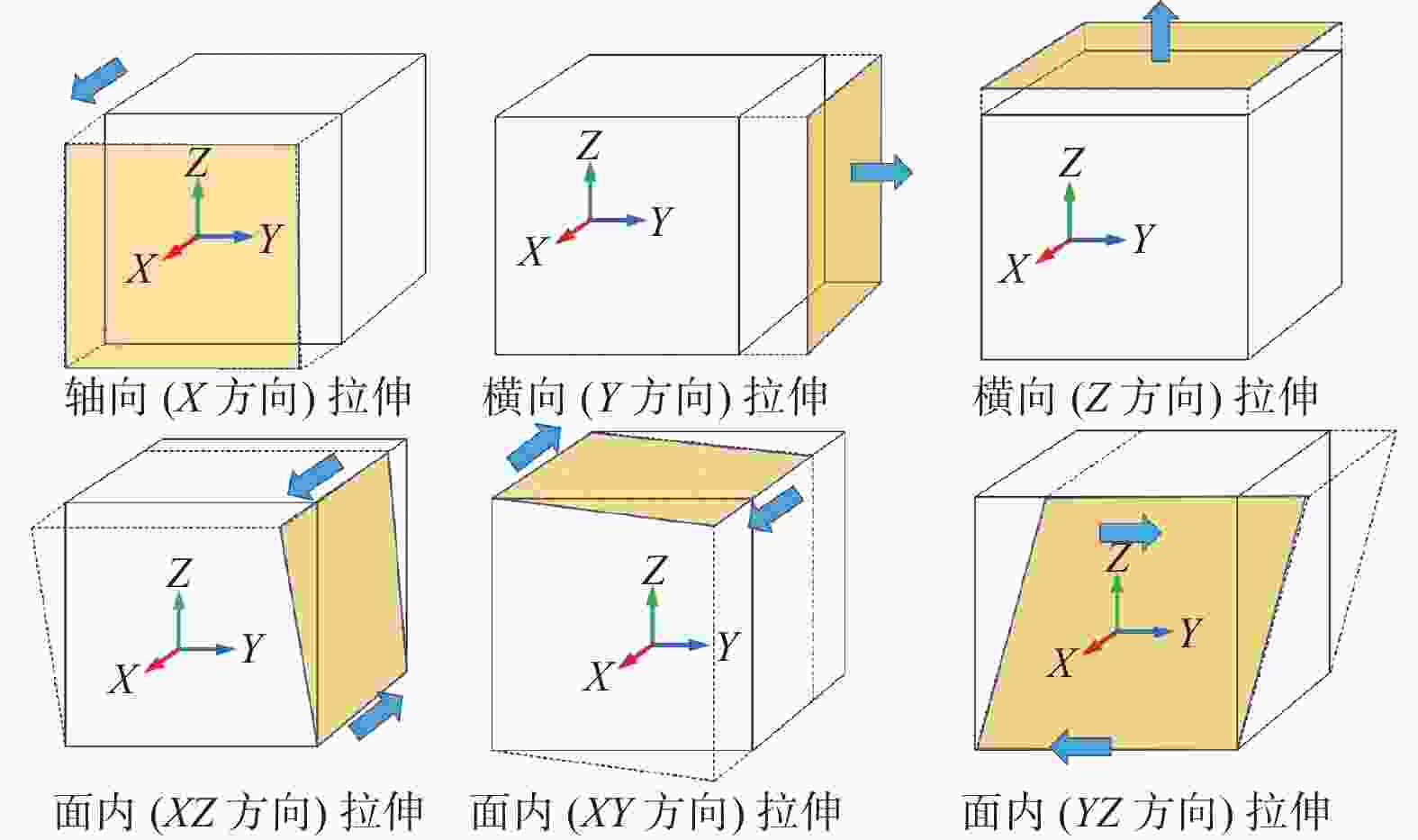

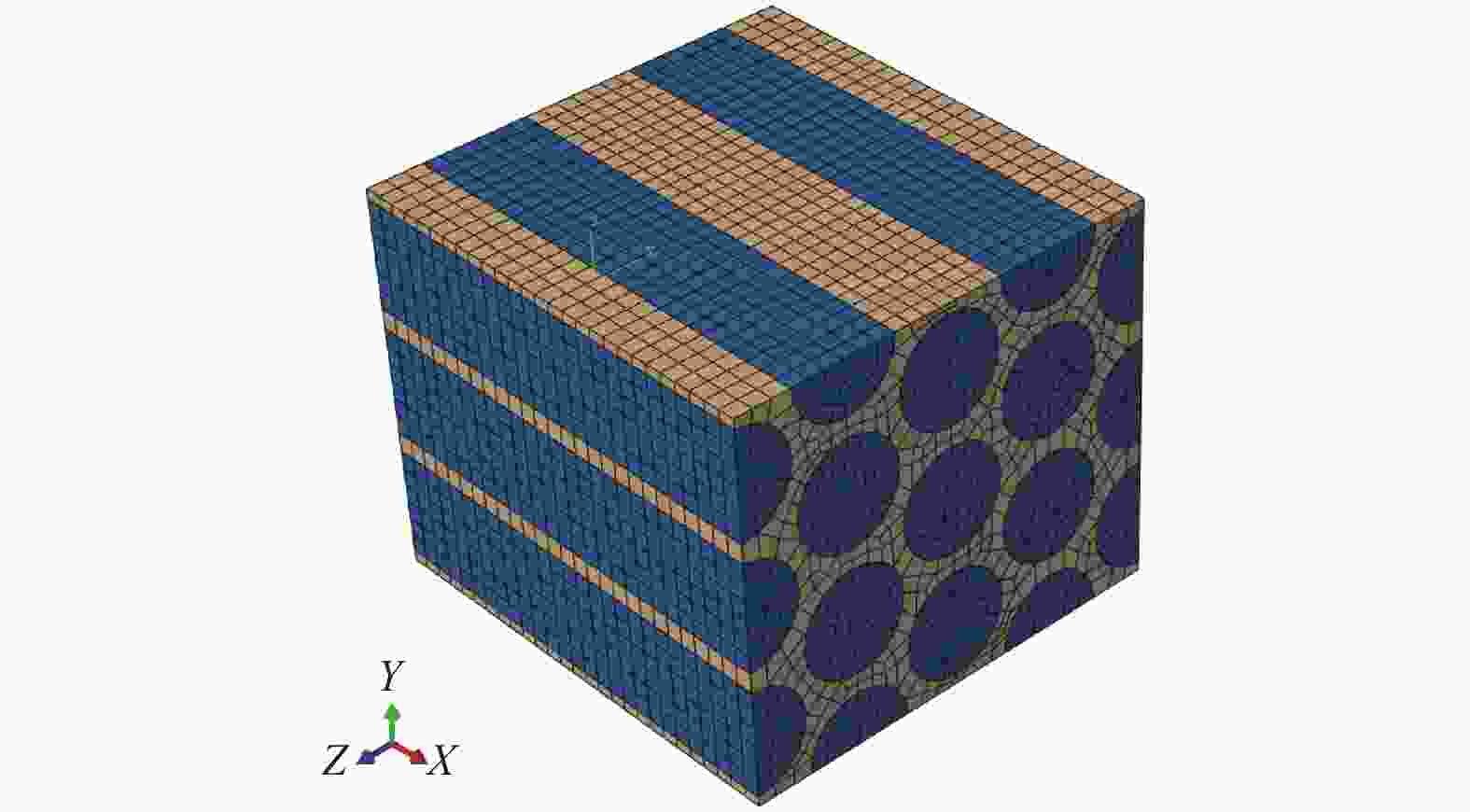

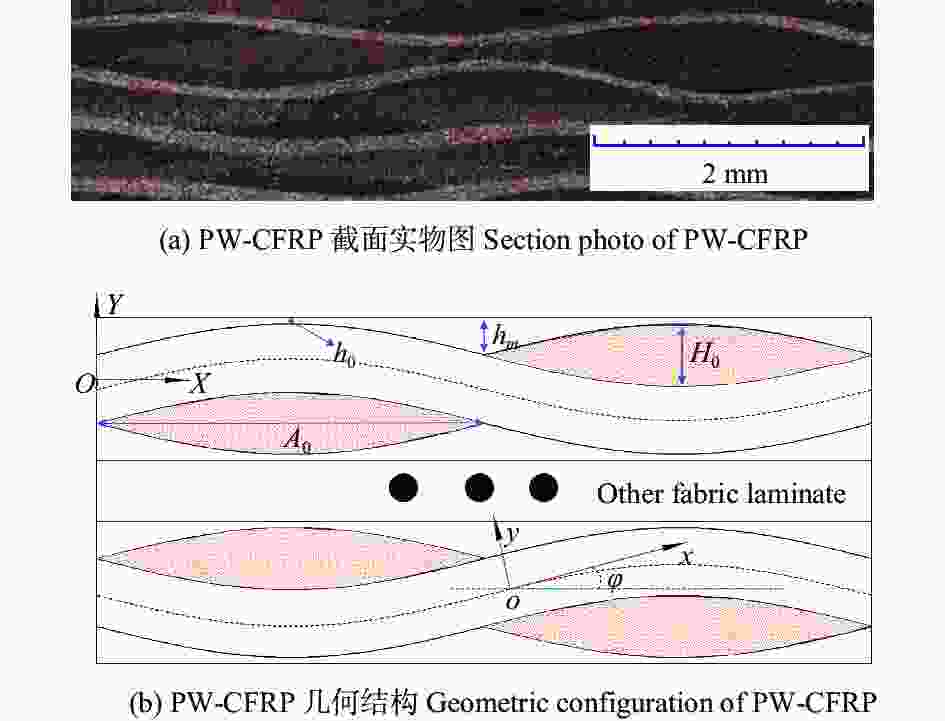

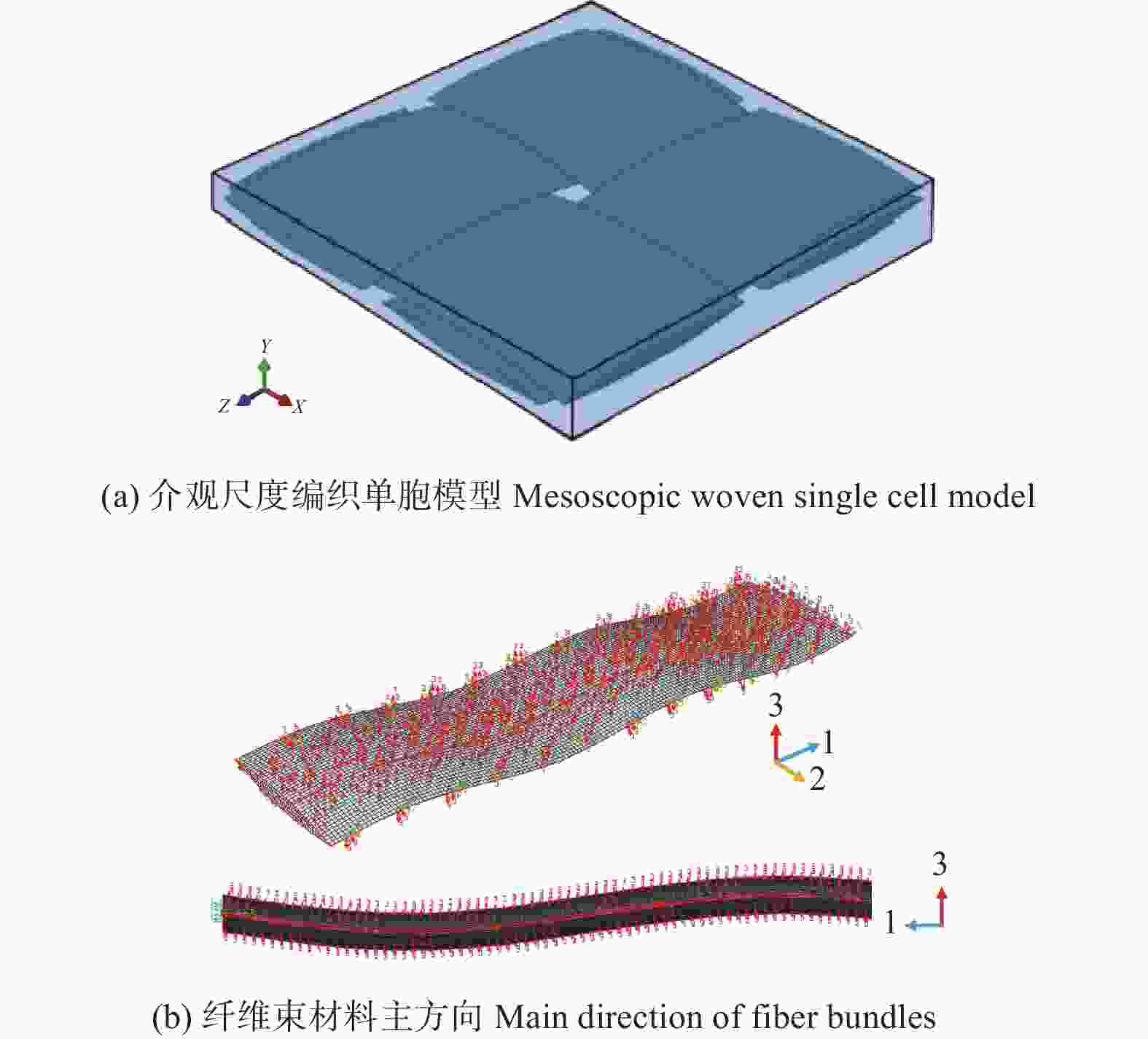

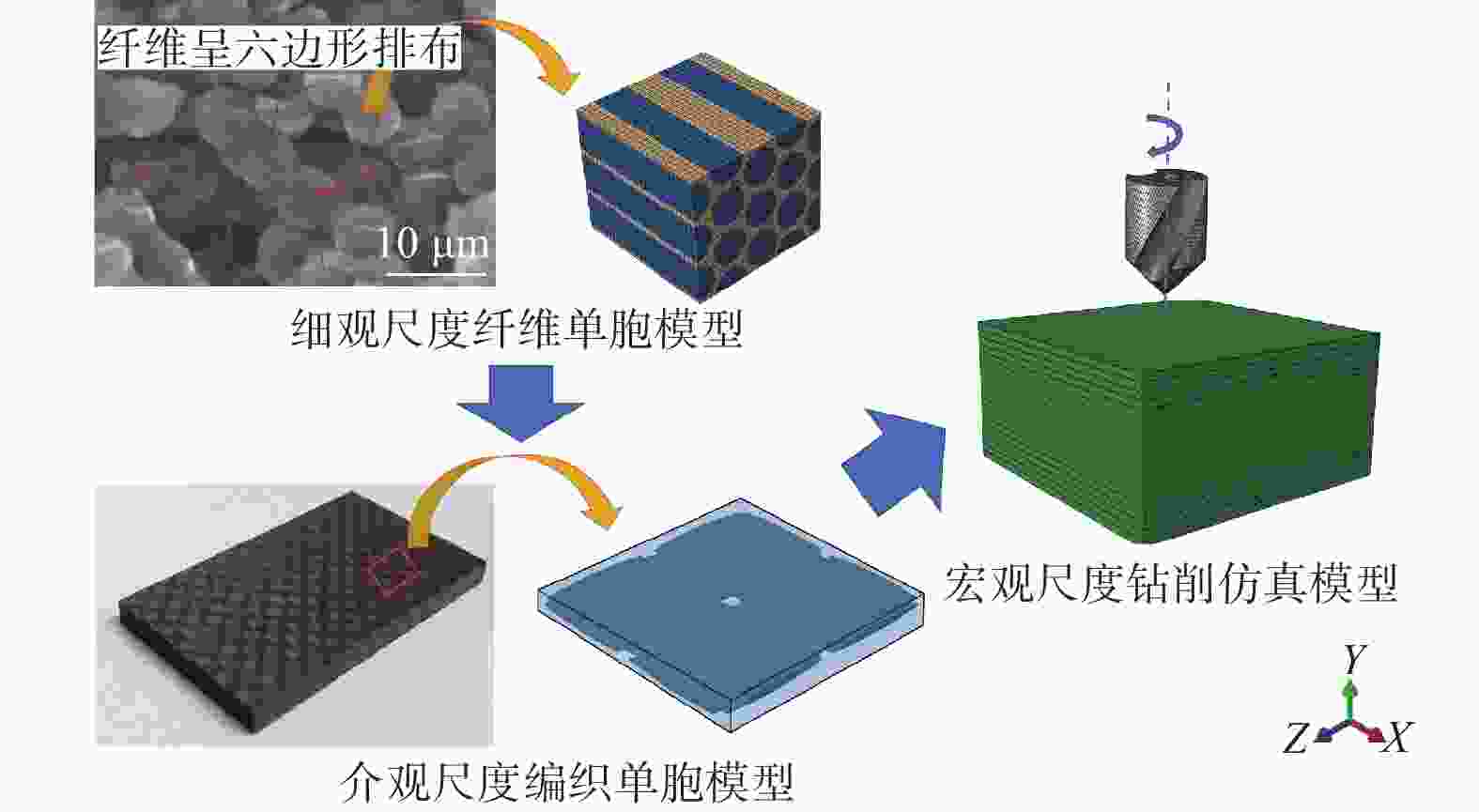

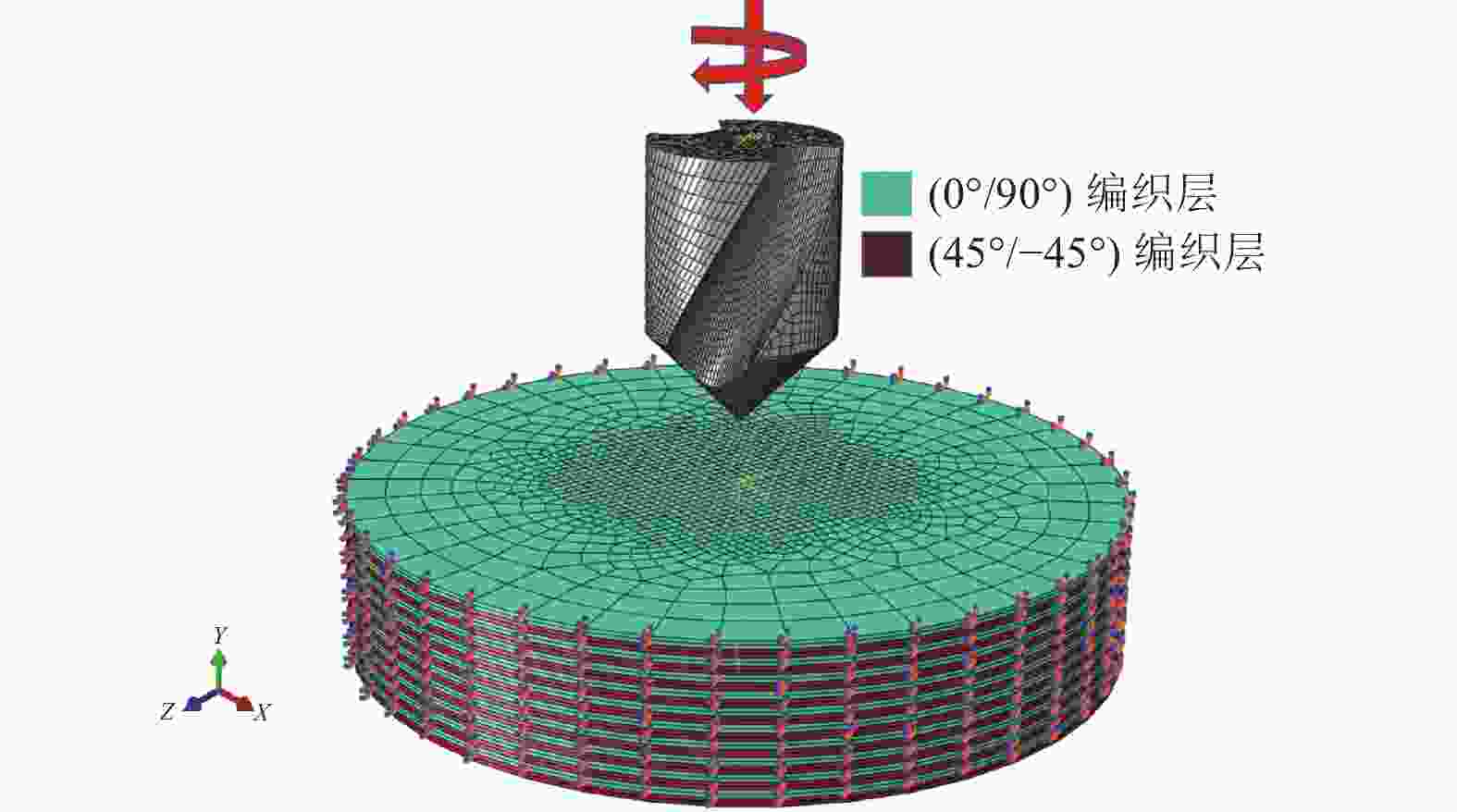

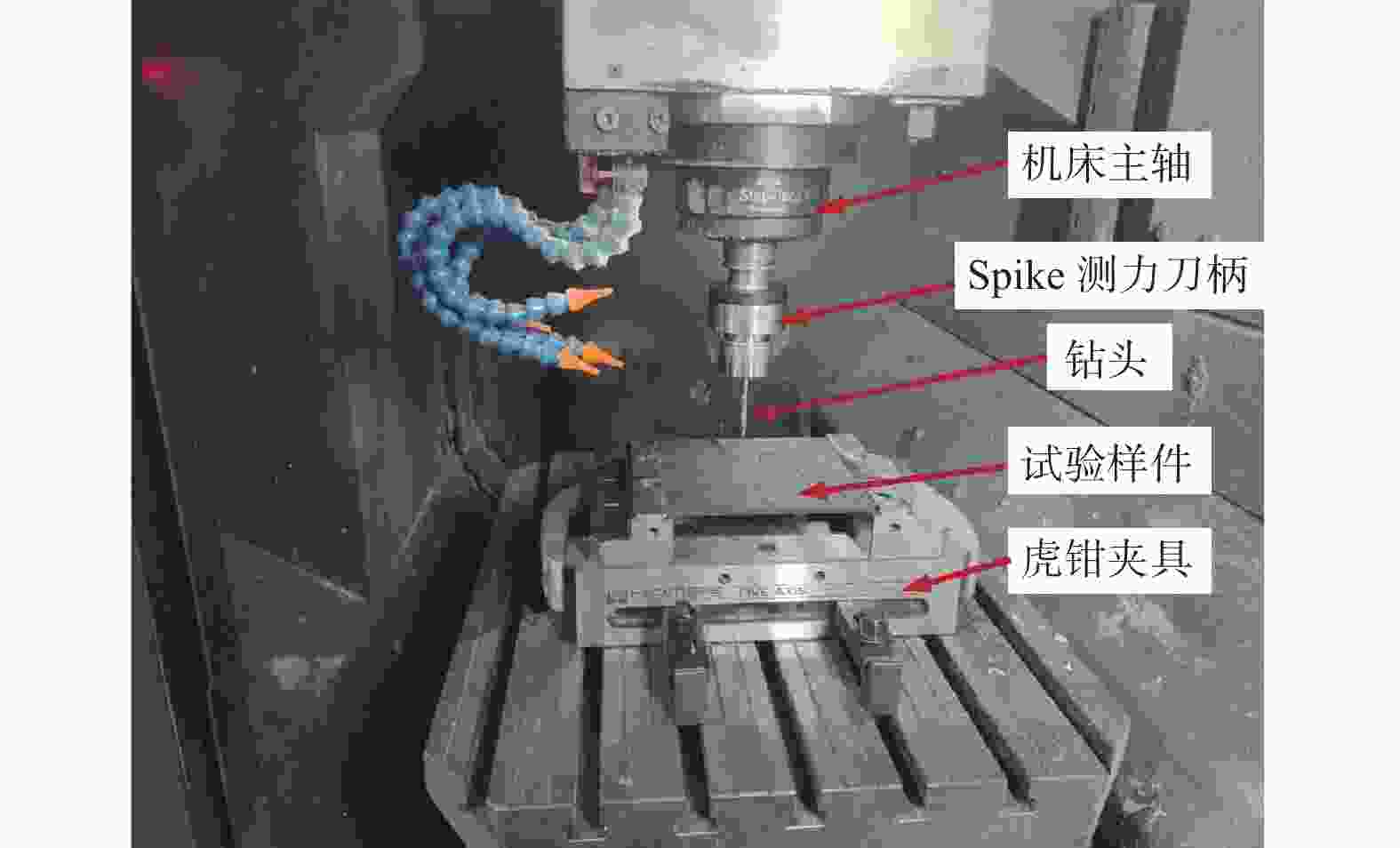

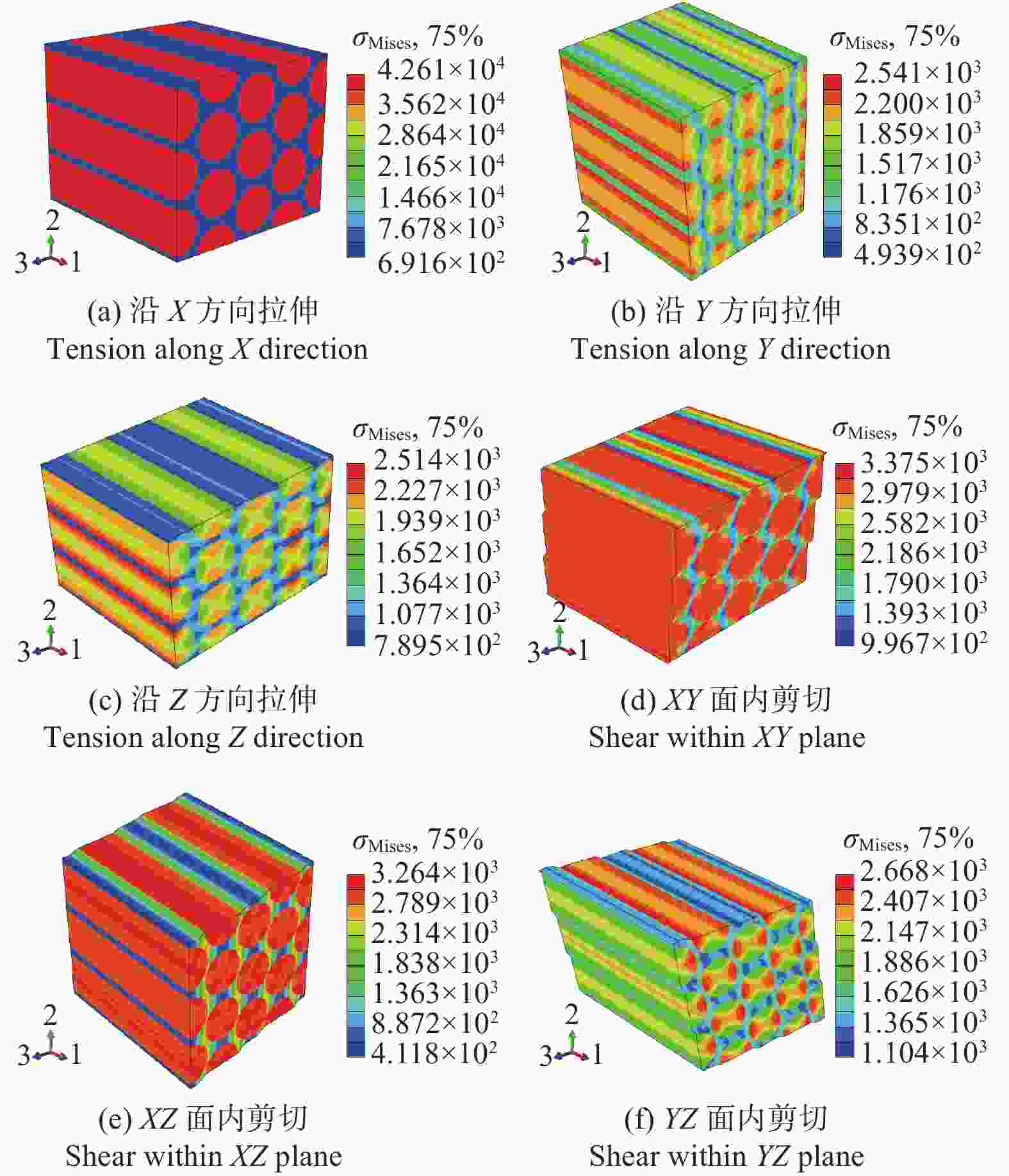

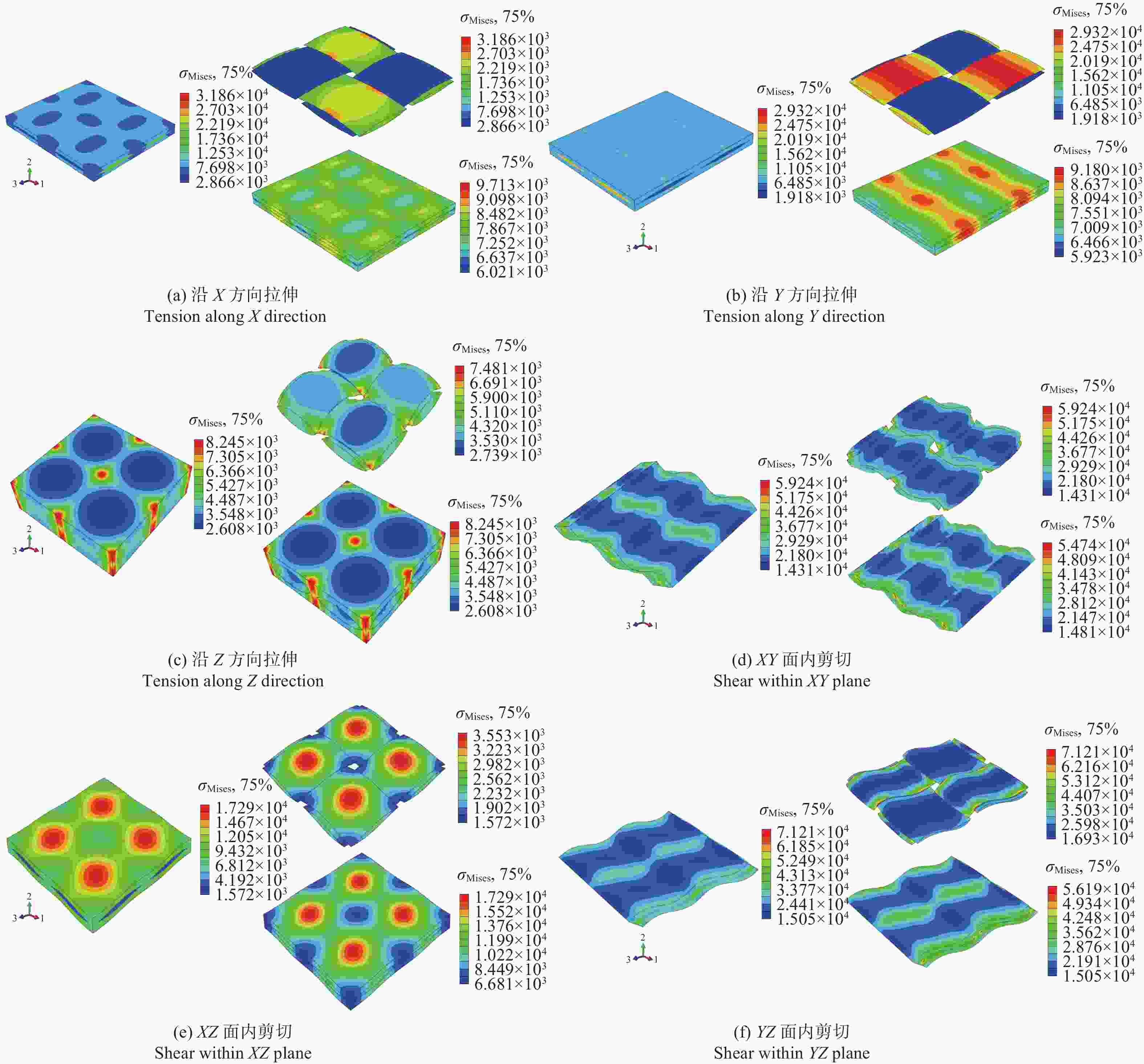

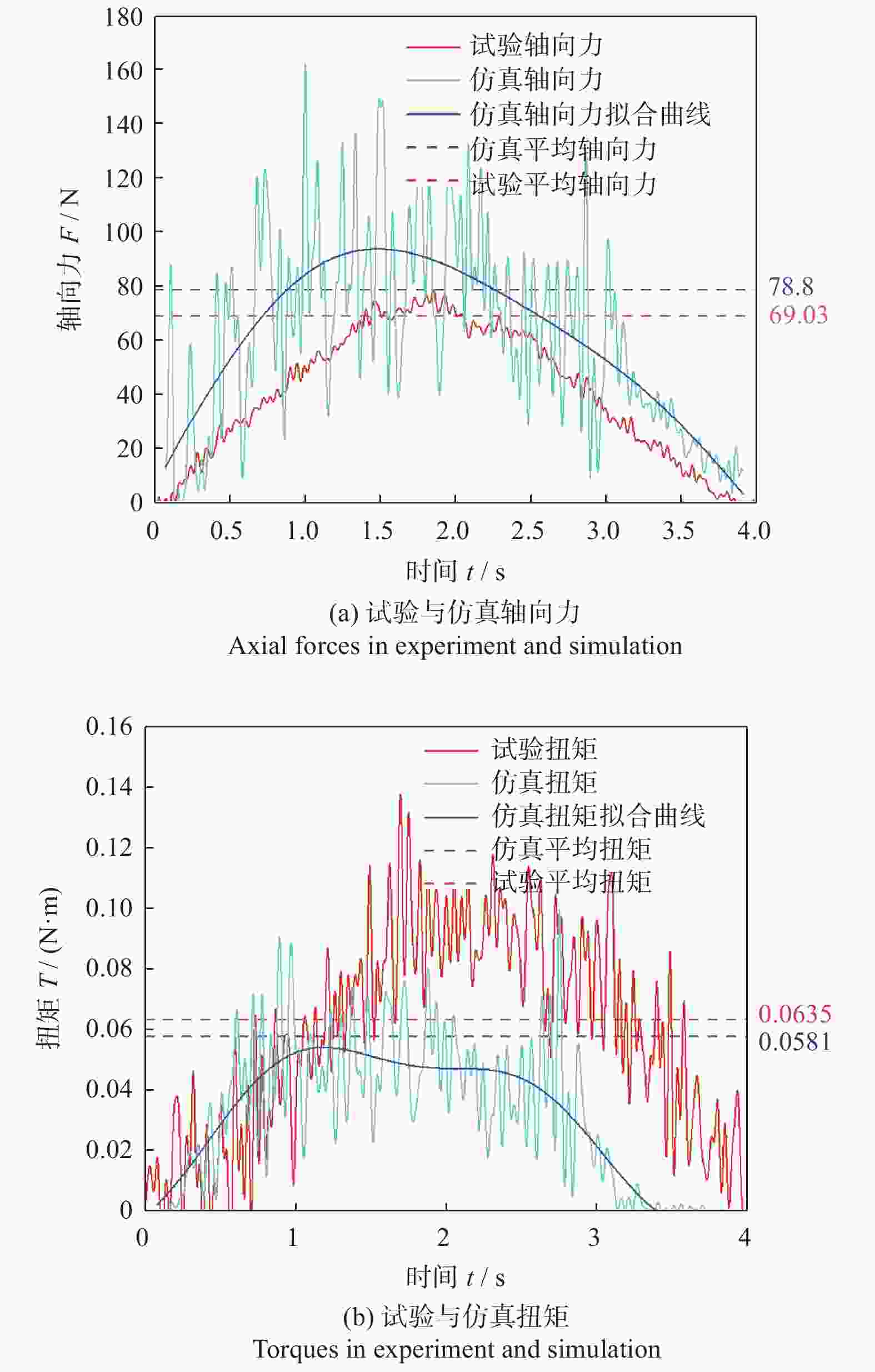

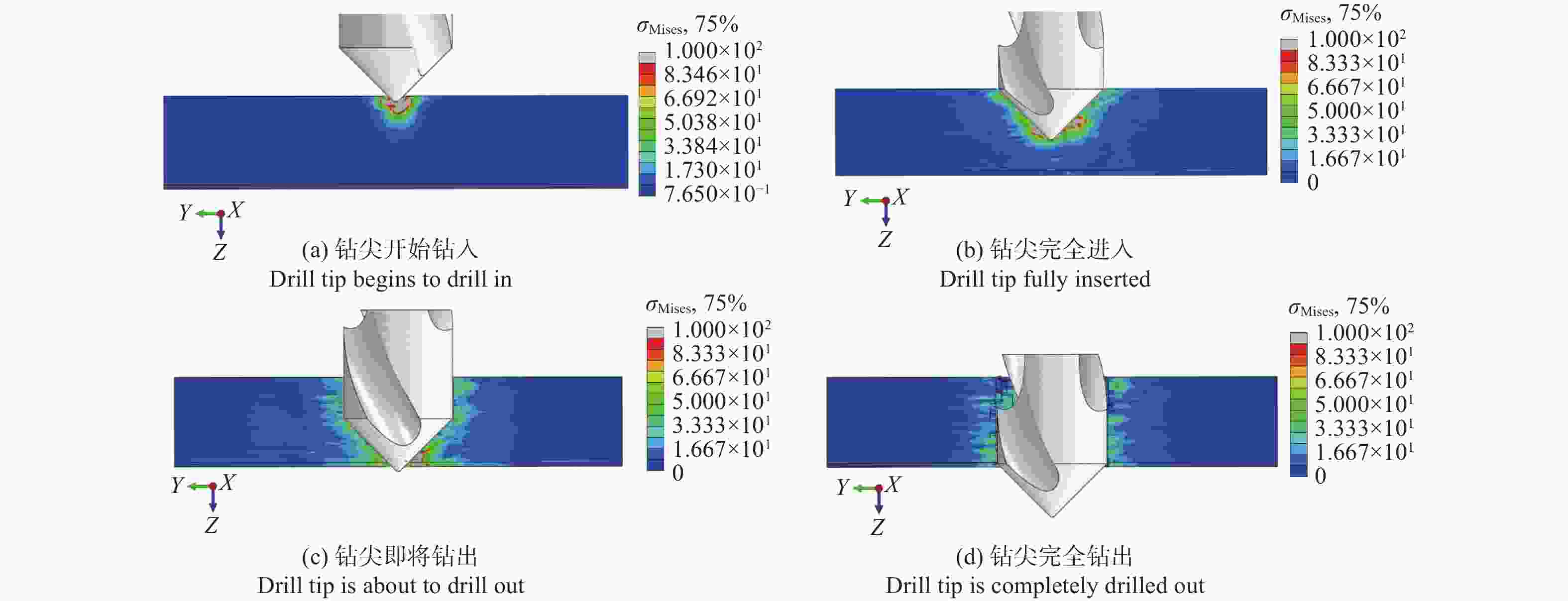

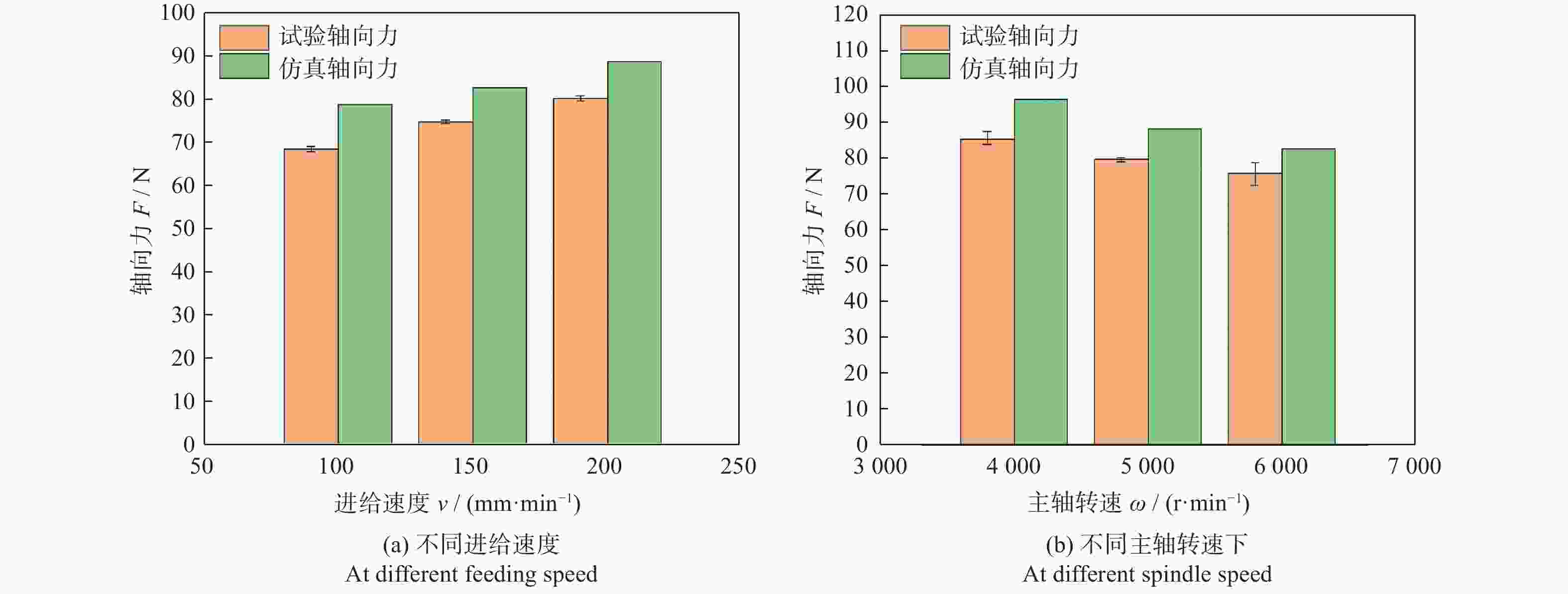

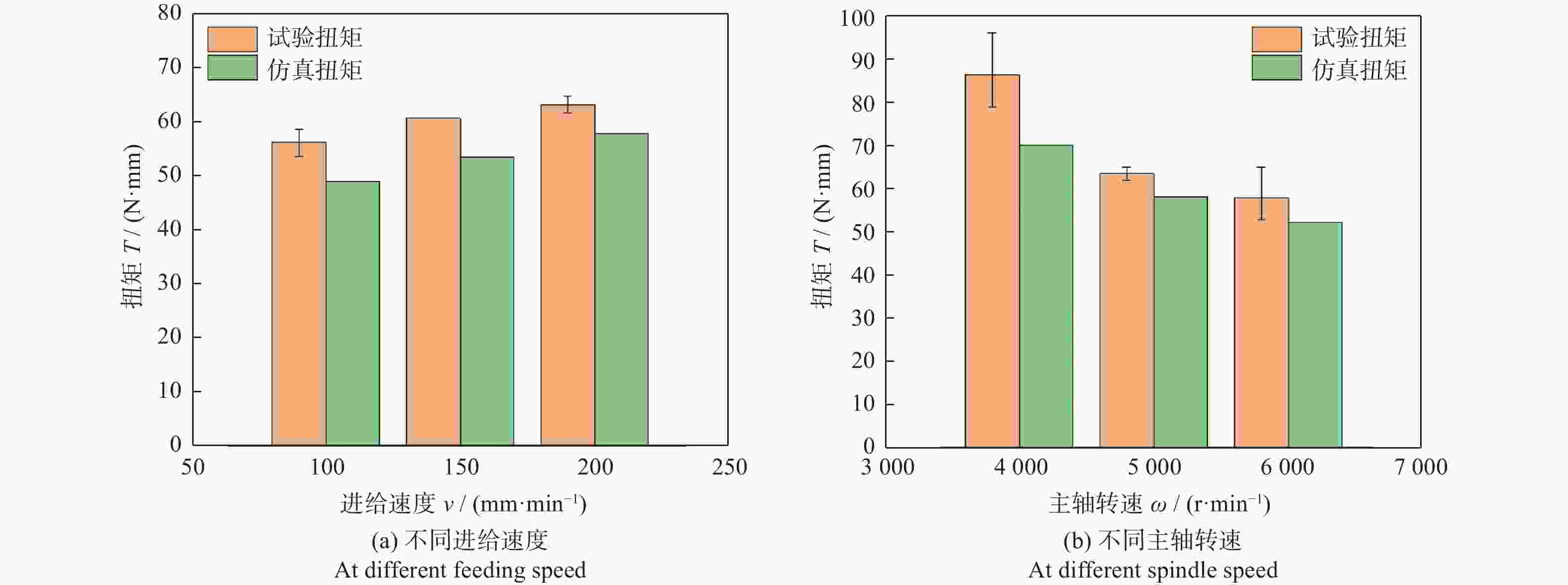

摘要: 平纹编织结构碳纤维增强树脂基复合材料(plain-woven carbon fiber-reinforced plastic,PW-CFRP)展现出高损伤容限特性,在航空航天领域应用广泛。针对PW-CFRP钻削仿真中由于其材料弹性性能变化导致单一尺度钻削仿真难以体现实际钻削力的问题,研究其弹性性能预测及多尺度三维钻削仿真。基于周期性边界条件的弹性性能参数预测模型,利用预测的材料弹性性能参数,采用多尺度有限元方法,仿真PW-CFRP的三维钻削并开展试验验证。研究结果表明:基于周期边界条件的有限元法能准确预测编织复合材料的弹性常数;在剪切载荷下,其编织单胞的边界面均由平面变成曲面,发生凸凹翘曲变形;基于刚度预测模型基础的PW-CFRP三维钻削仿真模型能够准确预测制孔过程中的轴向力、扭矩;在相同工艺参数下,制孔轴向力和扭矩的仿真预测与试验结果相对误差分别为14.2%和8.5%。Abstract: Plain-woven carbon fiber-reinforced plastic (PW-CFRP) exhibits high damage tolerance and is widely used in the aerospace field. To address the issue that single-scale drilling simulation is difficult to reflect the practical drilling force due to the change in material elastic properties in PW-CFRP drilling simulation, this paper studies the prediction of elastic properties of PW-CFRP and multi-scale three-dimensional drilling simulation. Based on the prediction model of elastic performance parameters with periodic boundary conditions, the three-dimensional drilling simulation of PW-CFRP is carried out using the predicted material elastic performance parameters and the multi-scale finite element method, with experimental verification. The results show that the finite element method based on periodic boundary conditions can accurately predict the elastic constants of braided composites. For the woven unit cell, its boundary surface changes from plane to surface under shear load, and convex-concave warping deformation occurs. The PW-CFRP three-dimensional drilling simulation model, based on the stiffness prediction model, can accurately predict the axial force and torque during the drilling process. Under the same process parameters, the maximum relative errors between the simulation prediction and the experimental results of the drilling thrust force and torque are 14.2% and 8.5%, respectively. The multi-scale drilling simulation of PW-CFRP, from microscopic to mesoscopic to macroscopic, is realized.

-

Key words:

- CFRP /

- periodical boundary condition /

- multi-scale analyses /

- elastic constant /

- drilling simulation

-

表 1 单胞模型所需施加的线性不相关的宏观应力场

Table 1. Linearly uncorrelated macroscopic stress fields to be applied to single cell model

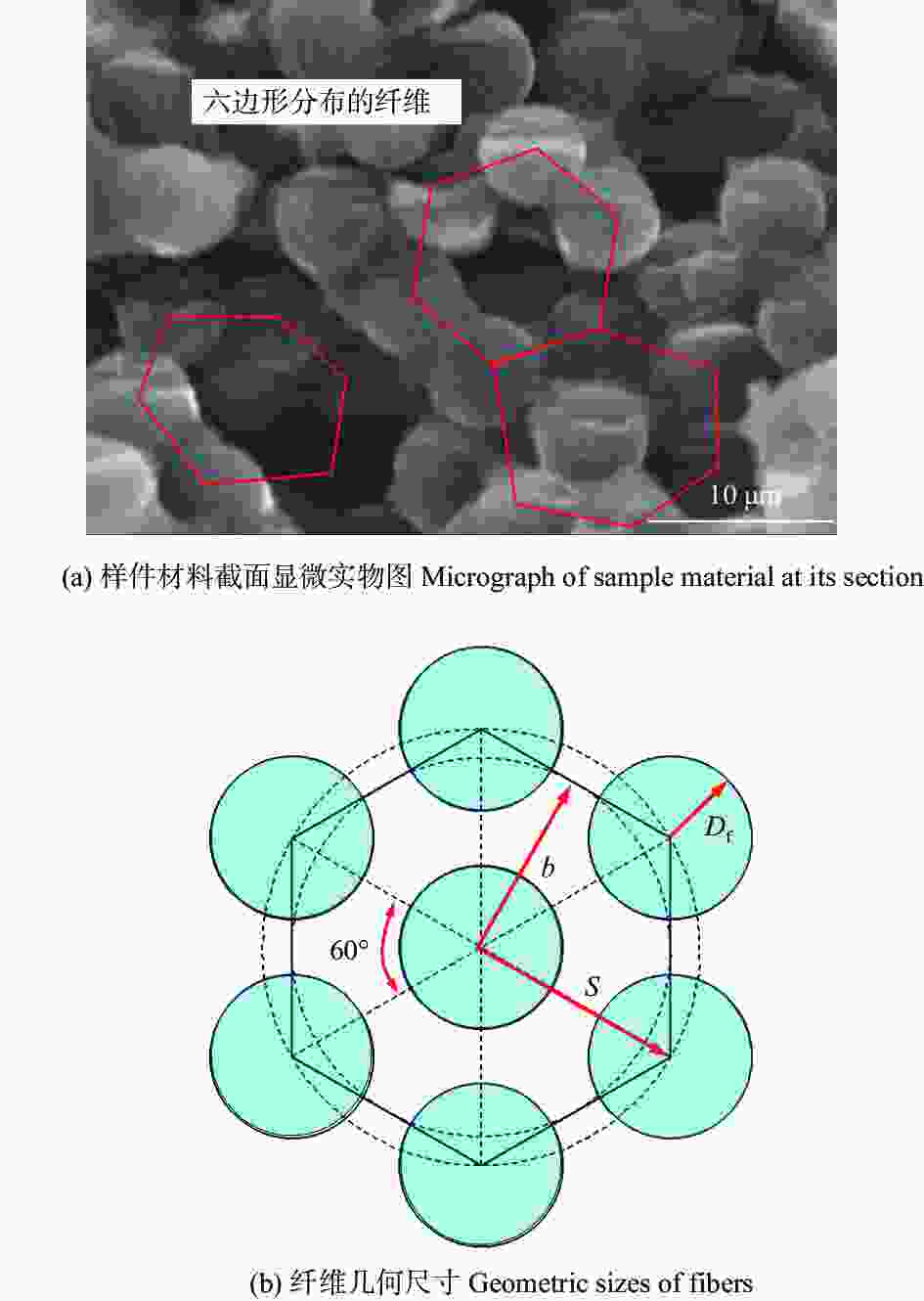

序号 $ \stackrel{-}{{\sigma }_{x}} $ $ \stackrel{-}{{\sigma }_{y}} $ $ \stackrel{-}{{\sigma }_{{\textit{z}}}} $ $ \stackrel{-}{{\tau }_{x}} $ $ \stackrel{-}{{\tau }_{y}} $ $ \stackrel{-}{{\tau }_{{\textit{z}}}} $ 1 $ \stackrel{-}{{\sigma }_{x}} $ 0 0 0 0 0 2 0 $ \stackrel{-}{{\sigma }_{y}} $ 0 0 0 0 3 0 0 $\stackrel{-}{ {\sigma }_{{\textit{z}}} }$ 0 0 0 4 0 0 0 $ \stackrel{-}{{\tau }_{x}} $ 0 0 5 0 0 0 0 $ \stackrel{-}{{\tau }_{y}} $ 0 6 0 0 0 0 0 $\stackrel{-}{ {\tau }_{ {{\textit{z}} } } }$ 表 2 纤维单胞模型的几何结构参数

Table 2. Geometric parameters of fiber unit cell model

序号 S/ μm b/ μm Df / μm Vf 1 8.268 7.161 7 65% 物理量 取 值 物理量 取 值 纤维 基体 纤维 基体 E11 / GPa 213.0 3.5 μ23 0.30 0.30 E22 / GPa 14.0 3.5 G12 / GPa 9.0 1.1 E33 / GPa 14.0 3.5 G13 / GPa 9.0 1.1 μ12 0.26 0.30 G23 / GPa 4.8 1.1 μ13 0.26 0.30 表 4 编织单胞模型的几何结构参数

Table 4. Geometric parameters of woven unit cell model

序号 A0 / mm H0 / mm Vf h0 / mm 1 1.8 0.15 55% 0.05 表 5 碳纤维织物层强度属性[21]

Table 5. Strength properties of carbon fiber fabric layer

PW-CFRP强度参数 数值 X1t=X2t / MPa 2720 X3t / MPa 111 X1c=X2c / MPa 1690 X3t / MPa 214 S12=S13=S23 / MPa 115 表 6 钻削刀具主要结构尺寸参数

Table 6. Main structure parameters of drilling tool

刀具主要参数 数值 直径 r / mm 4.851 顶角 α /(°) 90 螺旋角 θ /(°) 30 刀长 l / mm 75 表 7 纤维束等效弹性参数

Table 7. Equivalent elastic parameters of fiber bundle

物理量 数值 物理量 数值 E11 / GPa 137.5 μ23 0.40 E22 / GPa 8.2 G12 / GPa 5.7 E33 / GPa 8.2 G13 / GPa 5.7 μ12 0.29 G23 / GPa 2.8 μ23 0.29 表 8 织物层等效弹性参数

Table 8. Equivalent elastic parameters of fabric layer

物理量 数值 物理量 数值 E11 / GPa 49.0 μ23 0.297 E22/ GPa 49.0 G12/ GPa 11.0 E33/ GPa 18.3 G13 / GPa 6.4 μ12 0.110 G23 / GPa 6.6 μ23 0.280 -

[1] ZHU C, ZHU P, LIU Z. Uncertainty analysis of mechanical properties of plain woven carbon fiber reinforced composite via stochastic constitutive modeling [J]. Composite Structures,2019,207:684-700. doi: 10.1016/j.compstruct.2018.09.089 [2] 王新峰, 周光明, 周储伟, 等. 基于周期性边界条件的机织复合材料多尺度分析 [J]. 南京航空航天大学学报,2005(6):730-735. doi: 10.3969/j.issn.1005-2615.2005.06.012WANG Xinfeng, ZHOU Guangming, ZHOU Chuwei, et al. Multi-scale analyses of woven composite based on periodical boundary condition [J]. Journal of Nanjing University of Aeronautics & Astronautics,2005(6):730-735. doi: 10.3969/j.issn.1005-2615.2005.06.012 [3] KARKKAINEN R L, SANKAR B V. A direct micromechanics method for analysis of failure initiation of plain weave textile composites [J]. Composites Science and Technology,2006,66(1):137-150. doi: 10.1016/j.compscitech.2005.05.018 [4] GOYAL D, TANG X, WHITCOMB J D. Effect of various parameters on effective engineering properties of 2×2 braided composites [J]. Mechanics of Advanced Materials and Structures,2005,12(2):113-128. doi: 10.1080/15376490490493998 [5] 张超, 许希武. 二维二轴编织复合材料几何模型及弹性性能预测 [J]. 复合材料学报,2010,27(5):129-135. doi: 10.13801/j.cnki.fhclxb.2010.05.019ZHANG Chao, XU Xiwu. Geometrical model and elastic properties prediction of 2D biaxial braided composites [J]. Acta Material Compositae Sinica,2010,27(5):129-135. doi: 10.13801/j.cnki.fhclxb.2010.05.019 [6] PEI X, CHEN L, GAO Y, et al. Effect of reinforcement structures on vibration performance of composites [J]. Journal of Composite Materials,2017,51(22):3149-3161. doi: 10.1177/0021998316689602 [7] WHITCOMB J, SRIRENGAN K. Effect of various approximations on predicted progressive failure in plain weave composites [J]. Composite structures,1996,34(1):13-20. doi: 10.1016/0263-8223(95)00125-5 [8] COLBY C S, KIM H J. Multi-scale cell analyses of textile composites: "Proceedings of the 15th ASCE Engineering Mechanics Conference" [C/OL]. New York: [s.n.], 2002[2022-12-26]. http://user.engineering.uiowa.edu/~swan/presentations/asce_textiles.pdf [9] 翟军军. 基于多尺度理论的三维编织复合材料力学性能研究 [D]. 哈尔滨: 哈尔滨理工大学, 2018.ZHAI Junjun. Investigation of mechanical properties of 3D braided composites based on multi-scale theory [D]. Harbin: Harbin University of Science and Technology, 2018. [10] DENG Y, CHEN X, WANG H, et al. A multi-scale correlating model for the mechanical properties of tri-axial braided composites [J]. Journal of Reinforced Plastics & Composites,2013,32(24):1934-1955. doi: 10.1177/0731684413496337 [11] ROUF K, DENTON N L, FRENCH R M. Effect of fabric weaves on the dynamic response of two-dimensional woven fabric composites [J]. Journal of Materials Science,2017,52(17):10581-10591. doi: 10.1007/s10853-017-1183-6 [12] PERSSON E, ERIKSSON I, ZACKRISSON L. Effects of hole machining defects on strength and fatigue life of composite laminates [J]. Composites Part A: Applied Science and Manufacturing,1997,28(2):141-151. doi: 10.1016/S1359-835X(96)00106-6 [13] ISBILIR O, GHASSEMIEH E. Three-dimensional numerical modelling of drilling of carbon fiber-reinforced plastic composites [J]. Journal of Composite Materials,2014,48(10):1209-1219. doi: 10.1177/0021998313484947 [14] FEITO N, DÍAZ-ÁLVAREZ J, LÓPEZ-PUENTE J, et al. Experimental and numerical analysis of step drill bit performance when drilling woven CFRPs [J]. Composite Structures,2018,184:1147-1155. doi: 10.1016/j.compstruct.2017.10.061 [15] FEITO N, DIAZ-ALVAREZ A, CANTERO J L, et al. Experimental analysis of special tool geometries when drilling woven and multidirectional CFRPs [J]. Journal of Reinforced Plastics and Composites,2016,35(1):33-55. doi: 10.1177/0731684415612931 [16] 张向阳. 平纹编织复合材料钻削损伤机理及表征方法研究 [D]. 西安: 西安理工大学, 2021.ZHANG Xiangyang. Study on drilling damage mechanism and characterization method of plain weave composites [D]. Xi`an: Xi`an University of Technology, 2021. [17] XIA Z, ZHANG Y, ELLYIN F. A unified periodical boundary conditions for representative volume elements of composites and applications [J]. International Journal of Solids and Structures,2003,40(8):1907-1921. doi: 10.1016/S0020-7683(03)00024-6 [18] 邵兵. 大丝束碳纤维平纹编织复合材料孔边应力细观分析 [D]. 南昌: 南昌大学, 2018.SHAO Bing. The micromechanical analysis of stress near central hole in big carbon tow plain-woven composite [D]. Nanchang: Nanchang University, 2018. [19] 张宪丰. 平纹编织陶瓷基复合材料孔边应力多尺度分析 [D]. 南昌: 南昌大学, 2021.ZHANG Xianfeng. Multi-scale analysis of hole edge stress in plain weave ceramic matrix composites [D]. Nanchang: Nanchang University, 2021. [20] 陈继刚, 薛亚红, 闫世程. 二维机织复合材料弹性常数的有限元法预测 [J]. 复合材料学报,2016,33(8):1702-1709. doi: 10.13801/j.cnki.fhclxb.20151106.003CHEN Jigang, XUE Yahong, YAN Shicheng. Finite element prediction of elastic constants for 2D woven fabric composite [J]. Acta Material Compositae Sinica,2016,33(8):1702-1709. doi: 10.13801/j.cnki.fhclxb.20151106.003 [21] 张勋, 陈燕, 徐九华, 等. 大厚径碳纤维复合材料三维钻削有限元仿真及试验研究 [J]. 金刚石与磨料磨具工程,2020,40(2):53-60. doi: 10.13394/j.cnki.jgszz.2020.2.0010ZHANG Xun, CHEN Yan, XU Jiuhua, et al. Finite element simulation of and experimental study on three - dimensional drilling of large diameter carbon fiber composites [J]. Diamond & Abrasives Engineering,2020,40(2):53-60. doi: 10.13394/j.cnki.jgszz.2020.2.0010 [22] 徐陈林. 基于ABAQUS的CFRP/TC4叠层结构钻削技术研究 [D]. 南京: 南京航空航天大学, 2016.XU Chenlin. Research on drilling technology of CFRP/Ti6Al4V stacks based on ABAOUS [D]. Nanjing: Nanjing University of Aeronautics & Astronautics, 2016 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS