Influencing factors of power consumption in grinding iron ore with diamond cutter head

-

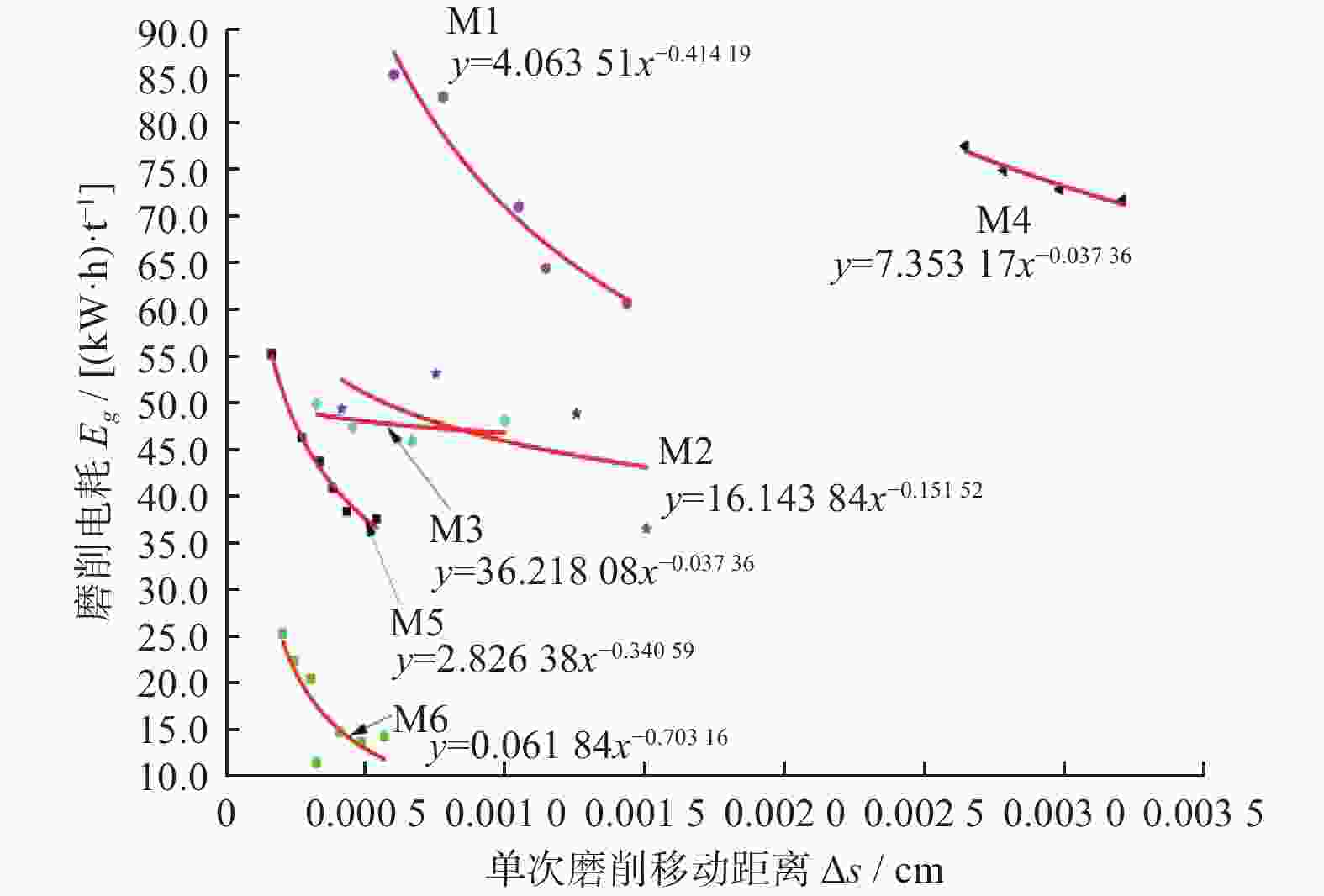

摘要: 金刚石刀头磨削铁矿石的电耗是磨采机作业的核心指标,通过搭建实验台并采用2种金刚石圆锯片和2种磨轮对2种铁矿石样本进行磨削实验,得到不同刀头及磨削线速度、磨削厚度、磨削宽度、磨削移动速率等参数下的电耗实验数据,据此计算及分析磨削效率和电耗间的关系。结果表明:矿石1的磁性铁区、矿石2的石英区和磁性铁区额定电机电耗平均值分别为50.41、36.05和15.17 (kW·h)/ t,且添加铁片的锋利型刀头可有效降低铁矿石的磨削电耗;在一定范围内增加磨削宽度和金刚石磨轮直径,可提高磨削效率并降低电耗,且矿石的岩石特性对磨削电耗影响较大。此外,合适的金刚石刀头磨削方向有利于矿浆收集,并最大化地切向推压对切削力的增益效果。单次磨削移动距离Δs与磨削效率密切相关,且与金刚石切入深度Δh直接相关。在M1~M6 6个实验方案中Δs值范围分别为6.01~14.35、3.23~9.96、4.14~15.04、26.44~32.09、1.62~5.37和2.02~5.64 μm时调整Δs值,能够有效降低磨削电耗;且当M1~M6的Δs值分别为14.35、6.65、15.04、32.09、5.37和3.22 μm时,磨削电耗最低。但要确定最适用的Δs值,需综合考虑金刚石工具的尺寸结构、刀头性能、矿石的岩石特性、作业参数、刀头受力情况等因素,以找到其适应不同情况的合理取值范围。Abstract:

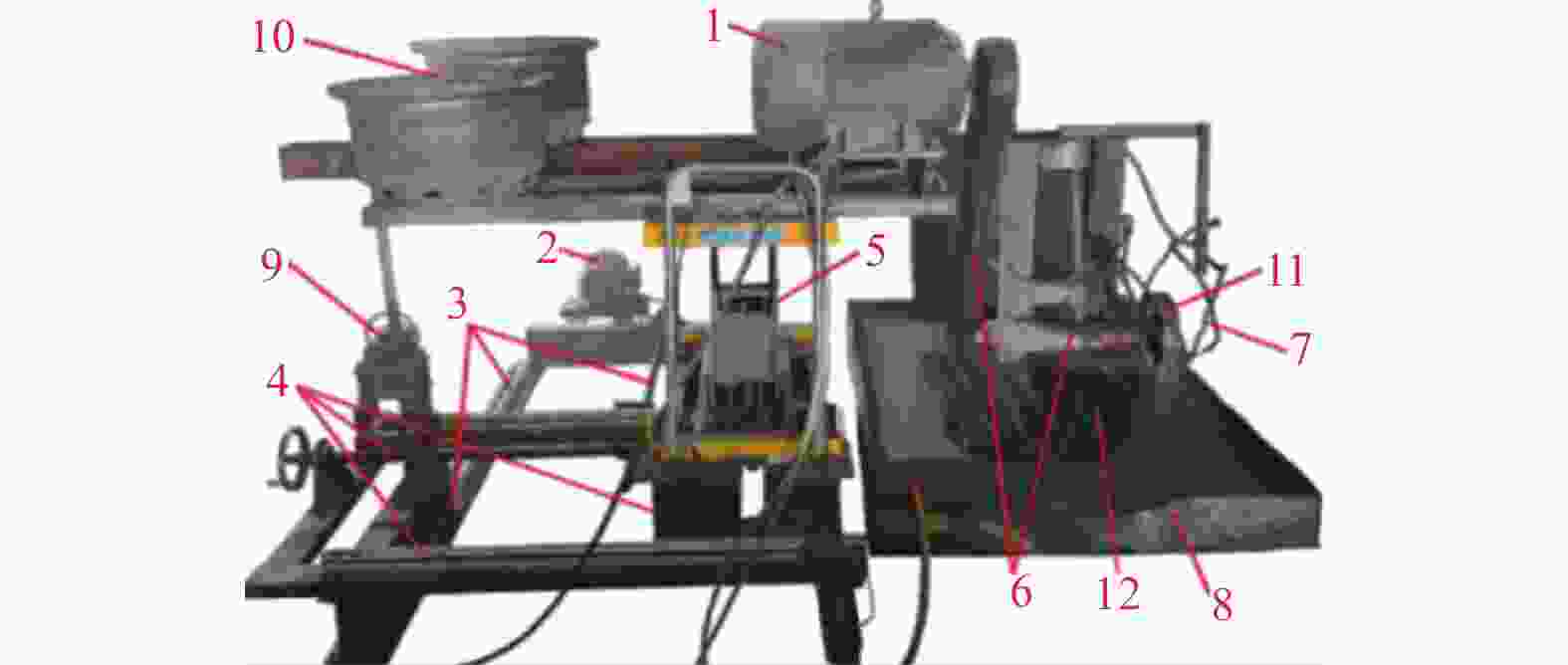

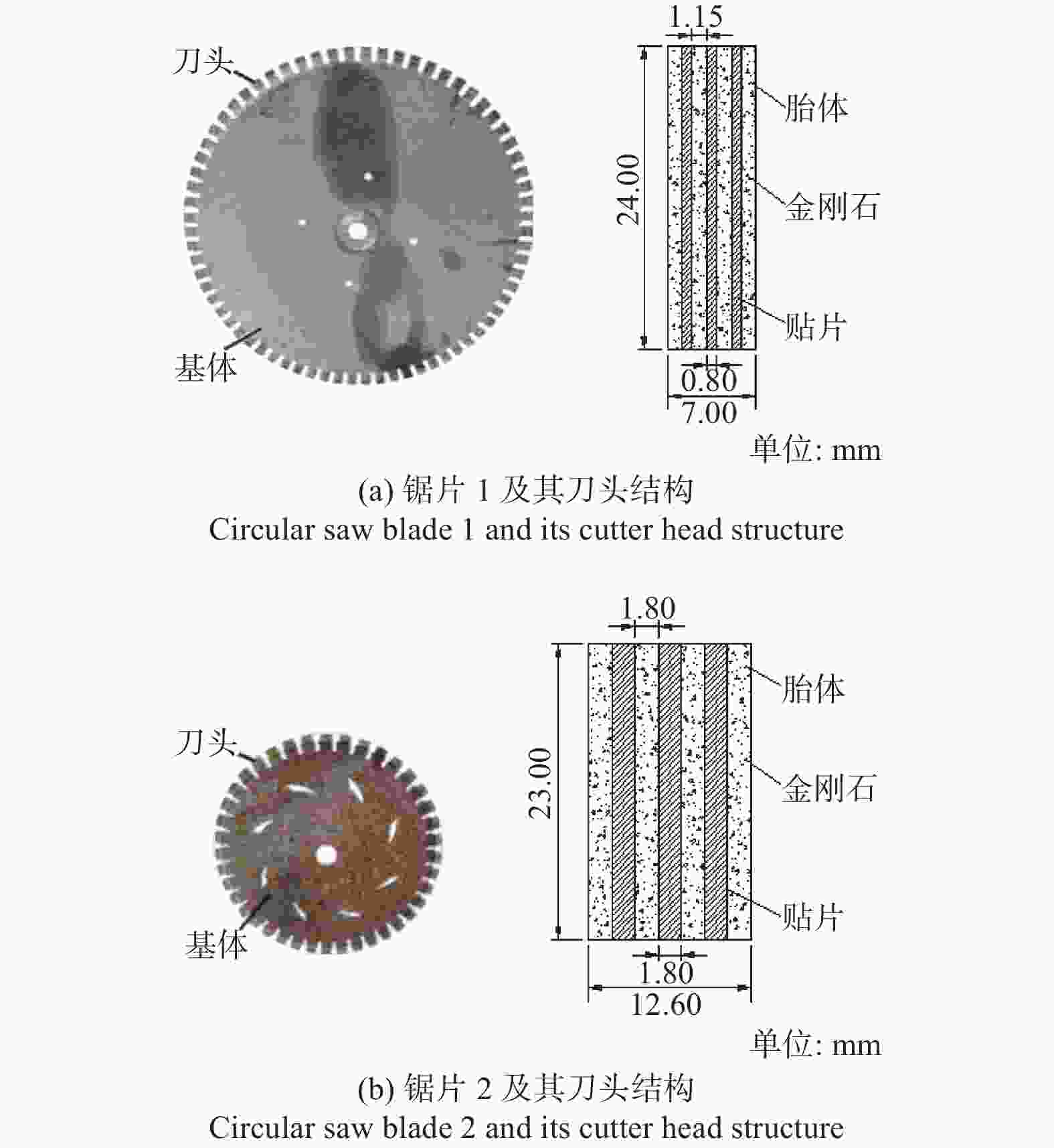

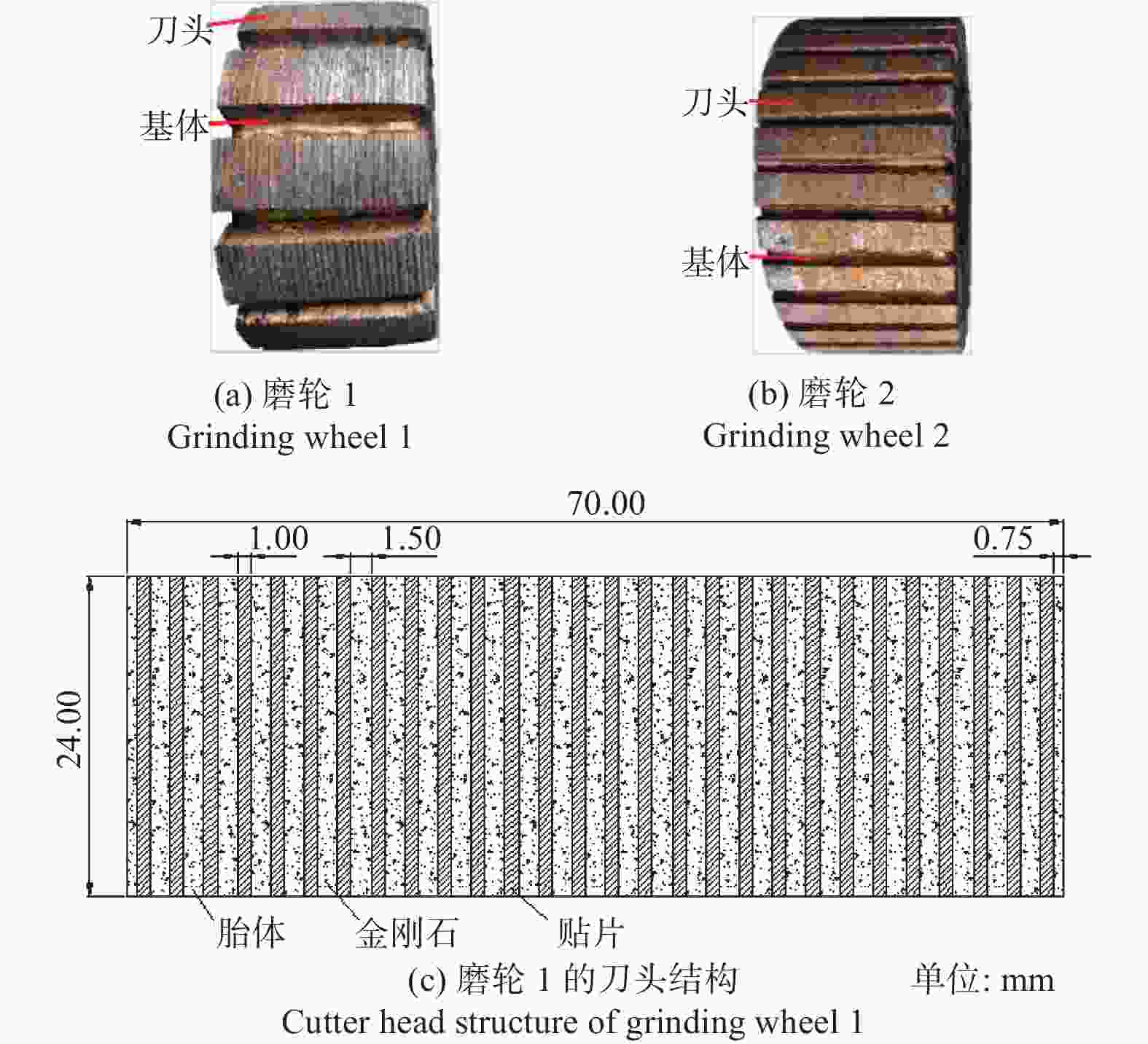

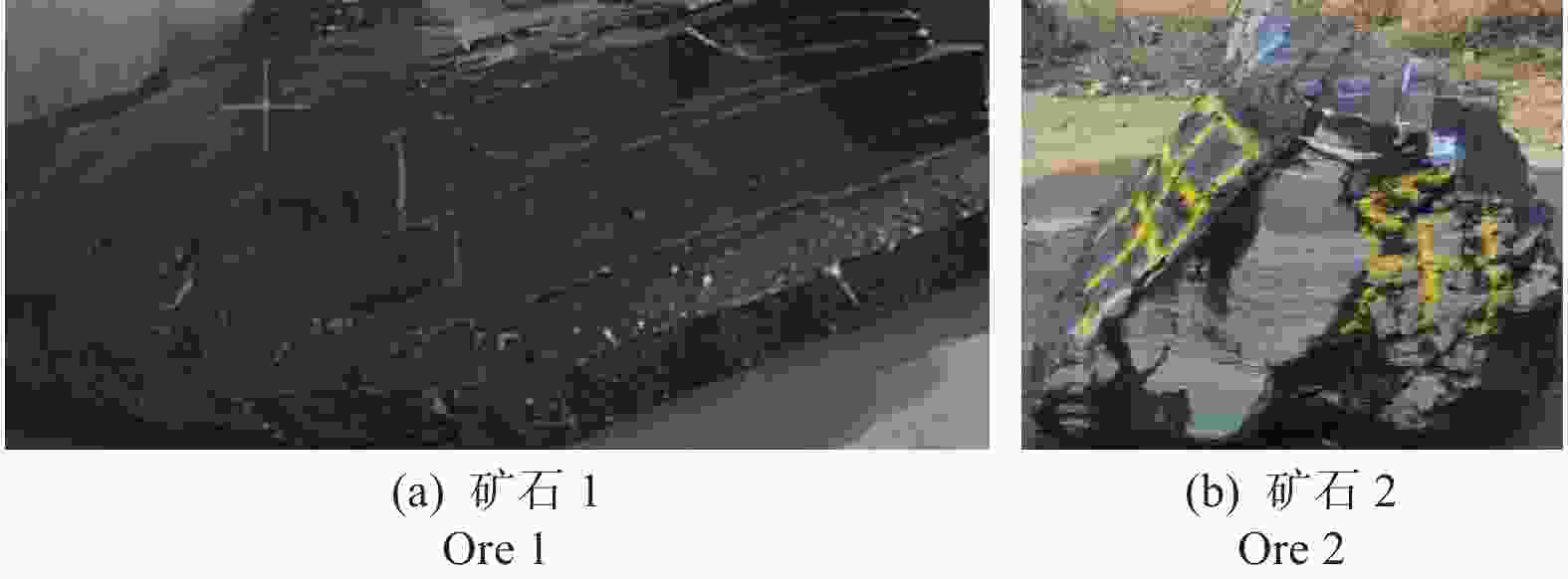

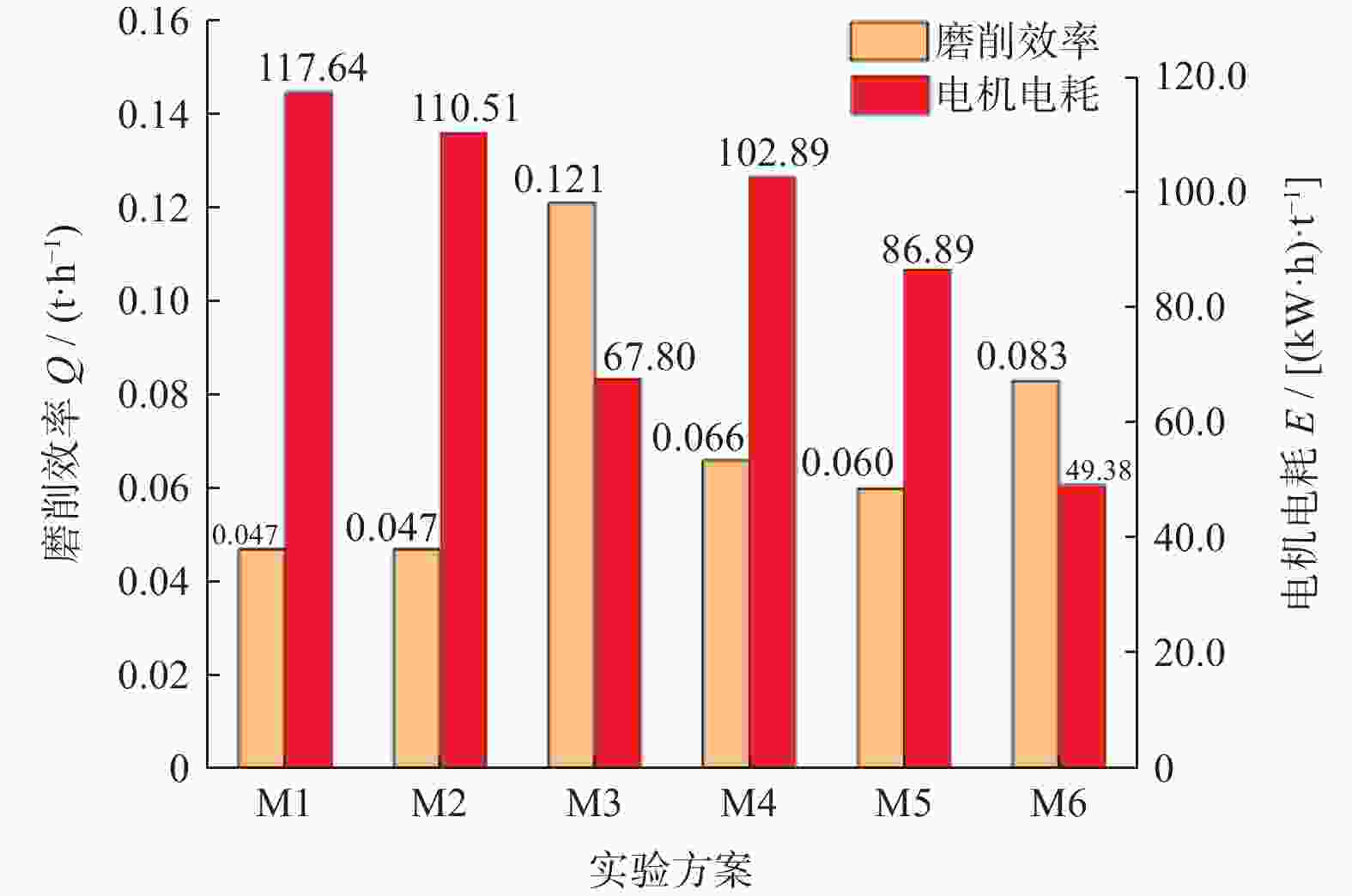

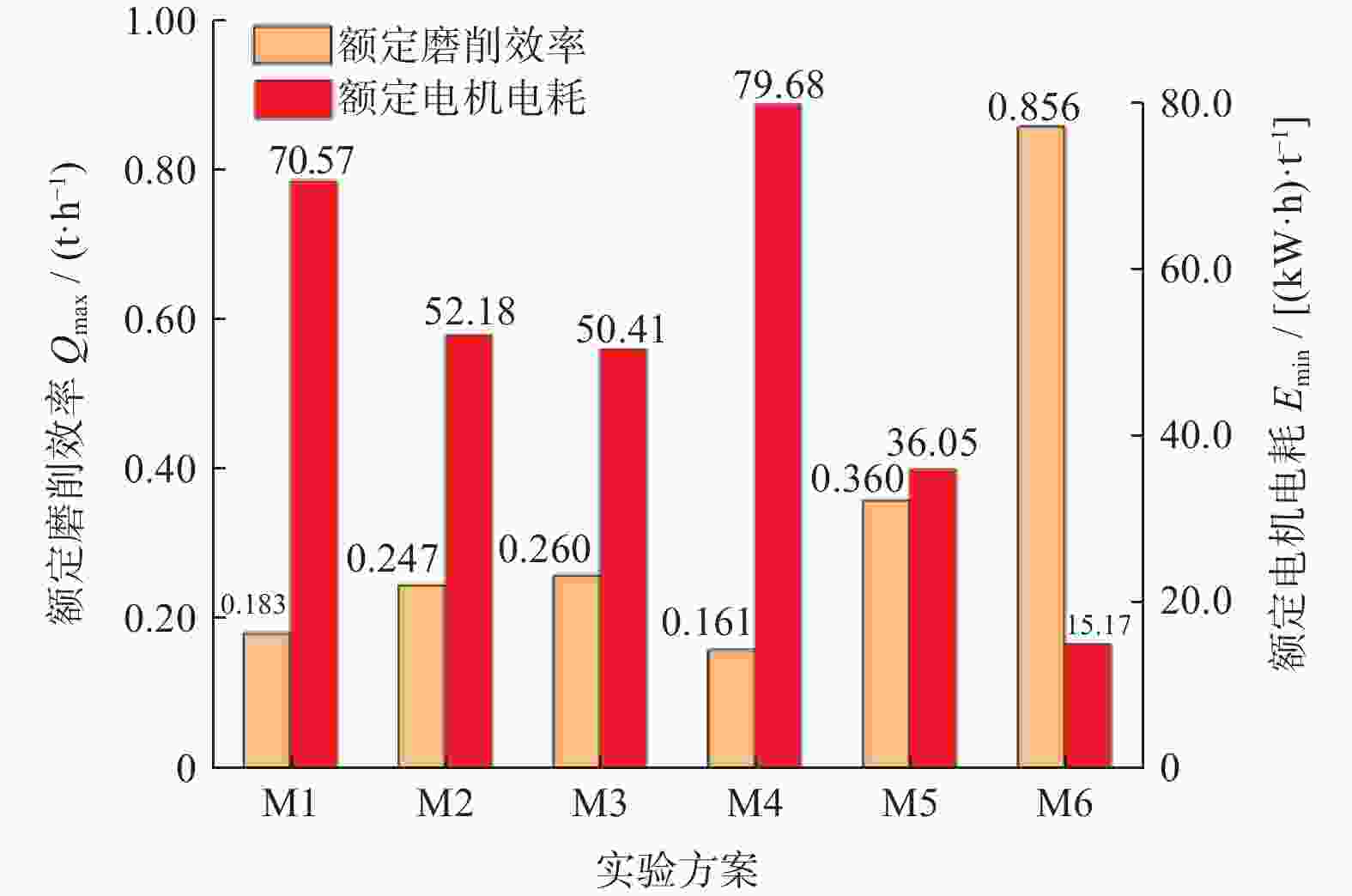

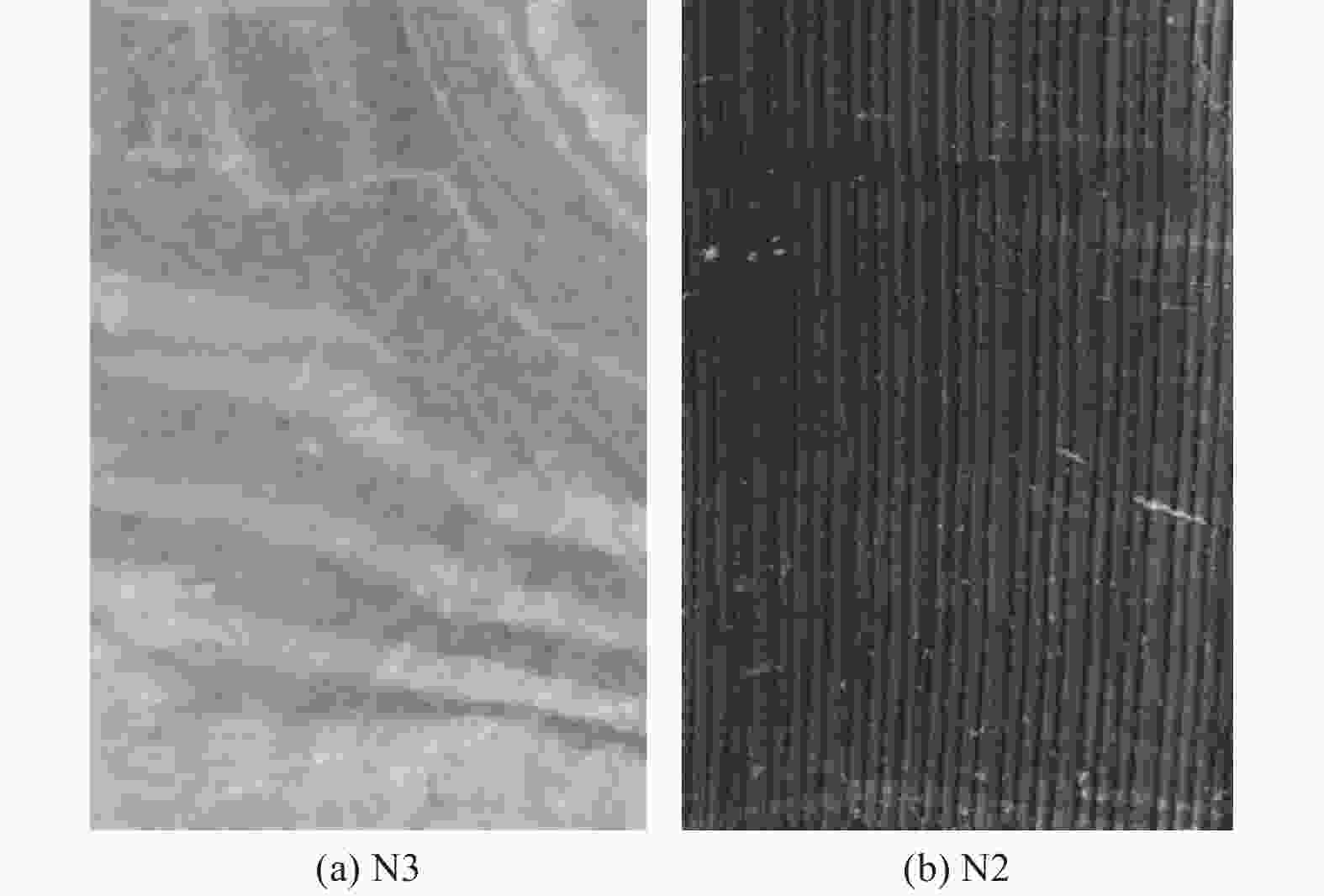

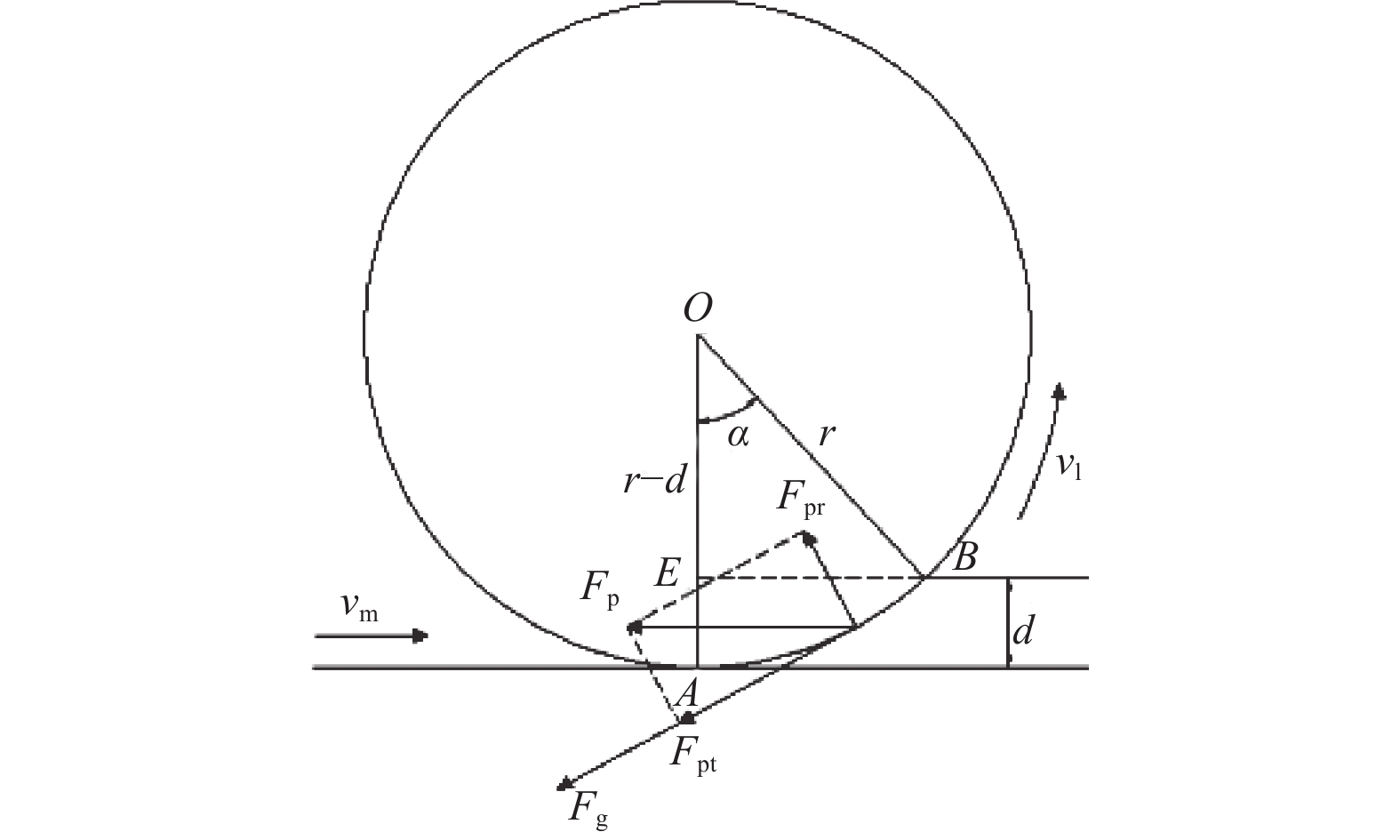

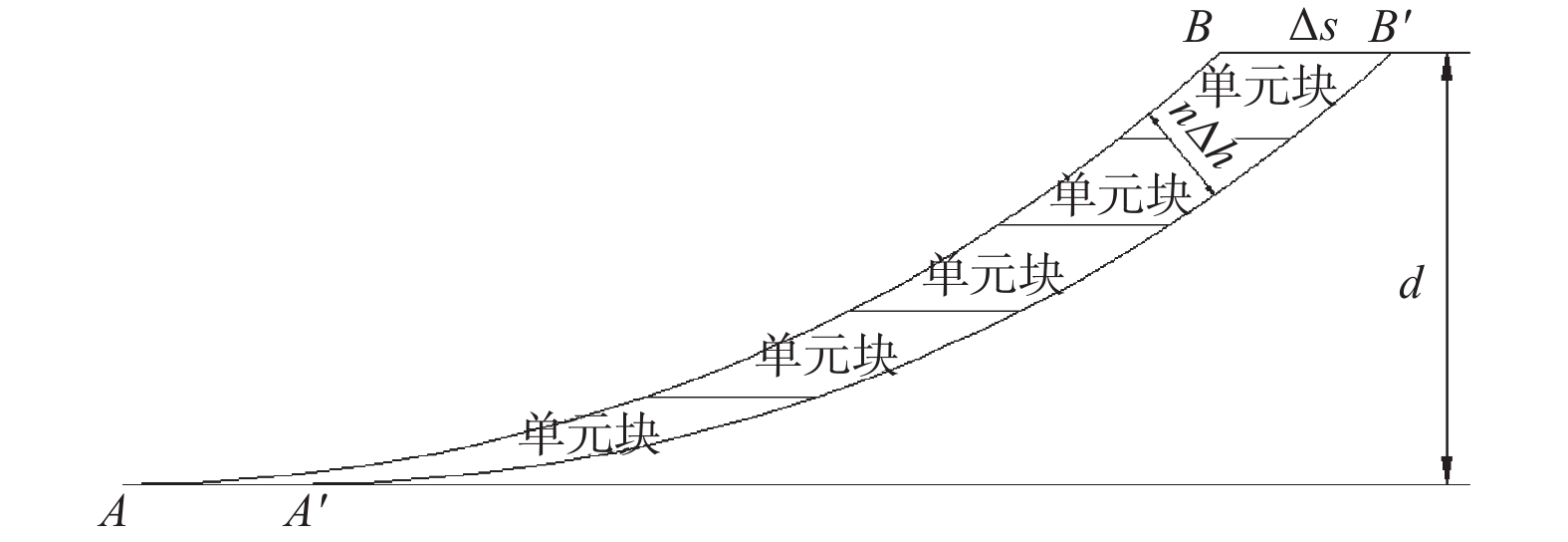

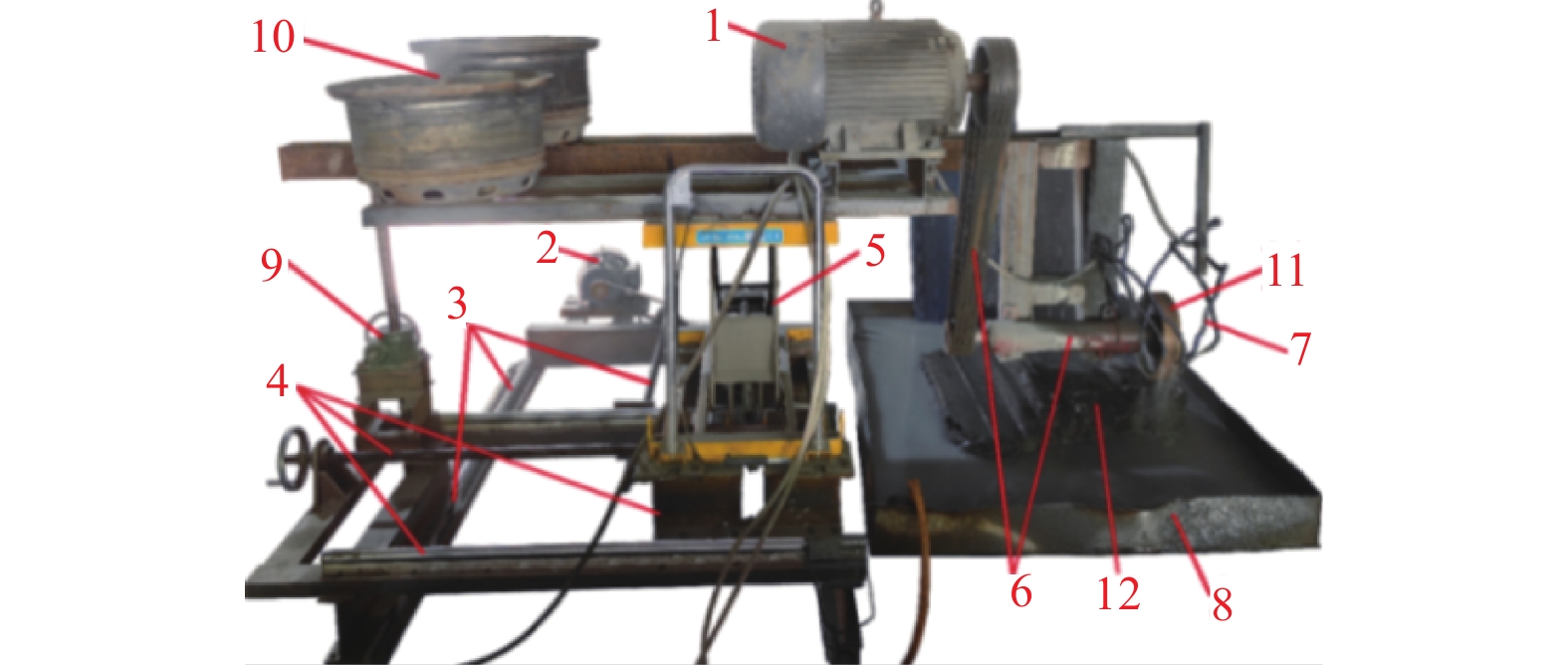

Objectives The existing mining equipments, such as coal mining machines, excavators, tunneling machines, and diamond tools, are combined to form a new mining equipment called the“grinding mining machine”, which is used for grinding mining. The main advantage of grinding mining applied in metal mines is that it greatly simplifies the mining process. However, whether it can be popularized and applied depends on whether its operating cost is close to or lower than the mining cost of drilling and blasting methods. Among these, the energy consumption cost of grinding mining machine operation is one of the most critical control indicators. The existing cutter heads of diamond tools, such as diamond circular saw blades and diamond grinding wheels, are used to grind iron ore. The relationship between grinding power consumption and the type of diamond cutter heads, the rock characteristics of iron ore, and the grinding operation parameters are studied. The factors affecting the grinding efficiency and the cost of the grinding mining machine are explored to find a reasonable range of values that can adapt to different situations. Methods An experimental platform was built, and two types of diamond circular saw blades and two types of diamond grinding wheels were used to conduct grinding experiments on two types of iron ore samples. There were a total of six experimental schemes, and power consumption experimental data were obtained for different blade heads and their grinding line speeds, grinding thicknesses, grinding widths, grinding movement rates, etc. Based on this, the rated grinding efficiency, the rated motor power consumption, and the rated grinding power consumption were calculated. The main influencing factors of power consumption in grinding iron ores with diamond cutter heads were analyzed by comparing the above data. Results According to the experimental data and the calculation analysis of the six experimental schemes, the following results were obtained: (1) The average rated motor power consumption of the magnetic iron zone of ore 1, the quartz zone, and the magnetic iron zone of ore 2 are 50.41, 36.05, and 15.17 (kW·h)/t, respectively. This indicates that the rock characteristics of ore, such as uniaxial compressive strength, quartz content, and particle size, have a significant impact on power consumption during grinding. The higher the uniaxial compressive strength of the ore, the higher the quartz content and the smaller the quartz particle size, the higher the power consumption of grinding the ore. (2) Two different types of diamond circular saw blades and two types of diamond grinding wheels were used to conduct grinding experiments on two different iron ore samples. Compared with other types of diamond heads, the use of sharp diamond heads with added iron sheets can significantly reduce power consumption during ore grinding operations. (3) Under the condition of constant rated power of the main motor, the grinding efficiency of the grinding wheel can be improved, and the power consumption of the motor can be reduced by optimizing the width and the diameter of the grinding wheel. (4) The single grinding movement distance Δs is closely related to grinding efficiency and directly related to the diamond cutting depth Δh. When the Δs value ranges from 6.01 to 14.35, 3.23 to 9.96, 4.14 to 15.04, 26.44 to 32.09, 1.62 to 5.37, and 2.02 to 5.64 μm in the six experimental schemes of M1 to M6, the grinding power consumption can be effectively reduced by adjusting the Δs value. When the Δs values of M1 to M6 are 14.35, 6.65, 15.04, 32.09, 5.37, and 3.22 μm, respectively, the grinding power consumption is the lowest. However, to determine the most suitable Δs value, it is necessary to comprehensively consider factors such as the size and the structure of the diamond tool, the performance of the cutting head, the characteristics of the ore rock, the operating parameters, and the force situation of the cutting head, in order to find a reasonable range of values that can adapt to different situations. Additionally, according to the force analysis of the diamond cutter head grinding ore and the phenomena observed in the experiment, selecting the appropriate grinding movement direction is conducive to pulp collection and maximizes the gain effect of tangential pushing on the cutting force. Conclusions The energy consumption of diamond cutter heads grinding ores should be optimized in two aspects: the manufacturing technology and the use parameters of the cutter heads. In terms of diamond cutter head manufacturing technology, optimization should be carried out from the aspects of diamond grade, diamond particle size, and matrix compositions, formula, processing technology, as well as the size design, shape and arrangement of diamond cutting heads. Cutting heads that are both sharp and durable for grinding different types of ores should be developed to reduce energy consumption and operating costs. In terms of using operational parameters, further optimization research should be conducted on grinding size parameters and dynamic parameters to improve grinding efficiency, reduce grinding energy consumption and operational costs, and provide experimental and theoretical basis for the manufacturing of grinding and mining machines. The core technology of the grinding mining machine lies in the manufacturing technology of the grinding drum, and optimizing diamond cutter head grinding ores is fundamental to improving the grinding drum manufacturing technology. -

表 1 2种金刚石圆锯片参数

Table 1. Two types of diamond circular saw blade parameters

类型 外径

D1 / mm刀头宽

w1 / mm刀头长

L1 / mm刀头高

H1 / mm刀头间距

h1/ mm刀头数量

n1 / 个锯片1 920 7.00 24.00 14.00 17.27 70 锯片2 530 12.60 23.00 15.00 16.25 40 表 2 2种金刚石磨轮参数

Table 2. Two types of diamond grinding wheel parameters

类型 外径

D2 / mm刀头宽

w2 / mm刀头长

L2 / mm刀头高

H2 / mm刀头间距

h2 / mm刀头组数

n2 / 组磨轮1 150 24.00 70.00 15.00 12.23 13 磨轮2 150 10.00 70.00 8.00 6.82 28 表 3 4种金刚石工具刀头的主要质量指标

Table 3. Main quality indicators of four types of diamond tool cutting heads

类型 金刚石

类型金刚石粒度

标记金刚石浓度

C / %结合剂 洛氏硬度 /

HRB锯片1 中南2140 40/45 40 铁基配方 90 锯片2 中南2280 35/40 35 铜基配方 85 磨轮1 中南2160 40/45 30 铁基配方 90 磨轮2 中南2160 35/40 25 铁基配方 90 表 4 2种铁矿石特性对比

Table 4. Comparison of characteristics of two iron ores

类型 矿石密度

ρ/ (t·m−3)单轴

抗压

强度

σ / MPaTFe

平均

品位

ω1 / %mFe

平均

品位

ω2 / %石英

质量

分数

ω3 / %石英

粒径

d1 / mm矿石1 3.4 185.22~

252.8430.05 50~60 0.06~0.41 矿石2 2.9 136.90 18.70 8.58 20~35 0.40~1.30 表 5 6个实验方案典型实验数据

Table 5. Typical experimental data of six experimental schemes

实验

方案实验

序号磨削线

速度

v l / (m·s−1)磨削

厚度

d / cm磨削

宽度

b / cm磨削移

动速率

vm / (cm·min−1)电机实际

平均功率

P / kW磨削效率

Q / (t·h−1)电机电耗

E / [(kW·h)·t−1]电机空

载功率

Pc / kW额定磨

削效率

Qmax / (t·h−1)额定电

机电耗

Emin / [(kW·h)·t−1]M1 1 23.11 1.40 0.70 225.6 5.91 0.045 112.30 3.00 0.186 69.12 2 23.11 1.61 0.70 112.8 4.82 0.026 159.28 3.00 0.171 75.18 3 23.11 1.85 0.70 225.6 7.05 0.060 101.38 3.00 0.177 72.80 4 23.11 3.51 0.70 112.8 6.44 0.057 97.62 3.00 0.197 65.18 平均 0.047 117.64 0.183 70.57 M2 1 26.63 8.50 1.26 11.4 4.45 0.025 153.11 3.20 0.235 54.67 2 26.63 8.80 1.26 22.7 5.56 0.051 92.80 3.20 0.257 50.07 3 26.63 8.80 1.26 34.0 6.90 0.077 76.89 3.20 0.245 52.41 4 26.63 12.00 1.26 11.3 4.85 0.035 119.25 3.20 0.249 51.57 平均 0.047 110.51 0.247 52.18 M3 1 28.26 3.00 7.30 22.6 8.37 0.101 71.04 3.00 0.226 56.97 2 28.26 3.30 6.30 11.3 5.37 0.048 96.03 3.00 0.243 52.98 3 28.26 4.00 6.30 33.8 9.37 0.174 46.21 3.00 0.327 39.27 4 28.26 2.50 7.00 45.1 10.88 0.161 57.91 3.00 0.245 52.43 平均 0.121 67.80 0.260 50.41 M4 1 28.26 3.70 1.20 67.7 7.60 0.061 106.22 3.00 0.160 80.36 2 28.26 3.20 1.20 90.2 8.08 0.071 98.00 3.00 0.167 77.02 3 28.26 3.40 1.25 79.0 8.00 0.068 100.10 3.00 0.164 78.20 4 28.26 3.50 1.30 68.0 7.90 0.063 107.26 3.00 0.155 83.16 平均 0.066 102.89 0.161 79.68 M5 1 28.26 4.50 6.50 11.4 5.16 0.058 76.22 3.50 0.402 31.98 2 28.26 4.00 6.60 22.6 7.40 0.104 61.09 3.50 0.306 41.99 3 28.26 2.50 5.50 13.5 4.53 0.032 120.20 3.50 0.361 35.65 4 28.26 4.00 6.00 11.3 4.96 0.047 90.08 3.50 0.372 34.59 平均 0.060 86.89 0.360 36.05 M6 1 28.26 1.20 6.40 45.1 4.19 0.060 59.58 3.50 1.004 12.80 2 28.26 1.20 6.40 56.6 4.62 0.076 52.35 3.50 0.777 16.55 3 28.26 1.20 6.40 67.7 4.74 0.090 44.90 3.50 0.839 15.32 4 28.26 1.20 6.40 79.0 5.01 0.106 40.67 3.50 0.804 15.99 平均 0.083 49.38 0.856 15.17 -

[1] 任贺旭, 李占金, 李力. 铁矿石采选破碎系统节能途径研究 [J]. 矿业研究与开发,2015,35(12):97-100. doi: 10.13827/j.cnki.kyyk.2015.12.022REN Hexu, LI Zhanjin, LI Li. Study on the energy saving way in crushing system of iron ore mining and dressing [J]. Mining Research and Development,2015,35(12):97-100. doi: 10.13827/j.cnki.kyyk.2015.12.022 [2] 罗春梅. 球磨机节能降耗新途径机理及应用研究 [D]. 昆明: 昆明理工大学, 2009.LUO Chunmei. Mechanism and application research on energy conservation and consumption reduction of ball mills [D]. Kunming: Kunming University of Technology, 2009. [3] 刘安平, 吴彩斌, 严刘学, 等. 梅山铁矿精确化磨矿工业试验研究 [J]. 矿冶工程,2014,34(5):58-61. doi: 10.3969/j.issn.0253-6099.2014.05.015LIU Anping, WU Caibin, YAN Liuxue, et al. Commercial tests on precise grinding of iron ore from meishan iron mine [J]. Mining and Metallurgical Engineering,2014,34(5):58-61. doi: 10.3969/j.issn.0253-6099.2014.05.015 [4] 张昊, 刘文宝, 刘文刚, 等. 辽宁鞍本地区某铁矿废石碎磨特性研究 [J]. 金属矿山,2022(3):93-98. doi: 10.19614/j.cnki.jsks.202203011ZhANG Hao, LIU Wenbao, LIU Wengang, et al. Study on comminution characteristics of waste rock in iron mine from Anben region in Liaoning Province [J]. Metal Mine,2022(3):93-98. doi: 10.19614/j.cnki.jsks.202203011 [5] 肖硕, 黄自力, 黄涛, 等. 澳洲某铁矿石可磨可选性研究 [J]. 矿冶工程,2019,43(3):72-74,83. doi: 10.3969/j.issn.0253-6099.2023.03.016XIAO Shuo, HUANG Zili, HUANG Tao, et al. Grindability and beneficiability of iron ore from Australia [J]. Mining and Metallurgical Engineering,2019,43(3):72-74,83. doi: 10.3969/j.issn.0253-6099.2023.03.016 [6] 徐寒冰, 刘瑜, 曾志飞, 等. 江西某钨矿选矿厂精确化磨矿研究 [J]. 矿冶工程,2019,39(5):34-37,40. doi: 10.3969/j.issn.0253-6099.2019.05.009XU Hanbing, LIU Yu, ZENG Zhifei, et al. Precision grinding-classification circuit adopted by tungsten ore dressing plant in Jiangxi [J]. Mining and Metallurgical Engineering,2019,39(5):34-37,40. doi: 10.3969/j.issn.0253-6099.2019.05.009 [7] 宋月清, 刘一波, 张绍和, 等. 人造金刚石工具手册 [M]. 北京: 冶金工业出版社, 2014.SONG Yueqing, LIU Yibo, ZHANG Shaohe, et al. Manual of synthetic diamond tools [M]. Beijing: Metallurgical Industry Press, 2014. [8] 邱陆一, 白硕玮, 林润泽, 等. 石材锯切专用金刚石刀头设计因素分析 [J]. 石材,2020,(11):52-55. doi: 10.14030/j.cnki.scaa.2020.0212QIU Luyi, BAI Shuowei, LIN Runze, et al. Analysis of design factors of diamond cutter head for Stone sawing [J]. Stone Science,2020,(11):52-55. doi: 10.14030/j.cnki.scaa.2020.0212 [9] 万元华, 石晓义, 李水堤, 等. 关于烧结金刚石锯片分类设计的研究 [J]. 超硬材料工程,2018,30(6):27-32. doi: 10.3969/j.issn.1673-1433.2018.06.009WAN Yuanhua, SHI Xiaoyi, LI Shuidi, et al. Research on classification design of sintered diamond saw blade [J]. Superhard Material Engineering,2018,30(6):27-32. doi: 10.3969/j.issn.1673-1433.2018.06.009 [10] 吴杰, 董小雷, 任海霞, 等. 低成本锋利型金刚石圆锯片的开发 [J]. 超硬材料工程,2018,30(4):16-20. doi: 10.3969/j.issn.1673-1433.2018.04.004WU Jie, DONG Xiaolei, REN Haixia, et al. Development of low cost sharp diamond circular saw blade [J]. Superhard Materials Engineering,2018,30(4):16-20. doi: 10.3969/j.issn.1673-1433.2018.04.004 [11] 辽宁科技学院. 一种磨采采矿方式的短壁作业磨采机: 2022219421159 [P]. 2022-07-26.Liaoning University of Science and Technology. A short wall operation grinding machine for grinding mining method: 2022219421159 [P]. 2022-07-26. [12] 辽宁科技学院. 一种磨采采矿方式的短壁作业磨采机: 2022108873848 [P]. 2022-07-26.Liaoning University of Science and Technology. A short wall operation grinding machine for grinding mining method: 2022108873848 [P]. 2022-07-26. [13] 辽宁科技学院. 一种具有铰接式动臂的液压磨采机: 2023205583415 [P]. 2023-03-21.Liaoning University of Science and Technology. A hydraulic grinding and mining machine with articulated boom: 2023205583415 [P]. 2023-03-21. [14] 辽宁科技学院. 一种具有铰接式动臂的液压磨采机: 2023102762583 [P]. 2023-03-21.Liaoning University of Science and Technology. A hydraulic grinding and mining machine with articulated boom: 2023102762583 [P]. 2023-03-21. [15] KARAKURTT I, AYDIN G, AYDINER K. Experimental and statistical analysis of cutting force acting on diamond sawblade in sawing of granitic rocks [J]. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture,2013,227(B2):286-300. doi: 10.1177/0954405412460971 [16] 张美琴, 贾敏忠, 黄国钦. 金刚石圆锯片锯切过程能效分析 [J]. 福建工程学院学报,2015,13(4):357-361. doi: 10.3969/j.issn.1672-4348.2015.04.011ZHANG Meiqin, JIA Minzhong, HUANG Guoqin. Analysis of energy efficiency in diamond circular sawing [J]. Journal of Fujian University of Technology,2015,13(4):357-361. doi: 10.3969/j.issn.1672-4348.2015.04.011 [17] 徐宝德, 苏宏华, 丁兰英, 等. 新型自润滑金刚石锯片的锯切力特征研究 [J]. 金刚石与磨料磨具工程,2013,33(2):31-34. doi: 10.13394/j.cnki.jgszz.2013.02.007XU Baode, SU Honghua, DING Lanying, et al. Characteristics of sawing granite using a new self-lubricating diamond sawblade [J]. Diamond & Abrasives Engineering,2013,33(2):31-34. doi: 10.13394/j.cnki.jgszz.2013.02.007 [18] ZHAO M, LANG X Y, QI F L, et al. Dynamic analysis of the diamond saw blade cutting granite based on LS-DYNA [J]. Applied Mechanics and Materials, 2011: 130-134. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS