Grinding damage characteristics of silicon carbide ceramics

-

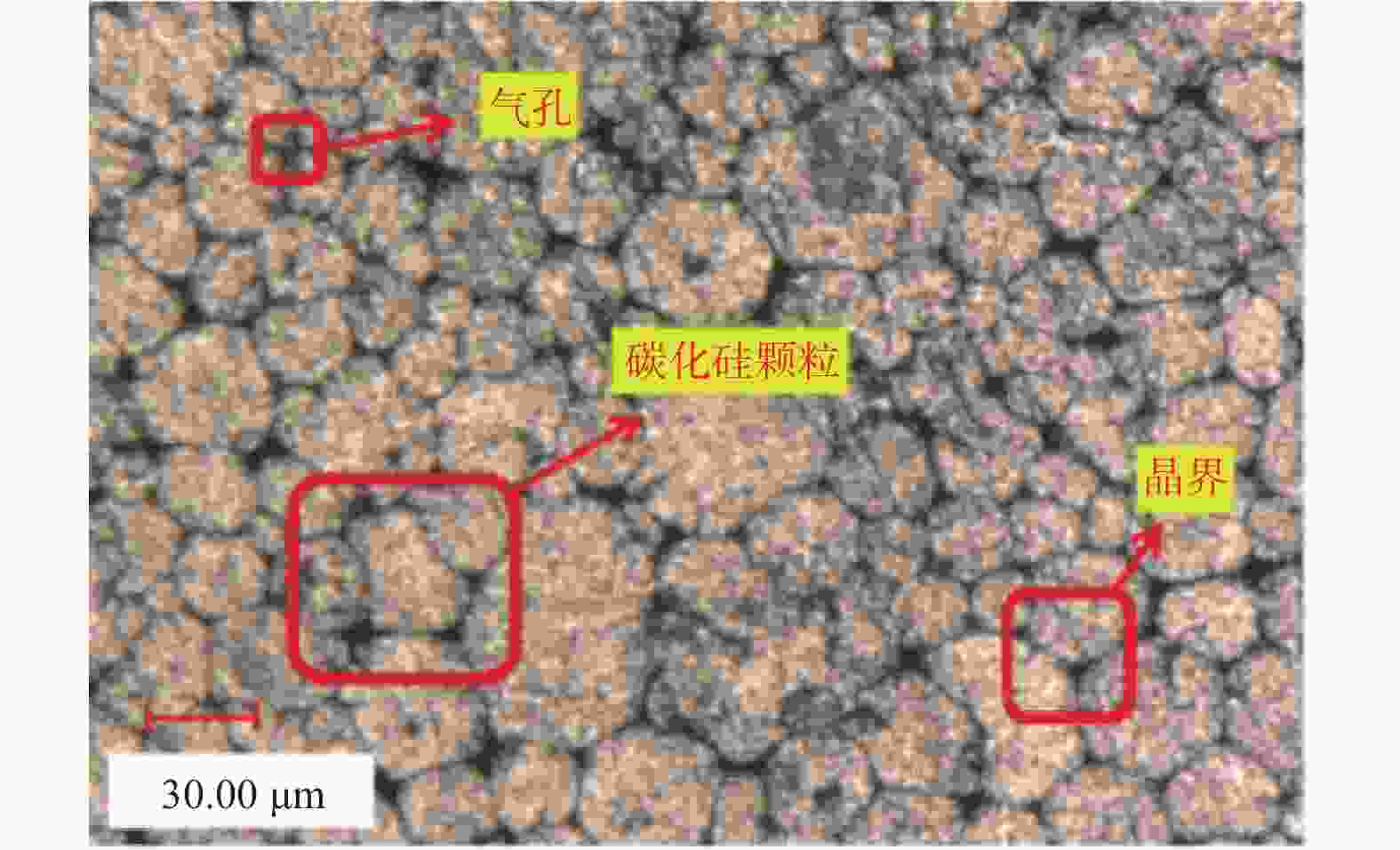

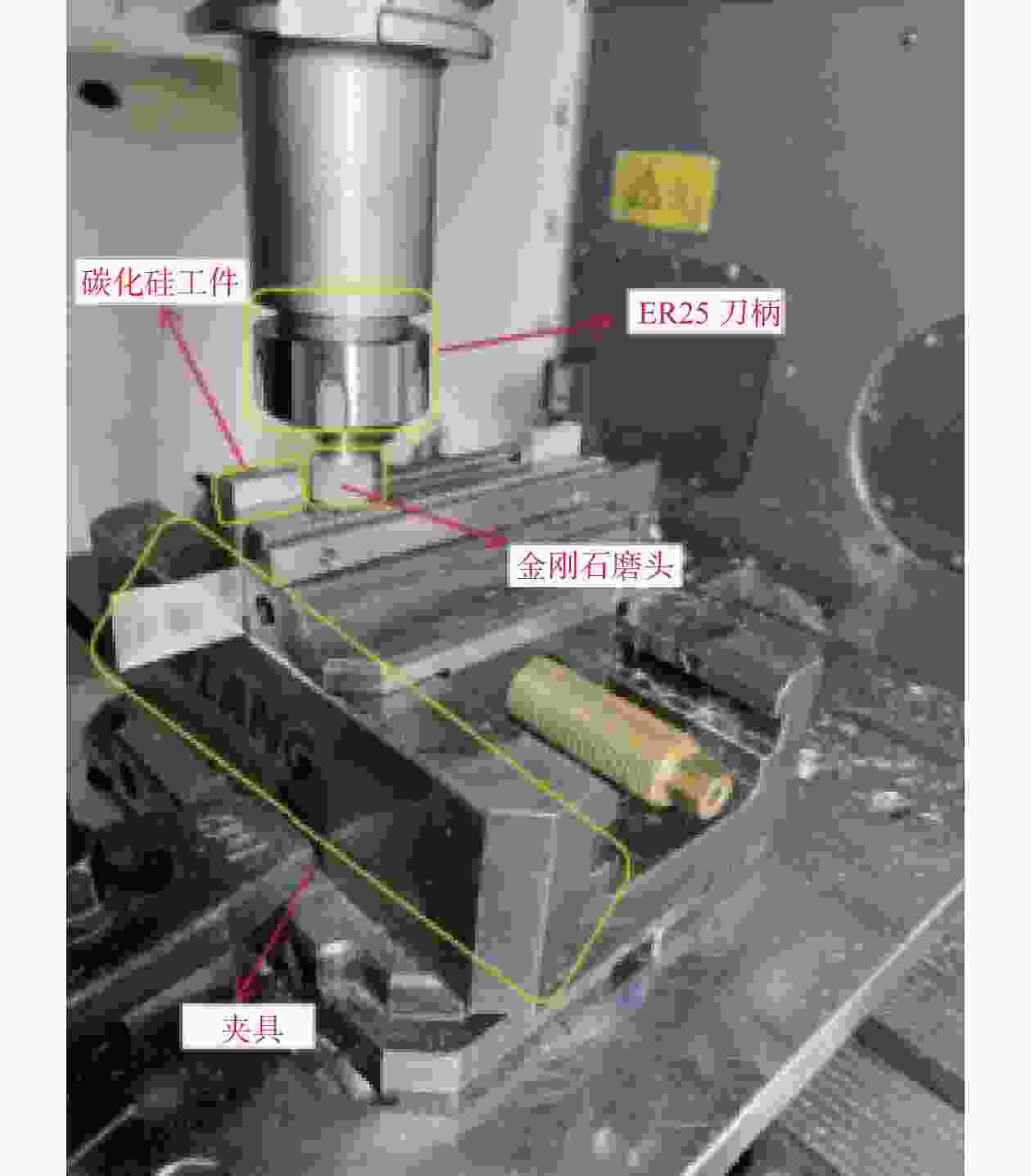

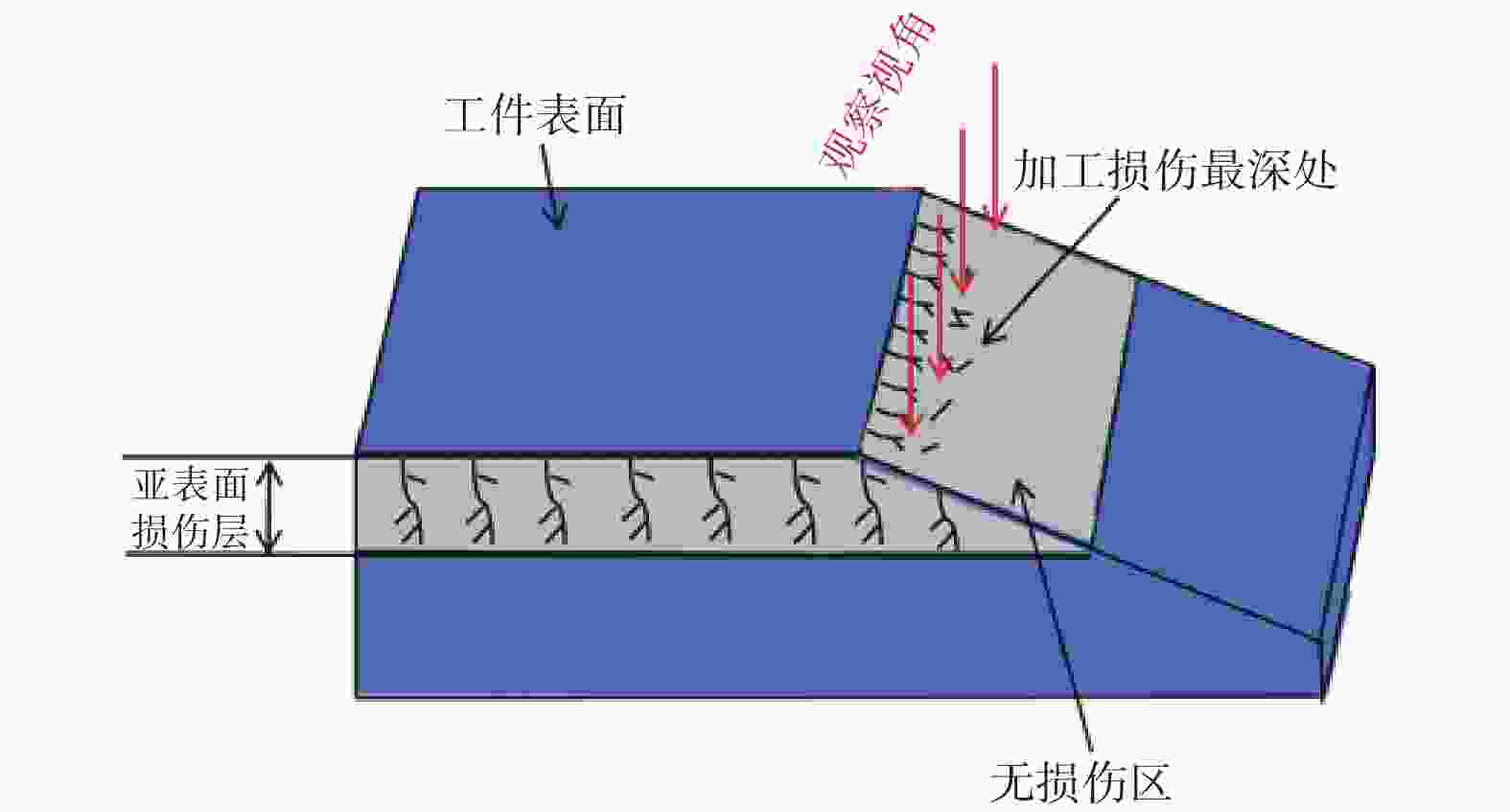

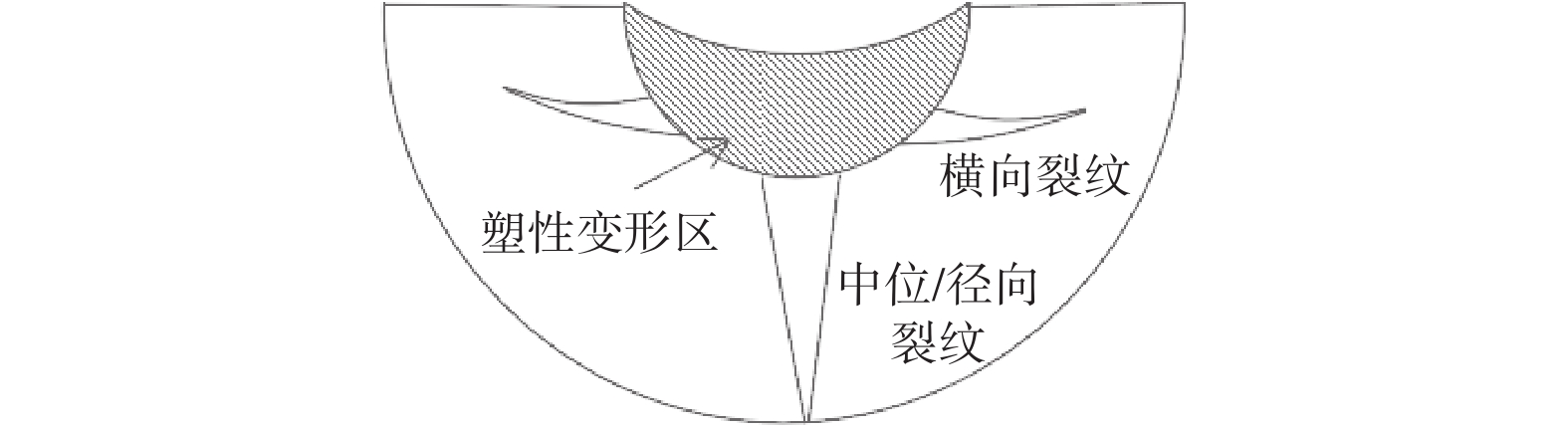

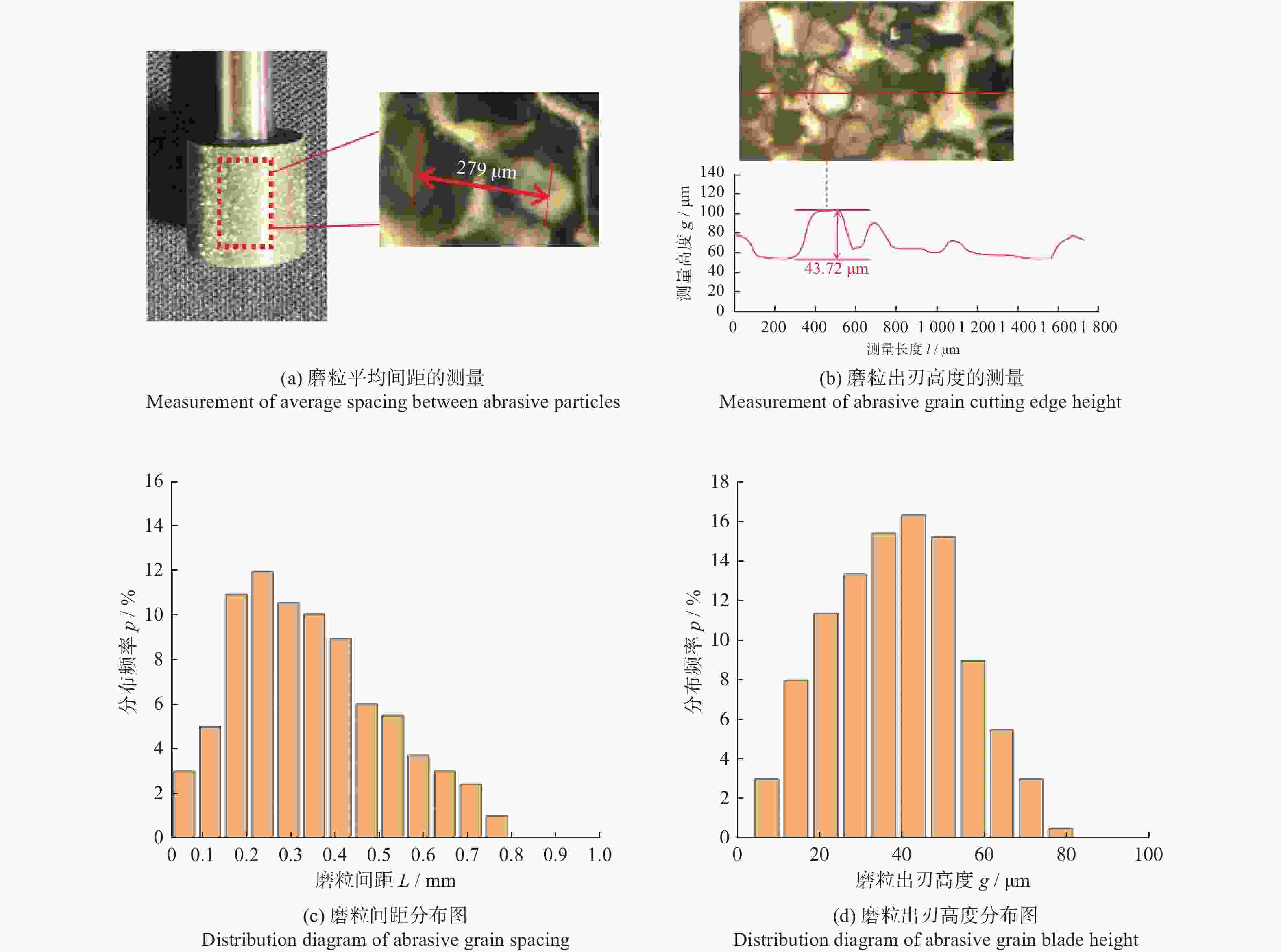

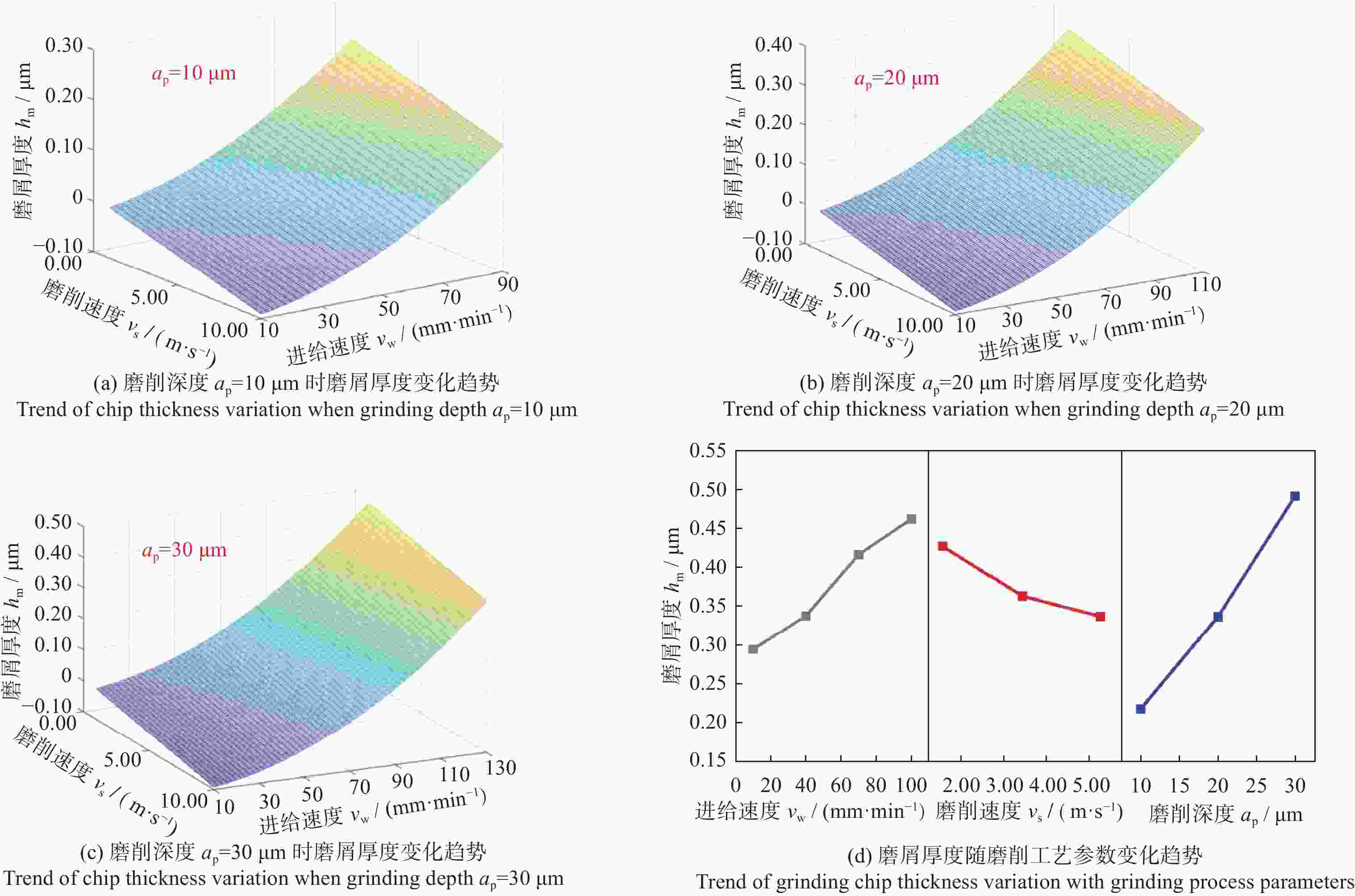

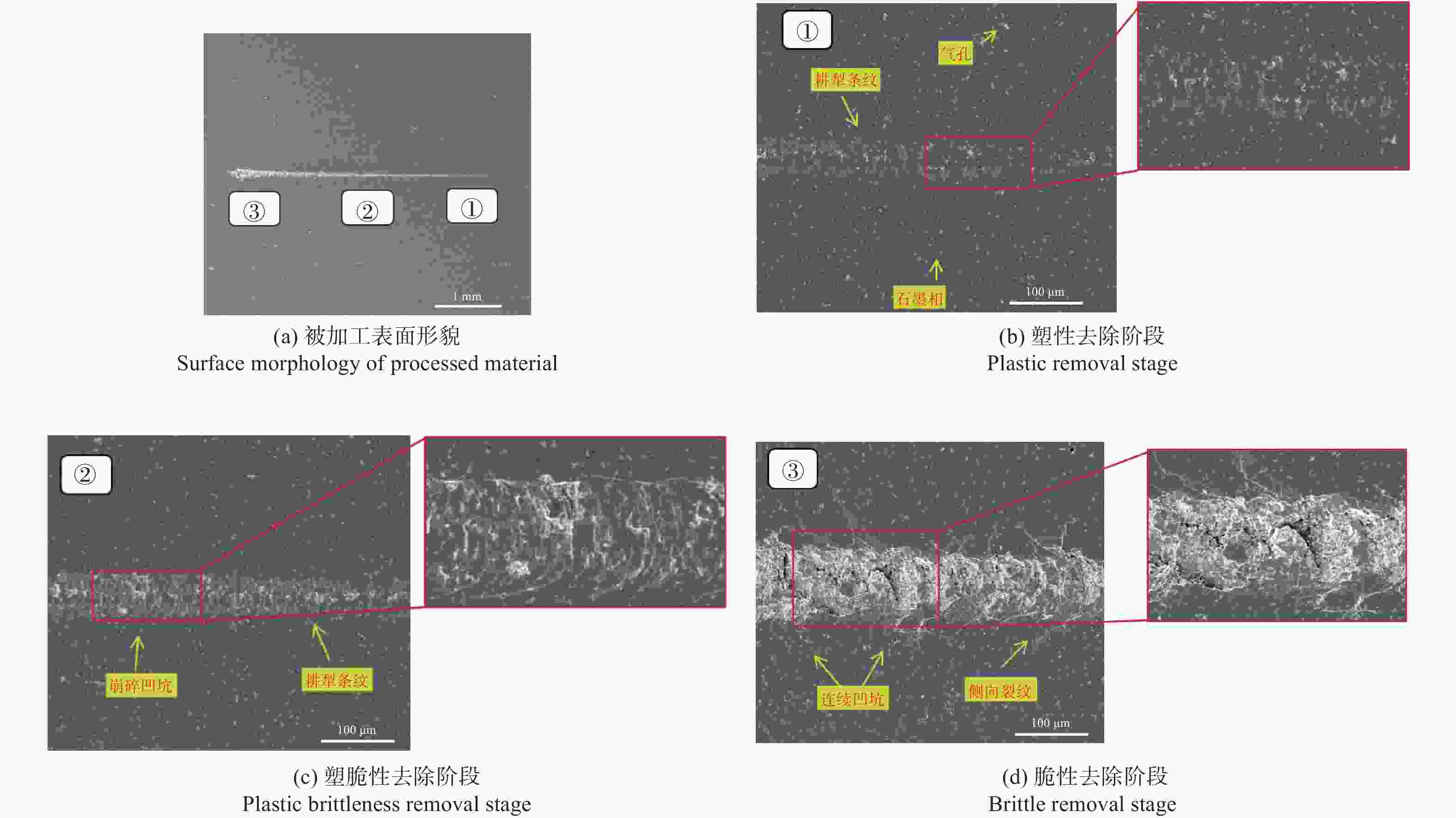

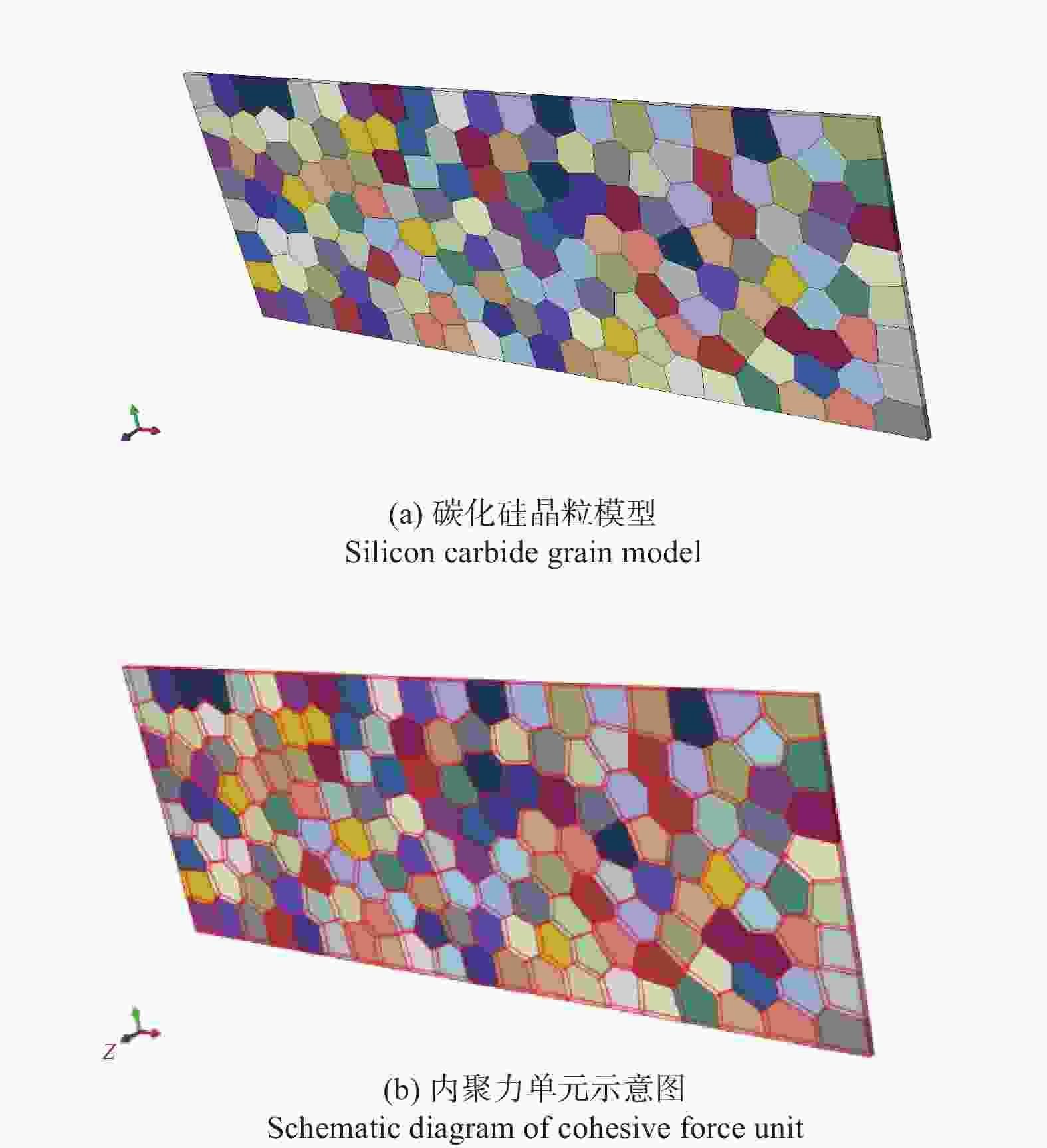

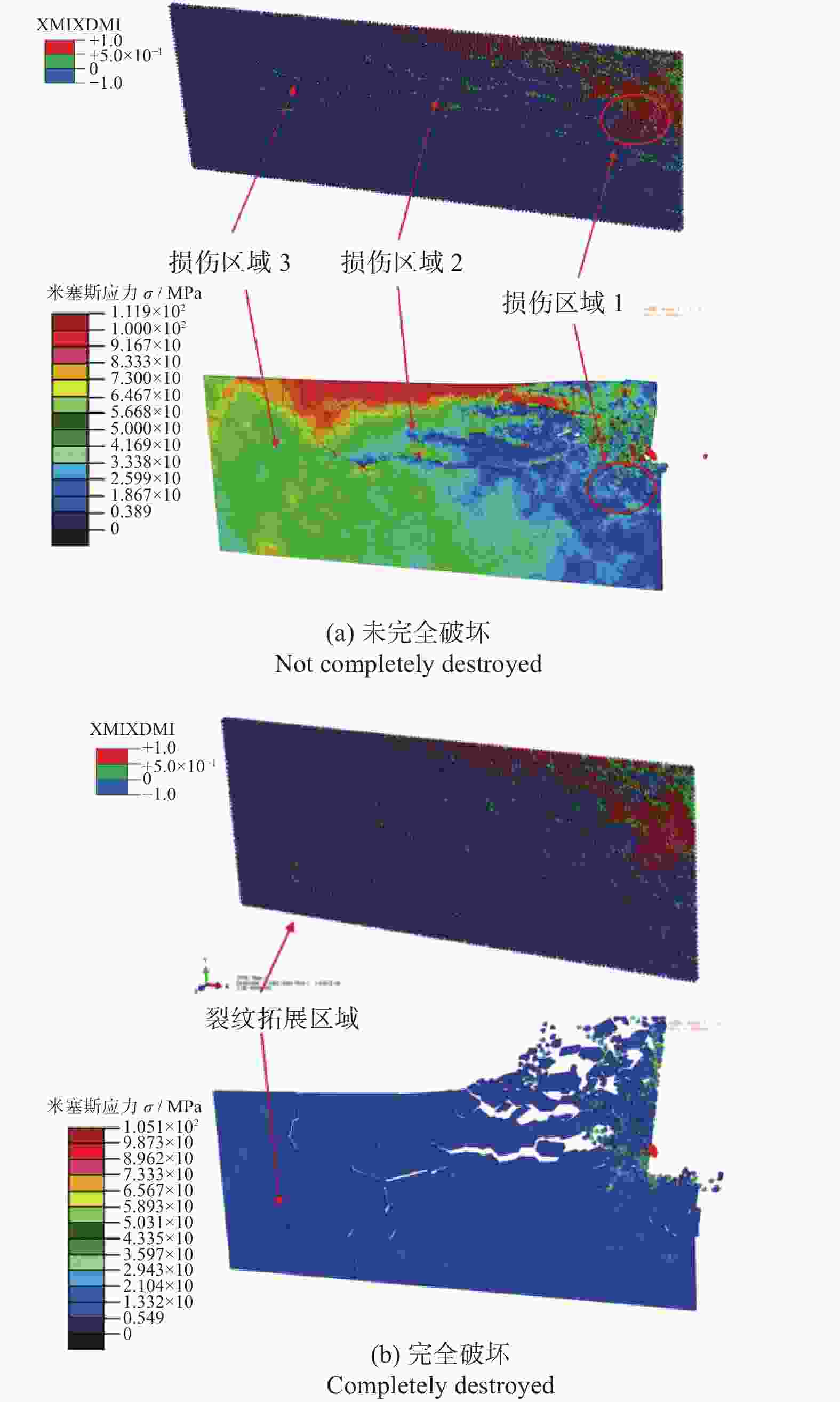

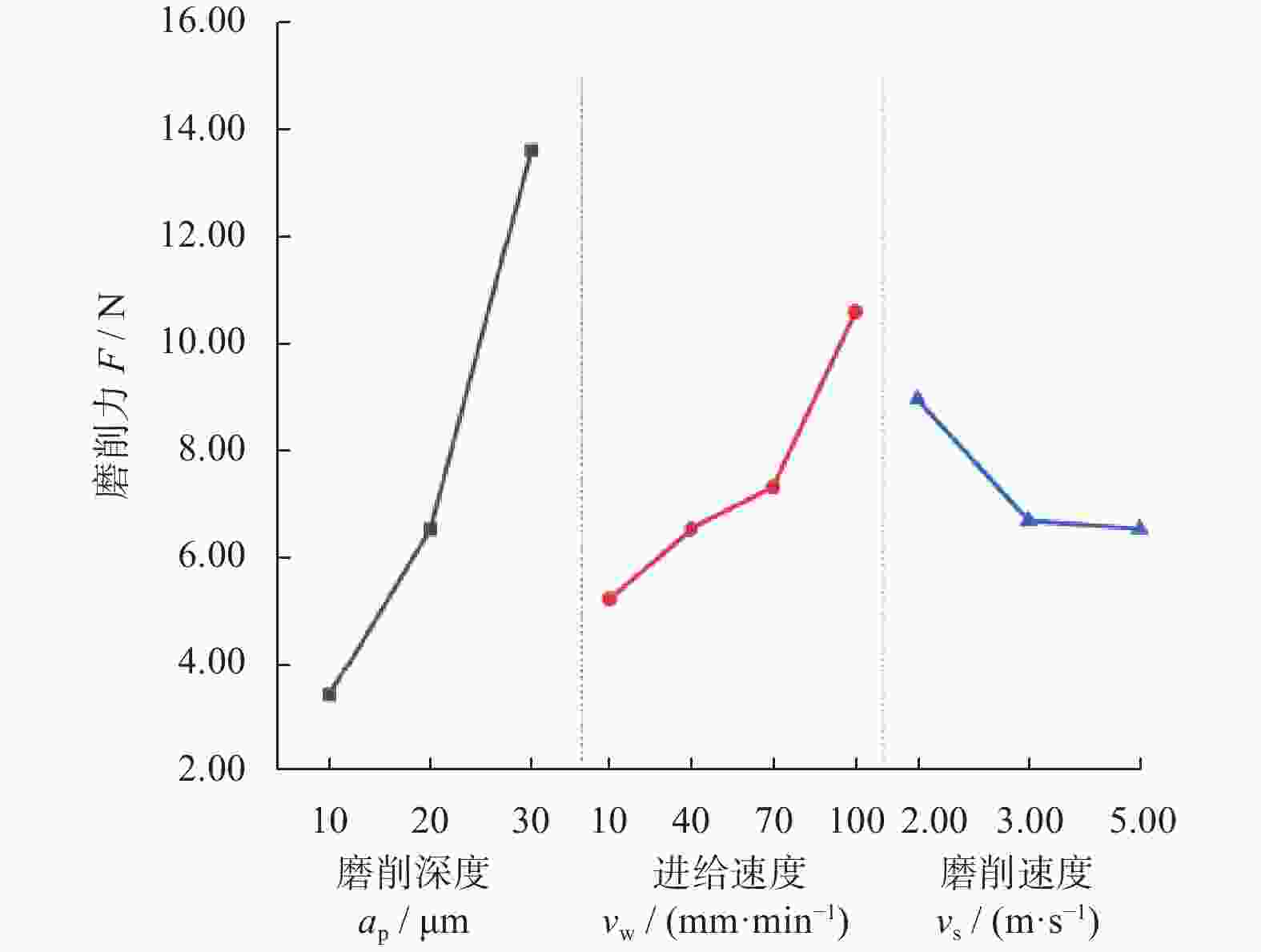

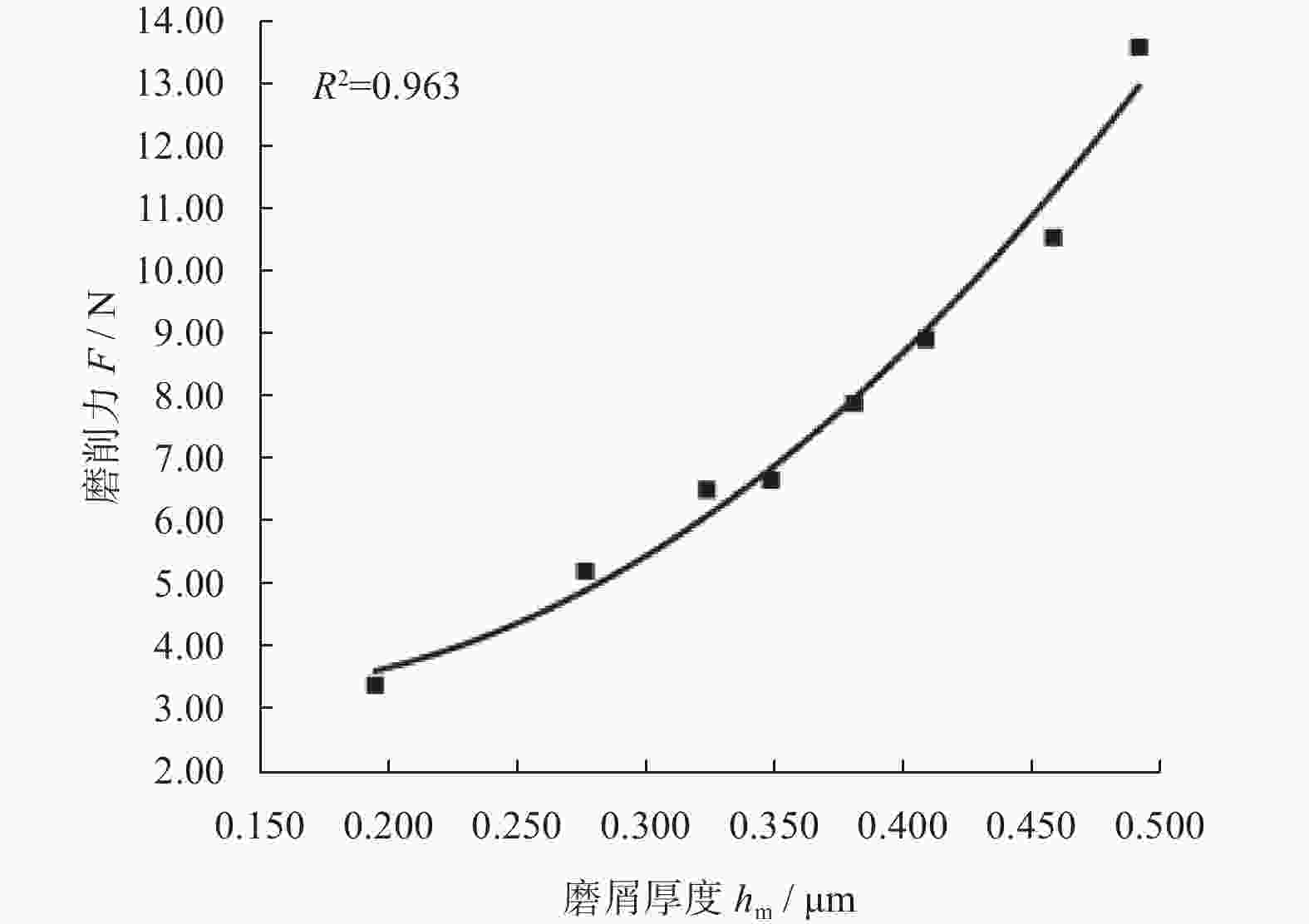

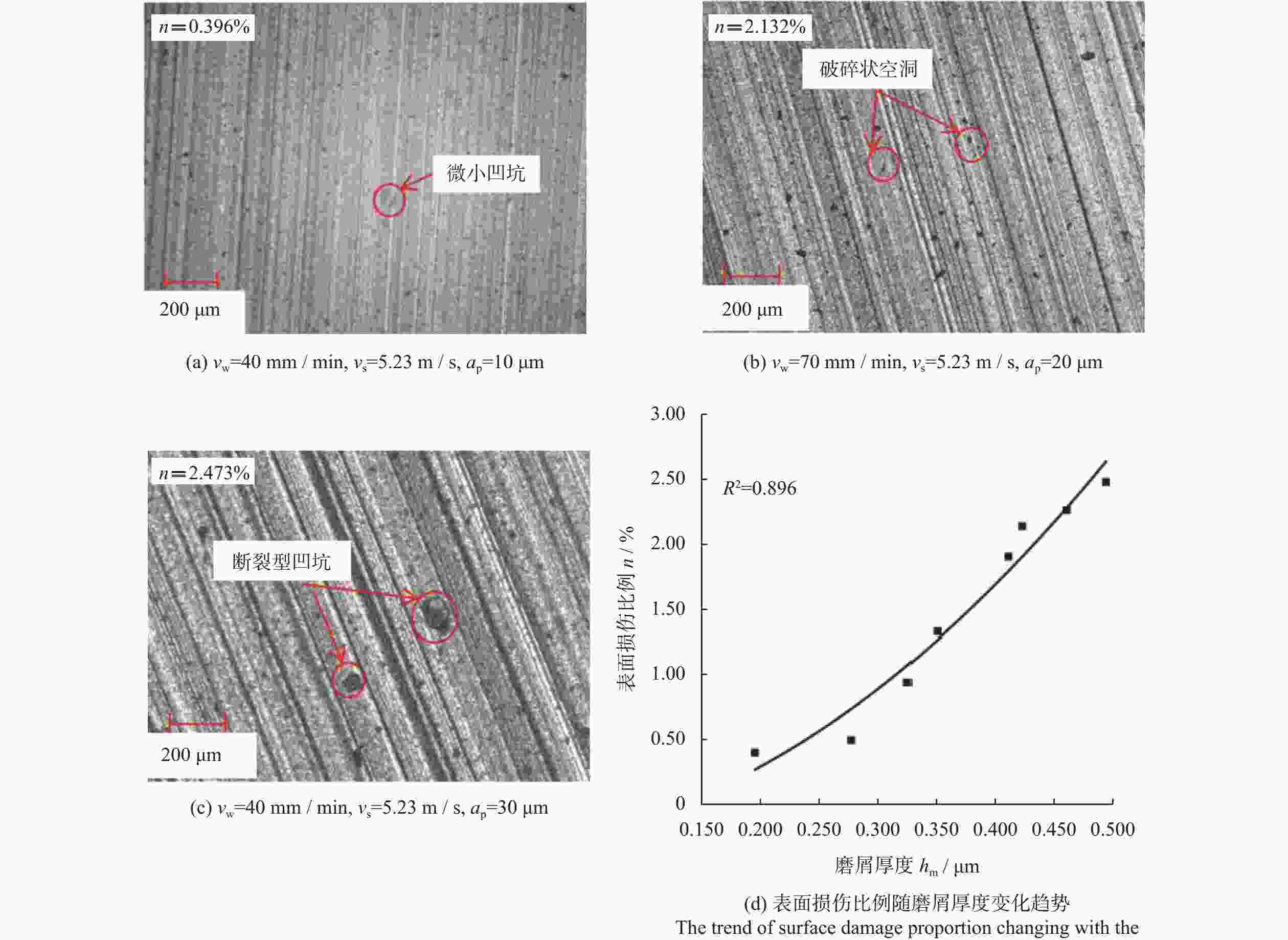

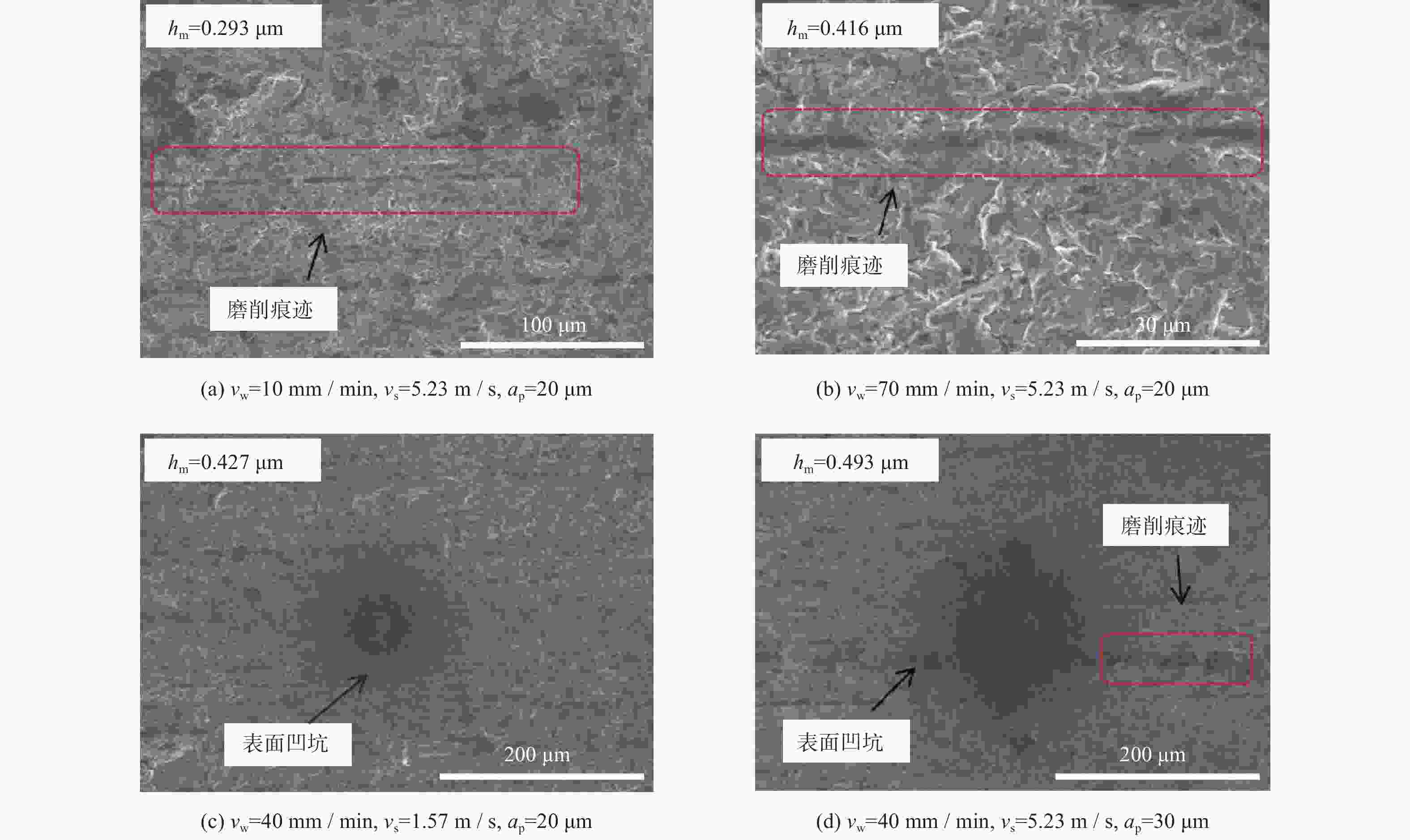

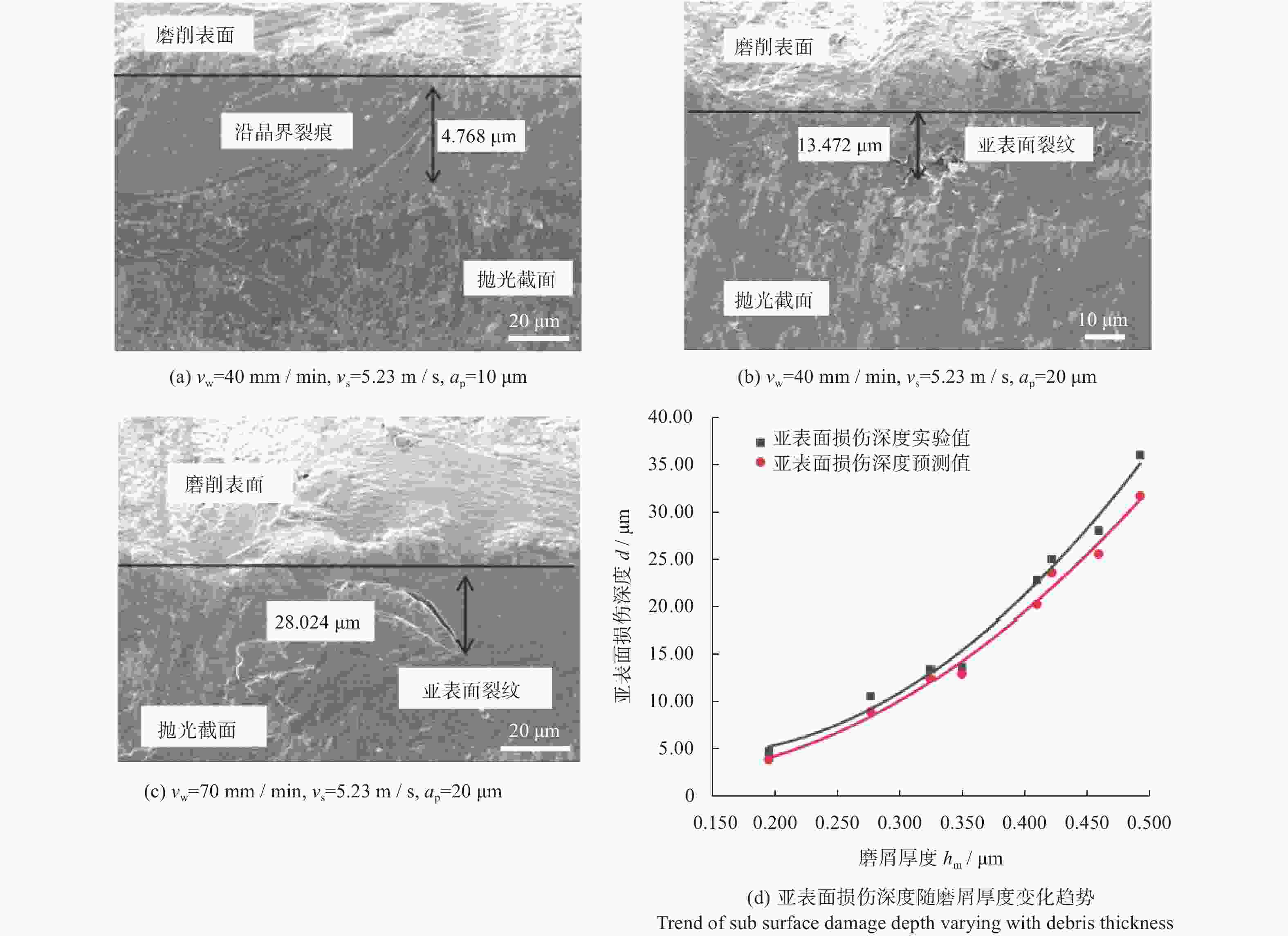

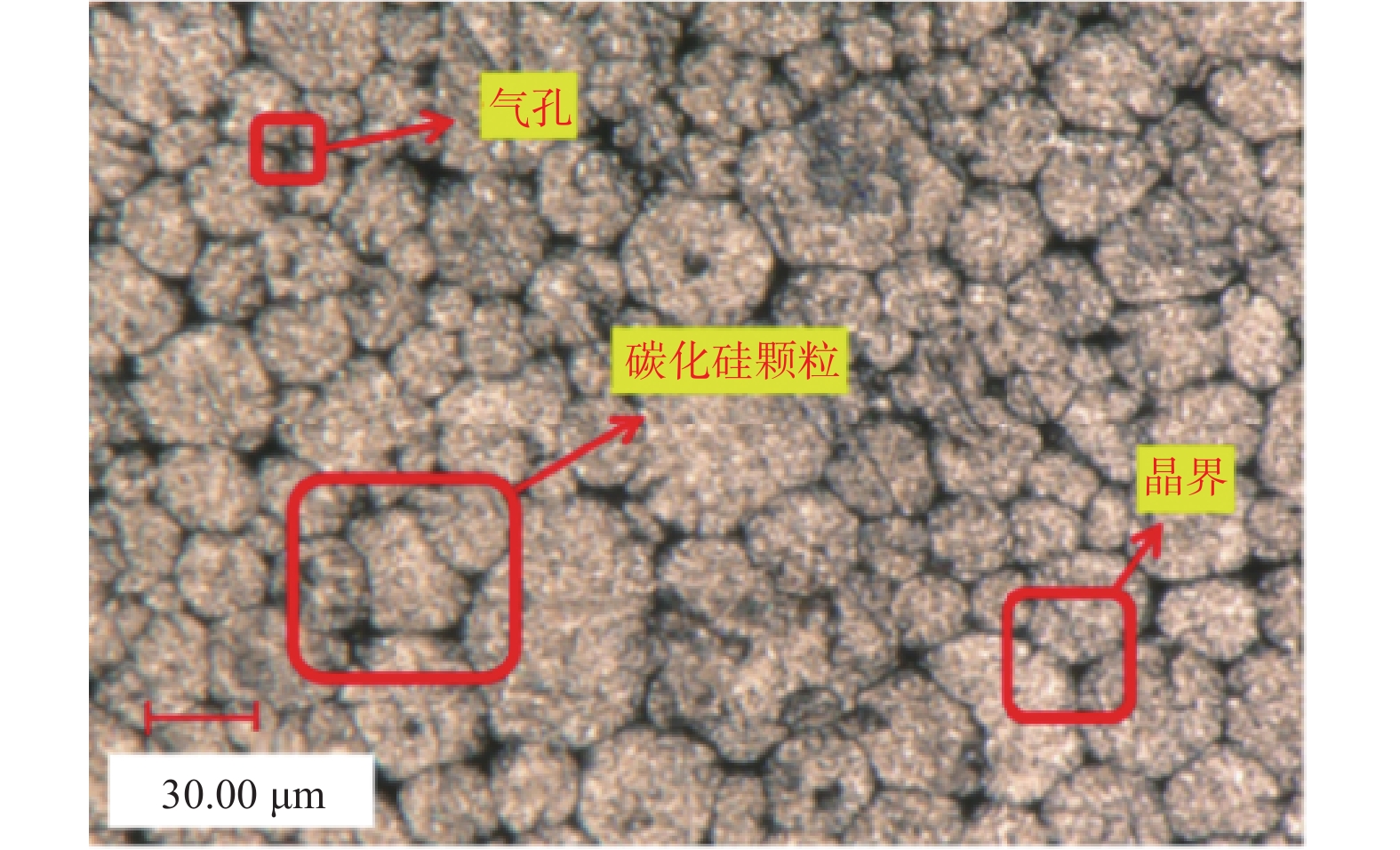

摘要: 为探究碳化硅陶瓷的磨削损伤特性,通过单颗粒划擦实验和磨削实验,结合有限元仿真,明确碳化硅陶瓷塑脆性去除转变的临界应力值以及磨削参数对材料损伤的影响。单颗粒划擦实验表明,实验中使用的碳化硅陶瓷的断裂强度约为344 MPa。实验与仿真结果都表明:不同载荷下的材料微观结构作用不同,当接触应力小于材料晶界的临界断裂强度时,晶界结构起到黏性作用,消耗应力以抑制裂纹拓展;随着载荷进一步增加,虽未达到材料断裂极限,但材料表面依旧会存在由晶界、石墨相以及气孔等结构破坏而产生的裂纹和坑洞;当接触应力大于材料晶界的临界断裂强度时,其微观结构对裂纹增长起到促进作用,使得碳化硅陶瓷损伤区域进一步扩大。磨削实验表明:优化磨削工艺参数可获得最小的磨粒未变形磨屑厚度和磨削力,从而最小化材料表面损伤比例和亚表面损伤深度,分别为0.396%和4.768 μm,相较于最差参数,其损伤值仅为各自对应值的16.01%和13.22%;材料磨削损伤进程与单颗磨粒划擦损伤进程类似,依次经历塑性去除、塑脆性去除和脆性去除3个阶段,且磨削力、磨粒未变形最大磨屑厚度变化与材料损伤变化趋势相同,即随着进给速度和磨削深度的增加而增大,随着砂轮转速的提高而减小。同时,陶瓷材料的内部结构降低了材料损伤产生阈值,是导致其容易产生加工损伤的重要原因。

-

关键词:

- 碳化硅陶瓷 /

- 磨削加工 /

- 磨粒未变形最大磨屑厚度 /

- 表面/亚表面损伤

Abstract:Objectives To explore the grinding damage mechanism and surface/subsurface damage distribution law of silicon carbide ceramics. Methods Combined with single-particle scratching experiments, grinding experiments, and finite element simulation analyses, the critical stress value of the plastic-brittle transition of the material, as well as the trend of the influence of the grinding parameters on the damage distribution, are clarified. Results The ultimate fracture strength of the silicon carbide ceramics used in this experiment is about 344 MPa, and the grain boundary fracture strength is about 25.9 MPa. Both the experimental and simulation results show that the microstructure of the material plays different roles under different loads. When the contact stress is less than the critical fracture strength of the grain boundaries, the grain boundary structure plays a viscous role, consuming stresses to inhibit the expansion of cracks. With a further increase in load, although not reaching the critical stress value of the grain boundaries, the cracks are still generated but not as severe. Further increase in load, although the material fracture limit is not reached, the material surface will still exhibit cracks and pits due to microstructural damage caused by grain boundaries, graphite, and pores. When the contact stress exceeds the critical strength of the material and the grain boundaries, the microstructure promotes the growth of cracks, further expanding the damage area of the SiC ceramics. In the paper, through the optimization of the grinding process parameters, the best parameters for achieving the minimum grit undeformed chip thickness and grinding force are determined, thus minimizing the percentage of material surface damage and the depth of subsurface damage, which are 0.396% and 4.768 μm, respectively. Compared with the worst parameters, the damage values are only 16.01% and 13.22% of their respective counterparts. Conclusions The process of material grinding damage is similar to that of single grit scratch damage, which progresses three stages: plastic removal, plastic-brittle removal, and brittle removal. The grinding force, the change in maximum grit thickness without deformation, and the extent of material damage all tend to increase with the increase of feed rate and grinding depth, and decrease with the increase of grinding wheel speed. The microstructure of ceramic materials is an important reason for their machining susceptibility to machining damage. In order to achieve low-defect processing of silicon carbide ceramics, it is not only necessary to optimize the grinding process parameters but also to consider the role of the microstructure. The experimental results provide theoretical guidance for achieving low-damage and high-quality processing. -

表 1 磨削加工参数及结果

Table 1. Grinding parameters and results

样品编号 进给速度

vw /(mm·min−1)磨削速度

vs /(m·s−1)磨削深度

ap / μm磨屑厚度

hm / μm磨削力

F / N表面损伤比例

n / %亚表面损伤深度

d / μm#1 10 5.23 20 0.293 5.187 0.493 10.616 #2 40 5.23 20 0.337 6.491 0.937 13.472 #3 70 5.23 20 0.416 7.273 2.132 22.816 #4 100 5.23 20 0.462 10.537 2.256 28.024 #5 40 1.57 20 0.427 8.904 1.898 25.008 #6 40 3.41 20 0.363 6.642 1.324 13.728 #7 40 5.23 10 0.217 3.358 0.396 4.768 #8 40 5.23 30 0.493 13.594 2.473 36.056 表 2 碳化硅颗粒JH-2本构模型参数

Table 2. JH-2 constitutive model parameters of silicon carbide particles

参数名称 数值 $ \rho_0 $ / (kg·m−3) 3 125 G / GPa 170 A 0.96 N 0.65 B 0.35 M 1 C 0.09 $ \dot{\varepsilon}/\mathrm{s}^{-1} $ 1 T / GPa 0.75 表 3 碳化硅陶瓷晶界内聚力单元模型参数

Table 3. Cohesive model parameters for grain boundaries in silicon carbide ceramics

参数名称 数值或类型 单元类型 晶界内聚力单元 E / GPa 170 v 0.96 Tmax / MPa 0.65 Γ / (J·m−2) 0.35 -

[1] DZURAK A. Quantum computing: Diamond and silicon converge [J]. Nature,2011,479(7371):47-48. doi: 10.1038/479047a [2] SHORE P, CUNNINGHAM C, DEBRA D, et al. Precision engineering for astronomy and gravity science [J]. CIRP Annals,2010,59(2):694-716. doi: 10.1016/j.cirp.2010.05.003 [3] 于思远. 工程陶瓷材料的加工技术及其应用 [M]. 北京: 机械工业出版社, 2008.YU Siyuan. Processing technology and application of engineering ceramic materials [M]. Beijing: China Machine Press, 2008. [4] GOPAL A V, RAO P V. Selection of optimum conditions for maximum material removal rate with surface finish and damage as constraints in SiC grinding [J]. International Journal of Machine Tools and Manufacture,2003,43(13):1327-1336. doi: 10.1016/S0890-6955(03)00165-2 [5] 王长昌. 硬脆材料小直径内圆磨削特性的研究[D]. 天津: 天津大学, 2005.WANG Changchang. Study on the small diameter internal grinding characteristics of hard and brittle materials [D]. Tianjin: Tianjin University, 2005. [6] HUANG H, LIU Y C. Experimental investigations of machining characteristics and removal mechanisms of advanced ceramics in high speed deep grinding [J]. International Journal of Machine Tools and Manufacture,2003,43(8):811-823. doi: 10.1016/S0890-6955(03)00050-6 [7] AGARWAL S, RAO P V. Experimental investigation of surface/subsurface damage formation and material removal mechanisms in SiC grinding [J]. International Journal of Machine Tools and Manufacture,2008,48(6):698-710. doi: 10.1016/j.ijmachtools.2007.10.013 [8] 戴剑博, 苏宏华, 傅玉灿, 等. 磨削速度对碳化硅陶瓷磨削损伤影响机制研究 [J]. 机械工程学报,2022,58(21):316-330. doi: 10.3901/JME.2022.21.316DAI Jianbo, SU Honghua, FU Yucan, et al. Effect of grinding speed on machining damage of silicon carbide ceramics [J]. Journal of Mechanical Engineering,2022,58(21):316-330. doi: 10.3901/JME.2022.21.316 [9] 于腾飞, 苏宏华, 戴剑博, 等. 单颗磨粒磨削碳化硅陶瓷力与比能研究 [J]. 南京航空航天大学学报,2018,50(1):120-125. doi: 10.16356/j.1005-2615.2018.01.017YU Tengfei, SU Honghua, DAI Jianbo, et al. Study on the force and specific energy of single abrasive grinding silicon carbide ceramics [J]. Journal of Nanjing University of Aeronautics & Astronautics,2018,50(1):120-125. doi: 10.16356/j.1005-2615.2018.01.017 [10] MAO C, LIANG C, ZHANG Y C, et al. Grinding characteristics of cBN-WC-10Co composites [J]. Ceramics International,2017,43(18):16539-16547. doi: 10.1016/j.ceramint.2017.09.040 [11] LAWN B R, EVANS A G, MARSHALL D B. Elastic/plastic indentation damage in ceramics: The median/radial crack system [J]. Journal of the American Ceramic Society,1980,63(9/10):574-581. doi: 10.1111/j.1151-2916.1980.tb10768.x [12] 温家宙. 单向Cf/SiC复合材料磨削性能试验研究[D]. 上海: 东华大学, 2023.WEN Jiazhou. Experimental study on grinding performance of unidirectional Cf/SiC composite materials [D]. Shanghai: Donghua University, 2023 [13] 戴剑博. 基于断裂力学的多晶碳化硅陶瓷磨削损伤机理及其影响机制研究 [D]. 南京: 南京航空航天大学, 2019.DAI Jianbo. Study on grinding damage mechanism and its influencing mechanism of polycrystalline silicon carbide ceramics based on fracture mechanics [D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2019. [14] 苏蕴华. 熔融石英玻璃单颗粒磨削理论研究与实验验证 [D]. 天津: 天津大学, 2017.SU Yunhua. Theoretical study and experimental verification of single particle grinding of fused silica glass [D]. Tianjin: Tianjin University, 2017. [15] LI S Y, WANG Z, WU Y L. Relationship between subsurface damage and surface roughness of ground optical materials [J]. Journal of Central South University of Technology,2007,14(4):546-551. doi: 10.1007/s11771-007-0105-1 [16] SOLHTALAB A, ADIBI H, ESMAEILZARE A, et al. Cup wheel grinding-induced subsurface damage in optical glass BK7: An experimental, theoretical and numerical investigation [J]. Precision Engineering,2019,57:162-175. doi: 10.1016/j.precisioneng.2019.04.003 [17] 阎秋生, 庄司克雄, 田中宪司. 金属结合层包覆单列磨粒小直径CBN砂轮端面磨削过程研究 [J]. 机械工程学报,2005,41(8):208-212. doi: 10.3321/j.issn:0577-6686.2005.08.037YAN Qiusheng, SYOJI K, TANAKA K. Studies on face grinding process of metal layer bond wrapped monorail grit cup CBN quill [J]. Chinese Journal of Mechanical Engineering,2005,41(8):208-212. doi: 10.3321/j.issn:0577-6686.2005.08.037 [18] 肖玉斌, 梁志强, 袁剑平, 等. 合金淬硬钢20Cr2Ni4A小直径CBN砂轮磨削研究 [J]. 组合机床与自动化加工技术,2023(2):134-137,142. doi: 10.13462/j.cnki.mmtamt.2023.02.031XIAO Yubin, LIANG Zhiqiang, YUAN Jianping, et al. Research on grinding alloy carburized steel 20Cr2Ni4A with small diameter CBN grinding wheel [J]. Modular Machine Tool & Automatic Manufacturing Technique,2023(2):134-137,142. doi: 10.13462/j.cnki.mmtamt.2023.02.031 [19] 李金旸, 严仁军. 基于Voronoi方法的二维混凝土细观骨料建模方法研究 [J]. 武汉理工大学学报(交通科学与工程版),2023,47(4):705-709. doi: 10.3963/j.issn.2095-3844.2023.04.023LI Jinyang, YAN Renjun. Research on two-dimensional concrete meso-aggregate modeling method based on Voronoi method [J]. Journal of Wuhan University of Technology (Transportation Science & Engineering),2023,47(4):705-709. doi: 10.3963/j.issn.2095-3844.2023.04.023 [20] 陈志颖. 基于内聚力模型的钢-铝接头结合界面强度研究 [D]. 大连: 大连理工大学, 2020.CHEN Zhiying. Study on interface strength of steel-aluminum joint based on cohesion model [D]. Dalian: Dalian University of Technology, 2020. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS