Experimental research on creep feed deep profile grinding of small-module gears

-

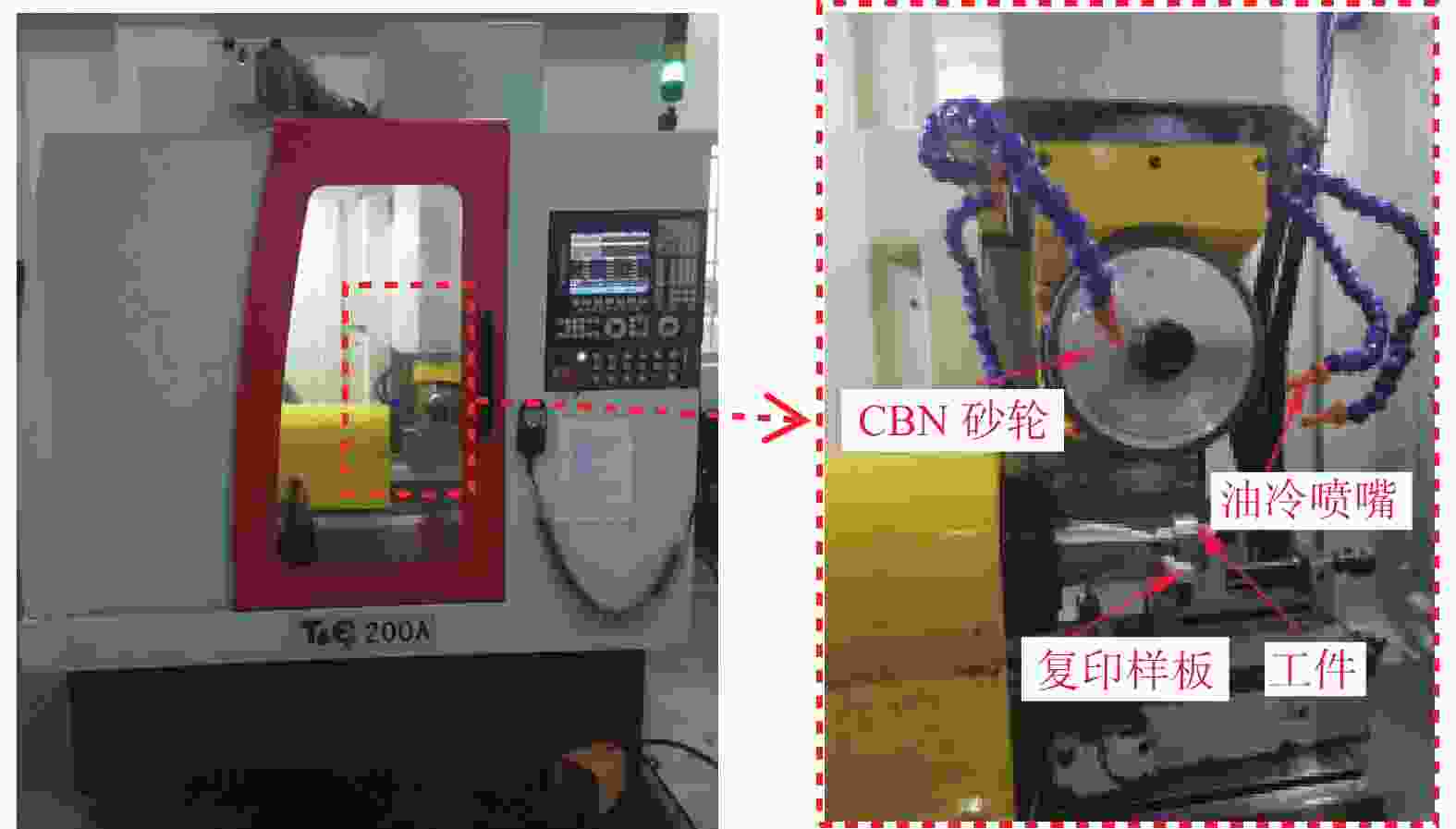

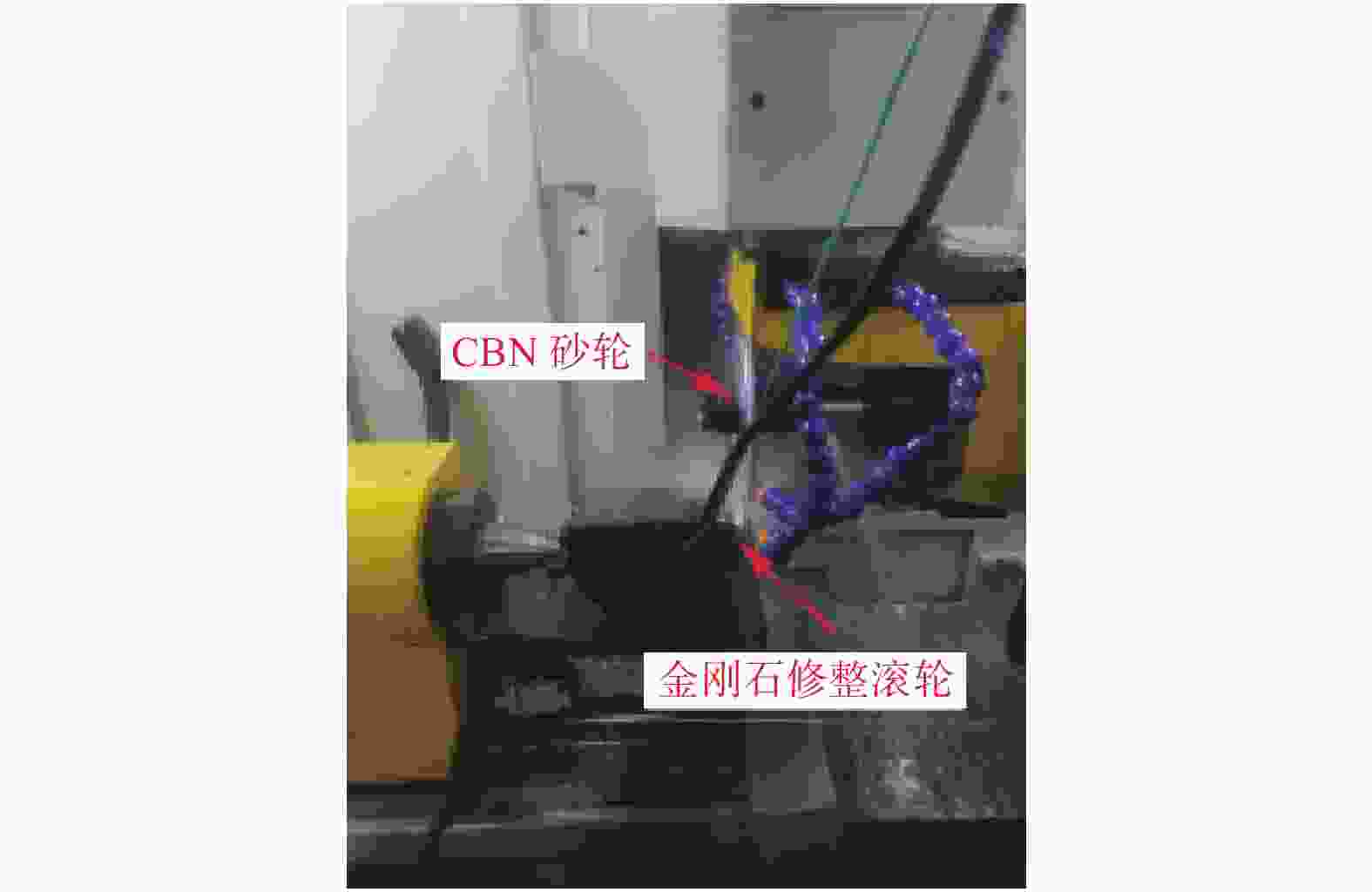

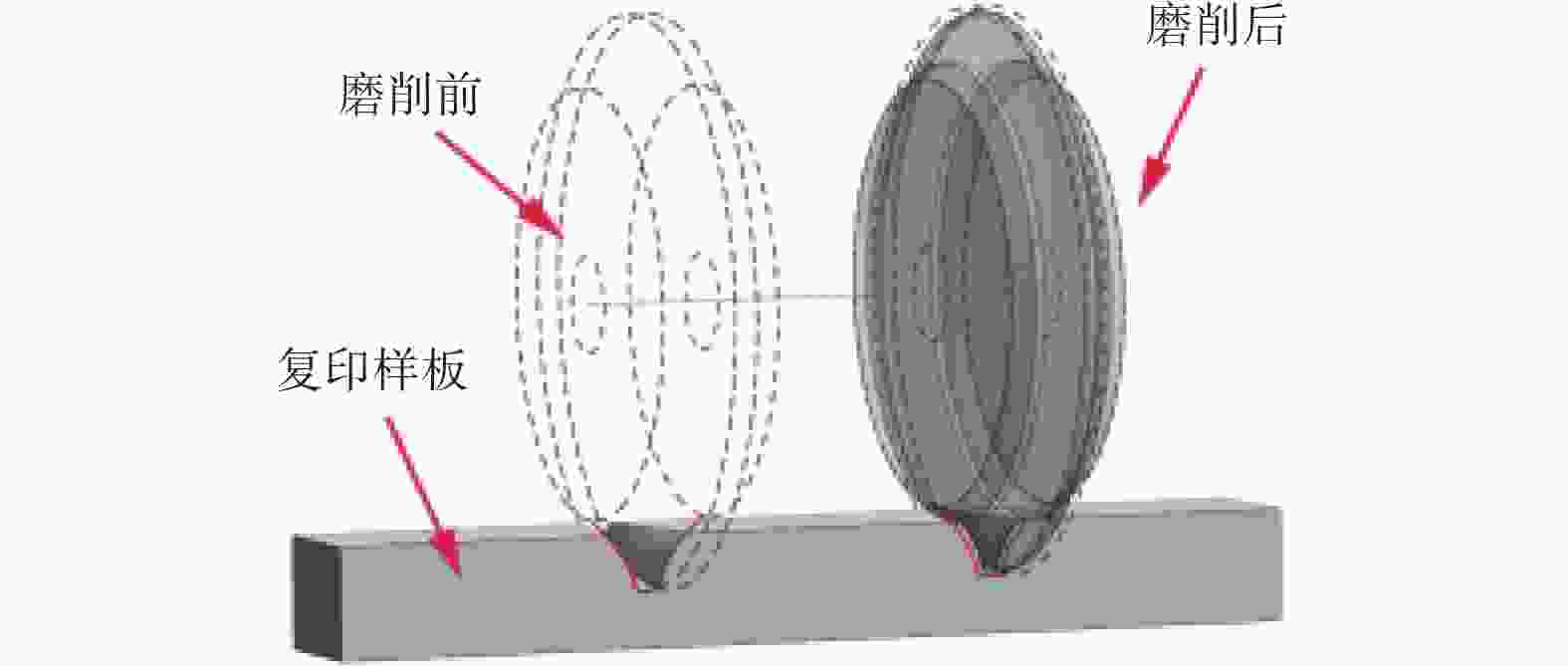

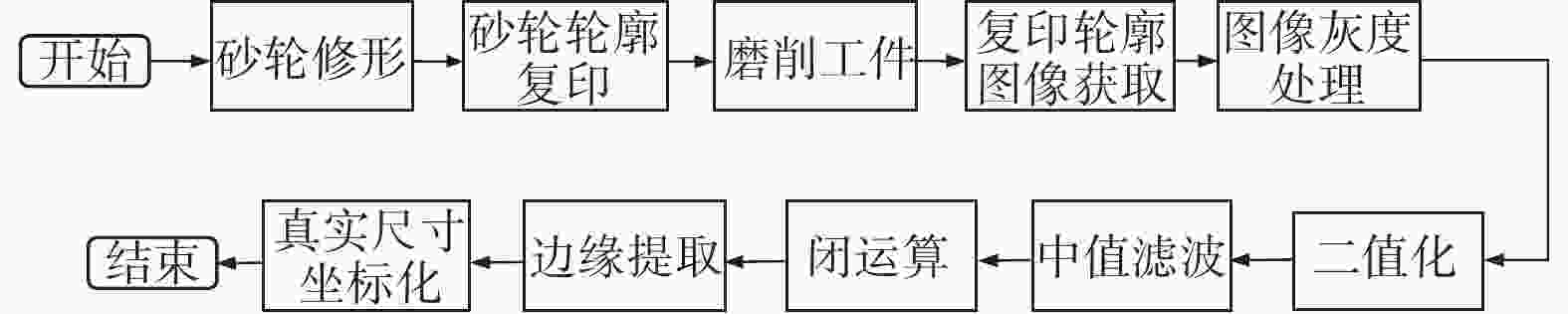

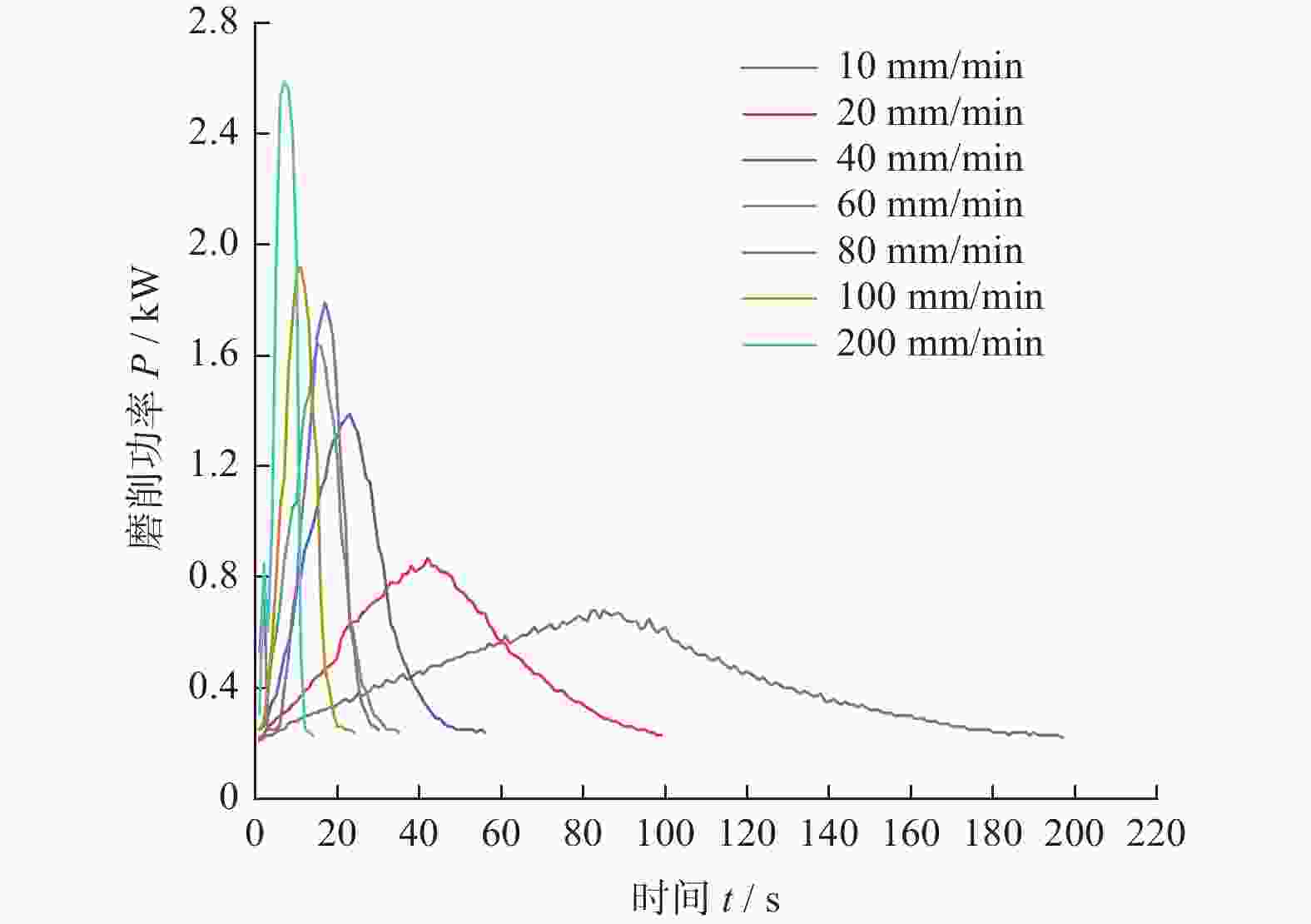

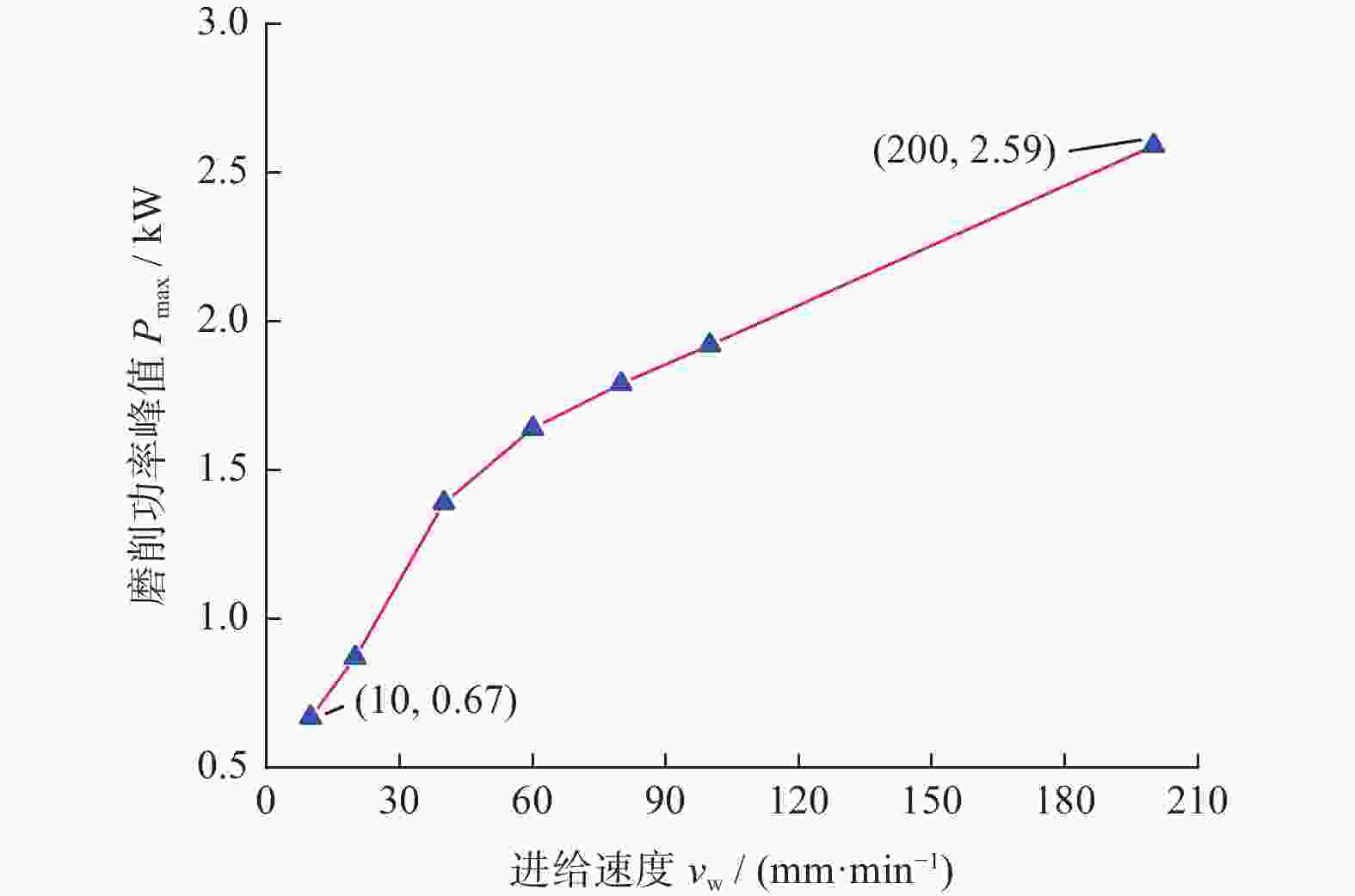

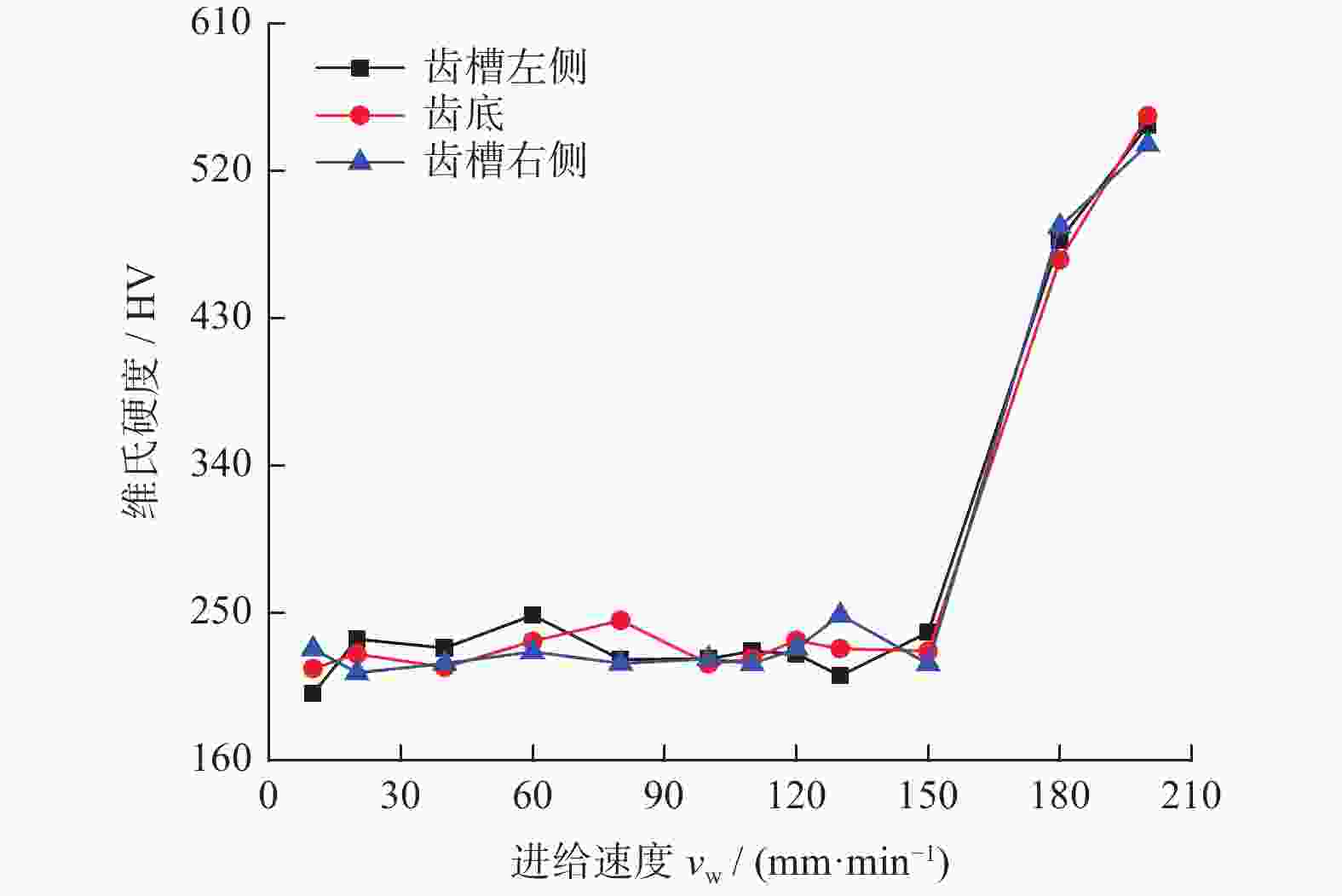

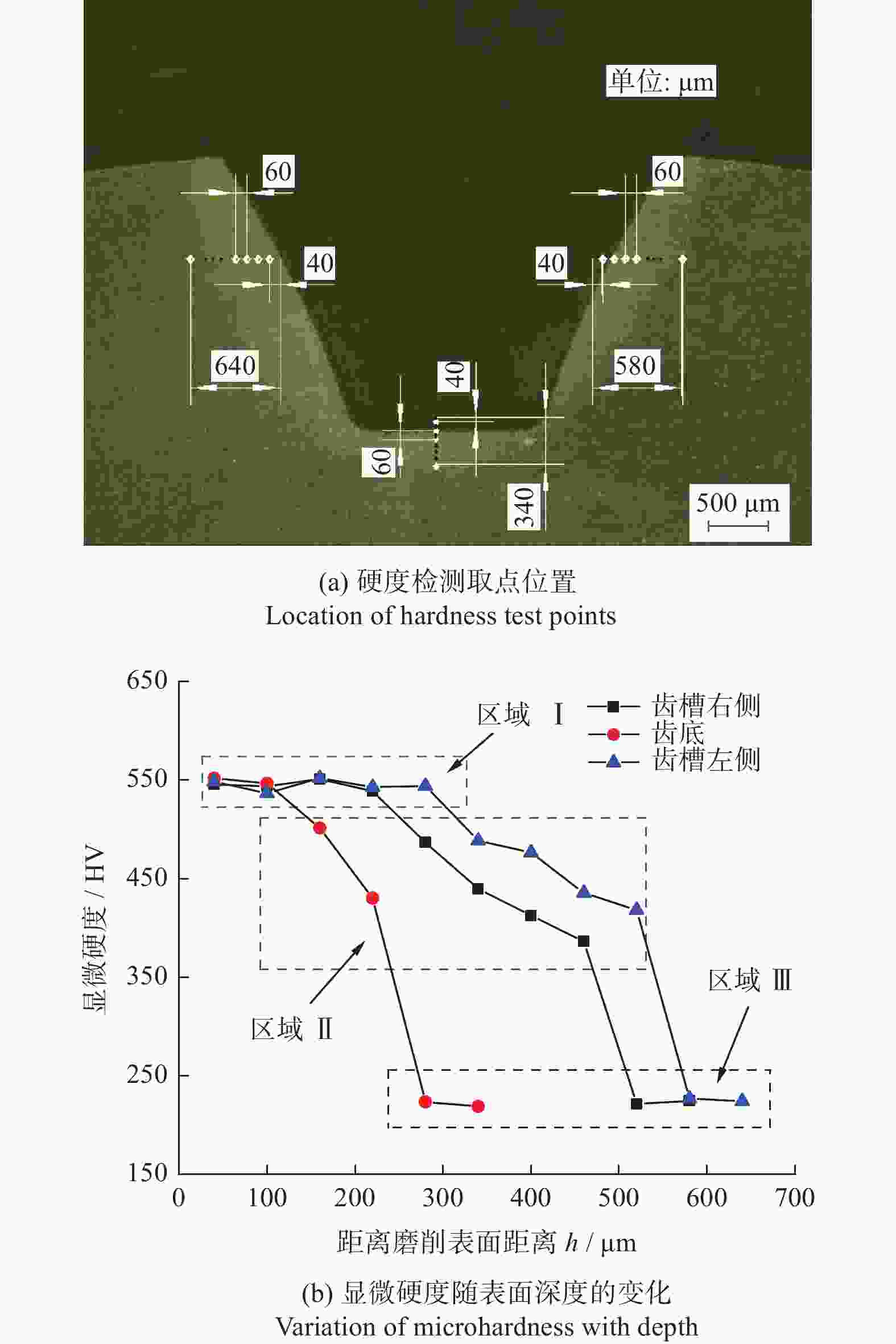

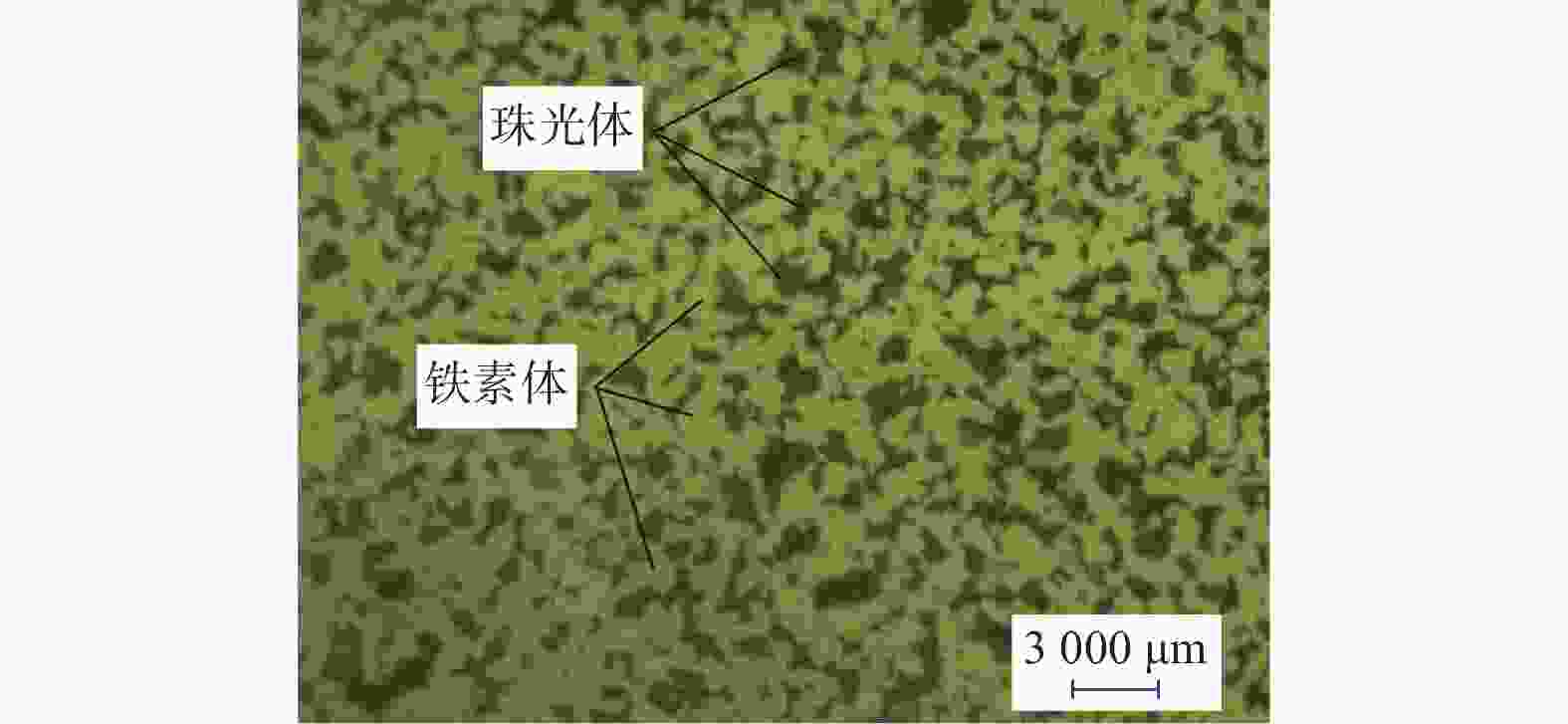

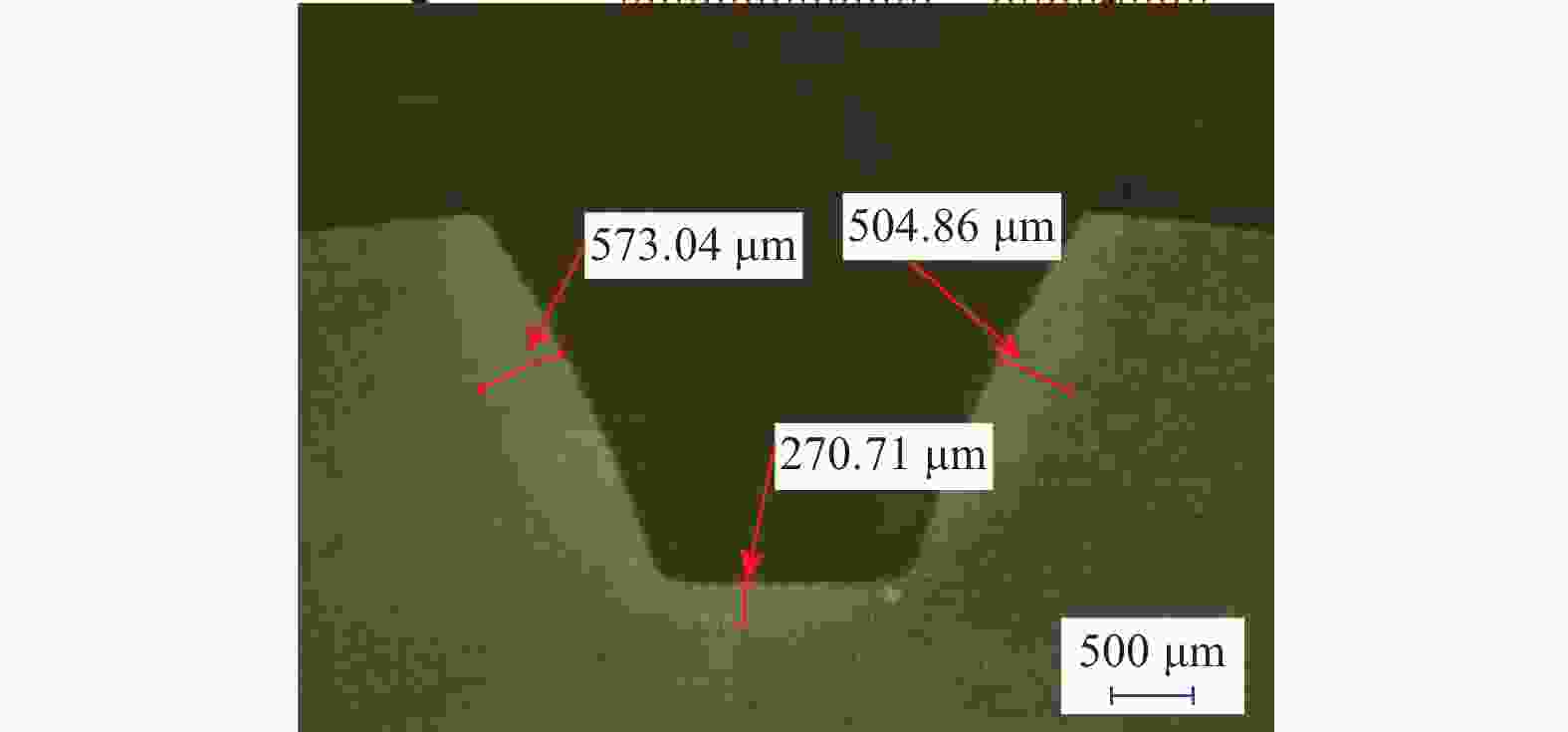

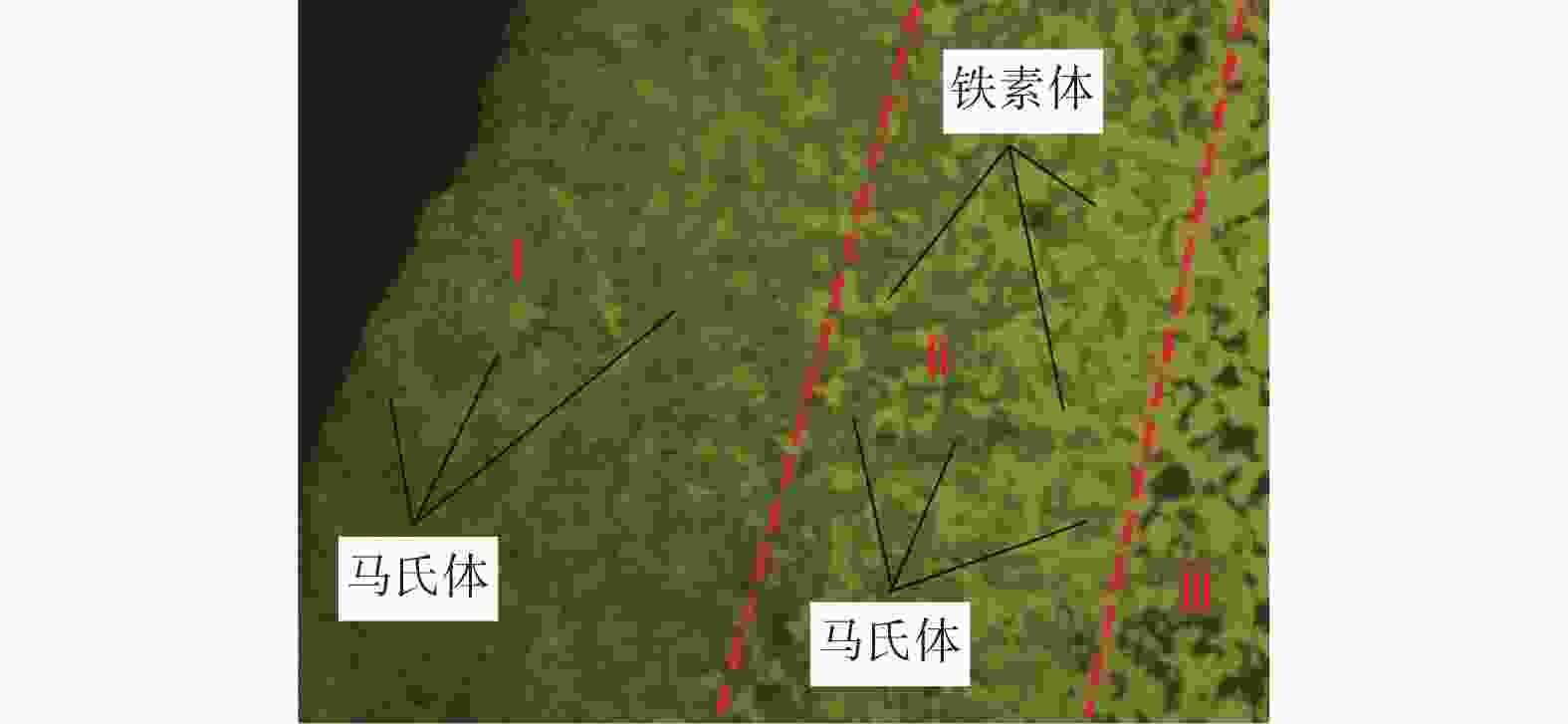

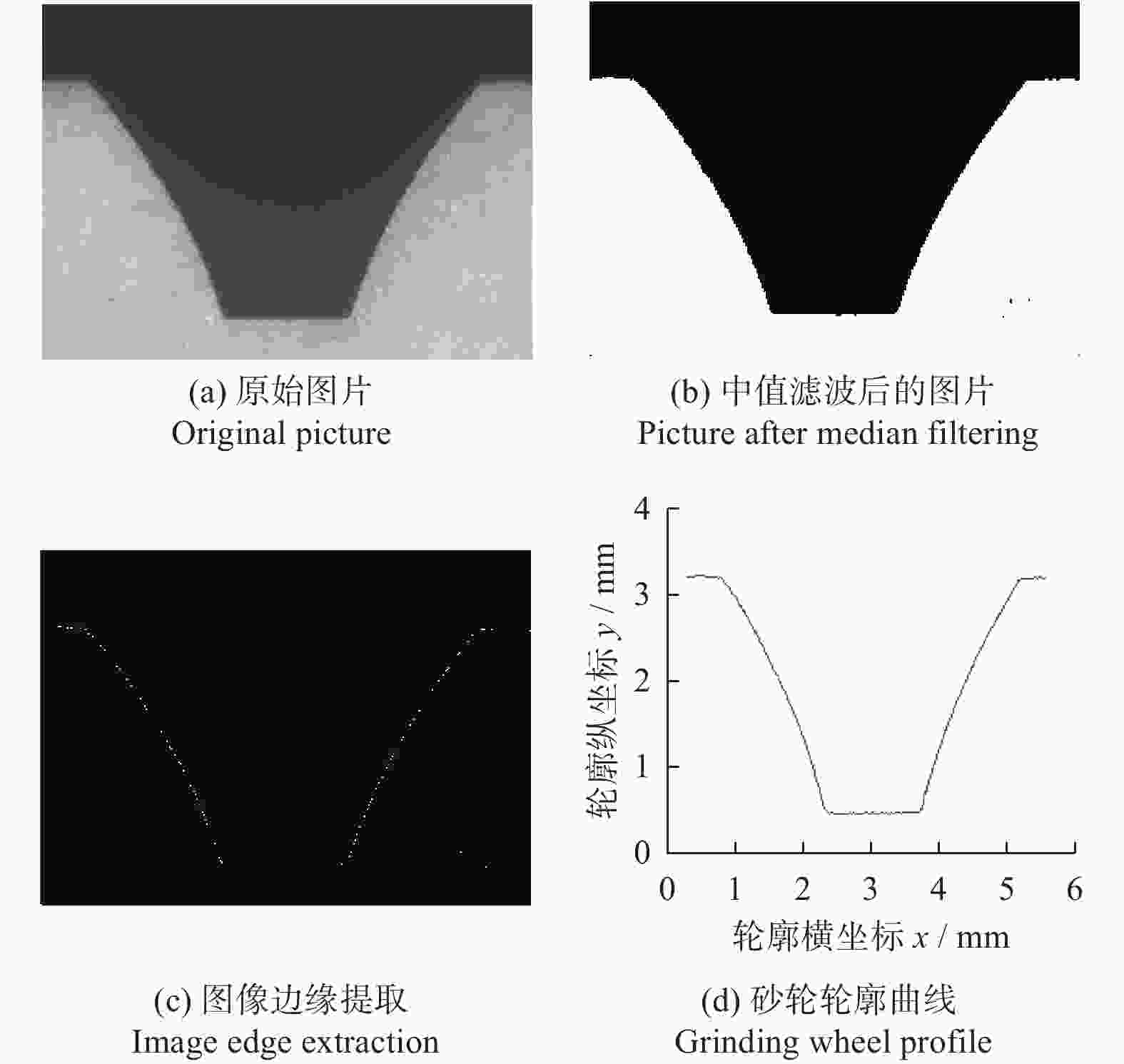

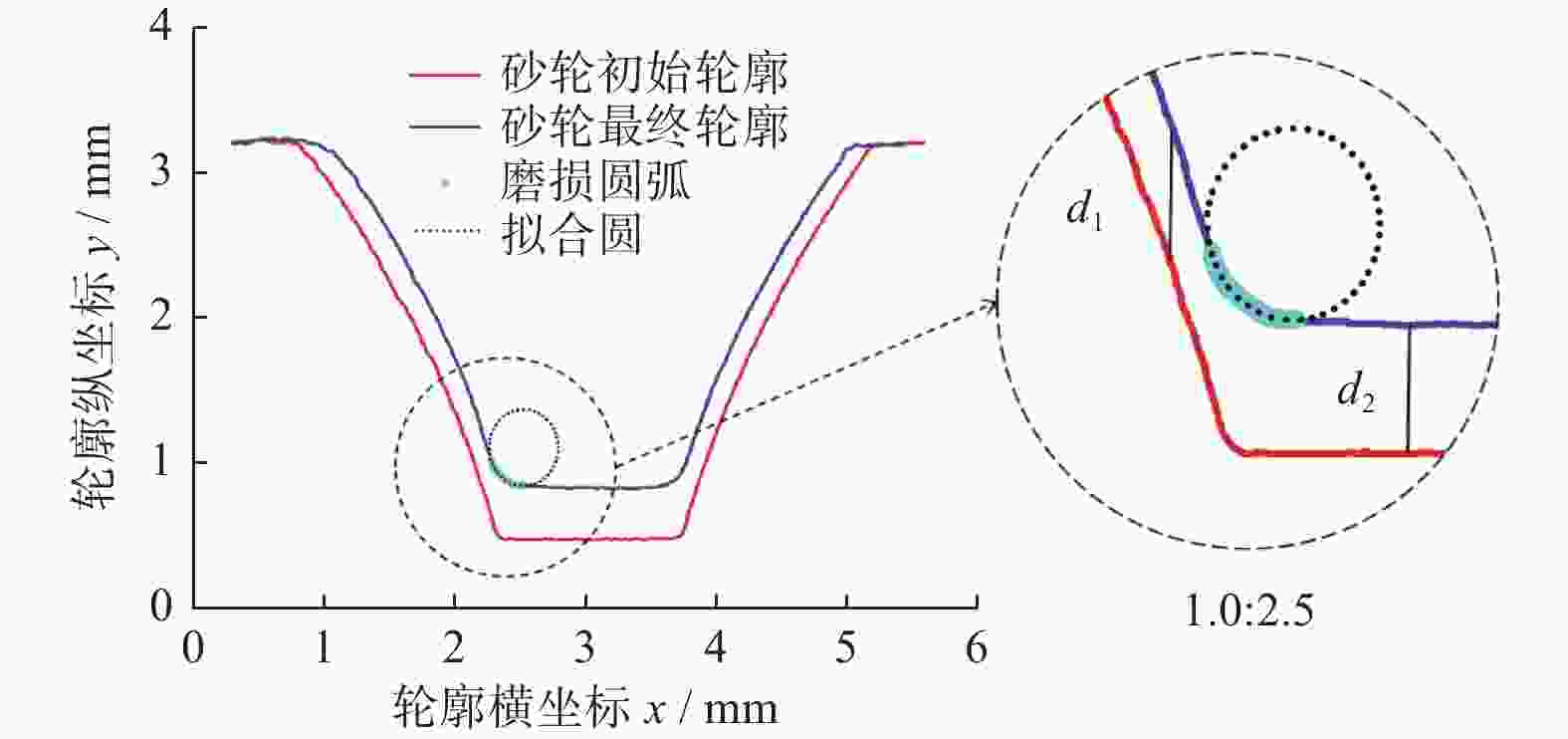

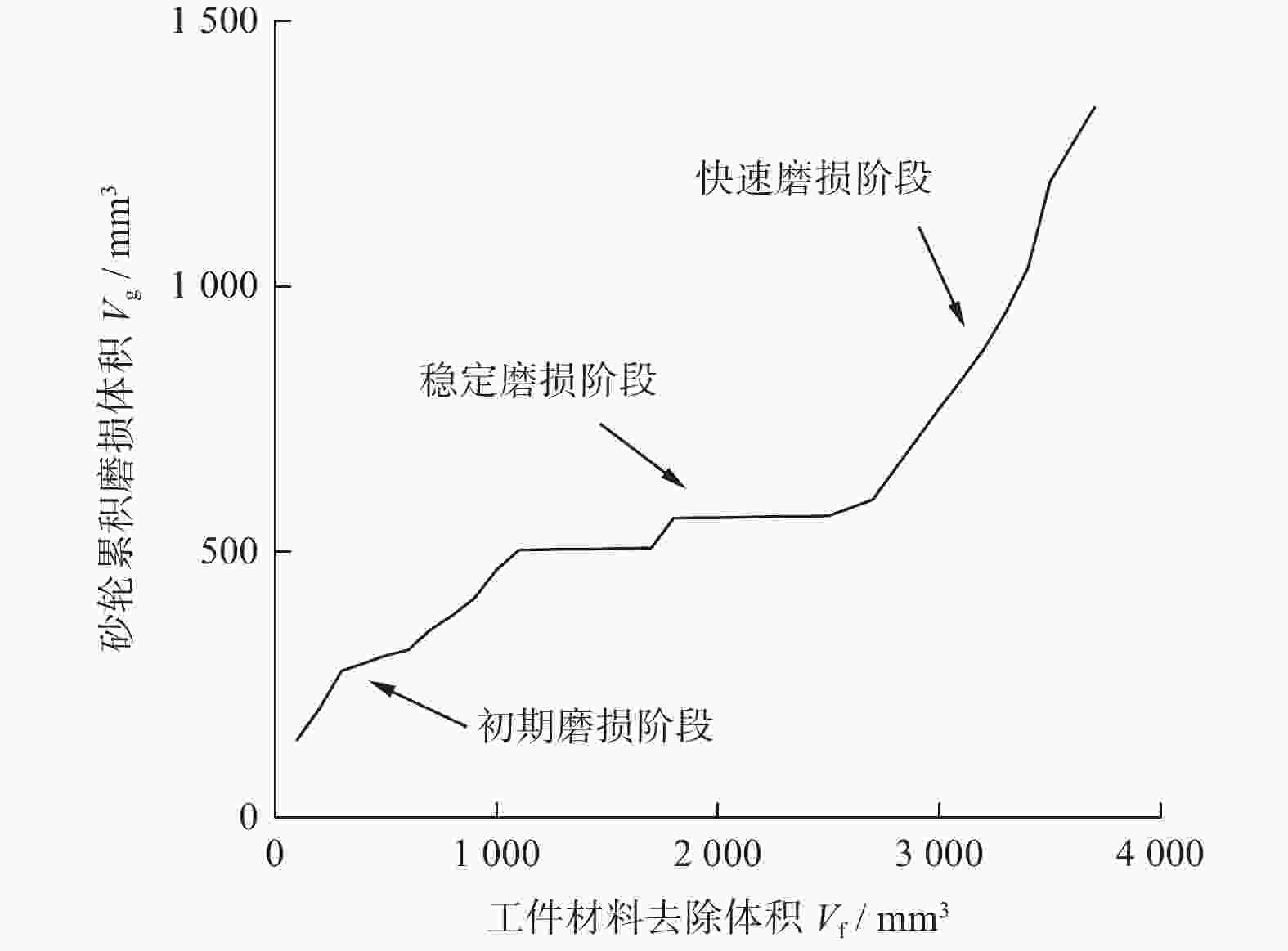

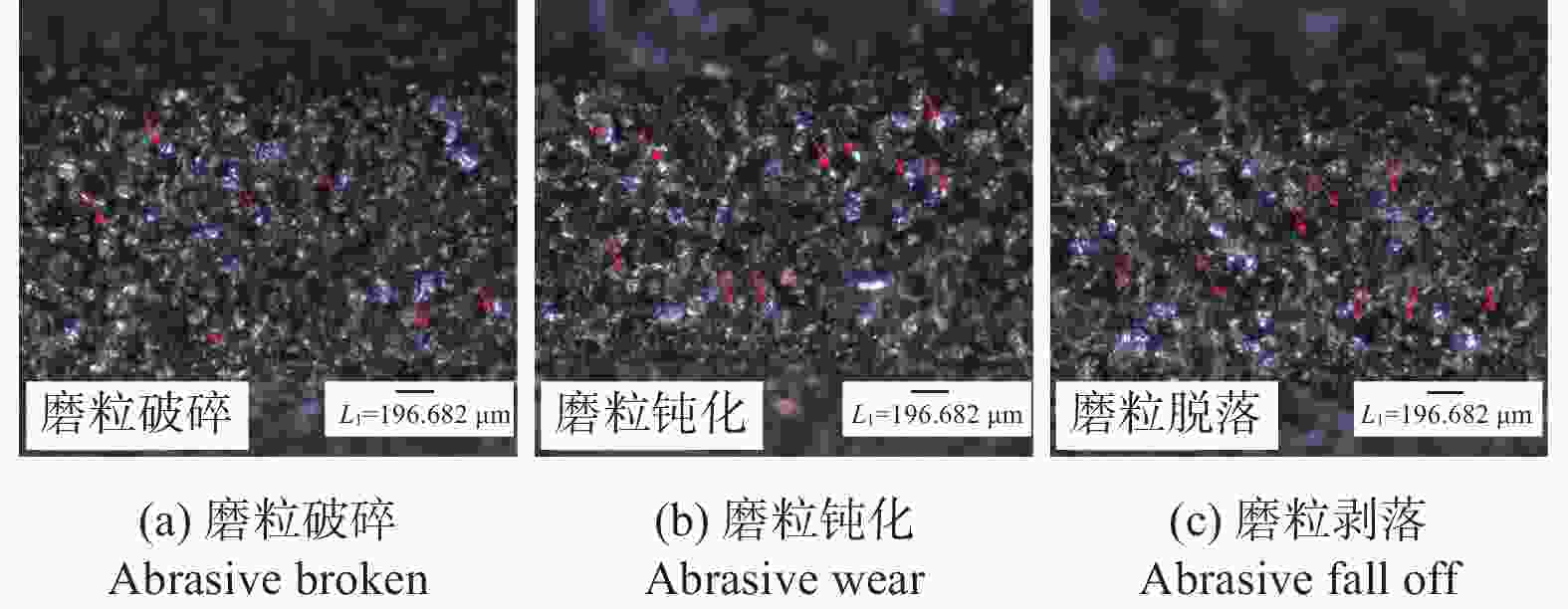

摘要: 针对高精度齿轮加工工艺路线长的问题,提出小模数齿轮缓进深切成形磨削方法并开展磨削实验,分析不同进给速度对磨削功率、工件磨削烧伤、砂轮磨损等的影响规律,且采用复刻法研究砂轮的磨损过程。结果表明:磨削功率峰值随进给速度的增加而增大;当进给速度超过150 mm/min时,工件表面发生磨削烧伤,其磨削表面的硬度明显高于工件初始表面的硬度,且工件表层发生了马氏体相变;距离磨削表面的深度增加,其硬度值均呈下降趋势,且齿底位置的硬化层深度小于齿廓两侧的硬化层深度;砂轮的磨损过程分为初期磨损、稳定磨损和快速磨损阶段3个阶段,其中稳定磨损阶段的材料去除体积约为2 000 mm3,过大的进给速度将引起砂轮的严重磨损。Abstract: In view of the long process route of high-precision gear machining, a method of creep feed deep profile grinding of small-module gears was proposed. The experiments of creep feed deep profile grinding of small-module gears were carried out. The effects of different feed speeds on the grinding power, the workpiece grinding burn and the grinding wheel wear were analyzed. The wear process of grinding wheels was studied by replica method. The results show that the grinding power peak increases with the increase of feed speed. When the feed speed exceeds 150 mm/min, the grinding burns occur on the workpiece surface. Besides, the hardness of the grinding surface is significantly higher than that of the initial hardness, and the martensitic phase transformation occurs on the workpiece surface. As the depth from the grinding surface increases, the hardness values show a downward trend, and the depth of the hardness layer at the tooth bottom is smaller than that at the both sides of the tooth profile. The wear process of grinding wheels is divided into initial wear stage, stable wear stage and rapid wear stage. The material removal volume of stable wear stage is about 2 000 mm3. Excessive feed rate will cause severe wear of the grinding wheel.

-

Key words:

- gear /

- creep feed deep profile grinding /

- grinding power /

- grinding burn /

- grinding wheel wear

-

表 1 磨削工艺参数

Table 1. Grinding process parameters

实验

组号砂轮线速度

vs / (m·s−1)磨削深度

ap / mm进给速度

vw /(mm·min−1)磨削次数n1 1 60 2.456 10,20,40,60,

80,100,2007 2 10 6 3 60 6 4 80 6 5 90,100,110,120,

130,150,1807 6 110 6 7 120 6 -

[1] 康玉辉, 李美美. 逆向工程技术在小模数齿轮加工检测中的应用 [J]. 机电工程,2020,37(11):1372-1375. doi: 10.3969/j.issn.1001-4551.2020.11.020KANG Yuhui, LI Meimei. Application of reverse engineering technology in machining and measuring of small module gear [J]. Journal of Mechanical & Electrical Engineering,2020,37(11):1372-1375. doi: 10.3969/j.issn.1001-4551.2020.11.020 [2] 徐敏, 冯育敏, 杜改梅, 等. 小模数硬齿面齿轮磨削烧伤分析与预防 [J]. 机械传动,2014,38(7):127-130. doi: 10.16578/j.issn.1004.2539.2014.07.005XU Min, FENG Yumin, DU Gaimei, et al. Analysis and prevention grinding burn of small modulus hardened gear [J]. Journal of Mechanical Transmission,2014,38(7):127-130. doi: 10.16578/j.issn.1004.2539.2014.07.005 [3] HOOD R, LECHNER F, ASPINWALLl D K, et al. Creep feed grinding of gamma titanium aluminide and burn resistant titanium alloys using SiC abrasive [J]. International Journal of Machine Tools and Manufacture,2007,47(9):1486-1492. doi: 10.1016/j.ijmachtools.2006.10.008 [4] JIN T, STEPHENSON D J. Investigation of the heat partitioning in high efficiency deep grinding [J]. International Journal of Machine Tools and Manufacture,2003,43(11):1129-1134. doi: 10.1016/S0890-6955(03)00123-8 [5] 冯克明, 赵金坠. 先进磨削技术应用现状与展望 [J]. 轴承,2020(4):60-67. doi: 10.19533/j.issn1000-3762.2020.04.014FENG Keming, ZHAO Jinzhui. Present situation and prospect of advanced grinding technology application [J]. Bearing,2020(4):60-67. doi: 10.19533/j.issn1000-3762.2020.04.014 [6] DANG J, ZANG H, AN Q, et al. Feasibility study of creep feed grinding of 300M steel with zirconium corundum wheel [J]. Chinese Journal of Aeronautics,2022,35(3):565-578. doi: 10.1016/j.cja.2021.01.029 [7] 丁文锋, 曹洋, 赵彪, 等. 超声振动辅助磨削加工技术及装备研究的现状与展望 [J]. 机械工程学报,2022,58(9):244-269.DING Wenfeng, CAO Yang, ZHAO Biao, et al. Research status and future prospects of ultrasonic vibration-assisted grinding technology and equipment [J]. Journal of Mechanical Engineering,2022,58(9):244-269. [8] 毕雪峰, 杨承三, 景璐璐. 深切缓进给磨削烧伤实验研究 [J]. 上海理工大学学报,2014,36(3):303-306. doi: 10.13255/j.cnki.jusst.2014.03.018BI Xuefeng, YANG Chengsan, JING Lulu. Experimental research on grinding burn in creep feed grinding [J]. Journal of University of Shanghai for Science and Technology,2014,36(3):303-306. doi: 10.13255/j.cnki.jusst.2014.03.018 [9] 刘爽, 李敏, 丁文锋, 等. 刚玉砂轮缓进深切磨削K444镍基高温合金研究 [J]. 金刚石与磨料磨具工程,2021,41(4):72-81. doi: 10.13394/j.cnki.jgszz.2021.4.0011LIU Shuang, LI Min, DING Wenfeng, et al. Study on creep-feed deep grinding of K444 nickel-based superalloy with corundum grinding wheel [J]. Diamond & Abrasives Engineering,2021,41(4):72-81. doi: 10.13394/j.cnki.jgszz.2021.4.0011 [10] 梁国星, 李光, 韩阳, 等. 窄深槽缓进给干式磨削的试验研究 [J]. 太原理工大学学报,2017,48(5):778-782. doi: 10.16355/j.cnki.issn1007-9432tyut.2017.05.013LIANG Guoxing, LI Guang, HAN Yang, et al. Study on the creep feed dry grinding process of narrow deep groove [J]. Journal of Taiyuan University of Technology,2017,48(5):778-782. doi: 10.16355/j.cnki.issn1007-9432tyut.2017.05.013 [11] 张昊, 梁国星, 马志飞, 等. AISI1045钢窄深槽磨削表面完整性试验研究 [J]. 机械设计与制造,2021(7):117-120. doi: 10.3969/j.issn.1001-3997.2021.07.028ZHANG Hao, LIANG Guoxing, MA Zhifei, et al. Experimental study on surface integrity for grinding narrow deep groove of AISI 1045 Steel [J]. Machinery Design & Manufacture,2021(7):117-120. doi: 10.3969/j.issn.1001-3997.2021.07.028 [12] 李征, 丁文锋, 徐九华, 等. 颗粒增强钛基复材缓进深切磨削加工研究 [J]. 航空制造技术,2017(Z1):48-54. doi: 10.16080/j.issn1671-833x.2017.1/2.048LI Zheng, DING Wenfeng, XU Jiuhua, et al. Research on creep-feed deep grinding of particle-reinforced titanium matrix composites [J]. Aeronautical Manufacturing Technology,2017(Z1):48-54. doi: 10.16080/j.issn1671-833x.2017.1/2.048 [13] MIAO Q, DING W, GU Y, et al. Comparative investigation on wear behavior of brown alumina and microcrystalline alumina abrasive wheels during creep feed grinding of different nickel-based superalloys [J]. Wear,2019,426/427:1624-1634. doi: 10.1016/j.wear.2019.01.080 [14] 顾玉栊. 刚玉砂轮缓进深切磨削加工镍基单晶合金叶片榫头研究 [D]. 南京: 南京航空航天大学, 2019.GU Yulong. Creep-feed deep grinding of nickel-based single-crystal superalloy blade tenon with corundum abrasive wheels [D]. Nanjing: Nanjing University of Aeronautics And Astronautics, 2019. [15] YI J, JIN T, ZHOU W, et al. Theoretical and experimental analysis of temperature distribution during full tooth groove form grinding [J]. Journal of Manufacturing Processes,2020,58:101-115. doi: 10.1016/j.jmapro.2020.08.011 [16] 陈明. 难加工材料成形磨削烧伤研究 [J]. 上海: 上海交通大学学报,1997,31(9):56-60.CHEN Ming. Study on profile grinding burn in the process of grinding difficult to machine materials [J]. Journal of Shanghai Jiaotong University,1997,31(9):56-60. [17] ZHAO Z, QIAN N, DING W, et al. Profile grinding of DZ125 nickel-based superalloy: Grinding heat, temperature field, and surface quality [J]. Journal of Manufacturing Processes,2020,57:10-22. doi: 10.1016/j.jmapro.2020.06.022 [18] 易军, 金滩, 张明东. 基于磨削功率测量和巴克豪森无损检测的齿轮成形磨削烧伤研究 [J]. 机械传动,2019,43(9):109-112, 132. doi: 10.16578/j.issn.1004.2539.2019.09.018YI Jun, JIN Tan, ZHANG Mingdong. Research of gear form grinding burn based on grinding power measurement and barkhausen nondestructive test [J]. Journal of Mechanical Transmission,2019,43(9):109-112, 132. doi: 10.16578/j.issn.1004.2539.2019.09.018 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS