Effect of brazing process on microstructure and properties of brazed diamond interface

-

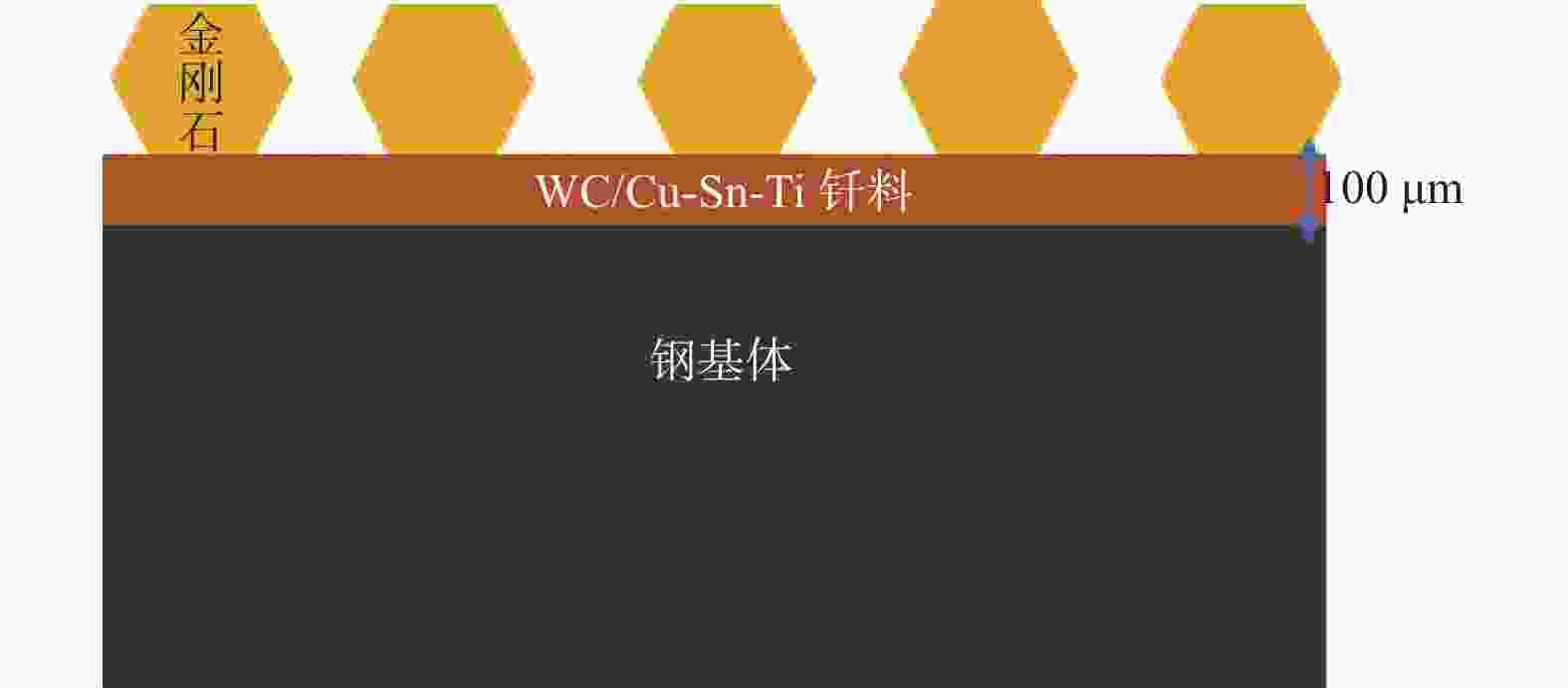

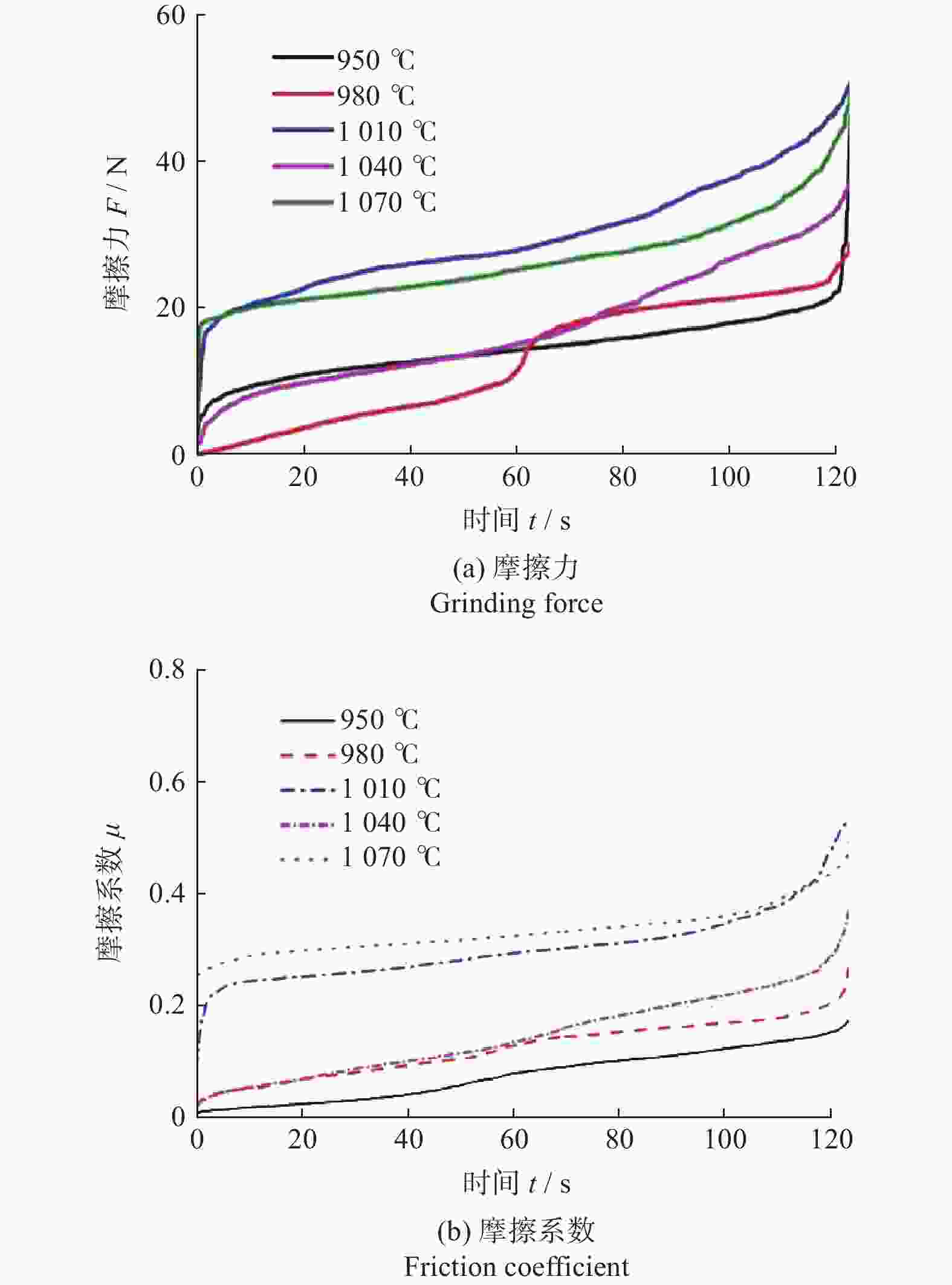

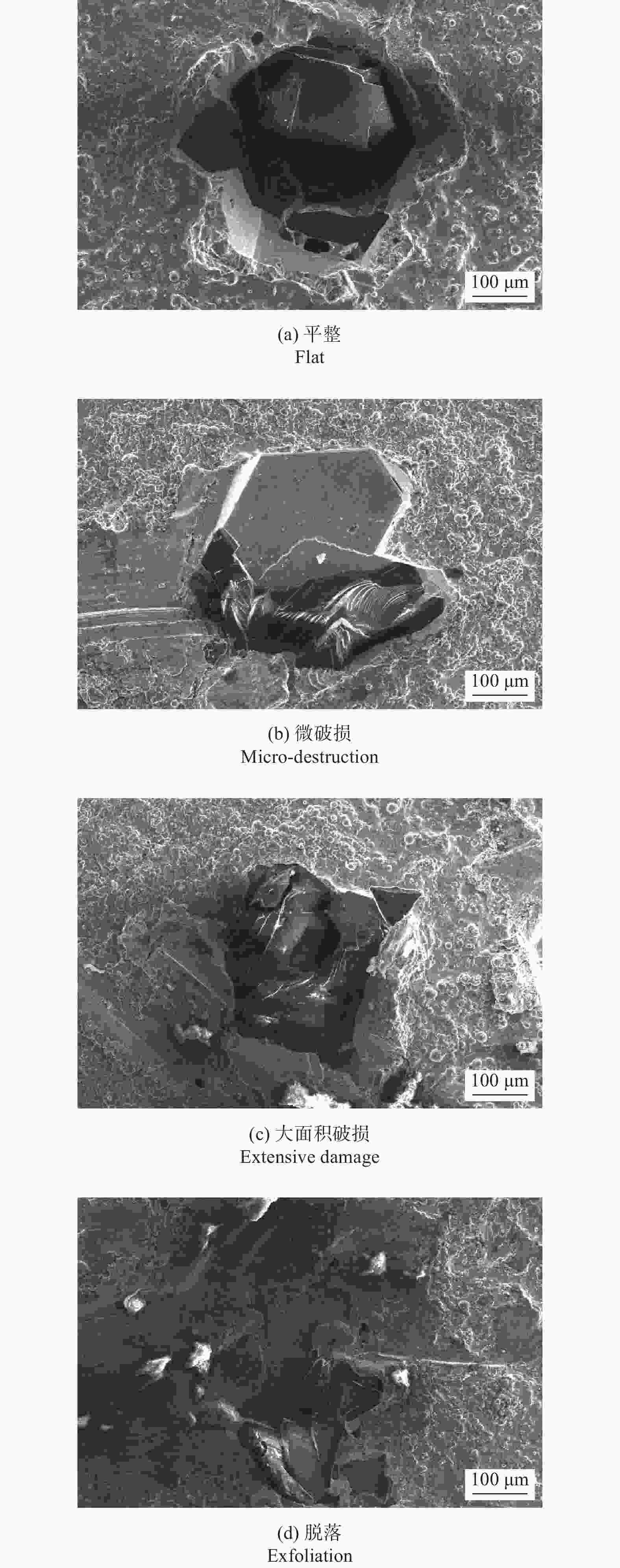

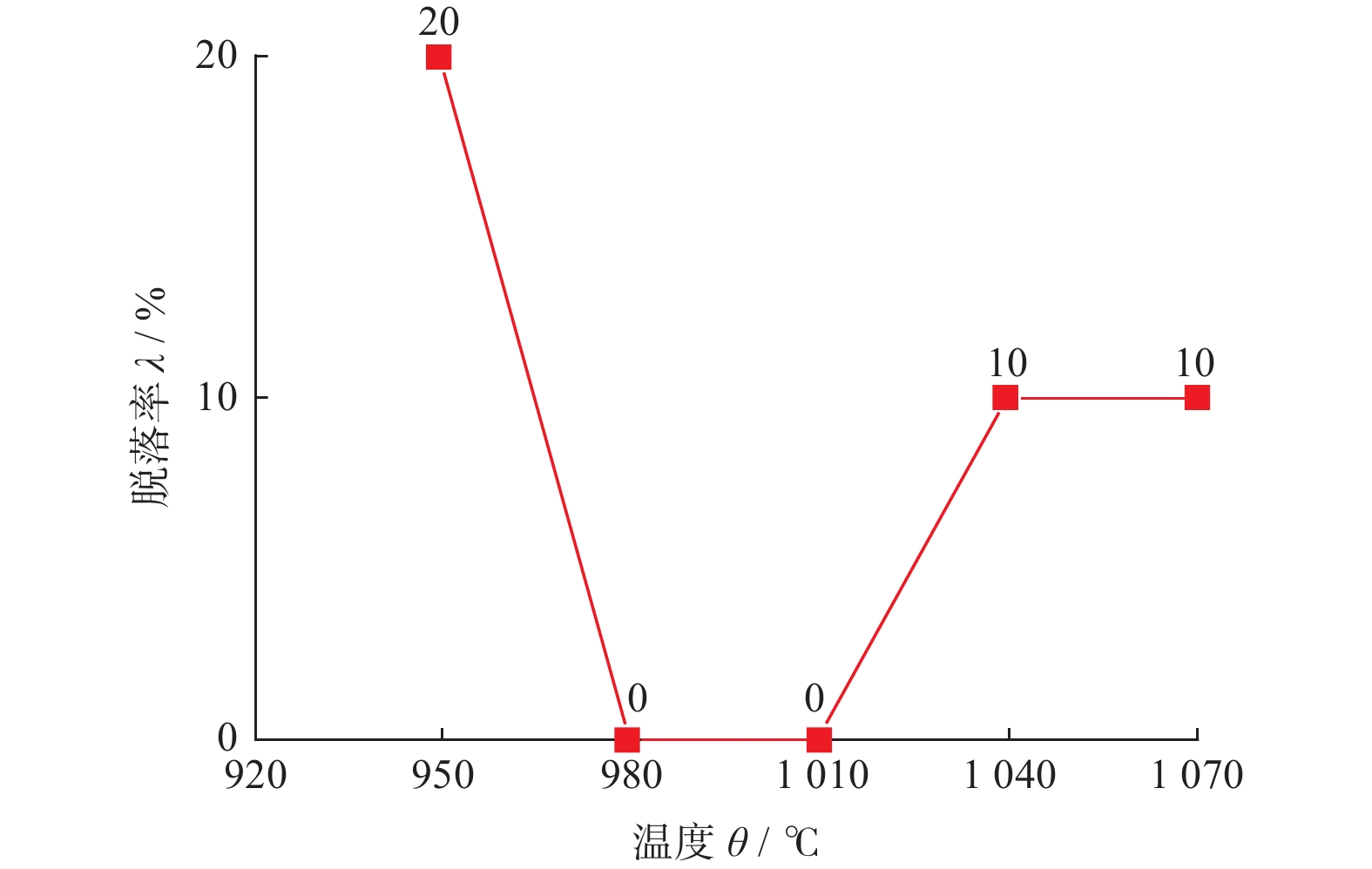

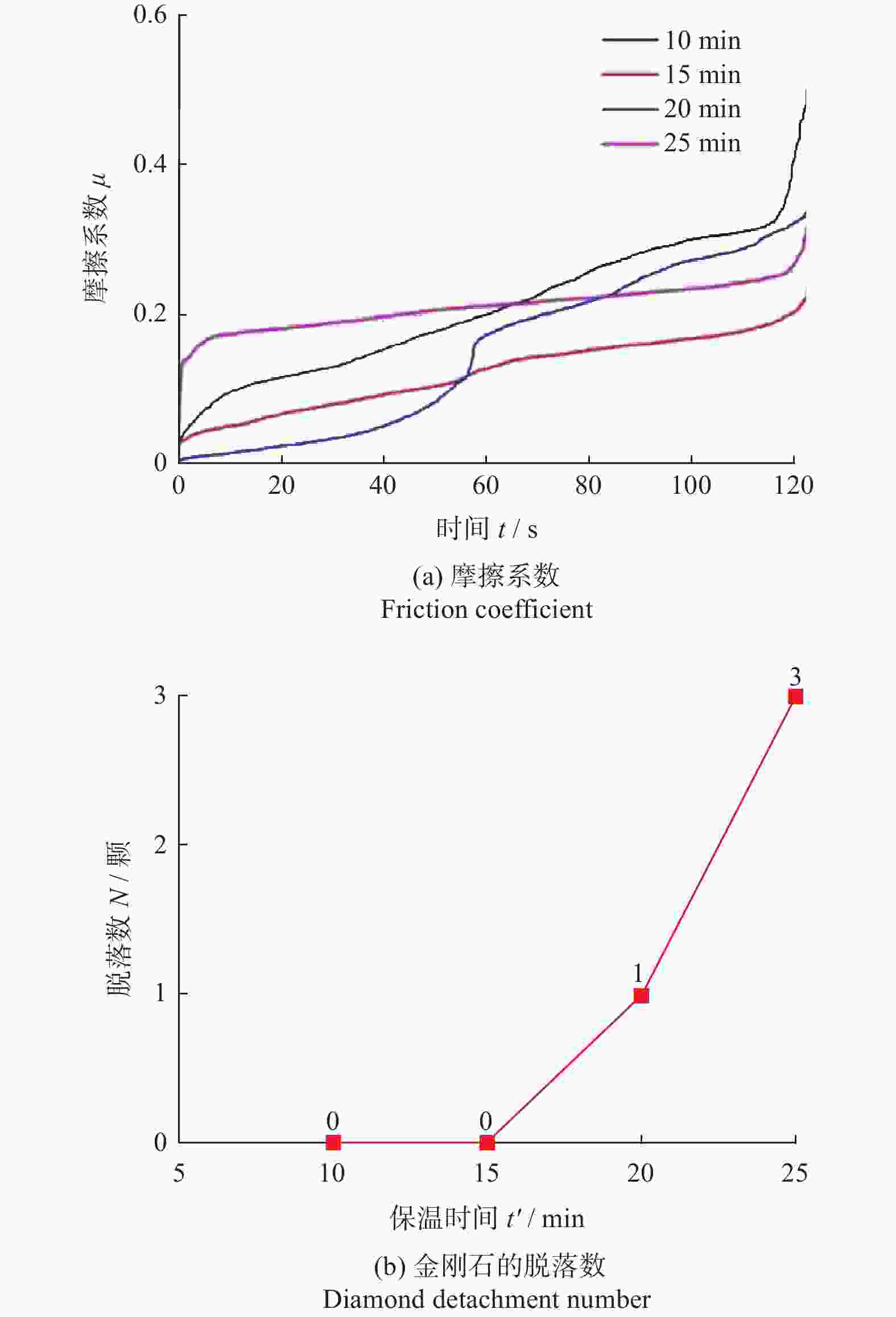

摘要: 采用WC/Cu-Sn-Ti钎料对金刚石进行真空钎焊,借助扫描电子显微镜、X射线衍射仪、能谱仪以及磨削试验等手段,研究钎焊温度和保温时间对钎焊金刚石形貌、界面组织和力学性能的影响。结果表明:金刚石颗粒与WC/Cu-Sn-Ti复合钎焊界面形成的化合物层均匀连续且致密,且在金刚石颗粒表面形成了薄而连续的层片状TiC和少量W2C相,提高了金刚石与钢基体的结合强度;随着钎焊温度升高及保温时间延长,钎焊界面缺陷逐渐减少,金刚石石墨化程度升高;在钎焊温度为980 ℃、保温时间为15 min的条件下,金刚石颗粒在磨削过程中的摩擦力和摩擦系数相对较小,对大理石工件的磨削体积最大,且金刚石颗粒的脱落率最低。

-

关键词:

- Cu-Sn-Ti钎料 /

- 钎焊工艺 /

- 力学性能 /

- 金刚石磨具

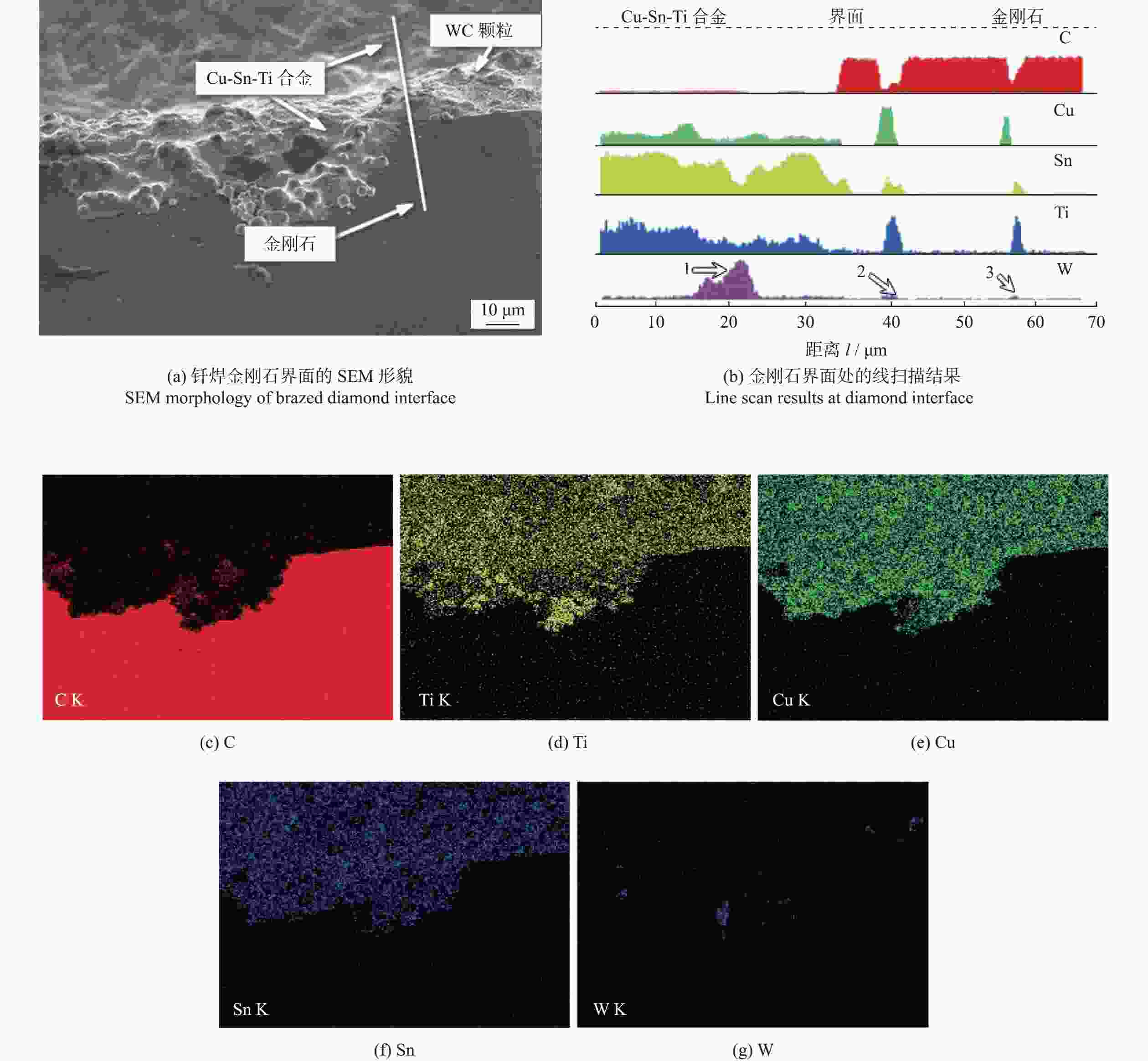

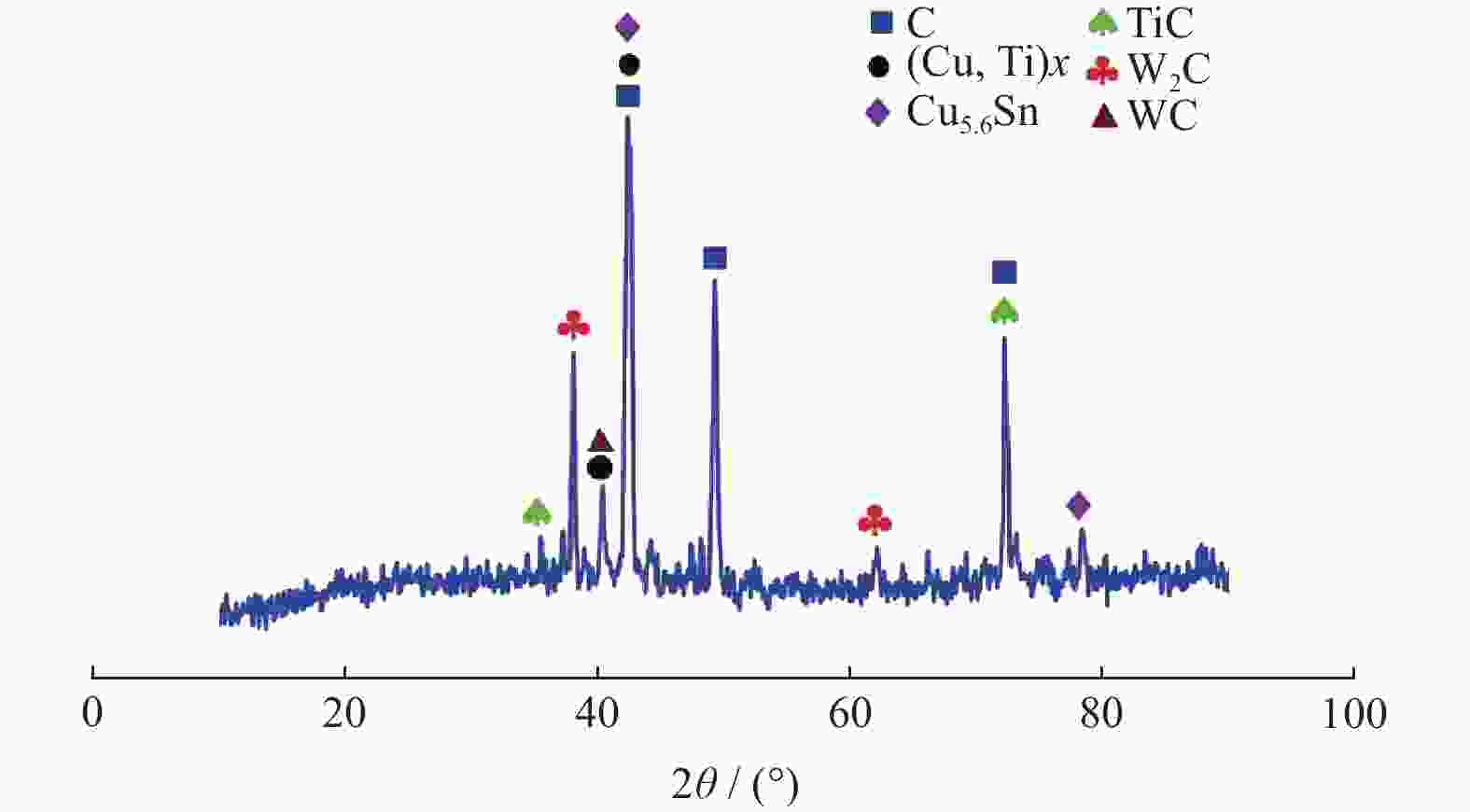

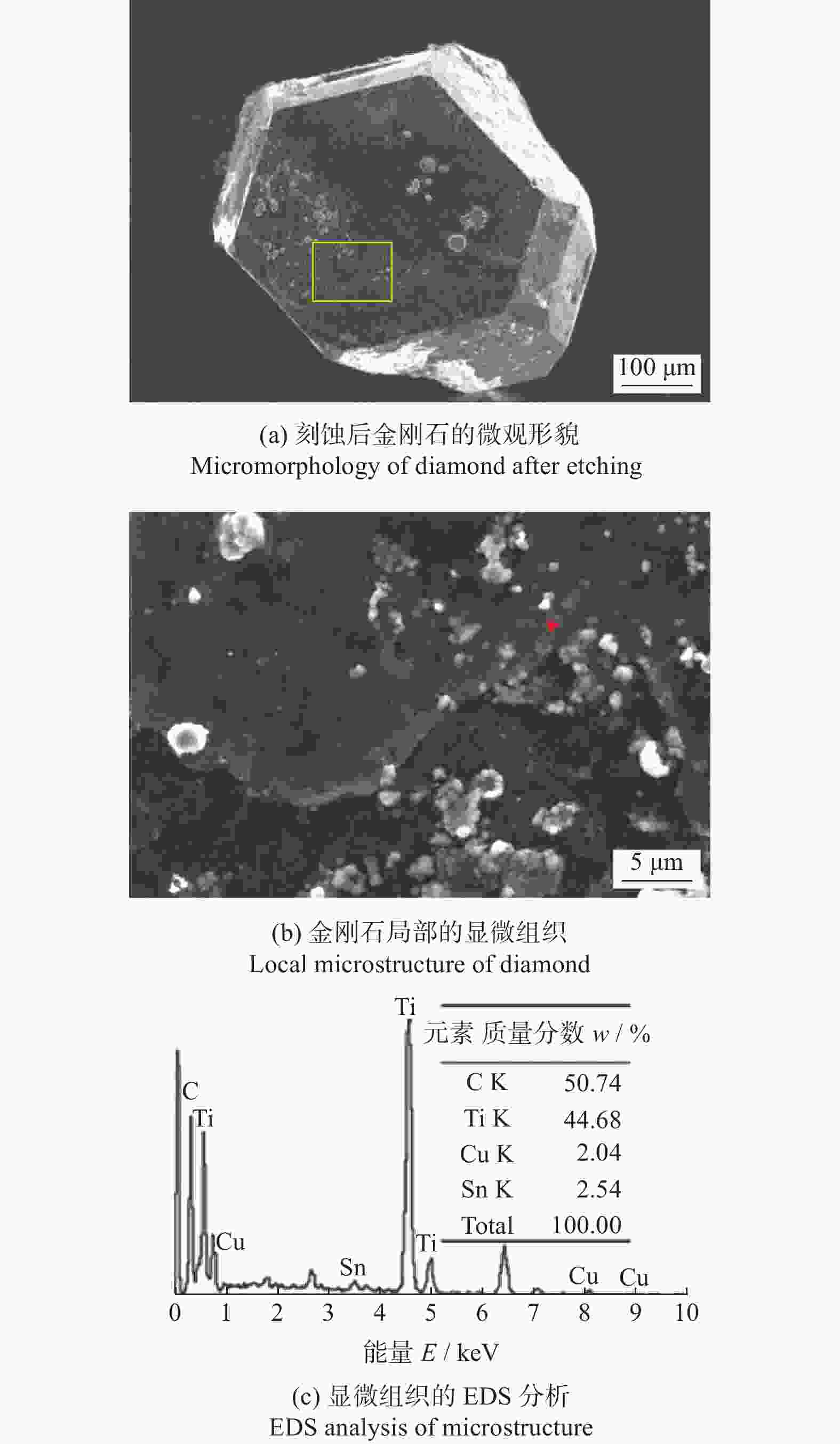

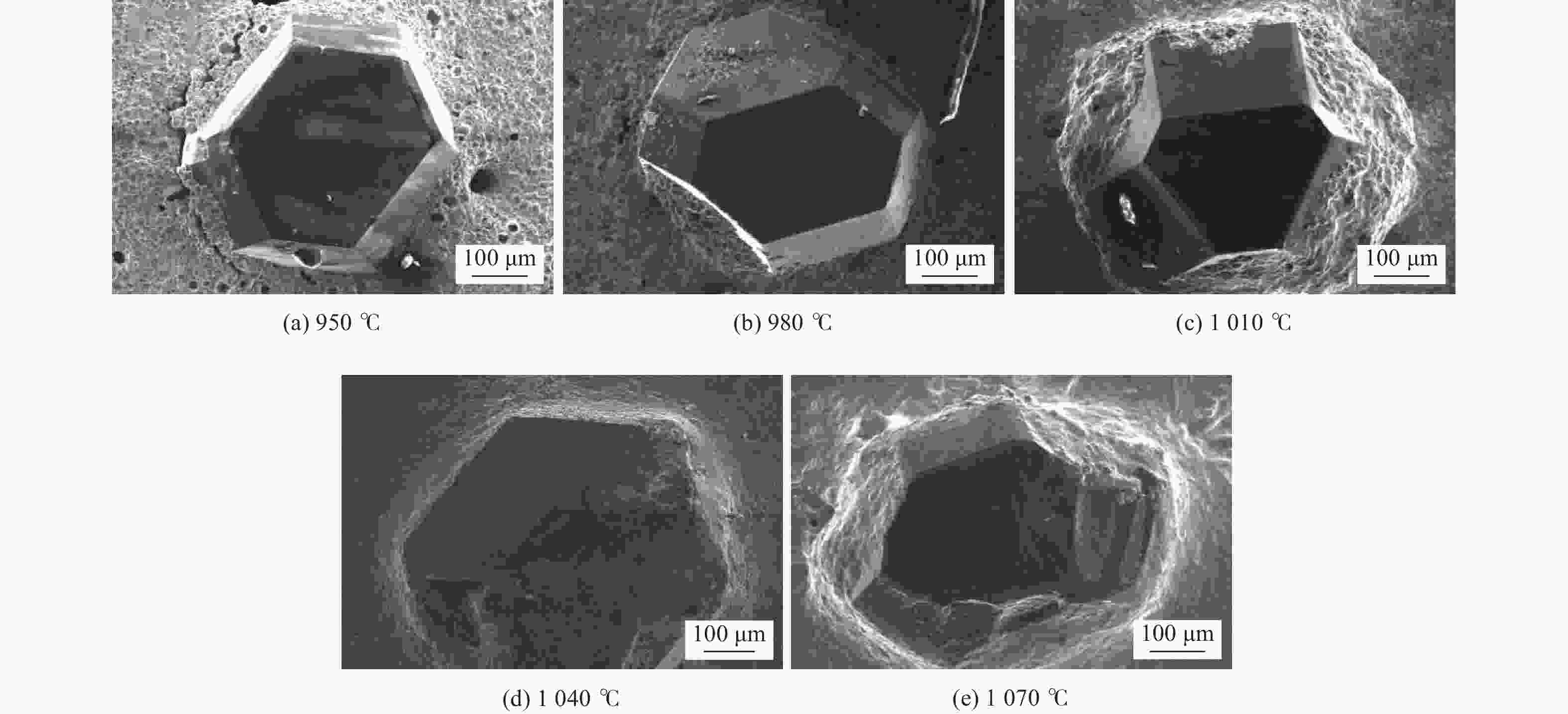

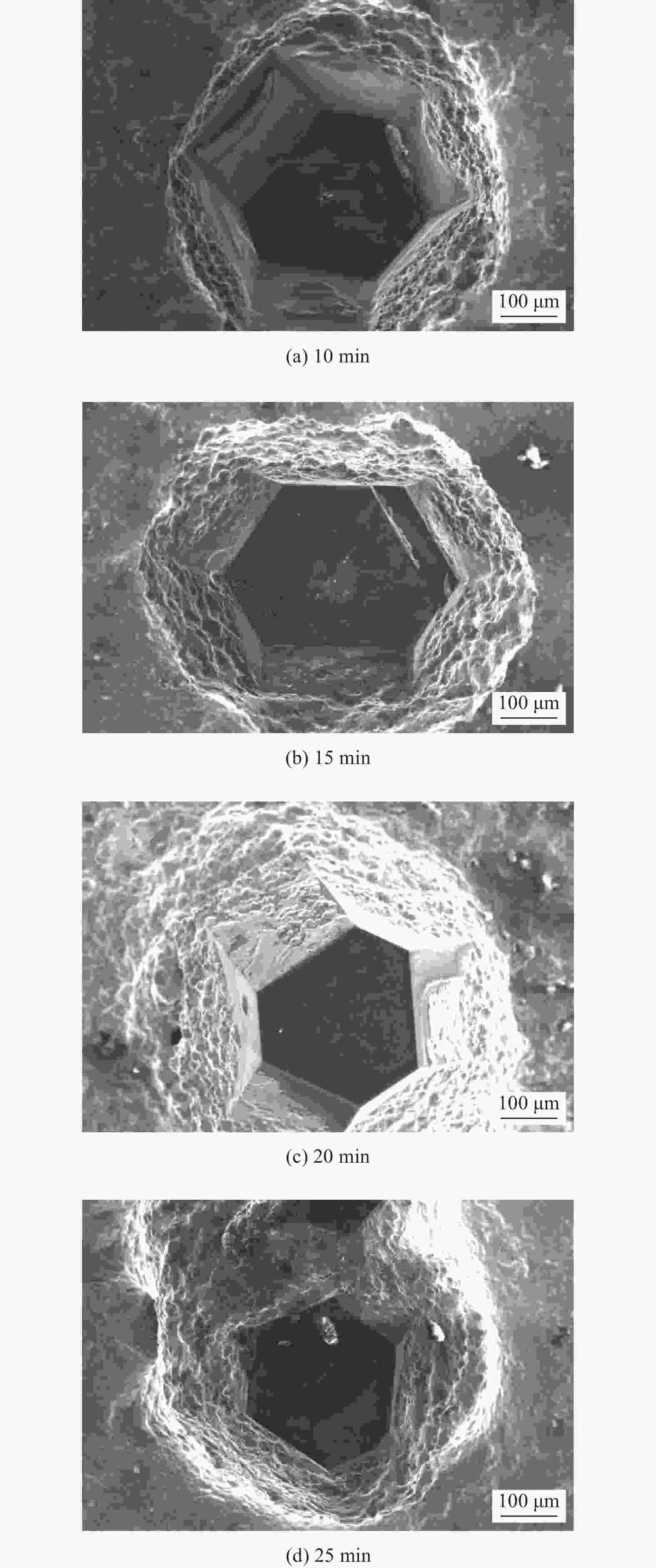

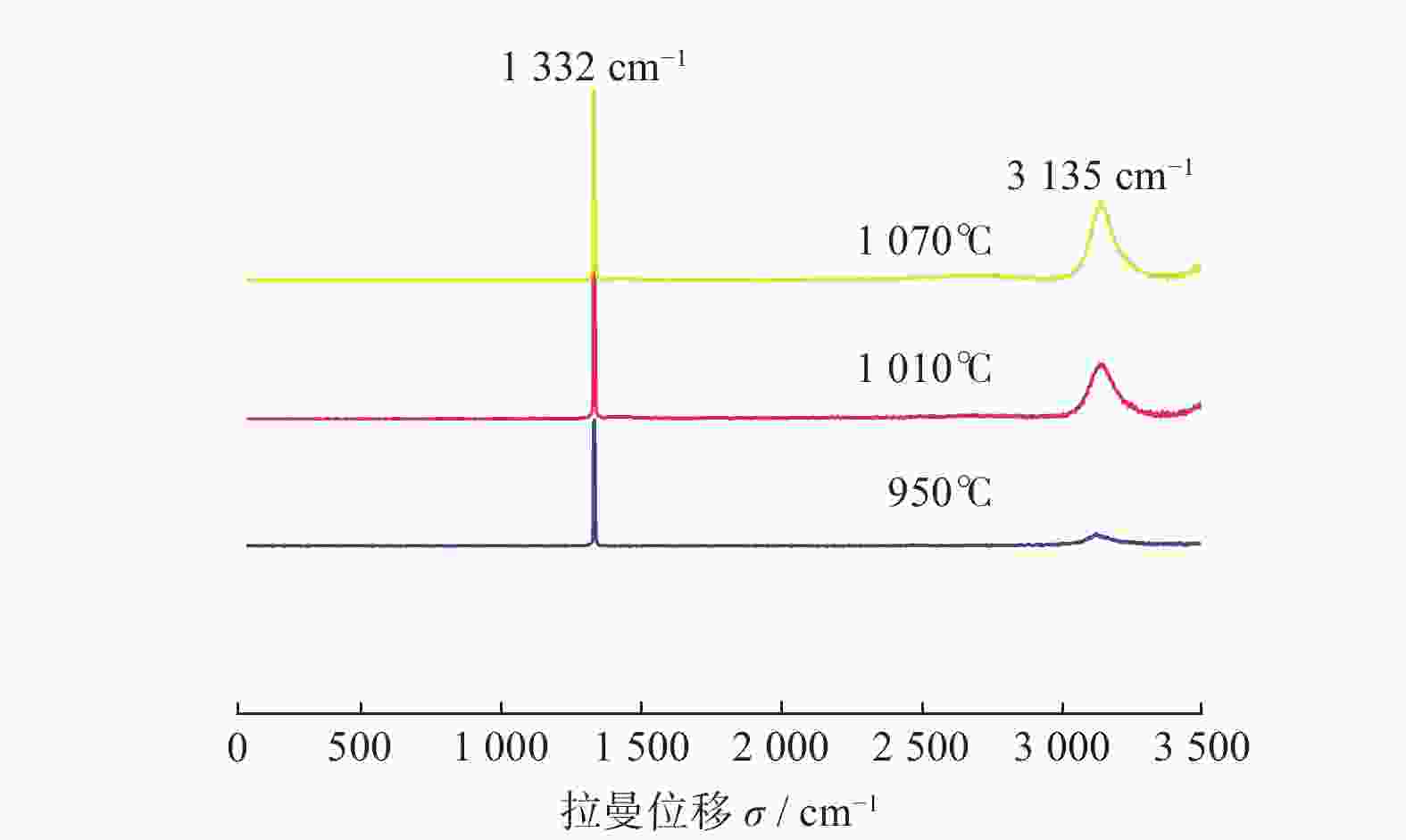

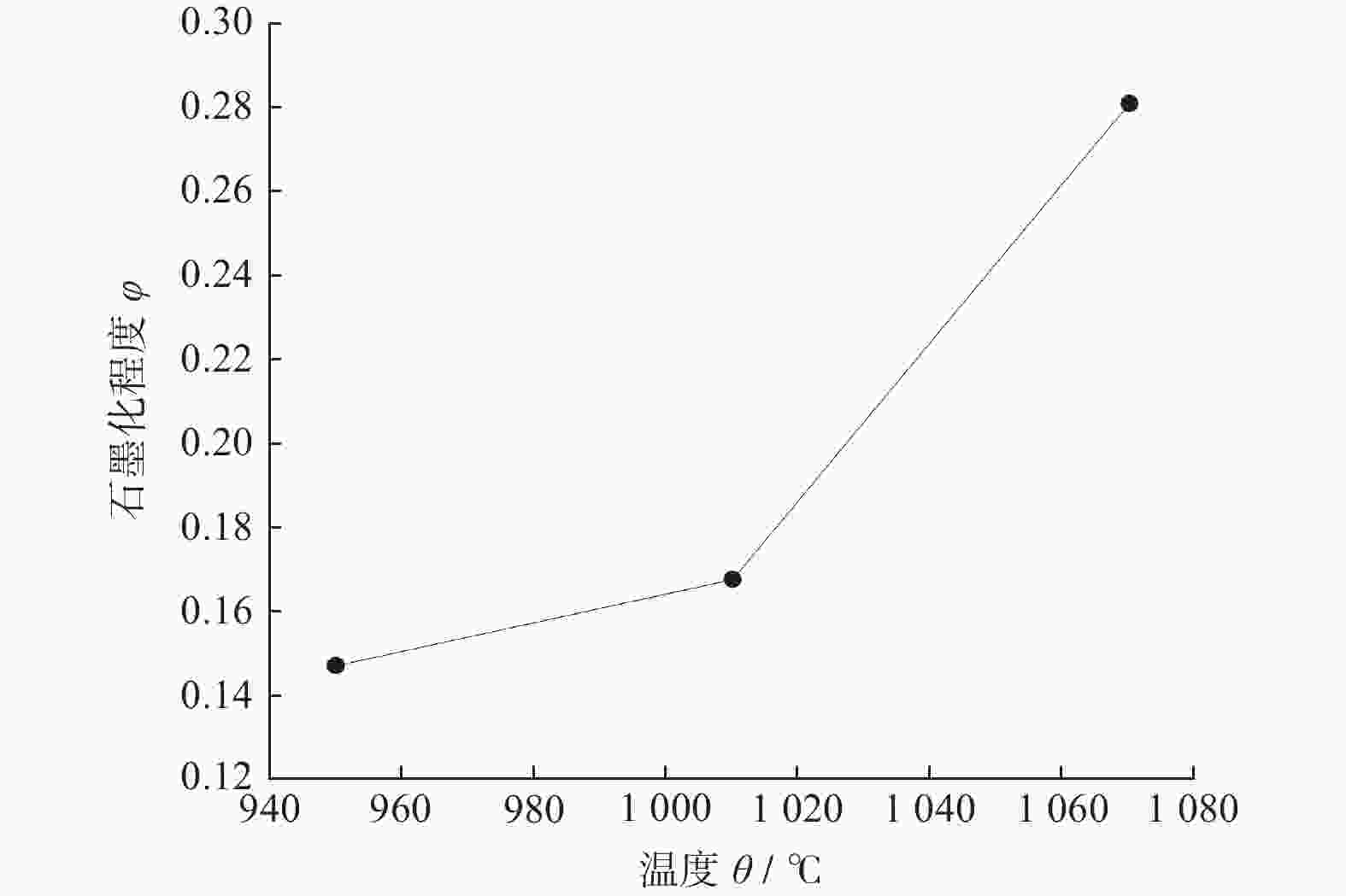

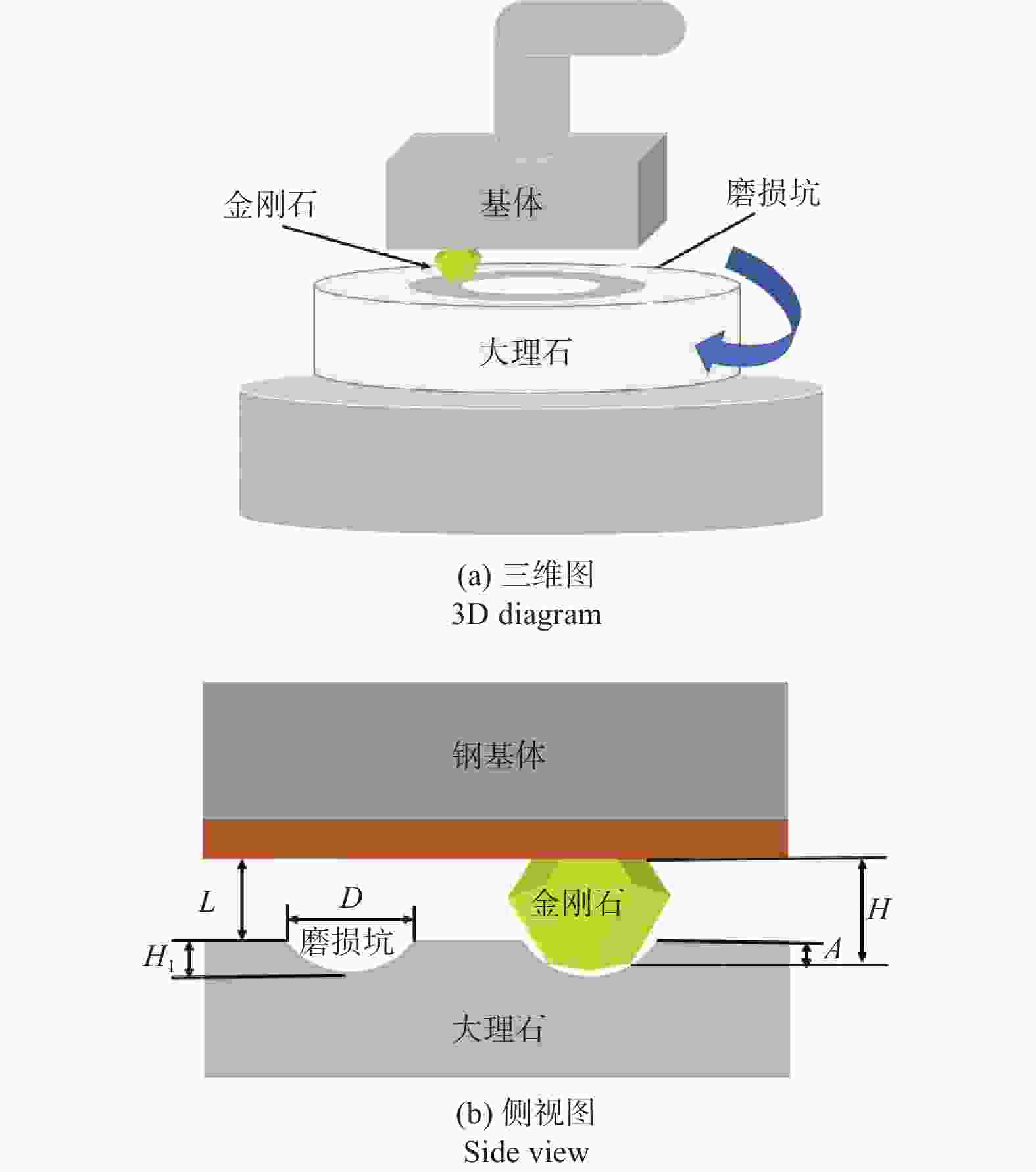

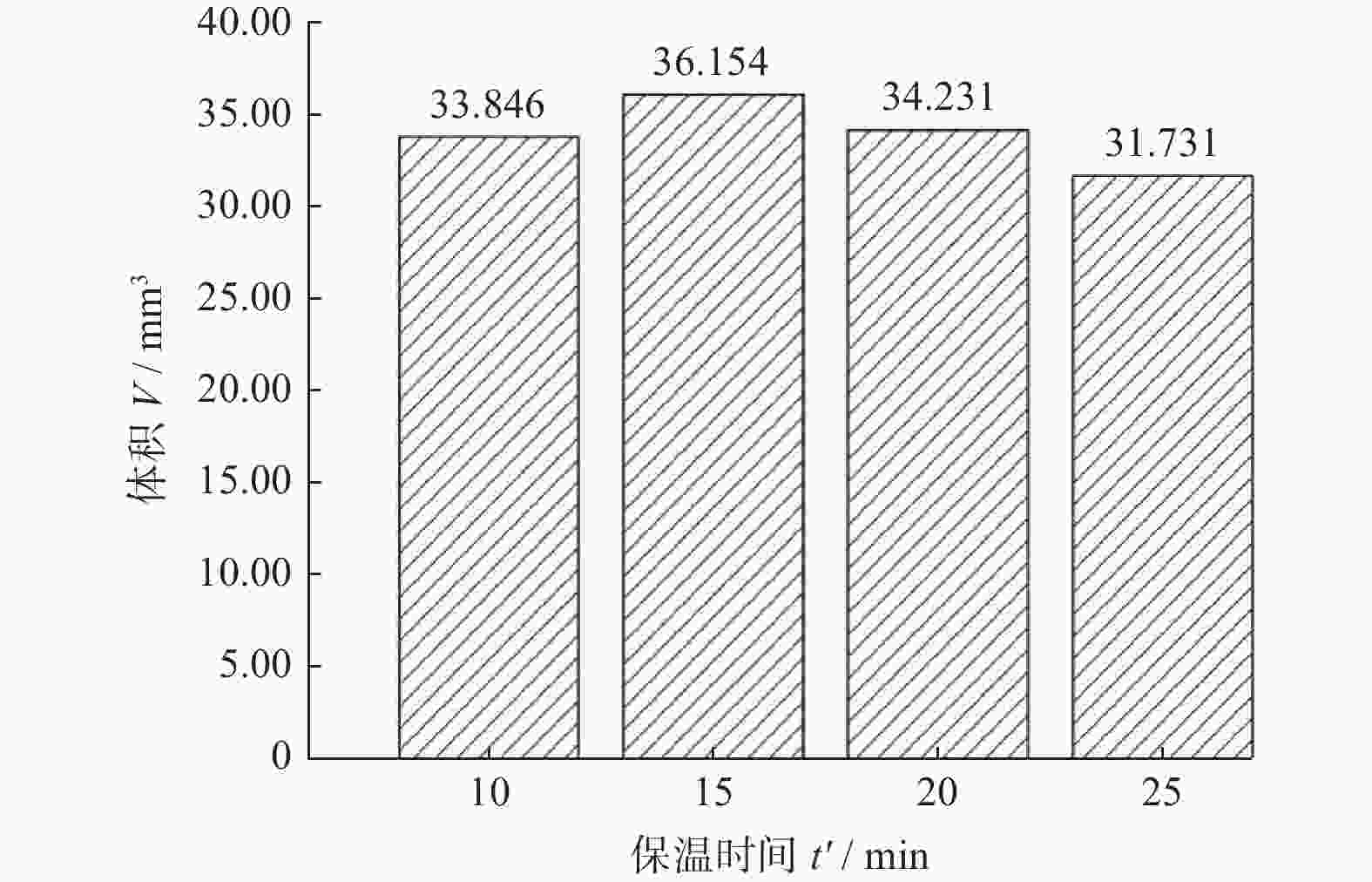

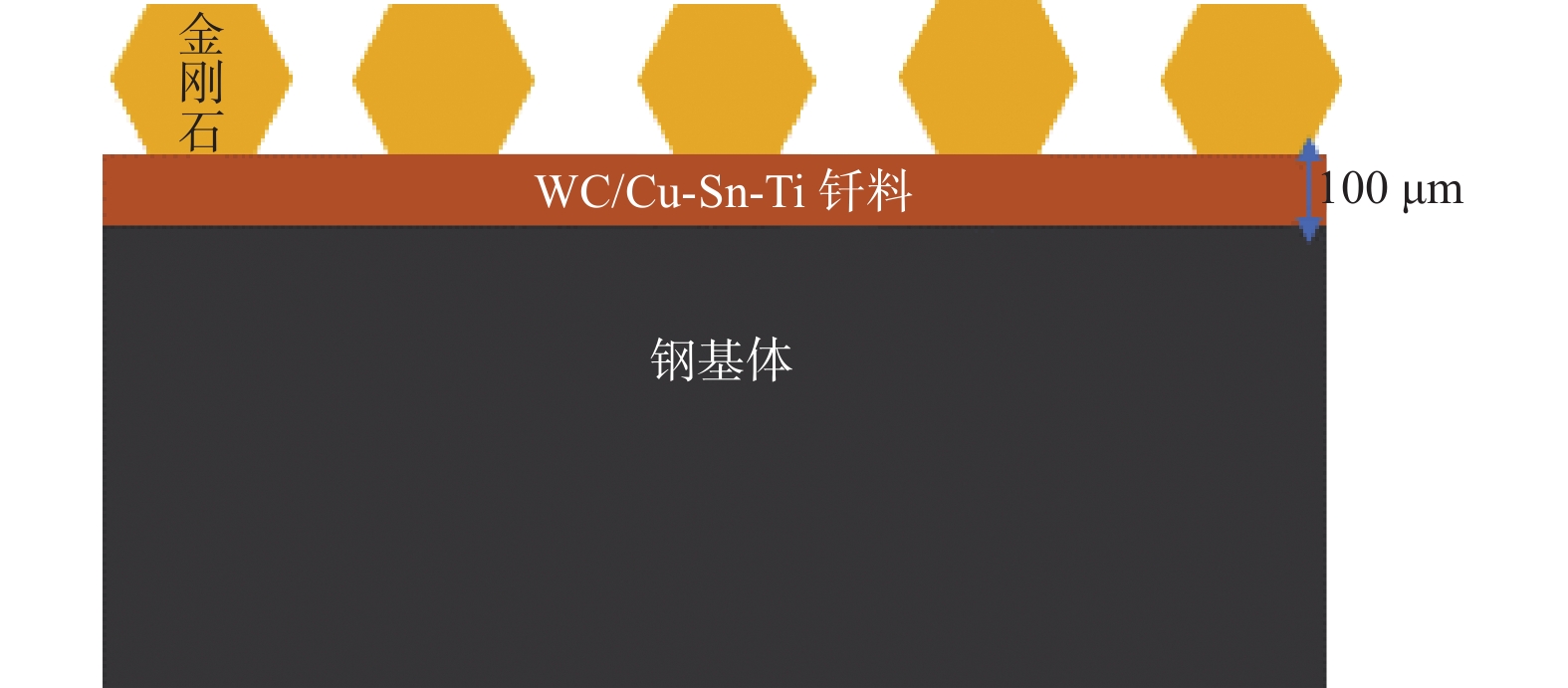

Abstract:Objectives Diamond tools are widely used in various fields. Copper-based brazing materials are used for brazing diamond tools. In response to the problems of low-temperature phase flow and low bonding strength of copper-based brazing materials at high temperatures, different brazing temperatures and brazing times are designed, and the WC/Cu-Sn-Ti composite brazing material is used for vacuum induction brazing to study the changes in microstructure and mechanical properties of brazed joints. Methods The brazing samples were made of HWD40 diamond with a particle size code of 35/40, a 45 steel matrix, and WC/Cu-Sn-Ti composite brazing filler metal. The vacuum degree was 1×10−3 Pa, the brazing temperature were 950, 980, 1 010, 1 040 and 1 070 ℃, and the brazing time was 10, 15, 20 and 25 min, respectively. The SEM observation and XRD phase analysis were carried out on different samples after brazing. At the same time, friction and wear tests were carried out on brazing samples at different temperatures and different holding times to obtain the grinding amount and diamond drop rate of the samples, so as to analyze the mechanical properties of the joint structures. Results (1) Under the conditions of a brazing temperature of 980 ℃ and a holding time of 15 min, the line scan analysis is conducted on the elements at the brazed diamond interface. It is found that the W element is enriched near the brazed diamond interface, possibly due to the diffusion of elements in WC. The XRD phase analysis showes the formation of TiC and W2C compounds at the diamond interface, which can improve the wettability between the diamond and brazing material, and enhance the adhesion of the brazing material to the diamond. In order to further determine the formation of TiC, the sample is subjected to aqua regia etching, and the surface of the diamond particle is analyzed by SEM and EDS to determine that the TiC is formed by the metallurgical reaction between the active element Ti and the C element on the diamond surface. (2) To investigate the effect of the brazing process on the surface morphology of brazed diamond, the morphology of the diamond surface is analyzed at different brazing temperatures with a holding time of 15 minutes. It is found that the diamond surface has obvious pores and cracks at a brazing temperature of 950 ℃. When the brazing temperature is raised to 980 ℃, the cutting edge of the diamond remaines intact, and the diamond is exposed the most. As the brazing temperature continues to rise, the diamond graphitization phenomenon in the brazed sample becomes severe. Therefore, the brazing process with a holding time of 15 minutes and a brazing temperature of 980 ℃ has the best effect. (3) Raman analysis is performed on the samples at 950, 1 010, and 1 070 ℃ to calculate the ratios of the diamond peak and graphite peak in the samples. It is found that when the temperature increases from 950 ℃ to 1 070 ℃, the temperature increases by 12%, and the degree of graphitization of diamond increases by 90%. At the same time, when the brazing temperature is 980 ℃, the main wear form of the diamond is flat and micro-damage, and the diamond shedding rate is 0. (4) To further compare the effect of insulation time on the performance of brazed joints, friction and wear tests are conducted on samples with different insulation times at the optimal brazing temperature of 980 ℃. It is found that as the insulation time increases, the number of diamond drops increases from 0 to 3. However, if the insulation time is too long, the diamond particles suffer thermal damage. When the brazed sample with an insulation time of 15 minutes is used to grind marble, the marble grinding volume of the sample is 36.154 mm3, and the grinding performance of the sample is the best. Conclusions The compound layer at the interface between the diamond particles and the WC/Cu-Sn-Ti composite brazing is uniform, continuous and dense. A thin and continuous layered TiC and a small amount of W2C phase are formed on the surface of diamond particles, which improves the bonding strength between the diamond and steel substrate. Under the conditions of a brazing temperature of 980 ℃ and a holding time of 15 min, the friction coefficient of diamond particles in the grinding process is small, the grinding amount of the marble workpiece is large, and the diamond particle shedding rate is low. By reasonably controlling the brazing temperature and holding time, the efficiency and quality of diamond-abrasive tools in the processing of marble and other materials can be improved, the shedding rate of diamond particles can be reduced, and the service life of abrasive tools can be extended. At a brazing temperature of 980 °C and a holding time of 15 minutes, the diamond particles exhibit a low friction coefficient during the grinding process, a high grinding volume on marble workpieces, and a low diamond drop-out rate. By controlling the brazing temperature and holding time, the efficiency and quality of diamond grinding tools in processing materials such as marble can be improved, reducing the diamond particle drop-out rate and extending the tool's service life. The WC/Cu-Sn-Ti brazing material was used for vacuum brazing of diamond. The effects of brazing temperature and holding time on the morphology, the interfacial structure, and mechanical properties of brazed diamond were studied using a scanning electron microscope, X-ray diffractometer, energy spectrum analysis, and shear and grinding experiments. The results show that the compound layer formed at the composite brazing interface between diamond particles and WC/Cu-Sn-Ti is uniform, continuous and dense, and a thin and continuous layered TiC and a small amount of W2C phases are formed on the surface of diamond particles, which improves the bonding strength between the diamond and steel matrix. As the brazing temperature increases and the holding time prolongs, the interface defects of brazing gradually decrease, and the degree of diamond graphitization increases. Under the brazing temperature of 980 ℃ and a holding time of 15 minutes, the friction force and the coefficient of friction of diamond particles during the grinding process are relatively small, resulting in the largest grinding volume for the marble workpiece and the lowest detachment rate of diamond particles. -

-

[1] MONTEIRO W A, CARRIO J A G, DA SILVEIRA C R, et al. Structural and electrical properties of copper-nickel-aluminum alloys obtained by conventional powder metallurgy method [J]. Materials Science Forum, 2010, 660/661: 41-45 [2] SUNG J C, SUNG M. The brazing of diamond [J]. International Journal of Refractory Metals & Hard Materials,2009,27(2):382-393. doi: 10.1016/j.ijrmhm.2008.11.011 [3] SU S Y, ZANG J B, ZHOU Y K, et al. Efficient manufacture of high-performance electroplated diamond wires utilizing Cr-coated diamond micro-powder [J]. Materials Science in Semiconductor Processing,2024, 179:108511. doi: 10.1016/j.mssp.2024.108511 [4] 李鸿程. 新型金刚石分齿烧结锯片的半自动成型模具 [J]. 超硬材料工程, 2010, 22(2): 28-31.LI Hongcheng. New semi-automated forming mould for sintering diamond saw blade [J]. Superhard Material Engineering, 2010, 22(2): 28-31. [5] 关砚聪, 郑敏利, 姚德明. 铜基钎料焊接金刚石的界面结构与强度 [J]. 焊接学报,2012,33(7):65-68,116.GUAN Yancong, ZHENG Minli, YAO Deming. Interfacial structure and strength of Cu-based filler metal welding diamond [J]. Transactions of the China Welding Institution,2012,33(7):65-68,116. [6] 周玉梅, 张凤林. 钎焊单层金刚石工具研究现状 [J]. 焊接技术,2010,39(6):1-6. doi: 10.3969/j.issn.1002-025X.2010.06.001ZHOU Yumei, ZHANG Fenglin. Status of research on brazed monolayer diamond tool [J]. Welding Technology,2010,39(6):1-6. doi: 10.3969/j.issn.1002-025X.2010.06.001 [7] LU J B, LI H, LI Y, et al. Study on diamond vacuum brazed with Cu-based filler metal containing Cr [J]. International Journal of Advanced Manufacturing Technology,2017,91(5/6/7/8):1453-1460. doi: 10.1007/s00170-016-9802-y [8] 卢金斌, 李华, 刘威, 等. 添加Ni-Cr-B-Si的Cu基复合钎料真空钎焊金刚石界面微结构 [J]. 中国机械工程,2018,29(3):353-358, 365. doi: 10.3969/j.issn.1004-132X.2018.03.016LU Jinbing, LI Hua, LIU Wei, et al. Interfacial microstructure of diamond vacuum brazed with Cu-based composite filler metals adding Ni-Cr-B-Si alloy [J]. China Mechanical Engineering,2018,29(3):353-358, 365. doi: 10.3969/j.issn.1004-132X.2018.03.016 [9] ZHU M, CHUNG D. Active brazing alloy containing carbon fibre for metal-ceramic ioining [J]. Journal of the American Ceramic Society,1994,77:2715-2720. doi: 10.1002/chin.199507018 [10] TAO Y, WANG Z, WANG X. Effects of Ni–Cr–Mo–Si–B prealloy additives on the properties of Fe-based diamond composites [J]. Diamond and Related Materials,2024,148:111482. doi: 10.1016/j.diamond.2024.111482 [11] XIAO H Z, XIAO B, WU H H, et al. Microstructure and mechanical properties of vacuum brazed CBN abrasive segments with tungsten carbide reinforced Cu-Sn-Ti alloys [J]. Ceramics International,2019,45(9):12469-12475. doi: 10.1016/j.ceramint.2019.03.181 [12] DUAN D Z, HAN F, DING J J, et al. Microstructure and performance of brazed diamonds with multilayer graphene-modified Cu–Sn–Ti solder alloys [J]. Ceramics International,2021,47(16):22854-22863. doi: 10.1016/j.ceramint.2021.04.304 [13] YIN X H, XU F, MIN C Y, et al. Promoting the bonding strength and abrasion resistance of brazed diamond using Cu-Sn-Ti composite alloys reinforced with tungsten carbide [J]. Diamond and Related Materials,2021,112:108239. doi: 10.1016/j.diamond.2021.108239 [14] MÜHLBAUER G, KREMSER G, BOCK A, et al. Transition of W2C to WC during carburization of tungsten metal powder [J]. International Journal of Refractory Metals and Hard Materials,2018,72:141-148. doi: 10.1016/j.ijrmhm.2017.12.018 [15] 候逸群, 张锁怀, 徐少丽, 等. 基于第一性原理的涂层WC/α-Ti界面结合能、稳定性及电子结构的研究 [J]. 热加工工艺,2021,50(10):75-80, 85. doi: 10.14158/j.cnki.1001-3814.20200177HOU Yiqun, ZHANG Suohuai, XU Shaoli, et al. Research on binding enegy, Stability and electronic structure of coating WC/α-Ti interface based on first principles [J]. Hot Working Technology,2021,50(10):75-80, 85. doi: 10.14158/j.cnki.1001-3814.20200177 [16] MIAO Q, DING W, ZHU Y, et al. Joining interface and compressive strength of brazed cubic boron nitride grains with Ag-Cu-Ti/TiX composite fillers [J]. Ceramics International,2016:13723-13737. doi: 10.1016/j.ceramint.2016.05.171 [17] 邹明, 周莱. 金刚石切削黑色金属时刀具磨损机理的摩擦磨损试验 [J]. 光学精密工程,2013,21(7):1786-1794. doi: 10.3788/OPE.20132107.1786ZOU Ming, ZHOU Lai. Tool wear mechanism of diamond cutting of ferrous metals in frictional wear experiments [J]. Optics and Precision Engineering,2013,21(7):1786-1794. doi: 10.3788/OPE.20132107.1786 [18] YIN X H, XU F, MIN C Y, et al. Promoting the bonding strength and abrasion resistance of brazed diamond using Cu-Sn-Ti composite alloys reinforced with tungsten carbide [J]. Diamond and Related Materials,2021(112):108239. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS