Mechanical lapping and polishing process of polycrystalline diamond wafers

-

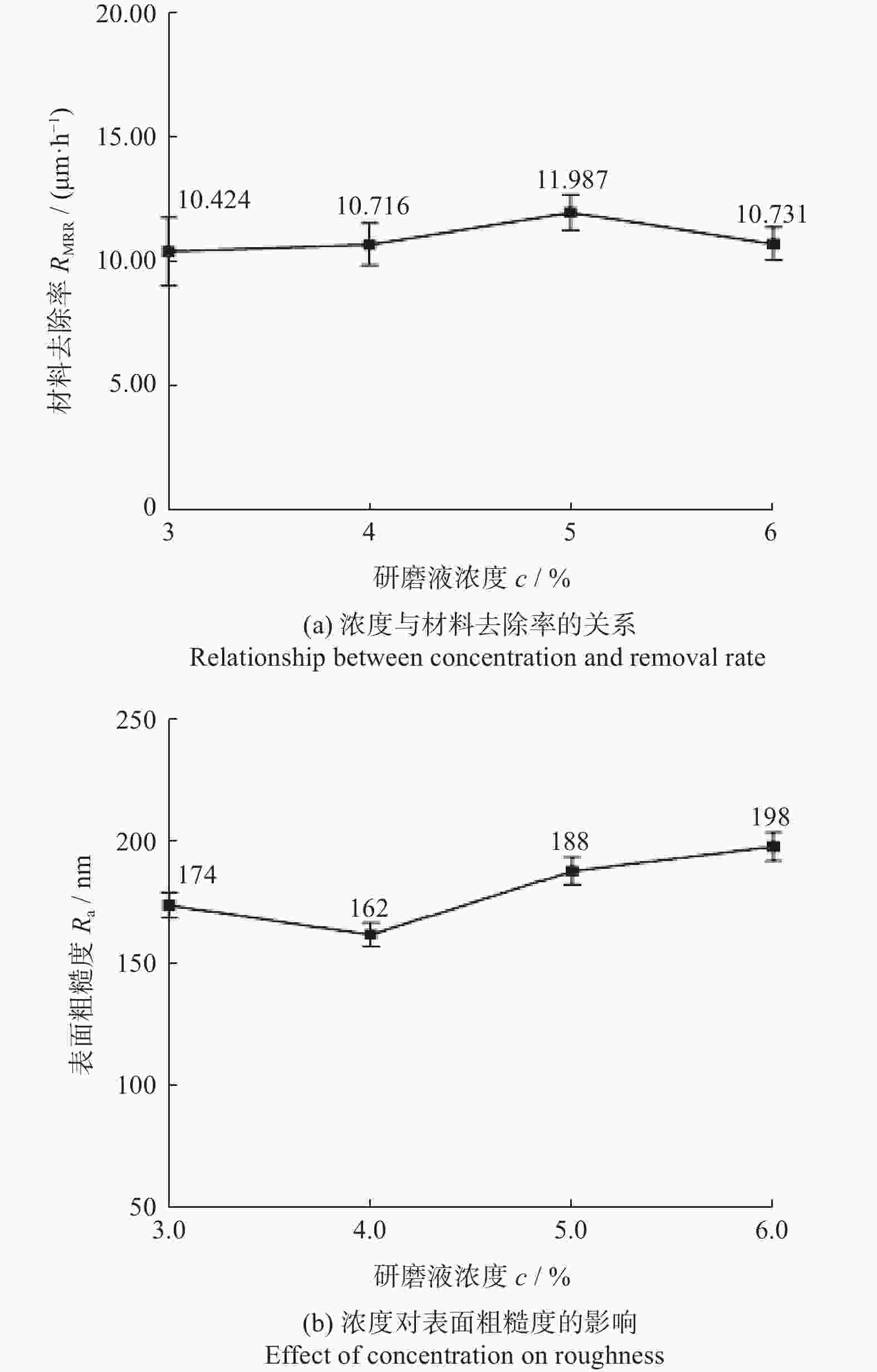

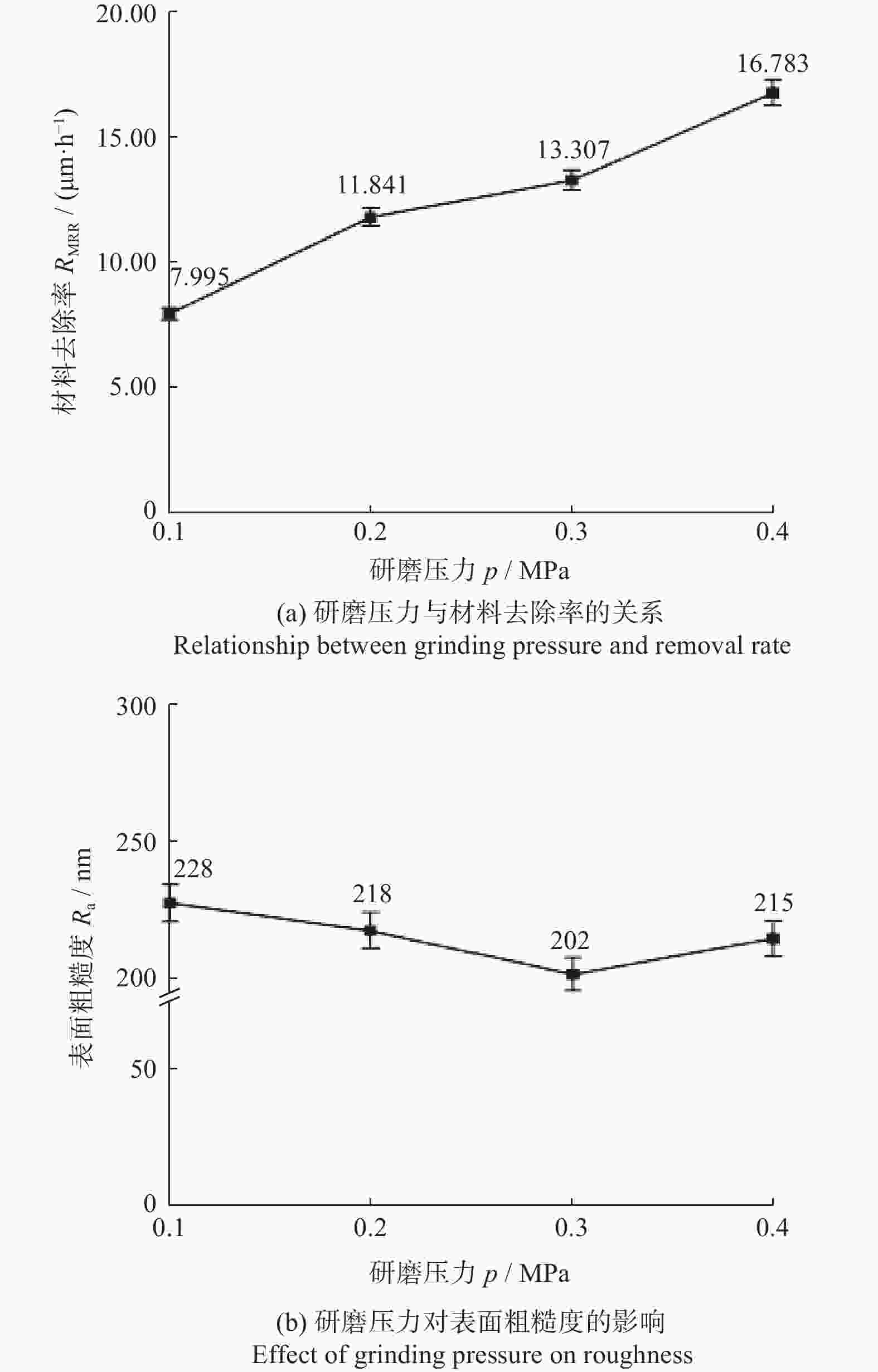

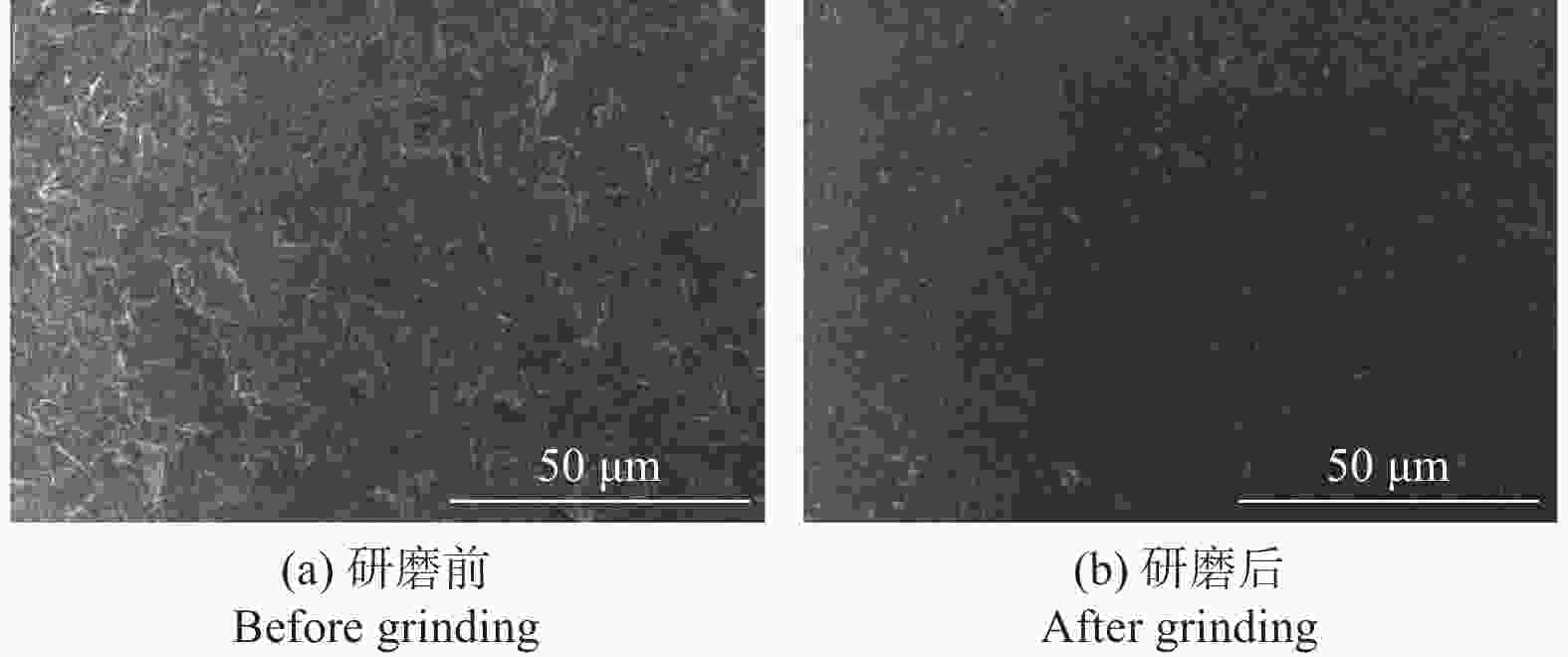

摘要: 使用游离磨料进行机械研磨是金刚石平坦化的主流加工手段之一。针对多晶金刚石的材料特性,开展变参数的游离磨料机械研磨实验。通过改变磨料粒度、研磨压力、研磨液浓度,研究其对多晶金刚石片机械研磨的材料去除率和表面粗糙度的影响规律。结果表明:材料去除率随磨料粒度和研磨压力的增大而增大,随研磨液浓度的增大先增大后趋于稳定,其中磨料粒度是对去除率影响最显著的因素;而表面粗糙度随磨料粒度的减小而降低,随研磨压力和研磨液浓度的增大呈现先降低后升高的变化趋势,其中磨料粒度对多晶金刚石加工表面质量的影响最为显著。据此可以确定最适合加工多晶金刚石的工艺参数为研磨压力0.3 MPa、磨粒粒度W10(7.5~10 μm)、研磨液浓度4%,此条件下加工的多晶金刚石片表面粗糙度最优,Ra约为96 nm,材料去除率为7.097 μm/h。Abstract:

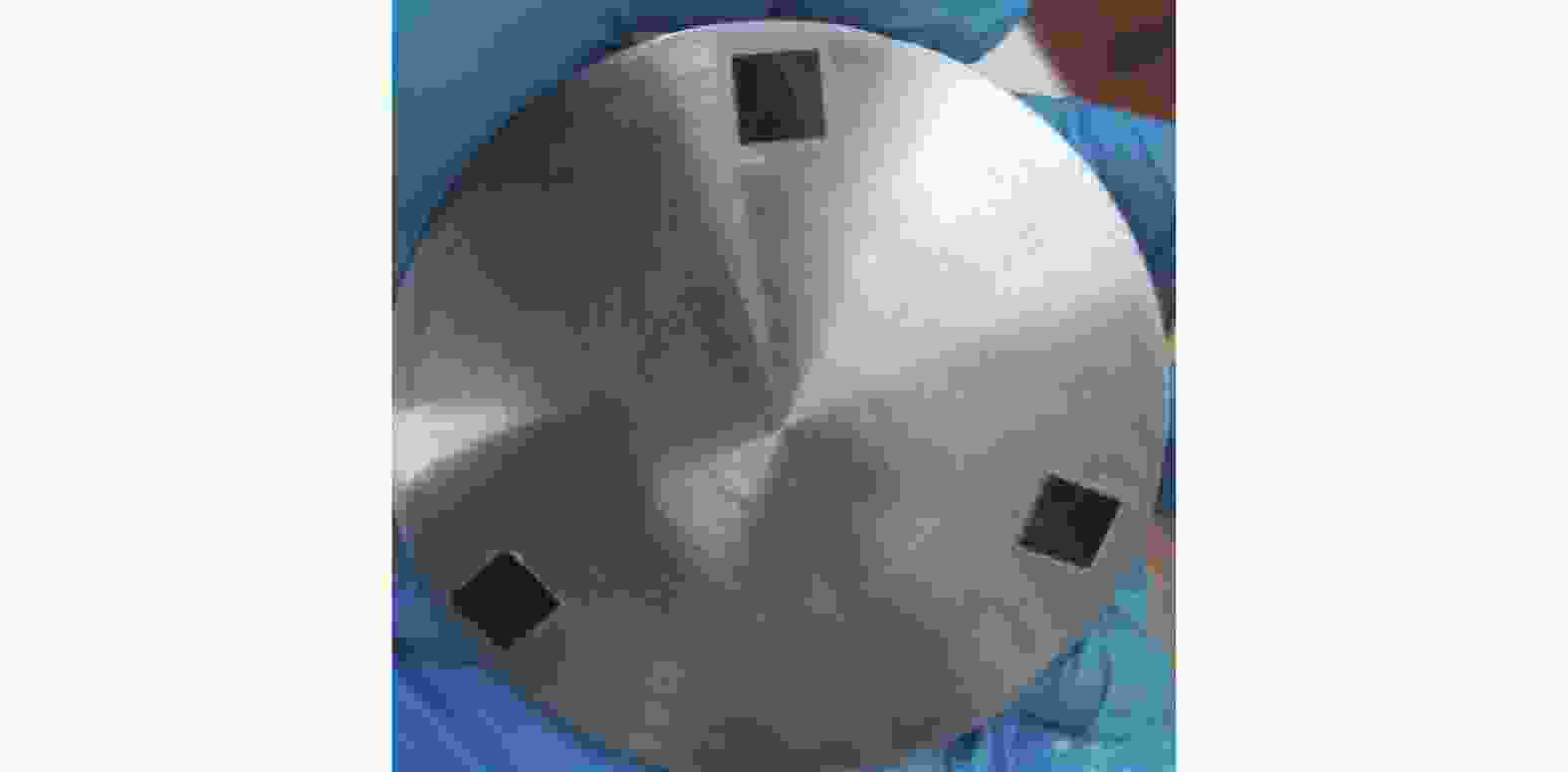

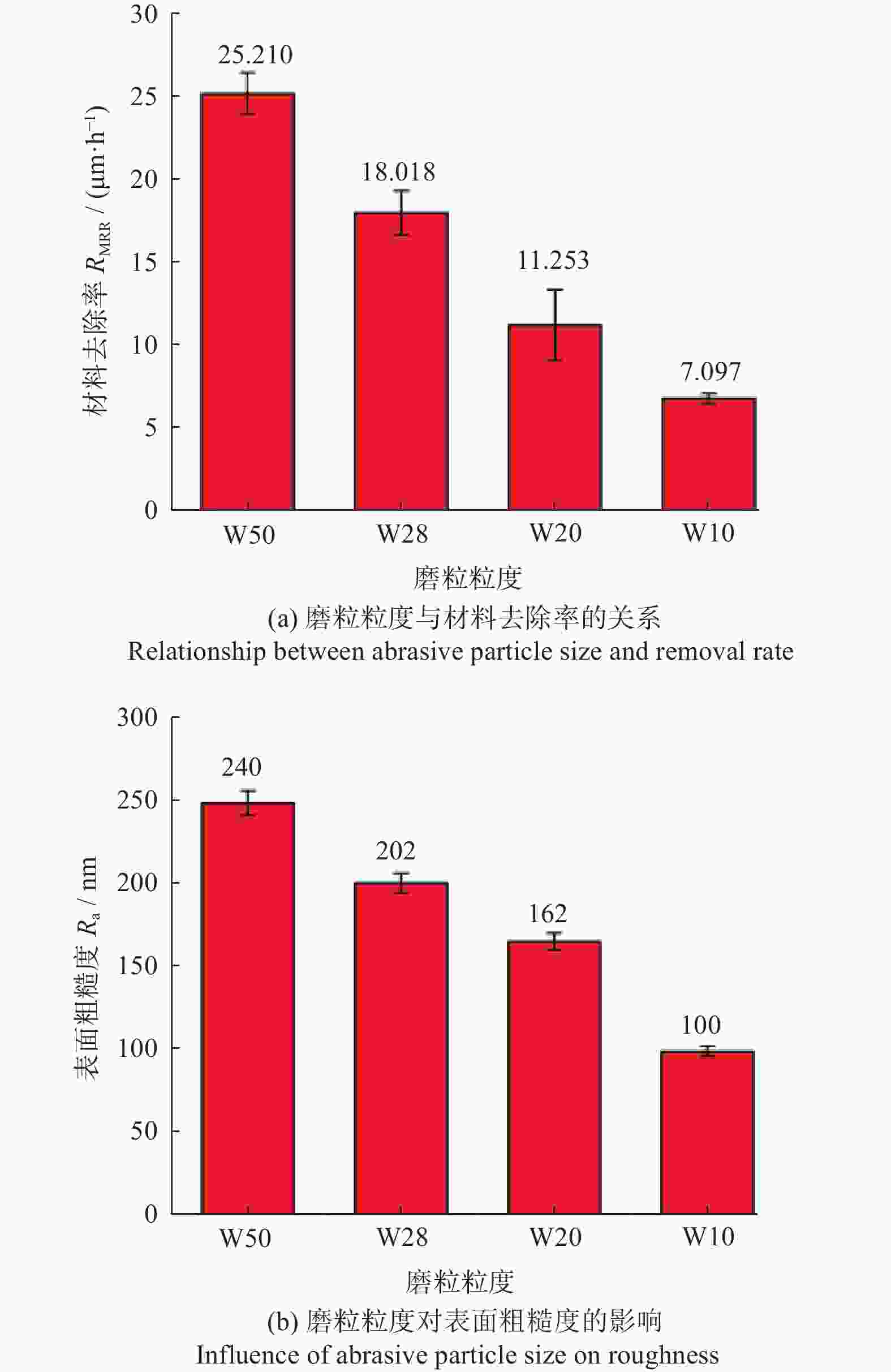

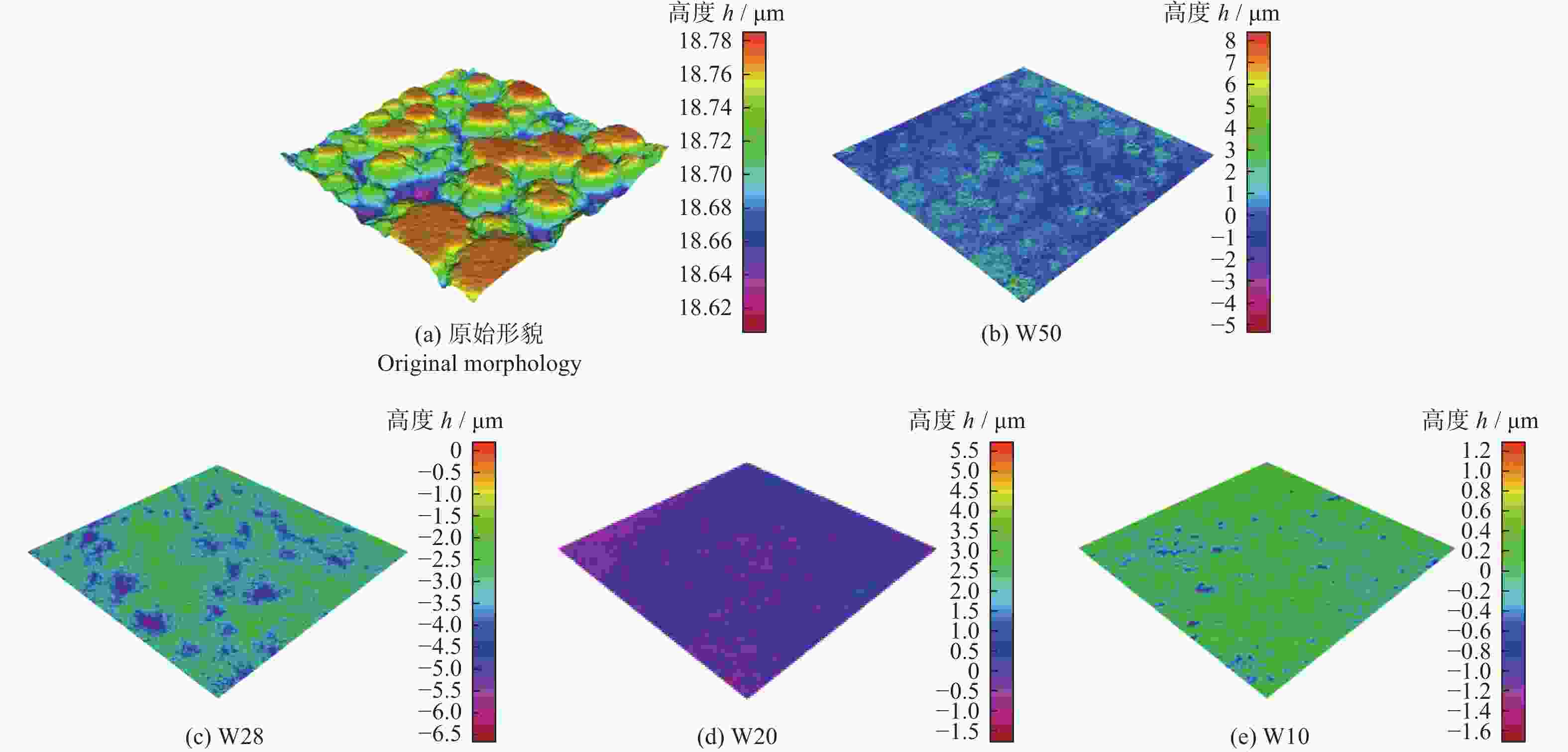

Objectives Diamond is a critical material potentially or already applied in infrared windows, electronic components and acoustic devices for its excellent optical transmittance, high eletron mobility and high breakdown voltage. Mechanical lapping is one of the mainstream methods for diamond planarization. However, it is more difficult to mechanically planarize polycrystalline diamond due to the grains and the boundaries which may lead to defects and internal stress release. Variable-parameter mechanical lapping are conducted on polycrystalline diamond to investigate the effects of abrasive grain size, lapping pressure and abrasive concentration on material removal rate (RMRR) and surface roughness Ra. Methods A group of {100} polycrystalline diamond wafers are attached to a load plate with lapping fluid speed of 8 mL/min, rotational speed of 30 r/min and orbital speed of 45 r/min. The grain size (W7~W50), the concentration of fluid (3%~6%) and the loading pressure (0.1~0.4 MPa) are tested for a reasonable process. A surface profiler is used to observe the morphology of three equal division points (800 μm×800 μm) on diamond surface along the diagonal of the 5 mm×5 mm×1 mm wafer. The average roughness are used to characterize the lapping effect. Results It is found that the RMRR increases with the increase of grain size, reaching its maximum of 25.210 μm/h with grain size of W50 and Ra of 240 nm. But there appears micro cracks on diamond surface. The RMRR slightly increases as the grain concentration increases from 3% to 5% but decreases at concentration of 6%, varying around 11 μm/h. The MRR also increases from ~8 μm/h to ~17 μm/h as the lapping pressure increases from 0.1 MPa to 0.4 MPa. Conversely, the surface roughness decrease from 240 nm to 100 nm with finer abrasive, which is a dominant factor affecting the surafce quality. The surface roughness also decreases first but increases then with higher lapping pressure and abrasive concentration. Conclusion The optimal process parameters for polycrystalline diamond wafer are determined, namely the lapping pressure of 0.3 MPa, the abrasive grain size of W10 and the lapping fluid concentration of 4%, where the processed polycrytalline diamond wafer achieves the best surface quality of Ra ~96 nm and a corresponding RMRR of 7.097 μm/h. -

Key words:

- diamond /

- lapping fluid /

- mechanical lapping /

- lapping pressure /

- abrasive grain

-

表 1 正交因素水平表

Table 1. Orthogonal factor level table

水平 因素 A 磨粒粒度 B 研磨压力 p / MPa C 研磨液浓度 c / % 1 W10 0.2 3 2 W20 0.3 4 3 W28 0.4 5 表 2 正交试验结果及分析

Table 2. Results and analysis of orthogonal experiments

序号 磨粒粒度

A研磨压力

B研磨液浓度

C表面粗糙度

Ra / nm材料去除率

RMRR /(μm·h−1)1 1 1 1 123 6.004 2 1 2 2 96 7.097 3 1 3 3 109 9.031 4 2 1 2 164 8.113 5 2 2 3 197 12.351 6 2 3 1 180 15.665 7 3 1 3 215 7.336 8 3 2 1 203 16.753 9 3 3 2 214 18.492 K1

329.000 503.000 507.000 A > C > B K2 541.000 496.000 474.000 K3 632.000 503.000 521.000 Kp1 109.667 167.667 169.000 Kp2 180.333 165.333 158.000 Kp3 210.667 167.667 173.667 极差Rj 101.000 2.333 15.667 优水平 A1 B2 C2 k1 22.132 21.453 38.422 B > A > C k 2 36.129 36.201 33.702 k 3 42.581 43.188 28.718 k p1 7.377 7.151 12.807 k p2 12.043 12.067 11.234 k p3 14.194 14.396 9.573 极差rj 6.816 7.245 3.235 优水平 A3 B3 C1 -

[1] 玄真武, 侯立, 王亨瑞, 等. 晶体院金刚石六十年研发 [J]. 人工晶体学报, 2023, 52(12): 2094-2107. doi: 10.3969/j.issn.1000-985X.2023.12.004XUAN Zhenwu, HOU Li, WANG Hengrui, et al. Sixty years research of diamond in Sinoma Snythetic Crystals Co., Ltd [J]. Journal of Synthetic Crystals, 2023, 52(12): 2094-2107. doi: 10.3969/j.issn.1000-985X.2023.12.004 [2] 李军男, 曲研, 潘长波, 等. 超宽禁带半导体材料的机遇与挑战 [J]. 新材料产业, 2018, (9): 60-65. doi: 10.19599/j.issn.1008-892x.2018.09.014LI Junnan, QU Yan, PAN Changbo, et al. Opportunities and challenges of ultrawide-bandgap semiconductor materials [J]. Advanced Materials Industry, 2018, (9): 60-65. doi: 10.19599/j.issn.1008-892x.2018.09.014 [3] 陈炳欣. 宽禁带功率半导体产业如何抢抓窗口期 [N]. 中国电子报, 2018-08-07.CHEN Bingxin. How to seize the window period in the wide bandgap power semiconductor industry [N]. China Electronics News, 2018-08-07. [4] THUMM M. Progress on gyrotrons for ITER and future thermonuclear fusion reactors [J]. IEEE Transactions on Plasma Science, 2011, 39(4): 971-979. doi: 10.1109/TPS.2010.2095042 [5] 李成明, 任飞桐, 邵思武, 等. 化学气相沉积(CVD)金刚石研究现状和发展趋势 [J]. 人工晶体学报,2022,51(5):759-780. doi: 10.16553/j.cnki.issn1000-985x.2022.05.008LI Chengming, REN Feitong, SHAO Siwu, et al. Progress of chemical vapor deposition (CVD) diamond [J]. Journal of Synthetic Crystals, 2022, 51(5): 759-780. doi: 10.16553/j.cnki.issn1000-985x.2022.05.008 [6] 董伯先. CVD金刚石膜化学机械抛光液的研制 [D]. 大连: 大连理工大学, 2008.DONG Boxin. Study on CMP slurry of CVD diamond film [D]. Dalian: Dalian University of Technology, 2008. [7] 庞飞, 雷大江, 王伟. 基于控制研磨深度的金刚石研磨质量分析 [J]. 金刚石与磨料磨具工程, 2023, 43(1): 118-125. doi: 10.13394/j.cnki.jgszz.2022.0048PANG Fei, LEI Dajiang, WANG Wei. Diamond grinding quality analysis based on controlled grinding depth [J]. Diamond & Abrasives Engineering, 2023, 43(1): 118-125. doi: 10.13394/j.cnki.jgszz.2022.0048 [8] YUAN Z W, JIN Z J, DONG B X, et al. Polishing of free-standing CVD diamond filmsby the combination of EDM and CMP [J]. Advanced Materials Research, 2008, 750(53/54): 111-118. doi: 10.4028/www.scientific.net/AMR.53-54.111 [9] LIU H Z, ZONG W J, CHENG XIAO. Behaviors of carbon atoms induced by friction in mechanical polishing of diamond [J]. Computational Materials Science,2021,186:110069. doi: 10.1016/j.commatsci.2020.110069 [10] CHEN C C A, HSU L S. A process model of wafer thinning by diamond grinding [J]. Journal of Materials Processing Technology,2008,201(1/2/3):606-611. doi: 10.1016/j.jmatprotec.2007.11.243 [11] 范前峰. 平稳弹性浮动研磨的扰动抑制控制系统研究 [D]. 广州: 广东工业大学, 2012.FAN Qianfeng. Reserach on the disturbance rejection control system of smooth slastic floating lapping [D]. Guangzhou: Guangdong University of Technology, 2012. [12] LAVRINENKO V I, SOLOD V Y. Determining the conditions for achieving the plastic regime of diamond grinding of ceramics from the standpoint of estimating energy costs of processing [J]. Journal of Superhard Materials, 2023, 45(1): 65-71. doi: 10.3103/S1063457623010070 [13] 王振. 自支撑单晶金刚石膜的制备与研磨 [D]. 西安: 西安理工大学, 2019.WANG Zhen. Preparation and grinding of self-supporting single crystal diamond film [D]. Xi'an: Xi'an University of Technology, 2019. [14] CHEN Z J, XIE J, ZHU X C. Experimental study on surface physical behaviour and integrity of polycrystalline diamond (PCD) in micron-scale abrasive flow assisted impulse-discharge machining [J]. International Journal of Refractory Metals and Hard Materials, 2023:106330. doi: 10.1016/j.ijrmhm.2023.106330 [15] 李强. 单晶金刚石的研磨与化学机械抛光工艺[D]. 大连: 大连理工大学, 2013.LI Qiang. Processing technique for single crystal dimond with mechanical lapping and chemical mechanical polishing [D]. Dalian: Dalian University of Technology, 2013. [16] 文星凯, 魏俊俊, 刘金龙, 等. 大面积自支撑金刚石膜的机械研磨研究 [J]. 金刚石与磨料磨具工程, 2013, 33(5): 22-26. doi: 10.13394/j.cnki.jgszz.2013.05.004WEN Xingkai, WEI Junjun, LIU Jinlong, et al. Study on mechanical grinding for large area free-standing diamond film [J]. Diamond & Abrasives Engineering, 2013, 33(5): 22-26. doi: 10.13394/j.cnki.jgszz.2013.05.004 [17] 王新玲. CVD金刚石膜的高速机械研磨机理 [D]. 沈阳: 沈阳理工大学, 2012.WANG Xinling. High-speed lapping mechanism of CVD diamong film [D]. Shenyang: Shenyang Ligong University, 2012. [18] 何艳, 苑泽伟, 段振云, 等. 单晶碳化硅晶片高效超精密抛光工艺 [J]. 哈尔滨工业大学学报, 2019, 51(1): 115-121. doi: 10.11918/j.issn.0367-6234.201712098HE Yan, YUAN Zewei, DUAN Zhenyun, et al. High-productively ultraprecise polishing technique of single crystal SiC wafer [J]. Journal of Harbin Institute of Technology, 2019, 51(1): 115-121. doi: 10.11918/j.issn.0367-6234.201712098 [19] 杨明鄂. 活塞杆连续驱动摩擦焊接工艺参数的设计与优化 [D]. 长沙: 湖南科技大学, 2012.YANG Ming'e. Design and Optimization of the piston rod continuous drive friction welding parameters [D]. Changsha: Hunan University of Science and Technology, 2012 [20] 张耀君. 塑料激光透射焊接工艺研究及其数值模拟 [D]. 广州: 华南理工大学, 2012.ZHANG Yaojun. Process research and numerical simulation of laser transmission welding plastic [D]. Guangzhou: South China University of Technology, 2012. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS