Force of dressing grinding wheels by diamond rollers with orderly arrangement grains

-

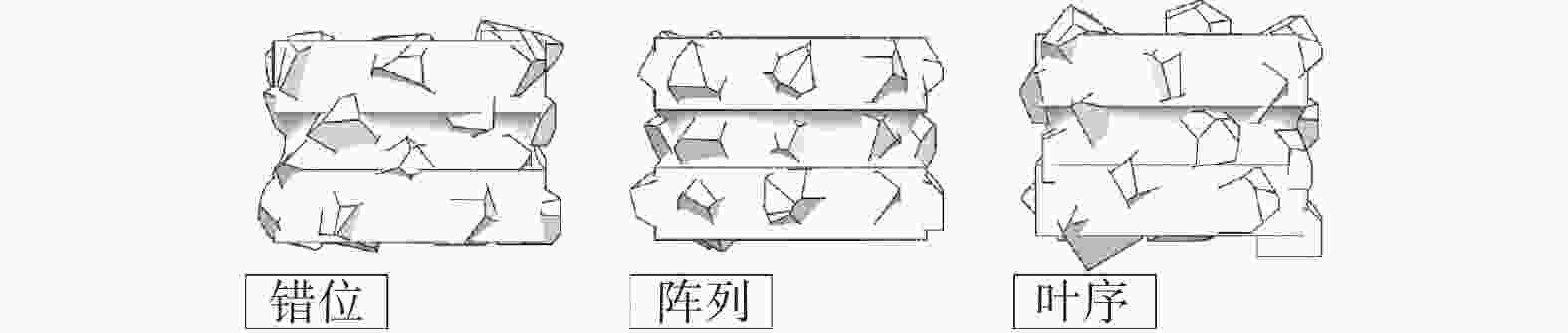

摘要: 为提升滚轮的修整性能和使用寿命,明确滚轮表面磨粒的不同排布对其修整性能的影响,采用错位、阵列和叶序3种磨粒排布的金刚石滚轮修整砂轮,对修整过程进行有限元仿真,并设计修整实验验证仿真结果。结果表明:在金刚石滚轮修整砂轮的过程中,磨粒的有序排布会对修整力产生影响,其中阵列排布的滚轮修整力最大,错位排布次之,叶序排布最小;叶序排布相较于错位与阵列排布,有利于减少滚轮表面磨粒磨损,提升滚轮的修整性能与使用寿命。Abstract:

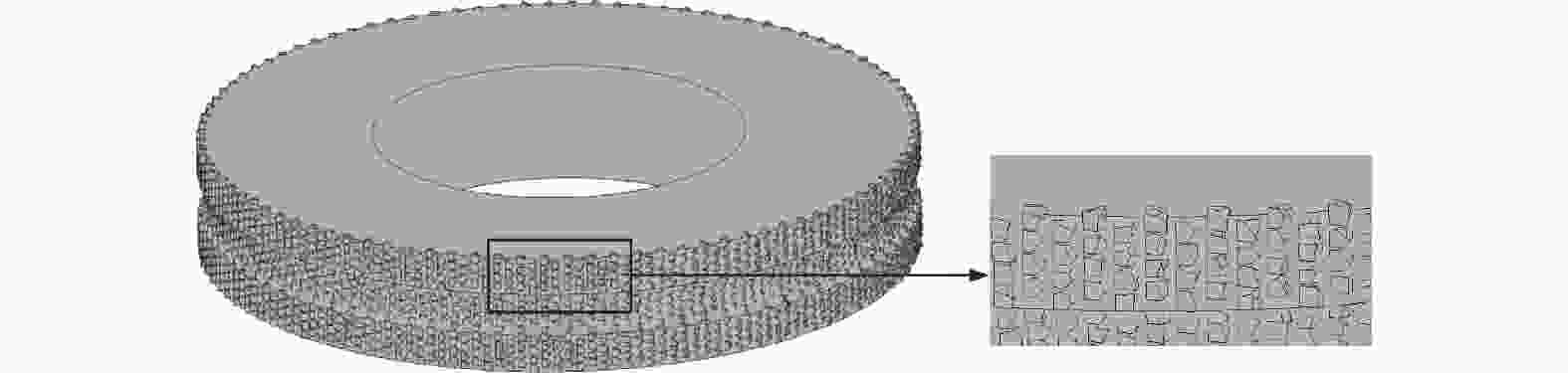

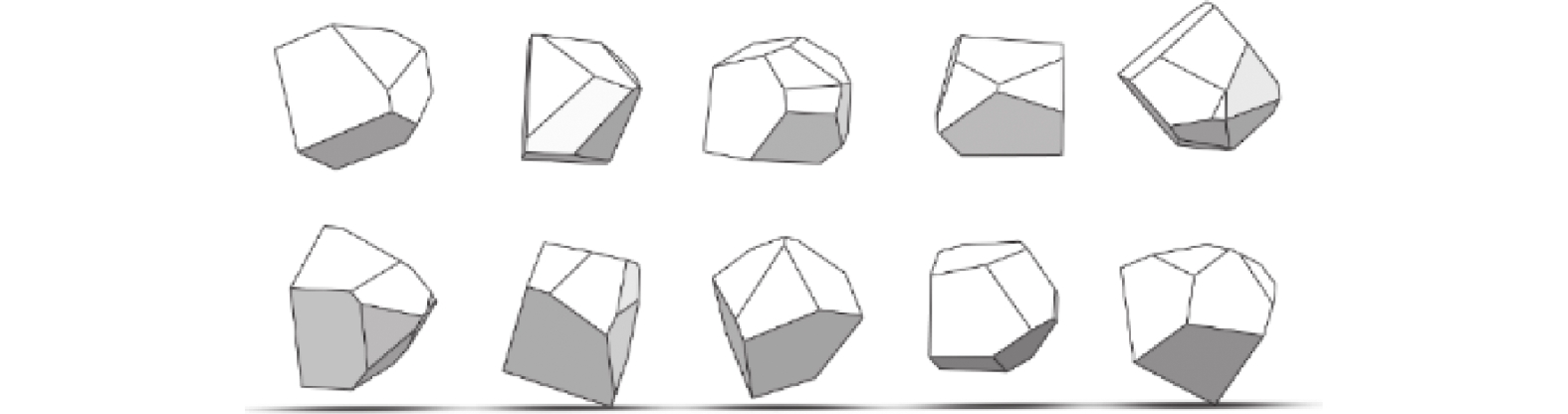

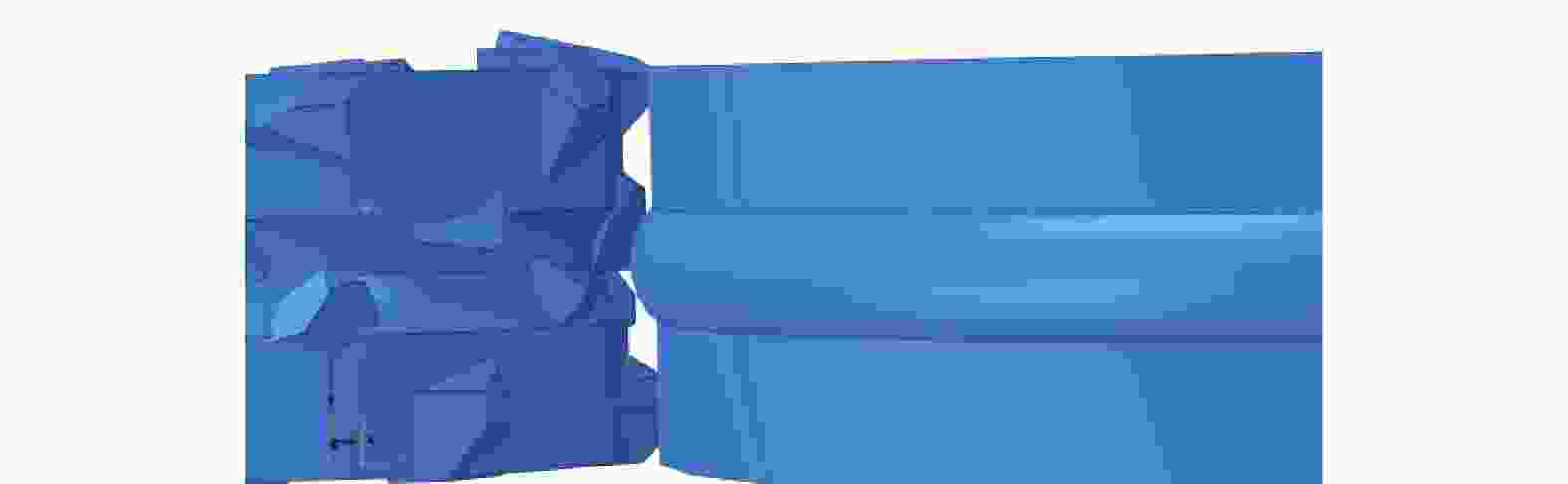

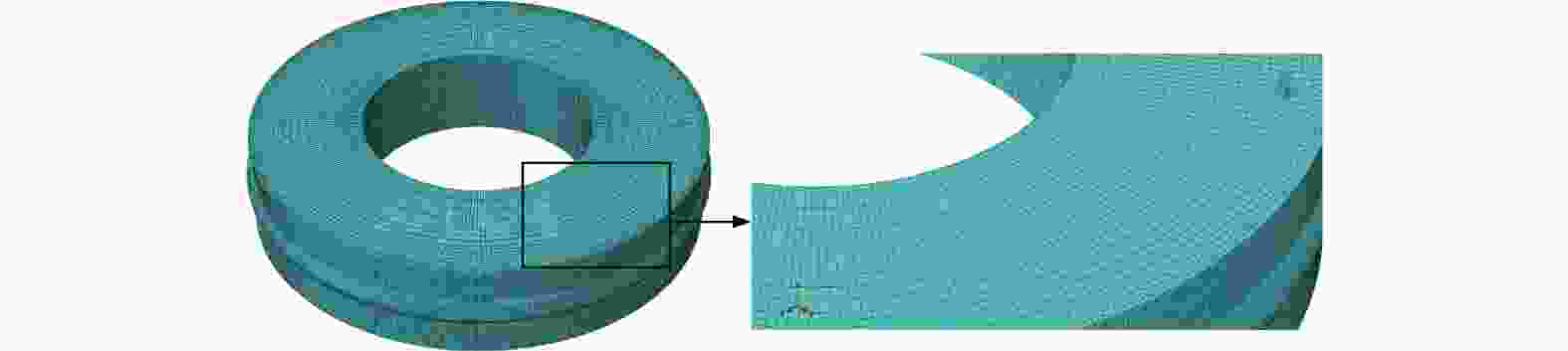

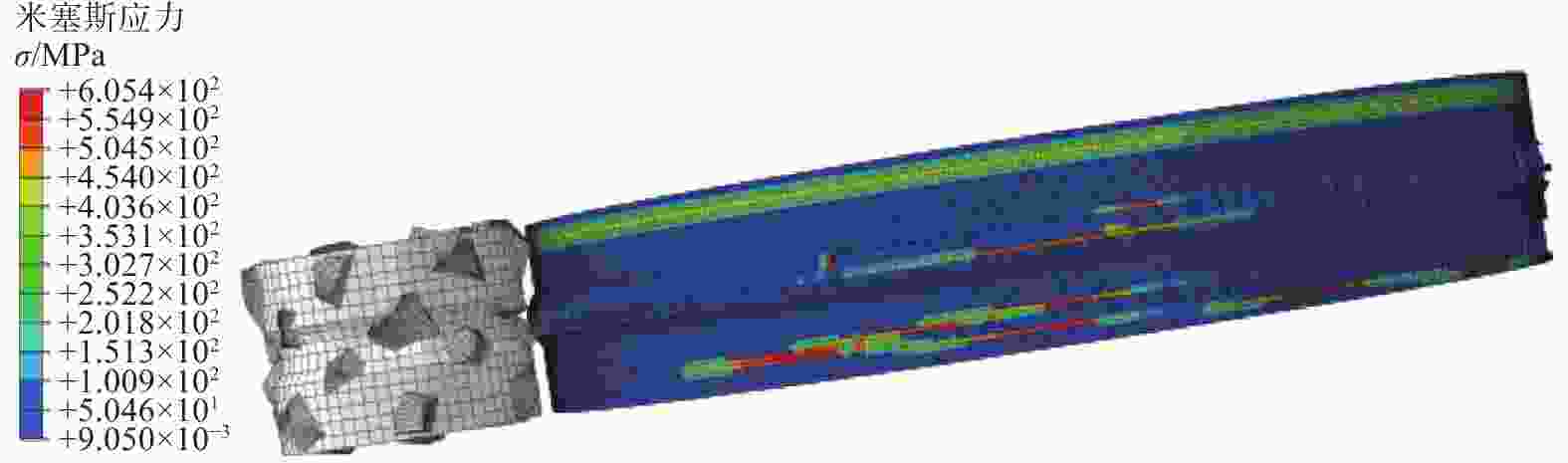

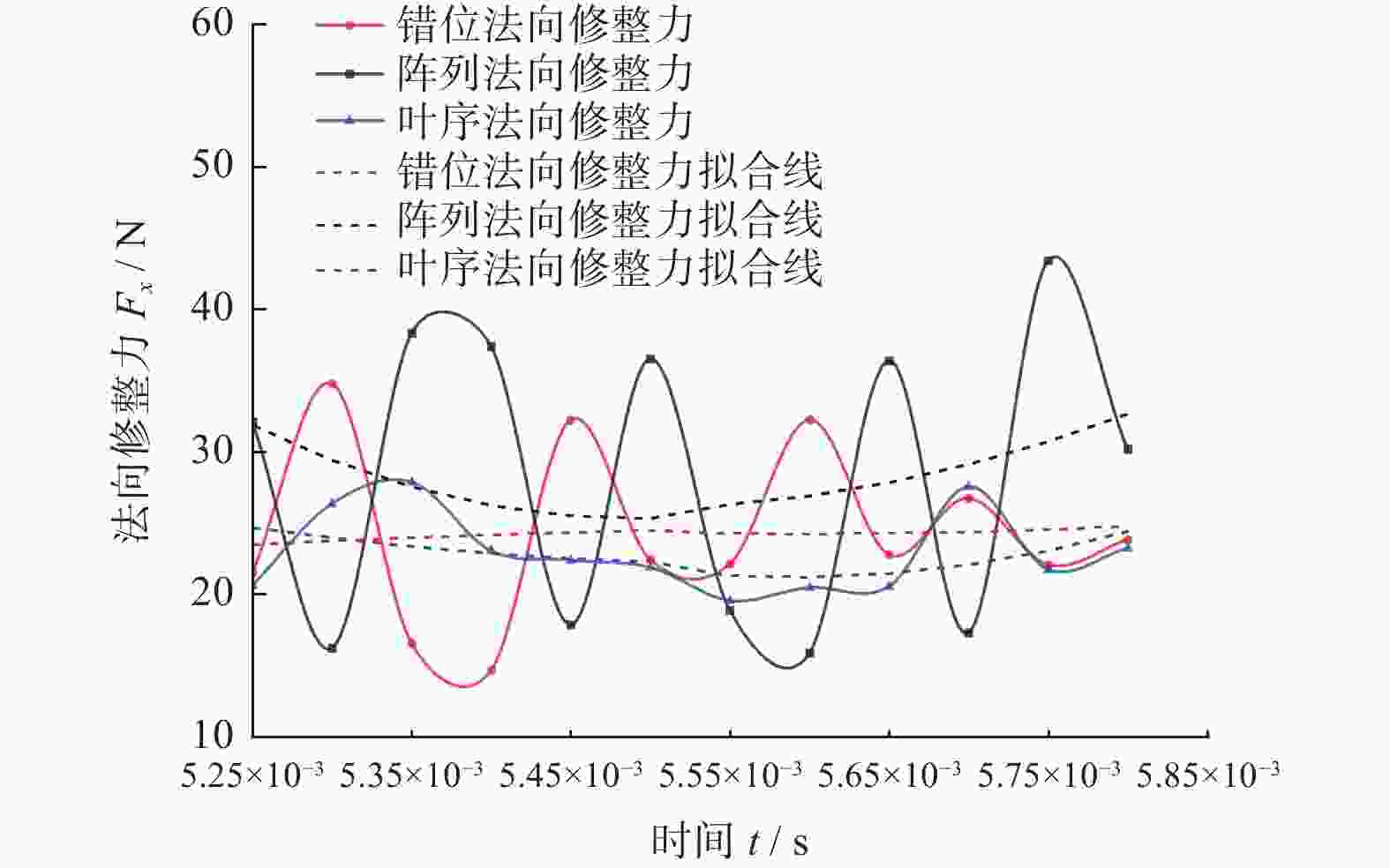

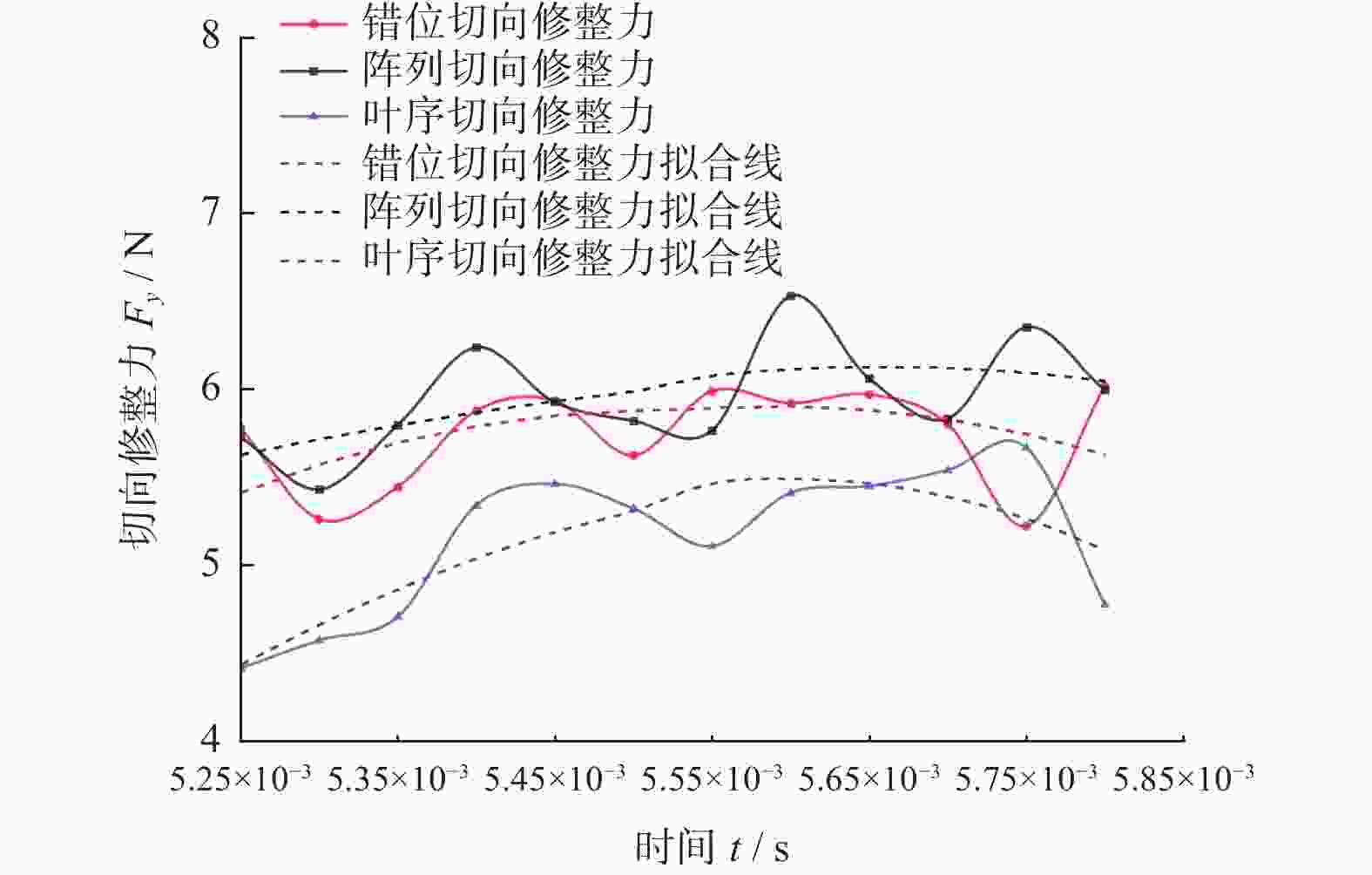

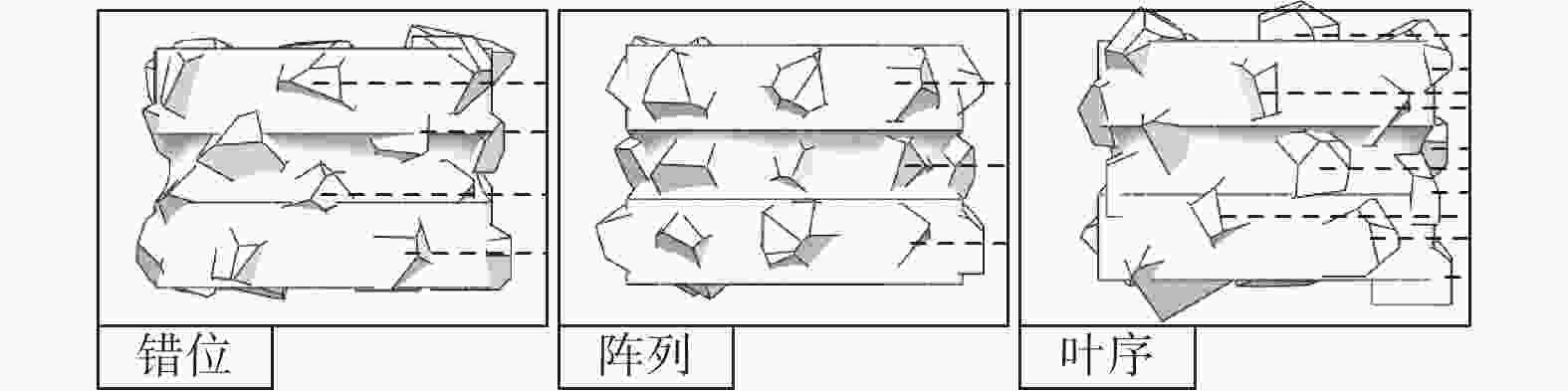

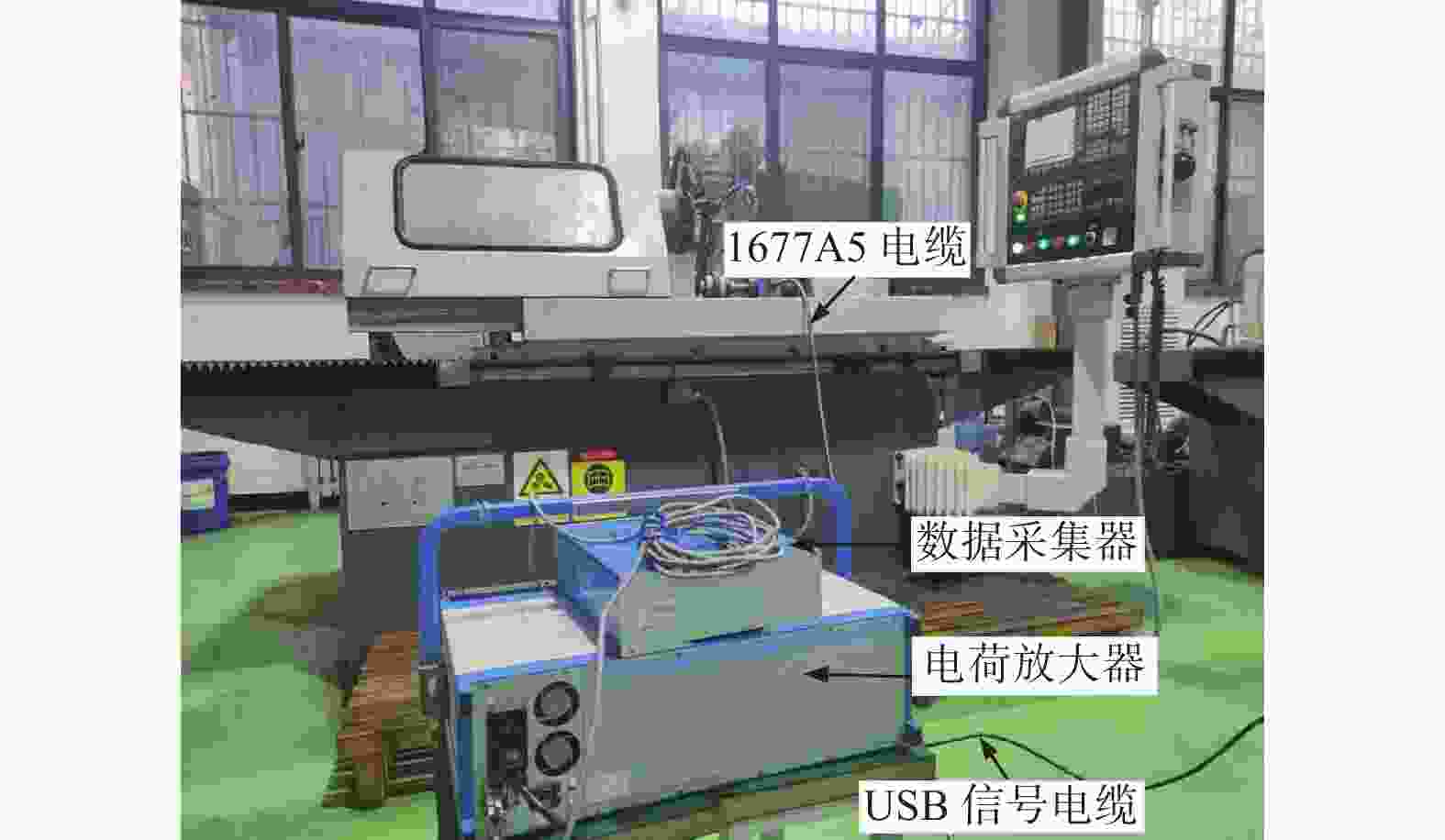

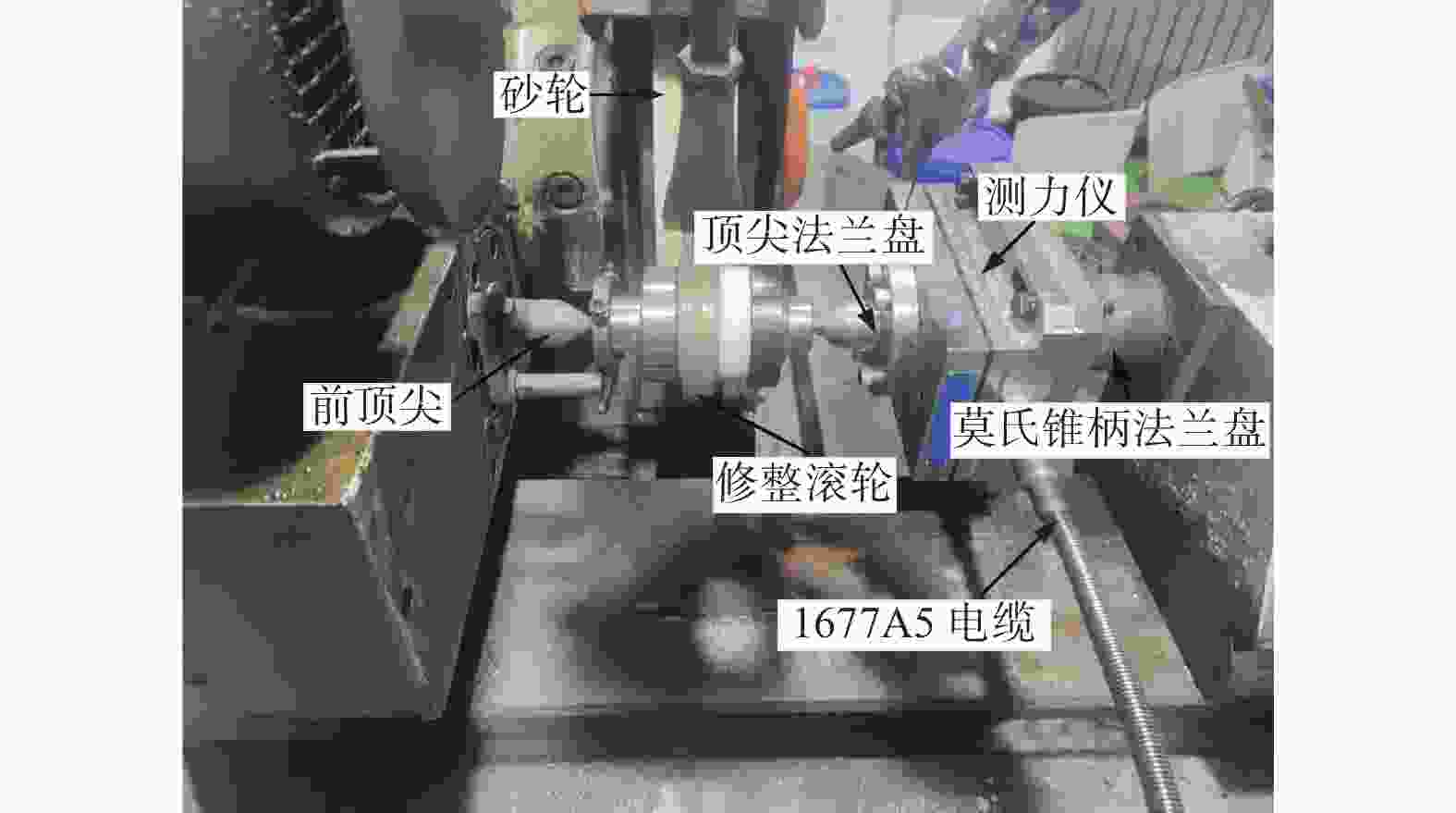

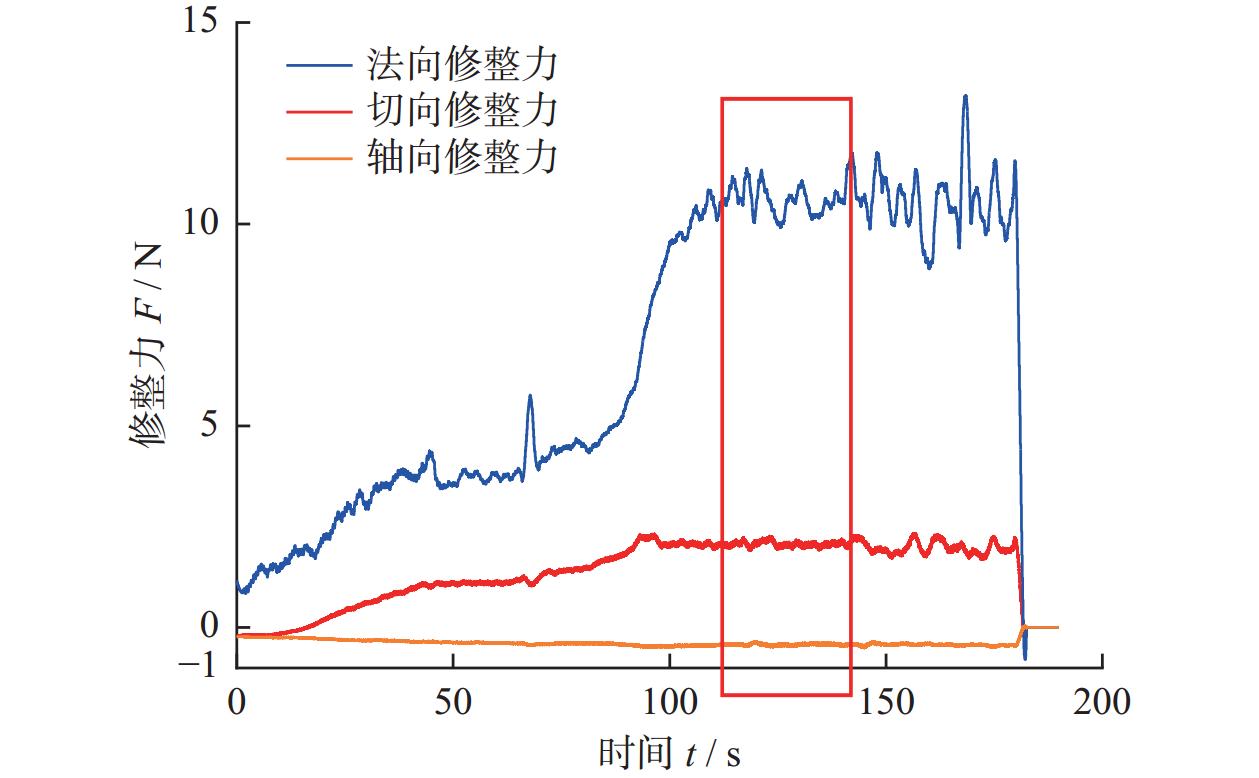

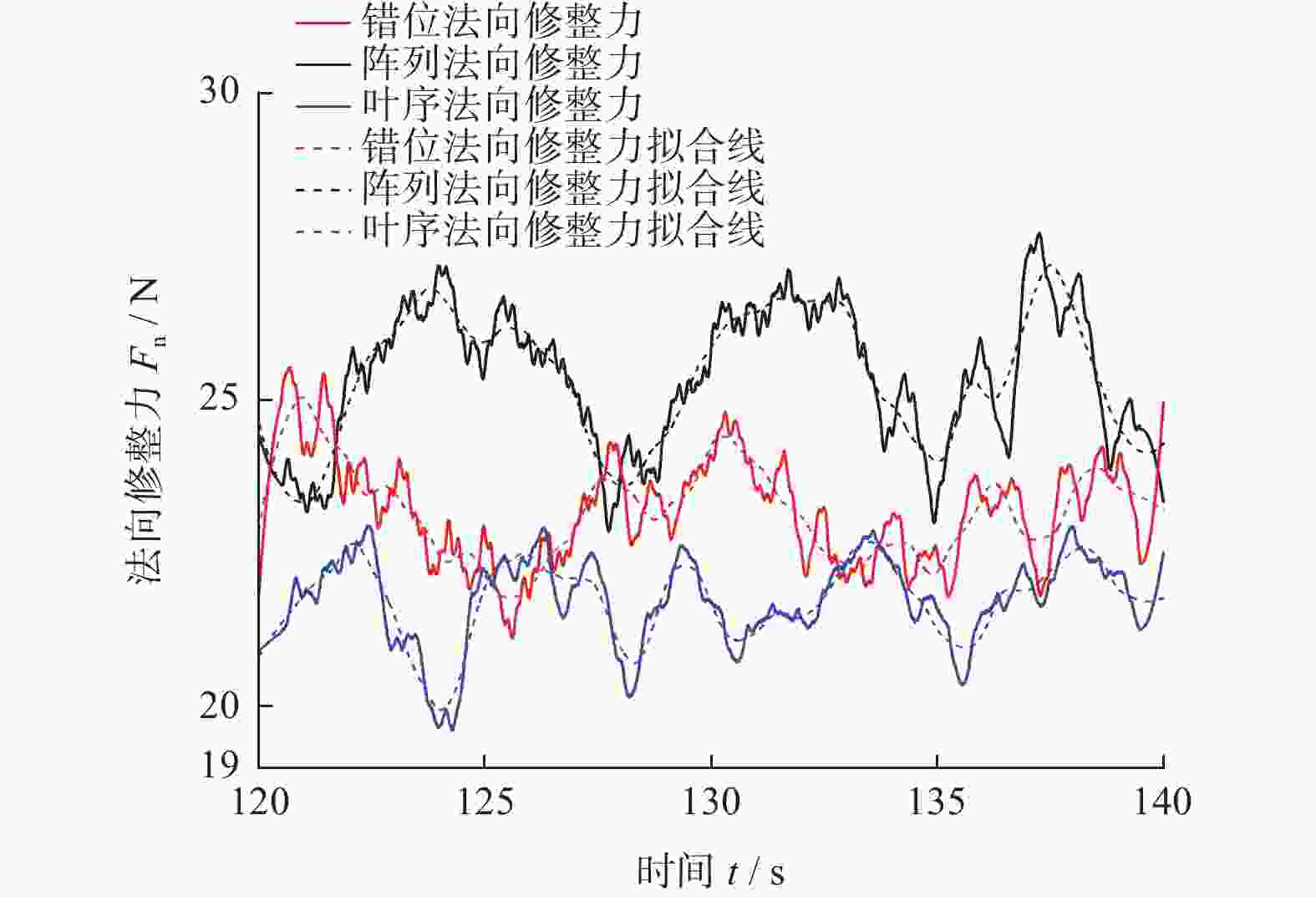

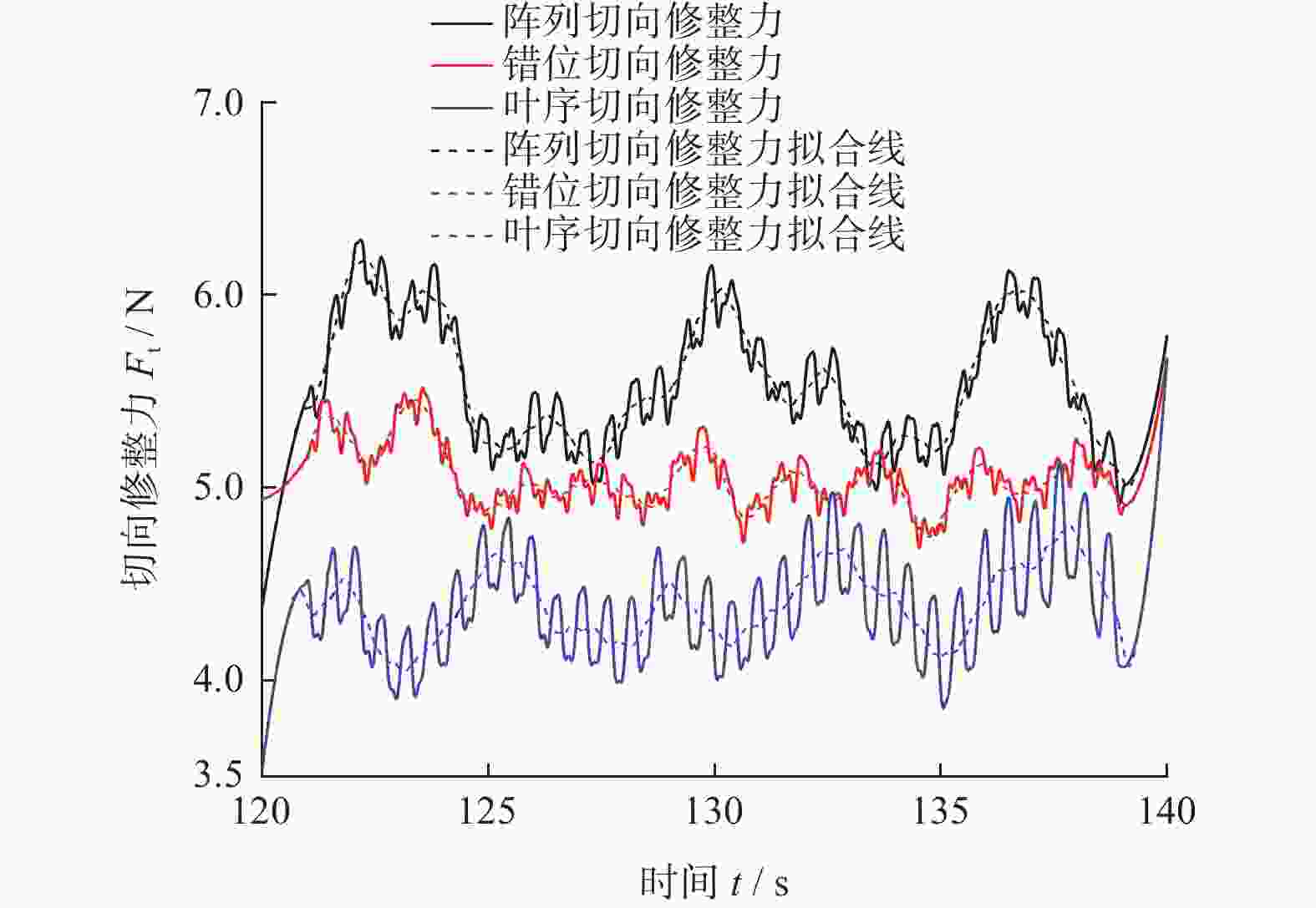

Objectives With the increasing improvement of science and technology and industrial levels, the modern manufacturing industry has higher and higher precision requirements for grinding processing, and the grinding quality can be improved by enhancing the ability of diamond dressing rollers. However, the current research on the grinding dressing process is mostly based on experiments. Since grinding is a high-speed and complex machining process, the dressing experimental cost of diamond rollers is higher. Therefore, this paper explores the influence of surface diamond grain arrangement on the dressing ability of diamond rollers through finite element simulation, and designs experiments to verify the reliability of the simulation results. Methods The finite element analysis software Abaqus is used to carry out kinematic simulation of the dressing grinding process of the roller. First of all, in order to simulate the randomness of the real abrasive grain shape, the sphere method of plane-cutting cubes is used to obtain a more realistic abrasive grain model. Algorithms are designed for the coordinates of abrasive grains in three types of arrangement: array, misalignment, and leaf sequence, to achieve the accurate arrangement of abrasive grains on the surface of the roller model. The Johnson-Holmquist-2 (JH-2) intrinsic parameters model of 99.5% alumina ceramics is used to approximately characterize the damage evolution of white corundum grinding wheels during dressing. To verify the accuracy of the results obtained through this simulation method, dressing experiments are set up to form a control with the simulation group. Results Taking the dressing force generated in the dressing process as the evaluation index, the simulation and experimental results are analyzed: (1) A comparative analysis of the data obtained from the simulation is carried out, and it is found that diamond wheels with surface abrasive grains arranged in an array manner would generate a larger dressing force during the dressing process, followed by the staggered-arrangement wheels, and the diamond wheels with a leaf-sequence arrangement would have the smallest dressing force. In other words, the arrangement of abrasive grains on the surface of the diamond dressing wheel affects the dressing force. (2) The dressing force results obtained from the experiments also show that under these three arrangements, the dressing force generated by the array roller is the largest, and the dressing force generated by the leaf sequence is the smallest. (3) Comparing the dressing force data obtained from the simulation and experiment, it can be seen that the fluctuation of the dressing force obtained from the experiment is smaller than that of the simulation. The maximum error of both normal dressing force is 12.87%, and the maximum error of tangential dressing force is 17.16%. Conclusions (1) Comparing the dressing force results of the simulation and experiment, it is found that the fluctuation of the experimental data is smaller than that of the simulation results. This is due to the fact that the abrasive grains in the simulation are generated randomly. Even if two neighboring abrasive grains differ in parameters such as protruding height, effective action area, and the angle of abrasive grains' vertices, the fluctuation of the dressing force is still larger under the state of smooth grinding. The diamond rollers used in the experiments have undergone surface reshaping treatment, and the parameters such as the emergence height and vertex angle of the abrasive grains on the surface are more consistent with the simulation model. As a result, the fluctuation of the dressing force is smaller and smoother. The dressing force measured in the experiment is smaller compared with the simulation, which indicates that the dressing roller can be shaped to make the dressing process smoother and improve its dressing ability. (2) The reason for the difference in dressing force of diamond wheels with different arrangements of abrasive grains: Under the condition of the same concentration of abrasive grains on the surface, the abrasive grains of the roller with an array arrangement result in fewer effective abrasive grains due to a large number of overlapping grinding trajectories. In contrast, the leaf-sequence arrangement has the unique characteristic where each abrasive grain is located on a circumference that is different from that of any other abrasive grain. Therefore, the trajectory lines of each abrasive grain on it do not overlap, resulting in the largest number of effective abrasive grains and the smallest dressing force. (3) The similarity between the simulation and the dressing force obtained from the experiment verifies the reliability of the simulation of the dressing process of the wheel by finite element analysis. It also proves the feasibility of replacing the material properties of the white corundum grinding wheel with the JH-2 intrinsic parameter of alumina ceramics with 99.5% content in the kinetic simulation. -

Key words:

- diamond /

- orderly arrangement /

- grinding /

- dressing /

- phyllotactic pattern

-

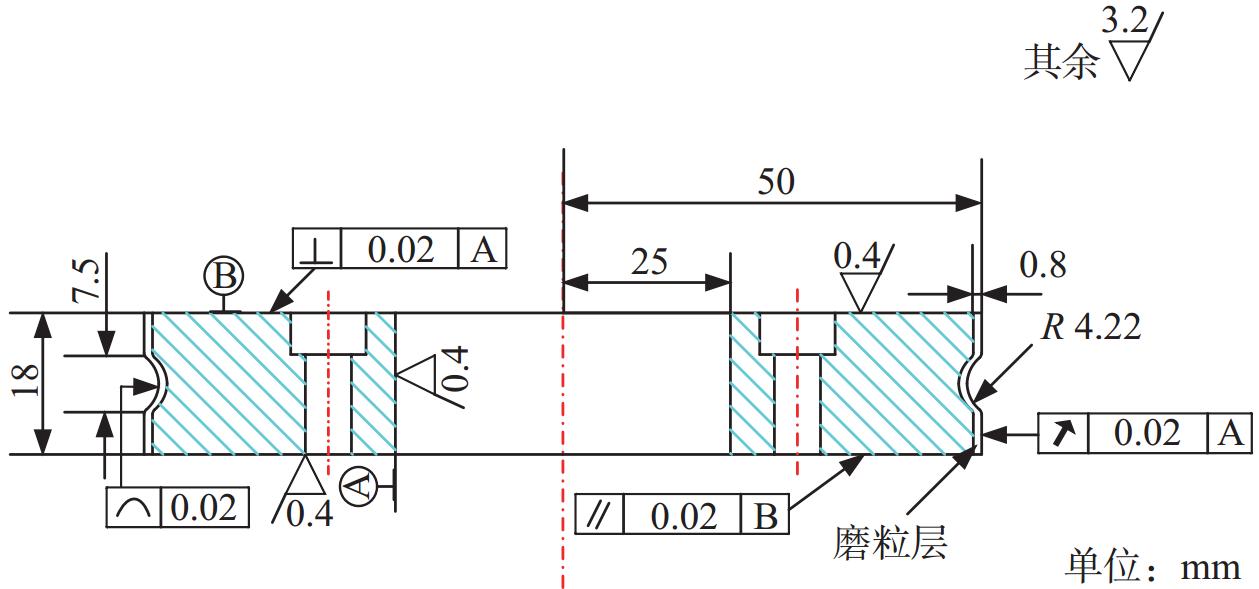

表 1 滚轮与砂轮仿真模型参数

Table 1. Parameters of roller and grinding wheel simulation model

模型 外径 d1 / mm 孔径 d2 / mm 厚度 t / mm 金刚石滚轮 5 2.5 3.65 白刚玉砂轮 20 10 3.65 表 2 金刚石与白刚玉材料参数

Table 2. Diamond and white corundum material parameters

材料 密度 ρ /

(t·mm−3)杨氏模量 E / MPa 泊松比 v 金刚石 3.52 × 10−9 1.05 × 106 0.1 白刚玉 3.98 × 10−9 3.5 × 105 0.22 材料 热膨胀系数 $ \alpha $ 热导率 $ \lambda $ /

(W·m−1·K−1)比热容 c /

(mJ·t−1·K−1)金刚石 1.26 × 10−6 2 000 4.2 × 108 白刚玉 30.145 6.0 × 108 本构

模型密度 ρ /

(t·mm− 3)剪切模量

G / MPaA N B M C 3.7 × 10− 9 90 160 0.93 0.6 0.31 0.6 0 $ \dot{\varepsilon}_0 $ 拉伸强度

Rm / MPa$ {\sigma }_{\mathrm{i}}^{\mathrm{m}\mathrm{a}\mathrm{x}} $ $ {\sigma }_{\mathrm{f}}^{\mathrm{m}\mathrm{a}\mathrm{x}} $ HEL /

MPa$ {p}_{\mathrm{H}\mathrm{E}\mathrm{L}} $ /

MPa$ \beta $ 1 200 1.004 4 0.2 279 0 1 460.0 1 $ {K}_{1} $ $ {K}_{2} $ $ {K}_{3} $ 130950 0 0 损伤

模型$ {D}_{1} $ $ {D}_{2} $ $ {\stackrel{-}{\varepsilon }}_{\mathrm{f},\mathrm{m}\mathrm{a}\mathrm{x}}^{\mathrm{p}\mathrm{l}} $ $ {\stackrel{-}{\varepsilon }}_{\mathrm{f},\mathrm{m}\mathrm{i}\mathrm{n}}^{\mathrm{p}\mathrm{l}} $ FS IDamage 0.005 1.0 0.005 0 0.2 0 表 4 砂轮规格参数

Table 4. Grinding wheel specification

参数 取值 外径 d1 / mm 400 孔径 d2 / mm 203 厚度 t / mm 50 粒度 80 硬度 K 表 5 滚轮修整实验设计

Table 5. Roller dressing test design

阶段 滚轮转速

v1 / (r·min− 1)砂轮转速

v2 / (r·min− 1)磨削速度

v3 / (mm·min− 1)磨削量

d / mm成型修整 81 1 488 0.14 3.5 工件A 81 1 488 0.14 3.5 工件B 81 1 488 0.14 3.5 工件C 81 1 488 0.14 3.5 修整 81 1 488 0.14 0.7 -

[1] 李瑞昊, 石广慧, 黄辉. 磨粒有序排布曲面砂轮设计及磨削性能实验研究 [J]. 金刚石与磨料磨具工程,2021,41(4):58-63. doi: 10.13394/j.cnki.jgszz.2021.4.0009LI Ruihao, SHI Guanghui, HUANG Hui. Experimental research on design and performance of curved grinding wheels with orderly arrangement of abrasive grains [J]. Diamond & Abrasives Engineering,2021,41(4):58-63. doi: 10.13394/j.cnki.jgszz.2021.4.0009 [2] YUAN H P, GAO H, LIANG Y D. Fabrication of a new-type electroplated wheel with controlled abrasive cluster and its application in dry grinding of CFRP [J]. International Journal of Abrasive Technology,2010,3(4):299. doi: 10.1504/IJAT.2010.036963 [3] ZHANG G F, ZHANG B, DENG Z H, et al. An experimental study on a novel diamond whisker wheel [J]. CIRP Annals,2010,59(1):355-360. doi: 10.1016/j.cirp.2010.03.116 [4] KOSHY P, IWASALD A, ELBESTAWL M A. Surface generation with engineered diamond grinding wheels: Insights from simulation [J]. CIRP Annals,2003,52(1):271-274. doi: 10.1016/S0007-8506(07)60582-4 [5] OHI T. Trends and future developents for diamond CMP pad conditioners [J]. Industrial Diamond Review,2004(1):14-17,19,21. [6] 车东泽, 吕玉山, 陈天宇, 等. 用磨粒叶序排布砂轮磨削外圆生成的凹坑表面仿真 [J]. 金刚石与磨料磨具工程,2019,39(1):47-53. doi: 10.13394/j.cnki.jgszz.2019.1.0009CHE Dongze, LYU Yushan, CHEN Tianyu, et al. Simulation of the dimpled surface generated by grinding outer circle with abrasive phyllotactic arrangement wheel [J]. Diamond & Abrasives Engineering,2019,39(1):47-53. doi: 10.13394/j.cnki.jgszz.2019.1.0009 [7] 赵国伟, 吕玉山, 李雨菲, 等. 有序化砂轮磨削表面粗糙度仿真 [J]. 机械设计与制造,2018(3):223-225,229. doi: 10.3969/j.issn.1001-3997.2018.03.066ZHAO Guowei, LV Yushan, LI Yufei, et al. Simulation of the surface roughness with grinding wheel of ordered abrasive pattern [J]. Machinery Design & Manufacture,2018(3):223-225,229. doi: 10.3969/j.issn.1001-3997.2018.03.066 [8] 陈晨, 王军, 吕玉山, 等. 磨料有序化排布砂轮磨削TC4温度实验研究 [J]. 金刚石与磨料磨具工程,2015,35(5):25-28. doi: 10.13394/j.cnki.jgszz.2015.5.0006CHEN Chen, WANG Jun, LV Yushan, et al. Experimental investigation of grinding temperature when grinding TC4 with engineered grinding wheels [J]. Diamond & Abrasives Engineering,2015,35(5):25-28. doi: 10.13394/j.cnki.jgszz.2015.5.0006 [9] 李伟凡. 磨粒有序化排布超硬砂轮磨削力的研究 [D]. 沈阳: 沈阳理工大学, 2017.LI Weifan. Research on the grinding force of super-hard grinding wheel with ordering arrangement pattern [D]. Shenyang: Shenyang Ligong University, 2017. [10] 国家质量监督检验检疫总局, 中国国家标准化管理委员会. 超硬磨料 粒度检验: GB/T 6406—2016 [S]. 北京: 中国标准出版社, 2016.General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, Standardization Administration of the People’s Republic of China. Superabrasive—Checking the grain size: GB/T 6406—2016 [S]. Beijing: Standards Press of China, 2016. [11] 韩程宇. 平面磨削有限元仿真及磨削建模GUI平台开发 [D]. 郑州: 郑州大学, 2019.HAN Chengyu. Surface grinding finite element simulation and grinding modeling GUI platform development [D]. Zhengzhou: Zhengzhou University, 2019. [12] ITERSON V G. Mathematische und mikroskopish-anatomische studien über blattstellungen [J]. Nature,1907,77:145-146. doi: 10.1038/077145a0 [13] SUN J, WU Y H, ZHOU P, et al. Simulation and experimental research on Si3N4 ceramic grinding based on different diamond grains [J]. Advances in Mechanical Engineering,2017,9(6): 168781401770559. doi: 10.1177/1687814017705596 [14] CRONIN D S , BUI K , KAUFMANN C , et al. Implementation and validation of the Johnson-Holmquist ceramic material model in LS-DYNA [C]//4th European LS-DYNA Users Conference. Ulm, Germany, 2003: 47-60. [15] LIU M Z, LI C H, ZHANG Y B, et al. Analysis of grinding mechanics and improved grinding force model based on randomized grain geometric characteristics [J]. Chinese Journal of Aeronautics,2023,36(7):160-193. doi: 10.1016/j.cja.2022.11.005 [16] 马少奇. 18CrNiMo7-6钢外圆磨削力及表面完整性研究 [D]. 郑州: 郑州大学, 2021.MA Shaoqi. Research on grinding force and surface integrity of 18CrNiMo7-6 steel in cylindrical grinding [D]. Zhengzhou: Zhengzhou University, 2021. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS