Study on brazed diamond grinding wheel for rail grinding

-

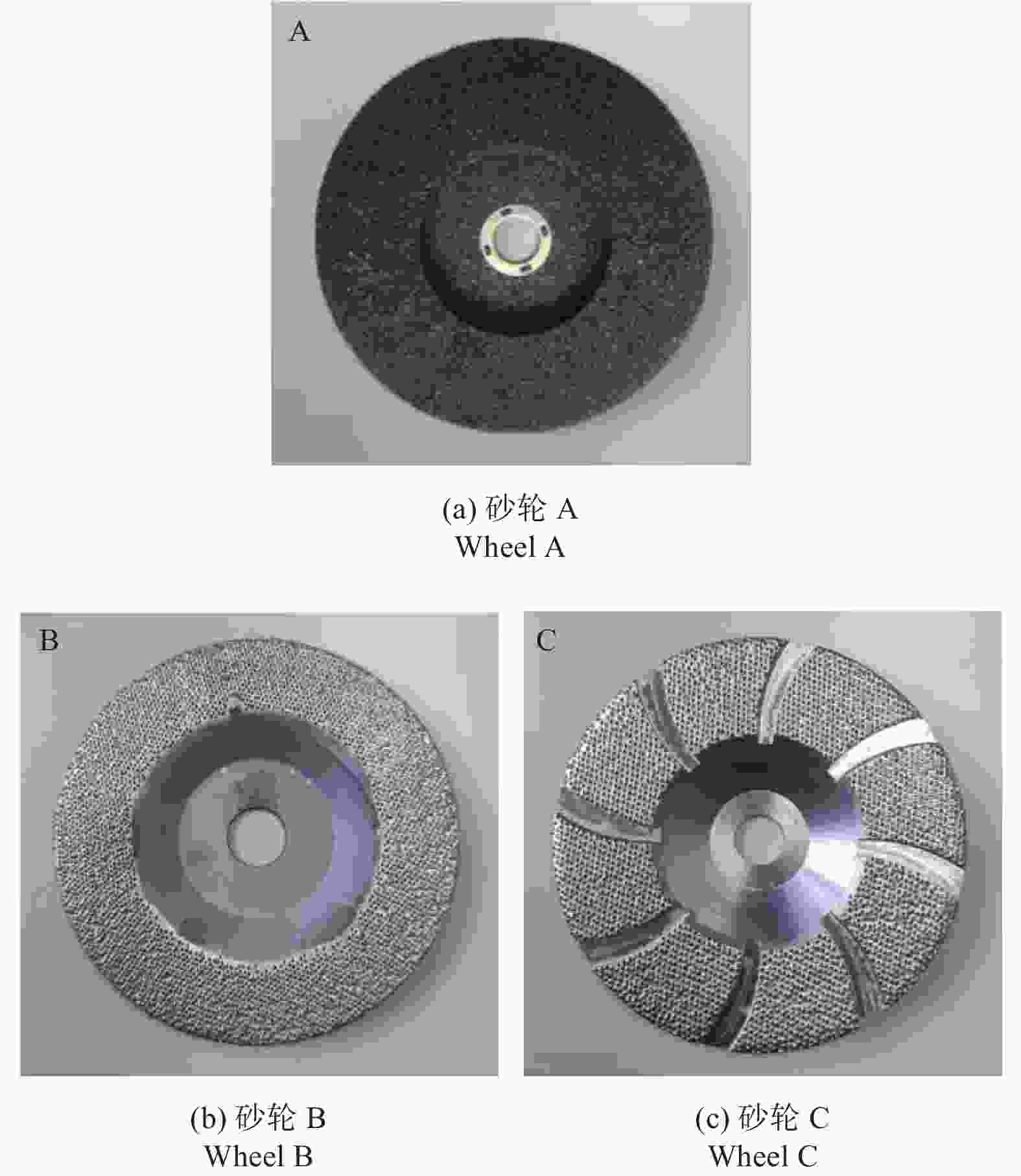

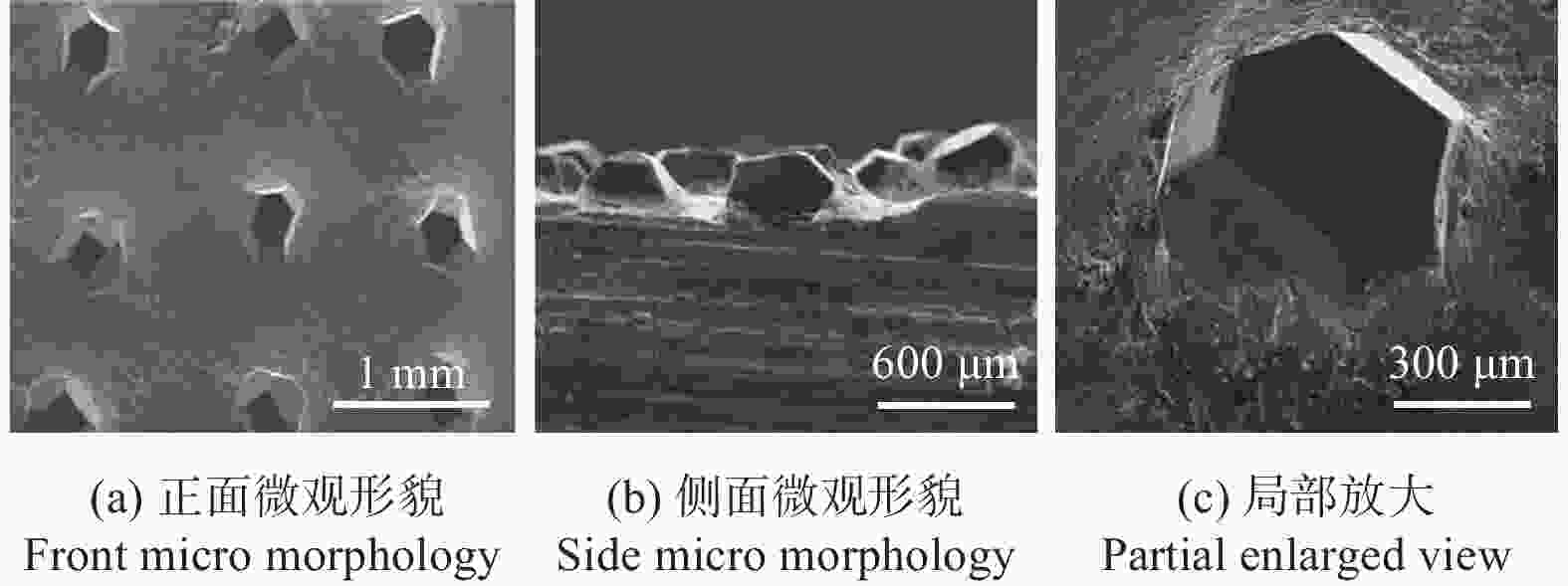

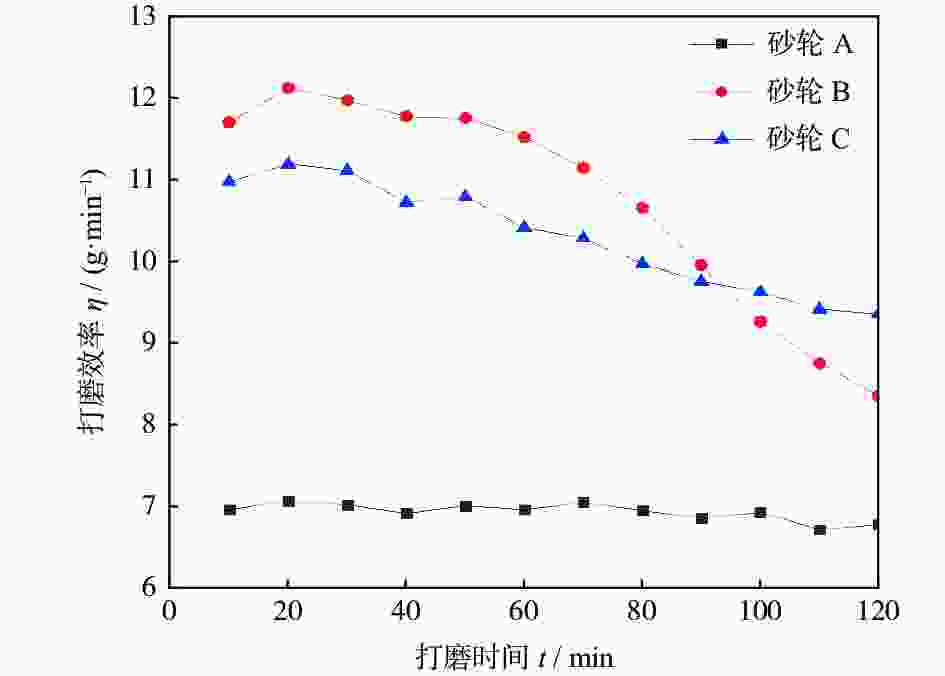

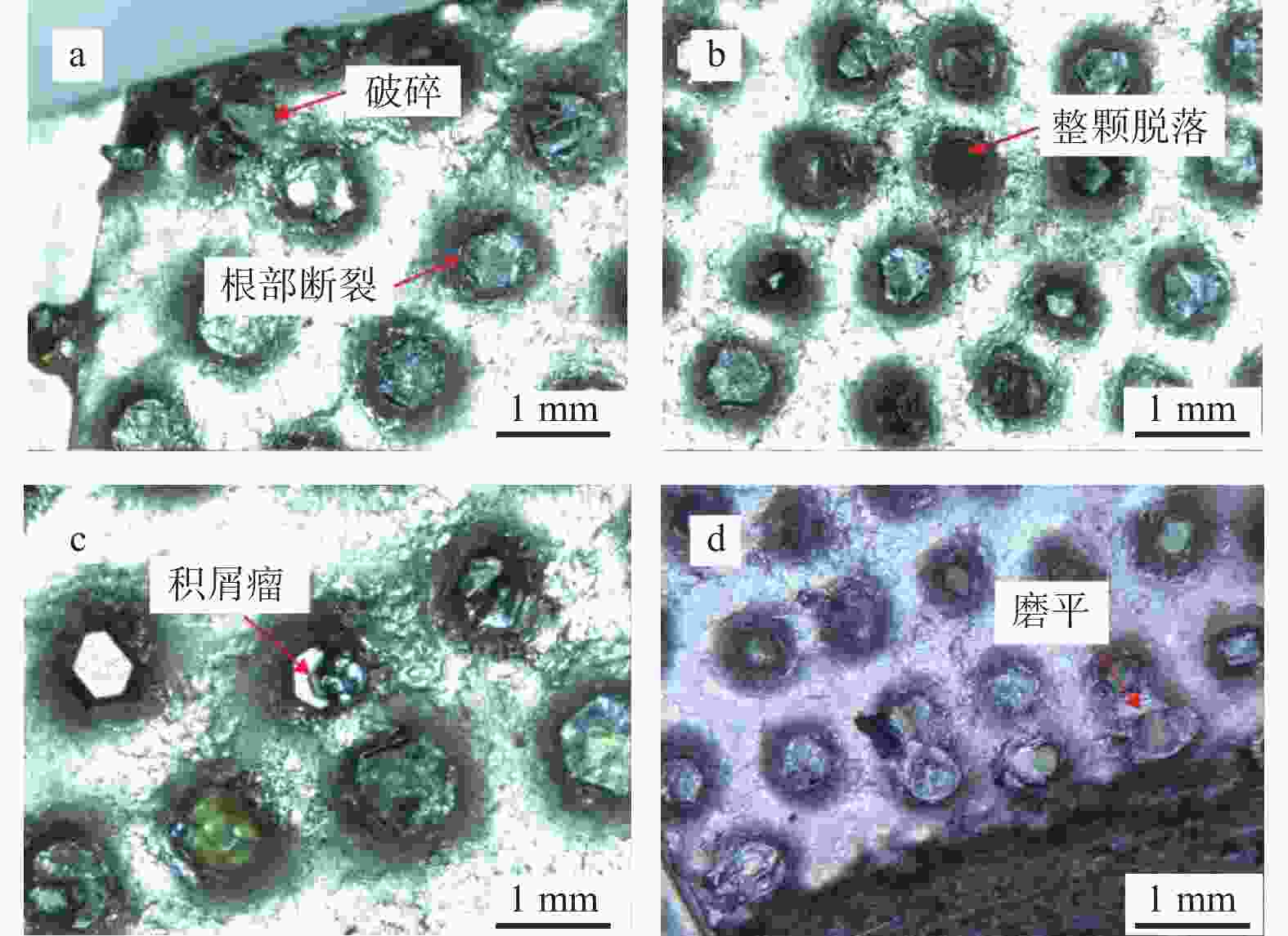

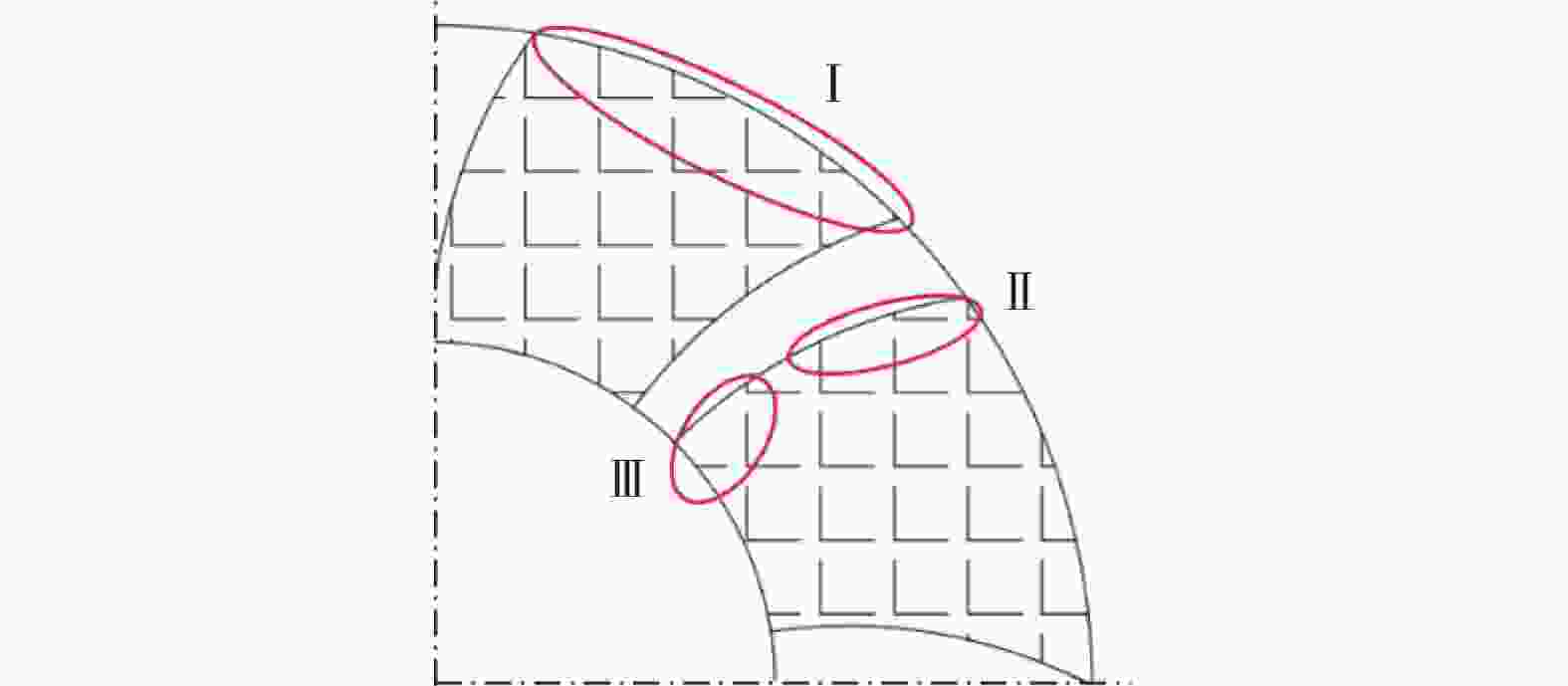

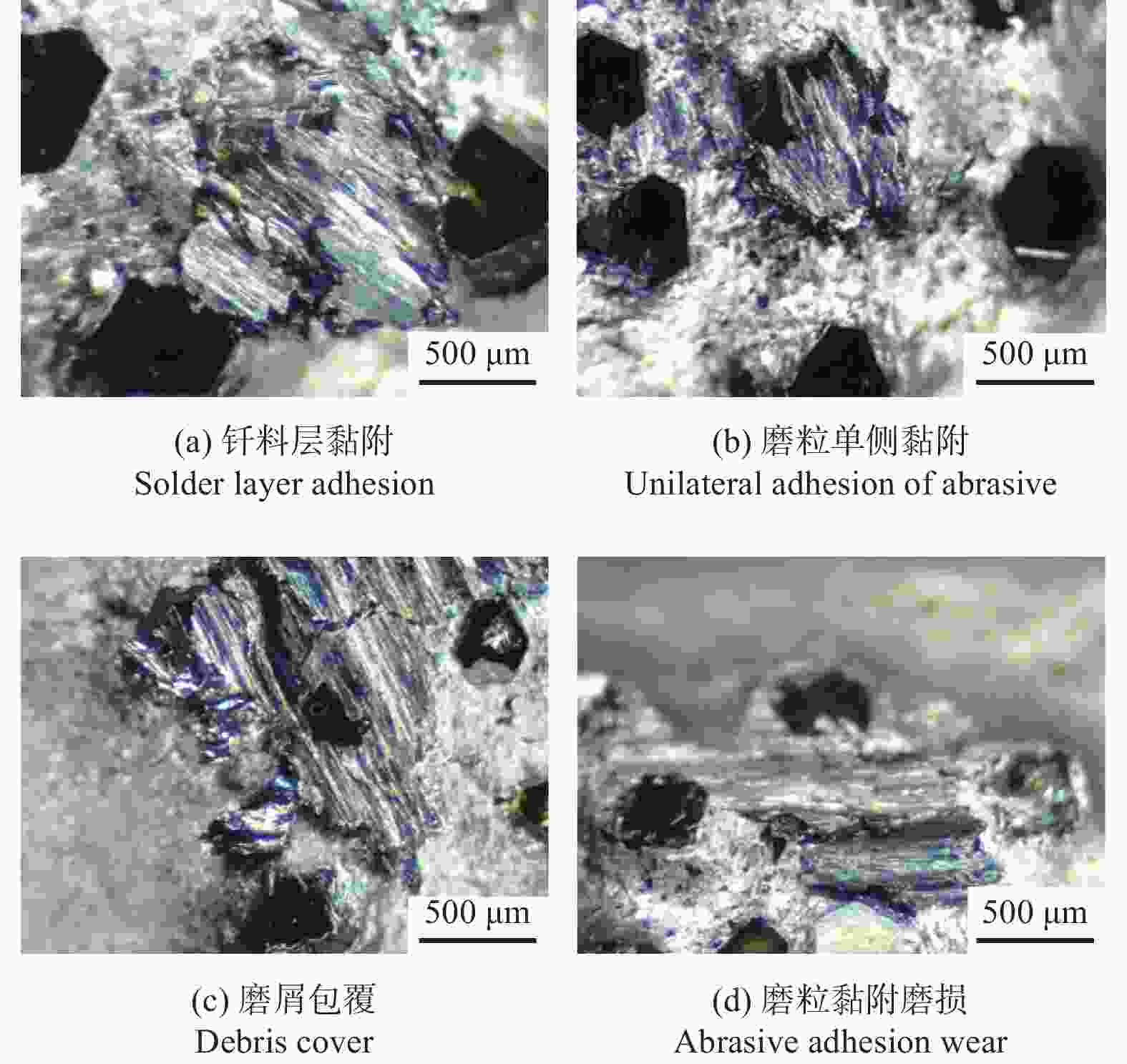

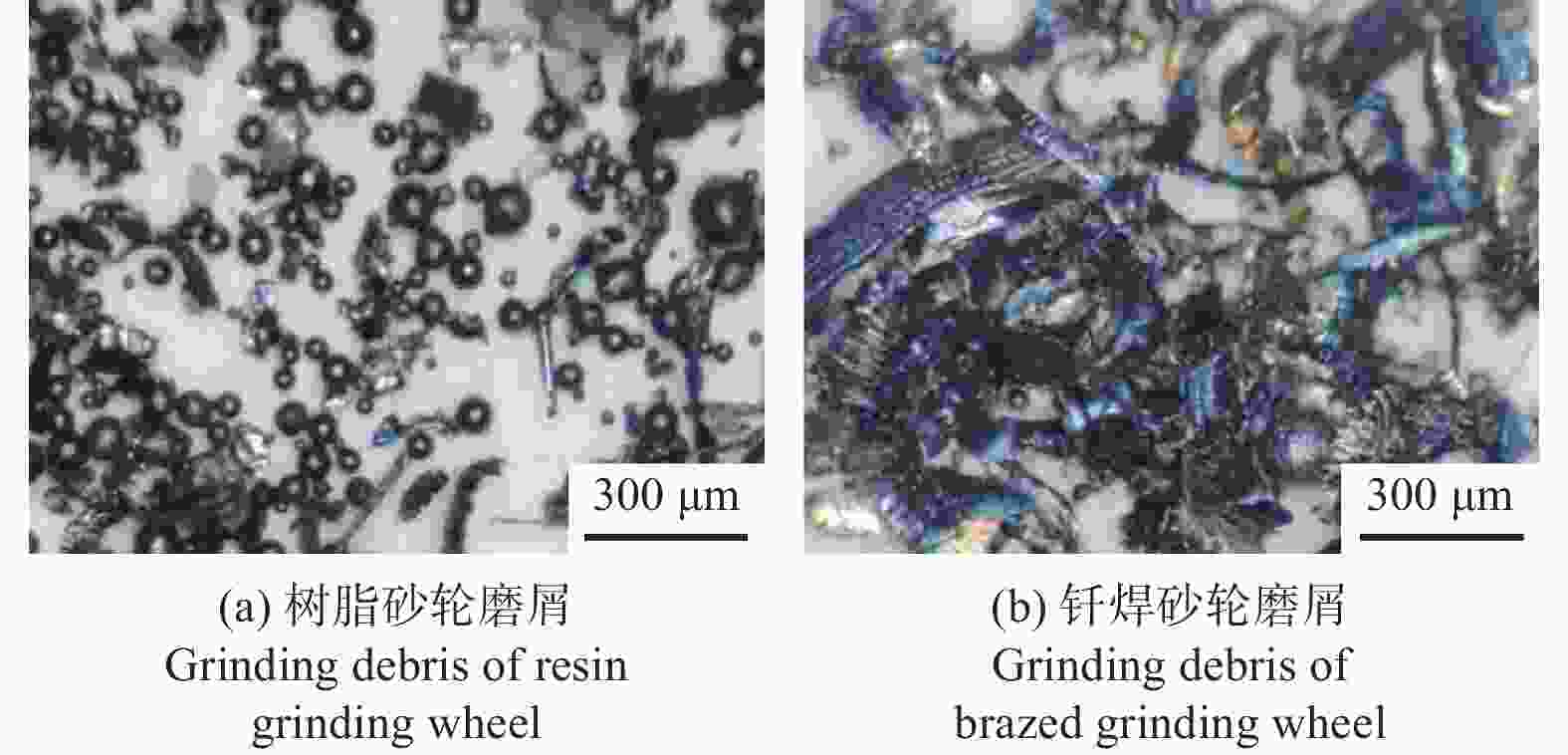

摘要: 为解决传统树脂砂轮打磨钢轨时存在的打磨效率低、易烧伤钢轨和粉尘污染大等问题,分析利用钎焊金刚石技术的优势制备新型钢轨打磨用砂轮的可行性。结合磨粒有序排布工艺,制备具有开槽结构的新型钎焊金刚石砂轮,并对U71Mn钢轨钢进行打磨对比试验。结果表明:相较于树脂锆刚玉砂轮,新型钎焊金刚石砂轮能提高50%左右的打磨效率,并有效降低磨削温度,避免钢轨烧伤。在钢轨打磨过程中,新型钎焊砂轮排屑效果显著,基本不发生磨屑黏附现象;但砂轮开槽导致磨削振动增大,加剧金刚石磨粒破碎,并增大钢轨表面粗糙度。新型砂轮磨屑多为带状,磨屑体积大且无熔融小球。Abstract: In order to solve the problems of low grinding efficiency, easy to burn rail and large dust pollution, when grinding rail with traditional resin wheel, the feasibility of taking advantage of brazed diamond technique for preparing a new rail grinding wheel was studied. The brazed diamond grinding wheel with slotted structure was prepared by using of the diamond orderly arrangement process. The comparative grinding tests were carried out on U71Mn rail steel. The results show that compares with resin corundum grinding wheel, the new brazed diamond grinding wheel can improve the grinding efficiency by about 50%, effectively reduce the grinding temperature and avoid rail burn. The new grinding wheel has remarkable chip removal effect in the process of rail grinding, and there is almost no chip adhesion. However, the slots on the grinding wheel increases the grinding vibration, aggravates the breakage of diamond abrasive particles and increases the surface roughness of rail. The grinding debris of the new grinding wheel is mostly band-shape with large size but no molten balls.

-

Key words:

- rail grinding /

- brazing diamond /

- structural optimization /

- grinding efficiency

-

表 1 砂轮相关参数

Table 1. Grinding wheel related parameters

编号 磨粒

类型结合剂

类型磨粒排布 是否开槽 A 锆刚玉 酚醛树脂 多层无序 否 B 金刚石 Ni–Cr钎料 单层有序 否 C 金刚石 Ni–Cr钎料 单层有序 是 表 2 打磨参数

Table 2. Grinding parameters

参数 类型或取值 砂轮转速 n /(r·min−1) 3 000 砂轮行进速度 v /(m·s−1) 0.1 打磨压力 F / N 600 磨削方式 干式磨削 -

[1] 周坤, 王文健, 刘启跃, 等. 钢轨打磨机理研究进展及展望 [J]. 中国机械工程,2019,30(3):284-294.ZHOU Kun, WANG Wenjian, LIU Qiyue, et al. Research progresses and prospect of rail grinding mechanism [J]. China Mechanical Engineering,2019,30(3):284-294. [2] GU K K, LIN Q, WANG W J, et al. Analysis on the effects of rotational speed of grinding stone on removal behavior of rail material [J]. Wear,2015,342:52-59. [3] 涂江洋. 高速铁路道岔钢轨焊接接头打磨技术研究 [D]. 成都: 西南交通大学, 2015.XU Jiangyang. The research of rail grinding technology for high-speed railway turnout [D]. Chengdu: Southwest Jiaotong University, 2015. [4] WANG R X, ZHOU K, YANG J Y, et al. Effects of abrasive material and hardness of grinding wheel on rail grinding behaviors [J]. Wear,2020,454/455:203332. doi: 10.1016/j.wear.2020.203332 [5] 傅玉灿, 徐九华, 丁文锋. 钎焊超硬磨料砂轮高效磨削理论与技术 [M]. 北京: 科学出版社, 2016.FU Yucan, XU Jiuhua, DING Wenfeng. Theory and technology of high efficiency grinding with brazed superhard abrasive wheel [M]. Beijing: Science Press, 2016. [6] WU H H, XIAO B, XIAO H Z, et al. Wear characteristics of brazed diamond sheets with different grinding time [J]. Wear,2019,432/433:202942. doi: 10.1016/j.wear.2019.202942 [7] 王佳佳. U71Mn钢轨材料开槽砂轮干式磨削机理与工艺研究 [D]. 长沙: 湖南大学, 2018.WANG Jiajia. Research on dry grinding mechanism and technology for U71Mn rail material using the slotted wheel [D]. Changsha: Hunan University, 2018. [8] 周明,邹莱. 金刚石切削黑色金属时刀具磨损机理的摩擦磨损试验 [J]. 光学精密工程,2013,21(7):1786-1794. doi: 10.3788/OPE.20132107.1786ZHOU Ming, ZOU Lai. Tool wear mechanism of diamond cutting of ferrous metals in frictional wear experiments [J]. Optics and Precision Engineering,2013,21(7):1786-1794. doi: 10.3788/OPE.20132107.1786 [9] SHIMADA S, TANAKA H, HIGUCHI M, et al. Thermo-chemical wear mechanism of diamond tool in machining of ferrous metals [J]. CIRP Annals-Manufacturing Technology,2004,53(1):57-60. [10] 王波, 肖冰, 邵明嘉. 干式磨抛用钎焊金刚石磨抛盘制备与试验 [J]. 中国机械工程,2015,26(22):3014-3020. doi: 10.3969/j.issn.1004-132X.2015.22.006WANG Bo, XIAO Bing, SHAO Mingjia. Fabrication and experiments of brazed diamond grinding disc for dry grinding [J]. China Mechanical Engineering,2015,26(22):3014-3020. doi: 10.3969/j.issn.1004-132X.2015.22.006 [11] 董华利. U71Mn、U75V和U78CrV钢轨在线热处理后性能改善比较 [J]. 金属热处理,2016,41(8):133-137.DONG Huali. Comparison of property improvement of U71Mn, U75V and U78CrV rail steels by online heat treatment [J]. Heat Treatment of Metals,2016,41(8):133-137. [12] 郭兵, 金钱余, 赵清亮, 等. 表面结构化砂轮磨削加工技术研究进展 [J]. 哈尔滨工业大学学报,2016,48(7):1-13. doi: 10.11918/j.issn.0367-6234.2016.07.001GUO Bing, JIN Qianyu, ZHAO Qingliang, et al. Research progress of grinding technology with surface structured wheels [J]. Journal of Harbin Institute of Technology,2016,48(7):1-13. doi: 10.11918/j.issn.0367-6234.2016.07.001 [13] FANG C, XU X. Analysis of temperature distributions in surface grinding with intermittent wheels [J]. The International Journal of Advanced Manufacturing Technology,2014,71:23-31. doi: 10.1007/s00170-013-5472-1 [14] GUO C, CHEN Y. Thermal modeling and optimization of interrupted grinding [J]. CIRP Annals-Manufacturing Technology,2018,67(1):321-324. doi: 10.1016/j.cirp.2018.04.083 [15] LIN B, ZHOU K, GUO J, et al. Influence of grinding parameters on surface temperature and burn behaviors of grinding rail [J]. Tribology International,2018,122:151-162. doi: 10.1016/j.triboint.2018.02.017 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS