Effect of TiN-Al system binder ratio on structure and properties of PcBN

-

摘要: 为研究TiN-Al体系结合剂配比对PcBN结构和性能的影响,在5.5 GPa、

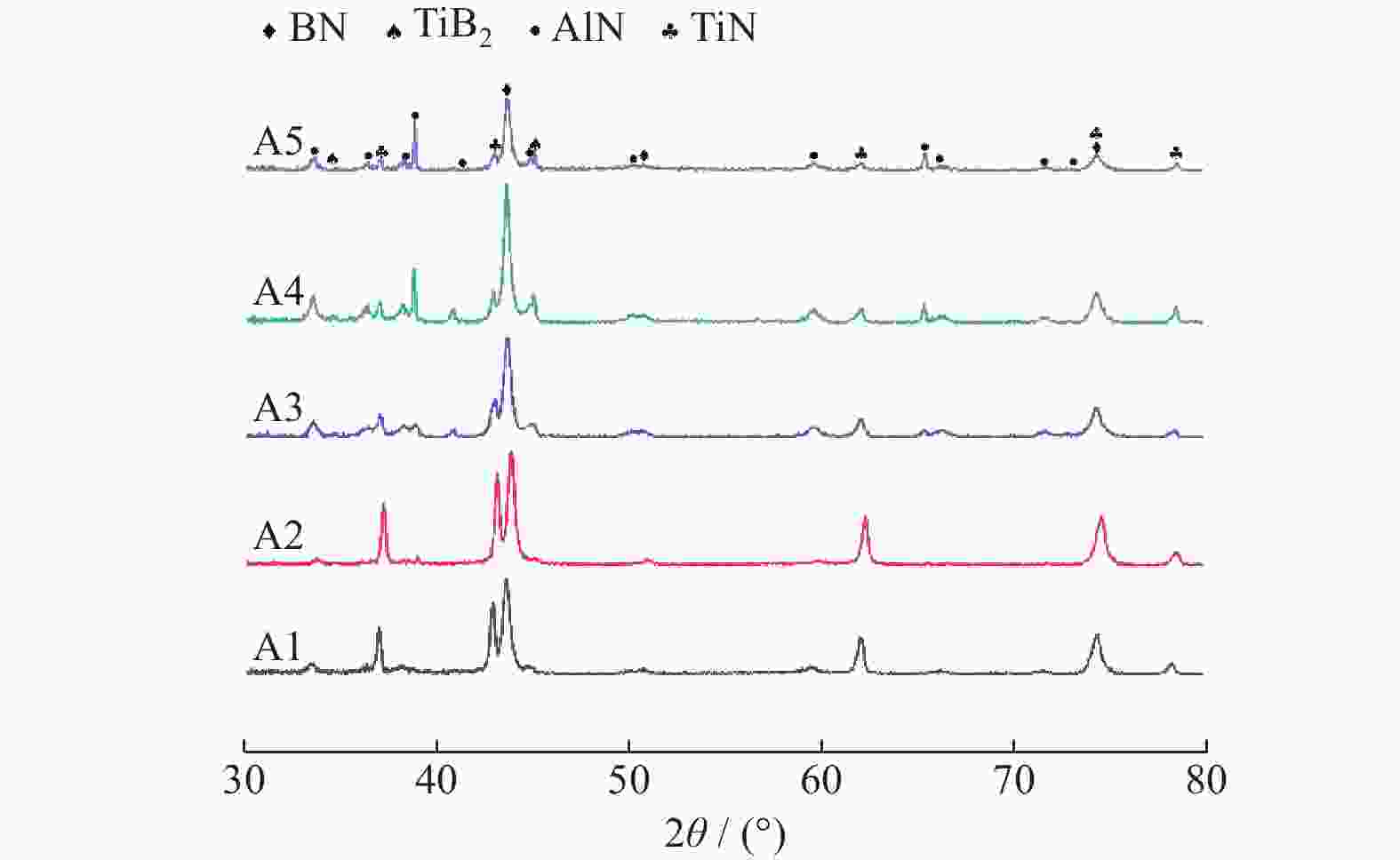

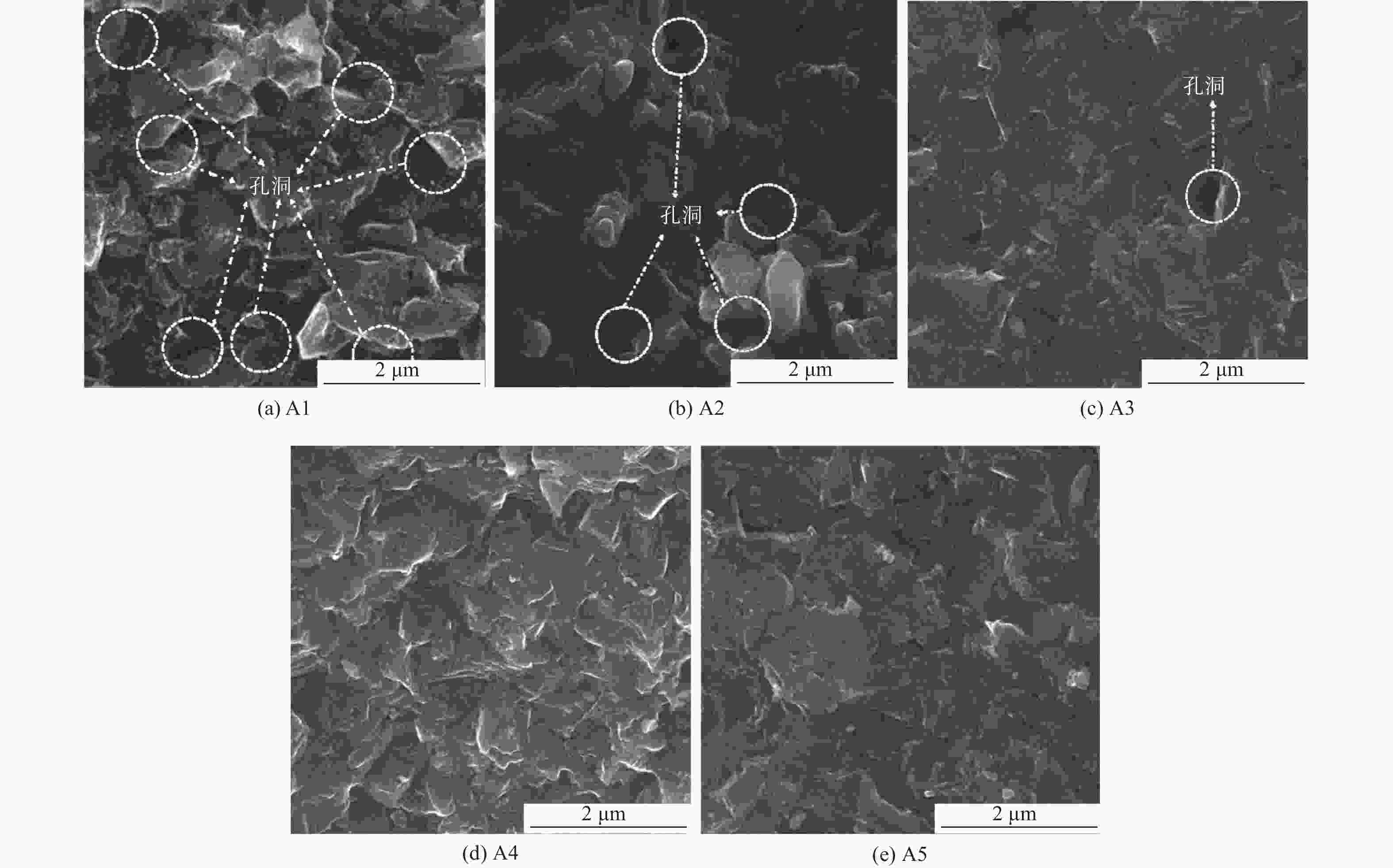

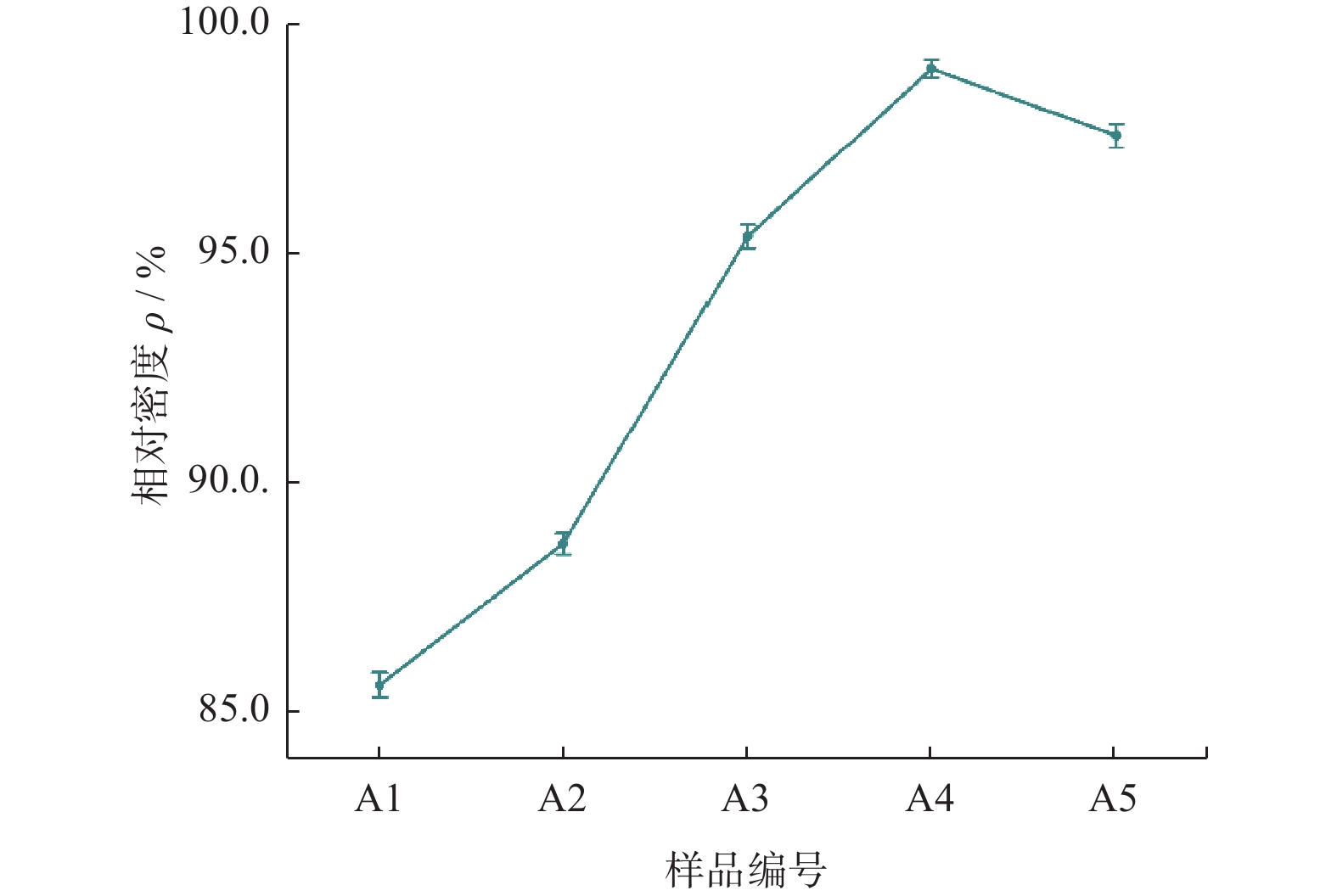

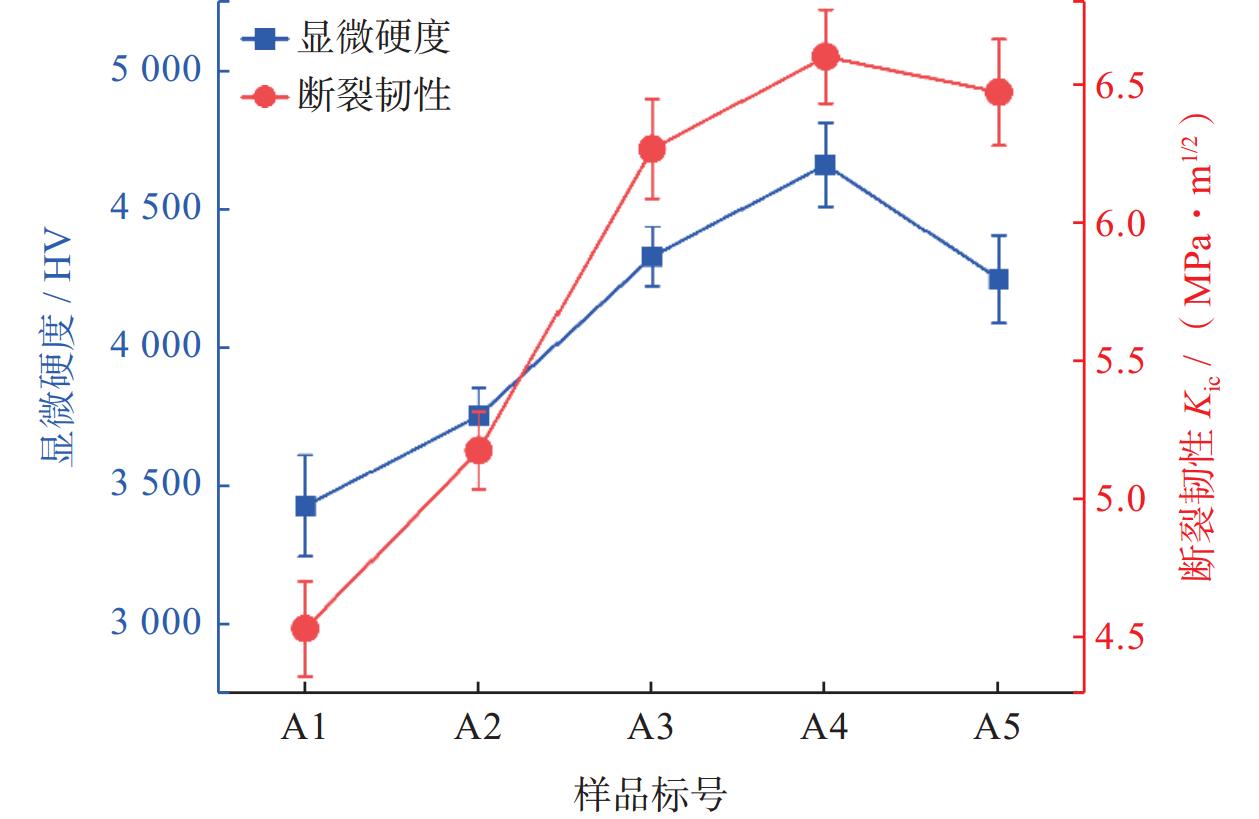

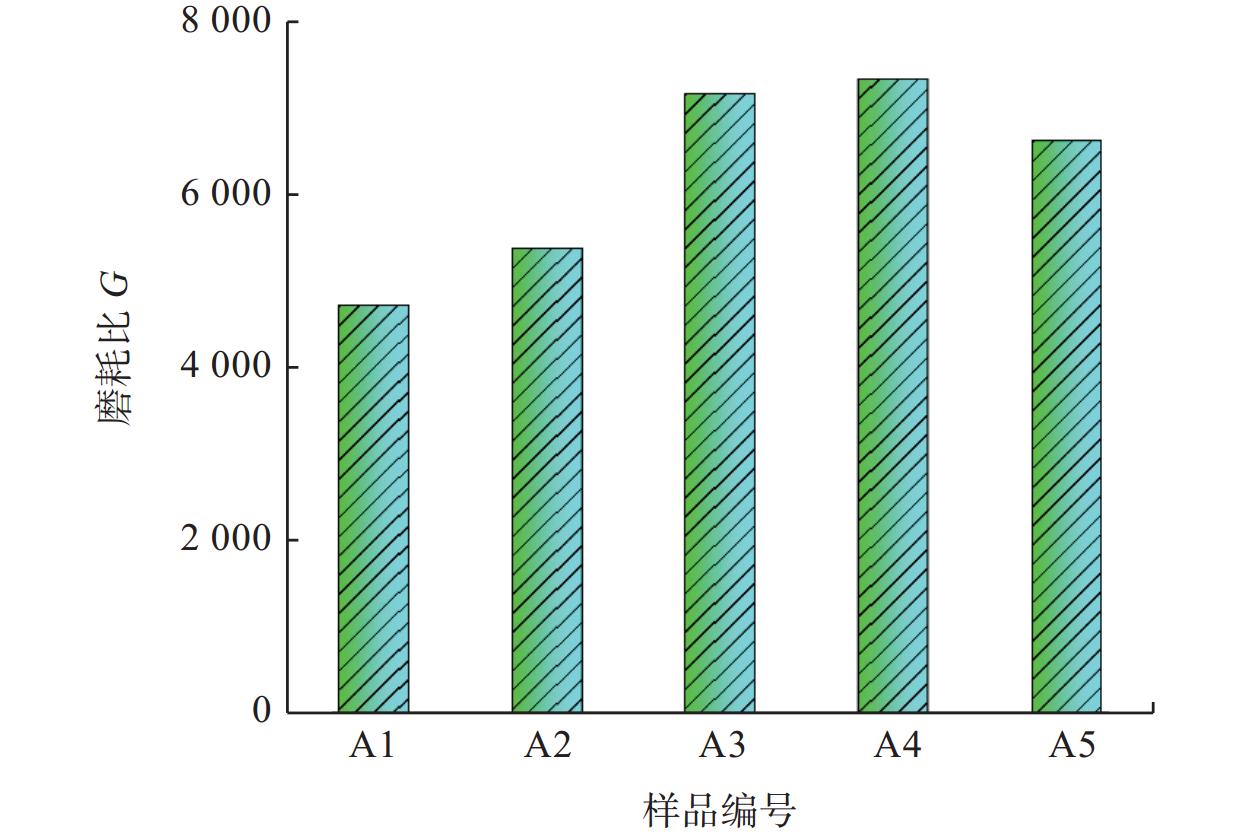

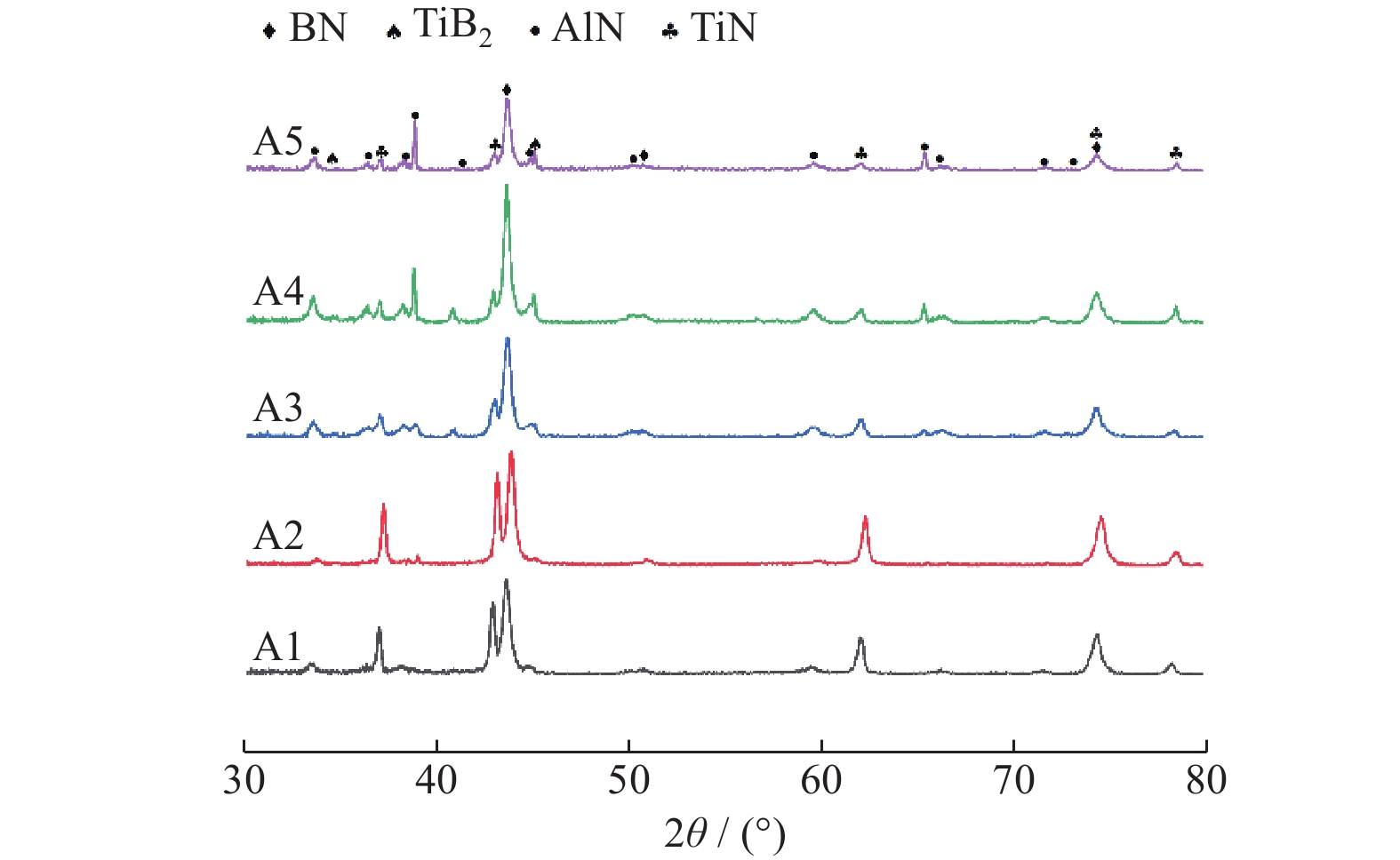

1500 ℃的条件下制备PcBN。研究发现:结合剂TiN、Al与cBN反应生成BN、TiB2、TiN和AlN 4种物相。随着Al含量的提高,样品中AlN和TiB2成分占比上升,TiN成分占比下降;当TiN和Al的质量配比 < 17∶8时,样品组织内存在大量的孔洞,样品不致密。随着Al含量的提高,孔洞数量减小以至消失,样品组织变得致密;经相对密度、维氏硬度、断裂韧性、耐磨性测试,结合剂中TiN与Al质量配比为9∶16时,PcBN样品组织最为致密,综合性能最好,此时其相对密度、维氏硬度、断裂韧性和磨耗比均达到最大值,分别为99.02%、4664 HV 、6.60 MPa·m1/2和7340 。Abstract:Objectives Al and TiN are commonly used components in PcBN synthesis under high temperature and high pressure. But the existing literature studying the TiN-Al bonding system always focuses on the single property variation, such as relative density, hardness, fracture toughness, impact resistance or abrasion resistance, rather than the comprehensive performance when analyzing the samples. In this paper, the TiN-Al ratio and its effect on the structure and the comprehensive performance of PcBN is explored. Methods The raw materials for the experiment are cBN powder sized 0.5-1.0 µm and binders of TiN powder sized of 2-10 µm and Al powder sized 1-2 µm. The high-temperature and high-pressure preparation conditions are provided by a hydraulic cubic press. The sintering pressure is 5.5 GPa and the sintering temperature is 1400 ℃, with a holding time of 10 minutes to obtain the PcBN sample. After grinding, polishing and other processing steps, the material properties are tested. The phase is analyzed using an X-ray diffractometer. The binding of cBN particles with the binder and its microscopic morphology are observed using a scanning electron microscope. The actual density, the microhardness and the fracture toughness of the samples are tested separately. The wear ratio of the specimens are measured under the following conditions: an 80-mesh grit SiC grinding wheel for counter grinding, axial force of 300 N and spindle speed of 300 r/min. The wear ratio of the samples is quantified by the ratio of the wheel wear to the PcBN wear.Results It is observed that the prepared PcBN consists of 4 phases: BN, AlN, TiN, and TiB2. As the proportion of Al increases, the diffraction peak intensities of AlN and TiB2 gradually become stronger while that of TiN gradually decreases. When the content of Al increases, the number of pores decreases to zero and the material become denser. The relative density of the samples reaches its maximum value of 99.02% at 9% TiN and 16% Al. The hardness, the fracture toughness and the abrasion resistance of PcBN increase initially and then decrease as TiN content increases. Conclusions The binding agents TiN and Al react with cBN, forming four phases: BN, TiB2, TiN and AlN. As the Al ratio increases, the proportions of AlN and TiB2 increase while that of TiN decreases. The comprehensive performance of PcBN is the best when the mass ratio of TiN∶Al in the binding agent is 9∶16, leading to uniform distribution of cBN and binder and ensuring a dense PcBN sintered body. At this condition, the relative density, the Vickers hardness, the fracture toughness and the wear ratio of the PcBN sample reach the maximum values, which are 99.02%, 4664 HV, 6.60 MPa·m1/2 and7340 , respectively.-

Key words:

- PcBN /

- high temperature and high pressure /

- TiN-Al /

- ratio /

- comprehensive performance

-

表 1 不同结合剂质量配比制备PcBN的实验配方

Table 1. Experimental formulations for preparation of PcBN with different mass ratios of binders

编号 cBN质量分数 w1 / % TiN质量分数 w2 / % Al 质量分数w3 / % A1 75 21 4 A2 75 17 8 A3 75 13 12 A4 75 9 16 A5 75 5 20 -

[1] 马金明, 肖长江, 张群飞, 等. 聚晶立方氮化硼材料国内外研究现状与进展 [J]. 超硬材料工程,2023,35(1):43-47. doi: 10.3969/j.issn.1673-1433.2023.01.012MA Jinming, XIAO Changjiang, ZHANG Qunfei, et al . Current research status and progress of polycrystalline cubic boron nitride materials in China and abroad [J]. Superhard Material Engineering ,2023,35(1):43-47. doi: 10.3969/j.issn.1673-1433.2023.01.012 [2] LI M L, LIANG L X, WANG H L, et al. Processing and properties of PcBN composites fabricated by HPHT using PSN and Al as sintering additive [J]. Rare Metals,2020,39(5):570-576. doi: 10.1007/s12598-020-01371-y [3] MO P C, CHEN J R, ZHANG Z, et al. The effect of cBN volume fraction on the performance of PcBN composite [J]. International Journal of Refractory Metals and Hard Materials,2021,100(11):105643-105650. doi: 10.1016/j.ijrmhm.2021.105643 [4] 崔金蒙, 孟德忠, 吴哲, 等. PCBN刀具切削性能和磨损机理研究综述 [J]. 金刚石与磨料磨具工程,2020,40(6):83-91. doi: 10.13394/j.cnki.jgszz.2020.6.0014CUI Jinmeng, MENG Dezhong, WU Zhe, et al . Review on cutting performance and wear mechanism of PcBN tools [J]. Diamond & Abrasives Engineering ,2020,40(6):83-91. doi: 10.13394/j.cnki.jgszz.2020.6.0014 [5] 张喆, 张俊. 聚晶立方氮化硼刀具研究进展 [J]. 超硬材料工程,2017,29(5):52-55. doi: 10.3969/j.issn.1673-1433.2017.05.012ZHANG Zhe, ZHANG Jun . The research progress of the polycrystalline cubic boron nitride cutting tool [J]. Superhard Material Engineering ,2017,29(5):52-55. doi: 10.3969/j.issn.1673-1433.2017.05.012 [6] 邓福铭, 陈启武. 我国超硬刀具材料发展中的几个问题思考与对策 [J]. 超硬材料工程,2006,17(4):32-35. doi: 10.3969/j.issn.1673-1433.2005.04.009DENG Fuming, CHEN Qiwu. On the problems and its solutions of superhard cutting tool materials in China [J]. Superhard Material Engineering ,2006,17(4):32-35. doi: 10.3969/j.issn.1673-1433.2005.04.009 [7] 马尧. 高温高压制备聚晶立方氮化硼的工艺及性能研究 [D]. 郑州: 郑州大学, 2016.MA Yao. Study on preparation technology and properties of polycrystalline cubic boron nitride at high temperature and high pressure [D]. Zhengzhou: Zhengzhou University, 2016. [8] 纪焕丽. 立方氮化硼复合材料高温高压制备及性能研究 [D]. 天津: 天津大学, 2020.JI Huanli. Preparation and performance of cubic boron nitride composite by high temperature high pressure sintering [D]. Tianjin: Tianjin University, 2020. [9] 孙坤. 聚晶立方氮化硼的制备及机械性能研究 [D]. 天津: 天津大学, 2019.SUN Kun. Mechanical properties and preparation of polycrystalline cubic boron nitride [D]. Tianjin: Tianjin University, 2019. [10] 马金明. 纳米/亚微米cBN粉高温高压制备PcBN刀具的工艺和性能研究 [D]. 郑州: 河南工业大学, 2023.MA Jinming. Study on the technology and properties of PcBN tool prepared by nano/submicron cBN powder at high temperature and high pressure [D]. Zhengzhou: Henan University of Technology, 2023. [11] 谢辉, 冯飞, 方海江, 等. cBN-TiN-AI烧结体黏结剂组分配比研究 [J]. 金刚石与磨料磨具工程,2012,32(1):60-63. doi: 10.3969/j.issn.1006-852X.2012.01.016XIE Hui, FENG Fei, FANG Haijiang, et al. Research on distribution ratio of binder compositions of cBN-TiN-Al sintered compact [J]. Diamond & Abrasives Engineering,2012,32(1):60-63. doi: 10.3969/j.issn.1006-852X.2012.01.016 [12] 陈超, 莫培程, 林峰, 等. cBN-TiN-Al合成PcBN复合片及其性能研究 [J]. 中国陶瓷,2019,55(7):36-41. doi: 10.16521/j.cnki.issn.1001-9642.2019.07.006CHEN Chao, MO Peicheng, LIN Feng, et al. Synthesis of PcBN composite by cBN-TiN-Al and performance research [J]. China Ceramics ,2019,55(7):36-41. doi: 10.16521/j.cnki.issn.1001-9642.2019.07.006 [13] 孙毓超, 刘一波, 王秦生. 金刚石工具与金属学基础 [M]. 北京: 中国建筑工业出版社, 1999.SUN Yuchao, LIU Yibo, WANG Qinsheng. Fundamentals of diamond tools and metallurgy [M]. Beijing: China Building Industry Press, 1999. [14] 罗涛, 江文清, 徐敏. TiN-Al体系结合剂配比对聚晶立方氮化硼复合材料性能的影响 [J]. 机械工程材料,2021,45(11):34-37. doi: 10.11973/jxgccl202111007LUO Tao, JIANG Wenqing, XU Min . Effect of TiN-Al system binder ratio on properties of polycrystalline cubic boron nitride composite [J]. Materials for Mechanical Engineering ,2021,45(11):34-37. doi: 10.11973/jxgccl202111007 [15] SLIPCHENKO K, BUSHLYA V, STRATIICHUK D, et al. Multicomponent binders for PcBN performance enhancement in cutting tool applications [J]. Journal of the European Ceramic Society,2022,42(11):4513-4527. doi: 10.1016/j.jeurceramsoc.2022.04.022 [16] KITIWAN M, ITO A, ZHANG J F, et al. Densification and mechanical properties of cBN–TiN–TiB2 composites prepared by spark plasma sintering of SiO2-coated cBN powder [J]. Journal of the European Ceramic Society,2014,34(15):3619-3626. doi: 10.1016/j.jeurceramsoc.2014.05.018 [17] 徐文会. 聚晶立方氮化硼(PcBN)复合材料的高温高压合成和研究 [D]. 长春: 吉林大学, 2010.XU Wenhui. Synthesis and studys on polycrystalline cubic boron nitride (PcBN) composite under HPHT [D]. Changchun: Jilin University, 2010. [18] ZHANG L L, LIN F, LV Z, et al. cBN-Al-HfC composites: Sintering behaviors and mechanical properties under high pressure [J]. International Journal of Refractory Metals and Hard Materials,2015,50(1):221-226. doi: 10.1016/j.ijrmhm.2015.01.015 [19] 王文龙. 不同黏结剂对聚晶立方氮化硼性能的影响研究 [J]. 超硬材料工程,2016,28(2):10-14. doi: 10.3969/j.issn.1673-1433.2016.02.003WANG Wenlong. Research of the influence of different binders on the performance of polycrystalline cubic boron nitride [J]. Superhard Material Engineering,2016,28(2):10-14. doi: 10.3969/j.issn.1673-1433.2016.02.003 [20] 姜紫凌. 聚晶立方氮化硼复合材料的高温高压合成及性能研究 [D]. 天津: 天津大学, 2021.JIANG Ziling. Research on preparation and properties of polycrystalline cubic boron nitride composites by high temperature and high pressure [D]. Tianjin: Tianjin University, 2021. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS