Simulation analysis of uniformity of optical sphere polishing motion trajectory

-

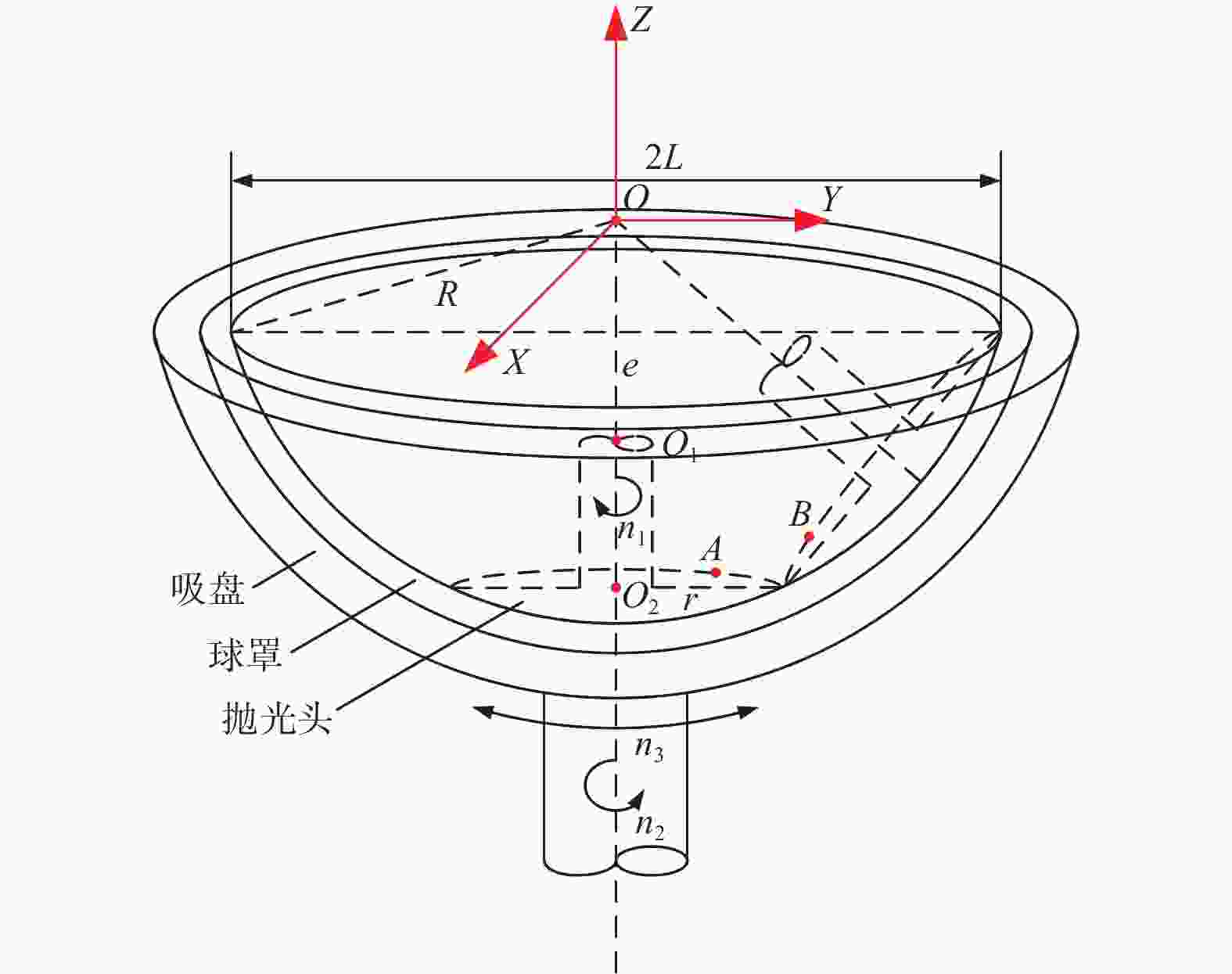

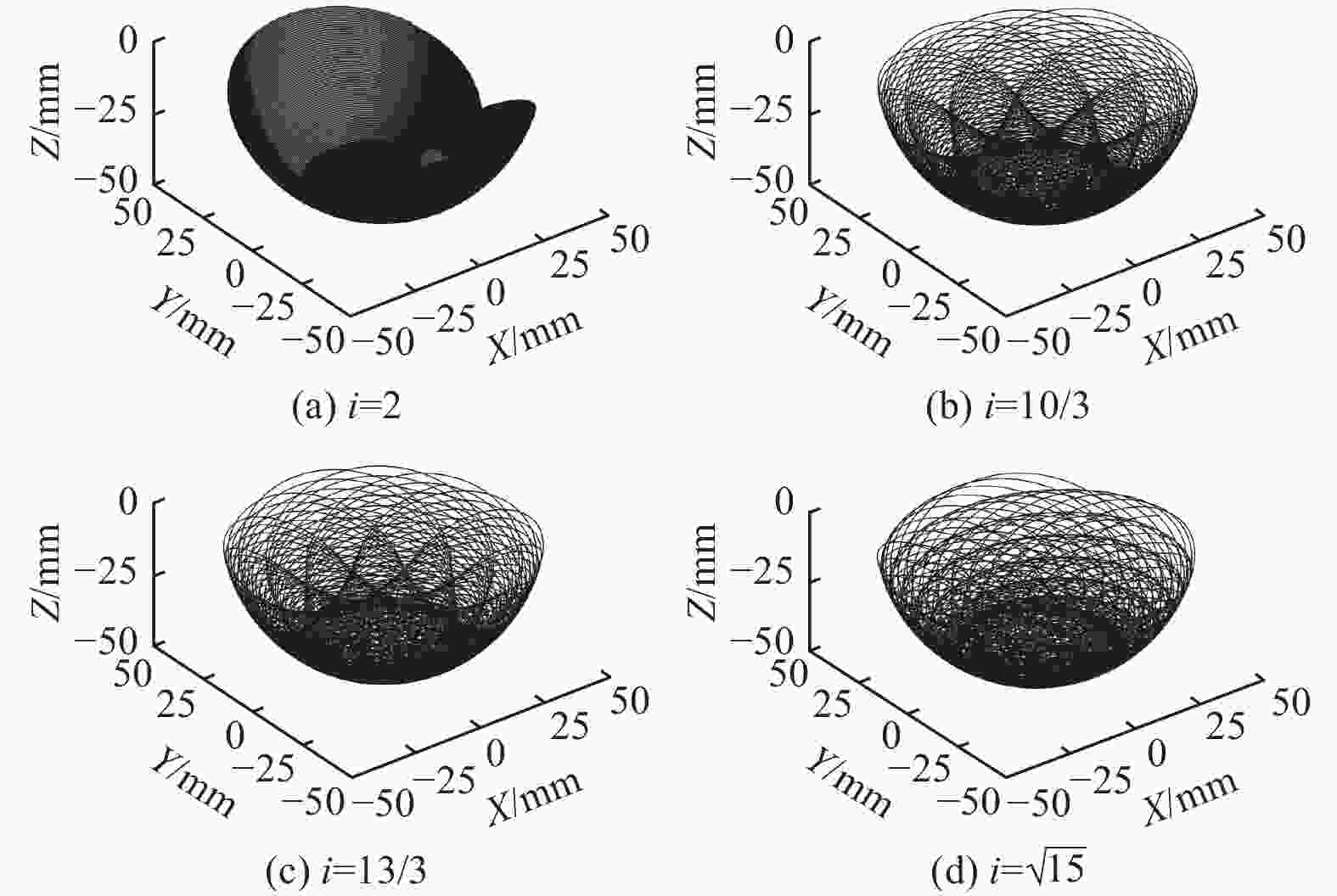

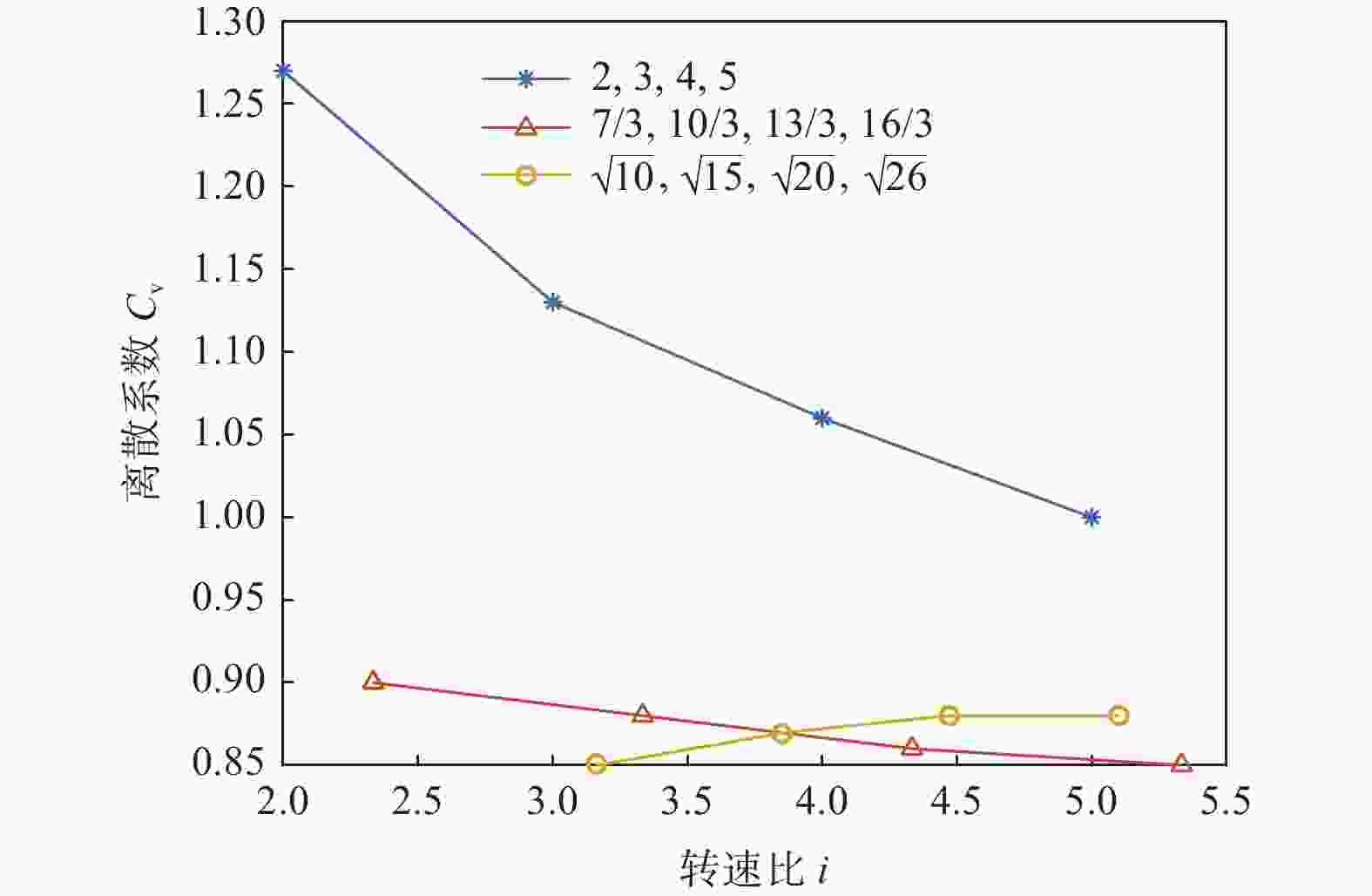

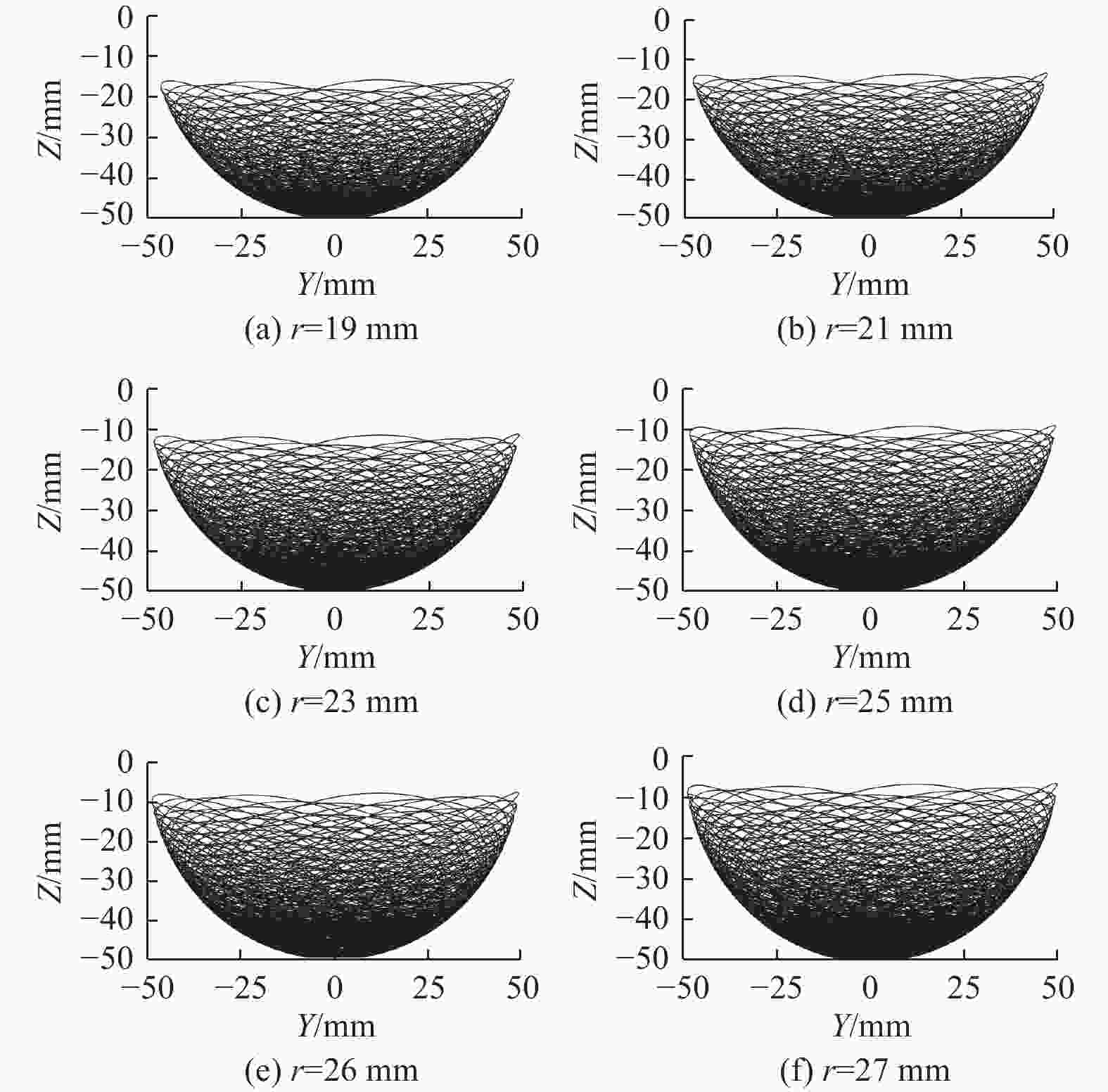

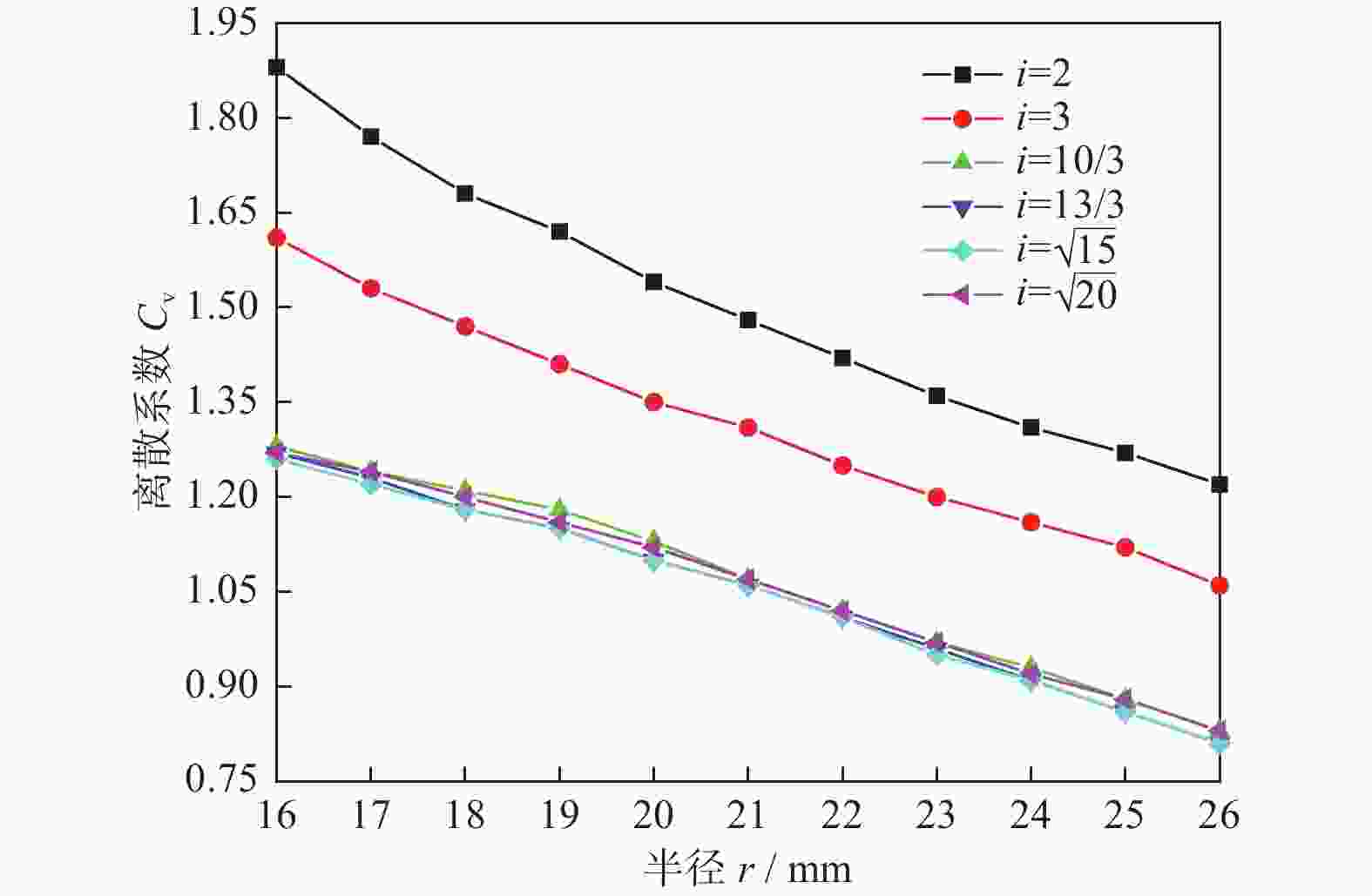

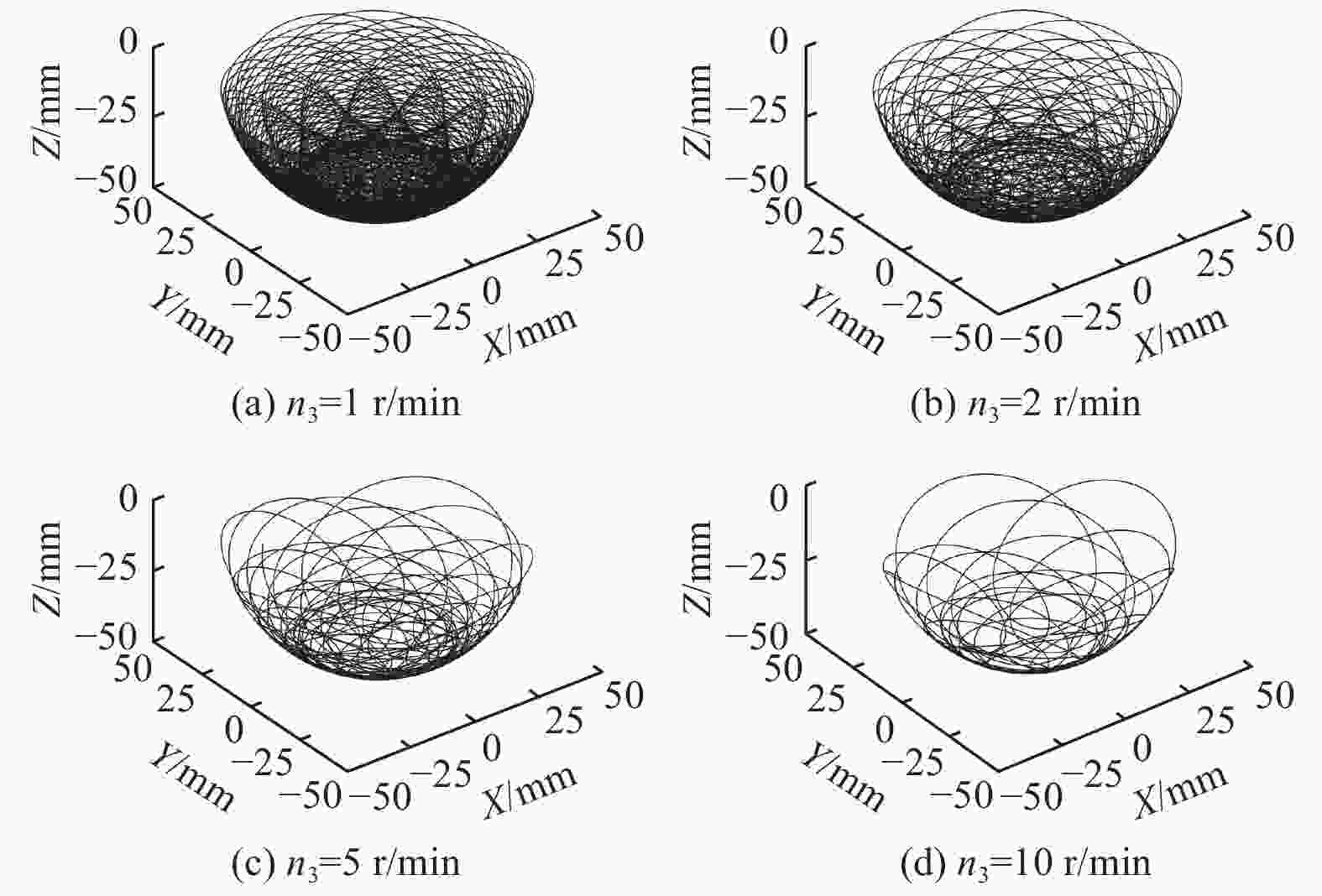

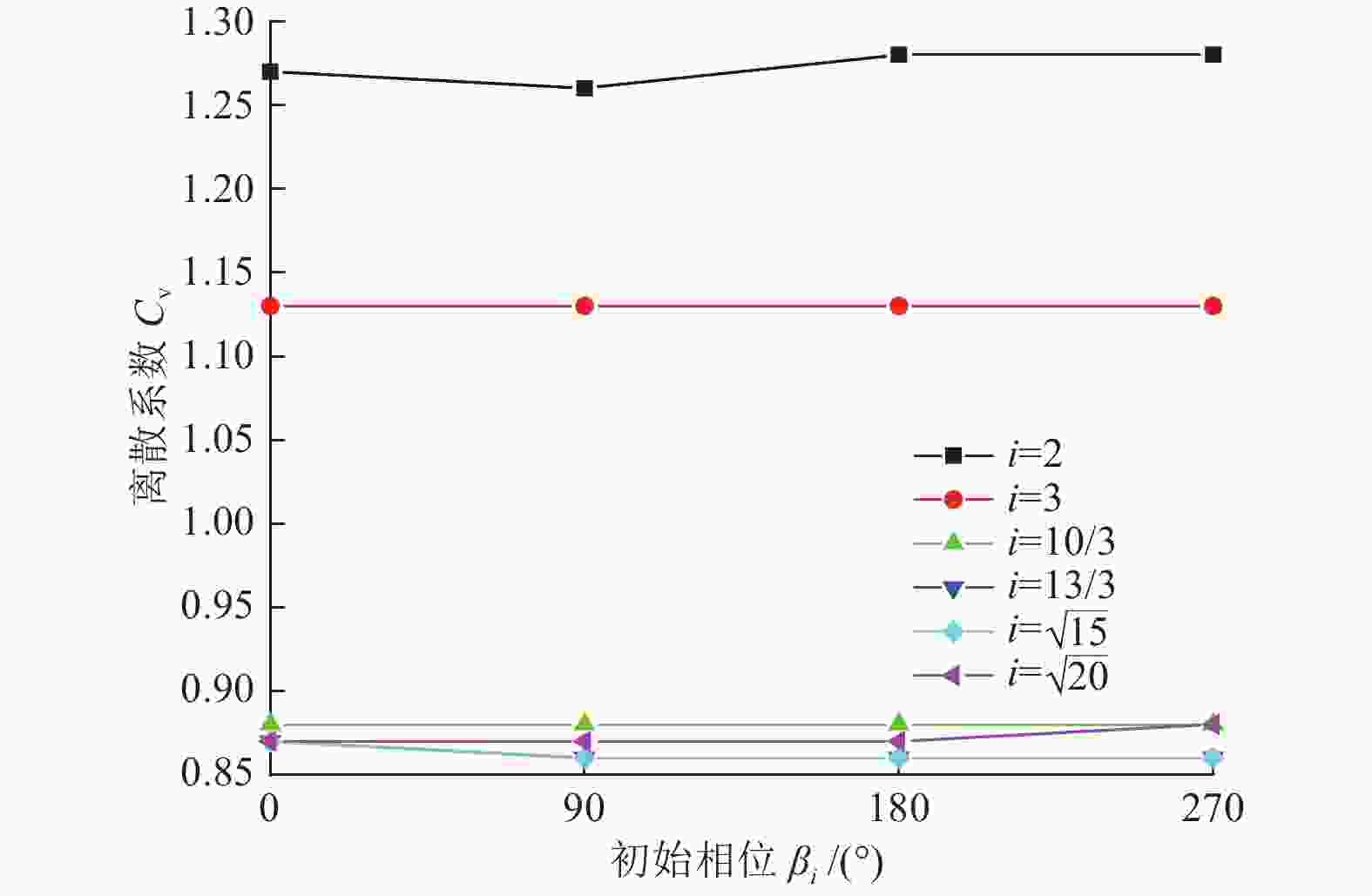

摘要: 为提高球罩表面的加工质量、加工效率,减少成本浪费,研究磨粒抛光过程中各运动参数对光学球罩表面材料去除均匀性的影响。以离散系数为评价指标,依据相对运动与向量法建立单颗磨粒运动轨迹模型。采用三角形网格对正二十面体表面进行迭代划分,统计各三角网格中的轨迹点数,用轨迹点数来表征抛光次数。结果表明:转速比对磨粒轨迹的分布与材料去除影响显著;相同转速比下,增大抛光头半径,离散系数逐渐降低,球罩表面材料去除均匀性由差变好;增大摆速,轨迹的长度与密度逐渐减小,离散系数随之变大,球罩表面非均匀性增强;磨粒初始相位改变对轨迹均匀性基本无影响。Abstract: In order to improve the processing quality, processing efficiency and reduce the cost wastage of the dome surface, the effect of each motion parameter on the uniformity of material removal from the optical dome surface during the polishing process was investigated. In this paper, the dispersion coefficient was used as the evaluation index, and the single abrasive particle motion trajectory model was established based on the relative motion and vector method. A triangular mesh was used to iteratively divide the surface of the orthorhombic icosahedron, and the number of trajectory points in each triangular mesh was counted to characterize the number of polishing times. It can be concluded that the speed ratio has a significant effect on the distribution of abrasive trajectories and material removal. With the same speed ratio, increasing the radius of the polishing head, the dispersion coefficient gradually decreases and the uniformity of dome surface material removal changes from poor to good. Increasing the pendulum speed, the length and density of the trajectory gradually decrease, the dispersion coefficient becomes larger, and the non-uniformity of the dome surface increases. The change in the initial phase of abrasive particles has essentially no effect on trajectory uniformity.

-

Key words:

- optical ball cover /

- abrasive trajectory /

- meshing /

- coefficient of variation /

- homogeneity

-

表 1 球罩尺寸及各运动参数

Table 1. Dome size and each movement parameter

参数 取值 球罩半径 R / mm 50 截面圆半径 L / mm 49 抛光头转速n 1与球罩转速n2之比i 2,3,4,5, 7/3,10/3,13/3,16/3, $\sqrt {10} ,\sqrt {15} ,\sqrt {20} ,\sqrt {26} $ 抛光头半径 r / mm 16~26 球罩摆速 n3 /(r·mim−1) 1~10 初始相位 β /(°) 0,90,180,270 仿真时间 t1 / s 50 采样时间 t2 / s 0.001 -

[1] 龚峰, 李康森, 闫超. 玻璃精密模压成形的研究进展 [J]. 光学精密工程,2018,26(6):1380-1391. doi: 10.3788/OPE.20182606.1380GONG Feng, LI Kangsen, YAN Chao. Progress on precision glass molding [J]. Optics and Precision Engineering,2018,26(6):1380-1391. doi: 10.3788/OPE.20182606.1380 [2] 李森森, 吴凡. 光电平台球罩的视轴指向误差分析 [J]. 光电技术应用,2017,32(6):67-70. doi: 10.3969/j.issn.1673-1255.2017.06.014LI Sensen, WU Fan. Analysis of optical axis error of spherical shell in electro-optical system [J]. Electro-Optic Technology Application,2017,32(6):67-70. doi: 10.3969/j.issn.1673-1255.2017.06.014 [3] WU F, LI S S, ZHU H B, et al. Analysis on the optical axis error of the spherical shell in the electro-optical system [J]. Optik,2018,168:458-461. doi: 10.1016/j.ijleo.2018.04.093 [4] 孙昌锋, 张兴德, 李荣刚, 等. 光学窗口的抗振结构优化分析 [J]. 激光与红外,2015,45(3):307-310. doi: 10.3969/j.issn.1001-5078.2015.03.016SUN Changfeng, ZHANG Xingde, LI Ronggang, et al. Anti-vibration structure optimization of the optical window [J]. Laser & Infrared,2015,45(3):307-310. doi: 10.3969/j.issn.1001-5078.2015.03.016 [5] 张庆鹏, 谭毅, 任戈, 等. 大口径光学窗口结构及支撑技术 [J]. 强激光与粒子束,2018,30(12):19-25. doi: 10.11884/HPLPB201830.180196ZHANG Qingpeng, TAN Yi, REN Ge, et al. Technology for the structure and supporting form of large aperture optic window [J]. High Power Laser and Particle Beams,2018,30(12):19-25. doi: 10.11884/HPLPB201830.180196 [6] NOVIKOV N V, ROZENBERG O A, MAMALIS A G, et al. Finish diamond machining of ceramic femoral heads [J]. International Journal of Advanced Manufacturing Technology,2005,25(3/4):244-247. [7] LING Y, VANCOILLE E, LEE L C, et al. High-quality grinding of polycrystalline silicon carbide spherical surfaces [J]. Wear,2004,256(1/2):197-207. [8] HOU H Y, LI D D, WEI C J, et al. Process optimization in two spherical surface grinding processes using trajectories analysis [J]. Proceedings of the Institution of Mechanical Engineers Part B-Journal of Engineering Manufacture,2011,225(12):2177-2188. doi: 10.1177/0954405411411404 [9] WU X, HUANG Z, WAN Y, et al. A novel force-controlled spherical polishing tool combined with self-rotation and co-rotation motion [J]. IEEE Access,2020,8:108191-108200. doi: 10.1109/ACCESS.2020.2997968 [10] ZHANG H, WANG P, LI Z, et al. Uniform polishing method of spherical lens based on material removal model of high-speed polishing procedure [J]. Micromachines,2020,11(10):938. doi: 10.3390/mi11100938 [11] SUN J, ZHANG L C, MAI Y W, et al. Computational modelling of a precision optical lens polishing process on small radius spherical surfaces [J]. Journal of Materials Processing Technology,2000,105(1/2):204-213. [12] 石小鹏. 人工髋关节球头抛光工艺研究 [D]. 秦皇岛: 燕山大学, 2021.SHI Xiaopeng. Study on polishing of artificial hip ball joint [D]. Qinhuangdao: Yanshan University, 2021. [13] 白建军, 孙文彬. 球面格网系统特征分析及比较 [J]. 地理与地理信息科学,2011,27(2):1-5.BAI Jianjun, SUN Wenbin. Character analysis and comparison of global grid system [J]. Geography and Geo-Information Science,2011,27(2):1-5. [14] 马原野. 近地全球重访星座轨道快速优化设计研究 [D]. 北京: 中国科学院大学, 2019.MA Yuanye. Research on rapid optimization design of global revisit constellation in low earth orbit [D]. Beijing: University of Chinese Academy of Sciences, 2019. [15] 张江永. 陶瓷球制备的偏心研磨理论与仿真 [D]. 大连: 大连理工大学, 2021.ZHANG Jiangyong. Theory and simulation of eccentric lapping of ceramic ball preparation [D]. Dalian: Dalian University of Technology, 2021. [16] 贾俊平, 何晓群, 金勇进. 统计学(第四版) [M]. 北京: 中国人民大学出版社, 2009.JIA Junping, HE Xiaoqun, JIN Yongjin. statistics (fourth edition) [M]. Beijing: China Renmin University Press, 2009. [17] 杨晓京, 李明. 平面光学元件研磨抛光磨粒运动轨迹研究 [J]. 半导体光电,2017,28(3):355-360.YANG Xiaojing, LI Ming. Study on the trajectory of the abrasive particle motion of plane optical element [J]. Semiconductor Optoelectronics,2017,28(3):355-360. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS