Surface quality of double-sided grinding Si3N4 cylindrical rollers

-

摘要:

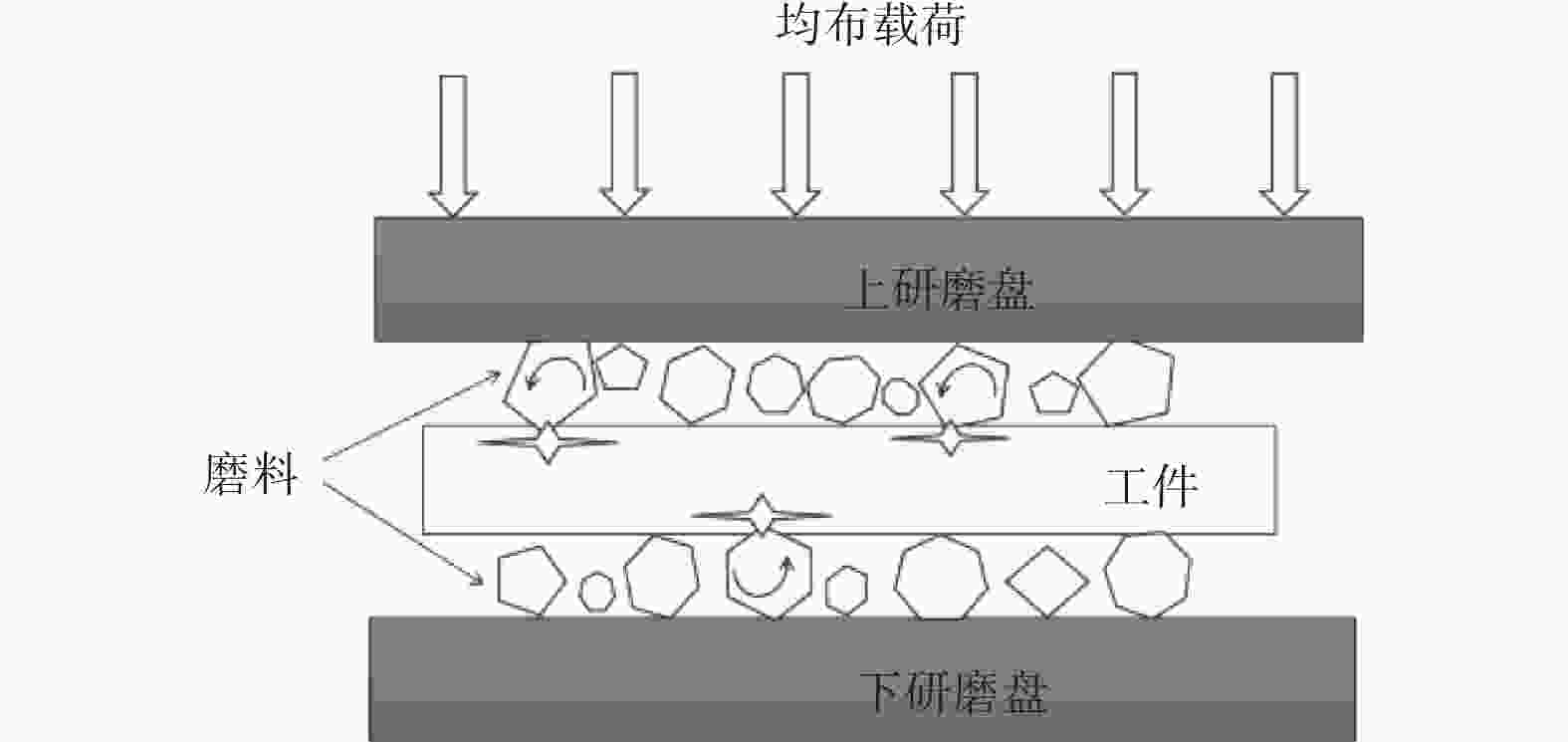

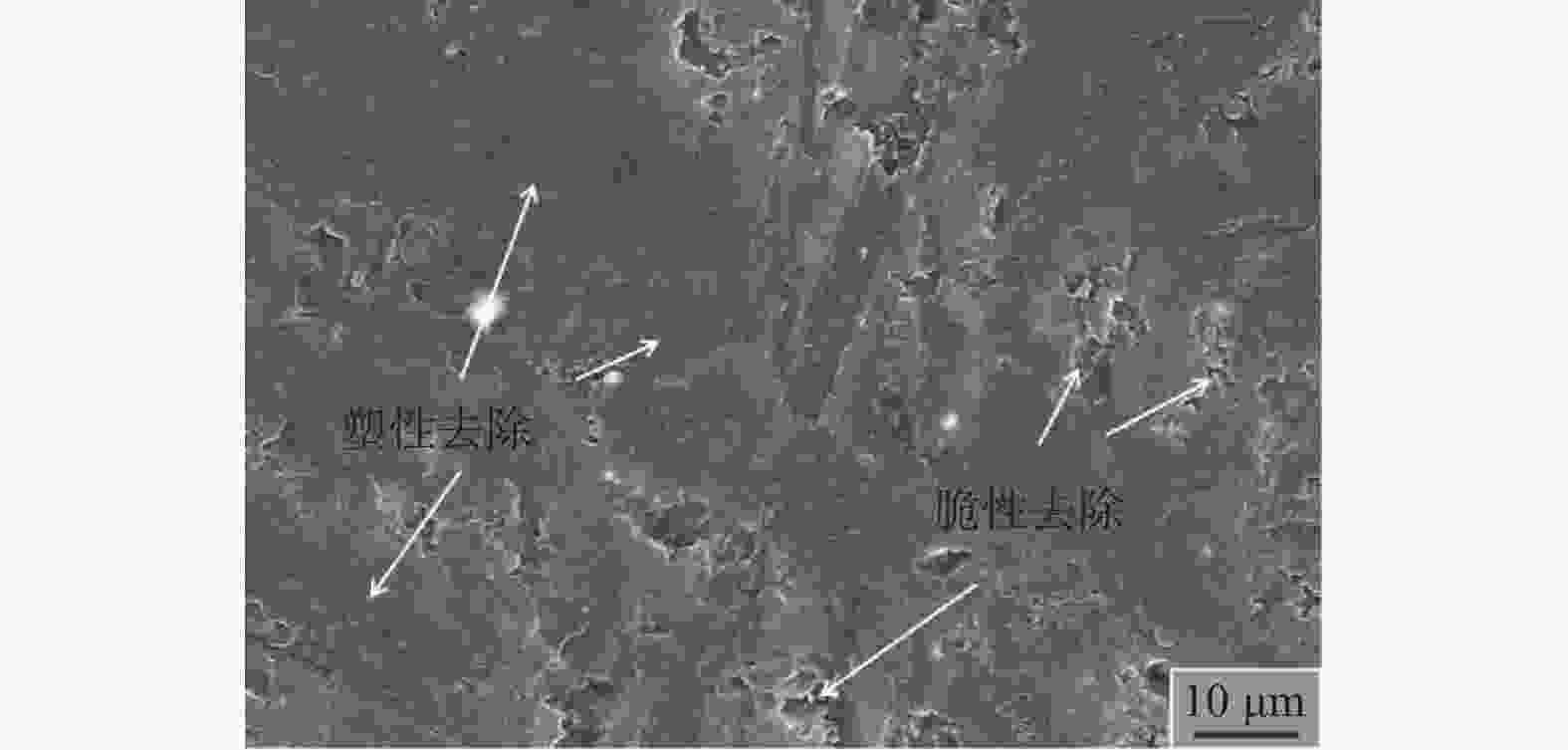

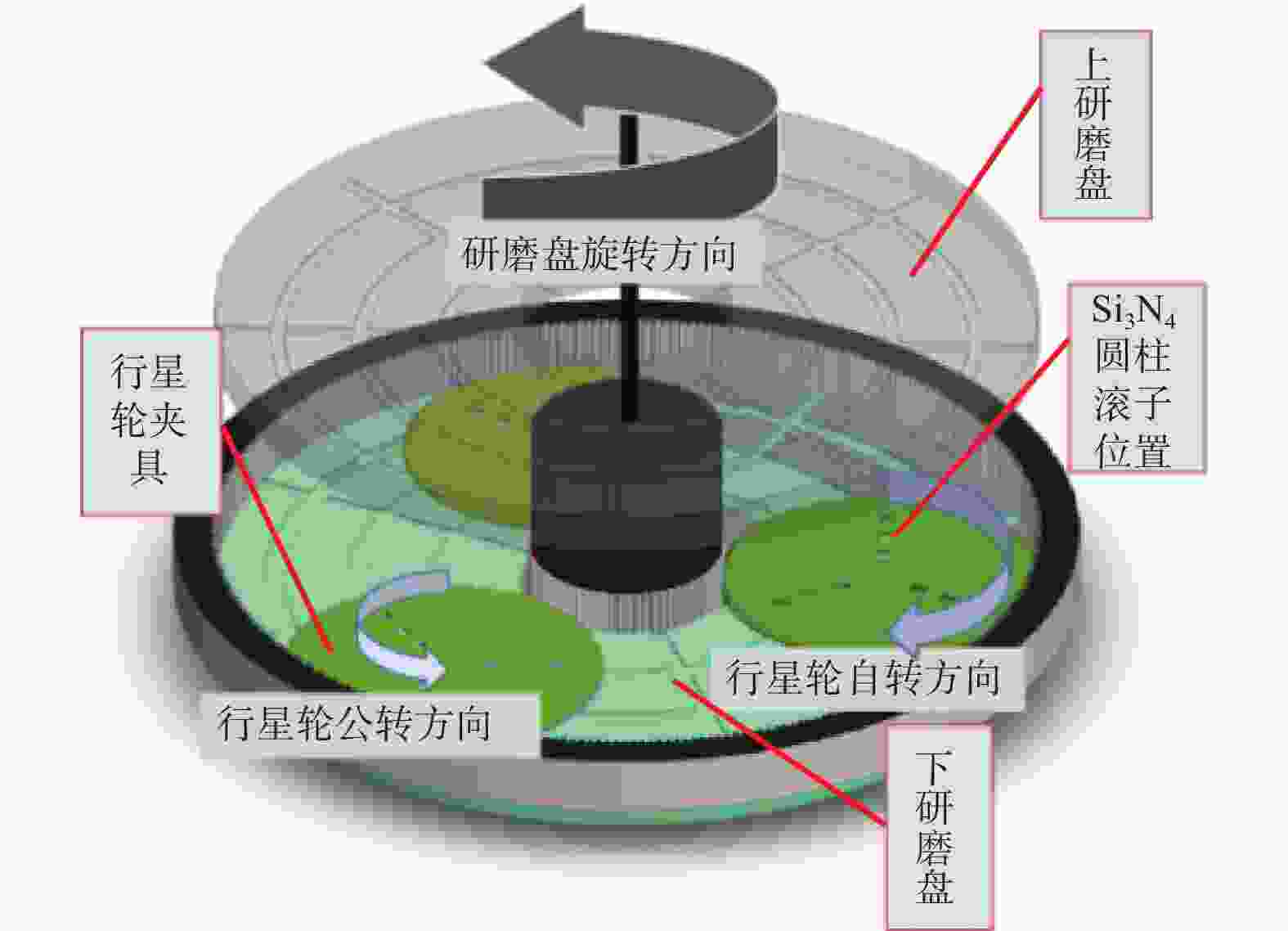

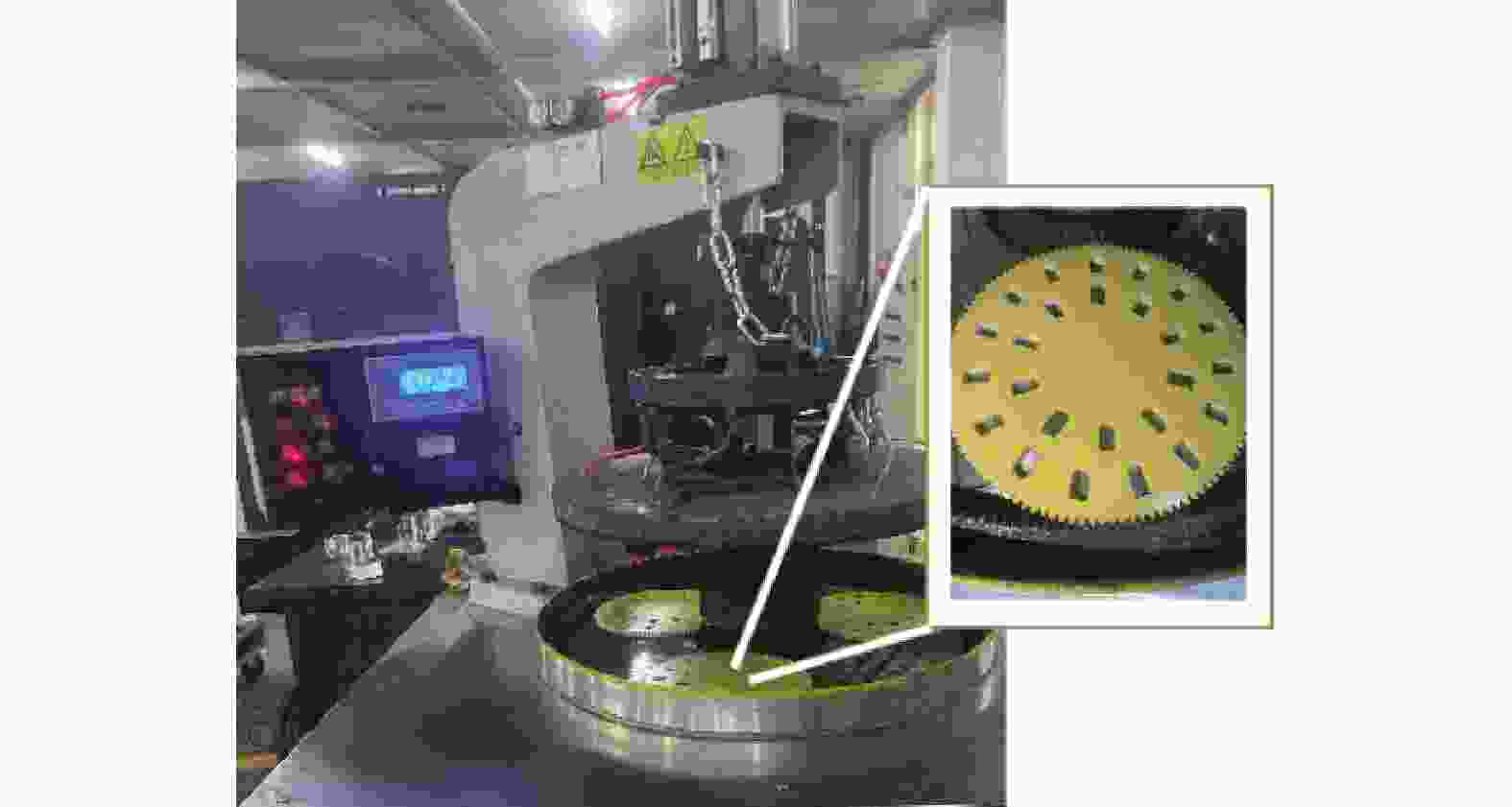

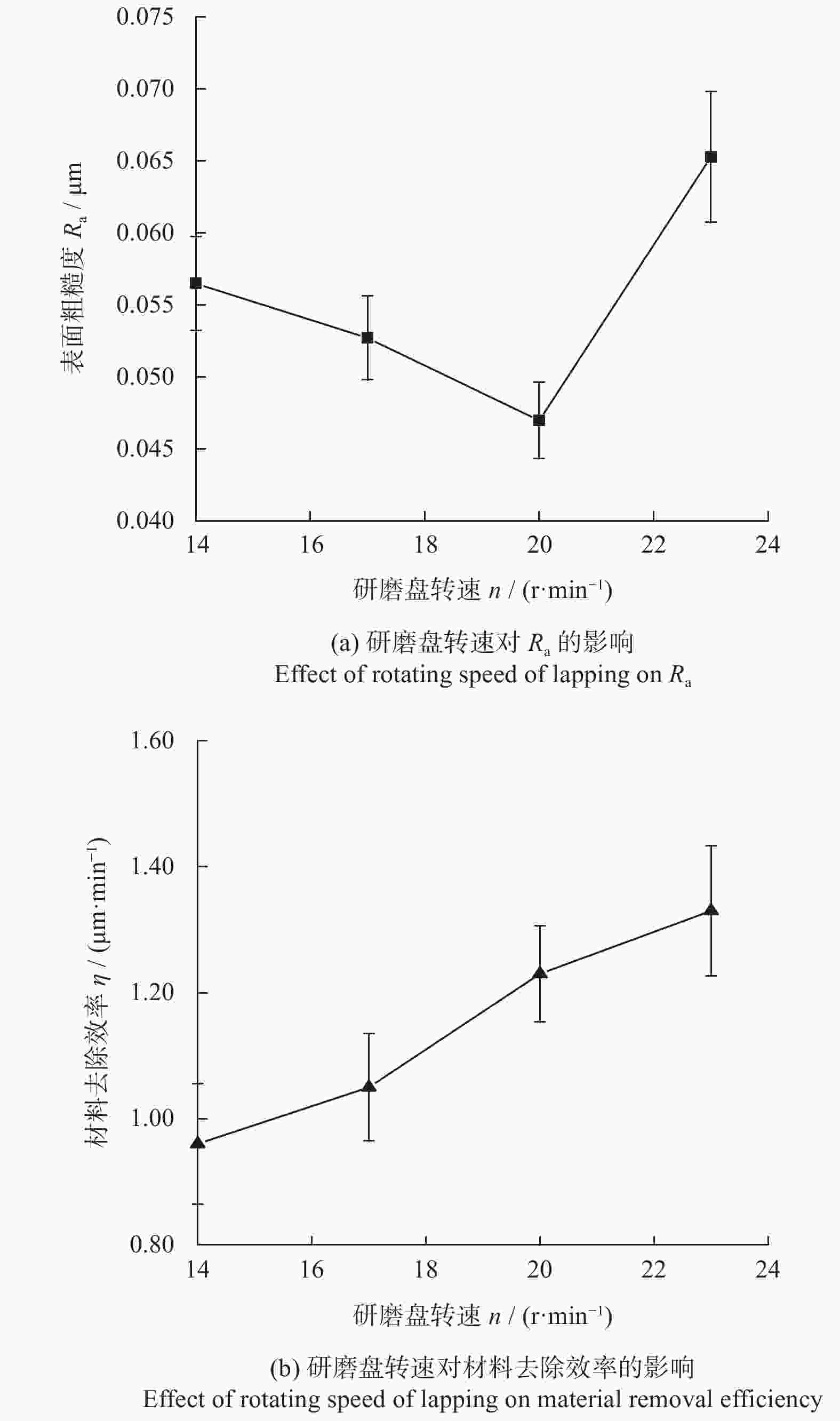

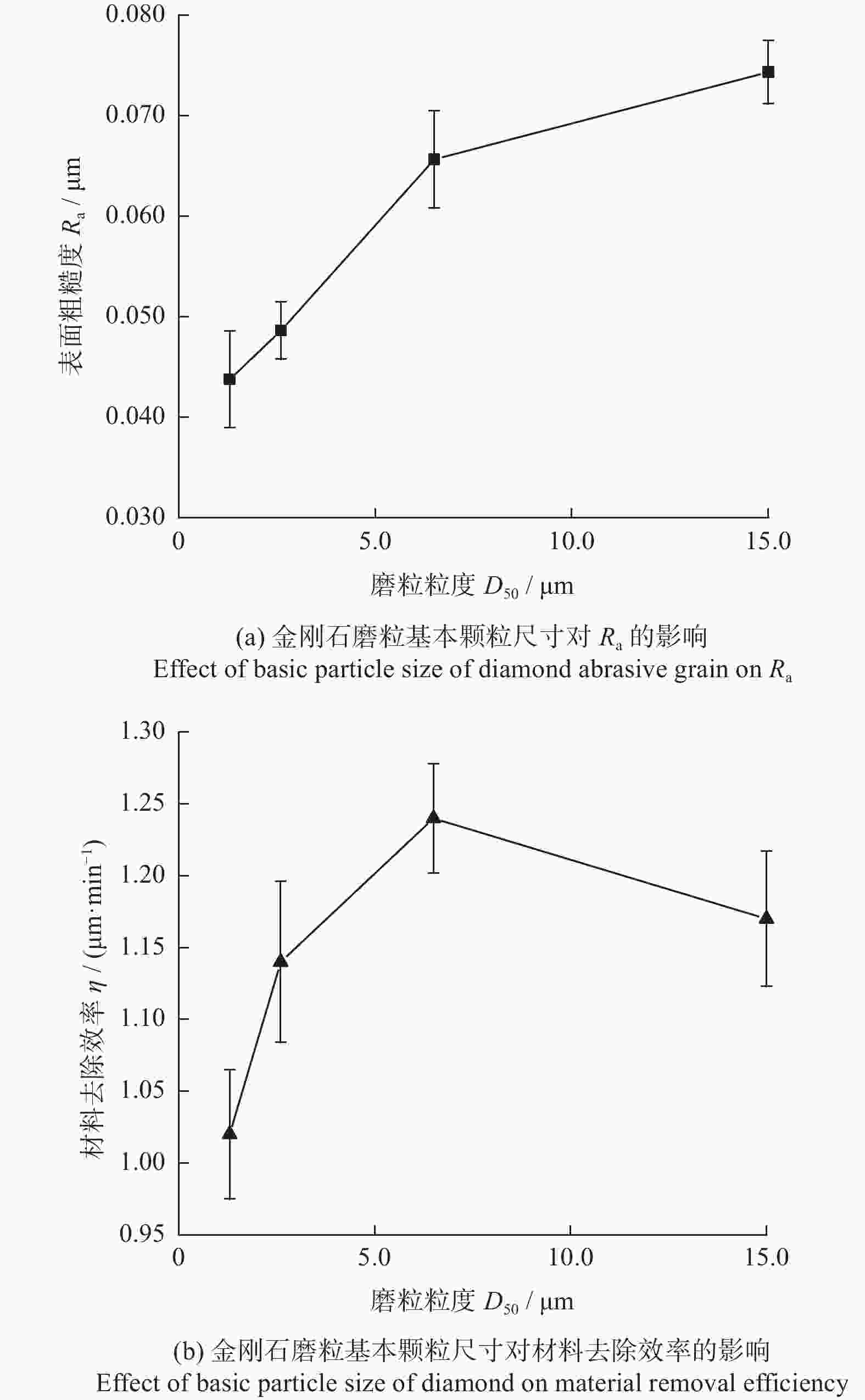

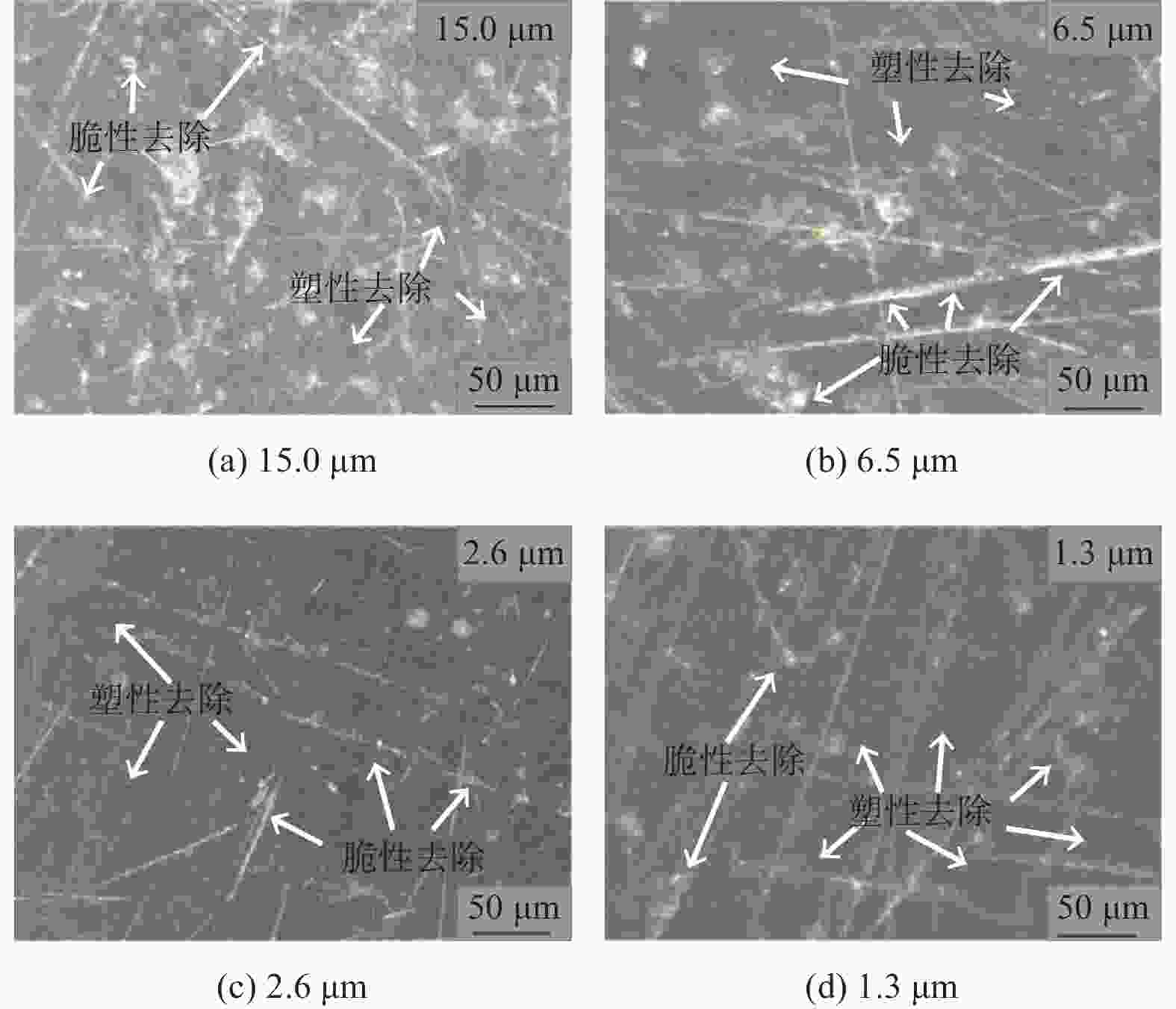

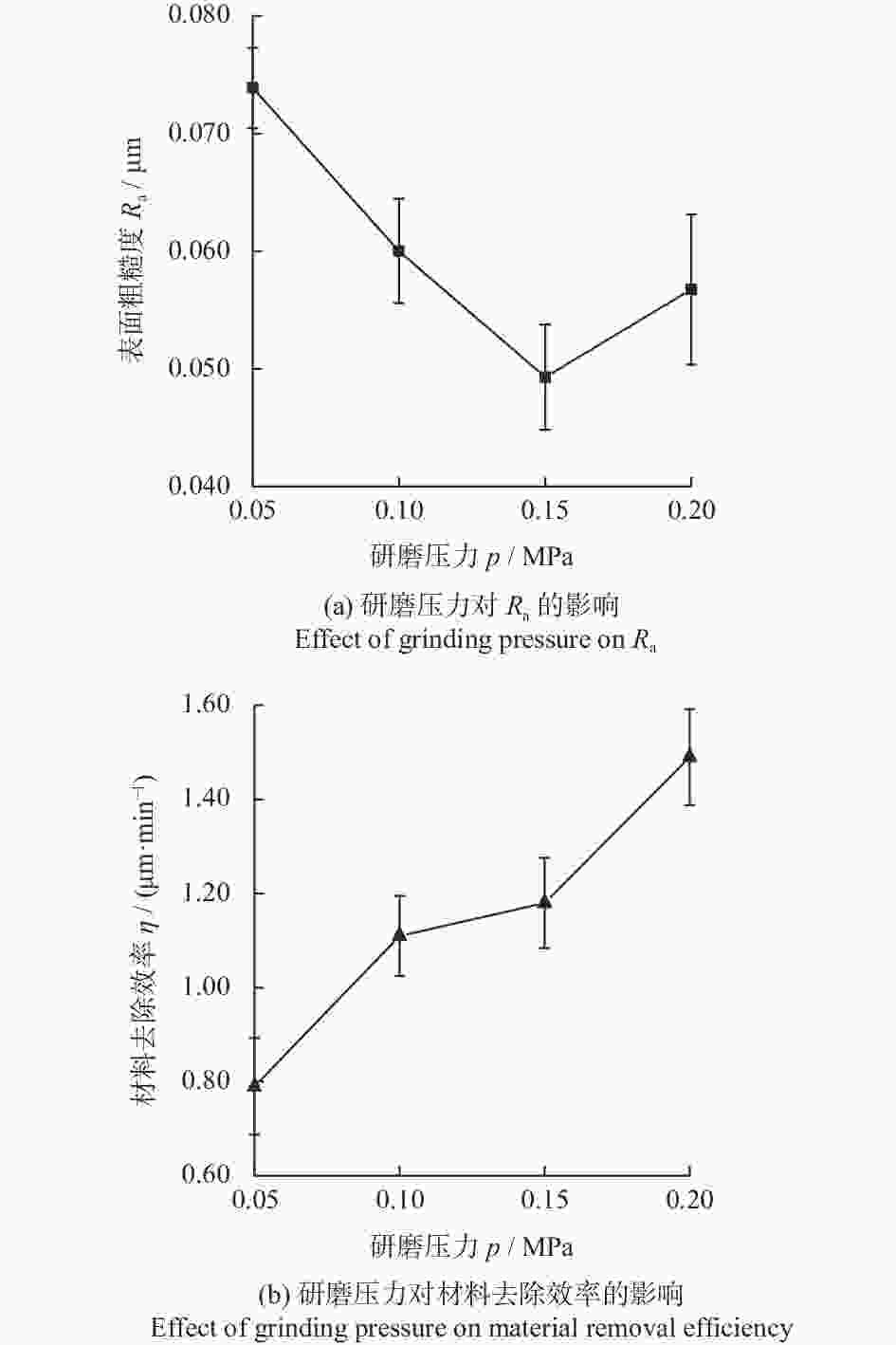

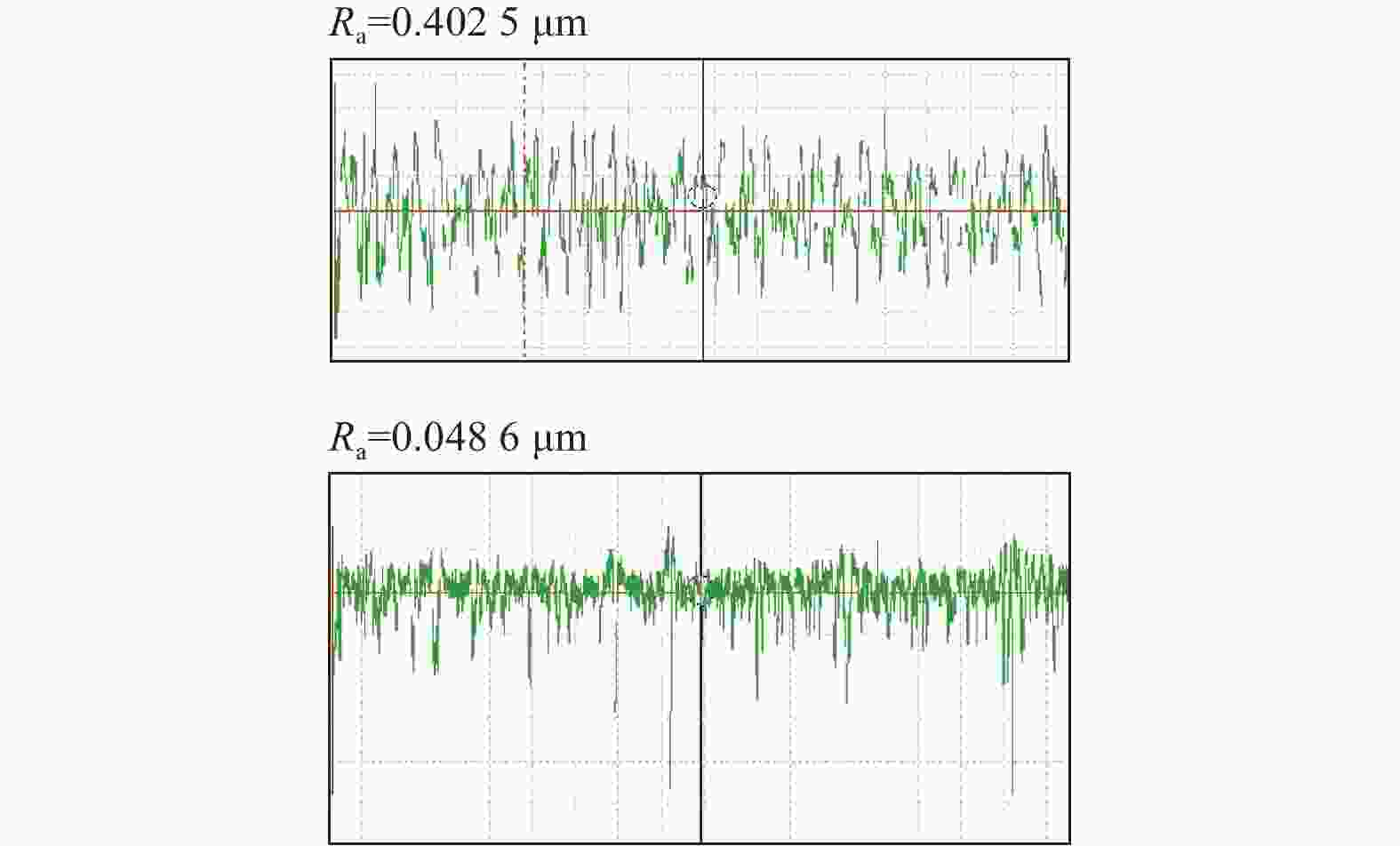

为获得双平面研磨Si3N4圆柱滚子的最佳工艺参数组合,采用正交试验法,探究研磨盘转速、研磨压力和磨粒基本颗粒尺寸对其表面质量和去除效率的影响规律,并以工件的表面粗糙度和材料去除效率作为研磨最佳工艺参数的优选依据。结果表明:随着研磨盘转速和研磨压力的增大,工件表面粗糙度先减小后增大;且磨粒基本颗粒尺寸和工件表面粗糙度、研磨盘转速和研磨压力和去除效率均呈正相关。Si3N4圆柱滚子研磨的最佳工艺参数组合是金刚石磨粒基本颗粒尺寸为2.6 μm、研磨盘转速为20 r/min、研磨压力为0.15 MPa;在此最优参数下,可获得表面粗糙度为0.0486 μm、材料去除效率为1.20 μm/min的光滑无损伤Si3N4圆柱滚子。

Abstract:In order to obtain the optimal process parameter combination of double-sided grinding Si3N4 cylindrical rollers, the orthogonal experiment method was used to explore the influences of the grinding disc speeds, the grinding pressures and the basic particle sizes of the abrasive particles on the surface quality and the removal efficiency of Si3N4 cylindrical rollers. The results of the surface roughness and the material removal efficiency of the specimen are taken as the basis for optimizing the grinding process parameters. The results show that the surface roughness of the specimen first decreases and then increases with the increase of the grinding disc pressure and the grinding speed. The basic particle sizes of the abrasive are positively correlated with the surface roughness of the specimen, while the grinding disc speed and the grinding pressure are positively correlated with the removal efficiency. The optimum combination of grinding parameters for Si3N4 cylindrical rollers is that the basic particle size of diamond abrasive is 2.6 μm, the grinding disc speed is 20 r/min and the grinding pressure is 0.15 MPa. Under the optimal parameters, the smooth and undamaged Si3N4 cylindrical rollers with surface roughness of 0.0486 μm and removal efficiency of 1.20 μm/min can be obtained.

-

Key words:

- double-sided grinding /

- Si3N4 cylindrical roller /

- surface roughness /

- removal efficiency

-

表 1 Si3N4陶瓷材料性能参数

Table 1. Si3N4 material performance parameters

性能指标 数值 密度 ρ / (g∙cm−3) 3.26 弹性模量 E / GPa 310 硬度 H / GPa 16 泊松比 ε 0.25 断裂韧性 KIC / (MPa∙m−2) 7.0 压碎载荷比 R 40 线膨胀系数 λ / K−1 3.2 × 10−6 表 2 试验因素及水平

Table 2. Experimental factors and levels

水平 因素 研磨盘转速

n / (r∙min−1)

A金刚石磨粒基本颗粒尺寸

D50 / μm

B研磨压力

p / MPa

C1 14 15.0 0.05 2 17 6.5 0.10 3 20 2.6 0.15 4 23 1.3 0.20 表 3 正交试验结果

Table 3. Orthogonal experimental results

组号 A B C 表面粗糙度

Ra / μm去除效率

η / (μm∙min−1)1 14 15.0 0.05 0.0758 0.46 2 14 6.5 0.10 0.0683 0.83 3 14 2.6 0.15 0.0409 1.00 4 14 1.3 0.20 0.0410 1.01 5 17 15.0 0.10 0.0699 0.99 6 17 6.5 0.15 0.0658 0.99 7 17 2.6 0.20 0.0444 1.07 8 17 1.3 0.05 0.0310 0.54 9 20 15.0 0.15 0.0633 1.04 10 20 6.5 0.20 0.0531 1.34 11 20 2.6 0.05 0.0394 0.75 12 20 1.3 0.10 0.0321 1.01 13 23 15.0 0.20 0.0885 1.51 14 23 6.5 0.05 0.0755 0.94 15 23 2.6 0.10 0.0699 1.07 16 23 1.3 0.15 0.0273 1.48 表 4 Ra响应表

Table 4. Ra response table

水平 A B C 1 0.0565 0.0438 0.0739 2 0.0527 0.0486 0.0600 3 0.0470 0.0657 0.0493 4 0.0653 0.0743 0.0567 极差 0.0183 0.0306 0.0246 表 5 材料去除效率响应表

Table 5. Material removal efficiency response table

水平 A B C 1 0.83 1.01 0.67 2 0.90 0.97 0.98 3 1.03 1.03 1.13 4 1.25 1.00 1.23 极差 0.42 0.06 0.56 -

[1] 赵礼辉, 李其宸, 冯金芝, 等. 随机道路载荷下轮毂轴承服役寿命预测方法研究 [J]. 机械工程学报,2021,57(10):77-86. doi: 10.3901/JME.2021.10.077ZHAO Lihui, LI Qichen, FENG Jinzhi, et al. Research on prediction method of hub-bearing service life under random road load [J]. Journal of Mechanical Engineering,2021,57(10):77-86. doi: 10.3901/JME.2021.10.077 [2] 何加群. 论我国重大技术装备轴承的自主安全可控 [J]. 轴承,2022(1):1-17.HE Jiaqun. Discussion on independence safety and controllability of bearings for major technical equipment in china [J]. Bearing,2022(1):1-17. [3] 曾献智, 奚强, 刘璇, 等. 有轨电车轮对轴承失效原因的分析及优化改进 [J]. 轴承,2020(11):34-39.ZENG Xianzhi, XI Qiang, LIU Xuan, et al. Failure reason analysis and optimized improvement on wheel bearings for tramcar [J]. Bearing,2020(11):34-39. [4] 李颂华, 王维东, 吴玉厚, 等. 金刚石油石超精加工氧化锆陶瓷轴承沟道的仿真与实验研究 [J]. 金刚石与磨料磨具工程,2018,38(4):64-71.LI Songhua, WANG Weidong, WU Yuhou, et al. Simulation and experimental study on diamond stick superfinishing bearing raceway made of zirconic ceramic [J]. Diamond & Abrasives Engineering,2018,38(4):64-71. [5] 吴玉厚, 王维东, 李颂华, 等. 干湿磨条件下氧化锆陶瓷表面粗糙度实验 [J]. 沈阳建筑大学学报(自然科学版),2017,33(6):1080-1087.WU Yuhou, WANG Weidong, LI Songhua, et al. Experiments of surface roughness of zirconia ceramics under wet and dry grinding [J]. Journal of Shenyang Jianzhu University ( Natural Science),2017,33(6):1080-1087. [6] OBRIEN M J, PRESSER N, ROBINSON E Y. Failure analysis of three Si3N4 balls used in hybrid bearings [J]. Engineering Failure Analysis,2003,10(4):453-473. doi: 10.1016/S1350-6307(03)00011-6 [7] 于琦, 张永乾, 杨泽琨, 等. 高性能氧化硅陶瓷滚子的研制 [J]. 轴承,2019,476(7):40-42, 66.YU Qi, ZHANG Yongqian, YANG Zekun, et al. Development of high performance Si3N4 ceramic rollers [J]. Bearing,2019,476(7):40-42, 66. [8] 李鸿亮, 张占立, 李建华, 等. 氮化硅陶瓷滚子轴承的高速性能试验 [J]. 轴承,2015(8):33-35, 40.LI Hongliang, ZHANG Zhanli, LI Jianhua, et al. High speed performance test for silicon nitride ceramic roller bearings [J]. Bearing,2015(8):33-35, 40. [9] 李文博, 张占立, 姚强, 等. 陶瓷滚子超声振动辅助磨削装置设计与试验 [J]. 机械设计与研究,2019,35(4):178-181.LI Wenbo, ZHANG Zhanli, YAO Qiang, et al. Design and test of ceramic roller ultrasonic vibration assisted grinding device [J]. Machine Design and Research,2019,35(4):178-181. [10] 张占立, 孙涛, 王恒迪, 等. 氮化硅陶瓷滚子的油基磁流变抛光液研究 [J]. 金刚石与磨料磨具工程,2014,34(6):60-63.ZHANG Zhanli, SUN Tao, WANG Hengdi, et al. Study on the oil-based magnetorheological fluid applied for Si3N4 ceramic rollers polishing [J]. Diamond & Abrasives Engineering,2014,34(6):60-63. [11] 孙涛. 氮化硅陶瓷滚子的化学机械复合抛光技术研究 [D]. 洛阳: 河南科技大学, 2015.SUN Tao. The study of the chemical-mechanical compound polishing technology for Si3N4 ceramic roller [D]. Luoyang: Henan University of Science and Technology, 2015. [12] 张占立, 熊明照, 王恒迪, 等. 氮化硅陶瓷滚子磁流变、化学与超声复合抛光工艺试验 [J]. 轴承,2016(2):14-19.ZHANG Zhanli, XIONG Mingzhao, WANG Hengdi, et al. Polishing processing test for silicon nitride ceramic rollers based on magnetorheological and chemo-ultrasonic compound technology [J]. Bearing,2016(2):14-19. [13] 张占立, 张运瑞, 叶秀玲, 等. 氮化硅陶瓷滚子磁流变与超声波复合抛光技术 [J]. 河南科技大学学报(自然科学版) , 2014, 35(4): 13-17.ZHANG Zhanli, ZHANG Yunrui, YE Xiuling, et al. Magnetorheological-ultrasonic technology for polishing Si3N4 ceramic roller [J]. Journal of Henan University of Science & Technology (Natural Science), 2014, 35(4): 13-17. [14] UMEHARA N, KALPAKJIAN S. Magnetic fluid grinding: A new technique for finishing advanced ceramics [J]. CIRP Annals,1994,43(1):185-188. doi: 10.1016/S0007-8506(07)62192-1 [15] 杨蕾, 任成祖. 圆柱滚子电磁推进装置仿真与推进实验分析 [J]. 工程设计学报,2019,26(5):611-618.YANG Lei, REN Chengzu. Simulation and propulsion experimental analysis of electromagnetic propulsion device for cylindrical roller [J]. Chinese Journal of Engineering Design,2019,26(5):611-618. [16] 姚蔚峰, 袁巨龙, 江亮, 等. 偏心运动双平面超精研抛圆柱面研究 [J]. 中国机械工程,2018,29(19):2327-2334. doi: 10.3969/j.issn.1004-132X.2018.19.009YAO Weifeng, YUAN Julong, JIANG Liang, et al. Study on both-side cylindrical ultra-precision lapping and polishing processes in eccentric rotations [J]. China MechanIcal Engineering,2018,29(19):2327-2334. doi: 10.3969/j.issn.1004-132X.2018.19.009 [17] 王志强, 方伟, 豁国燕, 等. LED蓝宝石衬底研磨工艺研究 [J]. 金刚石与磨料磨具工程,2015,35(2):59-62.WANG Zhiqiang, FANG Wei, HUO Guoyan, et al. Research on lapping technology of LED sapphire substrate [J]. Diamond & Abrasives Engineering,2015,35(2):59-62. [18] 李颂华, 严传振, 孙健. 双面研磨Si3N4圆柱滚子表面质量研究 [J]. 兵器材料科学与工程, 2021, 44(5): 23-28.LI Songhua, YAN Chuanzhen, SUN Jian. Study on surface quality of double-sided grinding Si3N4 cylindrical rollers [J]. Ordnance Material Science and Engineering, 2021, 44(5): 23-28. [19] 卢守相, 杨秀轩, 张建秋, 等. 关于硬脆材料去除机理与加工损伤的理性思考 [J]. 机械工程学报,2022,58(15):31-45.LU Shouxiang, YANG Xiuxuan, ZHANG Jianqiu, et al. Rational discussion on material removal mechanisms and machining damage of hard and brittle materials [J]. Journal of Mechanical Engineering,2022,58(15):31-45. [20] DING K, LI Q, ZHANG C. Experimental studies on material removal mechanisms in ultrasonic assisted grinding of SiC ceramics with a defined grain distribution brazed grinding wheel [J]. The International Journal of Advanced Manufacturing Technology, 2021, 116(11/12): 3663-3676. [21] CHENG X, WEI X T, YANG X H, et al. Unified criterion for brittle–ductile transition in mechanical microcutting of brittle materials [J]. Journal of Manufacturing Science and Engineering, 2014, 136: 5-12. [22] 吴书安, 祝锡晶, 王建青, 等. 单磨粒对硬脆性材料延性去除的建模分析 [J]. 表面技术,2016,45(5):219-223. doi: 10.16490/j.cnki.issn.1001-3660.2016.05.034WU Shu′an, ZHU Xijing, WANG Jianqing, et al. Modelling analysis on ductile removal of hard-brittle material by single grain [J]. Surface Technology,2016,45(5):219-223. doi: 10.16490/j.cnki.issn.1001-3660.2016.05.034 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS