Optimization of magnetic compound fluid polishing process parameters for PMMA workpieces based on grey relational analysis

-

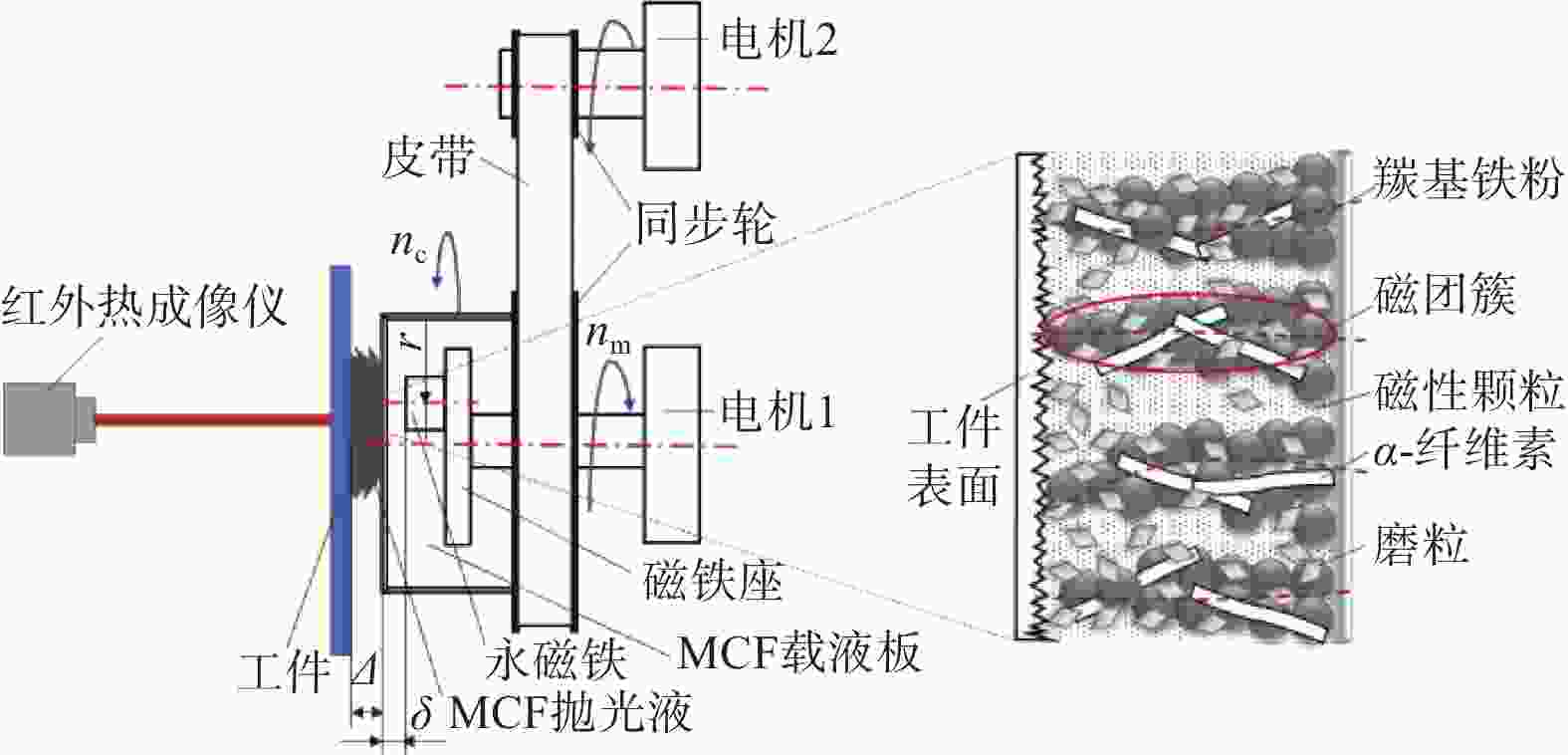

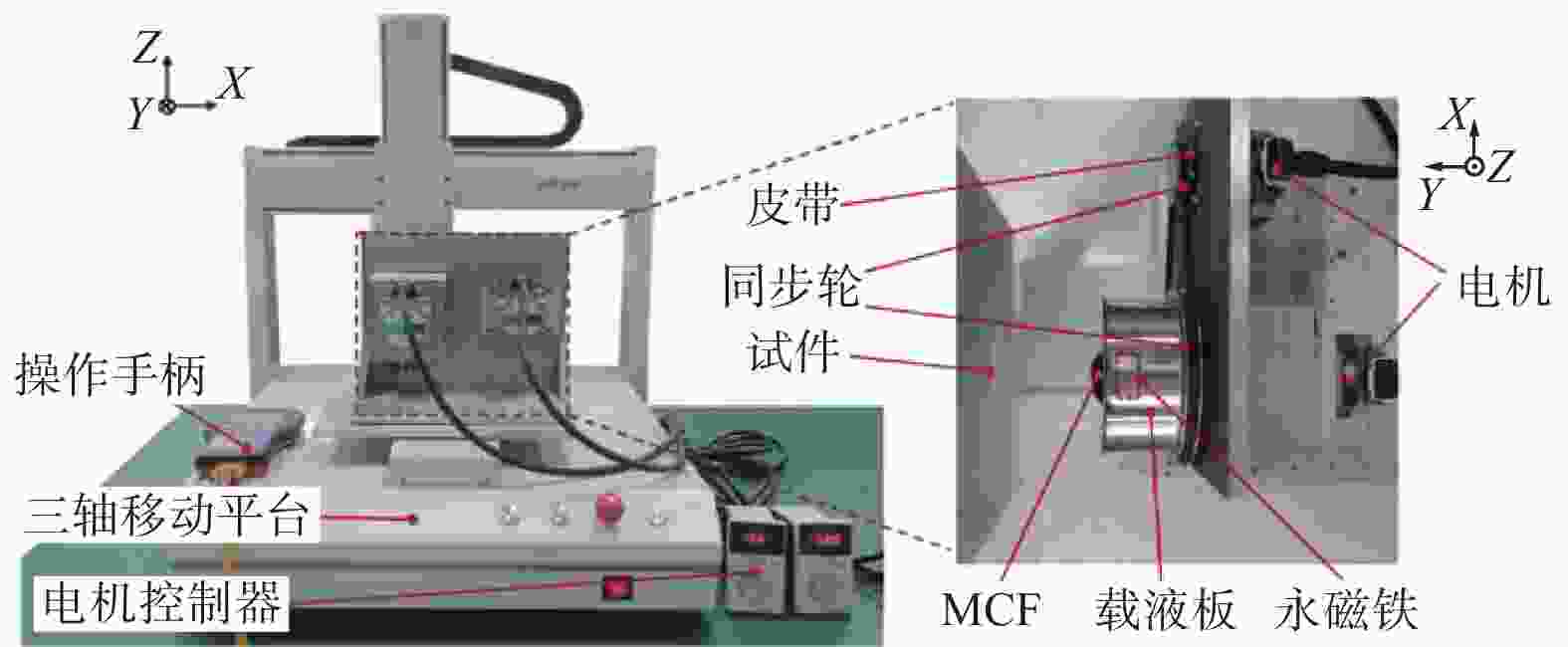

摘要: 针对磁性复合流体抛光PMMA工件取得最佳表面质量和最大加工效率时工艺参数不同的问题,基于灰色关联分析的工艺参数优化方法,设计3因素4水平正交试验,分析磁感应强度、羰基铁粉粒径、磨粒粒径对磁性复合流体抛光性能的影响。结果表明:优化后得到的磁性复合流体抛光PMMA工件的最佳方案为:磁感应强度,0.50 T;羰基铁粉粒径,7 μm;磨粒粒径,3 μm;使用优化后的工艺参数抛光, 工件的表面粗糙度为14 nm,材料去除率为2.088×108 μm3/min,提高了3.5%;通过灰色关联分析优化后获得的工艺参数,既能满足工件高表面质量的抛光要求,又能显著提高磁性复合流体抛光的材料去除率。Abstract:

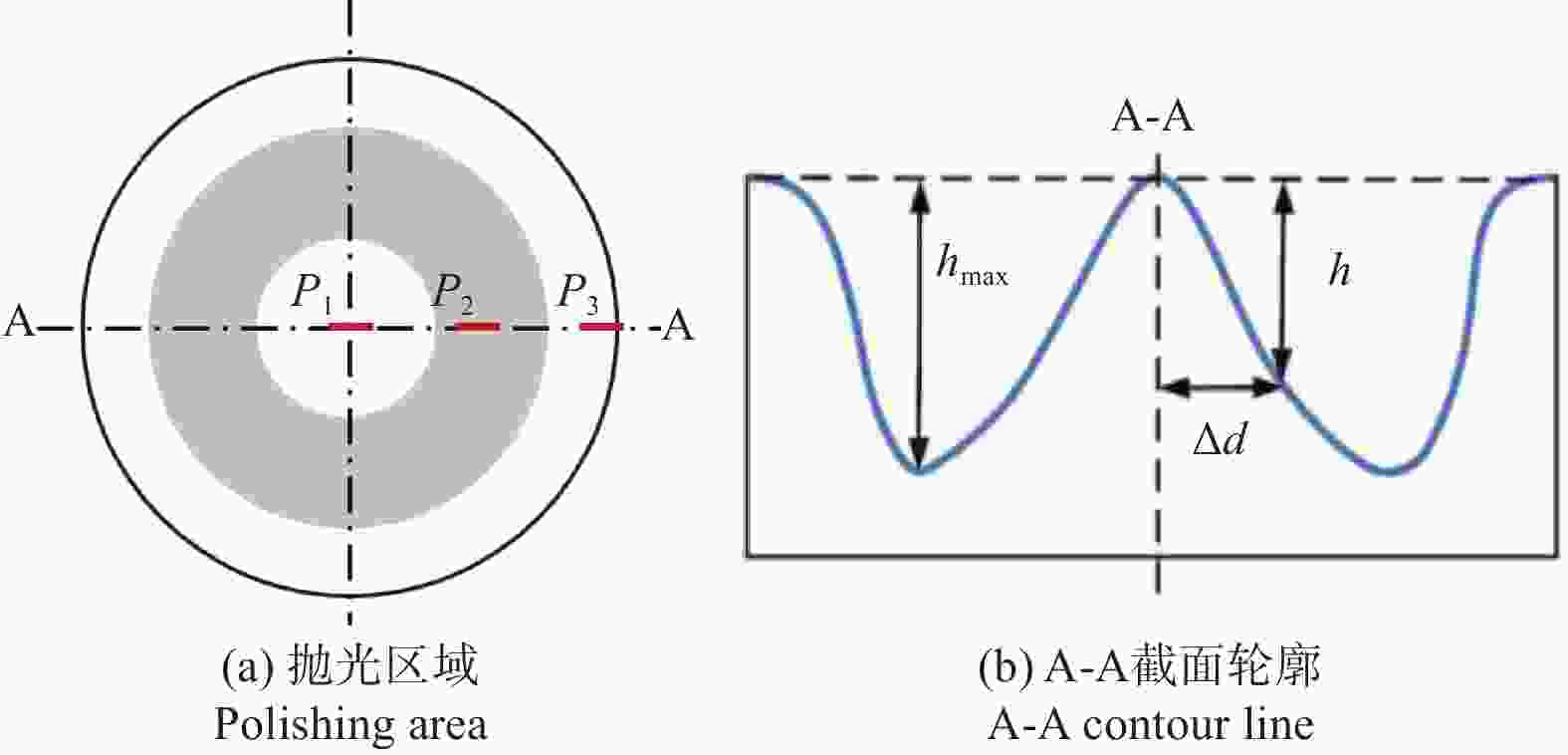

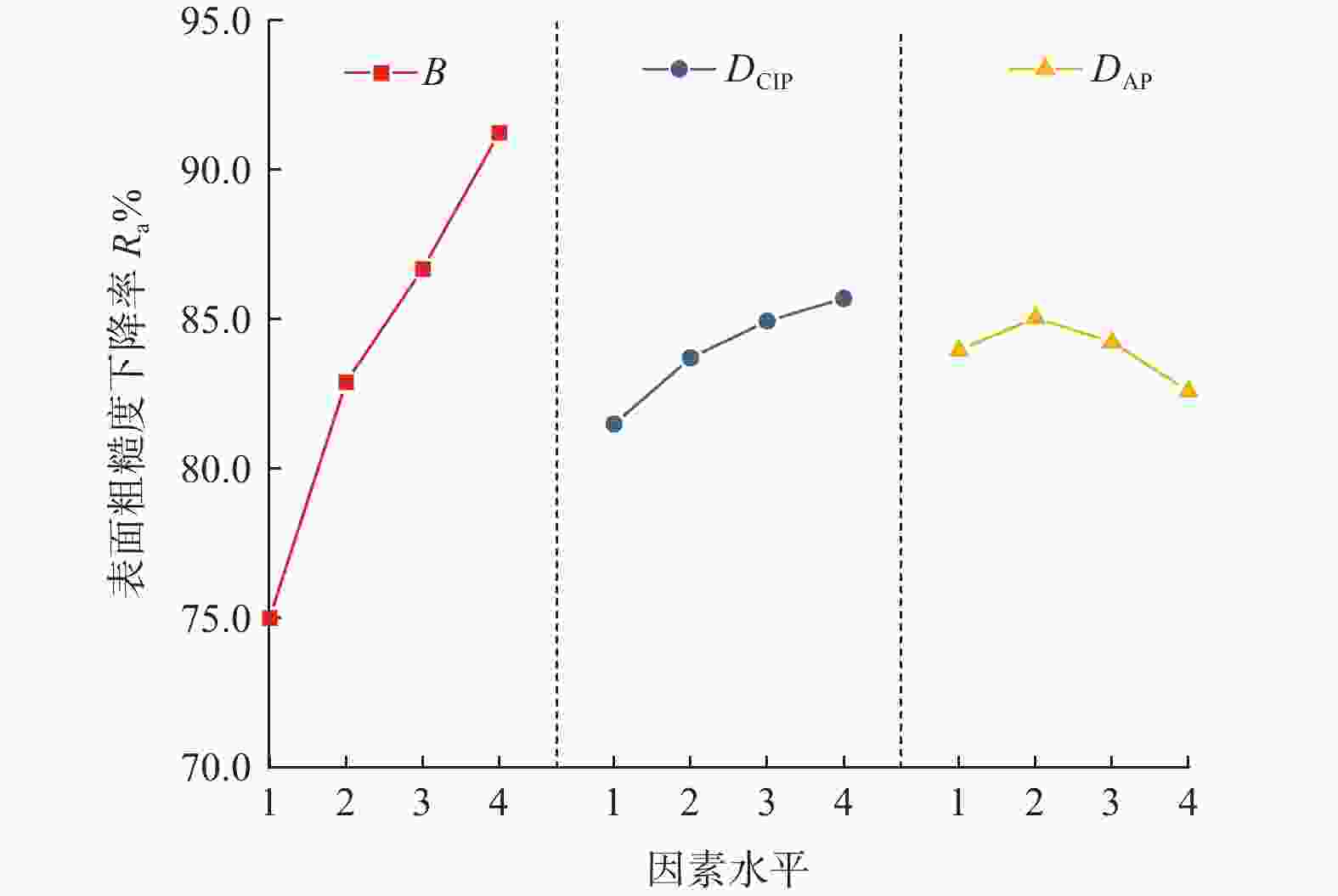

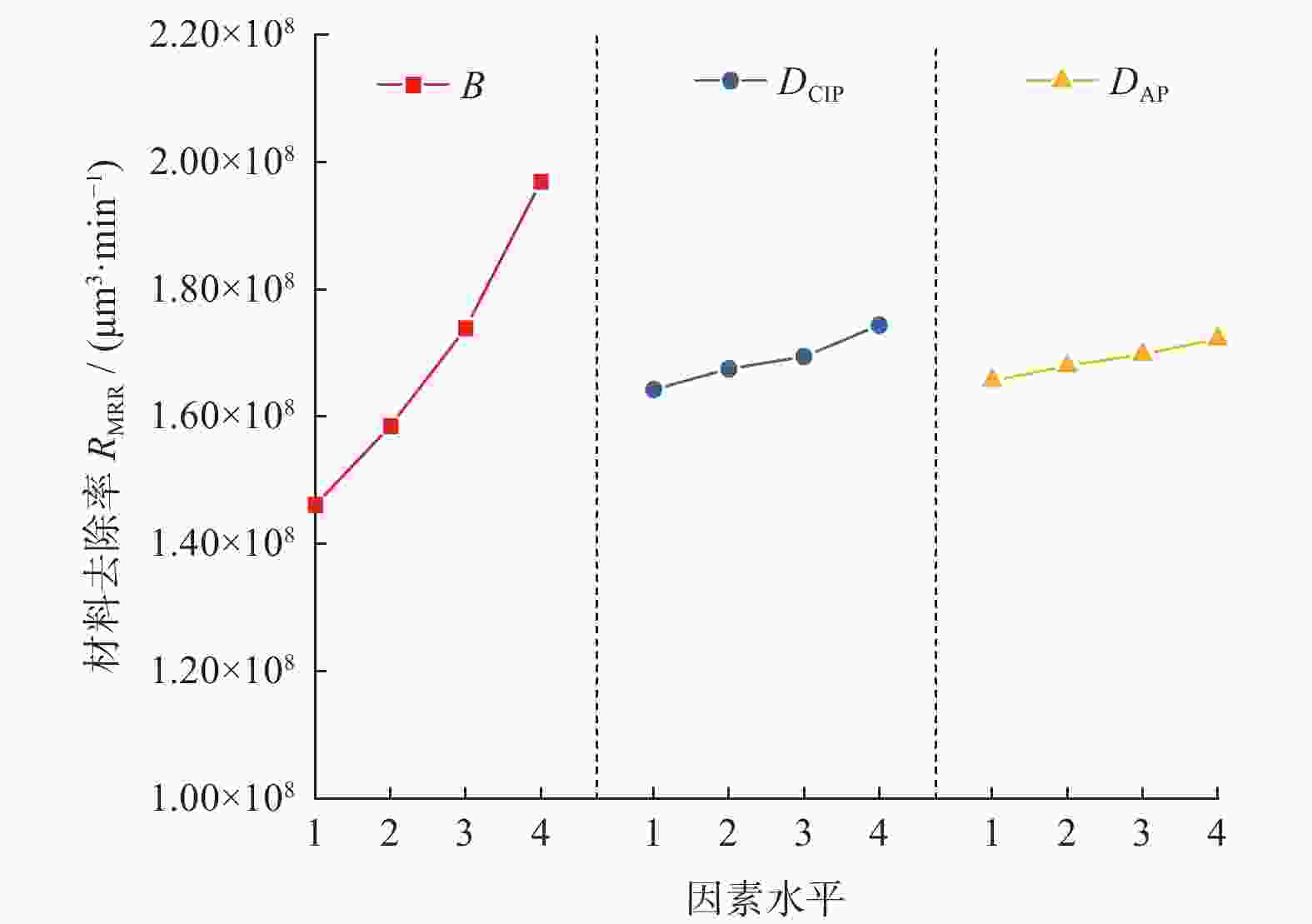

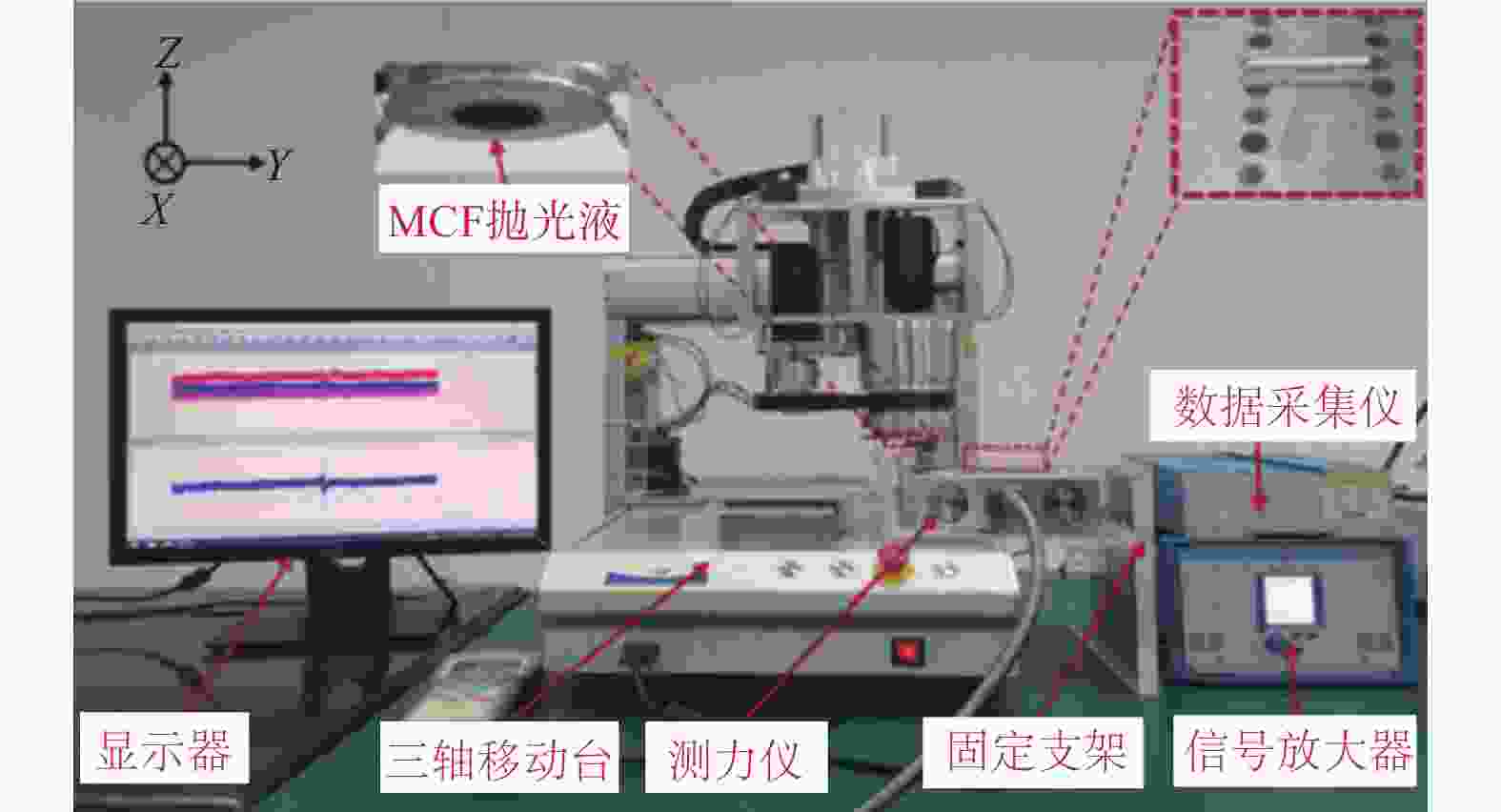

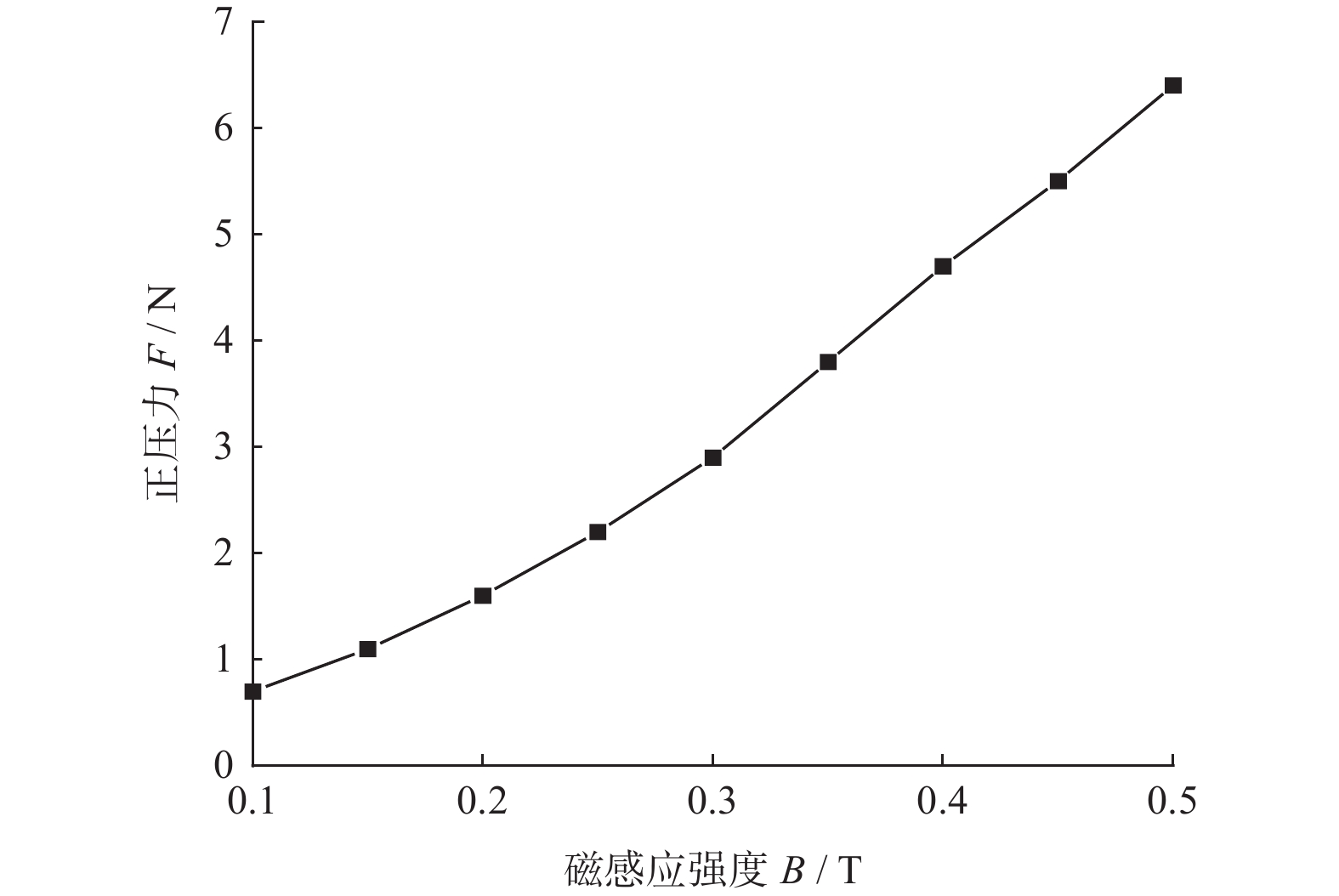

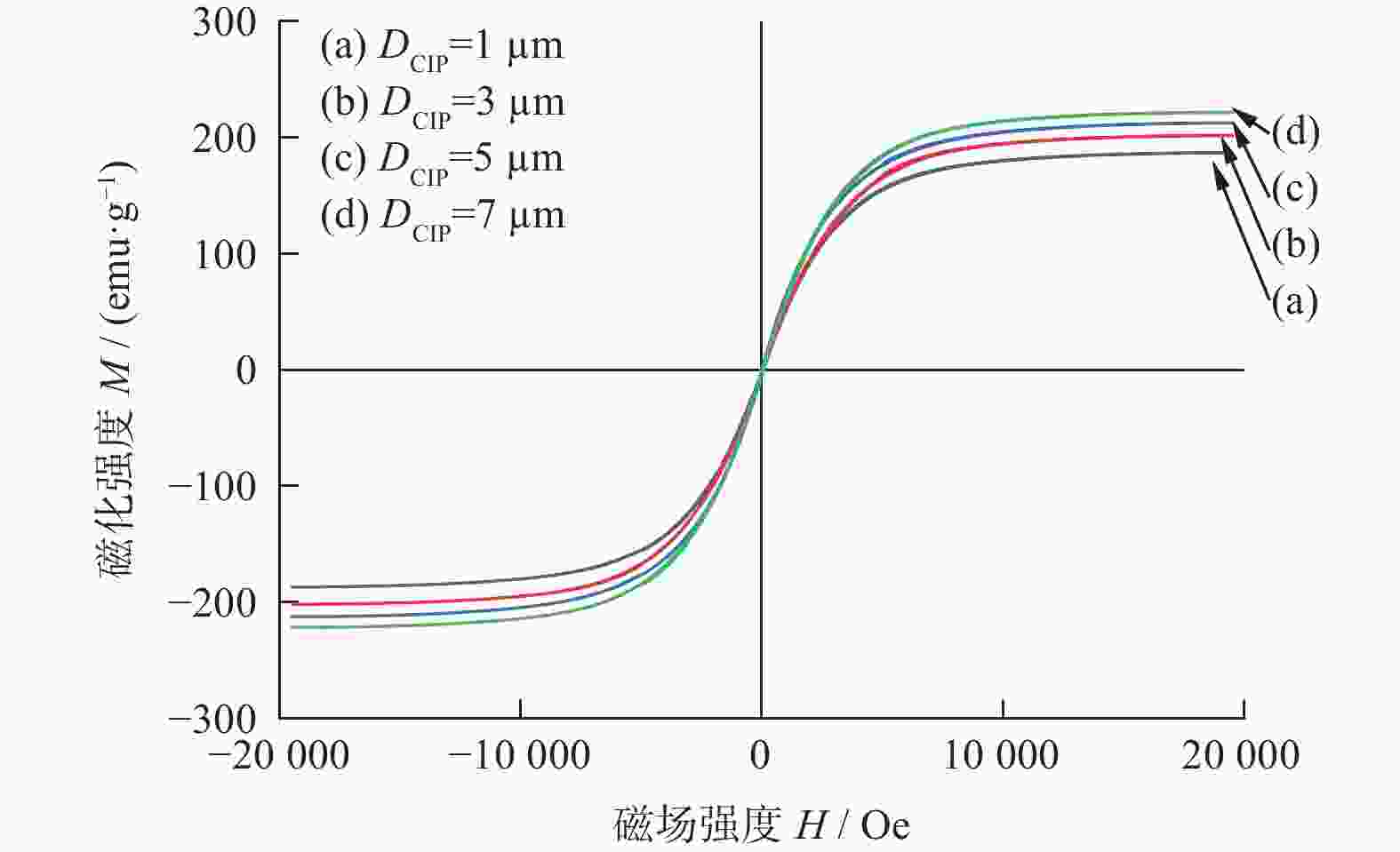

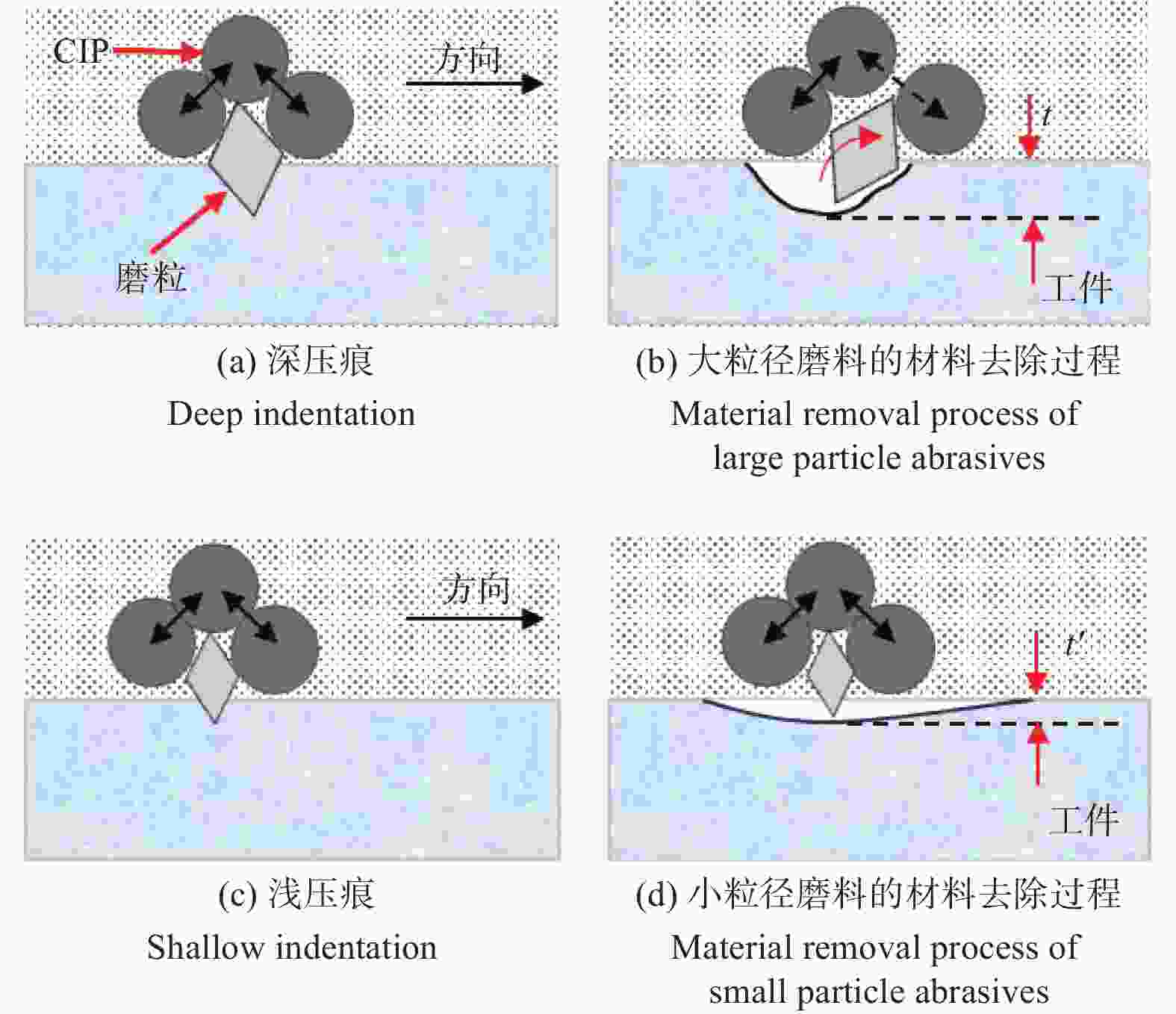

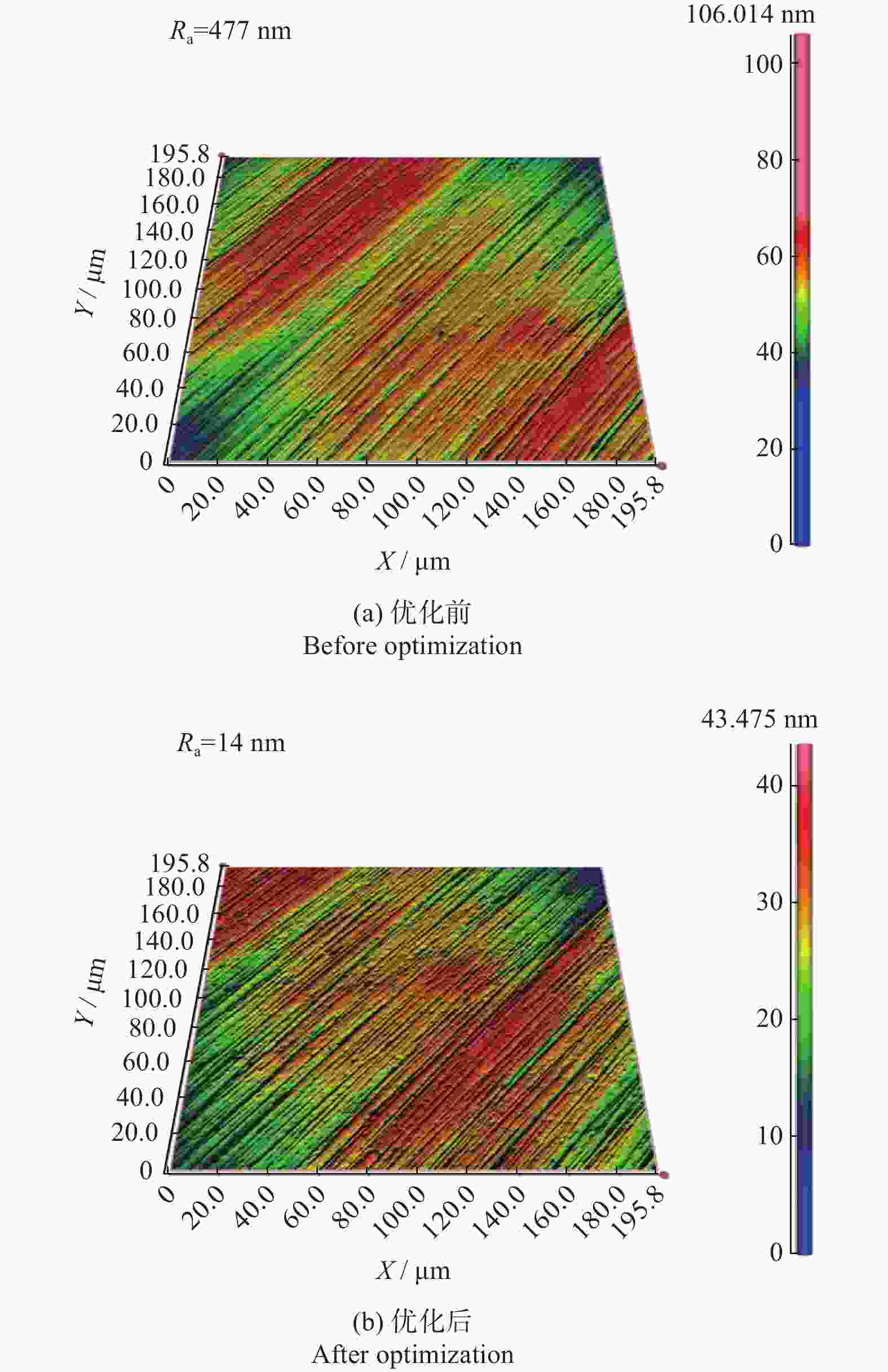

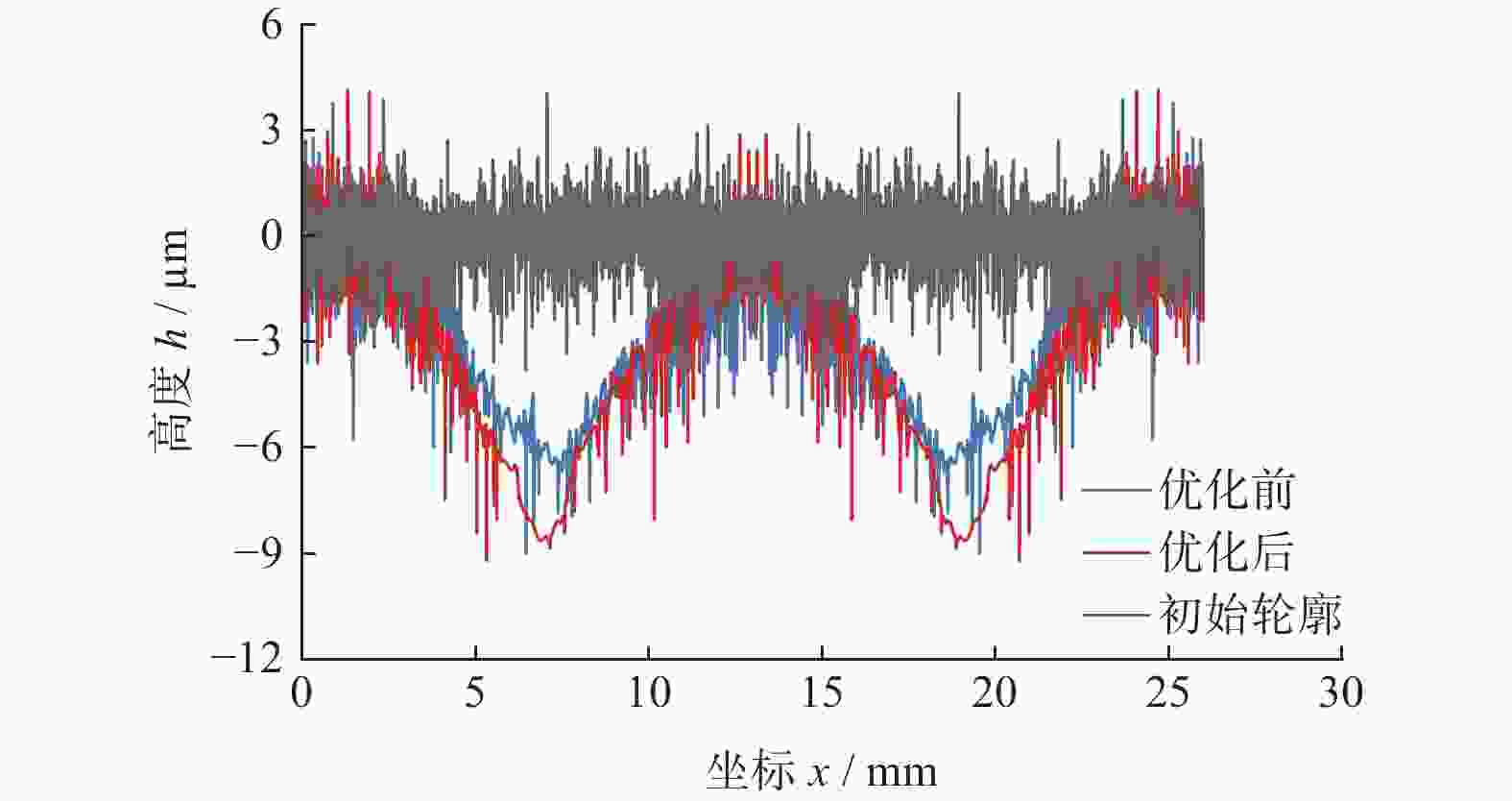

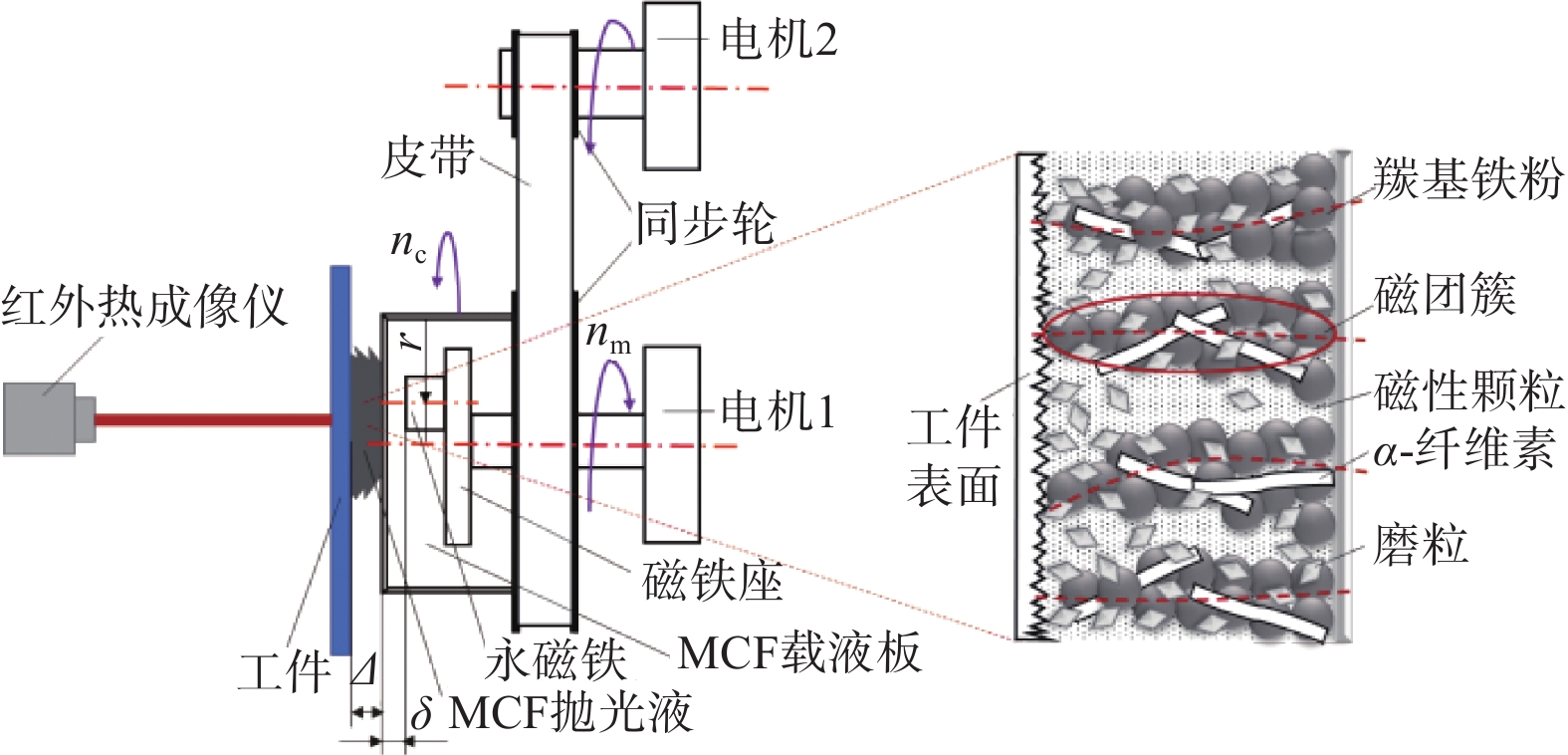

Objectives MCF polishing technology has become an advanced ultra-precision machining method. To address the issue of different process parameters in achieving optimal surface quality or maximum processing efficiency in MCF polishing technology, it is necessary to accurately control the range of each process parameter and deeply understand the impact of different process parameters on MCF polishing performance. Methods The process parameters of the MCF polishing tool are optimized based on grey relation analysis (GRA) to meet the requirements of minimum surface roughness while improving material removal efficiency. Under the given experimental conditions, it is verified that the optimized MCF polishing tool has excellent polishing performance, and the mechanism of the influences of various process parameters on the polishing performance of the MCF polishing tool is analyzed in detail. Firstly, a three-factor four-level PMMA workpiece polishing experiment is designed using the orthogonal test method, and the influence mechanism of each factor on MCF polishing performance is analyzed. Afterwards, the GRA method is used to optimize multi-objective factors, and the optimization scheme of process parameters with the best polishing effect is determined. Finally, the optimized process parameters are used to verify the polishing of the workpiece, and the surface morphology and the contour of the workpiece are obtained. Results When the magnetic induction intensity B = 0.5 T, the diameter of carbonyl iron powder DCIP = 7 μm, and the diameter of abrasive particle DAP = 3 μm, the surface finishing ability of the MCF polishing tool is the best. When the magnetic induction intensity B = 0.5 T, the diameter of carbonyl iron powder Dcip = 7 μm, and the diameter of abrasive particle DAP = 7 μm, the material removal efficiency of the MCF polishing tool is the highest. The magnetic induction intensity has the greatest impact on the polishing quality and the material removal efficiency of the MCF polishing tool, followed by the diameter of carbonyl iron powder, while the effect of the diameter of the abrasive particle is relatively small. During the polishing process, abrasive particle with a smaller diameter make the surface of the workpiece smoother, but the processing efficiency is lower. The polishing effect of abrasive particles with a larger diameter is uneven, but the processing efficiency is higher. The grey correlation degree of each orthogonal experimental group is calculated based on GRA, and the multi-objective factors were optimized to obtain the optimal combination of process parameters, comprehensively considering the workpiece surface quality and processing efficiency, that is, when the magnetic induction intensity B = 0.5 T, the diameter of carbonyl iron powder DCIP = 7 μm, and the diameter of abrasive particle DAP = 3 μm, the MCF polishing tools achieve the best comprehensive polishing performance. Under the given conditions, the PMMA workpiece is polished by using the optimal process parameter, reducing the surface roughness of the workpiece from 477 nm to 14 nm, with a surface roughness reduction rate of 97.06%, which is 3.49 percentage points higher than that before optimization. The material removal rate reaches 2.088×108 μm3/min, which is 3.5% higher than that without optimization. Conclusions The process parameter combination obtained through GRA optimization not only meets the requirements for high surface quality of the workpiece, but also significantly improves the material removal rate of the MCF polishing tool. After GRA optimization, the polishing ability of the MCF polishing tool is significantly enhanced. -

表 1 MCF抛光液组成

Table 1. Compositions of MCF slurry

成分 参数 取值 水基磁流体(MF) 平均粒径 d / nm 10 质量分数 ω1 / % 45 羰基铁粉(CIP) 粒径 DCIP / μm 1,3,5,7 质量分数 ω2 / % 40 磨料(α-Al2O3) 粒径 DAP / μm 1,3,5,7 质量分数 ω3 / % 12 α-纤维素 质量分数 ω4 / % 3 表 2 试验参数

Table 2. Experimental parameters

参数 类型或取值 工件尺寸(长×宽×高) 70 mm × 70 mm × 1 mm 永磁铁材料 钕铁硼N52 永磁铁尺寸 ϕ20 mm ×10 mm 磁场强度 B / T 0.50 永磁铁偏心距 r / mm 4 永磁铁转速 nm / (r·min−1) 600 MCF载液板转速 nc / (r·min−1) 500 MCF供应量 V / mL 1 加工间隙 Δ / mm 1 抛光时间 t1 / min 10 表 3 正交试验因素及水平表

Table 3. Orthogonal experimental factors and levels table

水平 因素 永磁铁磁感应强度

B / T羰基铁粉粒径

DCIP / μm磨粒粒径

DAP / μm1 0.20 1 1 2 0.30 3 3 3 0.40 5 5 4 0.50 7 7 表 4 正交试验方案及结果

Table 4. Orthogonal experimental plan and results

序号 加工参数 Ra% RMRR / (μm3·min−1) B / T DCIP / μm DAP / μm 1 0.20 1 1 72.43 1.383×108 2 0.20 3 3 74.74 1.456×108 3 0.20 5 5 76.99 1.477×108 4 0.20 7 7 75.86 1.530×108 5 0.30 1 3 81.92 1.533×108 6 0.30 3 1 83.44 1.518×108 7 0.30 5 7 82.53 1.639×108 8 0.30 7 5 83.68 1.651×108 9 0.40 1 5 84.91 1.705×108 10 0.40 3 7 85.27 1.768×108 11 0.40 5 1 86.65 1.708×108 12 0.40 7 3 89.92 1.776×108 13 0.50 1 7 86.71 1.949×108 14 0.50 3 5 91.36 1.958×108 15 0.50 5 3 93.57 1.953×108 16 0.50 7 1 93.33 2.017×108 表 5 Ra%的正交试验结果极差分析表

Table 5. Range analysis table of Ra% orthogonal experimental results

ki 加工参数 B DCIP DAP k1 75.005 00 81.492 50 83.962 50 k2 82.892 50 83.702 50 85.037 50 k3 86.687 50 84.935 00 84.235 00 k4 91.242 50 85.697 50 82.592 50 极差 R 16.237 50 4.205 00 2.445 00 表 6 RMRR正交试验结果的极差分析表

Table 6. Range analysis table of RMRR orthogonal experimental results

ki 加工参数 B DCIP DAP k1 1.461 50×108 1.642 50×108 1.656 50×108 k2 1.585 25×108 1.675 00×108 1.679 50×108 k3 1.739 25×108 1.694 25×108 1.697 75×108 k4 1.969 25×108 1.743 50×108 1.721 50×108 极差 R 0.507 75×108 0.101 00×108 0.065 00×108 表 7 灰色关联系数及灰色关联度

Table 7. Grey relational coefficient and grey relational degree

序号 灰色关联系数 $ \xi $ 灰色关联度 $\gamma $ Ra% RMRR 1 0.333 33 0.333 33 0.333 33 2 0.359 52 0.361 05 0.360 29 3 0.389 32 0.369 89 0.379 61 4 0.373 76 0.394 28 0.384 02 5 0.475 70 0.395 76 0.435 73 6 0.510 63 0.388 48 0.449 55 7 0.489 13 0.456 12 0.472 62 8 0.516 62 0.464 13 0.490 37 9 0.549 66 0.503 97 0.526 82 10 0.560 15 0.560 07 0.560 11 11 0.604 35 0.506 39 0.555 37 12 0.743 32 0.568 10 0.655 71 13 0.606 43 0.823 38 0.714 90 14 0.827 07 0.843 09 0.835 08 15 1.000 00 0.832 02 0.916 01 16 0.977 80 1.000 00 0.988 90 表 8 因素各水平下的平均灰色关联度

Table 8. Average grey relational degree of factors at different levels

因素 水平 1 2 3 4 B 0.364 31 0.462 07 0.574 50 0.863 72 DCIP 0.502 69 0.551 26 0.580 90 0.629 75 DAP 0.581 79 0.591 93 0.557 97 0.532 91 -

[1] 王承遇, 李松基, 陶瑛, 等. 超光滑超精密玻璃抛光新技术 [J]. 玻璃,2009,36(10):33-37. doi: 10.3969/j.issn.1003-1987.2009.10.012WANG Chengyu, LI Songji, TAO Ying, et al. New super-smooth and super-precision polishing technology for glass surface [J]. Glass,2009,36(10):33-37. doi: 10.3969/j.issn.1003-1987.2009.10.012 [2] 张韬, 何建国, 黄文, 等. 机械轴与虚拟轴复合的磁流变抛光 [J]. 光学精密工程,2021,29(2):286-296. doi: 10.37188/OPE.20212902.0286ZHANG Tao, HE Jianguo, HUANG Wen, et al. Magnetorheological finishing method that combines mechanical and virtual axes [J]. Optics and Precision Engineering,2021,29(2):286-296. doi: 10.37188/OPE.20212902.0286 [3] 袁巨龙, 张飞虎, 戴一帆, 等. 超精密加工领域科学技术发展研究 [J]. 机械工程学报,2010,46(15):161-177. doi: 10.3901/JME.2010.15.161YUAN Julong, ZHANG Feihu, DAI Yifan, et al. Development research of science and technologies in ultra-precision machining field [J]. Chinese Journal of Mechanical Engineering,2010,46(15):161-177. doi: 10.3901/JME.2010.15.161 [4] 康桂文. 磁流变抛光技术的研究现状及其发展 [J]. 机床与液压,2008,36(3):173-175, 182. doi: 10.3969/j.issn.1001-3881.2008.03.058KANG Guiwen. Research and development of magnetorheological finishing [J]. Machine Tool & Hydraulics,2008,36(3):173-175, 182. doi: 10.3969/j.issn.1001-3881.2008.03.058 [5] 赵卫, 豆立博, 刘玲. 磁流变抛光技术在SiC晶片加工工艺中的应用研究 [J]. 价值工程,2018,37(11):222-223. doi: 10.14018/j.cnki.cn13-1085/n.2018.11.114ZHAO Wei, DOU Lifu, LIU Ling. Application research on magnetorheological finishing in the SiC wafer processing [J]. Value Engineering,2018,37(11):222-223. doi: 10.14018/j.cnki.cn13-1085/n.2018.11.114 [6] 李改灵. 光学材料磨削加工亚表面损伤测量的理论与实验研究 [D]. 长沙: 国防科学技术大学, 2006.LI Gailing. Theoretical and experimental research on the measurement of grinding subsurface damages for optical materials [D]. Changsha: National University of Defense Technology, 2006. [7] SHIMADA K, AKAGAMI Y, KAMIYAMA S, et al. New microscopic polishing with magnetic compound fluid (MCF) [J]. Journal of Intelligent Material Systems and Structures,2002,13(7/8):405-408. doi: 10.1106/104538902026159 [8] 田可, 郭会茹, 吴勇波, 等. 旋转磁场下非球面工件的磁性混合流体抛光 [J]. 金刚石与磨料磨具工程,2022,42(4):495-503. doi: 10.13394/j.cnki.jgszz.2021.0211TIAN Ke, GUO Huiru, WU Yongbo, et al. Magnetic compound fluid polishing of aspheric workpiece under rotating magnetic field [J]. Diamond & Abrasives Engineering,2022,42(4):495-503. doi: 10.13394/j.cnki.jgszz.2021.0211 [9] 张军锋, 史耀耀, 蔺小军, 等. 基于灰色关联分析的叶片砂带抛光参数优化 [J]. 计算机集成制造系统,2017,23(4):806-814. doi: 10.13196/j.cims.2017.04.015ZHANG Junfeng, SHI Yaoyao, LIN Xiaojun, et al. Parameters optimization in belt polishing process of blade based on grey relational analysis [J]. Computer Integrated Manufacturing Systems,2017,23(4):806-814. doi: 10.13196/j.cims.2017.04.015 [10] BAN X, DUAN T, TIAN Z, et al. Process optimization of 4H-SiC chemical mechanical polishing based on grey relational analysis [J]. Semiconductor Science and Technology,2023,38(7):075014. doi: 10.1088/1361-6641/acd9e5 [11] 周虎, 李中会. 基于灰色系统理论的磁流变抛光工艺参数优化研究 [J]. 制造技术与机床,2010(5):89-93. doi: 10.3969/j.issn.1005-2402.2010.05.030ZHOU Hu, LI Zhonghui. Research on optimizing the processing parameters for magnetorheological finishing based on gray theory [J]. Manufacturing Technology & Machine Tool,2010(5):89-93. doi: 10.3969/j.issn.1005-2402.2010.05.030 [12] 史丽晨, 刘亚雄, 史炜椿, 等. 基于灰色关联分析的GH2132线材高精度切削参数优化 [J]. 表面技术,2022,51(11):373-384. doi: 10.16490/j.cnki.issn.1001-3660.2022.11.035SHI Lichen, LIU Yaxiong, SHI Weichun, et al. Optimization of high-precision cutting parameters of GH2132 wire based on grey relational analysis [J]. Surface Technology,2022,51(11):373-384. doi: 10.16490/j.cnki.issn.1001-3660.2022.11.035 [13] SHIMADA K, WU Y B, Wong Y C. Effect of magnetic cluster and magnetic field on polishing using magnetic compound fluid (MCF) [J]. Journal of Magnetism and Magnetic Materials,2003,262(2):242-247. doi: 10.1016/S0304-8853(02)01497-X [14] FENG M, WU Y B, WANG Y LI, et al. Effect of the components of magnetic compound fluid (MCF) slurry on polishing characteristics in aspheric-surface finishing with the doughnut-shaped MCF tool [J]. Precision Engineering,2020,65:216-229. doi: 10.1016/j.precisioneng.2020.04.021 [15] 姜晨, 刘剑, 魏久祥, 等. h形磁性复合流体抛光工具设计及工艺试验 [J]. 光学精密工程,2022,30(12):1452-1461. doi: 10.37188/OPE.20223012.1452JIANG Chen, LIU Jian, WEI Jiuxiang, et al. Design and process test of h-shaped magnetic composite fluid polishing tool [J]. Optics and Precision Engineering,2022,30(12):1452-1461. doi: 10.37188/OPE.20223012.1452 [16] 王道明, 侯友夫, 田祖织, 等. 颗粒尺寸及温度对羰基铁粉磁化性能的影响 [J]. 功能材料,2014,45(19):19006-19009. doi: 10.3969/j.issn.1001-9731.2014.19.002WANG Daoming, HOU Youfu, TIAN Zuzhi, et al. Effect of particle size and temperature on magnetization properties of carbonyl iron powder [J]. Journal of Functional Materials,2014,45(19):19006-19009. doi: 10.3969/j.issn.1001-9731.2014.19.002 [17] SIDPARA A, JAIN V K. Nano–level finishing of single crystal silicon blank using magnetorheological finishing process [J]. Tribology International,2012,47:159-166. doi: 10.1016/j.triboint.2011.10.008 [18] 朱斓瑛, 赵越, 戴玉, 等. 灰色关联度分析模型的特征与应用 [J]. 科学咨询(科技·管理),2019(8):79.ZHU Lanying, ZHAO Yue, DAI Yu, et al. Characteristics and applications of grey relational degree analysis model [J]. Technology & Management,2019(8):79. [19] 邓家云. 单晶SiC电芬顿化学机械抛光机理研究 [D]. 广州: 广东工业大学, 2022.DENG Jiayun. Mechanism of electro-fenton chemical mechanica polishing for single crystal SiC [D]. Guangzhou: Guangdong University of Technology, 2022. [20] DENG J L. Introduction to grey system theory [J]. The Journal of Grey System,1989,1(1):1-24. doi: 10.1007/978-3-642-16158-2_1 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS