Parameters optimization for ferrite slicing based on grey theory

-

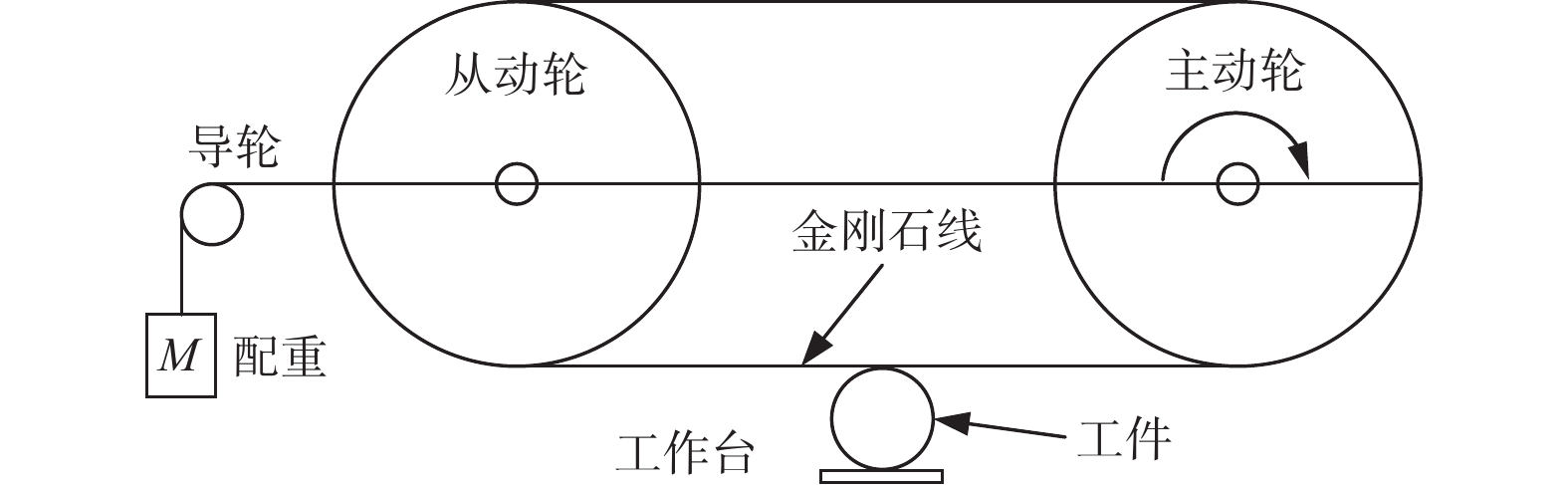

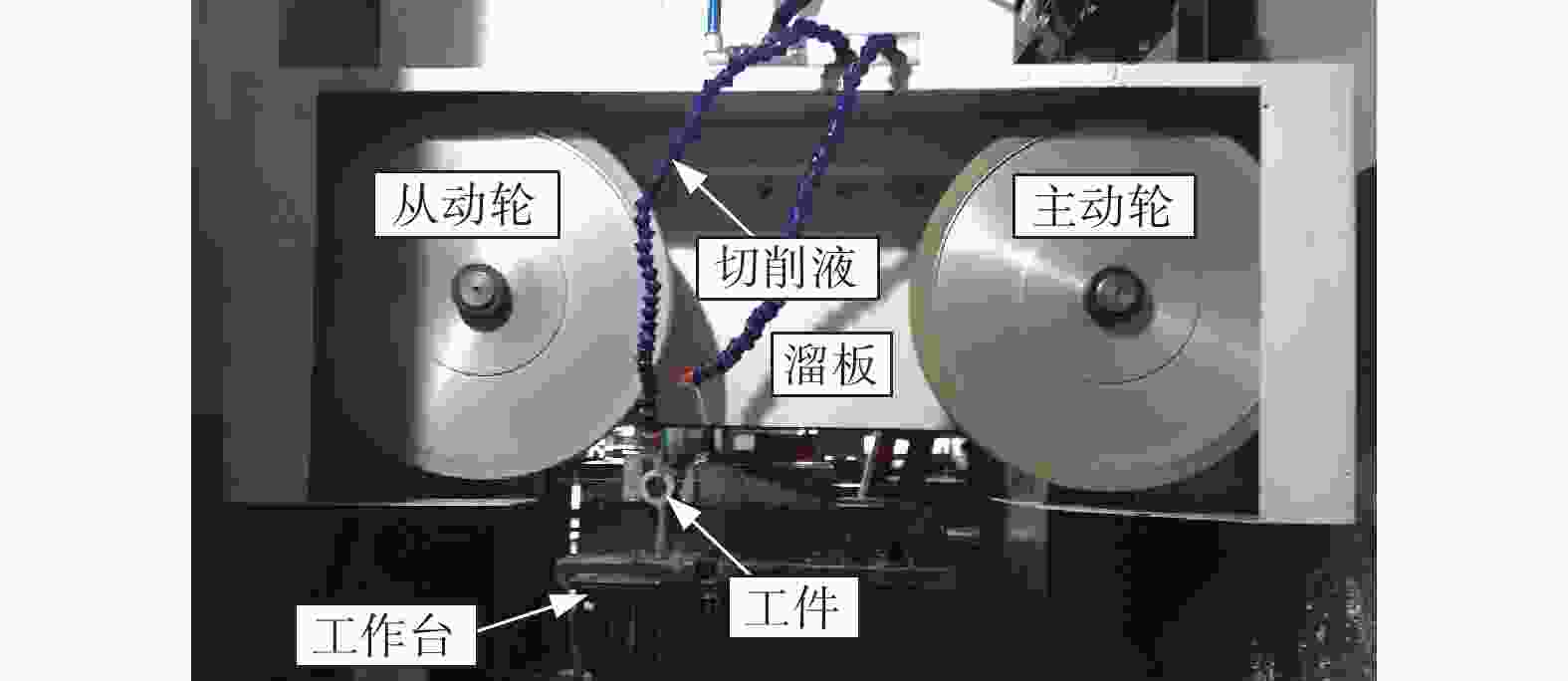

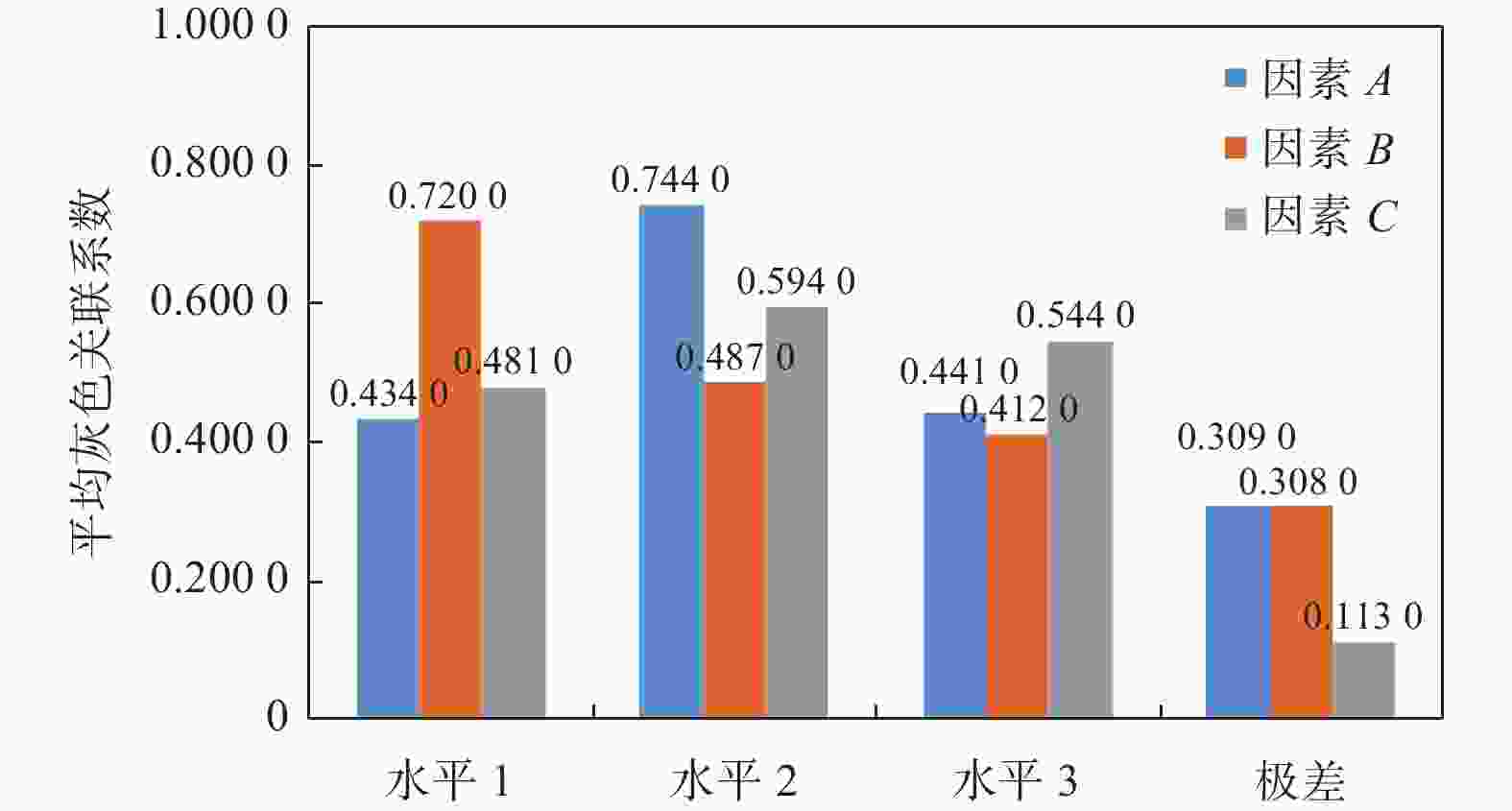

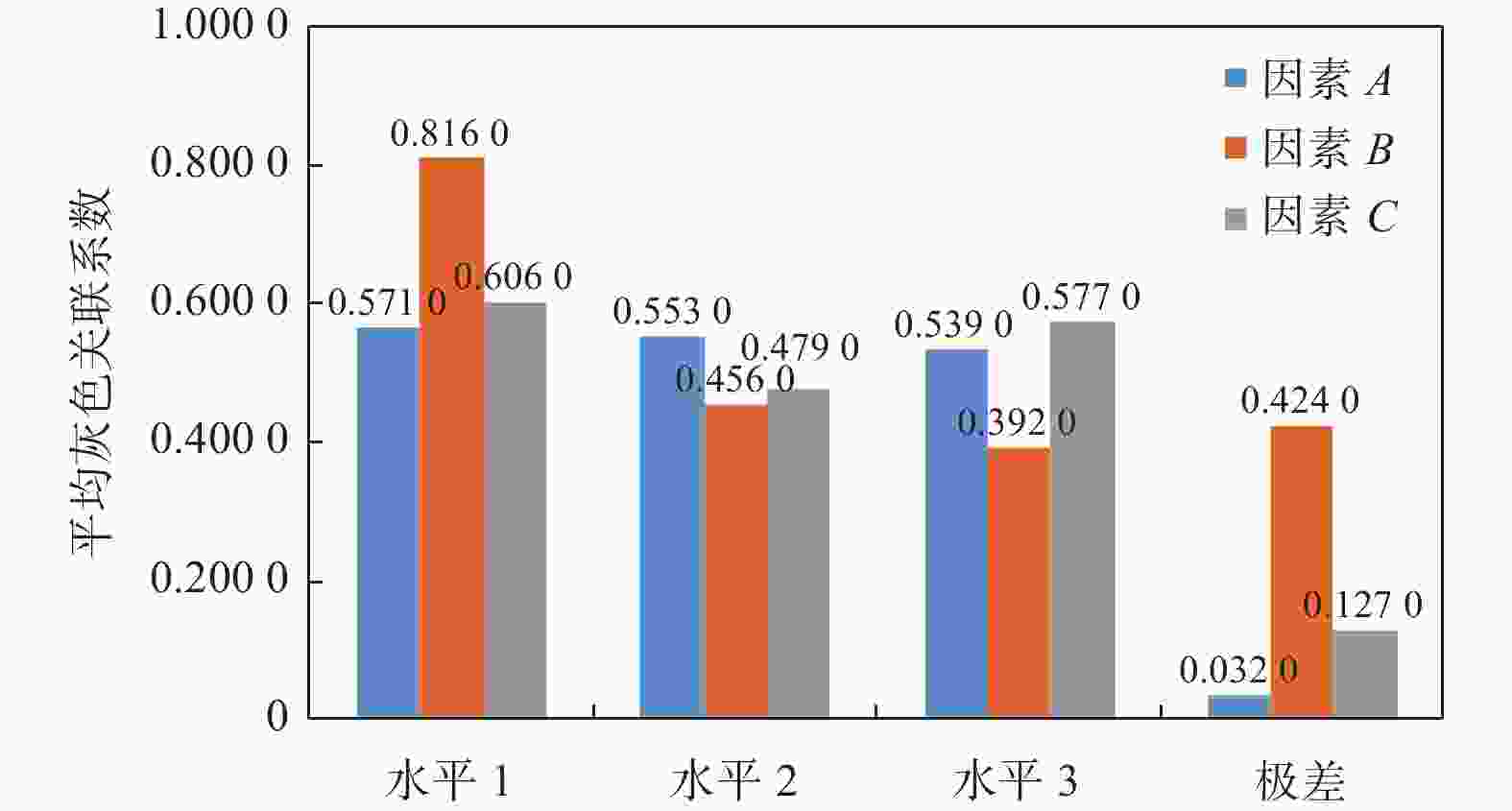

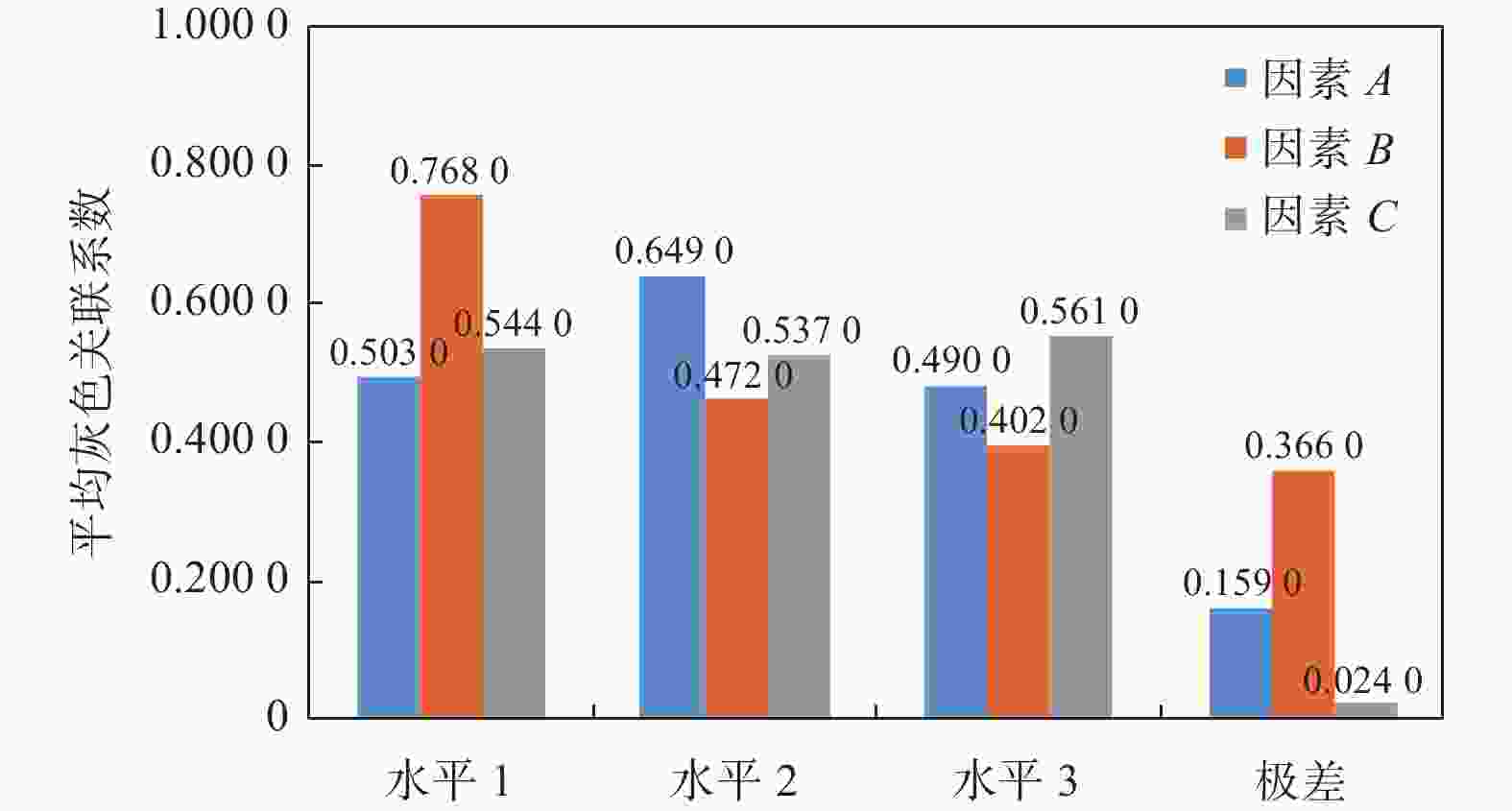

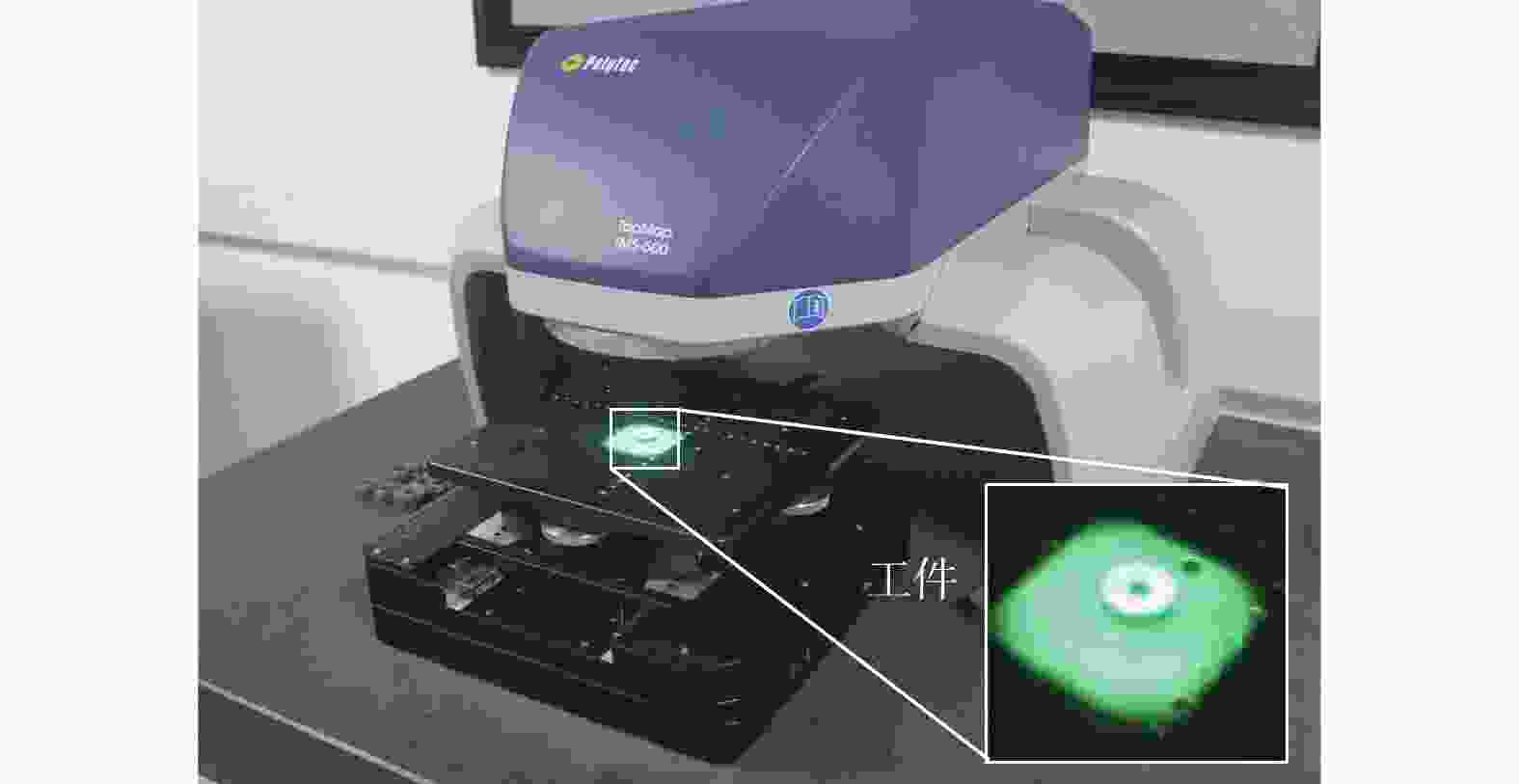

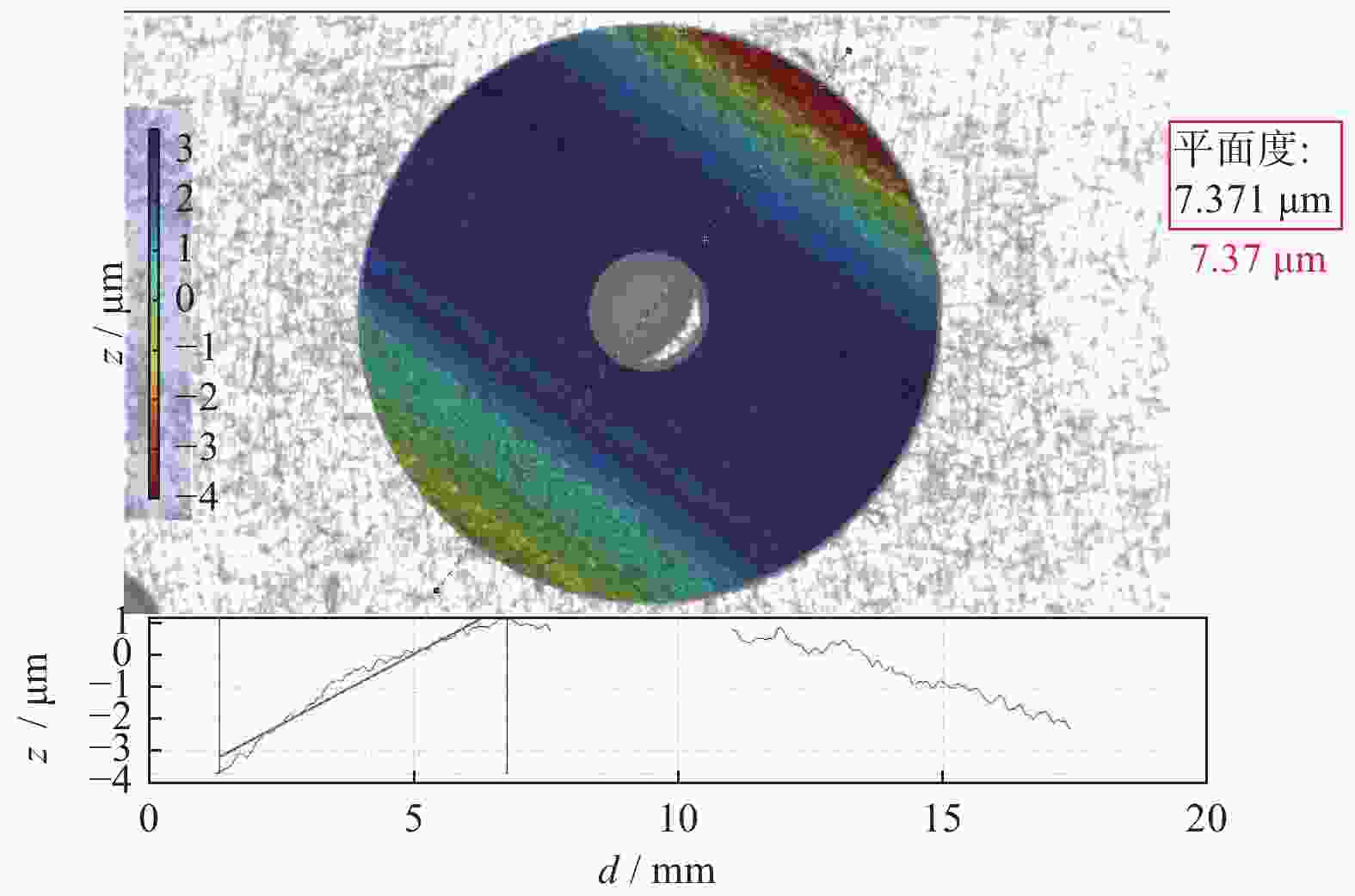

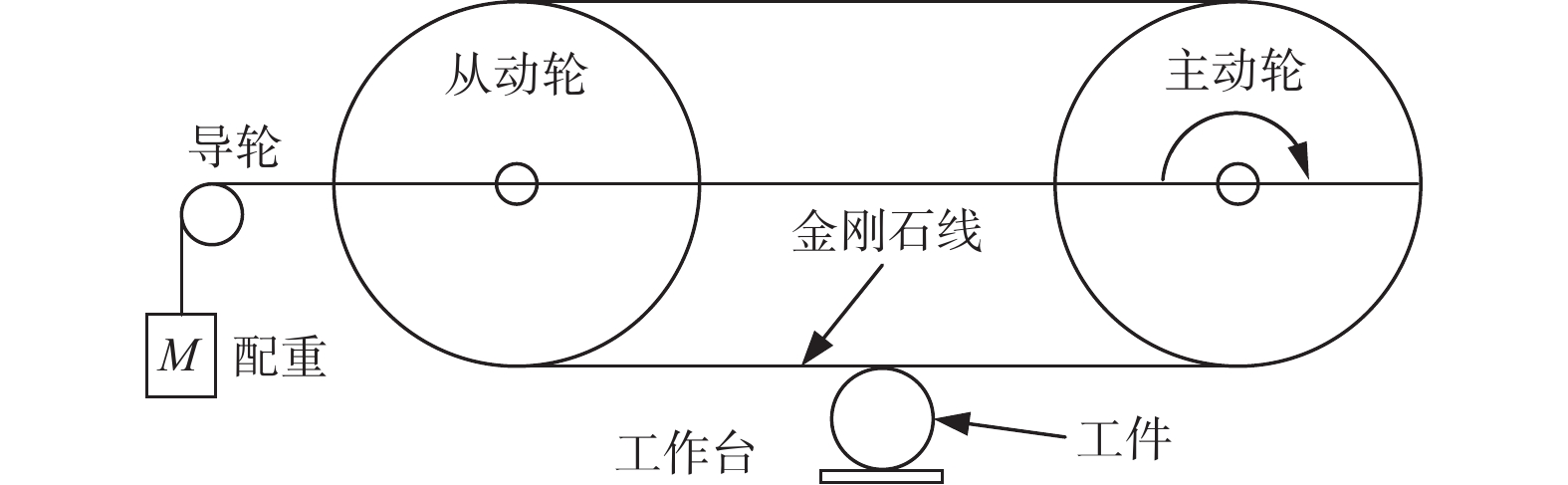

摘要: 针对铁氧体的高精度环形金刚石线锯切割工艺参数优化问题,以其切割后的面形精度和表面粗糙度作为评价指标,采用正交试验法研究主轴转速、进给速度和张紧力等工艺参数对切割表面质量的影响,并基于灰色理论对多工艺目标进行数据分析和综合评判,得到工艺参数组合优化方案为:主轴转速,1 000 r/min;进给速度,1.0 mm/min;张紧力,90 N。切割试验结果表明:用优化后的参数组合得到的面形精度PV为7.37 μm、表面粗糙度Ra为0.882 μm,加工表面质量提高,验证了铁氧体切割工艺参数优化的有效性和实用性。Abstract: To optimize the parameters of slicing ferrite with high precision diamond ring saw, an orthogonal test is designed with the fabricating surface accuracy and the surface roughness as evaluation indicators and the spindle speed, the feed speed and the tension force as factors. Based on the grey theory, the data analysis and the comprehensive evaluation of the multiple process targets are carried out to obtain an optimized process parameter combination, namely the spindle speed 1 000 r/min, the feed speed 1.0 mm/min and the tension force 90 N. The slicing test results show that the optimized parameter combination can obtain a surface accuracy of PV 7.37 μm and a surface roughness Ra of 0.882 μm, and the slicing surface quality is improved, which verifies the effectiveness and practicability of this method in the optimization of ferrite slicing process parameters.

-

Key words:

- diamond wire saw /

- surface quality /

- orthogonal test /

- grey theory

-

表 1 正交试验设计

Table 1. Orthogonal design

水平 因素 A

主轴转速

n / (r·min−1)B

进给速度

vf / (mm·min−1)C

张紧力

F / N1 800 1.0 50 2 1 000 2.0 70 3 1 200 3.0 90 表 2 试验结果

Table 2. Test results

序号 工艺参数 评价指标 A B C 面形精度 PV / μm 表面粗糙度 Ra / μm 1 1 1 1 10.12 0.967 2 1 2 2 11.32 1.352 3 1 3 3 12.46 1.437 4 2 1 2 8.56 1.098 5 2 2 3 9.41 1.128 6 2 3 1 10.26 1.285 7 3 1 3 9.84 1.024 8 3 2 1 12.15 1.328 9 3 3 2 11.92 1.296 表 3 处理后序列

Table 3. Sequence after processing

序号 归一化处理 绝对差值 面形精度 PV / μm 表面粗糙度 R a / μm Δ1(k) Δ2(k) 1 0.400 0 0 0.400 0 0 2 0.707 7 0.819 1 0.707 7 0.819 1 3 1.000 0 1.000 0 1.000 0 1.000 0 4 0.000 0 0.278 7 0.000 0 0.278 7 5 0.217 9 0.342 6 0.217 9 0.342 6 6 0.435 9 0.676 6 0.435 9 0.676 6 7 0.328 2 0.121 3 0.328 2 0.121 3 8 0.920 5 0.768 1 0.920 5 0.768 1 9 0.861 5 0.700 0 0.861 5 0.700 0 表 4 灰色关联系数及灰色关联度

Table 4. Grey relation coefficient and grey relation degree

序号 灰色关联系数 灰色关联度 面形精度 PV / μm 表面粗糙度 Ra / μm 数值 排序 1 0.555 6 1.000 0 0.777 8 2 2 0.414 0 0.379 0 0.396 5 6 3 0.333 3 0.333 3 0.333 3 9 4 1.000 0 0.642 1 0.821 0 1 5 0.696 4 0.593 4 0.644 9 4 6 0.534 2 0.425 0 0.479 6 5 7 0.603 7 0.804 8 0.704 3 3 8 0.352 0 0.394 3 0.373 1 8 9 0.367 2 0.416 7 0.391 9 7 -

[1] 王贵林, 张飞虎, 张晓宾, 等. 微波铁氧体基片高效磨削技术研究 [J]. 中国机械工程,2007,18(12):1479-1482. doi: 10.3321/j.issn:1004-132X.2007.12.022WANG Guilin, ZHANG Feihu, ZHANG Xiaobin, et al. Study on high efficiency grinding technology of ferrite microwave substrates [J]. China Mechanical Engineering,2007,18(12):1479-1482. doi: 10.3321/j.issn:1004-132X.2007.12.022 [2] 孙立鹏. 铁氧体表面加工质量与使役性能的映射关系研究 [D]. 天津: 天津大学, 2012.SUN Lipeng. Research on relationship between processing quality and causative performance of ferrite [D]. Tianjin: Tianjin University, 2012. [3] LI Z Q, GE P Q, BI W B, et al. Influence of anisotropy of KDP crystal on the surface shape deviation of slice by diamond wire saw [J]. The International Journal of Advanced Manufacturing Technology,2021,113(5):1771-1785. [4] COSTA E C, XAVIER F A, KNOBLAUCH R, et al. Effect of cutting parameters on surface integrity of monocrystalline silicon sawn with an endless diamond wire saw [J]. Solar Energy,2020,207:640-650. doi: 10.1016/j.solener.2020.07.018 [5] 曹连静, 孙玉利, 左敦稳, 等. 金刚石线锯切割氮化硅的实验研究 [J]. 金刚石与磨料磨具工程,2013,33(5):5-11.CAO Lianjing, SUN Yuli, ZUO Dunwen, et al. Slicing Si3N4 with fixed abrasive diamond wire saw [J]. Diamond & Abrasives Engineering,2013,33(5):5-11. [6] SUZUKI T, OTSUKI T, YAN J W. Study on precision slicing process of single-crystal silicon by using dicing wire saw [J]. Advanced Materials Research, 2016,1136:350-356. [7] GAO Y, CHEN Y. Sawing stress of SiC single crystal with void defect in diamond wire saw slicing [J]. The International Journal of Advanced Manufacturing Technology,2019,103:1019-1031. doi: 10.1007/s00170-019-03579-4 [8] 刘文涛, 赵惠英, 李彬, 等. 环形金刚石线锯切割YAG晶体的亚表面损伤预测 [J]. 金刚石与磨料磨具工程,2017,37(3):55-61,68.LIU Wentao, ZHAO Huiying, LI Bin, et al. Prediction of subsurface damage of endless diamond wire sawing YAG crystal [J]. Diamond & Abrasives Engineering,2017,37(3):55-61,68. [9] LIN Y C, LEE H S. Optimization of machining parameters using magnetic-force-assisted EDM based on gray relational analysis [J]. The International Journal of Advanced Manufacturing Technology,2008,42(11):1052-1064. [10] MEENA V K, AZAD M S. Grey relational analysis of micro-EDM machining of Ti–6Al–4V alloy [J]. Advanced Manufacturing Processes,2012,27(9):973-977. [11] ZHENG P, LIU D L, GUO J K, et al. A new method for optimizing process parameters of active measurement grinding based on grey target decision making [J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science,2020,234(23):4645-4658. doi: 10.1177/0954406220927052 [12] 迟玉伦, 李郝林. 基于灰色系统理论的外圆磨削工艺参数优化研究 [J]. 制造技术与机床,2014(2):97-101. doi: 10.3969/j.issn.1005-2402.2014.02.031CHI Yulun, LI Haolin. Study on parameters optimization for grinding based on grey system theory [J]. Manufacturing Technology & Machine Tool,2014(2):97-101. doi: 10.3969/j.issn.1005-2402.2014.02.031 [13] 赵建社, 郁子欣, 周旭娇, 等. 基于灰色理论的钛合金电火花加工工艺参数优化试验 [J]. 中国机械工程,2015,26(14):1877-1882. doi: 10.3969/j.issn.1004-132X.2015.14.007ZHAO Jianshe, YU Zixin, ZHOU Xujiao, et al. Experiments of parameter optimization of EDM titanium alloy based on gray relation theory [J]. China Mechanical Engineering,2015,26(14):1877-1882. doi: 10.3969/j.issn.1004-132X.2015.14.007 [14] 董龙超. 硬脆材料高精度环形金刚石线切割技术研究 [D]. 西安: 西安交通大学, 2017.DONG Longchao. Research on the technology of high precision endless diamond wire saw for hard and brittle material [D]. Xi'an: Xi'an Jiaotong University, 2017. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS