Application of cast tungsten carbide particles coated with cobalt powder in diamond saw blades

-

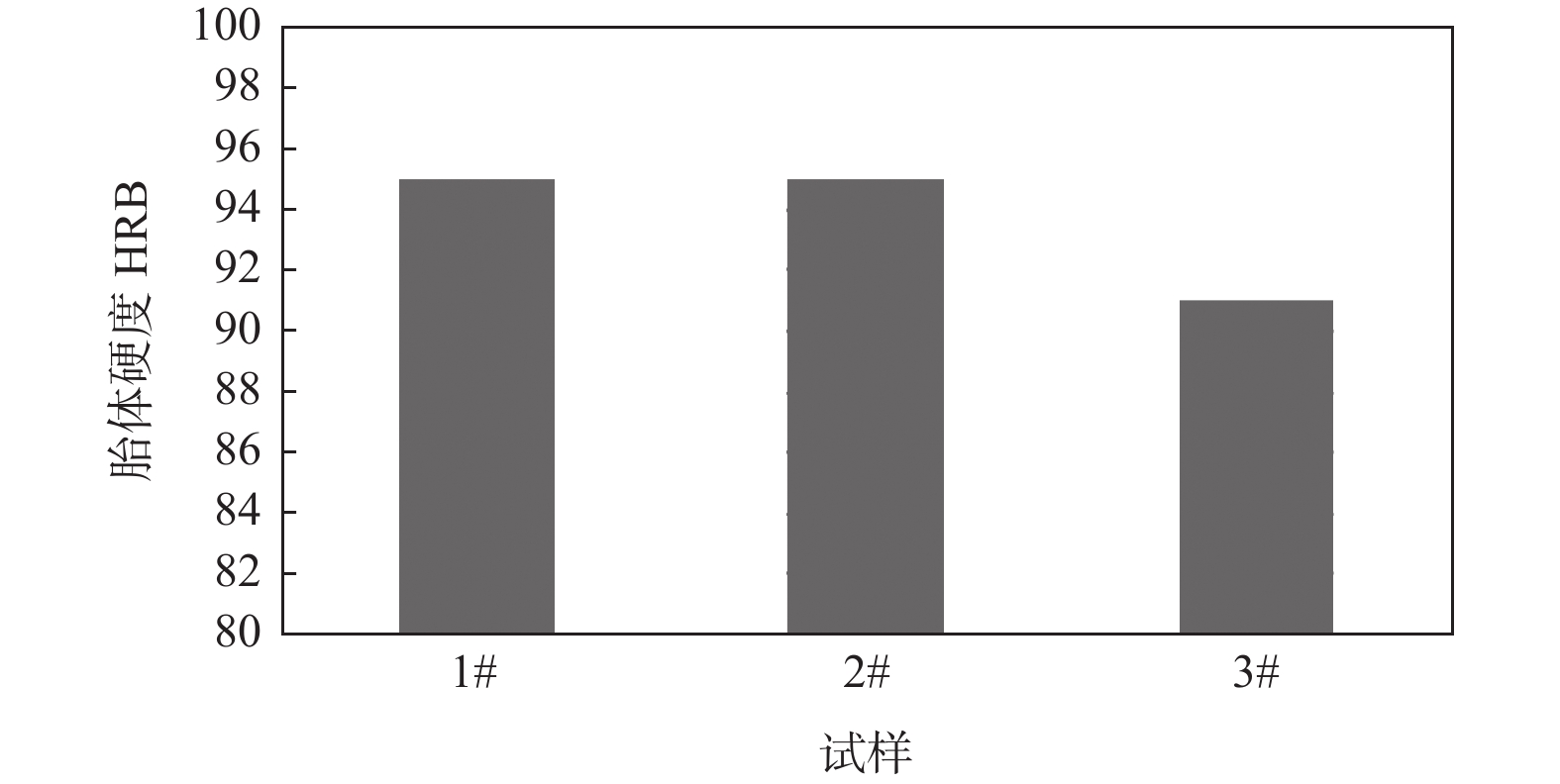

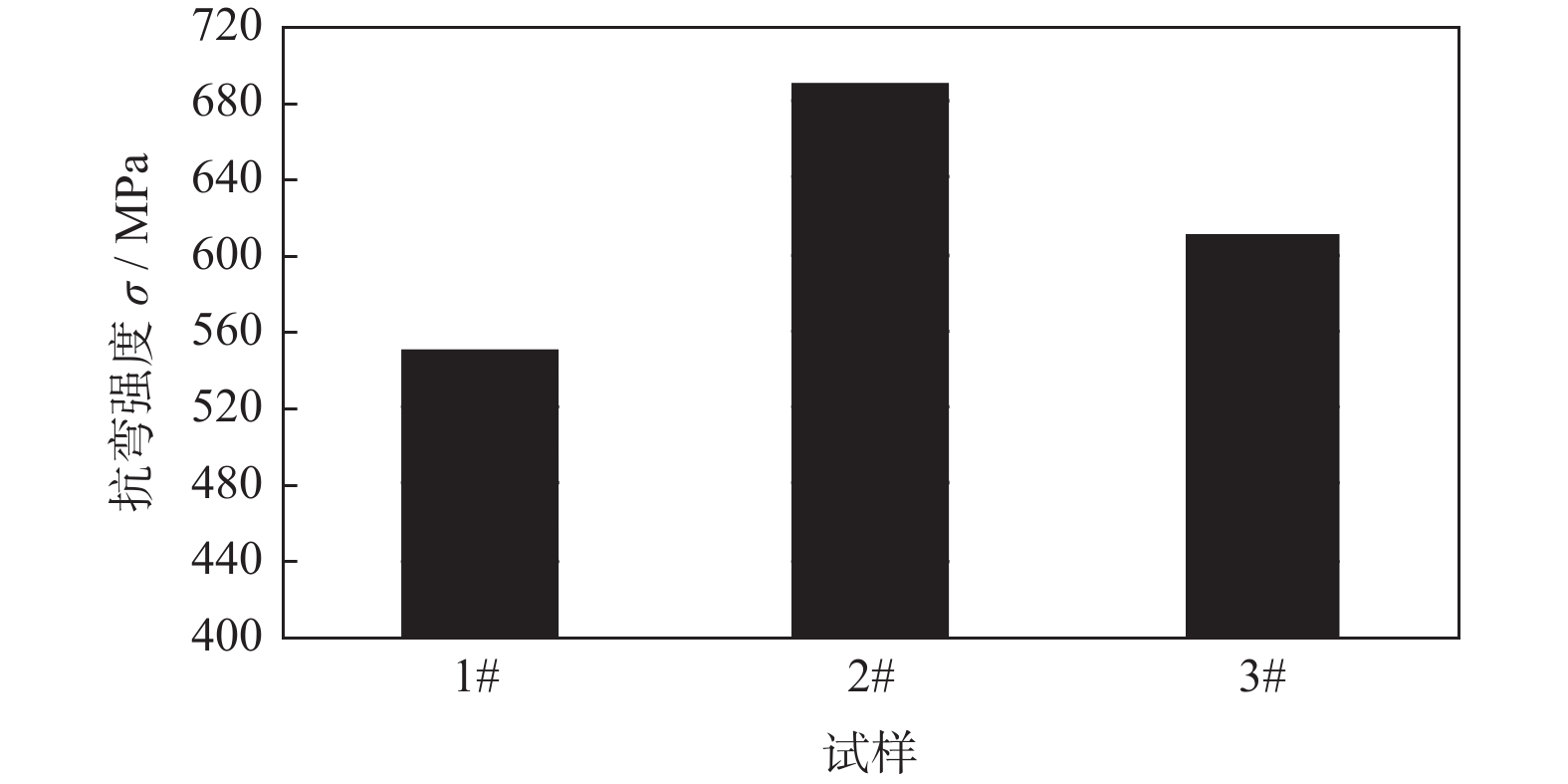

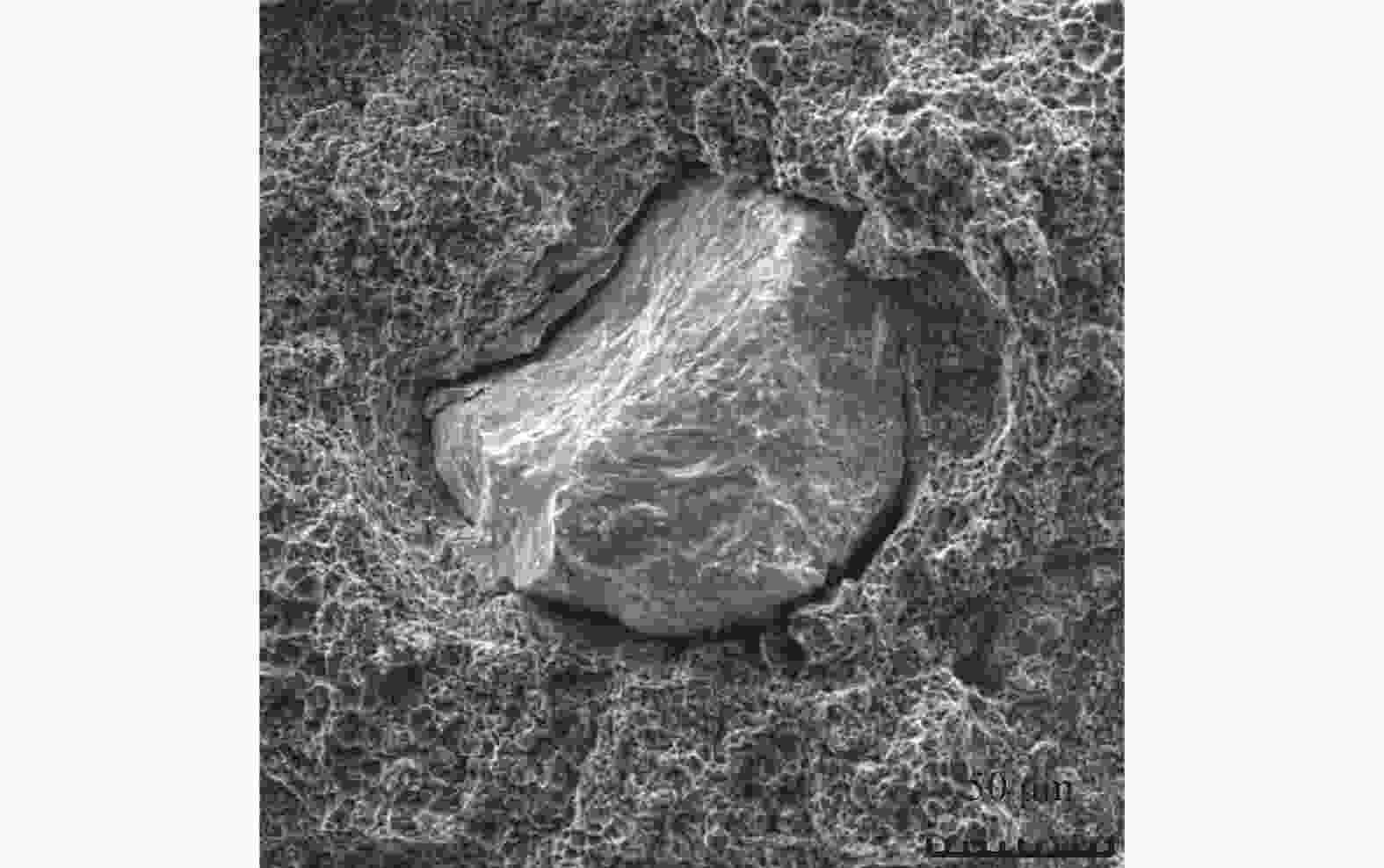

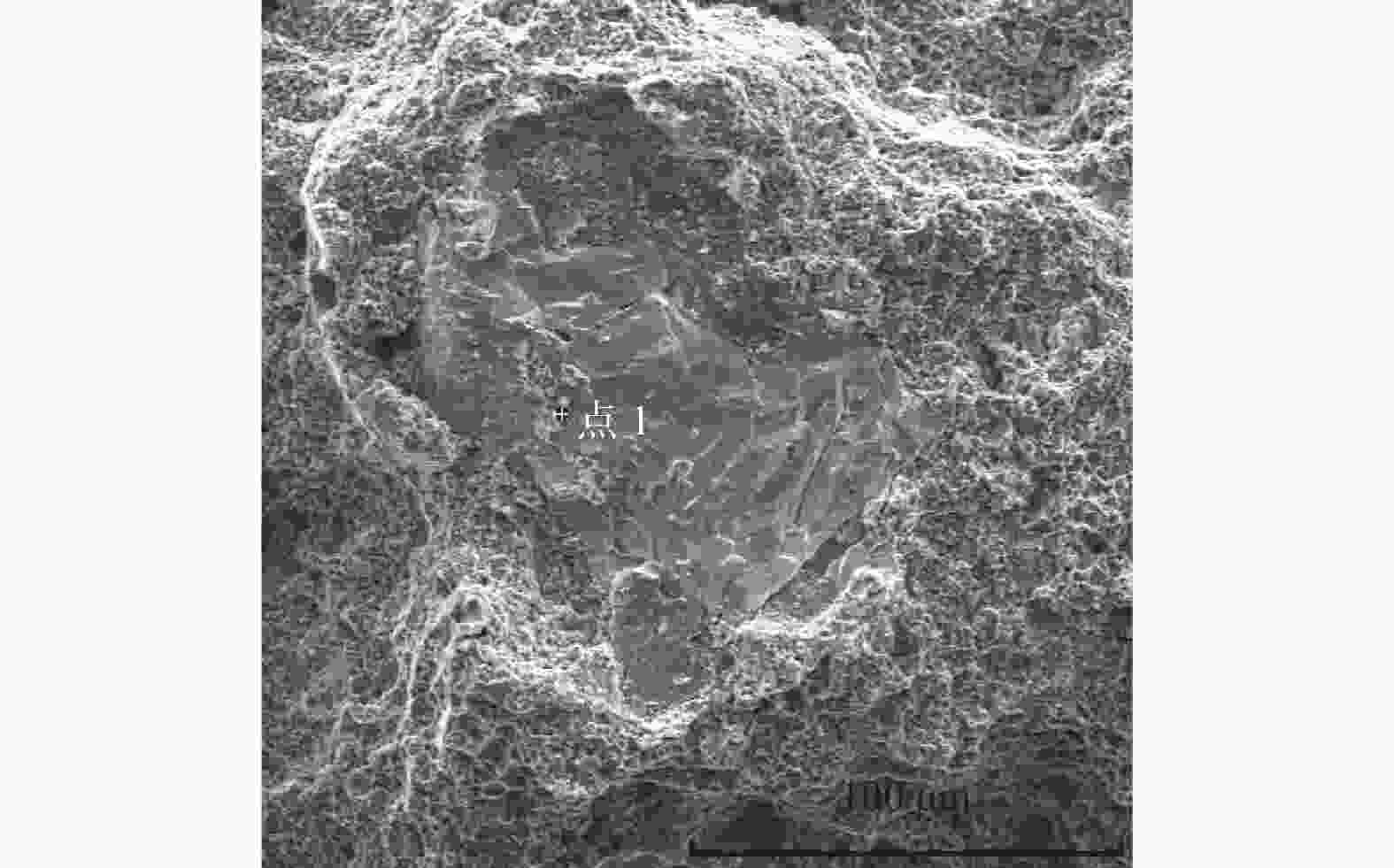

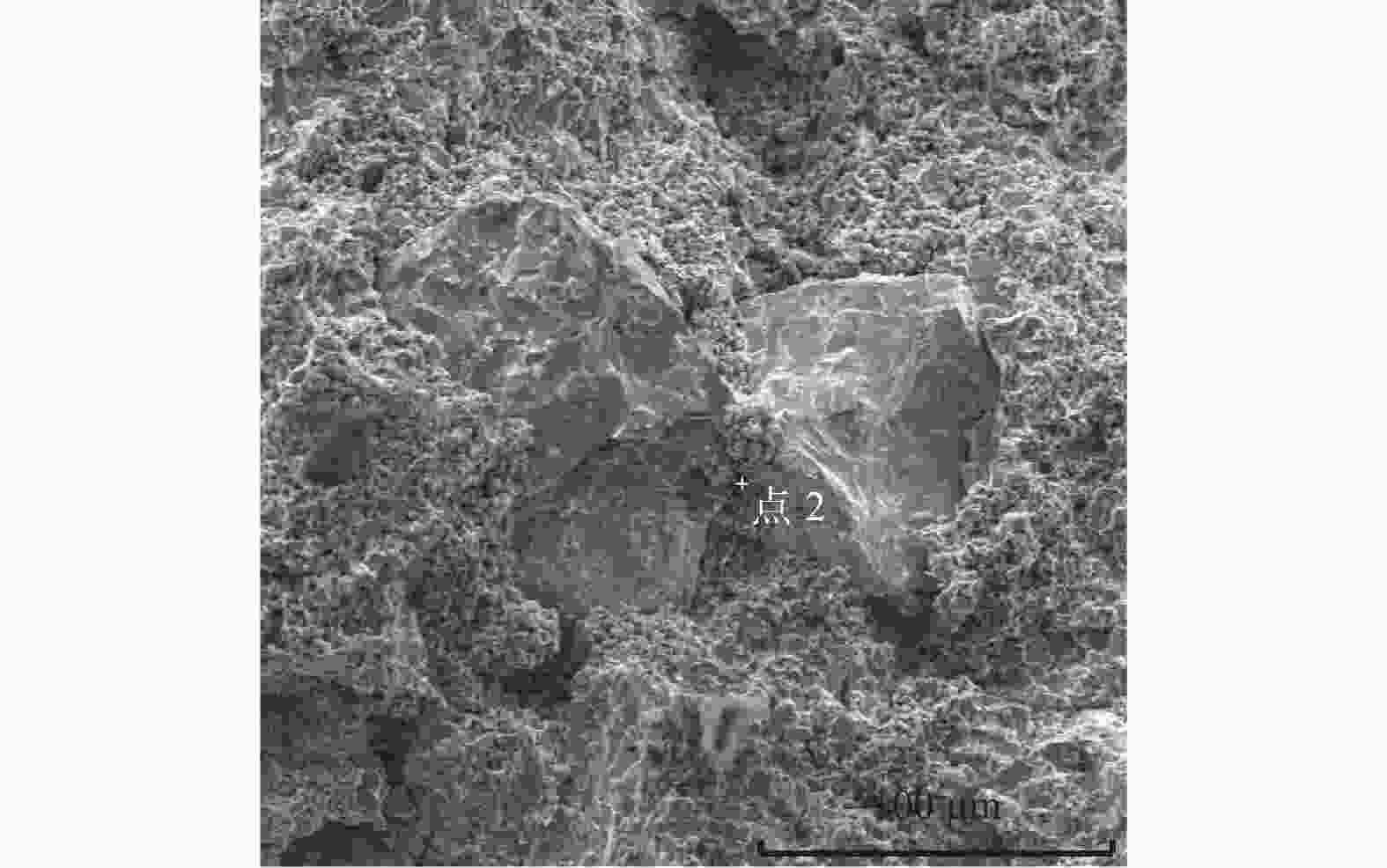

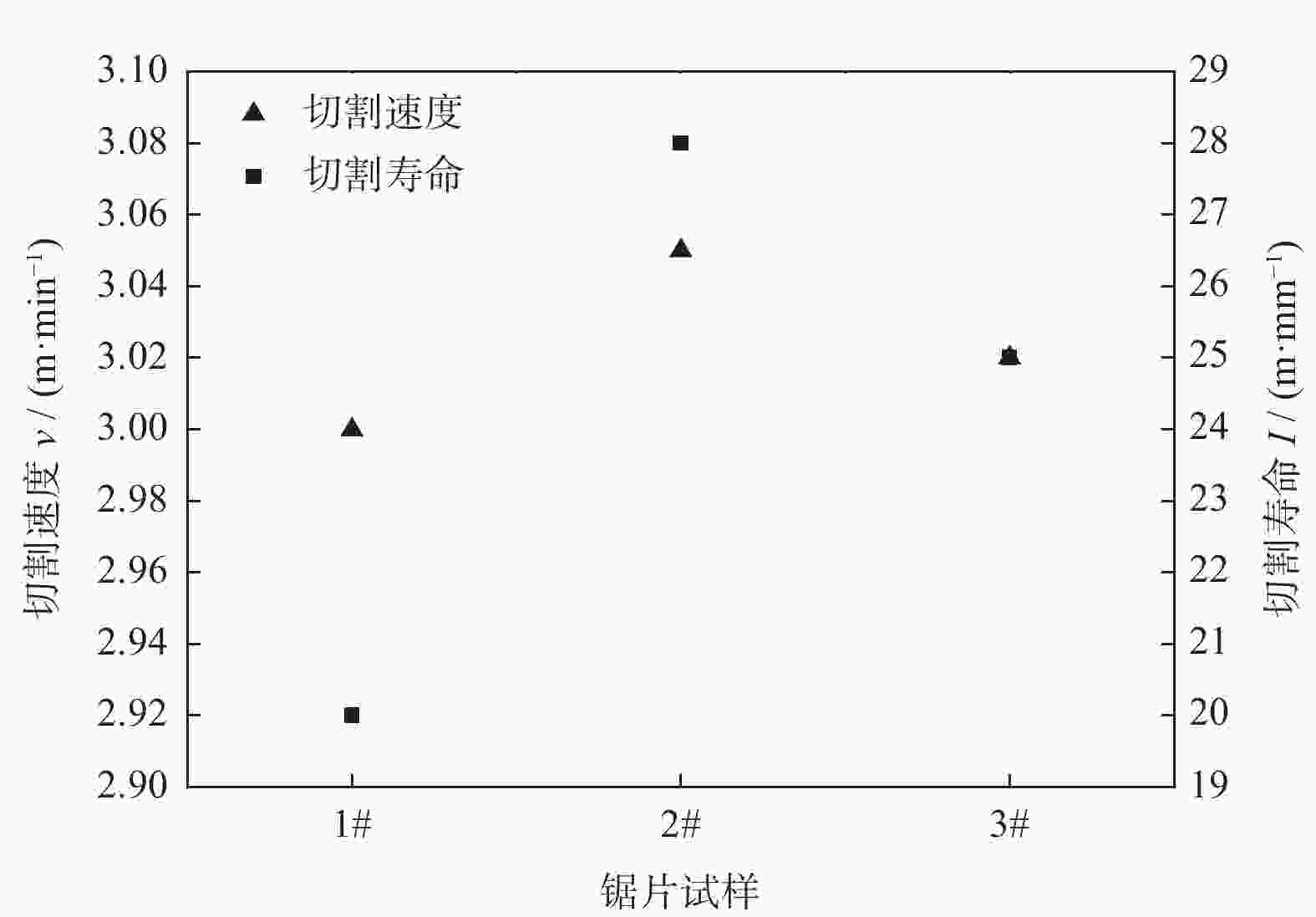

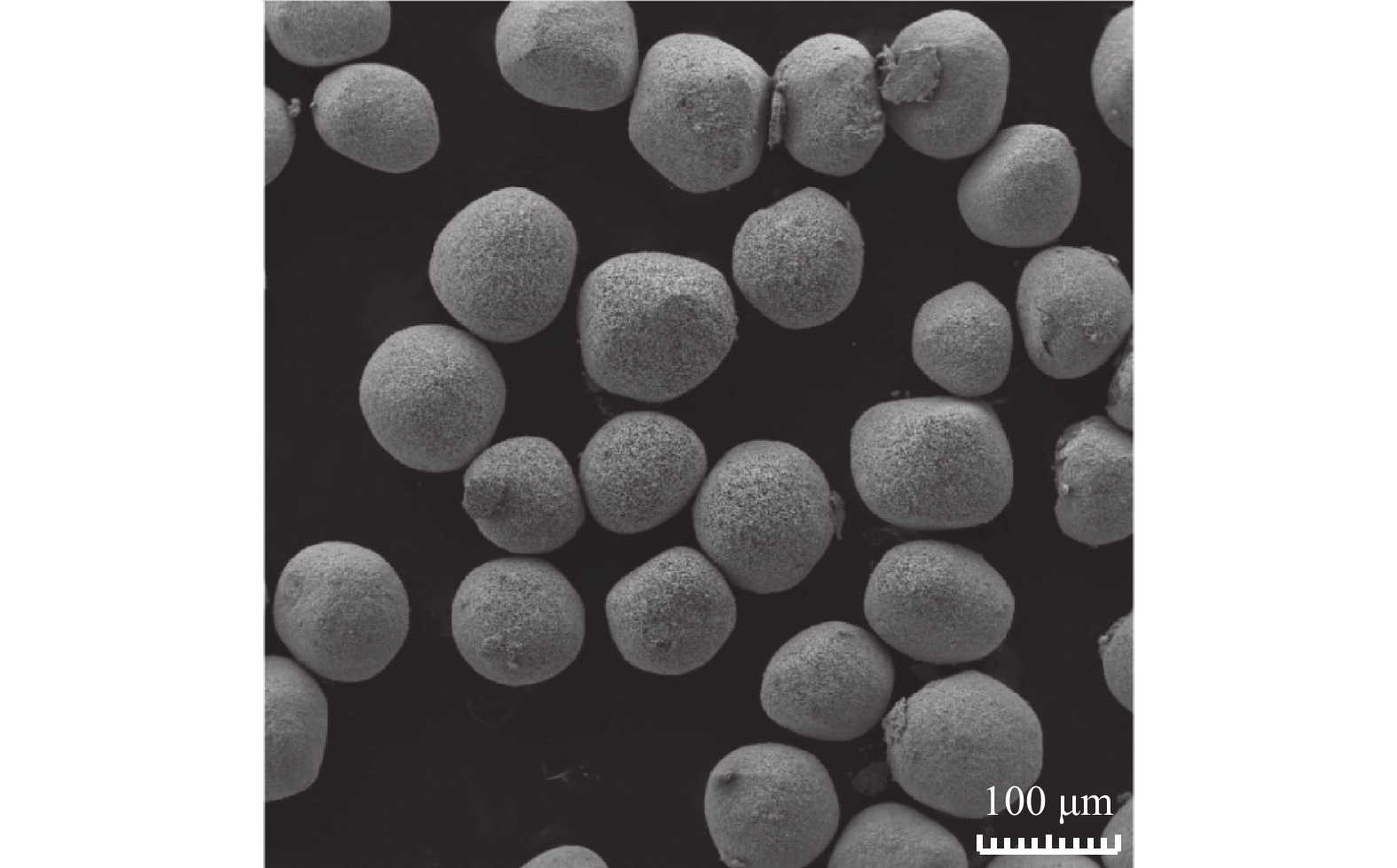

摘要: 对铸造WC、Co粉包覆铸造WC和Ni粉包覆铸造WC颗粒3种材料在金刚石锯片中的应用进行研究,探究其对金刚石锯片胎体机械性能、微观形貌及锯片切割性能的影响。结果表明:当3种材料与金属粉末的质量比都为3∶1时,形成的3种胎体的硬度相当。含Co粉包覆铸造WC的胎体抗弯强度最高,WC颗粒与胎体界面的结合最紧密,胎体显微组织最致密;含Ni粉包覆铸造WC的胎体的抗弯强度次之;仅加入铸造WC的胎体的抗弯强度最差。与仅加入铸造WC的锯片相比,Co粉包覆铸造WC应用到锯片中,其锯片的切割寿命最长,提高了40%。Abstract: The application of the cast WC, the Co powder coated cast WC and the Ni powder coated cast WC particles in diamond saw blades were studied, and their effects on the mechanical properties, the micro morphologies and the cutting properties of the diamond saw blade matrix were explored. The results show that when the mass ratio of the three kinds of WC material to the metal powder is 3∶1, the hardness of the three kinds of matrix is equivalent. The bending strength of the matrix containing Co powder coated cast WC is the highest, the interface between the WC particles and the matrix is the closest, and the microstructure of the matrix is the densest. The bending strength of the matrix containing Ni powder coated cast WC is the second. The matrix with only cast WC has the worst bending strength. Compared with the saw blade with only cast WC added, the cutting life of the saw blade with Co powder coated cast WC is the longest and increases by 40%.

-

Key words:

- diamond saw blade /

- cast WC /

- Co powder coated cast WC /

- bending strength /

- cutting life

-

表 1 胎体配方

Table 1. Matrix formula

编号 Cu

ω1/%Sn

ω2 / %Fe

ω3 / %Ni

ω4 / %Co

ω5 / %A

ωA / %B

ωB / %C

ωC / %1# 35 5 10 10 10 30 0 0 2# 35 5 10 10 0 0 40 0 3# 35 5 10 0 10 0 0 40 -

[1] 周强, 杨树忠, 常德民, 等. W对热压烧结铁基金刚石工具胎体组织性能的影响 [J]. 中国钨业,2018,33(3):61-66. doi: 10.3969/j.issn.1009-0622.2018.03.012ZHOU Qiang, YANG Shuzhong, CHANG Demin, et al. Effect of W on the microstructure and properties of hot pressed sintered iron matrix diamond tools [J]. China Tungsten Industry,2018,33(3):61-66. doi: 10.3969/j.issn.1009-0622.2018.03.012 [2] 左宏森, 徐坚, 王春华. 硬质材料在金刚石工具胎体中的作用 [J]. 金刚石与磨料磨具工程,2005(3):41-44.ZUO Hongsen, XU Jian, WANG Chunhua. Functions of hard material on the matrixes in diamond tools [J]. Diamond & Abrasives Engineering,2005(3):41-44. [3] 黄艳华, 贺跃辉, 谢志刚, 等. 金刚石工具用Ni-Co合金粉末的制备及表征 [J]. 超硬材料工程,2006(5):1-5. doi: 10.3969/j.issn.1673-1433.2006.05.001HUANG Yanhua, HE Yuehui, XIE Zhigang, et al. Preparation and characterization of Ni-Co alloyed powder used in diamond tools [J]. Superhard Material Engineering,2006(5):1-5. doi: 10.3969/j.issn.1673-1433.2006.05.001 [4] 宋月清, 殷声, 孙毓超, 等. 钴基金刚石工具胎体材料的研究 [J]. 机械工程材料,1993(3):42-44, 51.SONG Yueqing, YIN Sheng, SUN Yuchao, et al. Investigation on Co-base matrix of diamond tool [J]. Materials for Mechanical Engineering,1993(3):42-44, 51. [5] COSTA M, FLORES P, PEREIRA D, et al. Nickel-cobalt-based materials for diamond cutting tools [J]. The International Journal of Advanced Manufacturing Technology,2018,95(1):1059-1067. [6] SU Z, ZHANG S, LIU L, et al. Microstructure and performance characterization of Co-based diamond composites fabricated via fused deposition molding and sintering [J]. Journal of Alloys and Compounds,2021,871(3):159569. [7] 郑日升, 万隆, 曾成文, 等. FAM代钴预合金粉末在液相烧结条件下的性能研究 [J]. 超硬材料工程,2015,27(5):7-12. doi: 10.3969/j.issn.1673-1433.2015.05.002ZHENG Risheng, WAN Long, ZENG Chengwen, et al. Study of the performance of FAM cobalt replacing prealloy powder under liquid sintering condition [J]. Superhard Material Engineering,2015,27(5):7-12. doi: 10.3969/j.issn.1673-1433.2015.05.002 [8] 张健琼, 杨志威, 刘一波. 预合金粉末对金刚石石材锯片性能的影响 [J]. 超硬材料工程,2021,33(2):13-17. doi: 10.3969/j.issn.1673-1433.2021.02.005ZHANG Jianqiong, YANG Zhiwei, LIU Yibo. Impact of pr-alloyed powder on diamond saw blade performance [J]. Superhard Material Engineering,2021,33(2):13-17. doi: 10.3969/j.issn.1673-1433.2021.02.005 [9] 高冀芸, 刘晨辉, 王访, 等. 微波强化烧结制备铁钴基金刚石锯片刀头 [J]. 化工进展,2018,37(4):1529-1535.GAO Jiyun, LIU Chenhui, WANG Fang, et al. Fabrication of the diamond saw blade bits with Fe-Co metallic matrix by microwave strengthened sintering [J]. Chemical Industry and Engineering Progress,2018,37(4):1529-1535. [10] DUAN D Z, XIAO B, WANG B, et al. Microstructure and mechanical properties of pre-brazed diamond abrasive grains using Cu–Sn–Ti alloy [J]. International Journal of Refractory Metals and Hard Materials,2015,48:427-432. doi: 10.1016/j.ijrmhm.2014.10.015 [11] 杨金辉, 赖和怡. 硬质合金热处理和钴粘结相的转变温度 [J]. 北京钢铁学院学报,1988(2):183-189.YANG Jinhui, LAI Heyi. Heat treatment of WC-Co hard metals and transformation temperature of cobalt binder phase [J]. Journal of Beijing University of Iron and Steel Technology,1988(2):183-189. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS