Effect of chips on drilling process when drilling C/SiC ceramic matrix composite holes with brazed diamond abrasive drill

-

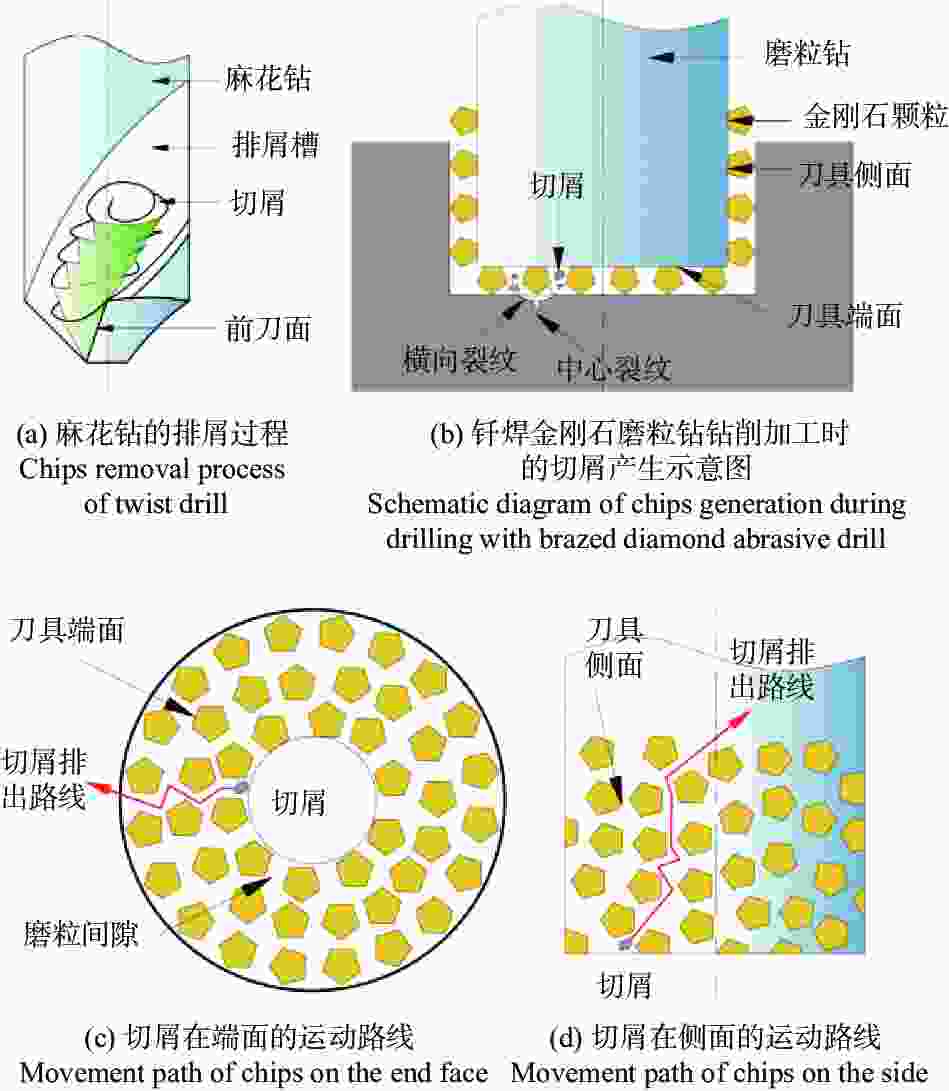

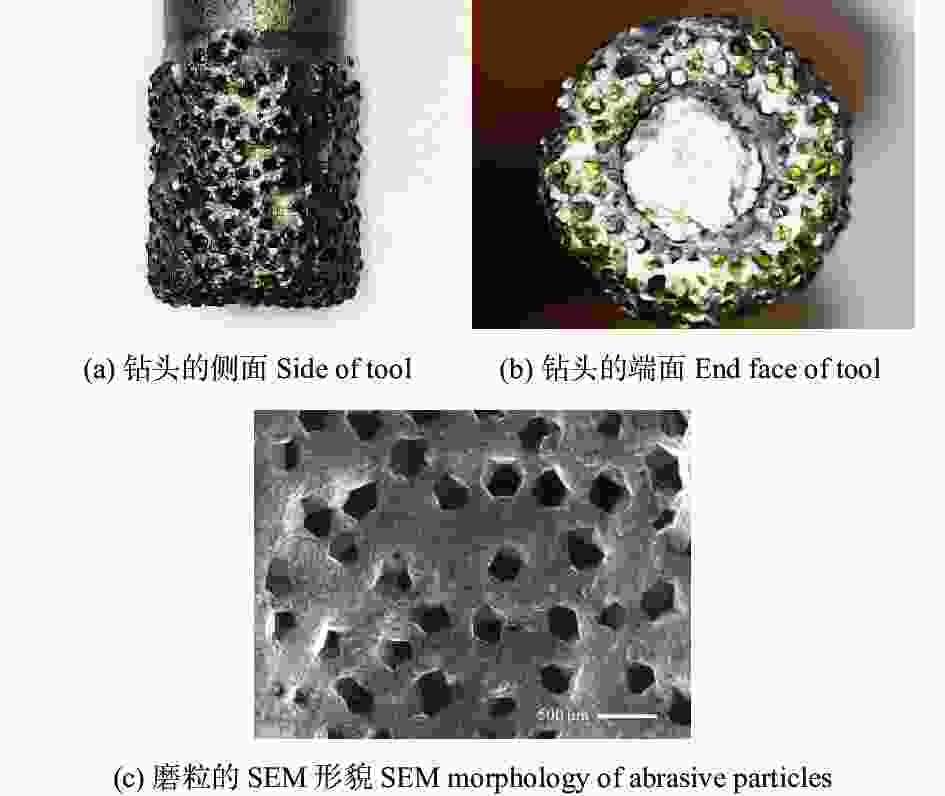

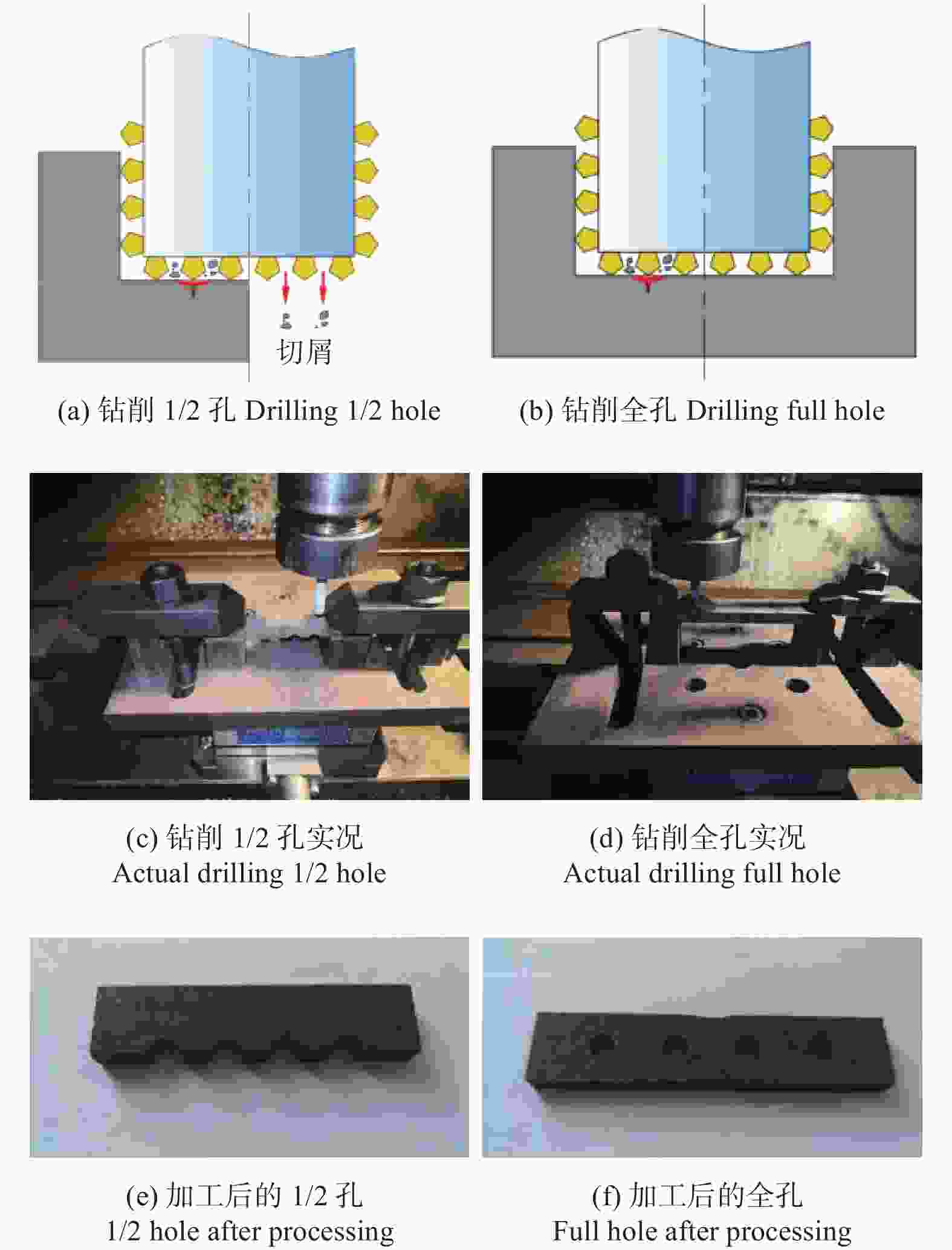

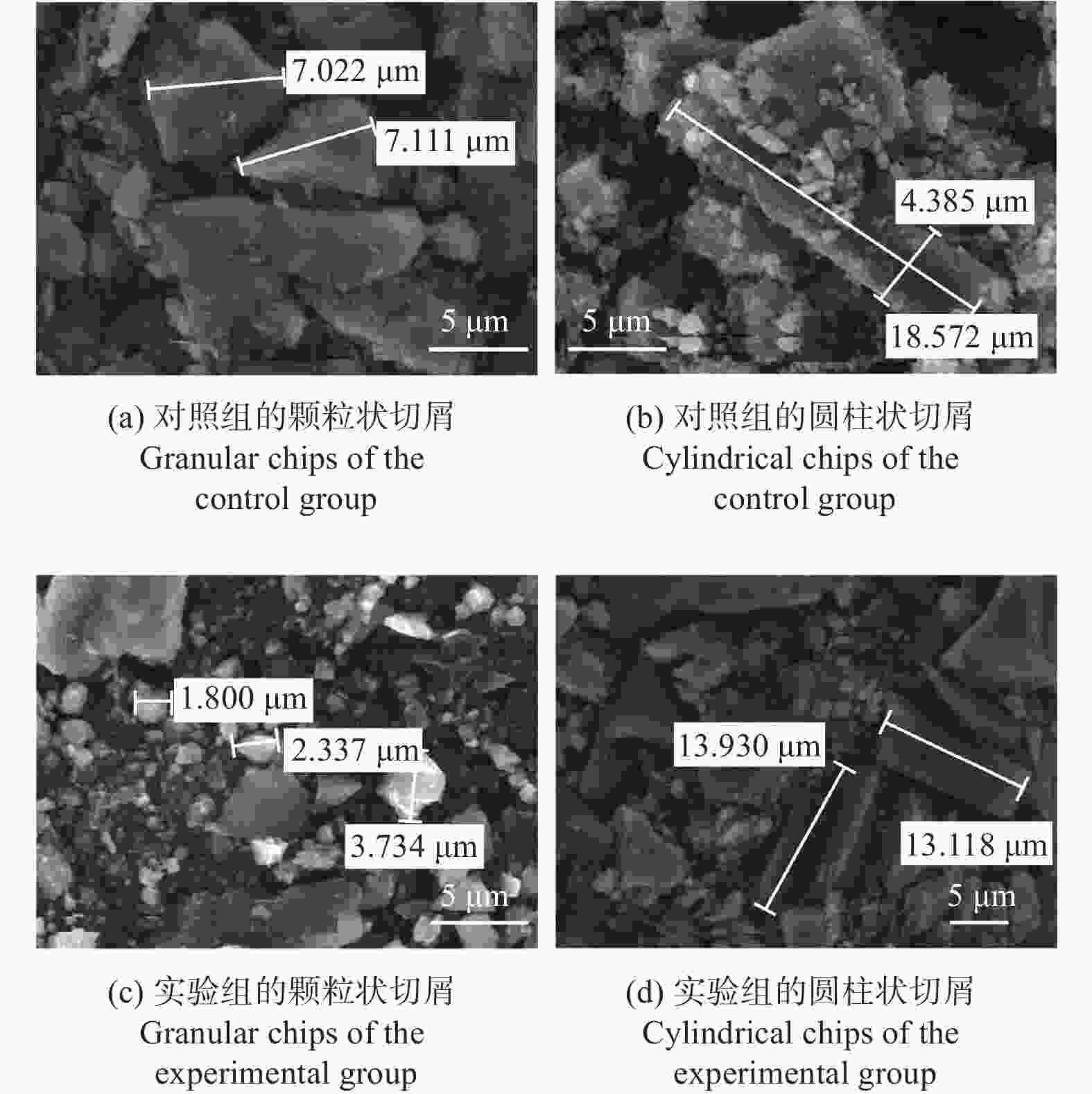

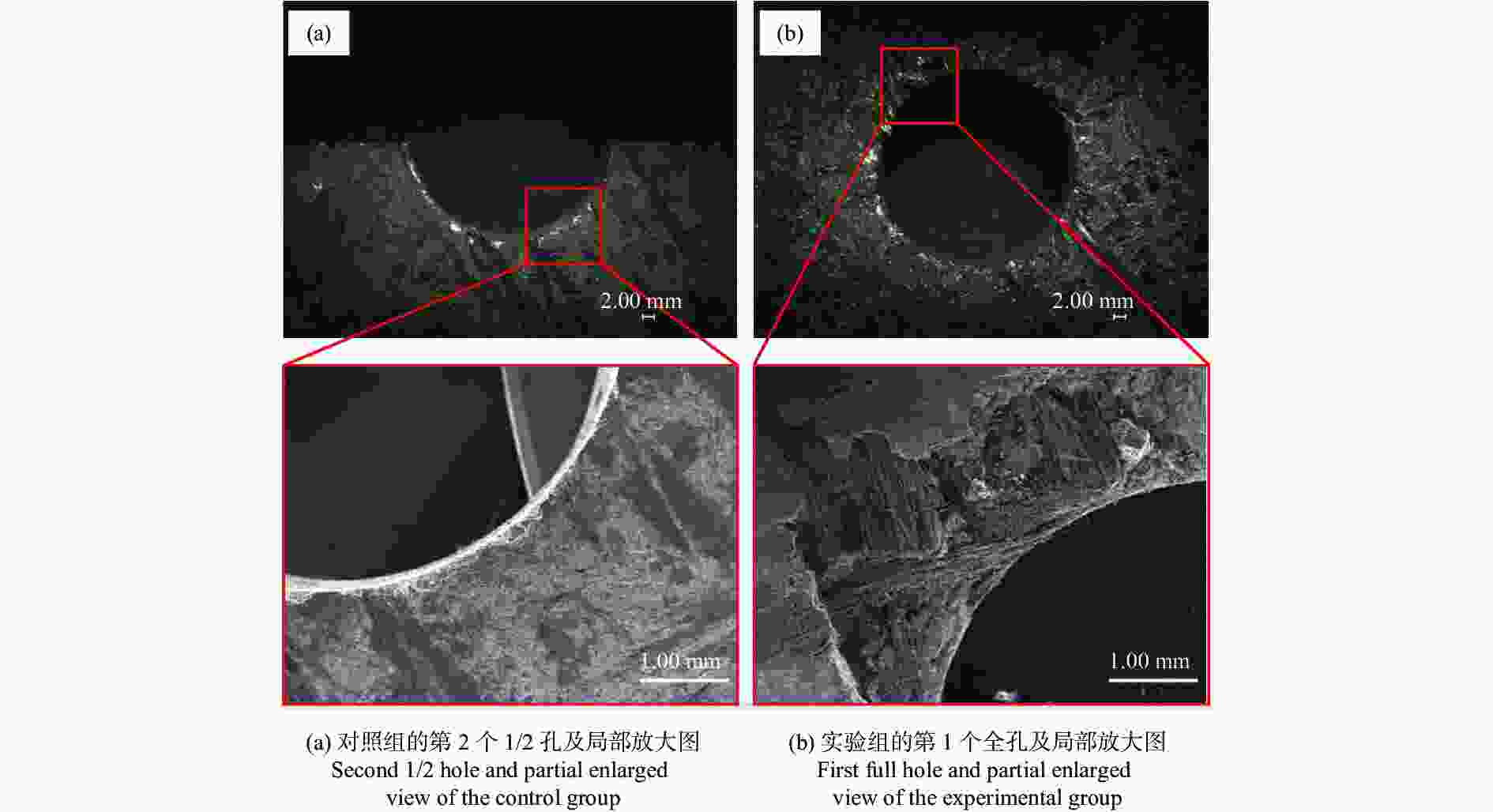

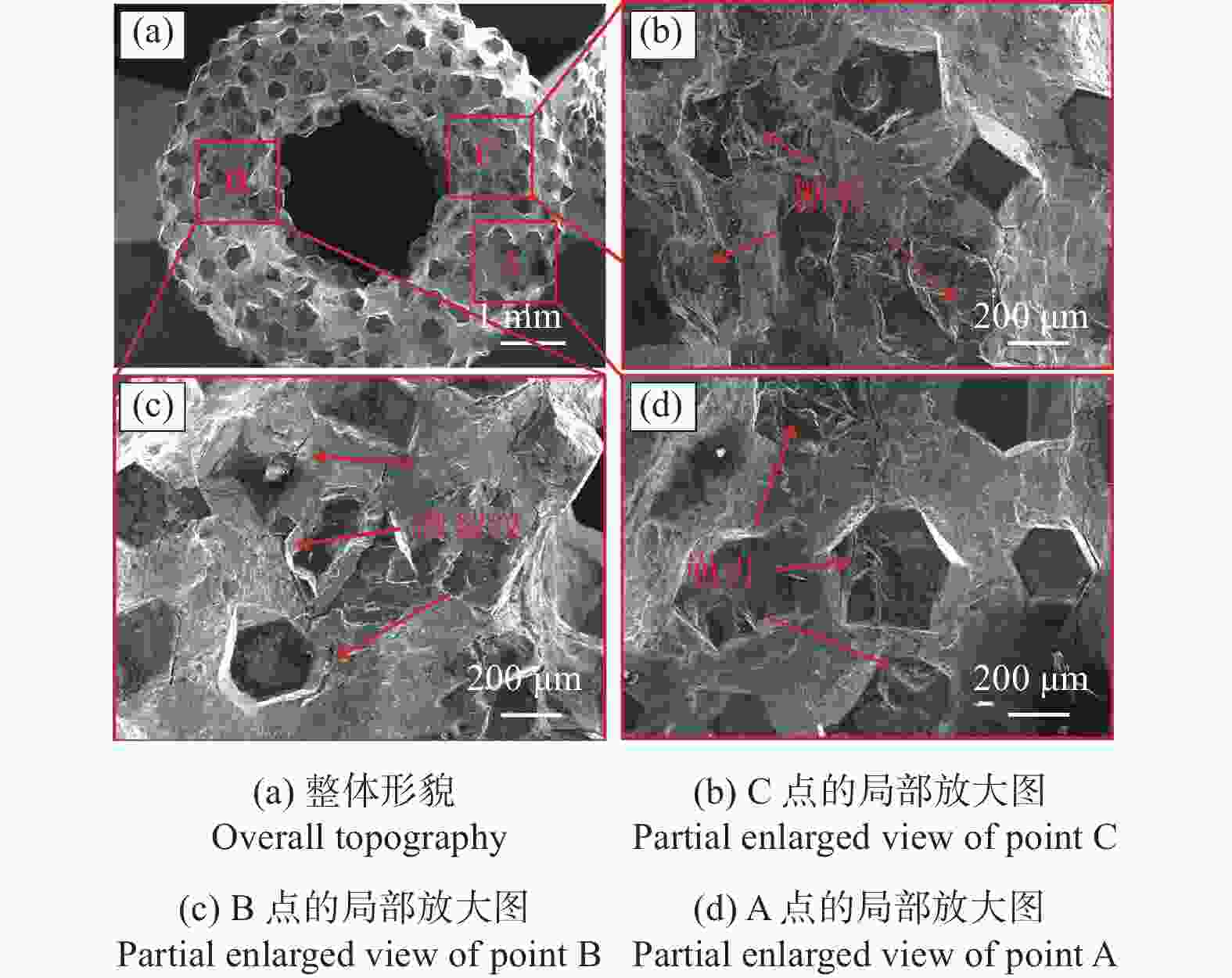

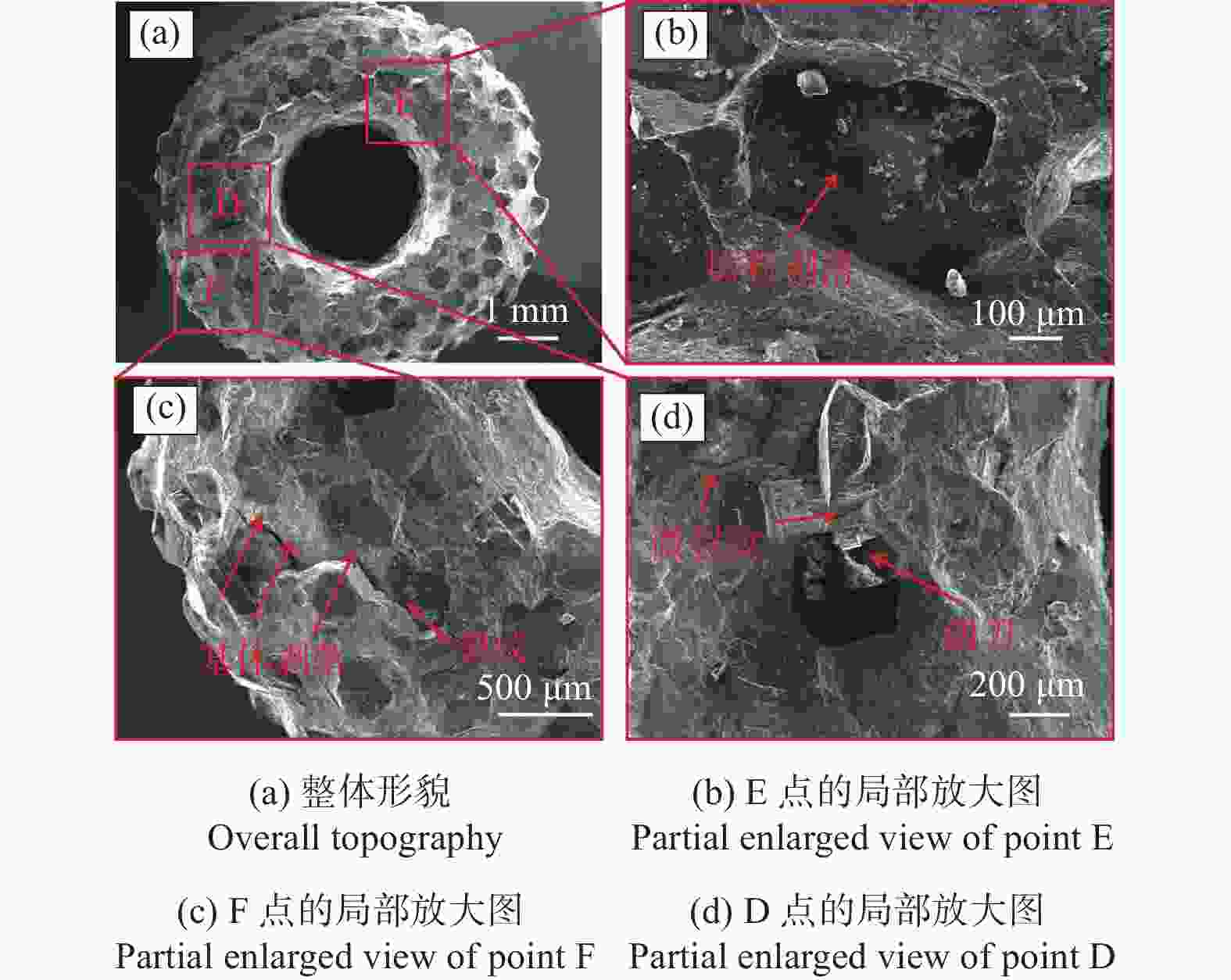

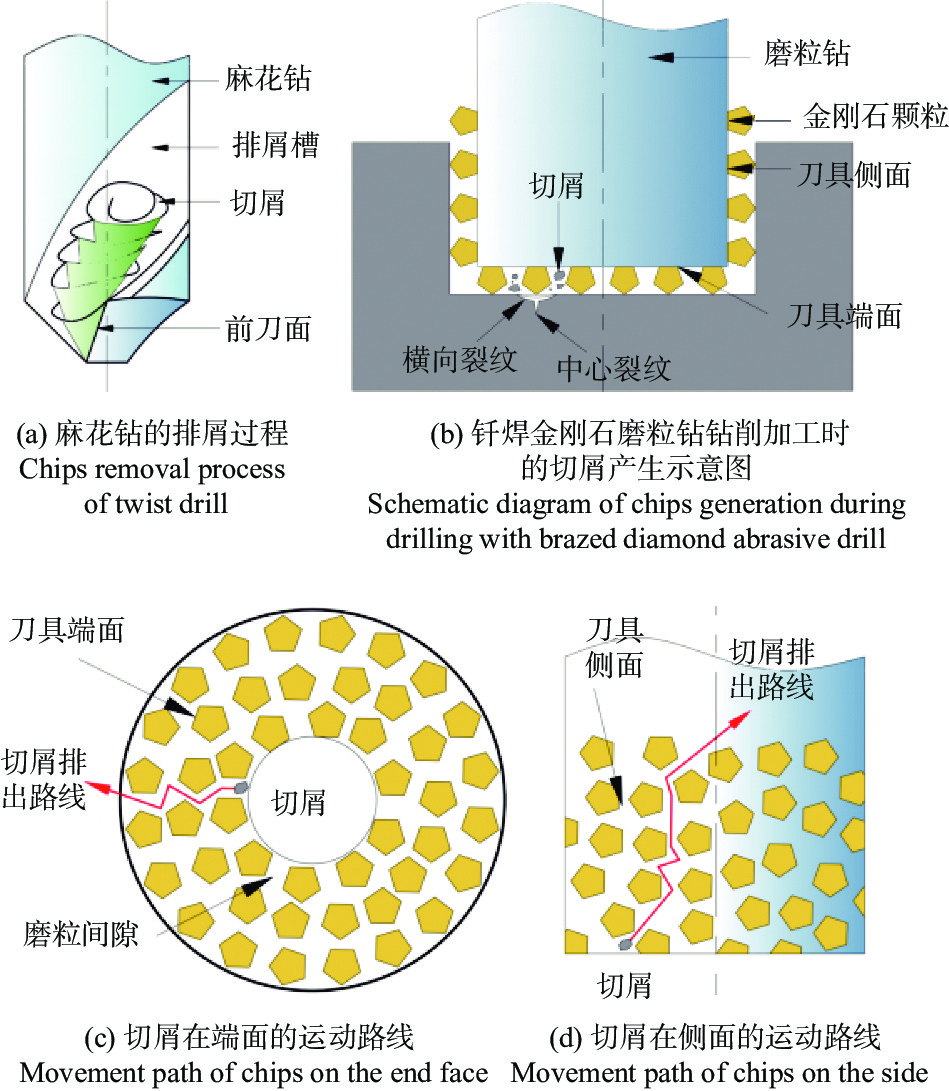

摘要: 钎焊金刚石磨粒钻适合钻削碳纤维增强碳化硅陶瓷基复合材料孔,但大量切屑会对孔的钻削过程产生不利影响。为此,针对切屑排出过程,分析切屑形貌,研究钻削时切屑对轴向钻削力、孔加工质量、钻头磨损的影响。结果表明:切屑对轴向钻削力有影响,尤其钻削深孔时影响显著。切屑对孔进口的加工质量几乎没有影响,只表现为孔进口处的轻微崩边;切屑对孔出口的加工质量影响显著,可引起严重的纤维断裂、撕裂缺陷以及基体的大区域脱落。同时,切屑加剧钻头磨损,使钻头不仅出现崩刃、微裂纹等轻微磨损,而且还产生基体剥落、金刚石剥落等严重磨损行为。

-

关键词:

- 碳纤维增强碳化硅陶瓷基复合材料 /

- 钎焊金刚石磨粒钻 /

- 切屑 /

- 轴向钻削力 /

- 钻头磨损

Abstract: Brazed diamond abrasive drill was suitable for drilling holes in carbon fiber reinforced silicon carbide ceramic matrix composites, but a large amount of chips could adversely affect the drilling process of the holes. Therefore, according to the chip discharge process, the chip morphology was analyzed, and the effects of chips on the axial drilling force, the hole processing quality and the drill wear during drilling were studied. The results show that the chips have an effects on the axial drilling forces, especially when drilling deep holes. The chips have little effects on the machining quality of the hole inlet, only a slight edge collapses at the hole inlet. The chips have a significant impacts on the processing quality of the hole outlet, which can cause serious fiber breakage, tear defects, and large areas of the matrix shedding. At the same time, the chip intensifies the drill wear, which not only causes slight wear such as edge collapse and micro crack, but also produces serious wear behaviors such as matrix peeling and diamond peeling. -

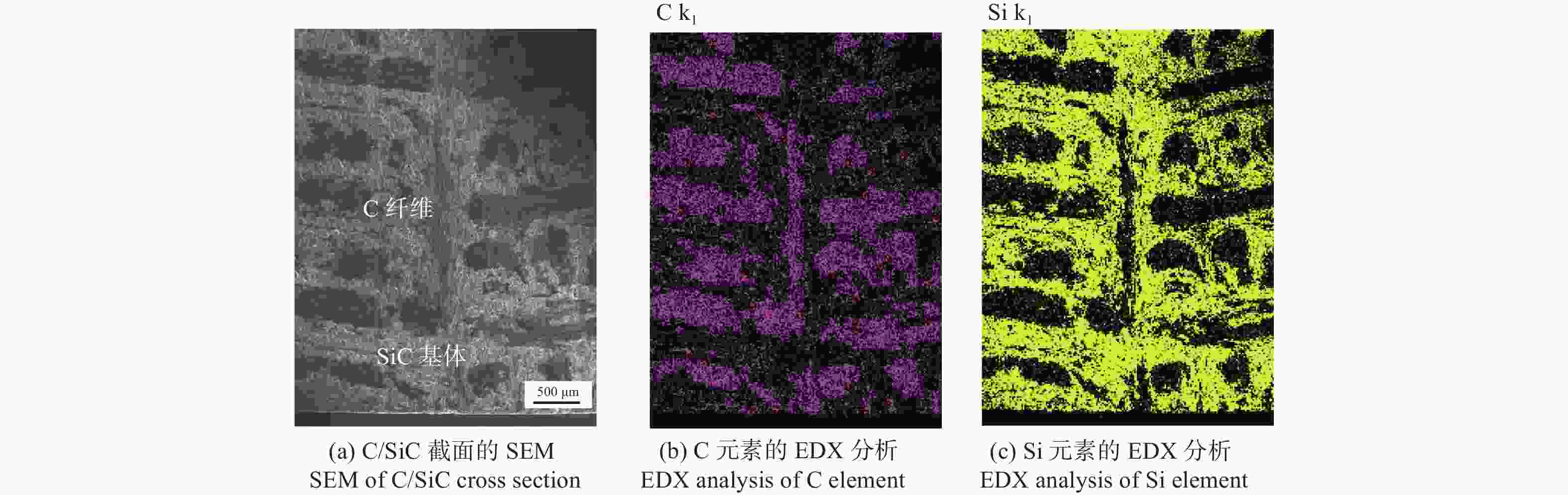

表 1 C/SiC的力学和物理性能参数

Table 1. Mechanical and physical properties of C/SiC

参数 取值 密度 ρ / (g·cm−3) 1.9 孔隙率 φ / % 5 拉伸强度 σ1 / MPa 87.5 压缩强度 σ2 / MPa 460 弯曲强度 σ3 / MPa 260 弹性模量 E / GPa 40 层间剪切强度 σ4 / MPa 20 断裂韧性 KIC / (MPa·m1/2) 10 SiC基体硬度 H / GPa 22.2 -

[1] DIAZ O G, LUNA G G, LIAO Z, et al. The new challenges of machining ceramic matrix composites (CMCs): Review of surface integrity [J]. International Journal of Machine Tools & Manufacture,2019,139:24-36. [2] 王晶, 成来飞, 刘永胜, 等. 碳化硅陶瓷基复合材料加工技术研究进展 [J]. 航空制造技术,2016(15):50-56.WANG Jing, CHENG Laifei, LIU Yongsheng, et al. Research development on processing technology of silicon carbide ceramic matrix composites [J]. Aeronautical Manufacturing Technology,2016(15):50-56. [3] DU J, ZHANG H, GENG Y, et al. A review on machining of carbon fiber reinforced ceramic matrix composites [J]. Ceramics International,2019,45(15):18155-18166. doi: 10.1016/j.ceramint.2019.06.112 [4] CHEN J, AN Q, MING W, et al. Hole exit quality and machined surface integrity of 2D Cf / SiC composites drilled by PCD tools [J]. Journal of the European Ceramic Society,2019,39(14):4000-4010. doi: 10.1016/j.jeurceramsoc.2019.05.057 [5] ZOU F, CHEN J, AN Q, et al. Influences of clearance angle and point angle on drilling performance of 2D Cf / SiC composites using polycrystalline diamond tools [J]. Ceramics International,2020,46(4):4371-4380. doi: 10.1016/j.ceramint.2019.10.161 [6] 朱彬, 张明军, 胡永乐, 等. 光纤激光钎焊金刚石磨粒工艺试验研究 [J]. 应用激光,2019,39(5):840-846.ZHU Bin, ZHANG Mingjun, HU Yongle, et al. Experimental research on fiber laser brazing of diamond grains [J]. Applied Laser,2019,39(5):840-846. [7] 黄武, 苏宏华, 张昆, 等. 单颗钎焊金刚石磨粒磨损试验研究 [J]. 金刚石与磨料磨具工程,2016,36(2):15-18.HUANG Wu, SU Honghua, ZHANG Kun, et al. Wear experiment of single brazed diamond abrasive [J]. Diamond & Abrasives Engineering,2016,36(2):15-18. [8] XING Y, DENG J, ZHANG G, et al. Assessment in drilling of C/C-SiC composites using brazed diamond drills [J]. Journal of Manufacturing Processes,2017,26:31-43. doi: 10.1016/j.jmapro.2017.01.006 [9] 张国栋. C/C-SiC复合材料钻削加工试验研究 [D]. 济南: 山东大学, 2015ZHANG Guodong. Experimental study on drilling C/C-SiC composites [D]. Jinan: Shandong University, 2015. [10] WANG J, FENG P, ZHANG J, et al. Modeling the dependency of edge chipping size on the material properties and cutting force for rotary ultrasonic drilling of brittle materials [J]. International Journal of Machine Tools & Manufacture,2016,101:18-27. [11] WANG J, FENG P, ZHENG J, et al. Improving hole exit quality in rotary ultrasonic machining of ceramic matrix composites using a compound step-taper drill [J]. Ceramics International,2016,42(12):13387-13394. doi: 10.1016/j.ceramint.2016.05.095 [12] LAWN B R, EVANS A G, MARSHALL D B. Elastic/plastic indentation damage in ceramics: The median/radial crack system [J]. Journal of the American Ceramic Society,1980,63(9/10):574-581. [13] MARSHALL D B, LAWN B R, EVANS A G. Elastic/plastic indentation damage in ceramics: The lateral crack system [J]. Journal of the American Ceramic Society,1982,65(11):561-566. doi: 10.1111/j.1151-2916.1982.tb10782.x [14] YANG Y, QU S, GONG Y. Investigating the grinding performance of unidirectional and 2.5D-C/SiCs [J]. Ceramics International,2021,47(4):5123-5132. doi: 10.1016/j.ceramint.2020.10.090 [15] OSO S, ISMAIL S O, PAGGI M, et al. A new analytical critical thrust force model for delamination analysis of laminated composites during drilling operation [J]. Composites Part B: Engineering,2017,124:207-217. doi: 10.1016/j.compositesb.2017.05.039 [16] CHENG H O, DHARAN H. Delamination during drilling in composite laminates [J]. Journal of Manufacturing Science and Engineering,1990,112(3):236-239. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS