Wear properties of HFCVD diamond films on SiC substrate

-

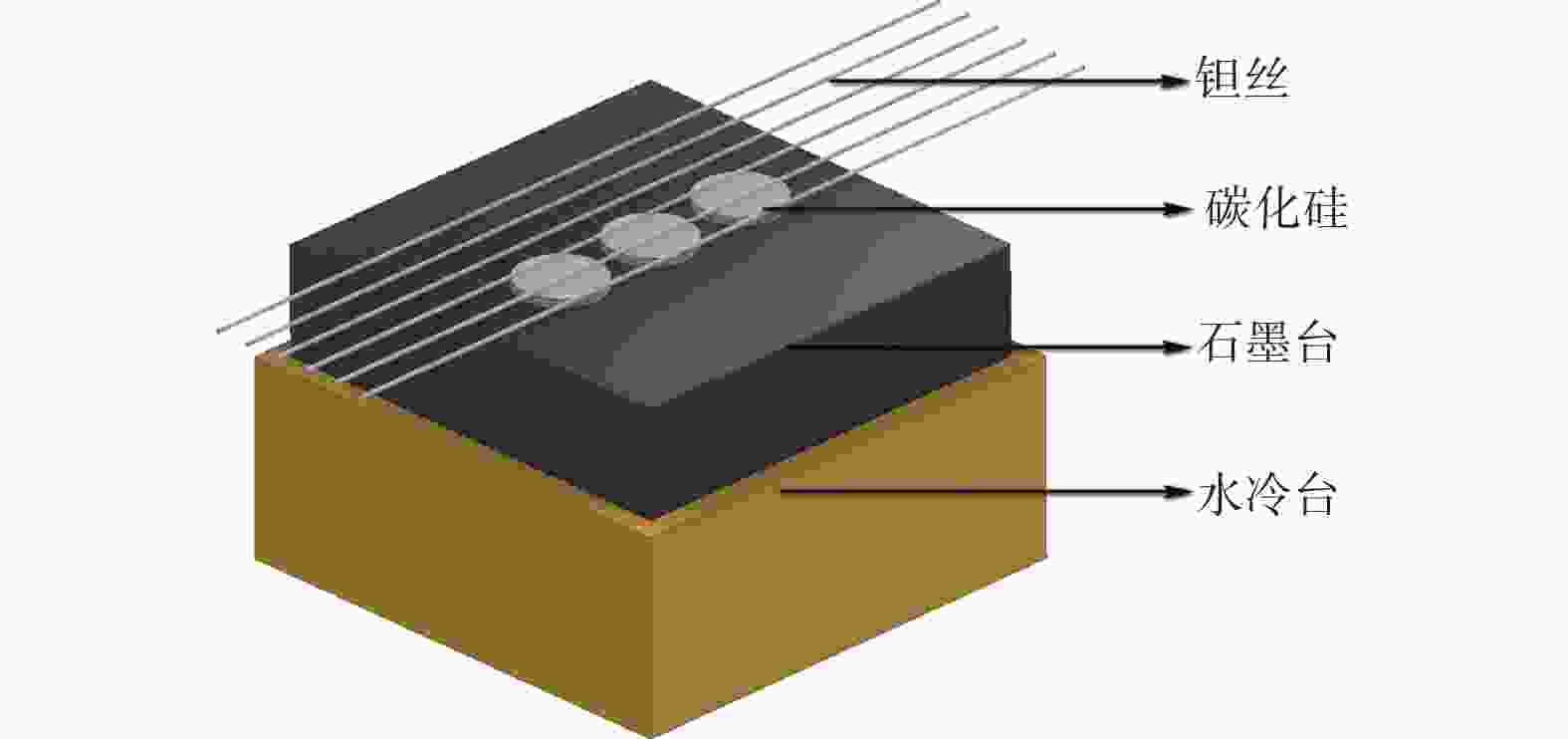

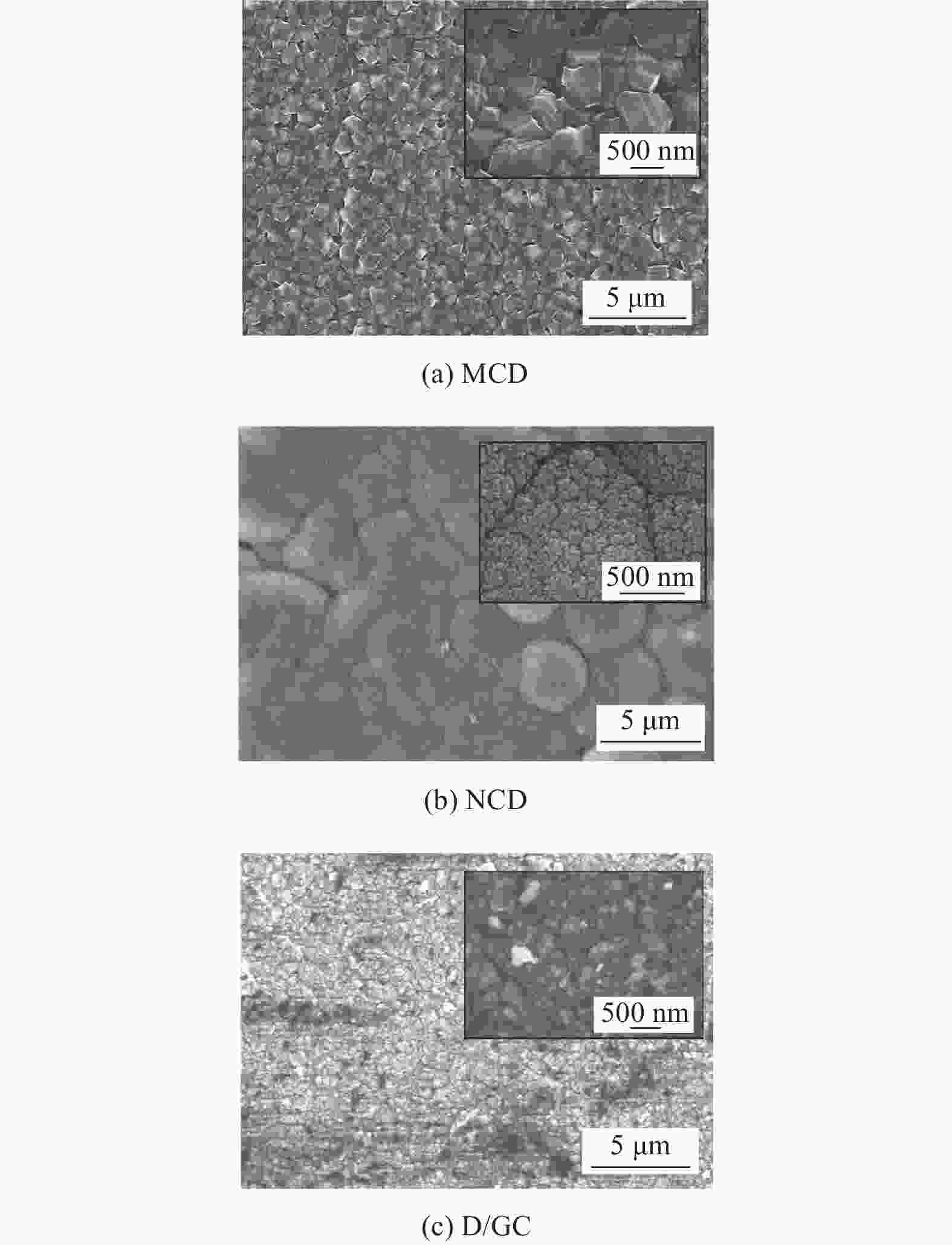

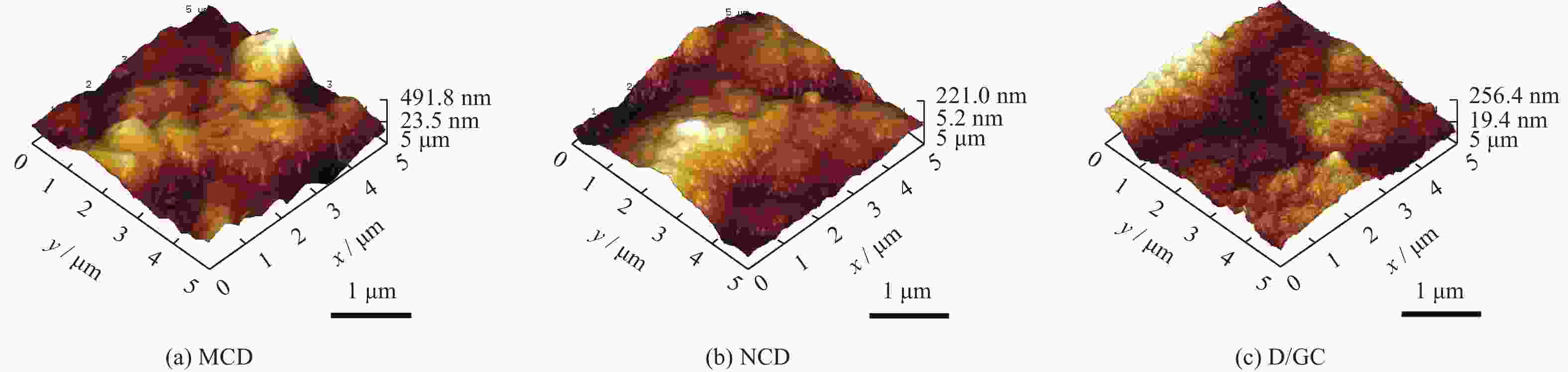

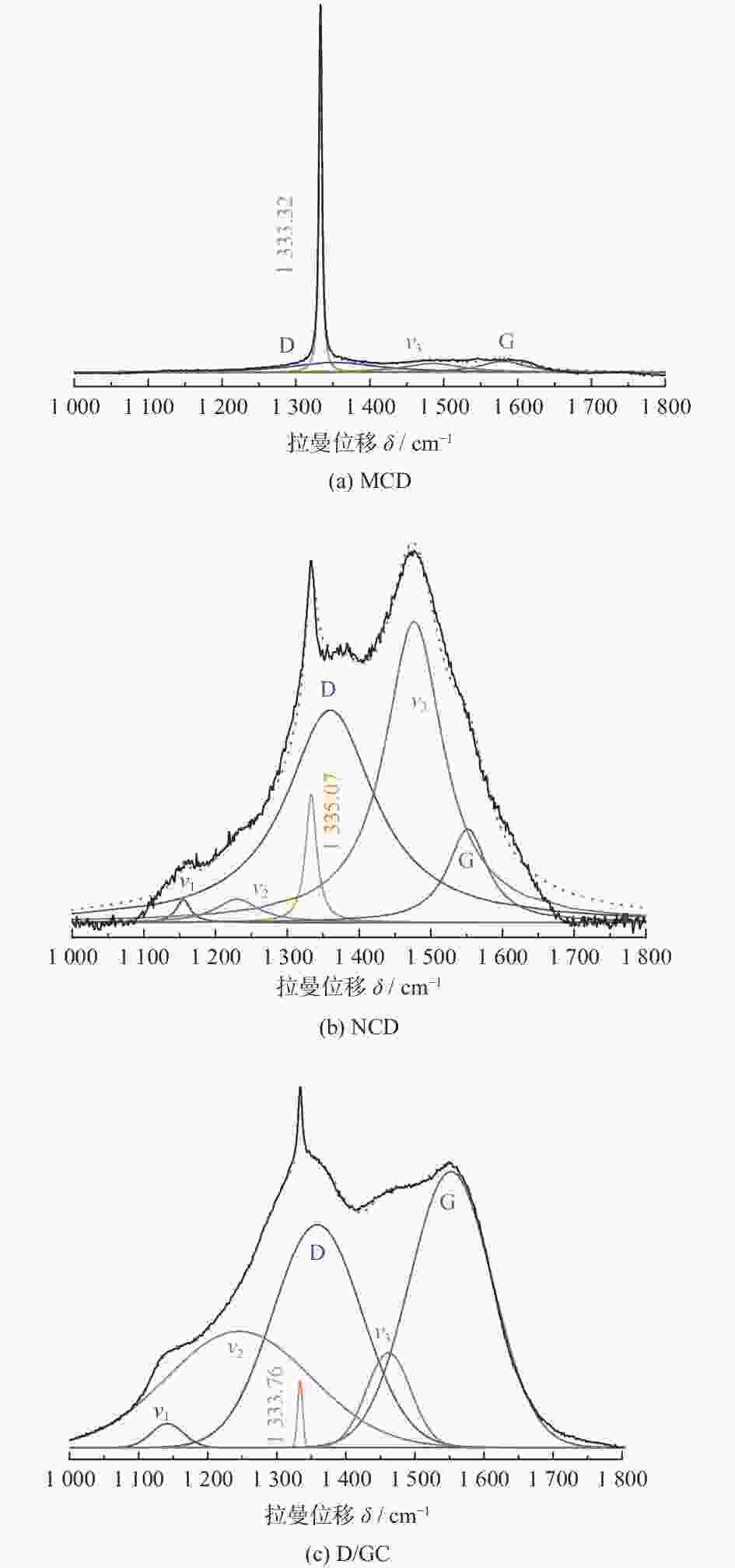

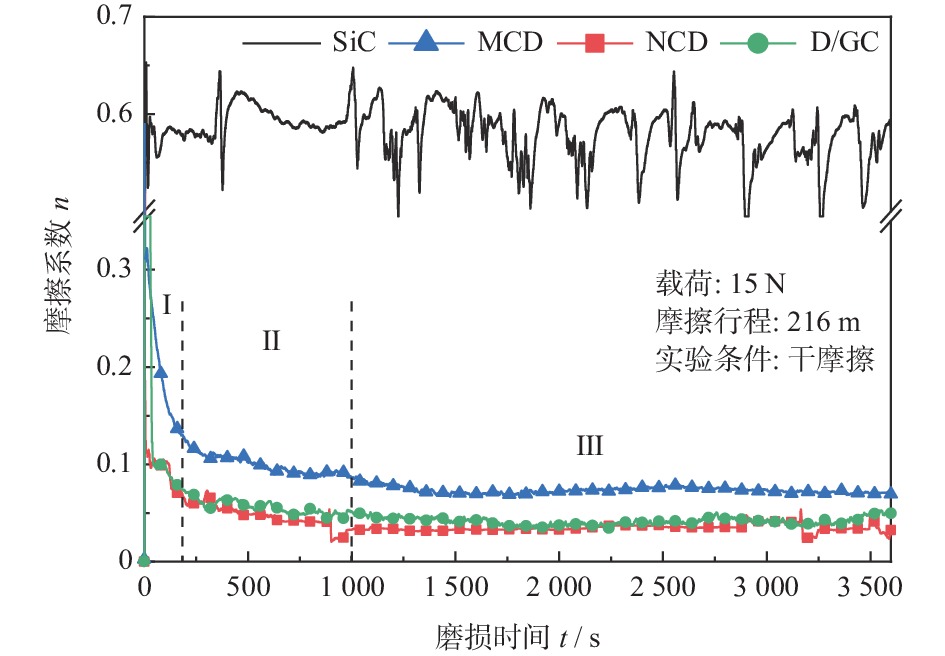

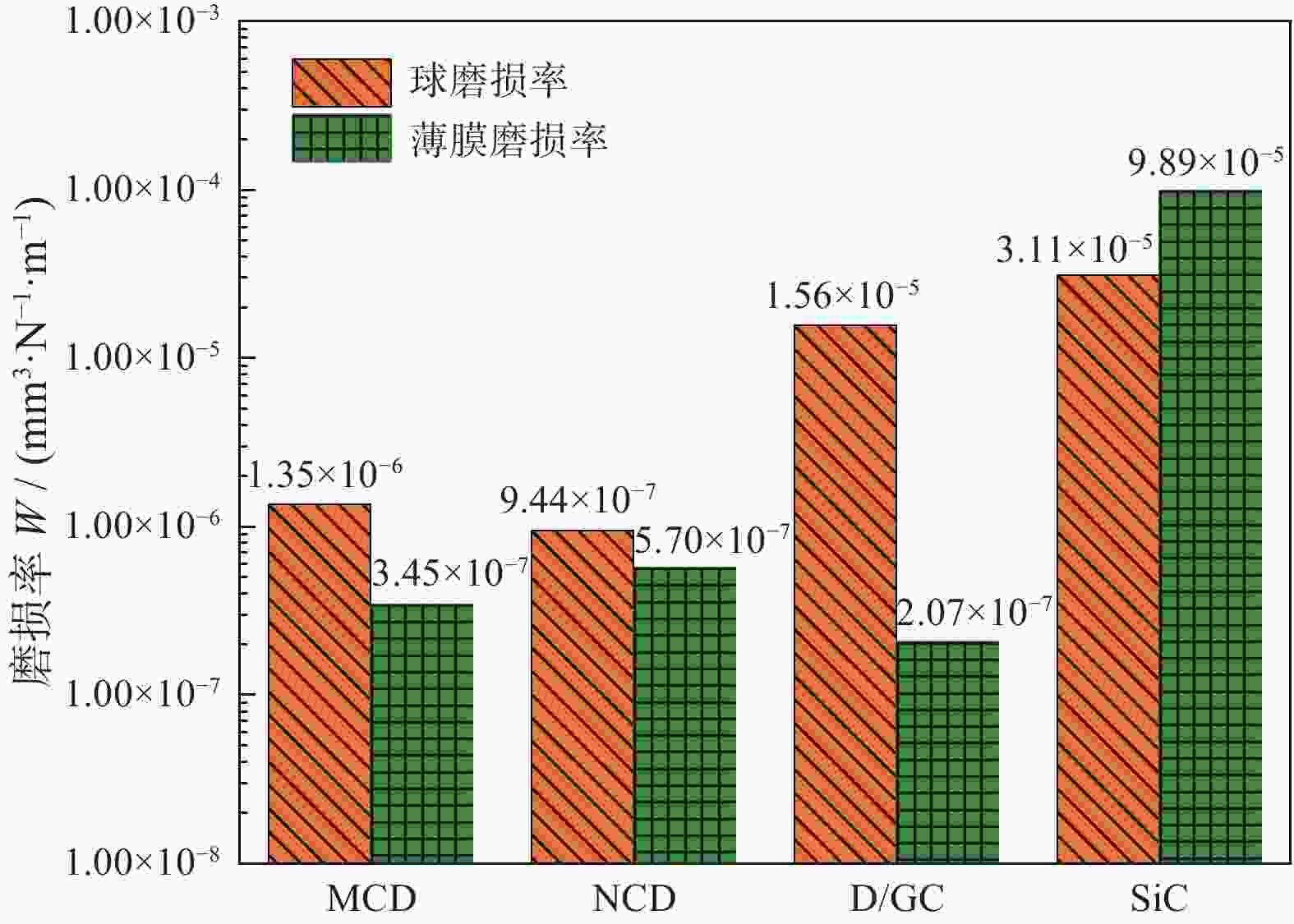

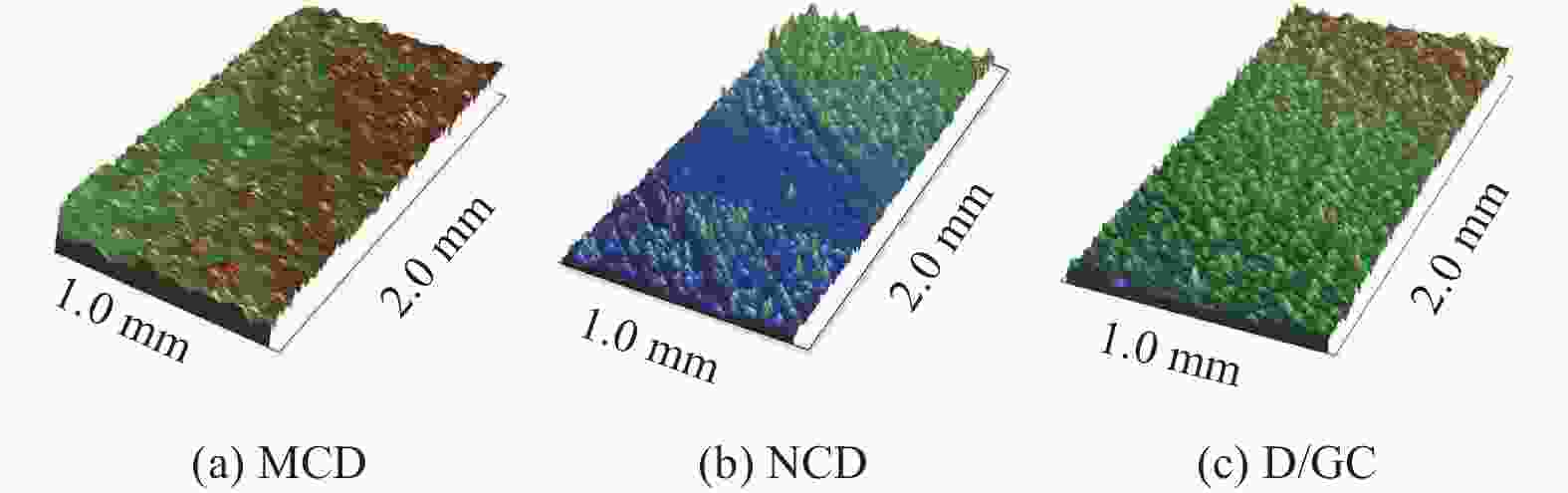

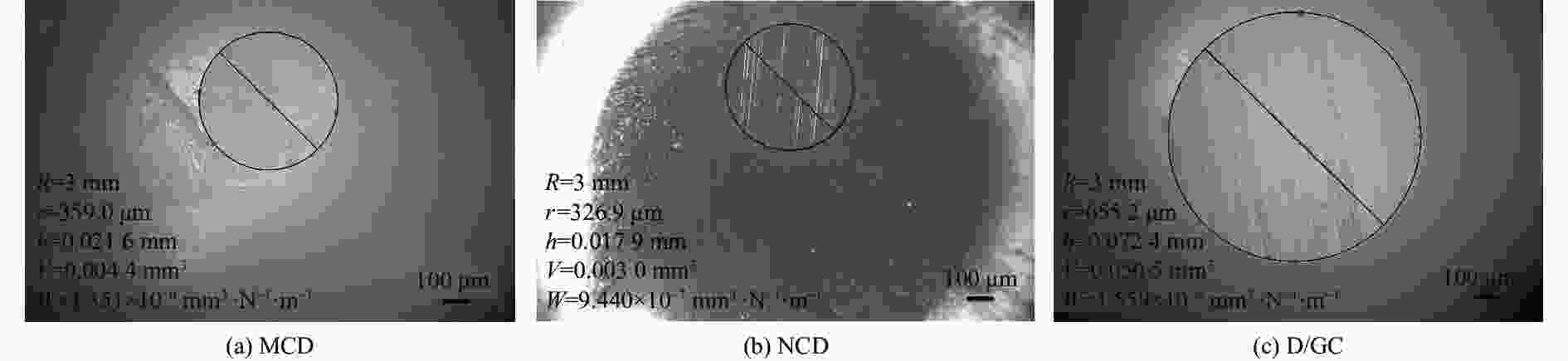

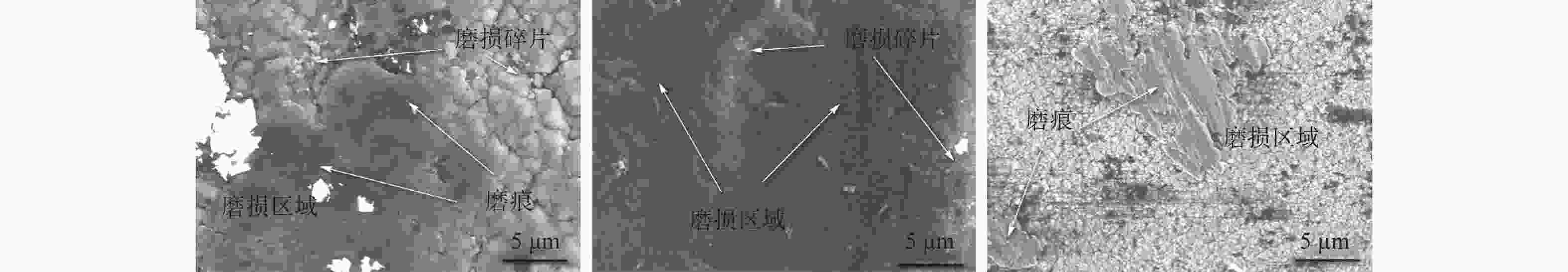

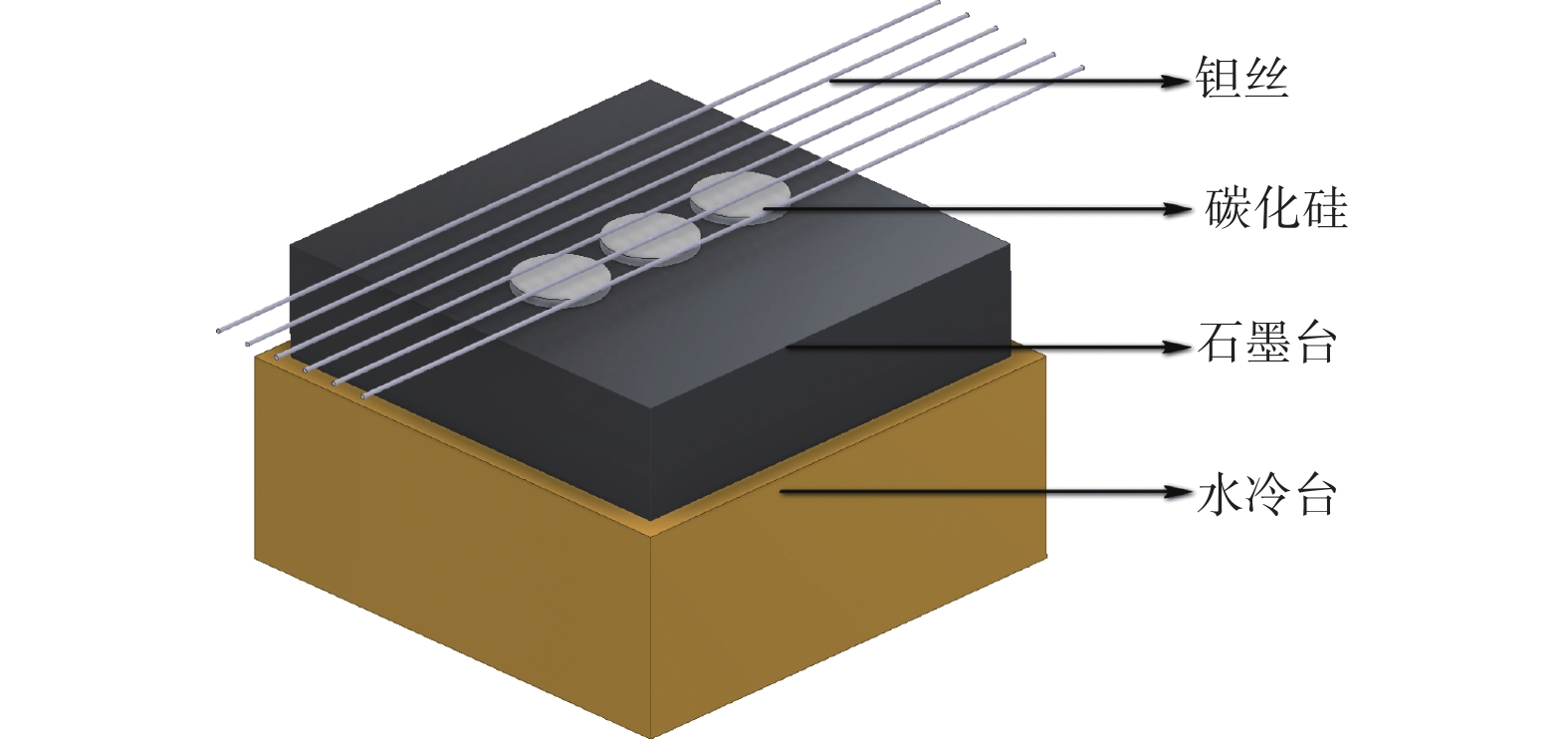

摘要: 利用热丝化学气相沉积技术在碳化硅基底上制备微米金刚石薄膜、纳米金刚石薄膜和金刚石–石墨复合薄膜,采用扫描电子显微镜、原子力显微镜和拉曼光谱仪对不同金刚石薄膜的表面形貌和微观结构进行表征,通过摩擦磨损实验测试金刚石薄膜的摩擦系数并计算其磨损率,对比研究不同种类金刚石薄膜的摩擦磨损性能。结果表明:金刚石–石墨复合薄膜具有较好的摩擦磨损性能,薄膜表面粗糙度为53.8 nm,摩擦系数为0.040,和纳米金刚石薄膜(0.037)相当;金刚石–石墨复合薄膜的磨损率最低,为2.07×10−7 mm3·N−1·m−1。在相同实验条件下,同碳化硅基底的磨损率(9.89×10−5 mm3·N−1·m−1)和摩擦系数(0.580)相比,所有金刚石薄膜的磨损率和摩擦系数均有明显提升,说明在SiC基体表面沉积金刚石薄膜能够显著提高碳化硅材料在摩擦学领域的使役性能。Abstract: Micro-diamond film, nano-diamond film and diamond-graphite composite film were deposited on silicon carbide substrate by hot filament chemical vapor deposition. The surface morphology and phase of the grown diamond films were analyzed using scanning electron microscope, atomic force microscope and Raman spectrometer. The friction coefficient and the wear rate of diamond films were measured by friction experiments. The friction and wear properties of diamond films were studied by comparing the experimental results. The results show that the diamond-graphite composite film has better friction and wear properties, the surface roughness of which is 53.8 nm. The friction coefficient (0.040) is similar to that of the nano-diamond film (0.037), while the wear rate is the lowest, 2.07×10−7 mm3·N−1·m−1. Compared with those of SiC substrate, the wear rate (9.89×10−5 mm3·N−1·m−1) and the friction coefficient (0.580) of the diamond films have been greatly improved, which indicates that depositing diamond on the surface of SiC substrate significantly improves the performance of the silicon carbide in the field of friction.

-

Key words:

- diamond film /

- silicon carbide /

- graphite /

- friction and wear /

- hot filament chemical vapor deposition

-

表 1 金刚石薄膜沉积参数

Table 1. Deposition parameters of diamond film

参数 MCD NCD D/GC 甲烷流量 VM /sccm① 4 20 20 基底温度 θs / ℃ 930±10 860±10 930±10 热丝数量 n 6 6 6 热丝直径 df / mm 0.5 0.5 0.5 热丝–基底间距 d / mm 8 8 8 腔室气压 p / Pa 1000 1000 1000 热丝温度 θf / oC 2600±50 2600±50 2600±50 沉积时间 t / h 3 3 3 氢气流量 VH /sccm 400 400 400 注:① sccm为体积流量单位(standard cubic centimeter per minute), 表示每分钟流过的标准状况下的气体体积(以cm3计)。 -

[1] GAYDAYCHUK A, LINNIK S. Tribological and mechanical properties of diamond films synthesized with high methane concentration [J]. International Journal of Refractory Metals and Hard Materials,2019,85:105057. doi: 10.1016/j.ijrmhm.2019.105057 [2] 范冰庆, 王传新, 徐远钊, 等. 沉积气压对金刚石膜微米纳米结构转变的影响 [J]. 金刚石与磨料磨具工程,2021,41(1):12-16. doi: 10.13394/j.cnki.jgszz.2021.1.0002FAN Bingqing, WANG Chuanxin, XU Yuanzhao, et al. Influence of deposition pressure on micron-nanometer transition of diamond film [J]. Diamond & Abrasives Engineering,2021,41(1):12-16. doi: 10.13394/j.cnki.jgszz.2021.1.0002 [3] 邓福铭, 陈立, 刘畅, 等. 微米、纳米及微/纳米复合金刚石涂层的切削性能研究 [J]. 金刚石与磨料磨具工程,2015,35(4):1-5,10. doi: 10.13394/j.cnki.jgszz.2015.4.0001DENG Fuming, CHEN Li, LIU Chang, et al. Study on the cutting properties of micro- nano- and micro/nano diamond coatings [J]. Diamond & Abrasives Engineering,2015,35(4):1-5,10. doi: 10.13394/j.cnki.jgszz.2015.4.0001 [4] 吕反修. 化学气相沉积金刚石膜的研究与应用进展 [J]. 材料热处理学报,2010,31(1):15-28.LÜ Fanxiu. Progress in research and application development of CVD diamond film [J]. Transactions of Materials and Heat Treatment,2010,31(1):15-28. [5] BUNDY F P, HALL H T, STRONG H M, et al. Man-made diamonds [J]. Nature,1955,176(4471):51-55. doi: 10.1038/176051a0 [6] WANG X C, ZHANG J G, SHEN B, et al. Erosion mechanism of the boron-doped diamond films of different thicknesses [J]. Wear,2014,312(1/2):1-10. doi: 10.1016/j.wear.2014.01.010 [7] CHEN N C, PU L W, SUN F H, et al. Tribological behavior of HFCVD multilayer diamond film on silicon carbide [J]. Surface and Coatings Technology,2015,272:66-71. doi: 10.1016/j.surfcoat.2015.04.023 [8] PRABHAKARAN G S, BHATTACHARYA S S, RAO M S R. Synthesis and characterisation of nanocrystalline, microcrystalline and functionally graded diamond coatings on reaction bonded SiC [J]. Materials Today: Proceedings,2018,5(3):10062-10070. doi: 10.1016/j.matpr.2017.10.207 [9] 黄元盛, 邱万奇, 罗承萍, 等. CVD金刚石的形核和生长 [J]. 理化检验(物理分册),2006,42(8):382-385.HUANG Yuansheng, QIU Wanqi, LUO Chengping, et al. Nucleation and growth of CVD diamond [J]. Physical Testing and Chemical Analysis (Part A: Physical Testing),2006,42(8):382-385. [10] 梁小平. Y-TZP基陶瓷材料摩擦磨损的研究 [D]. 天津: 天津大学, 2003.LIANG Xiaoping. Studies on the friction and wear of Y-TZP matrix ceramic materials [D]. Tianjin: Tianjin University, 2003. [11] PRABHAKARAN G S, BHATTACHARYA S S, RAO M S R. A comparative study of the mechanical and tribological properties of intermittently and continuously grown multilayer diamond films on RB-SiC [J]. Diamond and Related Materials,2020,110:108140. doi: 10.1016/j.diamond.2020.108140 [12] 杨国栋. 陶瓷基CVD金刚石薄膜的制备、摩擦试验及其应用研究 [D]. 上海: 上海交通大学, 2010.YANG Guodong. Study on the deposition, tribological properties and applications of CVD diamond films coated ceramics [D]. Shanghai: Shanghai Jiao Tong University, 2010. [13] 苏庆德. WC-Al2O3复合材料在不同工况下的摩擦磨损性能研究 [D]. 上海: 东华大学, 2020.SU Qingde. Investigation on the tribological properties of the WC-Al2O3 composites under different working conditions [D]. Shanghai: Donghua University, 2020. [14] TIAN Q Q, YANG B, ZHUANG H, et al. Hybrid diamond/graphite films: Morphological evolution, microstructure and tribological properties [J]. Diamond and Related Materials,2016,70:179-185. doi: 10.1016/j.diamond.2016.10.020 [15] 秦文波. 聚晶金刚石对磨陶瓷材料摩擦表界面结构演化机理 [D]. 北京: 中国地质大学(北京), 2019.QIN Wenbo. Structural evolution mechanism on the sliding interfaces of polycrystalline diamond sliding against ceramic materials [D]. Beijing: China University of Geosciences (Beijing), 2019. [16] PODGURSKY V, BOGATOV A, YASHIN M, et al. Relation between self-organization and wear mechanisms of diamond films [J]. Entropy (Basel),2018,20(4):279. doi: 10.3390/e20040279 [17] 张珂, 姜云浩, 陆峰, 等. 氮化硅表面生长金刚石薄膜及其摩擦磨损性能研究 [J]. 沈阳建筑大学学报(自然科学版),2017,33(4):688-695. doi: 10.11717/j.issn:2095-1922.2017.04.14ZHANG Ke, JIANG Yunhao, LU Feng, et al. Preparation and tribology property of diamond film on silicon nitride [J]. Journal of Shenyang Jianzhu University (Natural Science),2017,33(4):688-695. doi: 10.11717/j.issn:2095-1922.2017.04.14 [18] SHEN B, LIN Q, CHEN S L, et al. High-rate synthesis of ultra-nanocrystalline diamond in an argon-free hot filament chemical vapor deposition atmosphere for tribological films [J]. Surface and Coatings Technology,2019,378(7/8):124999. doi: 10.1016/j.surfcoat.2019.124999 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS