Effect of dressing with form grinding wheel on grinding surface integrity of 18CrNiMo7-6 steel

-

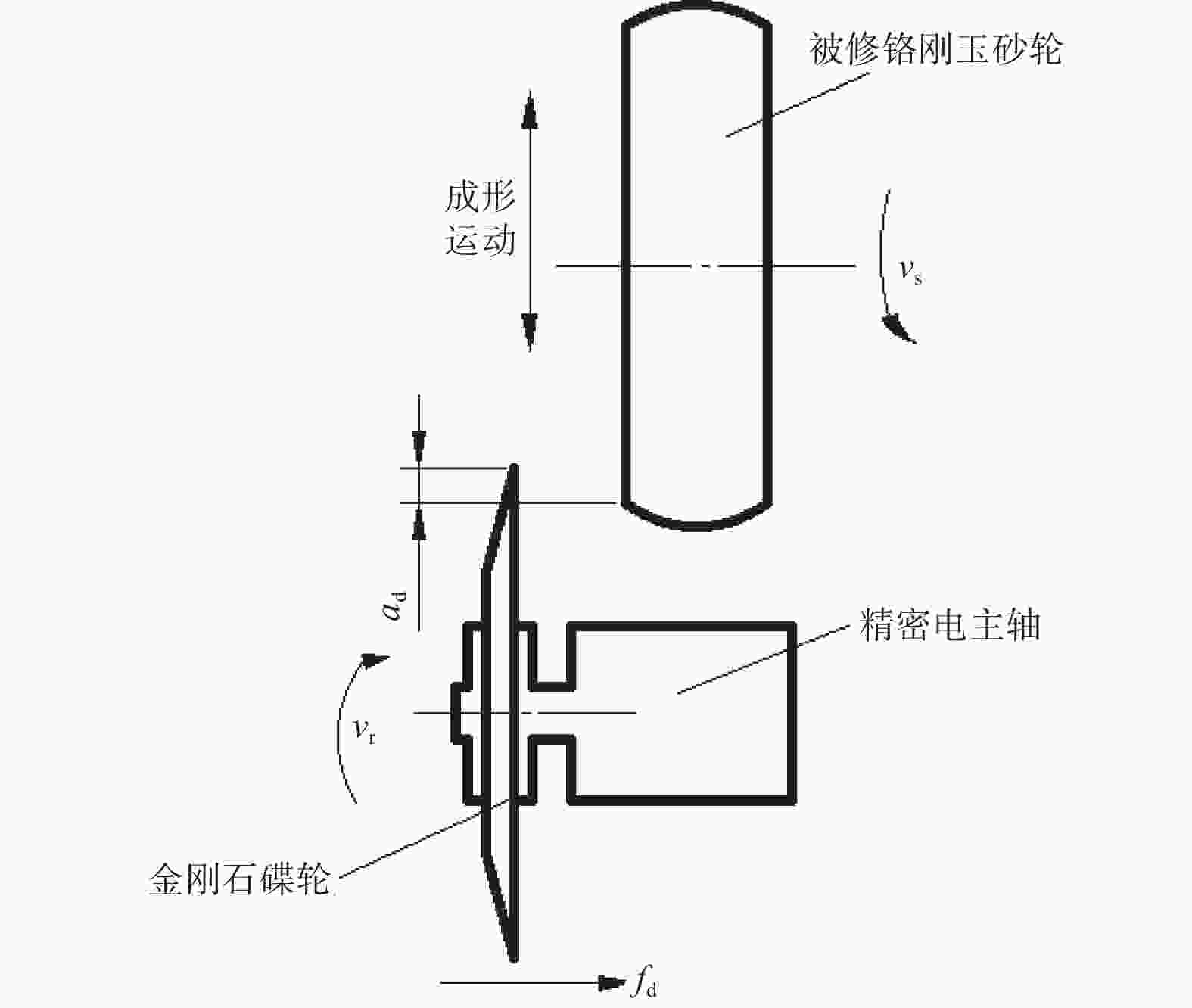

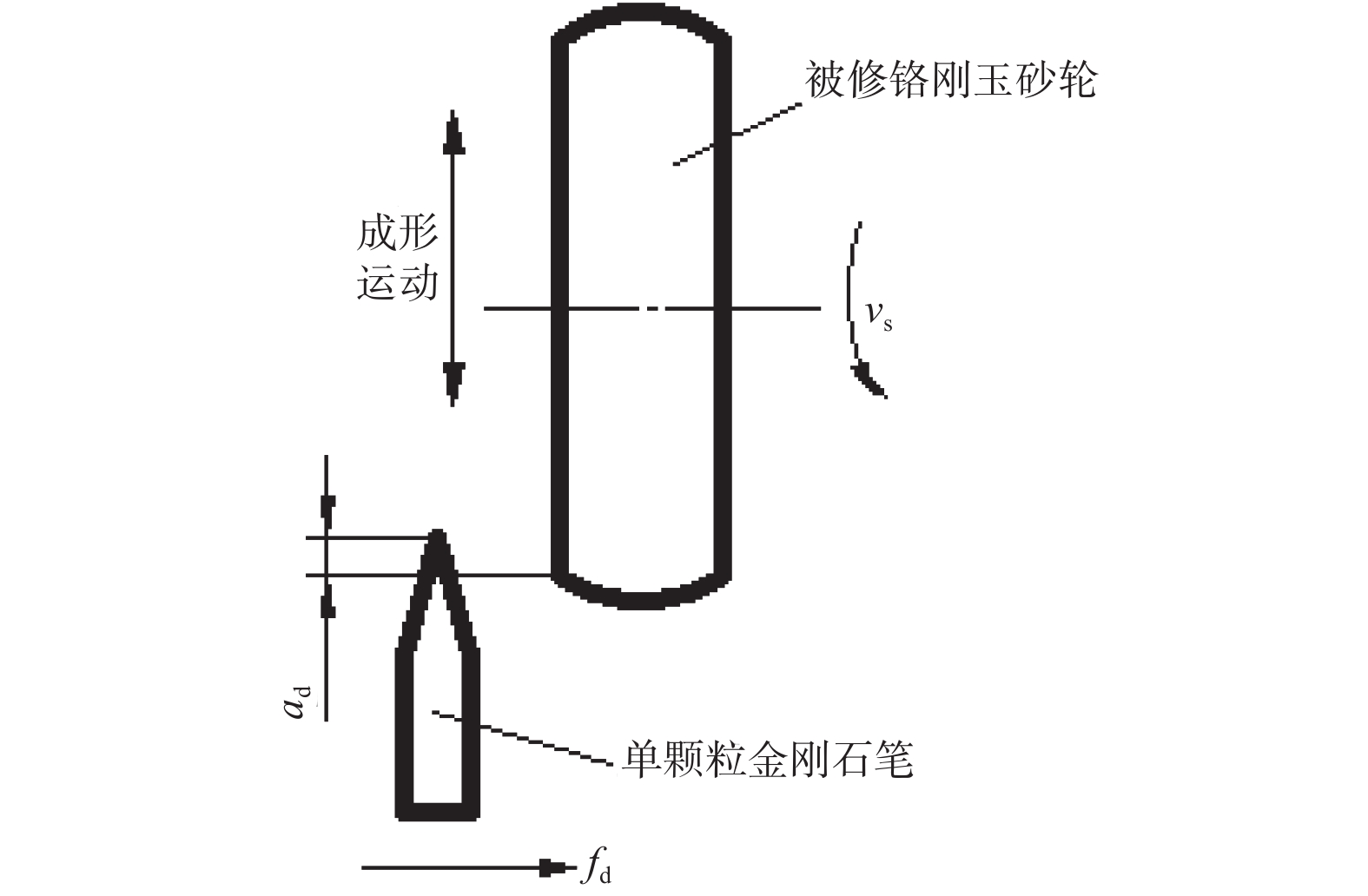

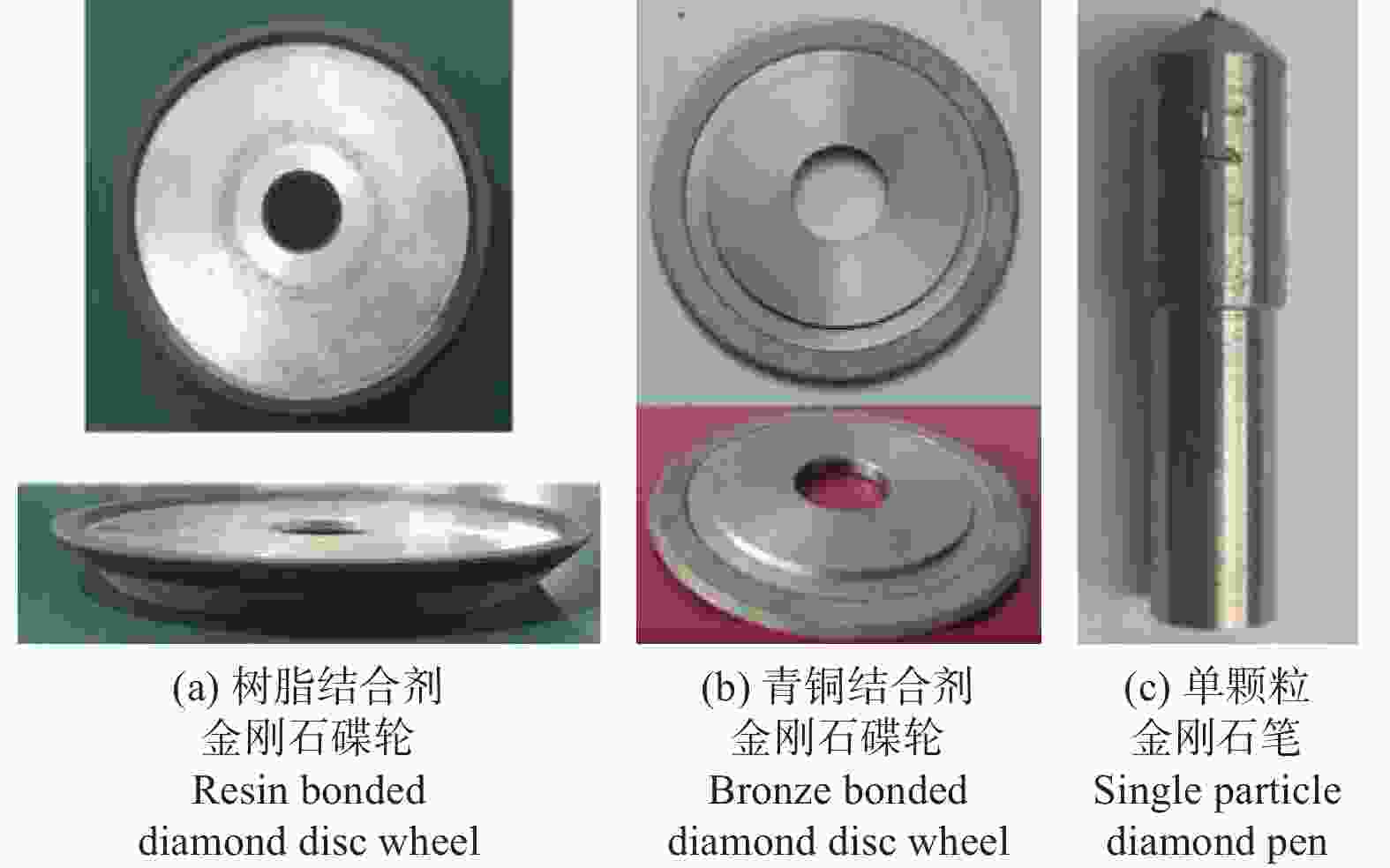

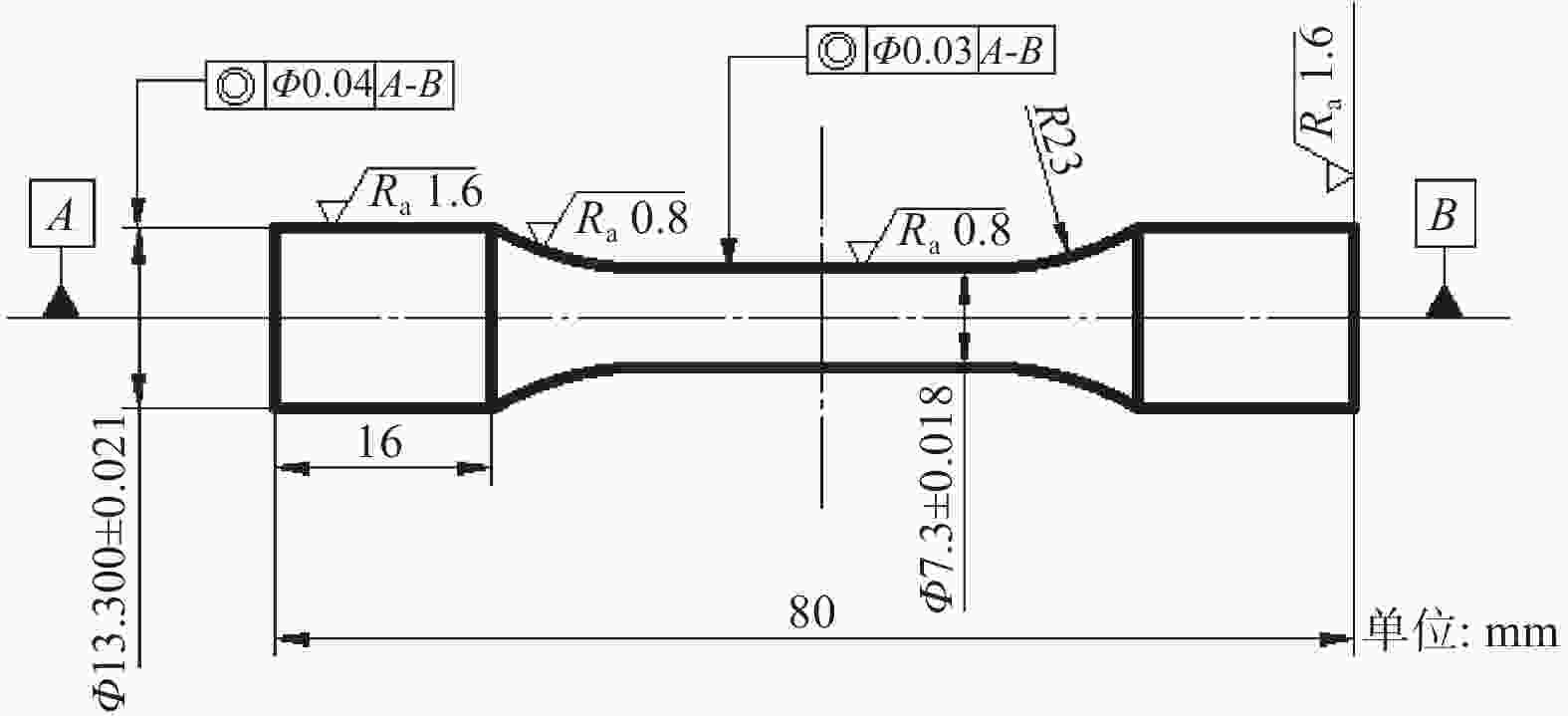

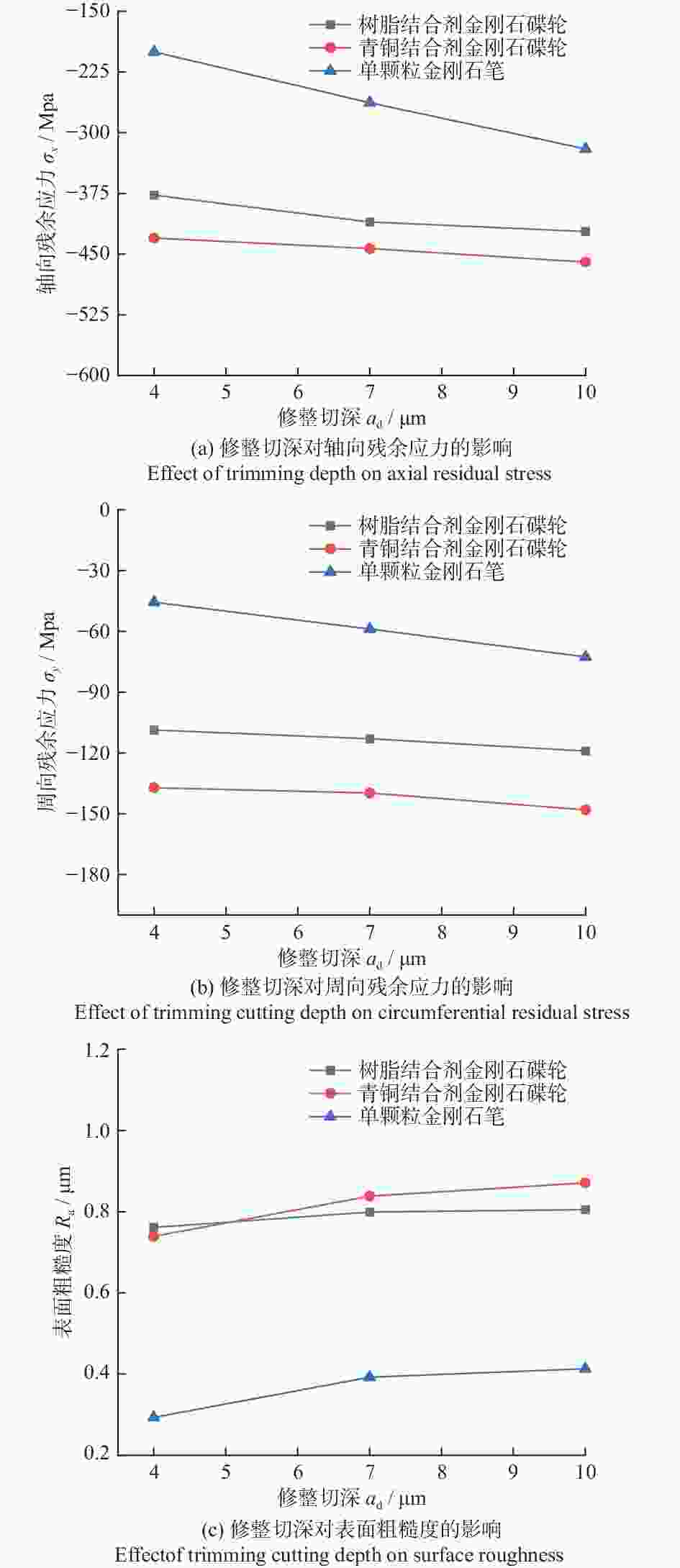

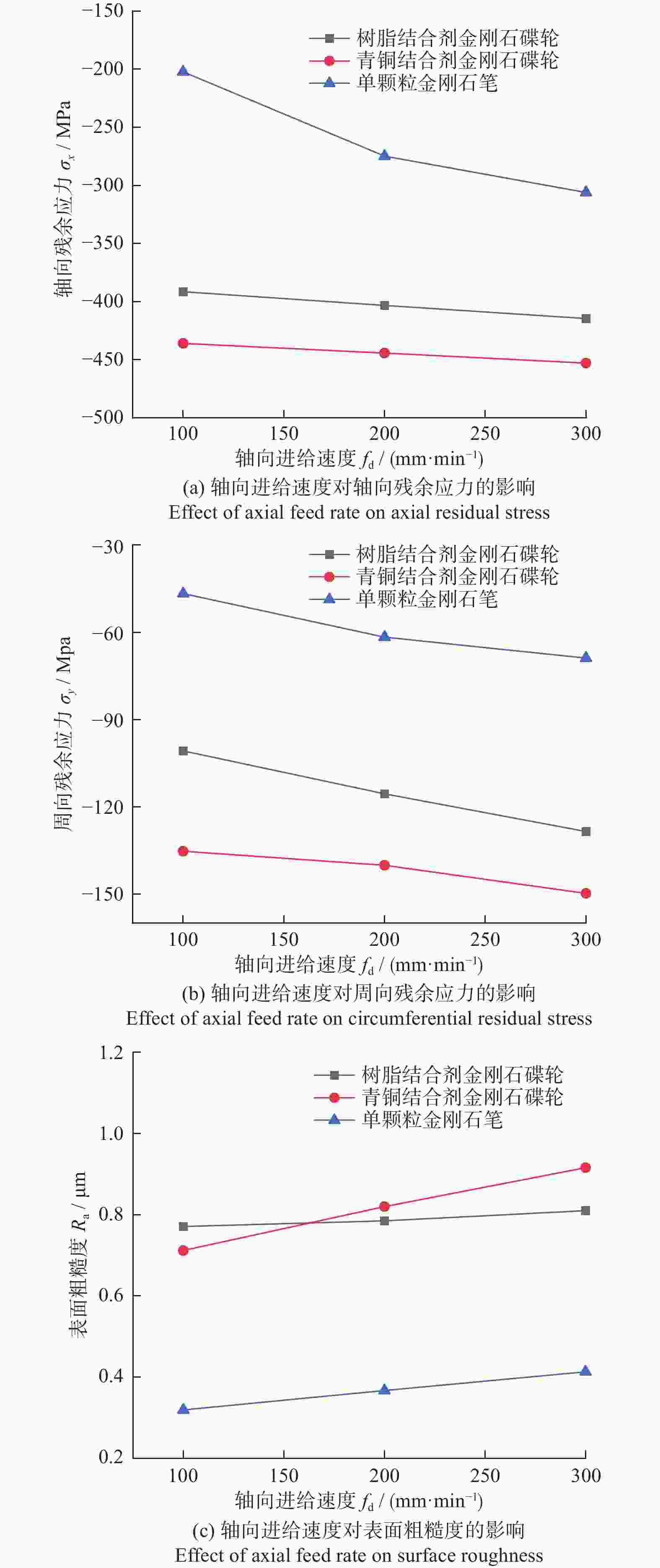

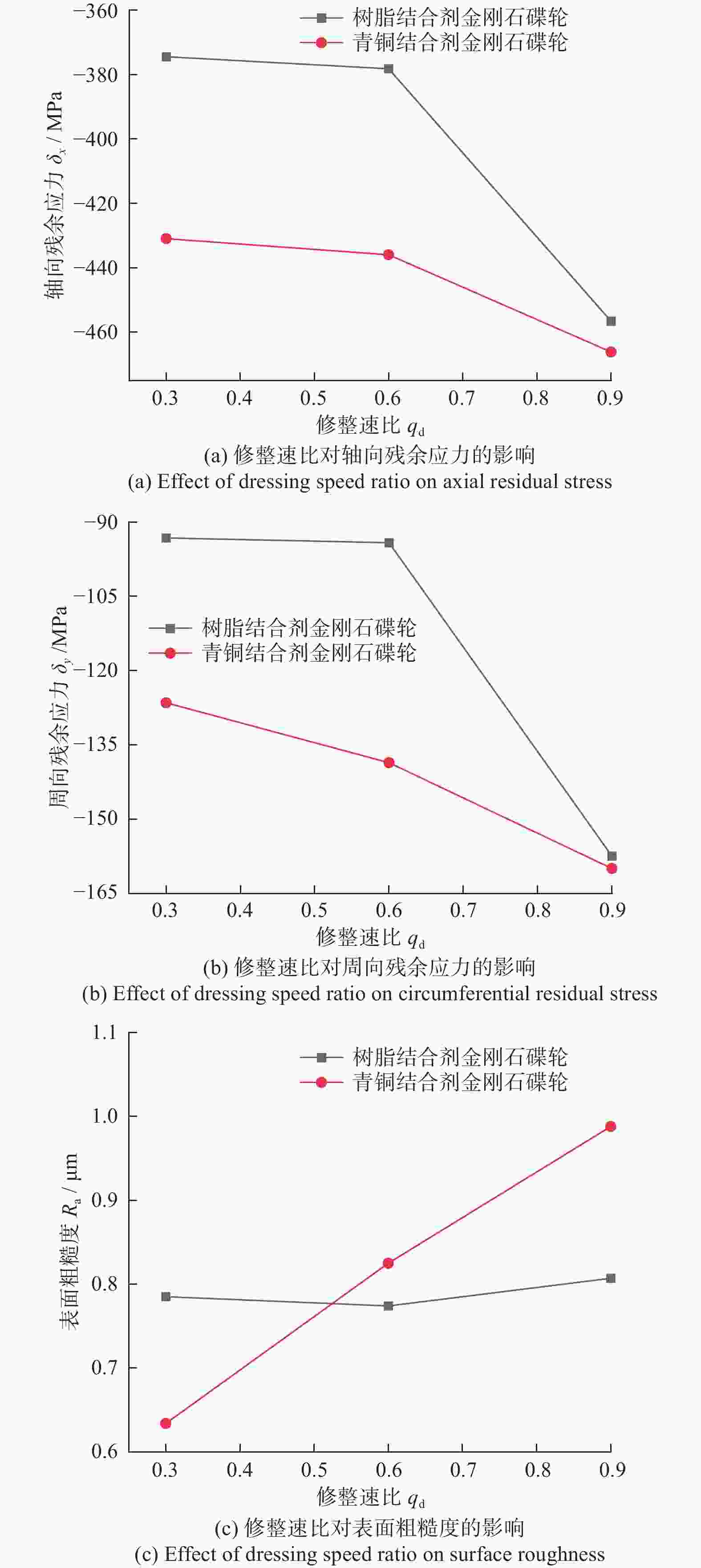

摘要: 为了探究修整切深ad、轴向进给速度fd和修整速比qd等修整工艺参数对18CrNiMo7-6齿轮钢磨削表面完整性的影响,分别采用树脂结合剂金刚石碟轮、青铜结合剂金刚石碟轮和单颗粒金刚石笔3种修整工具对陶瓷结合剂铬刚玉砂轮进行成形修整工艺正交试验,并用修整后的铬刚玉砂轮对18CrNiMo7-6齿轮钢进行横磨试验。结果表明:随着各修整工艺参数的增大,齿轮钢磨削加工表面粗糙度Ra增大,磨削表面更容易产生残余压应力;通过归一化无量纲方法综合评价3种修整工具的磨削表面完整性,表明采用青铜结合剂金刚石碟轮修整时的磨削表面完整性优于其余2种修整工具的,且当ad=4 μm,fd=100 mm/min,qd=0.3时齿轮钢,磨削表面的完整性较优。

-

关键词:

- 成形砂轮修整 /

- 金刚石碟轮 /

- 表面完整性 /

- 18CrNiMo7-6齿轮钢 /

- 正交试验

Abstract: In order to explore the influence of dressing process parameters, such as dressing depth ad, axial feed speed fd and dressing speed ratio qd, on the grinding surface integrity of 18CrNiMo7-6 gear steel, orthogonal experiments were conducted for shaping dressing process using ceramic bonded chrome corundum grinding wheels with resin bonded diamond disc wheels, bronze bonded diamond disc wheels and single particle diamond pens, respectively. The cross grinding test of 18CrNiMo7-6 gear steel was carried out with a chrome corundum wheel after dressing. The results show that the surface roughness Ra of the grinding process increased with the increase of the dressing process parameters, and residual compressive stresses were more easily obtained on the grinding surface. The comprehensive evaluation of the grinding surface integrity for the three dressing tools, using a normalized dimensionless method, shows that the grinding surface integrity of the bronze-bonded diamond disc wheel dressing is better than the other two dressing methods. Furthermore, the grinding surface integrity is better when ad=4 μm, fd=100 mm/min, and qd=0.3. -

表 1 砂轮线速度及修整速比试验参数

Table 1. Test parameters of grinding wheel linear speed and dressing speed ratio

修整轮线

速度 vr / (m·s−1)陶瓷结合剂铬刚玉

砂轮线速度 vs / (m·s−1)修整速比 qd 10.5 35 0.3 21.0 35 0.6 31.5 35 0.9 表 2 修整正交试验参数

Table 2. Trimming orthogonal test parameters

水平 X1 X2 X3 修整切深 ad / μm 轴向进给

速度 fd / (mm·min−1)修整速比 qd 1 4 100 0.3 2 7 200 0.6 3 10 300 0.9 表 3 横磨工艺参数设定

Table 3. Horizontal grinding process parameter setting

工艺参数 参数值 砂轮线速度 vs / (m·s−1) 35 工件转速 n / (r·min−1) 200 砂轮径向进给速度 vf / (mm·min−1) 0.2 磨削总量 d / μm 60 无进给光磨时间 t / s 3 表 4 金刚石碟轮修整后磨削表面完整性无量纲综合量值

Table 4. Dimensionless comprehensive value of grinding surface integrity of diamond disc wheel after dressing

试验编号 修整切深 ad / μm 轴向进给速度 fd / (mm·min−1) 修整速比 qd 综合量值(树脂) X树脂 综合量值(青铜) X青铜 1 4 100 0.3 0.462 828 0.706 182 2 4 200 0.6 0.490 994 0.629 858 3 4 300 0.9 0.671 446 0.619 218 4 7 100 0.6 0.467 726 0.651 310 5 7 200 0.9 0.680 168 0.569 448 6 7 300 0.3 0.529 538 0.641 498 7 10 100 0.9 0.668 686 0.637 474 8 10 200 0.3 0.500 632 0.692 488 9 10 300 0.6 0.565 014 0.575 290 综合量值平均值 0.559 670 0.635 863 表 5 单颗粒金刚石笔修整后磨削表面完整性无量纲综合量值

Table 5. Dimensionless comprehensive value of ground surface integrity after dressing with single particle diamond pen

试验编号 修整切深 ad / μm 轴向进给速度 fd / (mm·min−1) 综合量值 X笔 1 4 100 0.399 970 2 4 200 0.532 630 3 4 300 0.550 908 4 7 100 0.495 294 5 7 200 0.530 964 6 7 300 0.546 728 7 10 100 0.562 916 8 10 200 0.590 518 9 10 300 0.609 462 综合量值平均值 0.535 488 -

[1] 吴定柱, 彭栋梁, 宋雪伟, 等. 双曲线形面成型磨削工艺技术研究[J]. 制造技术与机床, 2017(11): 124-128.WU Dingzhu, PENG Dongliang, SONG Xuewei, et al. Research on hyperbola shaped grinding technology [J]. Manufacturing Technology and Machine Tools, 2017 (11): 124-128. [2] 杨小李, 郑阳伦, 钟睿, 等. 成形砂轮高精度数控修整方法研究[J]. 精密制造与自动化, 2020(3): 9-13.YANG Xiaoli, ZHENG Yanglun, ZHONG Rui, et al. Research on high-precision NC dressing method of formed grinding wheel [J] Precision Manufacturing and Automation, 2020 (3): 9-13 [3] 焦锋, 李成龙, 牛赢, 等. 砂轮修整技术研究现状与展望 [J]. 中国机械工程,2021,32(20):2435-2448. doi: 10.3969/j.issn.1004-132X.2021.20.006JIAO Feng, LI Chenglong, NIU Ying, et al. Research status and prospect of grinding wheel dressing technology [J]. China Mechanical Engineering,2021,32(20):2435-2448. doi: 10.3969/j.issn.1004-132X.2021.20.006 [4] 王江, 黄筱调, 张虎. 砂轮修整工艺参数对成形磨齿粗糙度的影响 [J]. 组合机床与自动化加工技术,2014(12):19-21, 26. doi: 10.13462/j.cnki.mmtamt.2014.12.005WANG Jiang, HUANG Xiaotiao, ZHANG Hu. The influence of grinding wheel dressing process parameters on the roughness of formed grinding teeth [J]. Modular Machine Tool and Automatic Machining Technology,2014(12):19-21, 26. doi: 10.13462/j.cnki.mmtamt.2014.12.005 [5] 邓效忠, 张艳珍, 李天兴, 等. 机器人RV减速机摆线轮成形磨削砂轮廓形修整 [J]. 机械传动,2016,40(10):23-27. doi: 10.16578/j.issn.1004.2539.2016.10.005DENG Xiaozhong, ZHANG Yanzhen, LI Tianxing, et al. Profile dressing of cycloidal shaped grinding wheel of robot RV reducer [J]. Mechanical Transmission,2016,40(10):23-27. doi: 10.16578/j.issn.1004.2539.2016.10.005 [6] 袁尚勇, 陈根余, 戴隆州, 等. 电火花机械磨削修整粗粒度成形砂轮试验研究 [J/OL]. 中国机械工程, (2022-11-07) [2022-11-09]. http://www.cmemo.org.cn/EN/10.3969/j.issn.1004-132X.2023.10.005.2022-11-07]. YUAN Shangyong, CHEN Genyu, DAI Longzhou, et al. Experimental study on EDM grinding and dressing of coarse grain formed grinding wheel [J/OL]. China Mechanical Engineering, (2022-11-07) [2022-11-09]. http://www.cmemo.org.cn/EN/10.3969/j.issn.1004-132X.2023.10.005. [7] DERKX J M, HOOGSTRATE A M, SAURWALT J J, et al. Form crush dressing of diamond grinding wheels [J]. CIRP Annals,2008,57(1):349-352. doi: 10.1016/j.cirp.2008.03.065 [8] HE H X, LIU H X. A calculating method for the movement contrail in the operation of dressing the profile shape of grinding wheel used for numerical control form grinding spur cylinder gear [J]. Applied Mechanics and Materials,2010,44(1):44-47. [9] 张银霞, 刘修武, 原少帅, 等. 硬态车削工艺对18CrNiMo7-6钢表层硬度及微观组织的影响 [J]. 郑州大学学报(工学版),2022,43(5):59-64. doi: 10.13705/j.issn.1671-6833.2022.05.004ZHANG Yinxia, LIU Xiuwu, YUAN Shaoshuai, et al. Effect of hard turning process on surface hardness and microstructure of 18CrNiMo7-6 steel [J]. Journal of Zhengzhou University (Engineering Edition),2022,43(5):59-64. doi: 10.13705/j.issn.1671-6833.2022.05.004 [10] 张银霞, 杨鑫, 原少帅, 等. 18CrNiMo7-6钢高速外圆磨削的残余应力 [J]. 中国机械工程,2021,32(5):540-546. doi: 10.3969/j.issn.1004-132X.2021.05.005ZHANG Yinxia, YANG Xin, YUAN Shaoshuai, et al. Residual stress in high-speed cylindrical grinding of 18CrNiMo7-6 steel [J]. China Mechanical Engineering,2021,32(5):540-546. doi: 10.3969/j.issn.1004-132X.2021.05.005 [11] 朱浩阳, 郜伟, 张银霞, 等. 外圆纵向磨削工艺对18CrNiMo7–6钢表面完整性的影响 [J]. 金刚石与磨料磨具工程,2022,42(3):300-306.ZHU Haoyang, GAO Wei, ZHANG Yinxia, et al. The influence of cylindrical longitudinal grinding process on the surface integrity of 18CrNiMo7 – 6 steel [J]. Diamond & Abrasives Engineering,2022,42(3):300-306. [12] 孔德群, 孔新建. 18CrNiMo7-6钢齿轮磨削烧伤裂纹分析 [J]. 金属加工(热加工), 2016(19): 20-24.KONG Dequn, KONG Xinjian. Analysis on grinding burn crack of 18CrNiMo7-6 steel gear [J]. Metal Processing (Hot Working), 2016 (19): 20-24. [13] 张锦涛. 18CrNiMo7-6钢外圆磨削温度及表面完整性研究 [D]. 郑州: 郑州大学, 2021.ZHANG Jintao. Research on cylindrical grinding temperature and surface integrity of 18CrNiMo7-6 steel [D]. Zhengzhou: Zhengzhou University, 2021. [14] ZHANG Y X, YUAN S, YANG X, et al. Effect of process parameters on hardness and microstructure of 18CrNiMo7-6 carburized steel in high-speed cylindrical grinding [J]. The International Journal of Advanced Manufacturing Technology, 2023, 124(9):3137-3147. [15] 王延忠, 殷永耀, 兰州, 等. 面齿轮磨削砂轮修整工艺参数试验研究 [J]. 机械设计与制造, 2019(1): 80-83.WANG Yanzhong, YIN Yongyao, LAN Zhou, et al. Experimental study on dressing process parameters of face gear grinding wheel [J]. Mechanical Design and Manufacturing, 2019 (1): 80-83. [16] 牛牧. 曲线磨削砂轮修整方法和修整工艺的研究 [D]. 上海: 上海交通大学, 2020.NIU Mu. Research on dressing method and dressing process of curved grinding wheel [D]. Shanghai: Shanghai Jiaotong University, 2020. [17] 武志斌. 修整砂轮的纵向进给速度对横磨粗糙度影响的研究 [J]. 安徽工学院学报, 1996(1): 65-70.WU Zhibin. Study on the influence of longitudinal feed speed of dressing wheel on cross grinding roughness [J]. Journal of Anhui Institute of Technology, 1996 (1): 65-70. [18] 方伟, 鲁涛. 修整工艺参数对陶瓷CBN砂轮磨削效果的影响 [J]. 金刚石与磨料磨具工程, 2010, 30(2): 25-28.FANG Wei, LU Tao. Influence of dressing process parameters on grinding effect of ceramic CBN wheel [J]. Diamond & Abrasives Engineering, 2010, 30 (2): 25-28. [19] 庄司克雄. 金属结合剂金刚石砂轮的修整研究(Ⅱ)−修整金属结合剂金刚石砂轮的机理 [J]. 磨料磨具与磨削,1993(3):6-11.ZHUANG Sikexiong. Study on dressing of metal bonded diamond wheel (Ⅱ): Mechanism of dressing metal bonded diamond wheel [J]. Abrasive Tools and Grinding,1993(3):6-11. [20] 叶宗裕. 关于多指标综合评价中指标正向化和无量纲化方法的选择 [J]. 浙江统计,2003(4):25-26.YE Zongyu. On the selection of index positive and dimensionless methods in multi index comprehensive evaluation [J]. Zhejiang Statistics,2003(4):25-26. [21] 龚军振. 精密铣削加工工艺参数对表面完整性的影响研究 [D]. 郑州: 郑州大学, 2018.GONG Junzhen. Study on the influence of precision milling process parameters on surface integrity [D]. Zhengzhou: Zhengzhou University, 2018. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS