Properties of WC-bronze based matrix material for diamond bit reinforced by multielement nanoparticles

-

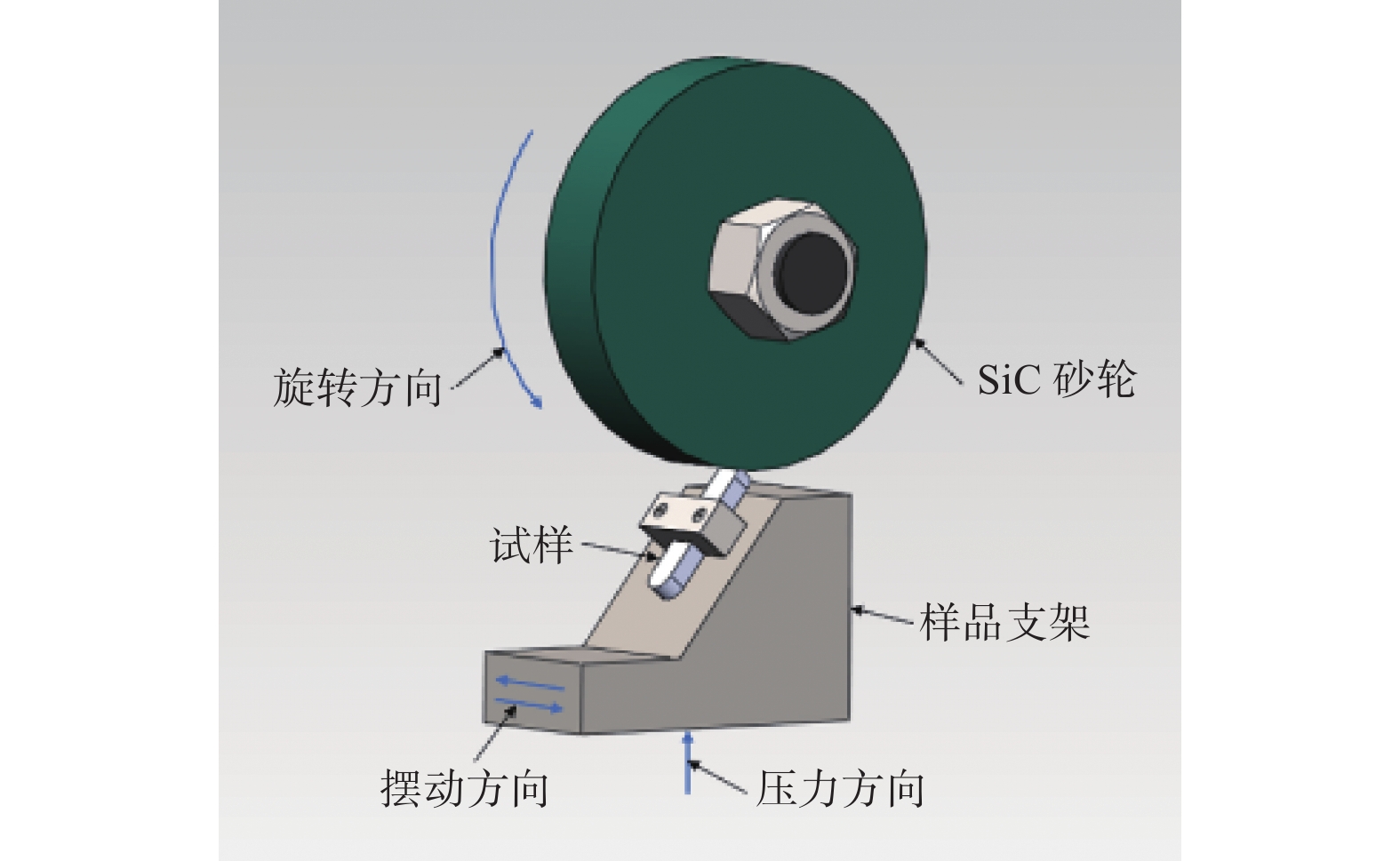

摘要: 为提高孕镶金刚石钻头胎体性能,使其更好地满足钻探需求,向WC–青铜基胎体材料中加入纳米NbC和纳米WC颗粒,研究其对胎体力学性能、微观结构的影响。利用配方均匀设计法、回归分析和规划求解得到纳米颗粒的最优添加量,并烧制钻头开展室内钻进试验。结果表明:加入纳米NbC和纳米WC后,WC–青铜基胎体材料的硬度和抗弯强度最高提高25.23%和5.73%;含金刚石的胎体材料的耐磨性明显增强,其磨耗比最高升高57.4%;金刚石与胎体之间结合得更加紧密。纳米颗粒强化后的孕镶金刚石钻头的机械钻速提高19.63%,单位进尺工作层消耗减少32.84%,说明纳米颗粒能强化孕镶金刚石钻头,提高其钻进效率,并延长钻头寿命。Abstract: Nano-NbC and nano-WC were added to the WC-bronze based matrix to improve the performance of the matrix of the impregnated diamond bit. The uniform design method, regression analysis and solver were used to obtain the optimal addition. Laboratory drilling experiments of the strengthened bits were carried out. The results show that after adding nanoparticles, the hardness and the bending strength of the matrix are improved by up to 25.23% and 5.73%. The wear resistance of the diamond composites is significantly increased, with wear ratio increased by up to 57.4%, indicating that the diamond and the matrix are more closely bonded. In conclusion, adding nanoparticles has positive significance on the performance of diamond composites. The mechanical drilling speed of the strengthened bits is 19.63% higher than that of the blank diamond bit, and that the matrix wear is reduced by 32.84%, indicating that the addition of nanoparticles to the matrix can strengthen the drill bit and improve drilling efficiency.

-

表 1 原始胎体配方成分

Table 1. Compositions of initial matrix

组分 质量分数 ω / % WC 55 锡青铜 35 Ni 5 Mn 5 表 2 纳米颗粒参数

Table 2. Nanoparticle parameters

名称 平均粒径 d / nm 纯度

ω0 / %密度 ρ / (g·cm−3) 颜色 纳米NbC 80 >99.9 7.6 黑褐色 纳米WC 80 >99.9 15.5 黑色 表 3 有约束的配方均匀设计

Table 3. Limited formula uniform design

编号 1 6 c1 c2 $ {c}_{1}^{\mathrm{*}} $ $ {c}_{2}^{\mathrm{*}} $ 1 1 7 0.05 0.65 0.904 0.976 2 2 3 0.15 0.25 0.908 0.971 3 3 10 0.25 0.95 0.912 0.979 4 4 6 0.35 0.55 0.916 0.975 5 5 2 0.45 0.15 0.920 0.970 6 6 9 0.55 0.85 0.924 0.978 7 7 5 0.65 0.45 0.927 0.973 8 8 1 0.75 0.05 0.931 0.969 9 9 8 0.85 0.75 0.935 0.977 10 10 4 0.95 0.35 0.939 0.972 表 4 胎体配方

Table 4. Matrix formula

编号 x1 / % x2 / % x3 / % 1 4.5 2.0 93.5 2 4.3 2.4 93.3 3 4.1 2.8 93.1 4 3.9 2.1 94.0 5 3.7 2.6 93.7 6 3.5 3.0 93.5 表 5 胎体试样的名称、成分

Table 5. Name and composition of matrix samples

编号 质量分数 ω1 / % 纳米NbC 纳米WC 胎体 S0 0 0 100.0 S1 4.5 2.0 93.5 S2 4.3 2.4 93.3 S3 4.1 2.8 93.1 S4 3.9 2.1 94.0 S5 3.7 2.6 93.7 S6 3.5 3.0 93.5 表 6 胎体试样的机械性能

Table 6. Mechanical properties of matrix samples

编号 硬度 HRC 抗弯强度 σ / MPa S0 30.04 860.52 S1 32.59 758.59 S2 34.56 864.34 S3 35.71 909.87 S4 35.50 682.47 S5 37.12 742.43 S6 37.62 733.66 表 7 含金刚石的胎体材料试样名称、成分

Table 7. Name and composition of the matrix material sample containing diamond

编号 质量分数 ω2 / % 纳米NbC 纳米WC 胎体 SD0 0 0 100.0 SD1 3.0 2.0 95.0 SD2 5.0 3.0 92.0 表 8 钻头结构参数

Table 8. Structural parameters of bits

名称 数值 外径 D1 / mm 60.0 内径 D2 / mm 41.5 工作层高 h1 / mm 6.0 非工作层高 h2 / mm 6.0 水口高 h3 / mm 8.0 水口宽 b1 /mm 6.0 水口数 n 6 表 9 钻进试验数据表

Table 9. Drilling experiment data

钻头类型 钻进

进尺

l / mm钻进

时间

t / min机械

钻速

v / (mm·s−1)工作层

磨损

d / mm单位进尺

工作层消耗

d0 / (mm·m−1)传统钻头 1 060 10.82 1.63 0.50 0.472 强化钻头 1 200 10.28 1.95 0.38 0.317 -

[1] MOSTOFI M, RICHARD T, FRANCA L, et al. Wear response of impregnated diamond bits [J]. Wear,2018,410/411:34-42. doi: 10.1016/j.wear.2018.04.010 [2] 蔡家品, 贾美玲, 沈立娜, 等. 难钻进地层金刚石钻头的现状和发展趋势 [J]. 探矿工程(岩土钻掘工程),2017,44(2):67-73.CAI Jiapin, JIA Meiling, SHEN Lina, et al. Present situation of diamond bit used in difficult drilling formations and the development trend [J]. Exploration Engineering (Rock & Soil Drilling and Tunneling),2017,44(2):67-73. [3] BAI R, ZHANG S, HAN Y, et al. Effect of CL192 pre-alloyed powder on matrix properties of impregnated diamond bit [J]. Diamond & Related Materials,2020,107:107878. [4] LI C, DUAN L, TAN S, et al. Effect of CaF2 and hBN on the mechanical and tribological properties of Fe-based impregnated diamond bit matrix [J]. International Journal of Refractory Metals and Hard Materials,2018,75:118-125. doi: 10.1016/j.ijrmhm.2018.04.011 [5] 叶宏煜, 谭松成, 杨展, 等. 强化热压烧结孕镶金刚石钻头试验研究 [J]. 超硬材料工程,2021,33(1):1-6. doi: 10.3969/j.issn.1673-1433.2021.01.001YE Hongyu, TAN Songcheng, YANG Zhan, et al. Experimental study on the impregnated diamond bit fabricated by intensive hot-press sintering [J]. Superhard Materials Engineering,2021,33(1):1-6. doi: 10.3969/j.issn.1673-1433.2021.01.001 [6] 刘鑫, 张伟龙, 赵小军, 等. 热压工艺参数对WC–Cu基胎体力学性能的影响 [J]. 金刚石与磨料磨具工程,2020,40(4):34-40.LIU Xin, ZHANG Weilong, ZHAO Xiaojun, et al. Effect of hot pressing parameters on the mechanical properties of WC–Cu matrix [J]. Diamond & Abrasives Engineering,2020,40(4):34-40. [7] 章兼植. 有关胎体设计的一些评述 [J]. 珠宝科技,2003(4):11-14.ZHANG Jianzhi. Statements for matrix design [J]. Jewellery Science and Technology,2003(4):11-14. [8] 高玉彬, 陈洋. 钻进坚硬致密岩层的金刚石钻头试验研究 [J]. 超硬材料工程,2021,33(3):1-6. doi: 10.3969/j.issn.1673-1433.2021.03.001GAO Yubin, CHEN Yang. Experimental study of diamond bit for drilling hard and compact rock [J]. Superhard Materials Engineering,2021,33(3):1-6. doi: 10.3969/j.issn.1673-1433.2021.03.001 [9] 吴燕平, 燕青芝. 金属结合剂金刚石工具研究进展 [J]. 金刚石与磨料磨具工程,2019,39(2):37-45.WU Yanping, YAN Qingzhi. Research progress of metal bond diamond tools [J]. Diamond & Abrasives Engineering,2019,39(2):37-45. [10] DUAN D Z, SUN L, FANG X D, et al. Microstructure and processing performance of brazed diamond drill bits with Ni–Cr+Cu–Ce composite solder [J]. Diamond and Related Materials,2019,93:216-223. doi: 10.1016/j.diamond.2019.01.023 [11] 王晋春, 张烈华, 胡三德. 孕镶材料与岩石适应性研究 [J]. 化学工程与装备,2015(5):13-16.WANG Jinchun, ZHANG Liehua, HU Sande. Research on the adaptability of impregnated materials and rocks [J]. Chemical Engineering & Equipment,2015(5):13-16. [12] 王帅, 吕智, 林峰, 等. WC含量对金刚石钻头胎体性能的影响研究 [J]. 金刚石与磨料磨具工程,2014,34(6):16-21.WANG Shuai, LYU Zhi, LIN Feng, et al. Effect of WC content on the properties of impregnated diamond bit matrix [J]. Diamond & Abrasives Engineering,2014,34(6):16-21. [13] 黄帆, 肖冬顺, 瞿霞, 等. 基于混料设计的WC基复合胎体性能研究 [J]. 探矿工程(岩土钻掘工程),2019,46(1):89-92.HUANG Fan, XIAO Dongshun, QU Xia, et al. Properties of WC-based composite matrix by mixture design [J]. Exploration Engineering (Rock & Soil Drilling and Tunneling),2019,46(1):89-92. [14] 宁新愿, 汪礼敏, 刘祥庆. 弥散强化金刚石工具胎体材料的研究进展 [J]. 粉末冶金工业,2015,25(1):49-53.NING Xinyuan, WANG Limin, LIU Xiangqing. Research progress of the dispersion strengthening diamond tool matrix [J]. Powder Metallurgy Industry,2015,25(1):49-53. [15] KUMAR S S, HIREMATH S S. Microstructure and mechanical behavior of nanoparticles reinforced metal matrix composites—A review [J]. Applied Mechanics and Materials,2014,592/593/594:939-944. doi: 10.4028/www.scientific.net/AMM.592-594.939 [16] SUN Y, WU H, MENG L, et al. The effect of ZrO2 nanoparticles on the microstructure and properties of sintered WC-bronze-based diamond composites [J]. Materials,2016,9(5):343. doi: 10.3390/ma9050343 [17] 高科, 徐小健, 谢晓波, 等. 纳米镍粉对孕镶金刚石切削工具胎体性能的影响 [J]. 探矿工程(岩土钻掘工程),2014,41(8):81-84.GAO Ke, XU Xiaojian, XIE Xiaobo, et al. Effect of nano-nickel powder on the performance of diamond impregnated cutting tools [J]. Exploration Engineering (Rock & Soil Drilling and Tunneling),2014,41(8):81-84. [18] LI S, HAN Z, MENG Q, et al. Effect of WC nanoparticles on the microstructure and properties of WC-bronze-Ni-Mn based diamond composites [J]. Applied Sciences,2018,8(9):1501. doi: 10.3390/app8091501 [19] LOGINOV P A, SIDORENKO D A, LEVASHOV E A, et al. Hybrid metallic nanocomposites for extra wear-resistant diamond machining tools [J]. International Journal of Refractory Metals & Hard Materials, 2018. [20] JEYASIMMAN D, NARAYANASAMY R, PONALAGUSAMY R. Role of hybrid reinforcement on microstructural observation, characterization and consolidation behavior of AA 6061 nanocomposite [J]. Advanced Powder Technology,2015,26(4):1171-1182. doi: 10.1016/j.apt.2015.05.013 [21] SRIBALAJI M, MUKHERJEE B, ISLAM A, et al. Microstructural and mechanical behavior of spark plasma sintered titanium carbide with hybrid reinforcement of tungsten carbide and carbon nanotubes [J]. Materials Science & Engineering: A,2017,702:10-21. [22] ALJAWAD H A, ALALKAWI H, AZIZ G A. Compression strength, dielectric and magnetic properties of new aluminium matrix hybrid nanocomposites [J]. IOP Conference Series: Materials Science and Engineering,2020,765(1):012056. doi: 10.1088/1757-899X/765/1/012056 [23] 徐强, 刘一波, 徐良, 等. 利用配方均匀设计优化金刚石钻头的胎体配方 [J]. 金刚石与磨料磨具工程,2016,36(4):49-53.XU Qiang, LIU Yibo, XU Liang, et al. Optimizing diamond drill bit formula using uniform design [J]. Diamond & Abrasives Engineering,2016,36(4):49-53. [24] 方开泰. 均匀设计与均匀设计表 [M]. 北京: 科学出版社, 1994.FANG Kaitai. Uniform design and uniform design tables [M]. Beijing: Science Press, 1994. [25] 汪琦, 付杰, 万鸣, 等. 混料均匀设计法优化茯苓代料栽培配方 [J]. 中药材,2016,39(11):2445-2449.WANG Qi, FU Jie, WAN Ming, et al. Optimization of poria substitution cultivation formula by mixing uniform design [J]. Journal of Chinese Medicinal Materials,2016,39(11):2445-2449. [26] YANG Y, JIANG M, XU J, et al. Uniform design of optimizing formulation of friction materials with composite mineral fiber (CMF) and their friction and wear behavior [J]. Applied Composite Materials,2012,19(2):161-170. doi: 10.1007/s10443-011-9188-9 [27] HUANG Q, LIU C, CHEN S, et al. Effects of formulation on set-to-touch time of waterborne alkyd resin by uniform design [J]. Progress in Organic Coatings,2015,87:189-196. doi: 10.1016/j.porgcoat.2015.06.001 [28] 陈莉, 张蓓. 配方均匀设计在植物防紫外整理剂复配中的应用 [J]. 上海纺织科技,2017,45(1):23-26.CHEN Li, ZHANG Bei. Application of formula uniform design in the mixture of anti-ultraviolet agents extracted from vegetable [J]. Shanghai Textile Science & Technology,2017,45(1):23-26. [29] 刘中常. 纳米材料中纳米粒子团聚的原因及解决方法 [J]. 价值工程,2017,36(13):157-158.LIU Zhongchang. Reason for aggregation of nanoparticles in nano-materials and solutions [J]. Value Engineering,2017,36(13):157-158. [30] ZHANG Z, CHEN D. Contribution of Orowan strengthening effect in particulate-reinforced metal matrix nanocomposites [J]. Materials Science and Engineering: A,2008,483(483/484):148-152. [31] NIE K, WANG X, XU F, et al. Microstructure and tensile properties of SiC nanoparticles reinforced magnesium matrix composite prepared by multidirectional forging under decreasing temperature conditions [J]. Materials Science & Engineering: A,2015,639:465-473. [32] 国秀花, 龙飞, 周延军, 等. 粉末冶金法制备氧化物颗粒增强Cu基复合材料 [J]. 特种铸造及有色合金,2018,38(2):205-209.GUO Xiuhua, LONG Fei, ZHOU Yanjun, et al. Microstructure and properties of oxide particle reinforced copper matrix composites by powder metallurgy [J]. Special Casting & Nonferrous Alloys,2018,38(2):205-209. [33] SCATTERGOOD R O, KOCH C C, MURTY K L, et al. Strengthening mechanisms in nanocrystalline alloys [J]. Materials Science & Engineering: A,2008,493(1/2):3-11. [34] YU H, GUO R X, XIA H T, et al. Study on the effect of WC size on the thermal expansion coefficient of WC/Cu composites [J]. Applied Mechanics & Materials,2013,275/276/277:1597-1600. [35] NYANOR P, EL-KADY O, YEHIA H M, et al. Effect of bimodal-sized hybrid TiC–CNT reinforcement on the mechanical properties and coefficient of thermal expansion of aluminium matrix composites [J]. Metals and Materials International,2020,27(4):753-766. [36] SUN W, GAO H, TAN S, et al. Wear detection of WC–Cu based impregnated diamond bit matrix based on SEM image and deep learning [J]. International Journal of Refractory Metals and Hard Materials,2021,98:105530. doi: 10.1016/j.ijrmhm.2021.105530 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS