Experimental study on working mechanics of PDC bit with worn teeth

-

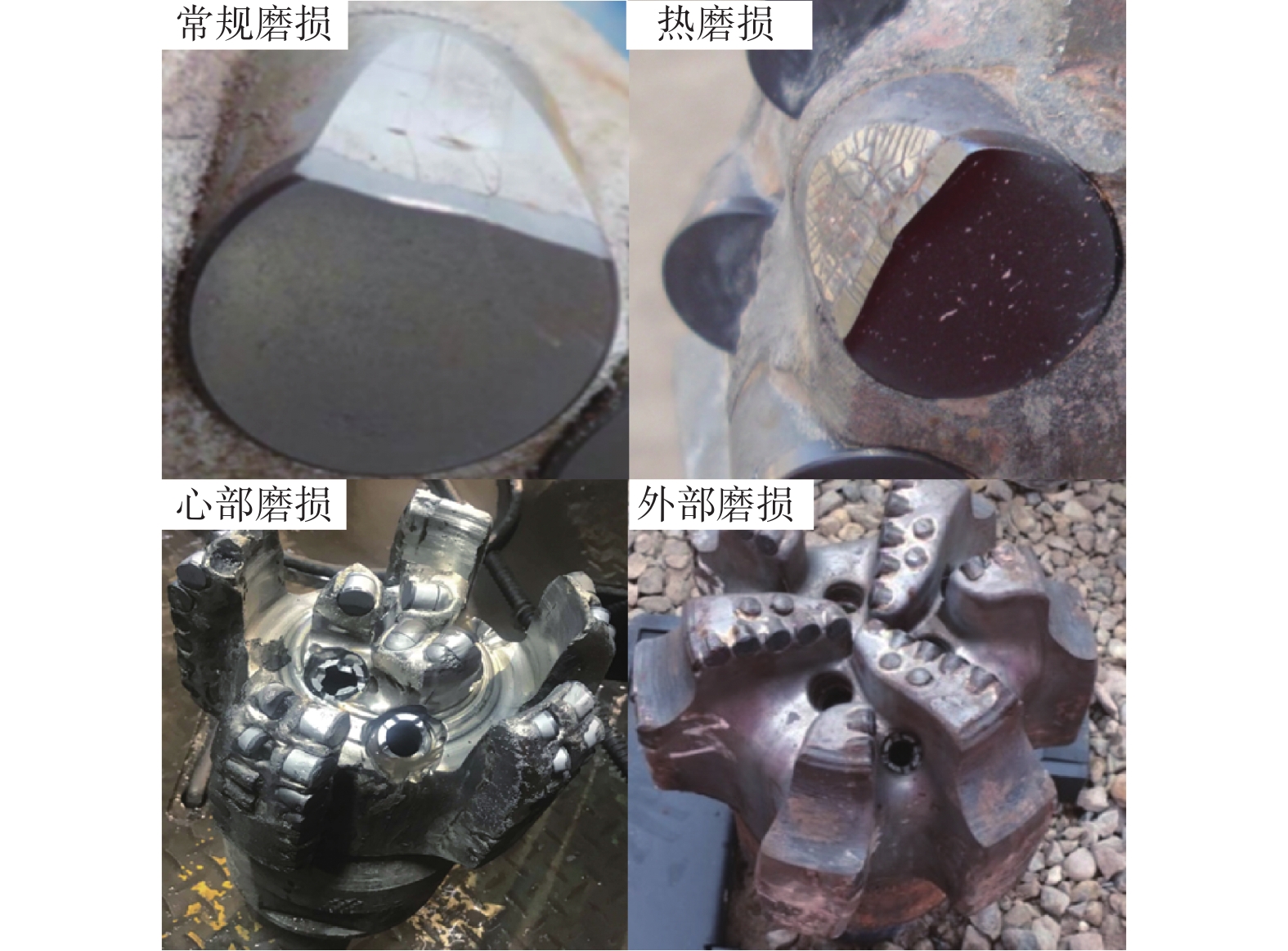

摘要: 为探究磨损齿PDC钻头的切削性能,避免其过早失效,通过单齿切削试验以及全尺寸磨损齿钻头钻进试验,分析磨损齿的受力状态以及钻头的钻进特性。结果表明:相比于新齿,磨损齿受载更大,且其“磨圆”后切岩过程中的钝搓现象普遍存在;在相同吃深条件下,齿的磨损高度越大,载荷波动越明显。相比于新钻头,磨损齿钻头更能产生光滑的井底,不利于其侵入地层。随齿的磨损高度增加,钻头的机械钻速下降,机械比能增加,振动程度减小,且钻头的径向加速值与齿的磨损高度无关。当齿的磨损高度大于3.0 mm时,钻头的机械比能和机械钻速对钻压不敏感。Abstract: PDC bits have been working in a worn state for a long time. To explore its cutting performance and avoid premature failure of the bit, this paper analyzes the load on the worn teeth and the drilling characteristics of the bit through single tooth cutting experiment and full-scale wear bit drilling experiment. The result shows that the worn teeth bear larger load compared with the new teeth, and the phenomenon of blunt rubbing is common in the process of rock cutting after the cutting teeth are “rounded”. Under the same depth, the greater the wear height is, the more obvious the load fluctuation appears. Through the full-scale bit drilling experiment, it is found that compared with the new bit, the worn bit can produce a smoother bottom hole, which is not beneficial for PDC bits' teeth intruding into the rock. With the increase of wear degree, the mechanical rate of penetration decreases and the mechanical specific energy increases. When the wear is greater than 3 mm, the mechanical specific energy and mechanical rate of penetration are not sensitive to weight on bit. With the increase of wear degree, the vibration degree of the bit decreases, and there is little difference in the radial acceleration value of the bit regardless of the wear degree.

-

表 1 岩石力学性质参数

Table 1. Mechanical property parameters of rock

岩性 弹性模量

E / GPa泊松比μ 抗压强度

σc / MPa密度

ρ / (g·cm−3)内摩擦角

φ / (°)砂岩 11.54 0.062 67.548 2.42 38.03 灰岩 31.20 0.171 105.951 2.46 43.62 花岗岩 31.78 0.118 126.519 2.73 45.29 表 2 磨损条件下单齿切削试验方案

Table 2. Experimental scheme of single tooth cutting under wear condition

试验

变量试验参数 磨损高度

h1 / mm岩石

种类前倾角

γ /(°)齿径

l / mm切削深度

h2 / mm钝化

类型磨损高度 0.6,0.9,

1.2,1.5砂岩 15 15 1.2 C 前倾角 0.6 砂岩 10,15,20 15 1.2 C 齿径 0.6 砂岩 15 15,17,19 1.2 C 钝化类型 0.6 砂岩 15 17 1.2 C, Y, Z 切削深度 0.6 砂岩 15 15 0.3,0.6,

1.2,1.5C 岩石种类 0.3 砂岩,灰岩,

花岗岩15 15 1.2 C -

[1] ZHANG C, YANG Y X, QI Q L, et al. Research on numerical drilling technology of mesh-like cutting PDC bit [J]. Energy Reports,2021,7(5):2068-2080. [2] 张春亮. 交叉刮切PDC钻头破岩机理及设计理论研究 [D]. 成都: 西南石油大学, 2018.ZHANG Chunliang. Research on rock–breaking mechanism and design theory of the cross–scraping PDC bit [D]. Chengdu: Southwest Petroleum University, 2018. [3] 黄鹏, 管锋, 郑立伟, 等. PDC钻头在砾岩层中的磨损规律研究 [J]. 石油机械,2020,48(7):1-6. doi: 10.16082/j.cnki.issn.1001-4578.2020.07.001HUANG Peng, GUAN Feng, ZHENG Liwei, et al. Study on the wear law of PDC bits in conglomerate [J]. Petroleum Machinery,2020,48(7):1-6. doi: 10.16082/j.cnki.issn.1001-4578.2020.07.001 [4] 梁尔国, 李子丰, 邹德永. PDC钻头综合受力模型的试验研究 [J]. 岩土力学,2009,30(4):938-942. doi: 10.3969/j.issn.1000-7598.2009.04.013LIANG Erguo, LI Zifeng, ZOU Deyong. Experimental research on integrated mechanical model of PDC bit [J]. Geotechnical Mechanics,2009,30(4):938-942. doi: 10.3969/j.issn.1000-7598.2009.04.013 [5] 朱光辉, 况雨春, 林伟. PDC磨损齿切削载荷与生热规律研究 [J]. 石油机械,2021,49(5):68-73. doi: 10.16082/j.cnki.issn.1001-4578.2021.05.010ZHU Guanghui, KUANG Yuchun, LIN Wei. Research on cutting load and heat generation law of PDC wearing cutter [J]. Petroleum Machinery,2021,49(5):68-73. doi: 10.16082/j.cnki.issn.1001-4578.2021.05.010 [6] 王滨, 李军, 邹德永, 等. 强研磨性硬岩PDC钻头磨损机理及磨损分布规律研究 [J]. 特种油气藏,2018,25(4):149-153. doi: 10.3969/j.issn.1006-6535.2018.04.030WANG Bin, LI Jun, ZOU Deyong, et al. Mechanisms and distribution pattern of abrasions on PDC bits for highly-abrasive hard-rock [J]. Special Oil and Gas Reservoirs,2018,25(4):149-153. doi: 10.3969/j.issn.1006-6535.2018.04.030 [7] IMAN R, BABAK A, BRIAN E. Analysis of rock cutting process with a blunt PDC cutter under different wear flat inclination angles [J]. Journal of Petroleum Science & Engineering,2018,171:771-783. [8] 马亚超, 张鹏, 黄志强, 等. 变温变载影响下PDC钻头的动态磨损趋势预测 [J]. 工程设计学报,2020,27(5):625-635. doi: 10.3785/j.issn.1006-754X.2020.00.080MA Yachao, ZHANG Peng, HUANG Zhiqiang, et al. Prediction of dynamic wear trend of PDC bit under the influence of varying temperature and load [J]. Journal of Engineering Design,2020,27(5):625-635. doi: 10.3785/j.issn.1006-754X.2020.00.080 [9] 郭健, 孙文磊. PDC钻头磨损过程中的应力分析 [J]. 机床与液压, 2008, 36(12): 25-27.GUO Jian, SUN Wenlei. The stress analysis of PDC drill bits in the process of drilling [J] Machine Tools and Hydraulics, 2008, 36(12): 25-27. [10] 蔡灿, 张沛, 孙明光, 等. 油气钻井中的分离式冲击—切削复合破岩机制研究 [J]. 岩土力学,2021,42(9):2535-2545. doi: 10.16285/j.rsm.2021.0066CAI Can, ZHANG Pei, SUN Mingguang, et al. Mechanism of rock breaking under combining of separated impact and cutting in oil and gas drilling [J]. Geotechnical Mechanics,2021,42(9):2535-2545. doi: 10.16285/j.rsm.2021.0066 [11] 蔡灿, 高超, 王海柱, 等. 高压CO2射流-PDC齿复合破岩流场及携岩增强机理 [J]. 天然气工业,2021,41(10):101-108. doi: 10.3787/j.issn.1000-0976.2021.10.011CAI Can, GAO Chao, WANG Haizhu, et al. Flow field and cuttings carrying enhancement mechanism of compound rock breaking by high pressure CO2 jet and PDC cut [J]. Natural Gas Industry,2021,41(10):101-108. doi: 10.3787/j.issn.1000-0976.2021.10.011 [12] 李美求, 李嘉文, 李宁, 等. 周向冲击扭矩作用下PDC钻头的黏滑振动分析[J]. 石油钻采工艺, 2018, 40(3): 287-292.LI Meiqiu, LI Jiawen, LI Ning, et al. Analysis of stick-slip vibration of PDC bit under the action of circumferential impact torque[J]. Petroleum Drilling and Production Technology, 2018, 40(3): 287-292. [13] 查春青, 柳贡慧, 李军, 等. PDC钻头扭转振动特性分析及减振工具设计 [J]. 石油机械,2017,45(3):1-5.ZHA Chunqing, LIU Gonghui, LI Jun, et al. Analysis of torsional vibration characteristics of PDC bit and design of the damping tool [J]. Petroleum Machinery,2017,45(3):1-5. [14] TEAL R. The concept of specific energy in rock drilling [J]. International Journal of Rock Mechanics & Mining Sciences & Geomechanics Abstracts,1965,2(2):57-73. [15] 管志川, 呼怀刚, 王斌, 等. 基于机械比能与滑动摩擦系数的PDC钻头破岩效率试验 [J]. 中国石油大学学报(自然科学版),2019,43(5):92-100.GUAN Zhichuan, HU Huaigang, WANG Bin, et al. Experimental study on rock-breaking efficiency of PDC bit based on mechanical specific energy and sliding frictional coefficient [J]. Journal of China University of Petroleum(Edition of Natural Science),2019,43(5):92-100. [16] 胡益涛, 程乐利, 姜波, 等. 基于机械比能—钻井效率的莺琼盆地地层压力监测方法 [J]. 钻采工艺,2021,44(4):7-10. doi: 10.3969/J.ISSN.1006-768X.2021.04.02HU Yitao, CHENG Leli, JIANG Bo, et al. Formation pressure monitoring method in Yingqiong Basin based on mechanical specific energy-drilling efficiency [J]. Drilling and Production Technology,2021,44(4):7-10. doi: 10.3969/J.ISSN.1006-768X.2021.04.02 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS