Stability and process control of single-diamond grinding based on clustering of processing morphology data

-

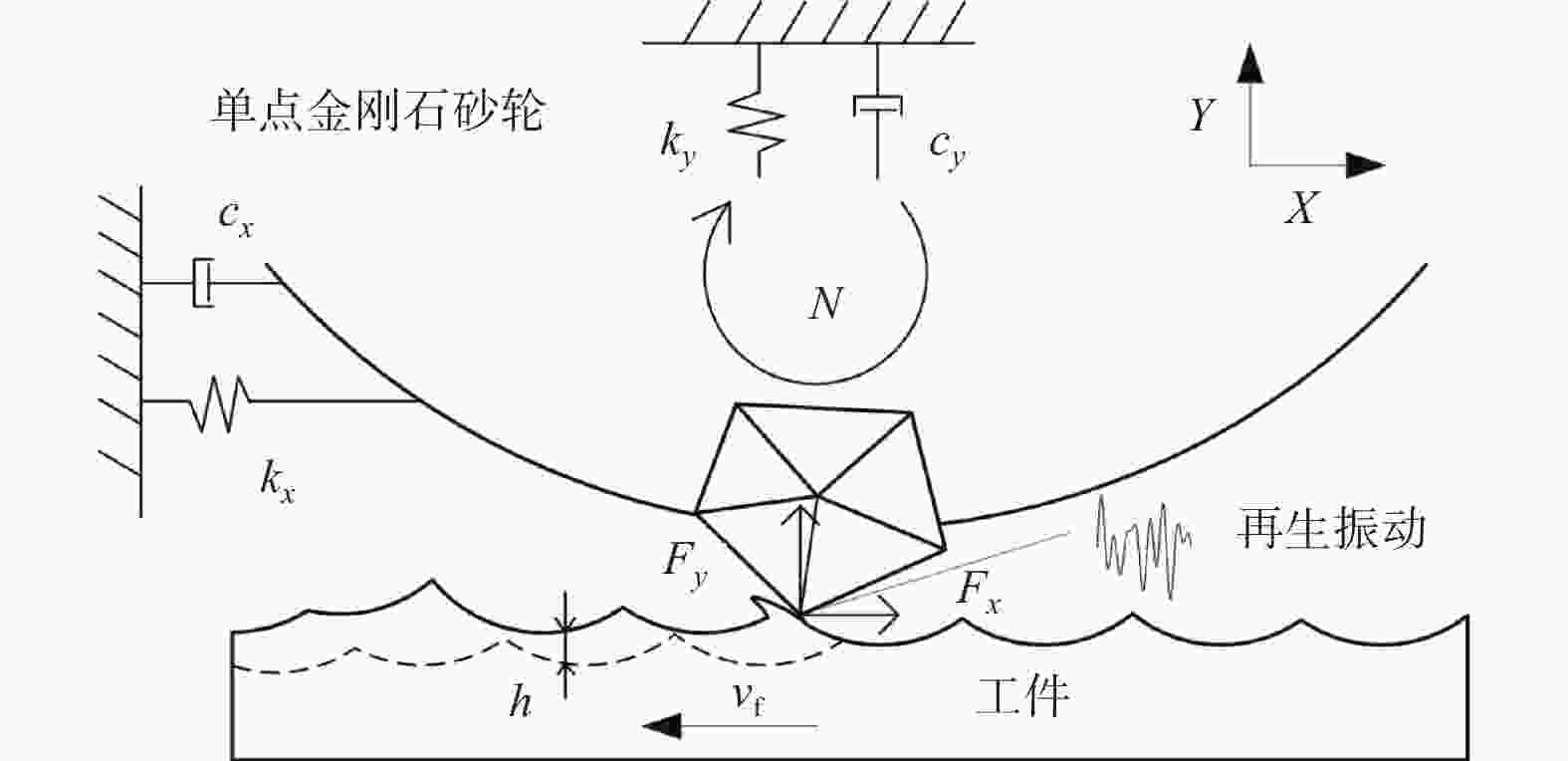

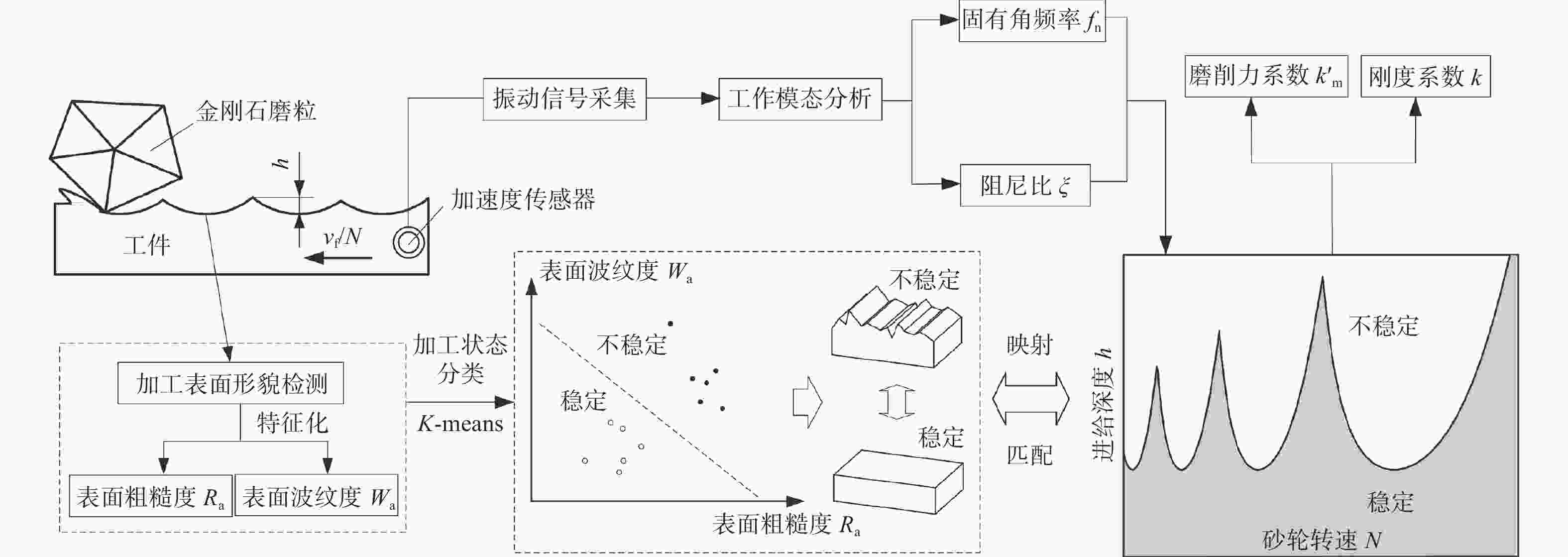

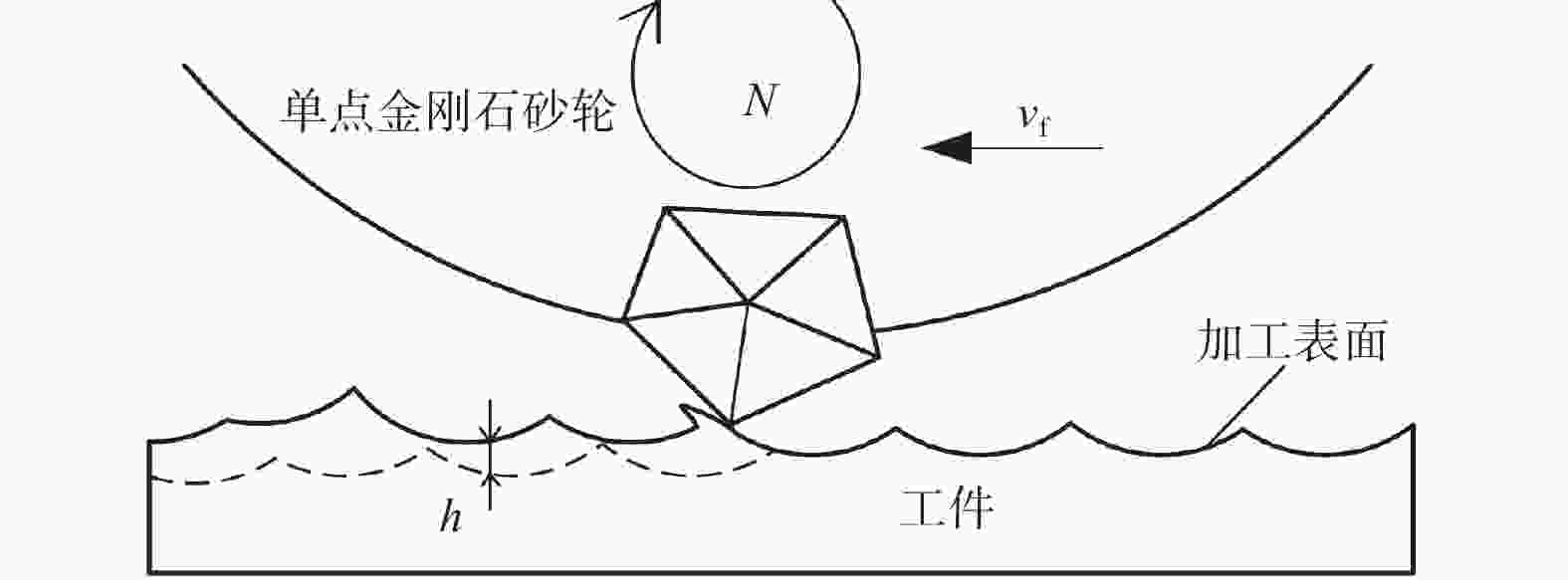

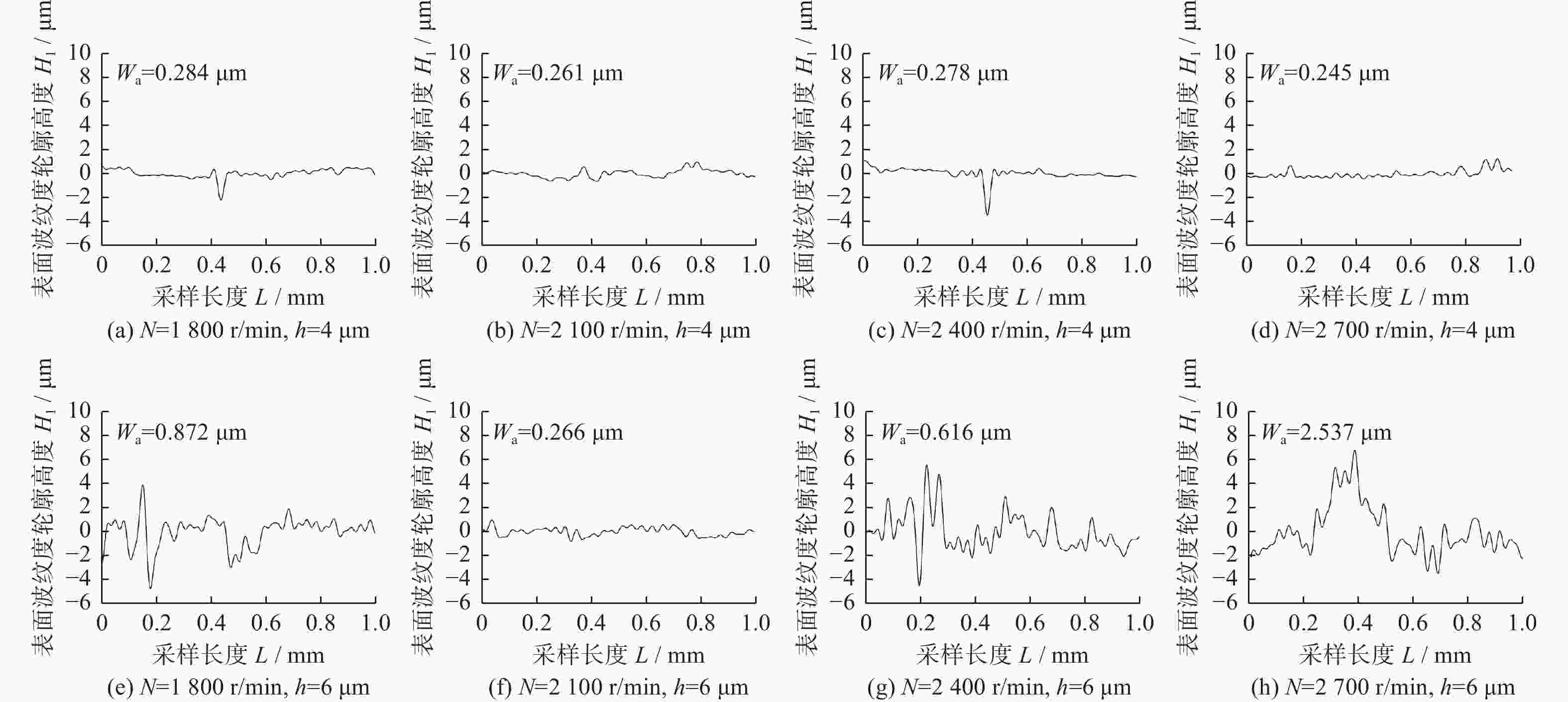

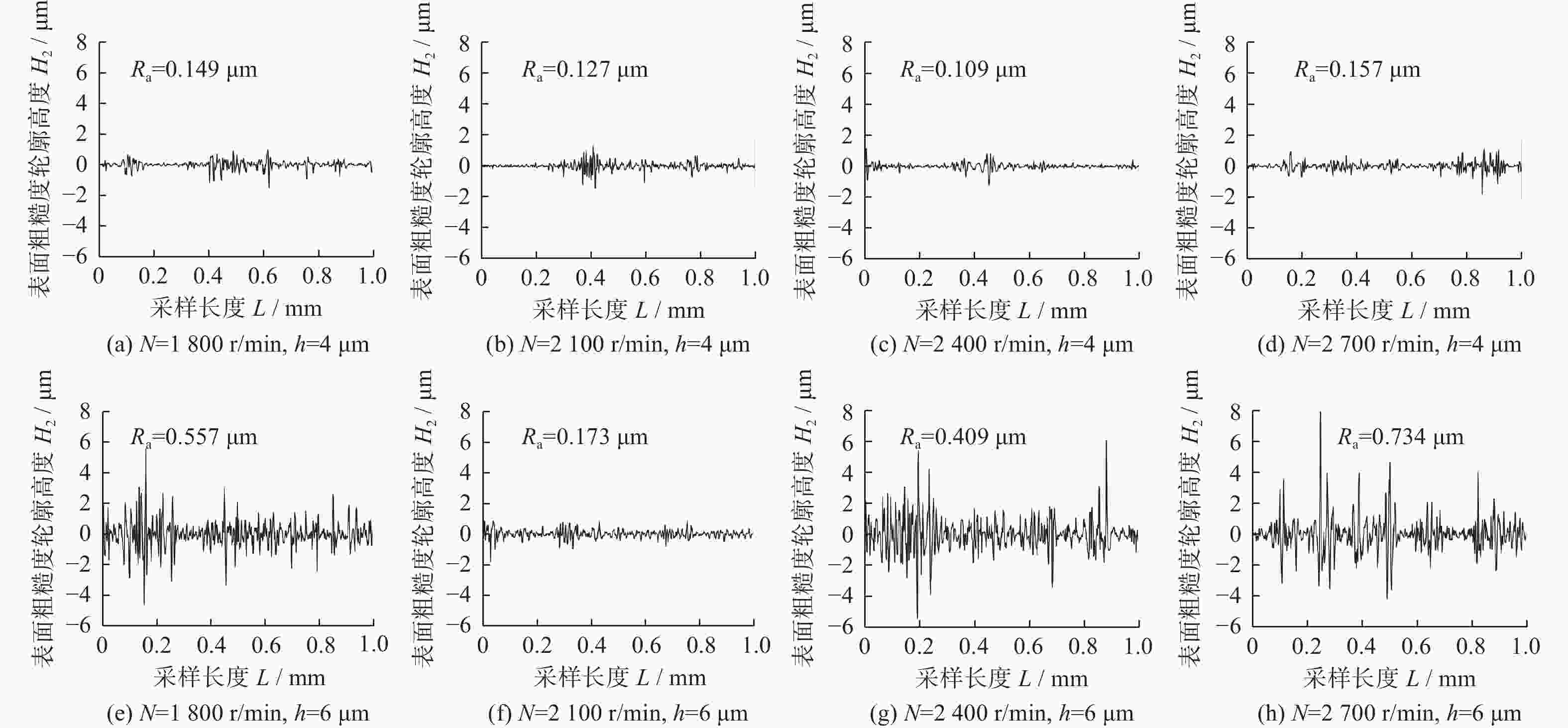

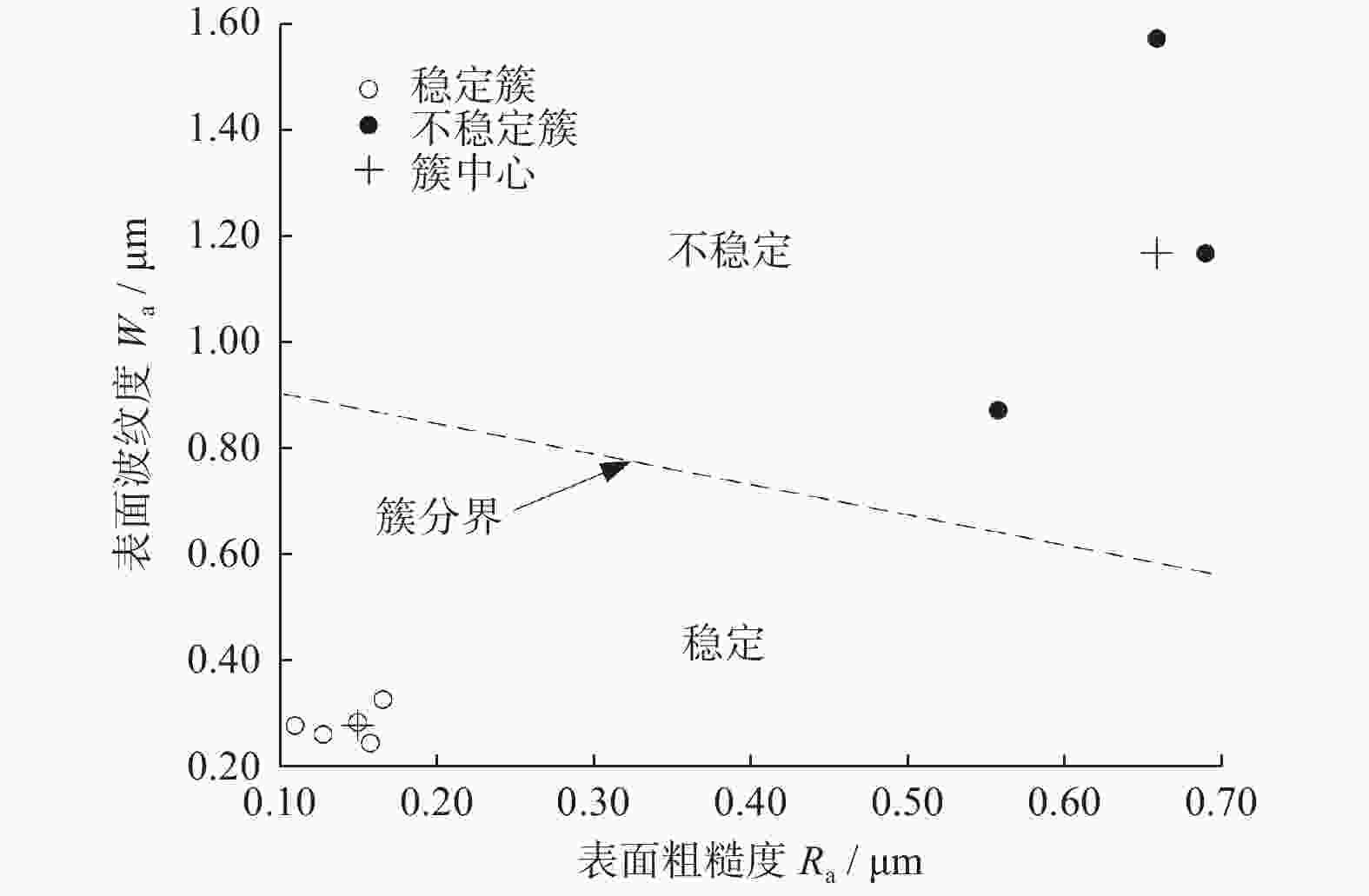

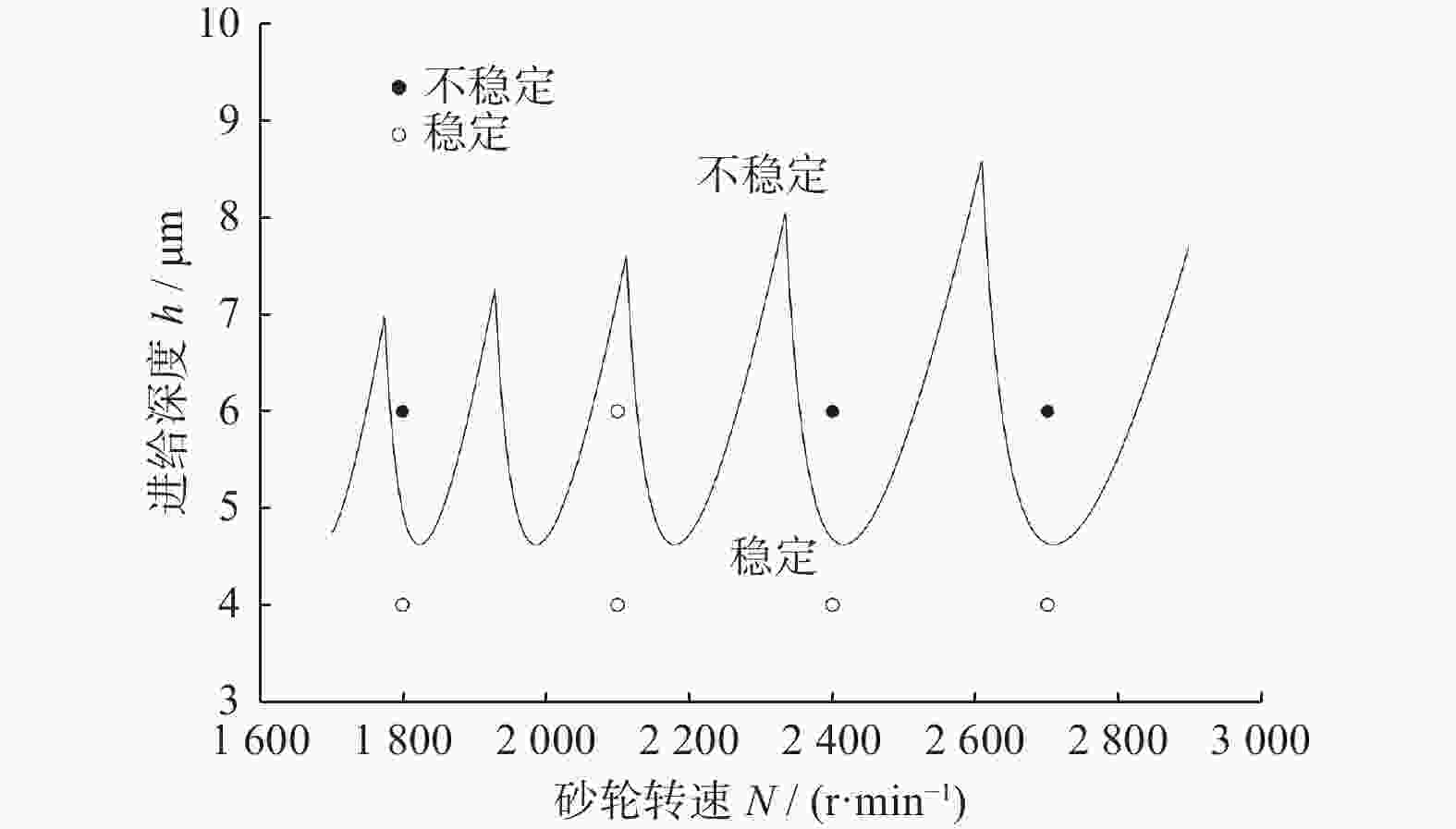

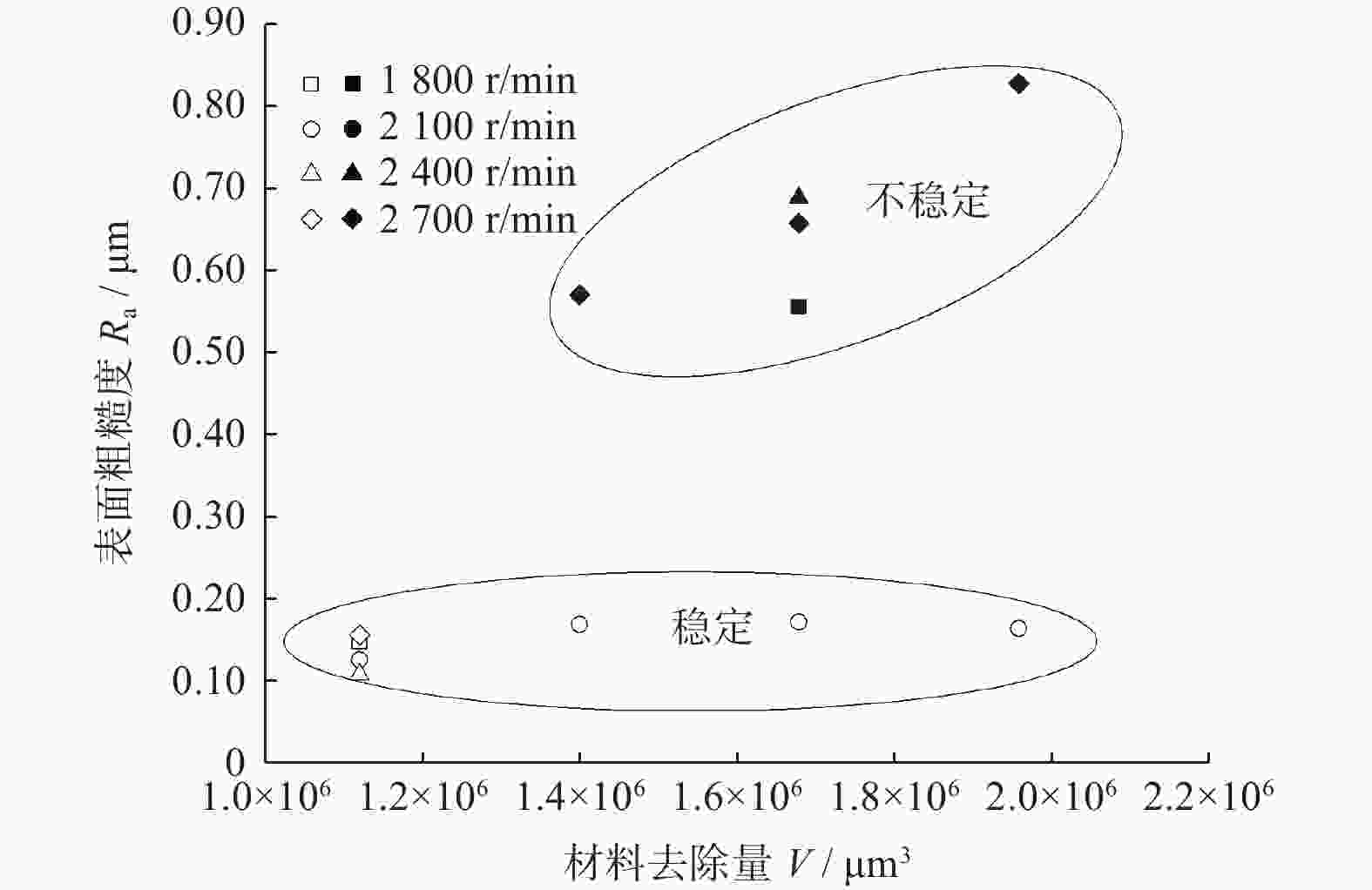

摘要: 硬质模具钢磨削过程中,加工深度的变化会引起磨削力变化,导致其加工状态不稳定。采用大颗粒单点金刚石磨削硬质模具钢,基于其加工表面的形貌特征分析磨削过程的动态特性及稳定性,探究工艺参数对加工效率和表面质量的影响,以实现其高效率高质量的磨削加工。首先,对单点金刚石磨削系统进行动力学建模,采用加速度传感器测量磨削振动信号并进行工作模态分析,求解磨削系统的固有频率和阻尼比。然后,基于不同加工工况的表面波纹度和表面粗糙度数据,关联进给深度和砂轮转速与稳定工况时的数据聚类,且与磨削稳定时的叶瓣图区域匹配,拟合出磨削系统刚度和磨削力系数,构建稳定磨削过程中的进给深度和砂轮转速实时调控区域。最后,通过模具钢的磨削实验验证及分析其加工效率和质量。结果表明:磨削过程的模态分析与加工表面形貌特征的聚类匹配能够映射磨削稳定域的加工工艺参数;在磨削稳定域内,采用更大的材料去除率可将模具钢的平均表面波纹度从1.203 μm降低到0.635 μm,平均表面粗糙度从0.267 μm降低到0.143 μm;且在相同的材料去除量下,磨削稳定域加工的模具钢表面粗糙度平均下降74%。因此,在加工过程中依据加工表面特征化的磨削稳定域实时调整进给深度和砂轮转速,可同时提高工件的加工质量和效率。Abstract:

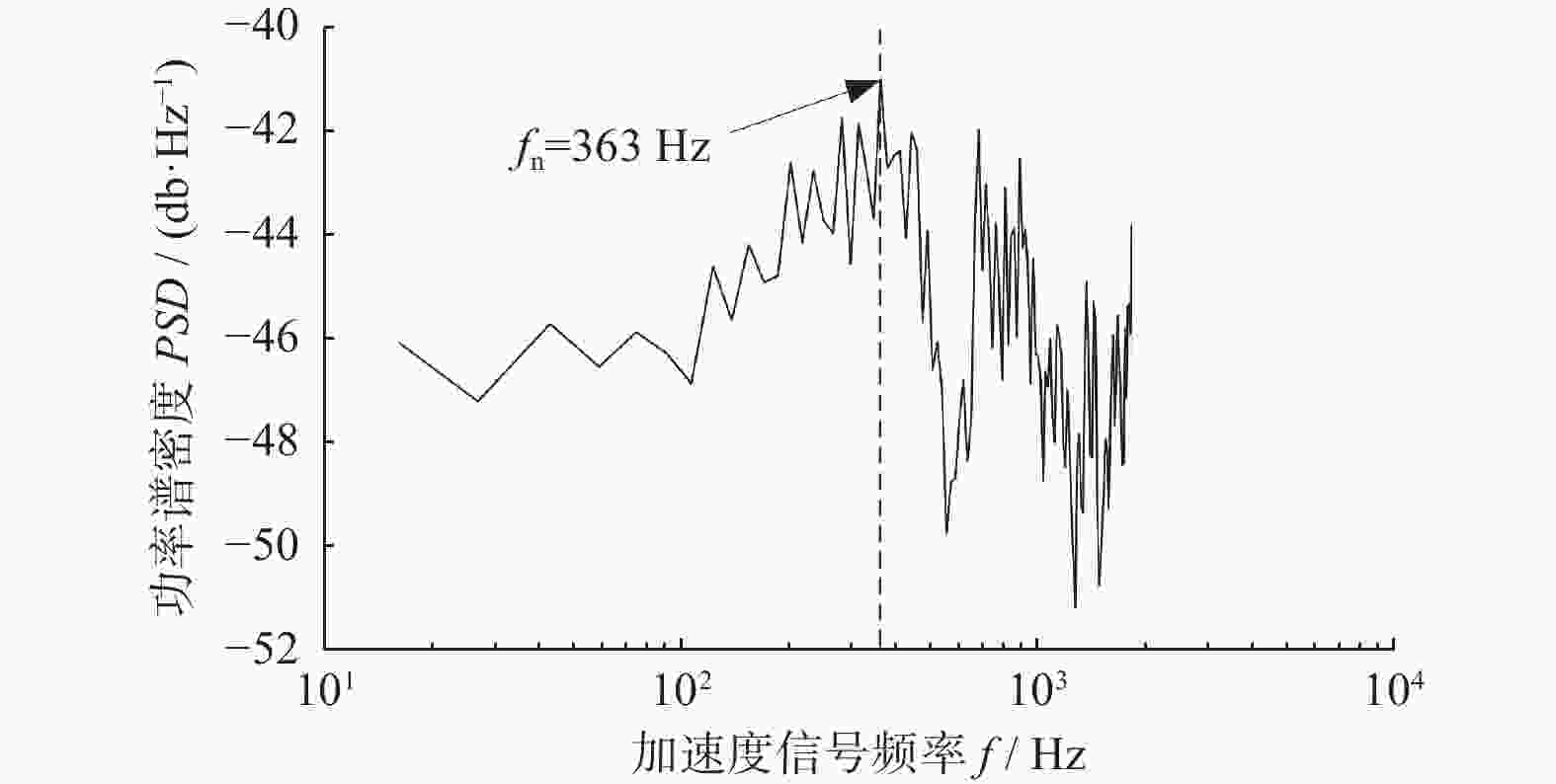

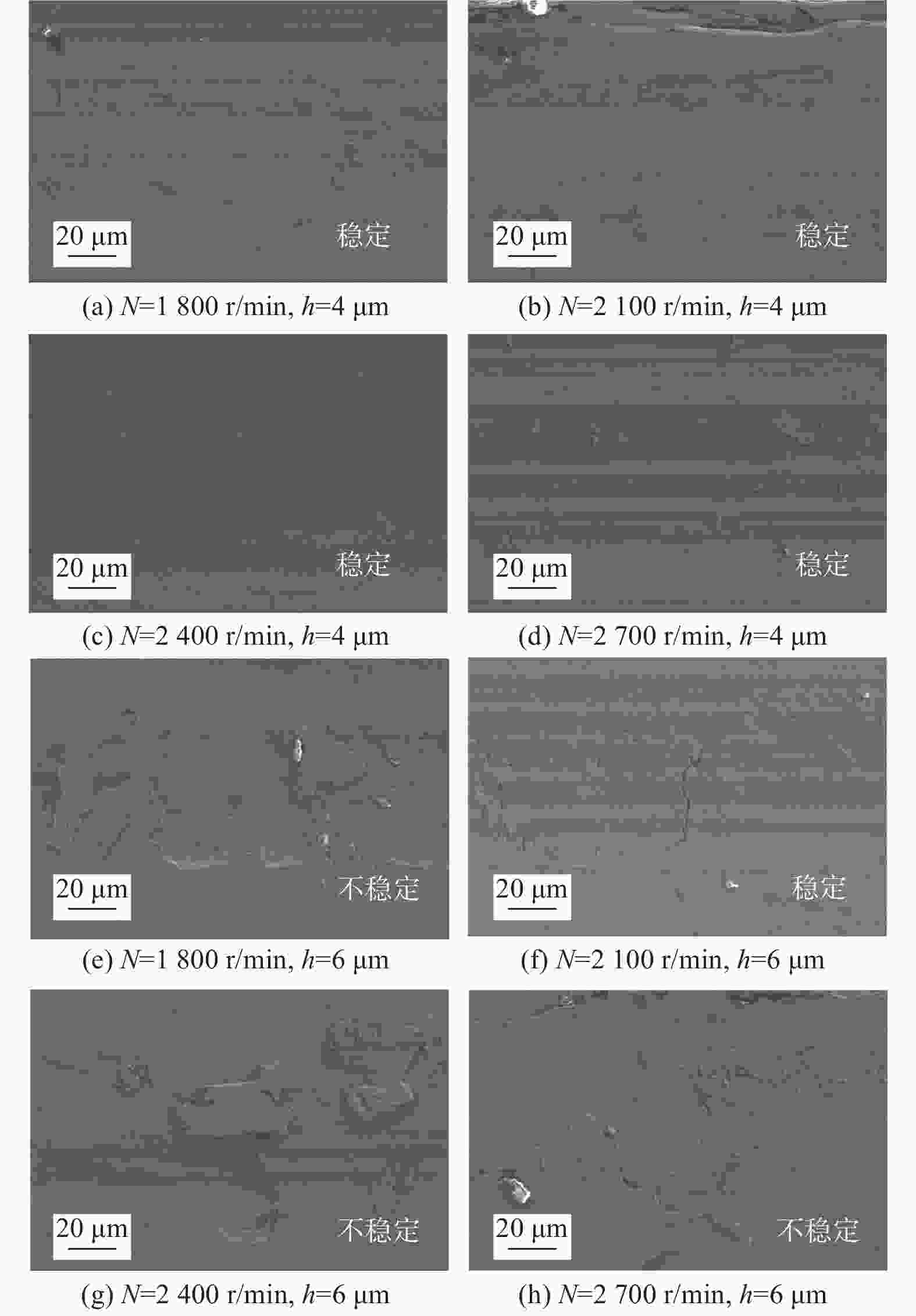

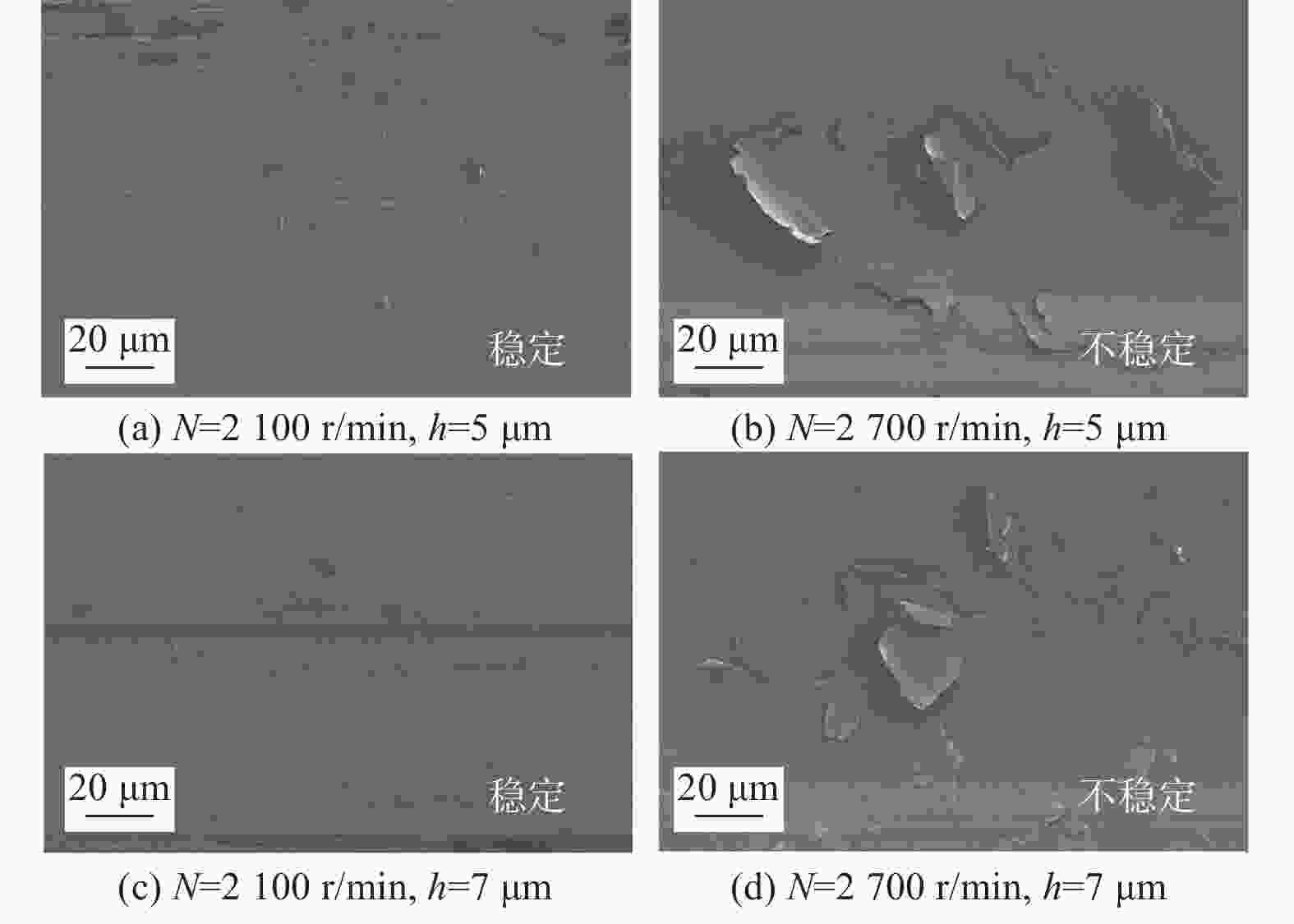

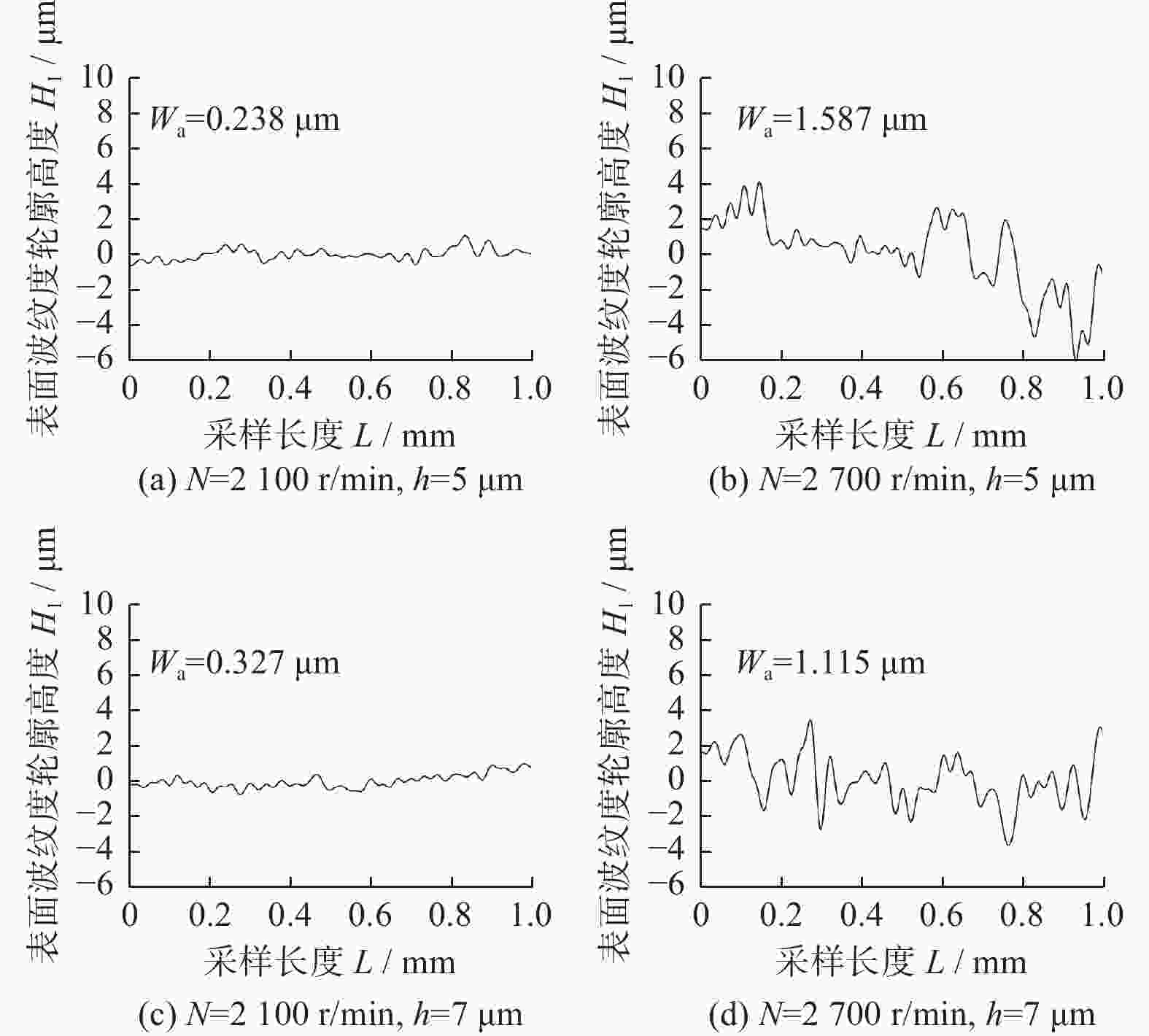

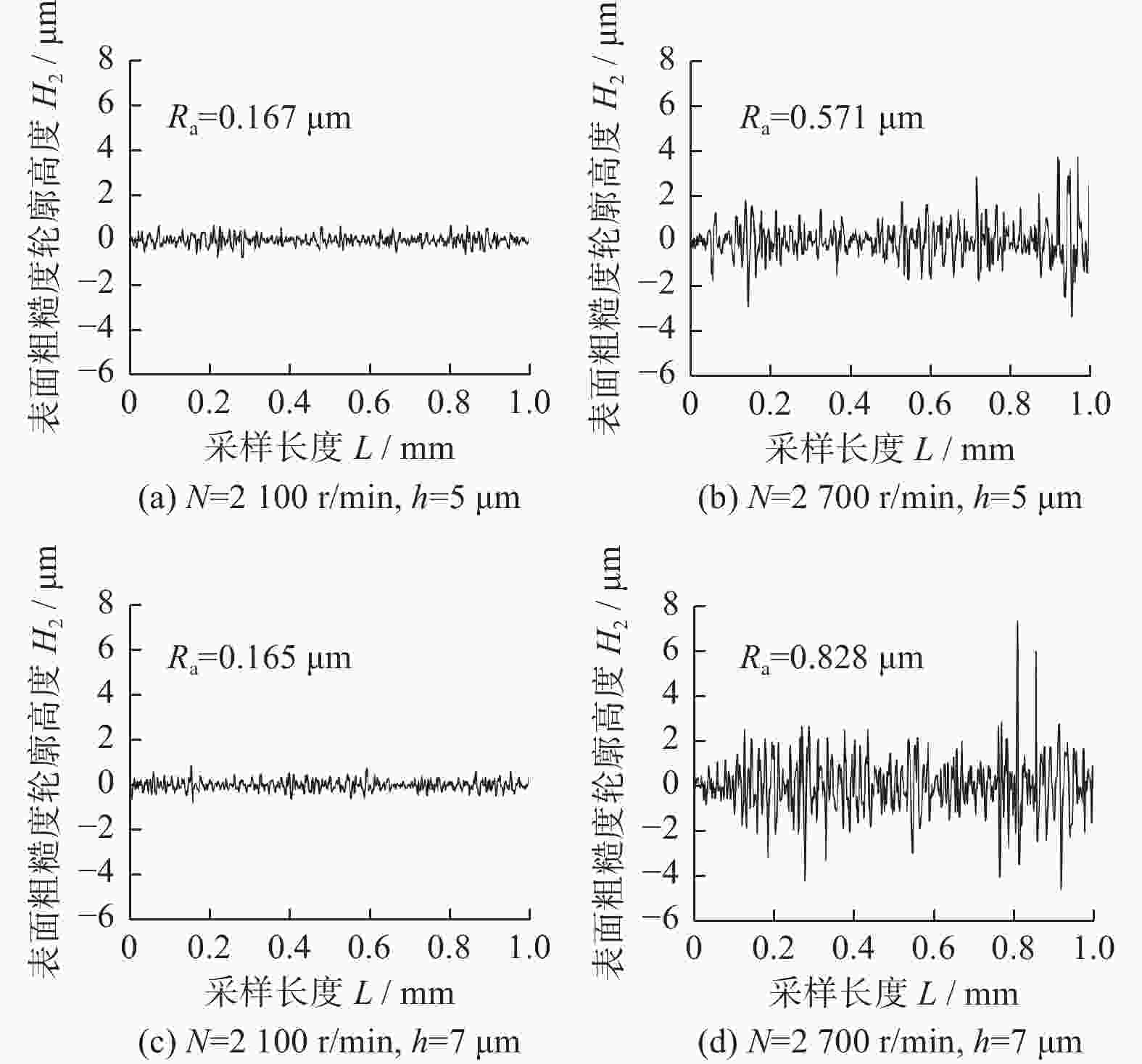

Objectives In the precision grinding process of hard mold steel workpieces, the subtle changes in machining depth can significantly cause dynamic changes in the magnitude and the direction of grinding forces, which directly lead to unstable machining conditions and affect machining accuracy and surface quality. To this end, the data clustering analysis is used to analyze the machining morphology data of the workpiece, and the stable single-point grinding of the workpiece is achieved through process control. Methods Using large particle diamond single-point grinding for hard mold steel, the dynamic characteristics and the stability of the grinding process are analyzed based on the morphology characteristics of the diamond processing surface. The influences of the process parameters on diamond processing efficiency and surface quality are explored to achieve high-efficiency and high-quality diamond grinding. Firstly, the dynamic modeling of the single point diamond grinding system is carried out, and the grinding vibration signal is measured by an accelerometer. The working mode analysis is performed to solve the natural frequency and the damping ratio of the machining system. Then, using a laser confocal microscope to obtain surface waviness and surface roughness data under different processing conditions, the feed depth and the wheel speed are correlated with the data clustering under stable conditions, and matched with the blade diagram area under stable grinding conditions to fit the stiffness and the grinding force coefficients of the processing system. A real-time control area for feed depth and the wheel speed during the stable grinding process is constructed. Finally, the machining efficiency and the quality of the mold steel are verified and analyzed through grinding experiments. Results The modal analysis of the grinding process and the clustering matching of the machined surface morphology features can map the machining process parameters in the stable domain of the grinding process. The working mode analysis method is applied to the stability analysis of single-point diamond grinding die steel, and the natural frequency and the damping ratio of the process system can be obtained under the working state. The natural frequency of the single-point diamond grinding die steel process system is fn = 363 Hz, and the damping ratio ξ = 0.027. The clustering analysis method is applied to the machining state classification, and the machining surface can be divided into stable machining and unstable machining according to the internal relationship between the surface waviness Wa and surface roughness Ra data. The surface morphologies of the two types of machining are obviously different. The surface of the stable processing state is smooth and flat, while the surface of the unstable processing state has a large area of plastic deformation and a large number of burrs. The surface machining quality of single-point diamond grinding die steel differs greatly under stable and unstable machining conditions. The average surface waviness Wa of single-point diamond grinding mold steel in the stable processing state is 0.635 μm, and the average surface roughness Ra is 0.143 μm. The average surface waviness Wa in the unstable state is 1.203 μm, and the average surface roughness Ra is 0.267 μm, which is about twice that of the stable state. The experimental points after clustering analysis are matched to the relevant areas on the grinding stability lobe diagram, and the experimental verification is carried out to obtain the system stiffness coefficient k = 7 × 106 N/m and the grinding force coefficient km' = 3 × 1015 N/m3 of the single-point diamond grinding die steel process system. Conclusions In the stable processing state, the single-point diamond grinding die steel can achieve a greater material removal rate while ensuring the surface quality as much as possible, thus improving the processing efficiency. In the case of the same amount of material removal, the surface roughness Ra of the stable region processing state is reduced by 74% on average compared with that of the unstable region processing state, which realizes the high-efficiency and the high-surface-quality machining of high-hardness metal materials. -

Key words:

- single-diamond /

- grinding stability /

- cluster analysis /

- surface quality /

- surface roughness

-

表 1 D-star工件材料参数

Table 1. Parameter of D-star workpiece material

参数 数值 密度 ρ / (g·cm−3) 7.75 弹性模量 E / GPa 200 热导率 K / [W·(m·K)−1] 24.7 硬度 / HRC 52~55 表 2 磨削加工实验条件

Table 2. Experimental conditions for grinding processing

实验条件 规格或取值 金刚石粒度代号 16/18 砂轮直径 D / mm 150 砂轮转速 N / (r·min−1) 1 800, 2 100, 2 400, 2 700 进给速度 vf / (mm·min−1) 50 进给深度 h / μm 4, 6 表 3 磨削稳定性叶瓣图参数

Table 3. Grinding stability lobe diagram parameters

参数 数值 固有频率 fn / Hz 363 阻尼比 ξ 0.027 刚度系数 k / (N·m−1) 7 × 106 磨削力系数 $ {k}'_{{\mathrm{m}}} $ / (N·m−3) 3 × 1015 磨粒宽度 b / m 2.8 × 10−5 表 4 磨削加工实验条件

Table 4. Experimental conditions for grinding processing

参数 取值 砂轮转速 N / (r·min−1) 2 100, 2 700 进给深度 h / μm 5, 7 表 5 磨削稳定性实验验证结果

Table 5. Experimental verification results of grinding stability

参数 加工状态 N = 2 100 r/min, h = 5 μm 稳定 N = 2 100 r/min, h = 7 μm 稳定 N = 2 700 r/min, h = 5 μm 不稳定 N = 2 700 r/min, h = 7 μm 不稳定 -

[1] 王林春, 吴永强, 王开坤, 等. 3Cr2NiMo钢模块锻后热处理的数值模拟 [J]. 金属热处理,2021,46(3):184-190. doi: 10.13251/j.issn.0254-6051.2021.03.037WANG Linchun, WU Yongqiang, WANG Kaikun, et al. Numerical simulation of heat treatment for 3Cr2NiMo steel module bulk after forging [J]. Heat Treatment of Metals,2021,46(3):184-190. doi: 10.13251/j.issn.0254-6051.2021.03.037 [2] 谢奕心, 程晓农, 鞠玉琳, 等. H13及H13改进型热作模具钢热处理过程中碳化物析出演化行为研究进展 [J]. 材料导报,2023,37(23):177-184. doi: 10.11896/cldb.22040214XIE Yixin, CHEN Xiaonong, JU Yulin, et al. Research progress on carbide precipitation and evolution for H13 and H13-modifies hot working die steels during different heat treatment schedules [J]. Materials Reports,2023,37(23):177-184. doi: 10.11896/cldb.22040214 [3] 王宇斌, 王勇, 陈旋, 等. 组织形态对718塑料模具钢切削性能的影响 [J]. 工程科学学报,2020,42(10):1343-1351. doi: 10.13374/j.issn2095-9389.2019.11.06.001WANG Yubin, WANG Yong, CHEN Xuan, et al. Machinability analysis of microstructures in pre-hardening plastic mold steel 718 [J]. Chinese Journal of Engineering,2020,42(10):1343-1351. doi: 10.13374/j.issn2095-9389.2019.11.06.001 [4] 孔令叶, 周旭光. 模具曲面包络磨削的圆弧砂轮寿命研究 [J]. 制造技术与机床,2018(7):129-133. doi: 10.19287/j.cnki.1005-2402.2018.07.025KONG Lingye, ZHOU Xuguang. Study on the life of arc grinding wheel for mold surface enveloping grinding [J]. Technology and Test,2018(7):129-133. doi: 10.19287/j.cnki.1005-2402.2018.07.025 [5] 刘涛, 邓朝晖, 罗程耀, 等. 基于动态磨削深度的非圆轮廓高速磨削稳定性建模与分析 [J]. 机械工程学报,2021,57(15):264-274. doi: 10.3901/JME.2021.15.264LIU Tao, DENG Chaohui, LUO Chengyao, et al. Stability modeling and analysis of non-circular high-speed grinding with consideration of dynamic grinding depth [J]. Journal of Mechanical Engineering,2021,57(15):264-274. doi: 10.3901/JME.2021.15.264 [6] FENG W, QIN P, CAO L, et al. Chatter reliability of high speed cylindrical grinding with uncertain parameters [J]. Journal of Manufacturing Processes,2023,102:874-884. doi: 10.1016/j.jmapro.2023.08.012 [7] 孙聪, 姚云龙, 修世超, 等. 预应力条件下系统颤振对磨削工件表面形貌的影响研究 [J]. 表面技术,2020,49(1):326-335. doi: 10.16490/j.cnki.issn.1001-3660.2020.01.039SUN Cong, YAO Yunlong, XIU Shichao, et al. Influences of system chatter on the ground workpiece's surface topography under prestress condition [J]. Surface Technology,2020,49(1):326-335. doi: 10.16490/j.cnki.issn.1001-3660.2020.01.039 [8] 张海瑞, 李先航, 方伟光, 等. 基于变可信度模型的飞行器翼结构模态分析 [J]. 宇航学报,2023,44(10):1496-1502. doi: 10.3873/j.issn.1000-1328.2023.10.002ZHANG Hairui, LI Xianhang, FANG Weiguang, et al. Modal analysis of flight vehicle wing structure based on multi-fidelity surrogate model [J]. Journal of Astronautics,2023,44(10):1496-1502. doi: 10.3873/j.issn.1000-1328.2023.10.002 [9] XIAO G, CHEN B, LI S, et al. Fatigue life analysis of aero-engine blades for abrasive belt grinding considering residual stress [J]. Engineering Failure Analysis,2022,131:105846. doi: 10.1016/j.engfailanal.2021.105846 [10] 孙海波, 圣小珍, 何光辉, 等. 基于锤击试验的钢轨扣件动刚度矩阵的测定 [J]. 噪声与振动控制,2023,43(6):282-288. doi: 10.3969/j.issn.1006-1355.2023.06.044SUN Haibo, SHENG Xiaozhen, HE Guanghui, et al. Determination of dynamic stiffness matrices of rail fasteners based on hammering test [J]. Noise and Vibration Control,2023,43(6):282-288. doi: 10.3969/j.issn.1006-1355.2023.06.044 [11] LIU L, RIPAMONTI F, CORRADI R, et al. On the experimental vibroacoustic modal analysis of a plate-cavity system [J]. Mechanical Systems and Signal Processing,2022,180:109459. doi: 10.1016/j.ymssp.2022.109459 [12] 罗德龙, 邓朝晖, 刘涛, 等. 基于Simulink仿真的凸轮轴高速磨削稳定性判定 [J]. 金刚石与磨料磨具工程,2019,39(4):56-61. doi: 10.13394/j.cnki.jgszz.2019.4.0009LUO Delong, DENG Chaohui, LIU Tao, et al. High speed grinding stability determination of camshaft based on Simulink simulation [J]. Diamond & Abrasives Engineering,2019,39(4):56-61. doi: 10.13394/j.cnki.jgszz.2019.4.0009 [13] 张氢, 陈文韬, 陈淼, 等. 数控凸轮轴磨床颤振稳定性研究 [J]. 湖南大学学报(自然科学版),2020,47(2):45-52. doi: 10.16339/j.cnki.hdxbzkb.2020.02.007ZHANG Qing, CHEN Wentao, CHEN Miao, et al. Study on cutting chatter stability of a computerized numerical control camshaft grinder [J]. Journal of Hunan University(Natural Sciences),2020,47(2):45-52. doi: 10.16339/j.cnki.hdxbzkb.2020.02.007 [14] 蒋永翔, 王太勇, 张莹, 等. 外圆切入磨再生颤振稳定性理论及评价方法 [J]. 天津大学学报,2009,42(4):283-286. doi: 10.3969/j.issn.0493-2137.2009.04.001JIANG Yongxiang, WANG Taiyong, ZHANG Ying, et al. Analysis of regenerative chatter stability theory and evaluation method on cylindrical plunging grinding [J]. Journal of Tianjin University,2009,42(4):283-286. doi: 10.3969/j.issn.0493-2137.2009.04.001 [15] 王千, 王成, 冯振元, 等. K-means聚类算法研究综述 [J]. 电子设计工程,2012,20(7):21-24. doi: 10.14022/j.cnki.dzsjgc.2012.07.034WANG Qian, WANG Cheng, FENG Zhenyuan, et al. Review of K-means clustering algorithm [J]. Electronic Design Engineering,2012,20(7):21-24. doi: 10.14022/j.cnki.dzsjgc.2012.07.034 [16] ZAGHBANI I, SONGMENE V. Estimation of machine-tool dynamic parameters during machining operation through operational modal analysis [J]. International Journal of Machine Tools and Manufacture,2009,49(12/13):947-957. doi: 10.1016/j.ijmachtools.2009.06.010 [17] LUO B, PAN DW, CAI H, et al. A method to predict position-dependent structural natural frequencies of machine tool [J]. International Journal of Machine Tools and Manufacture,2015,92:72-84. doi: 10.1016/j.ijmachtools.2015.02.009 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS