Experimental investigation on heat transfer performance diamond nanofluid gravity heat pipe

-

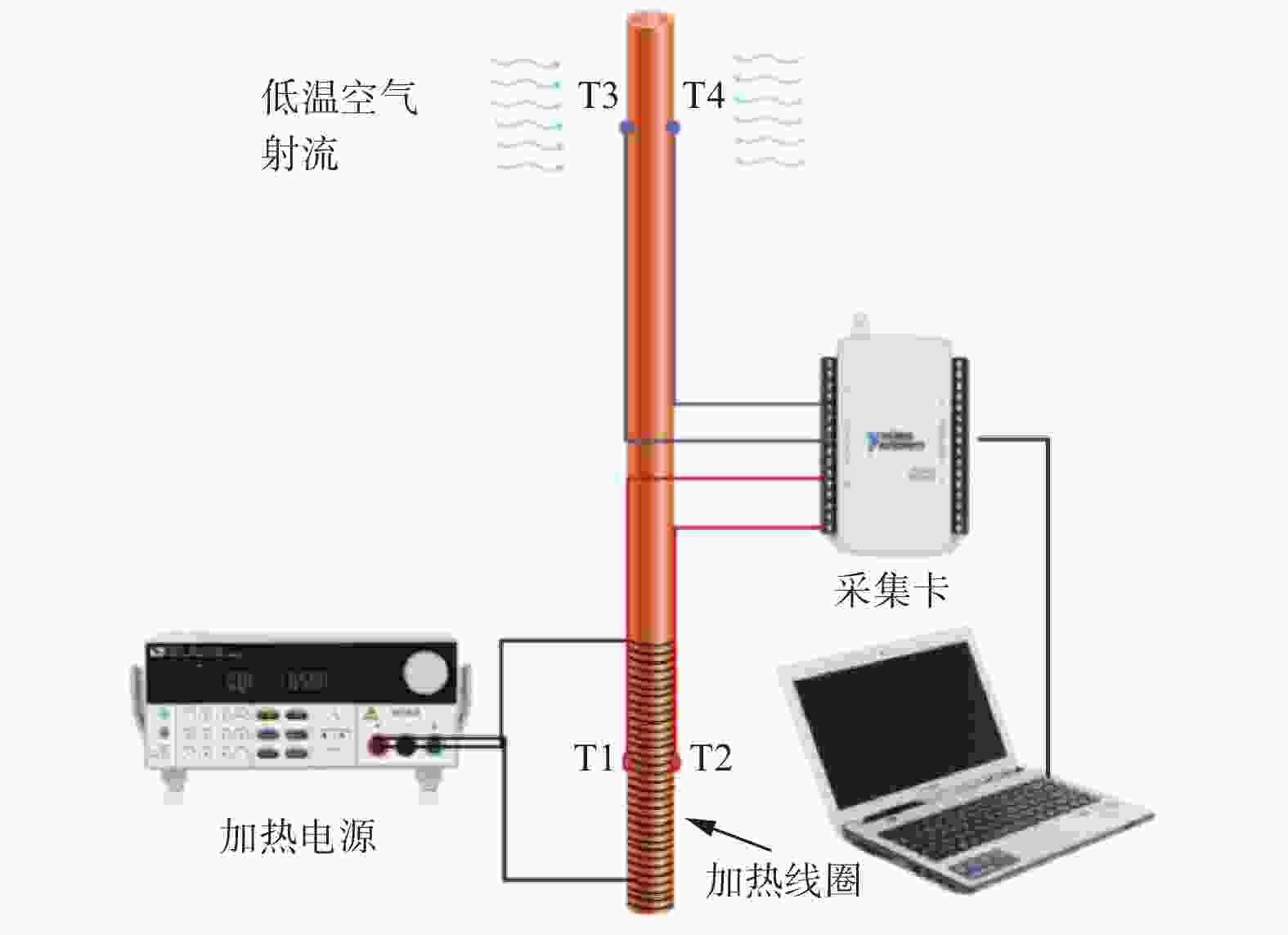

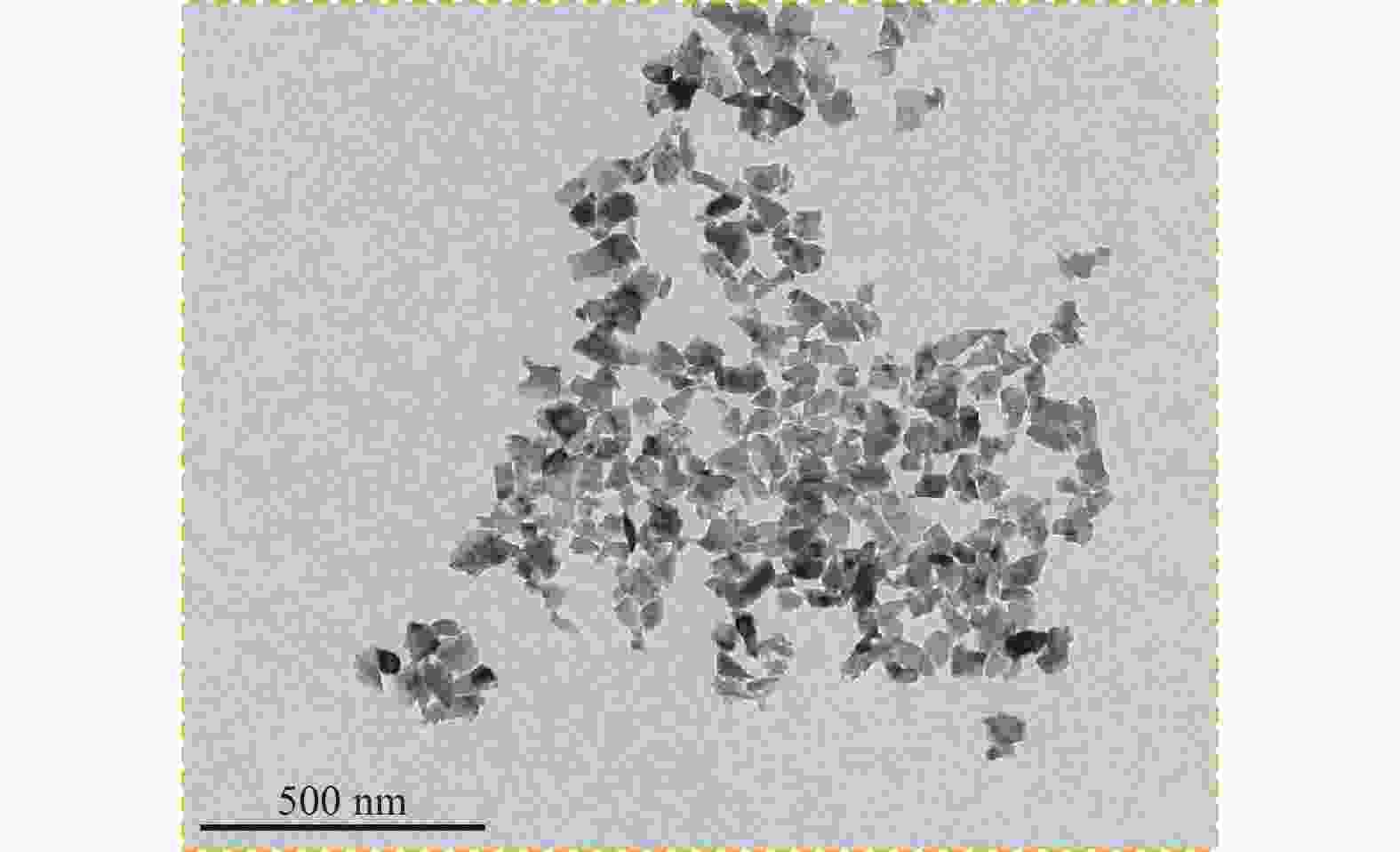

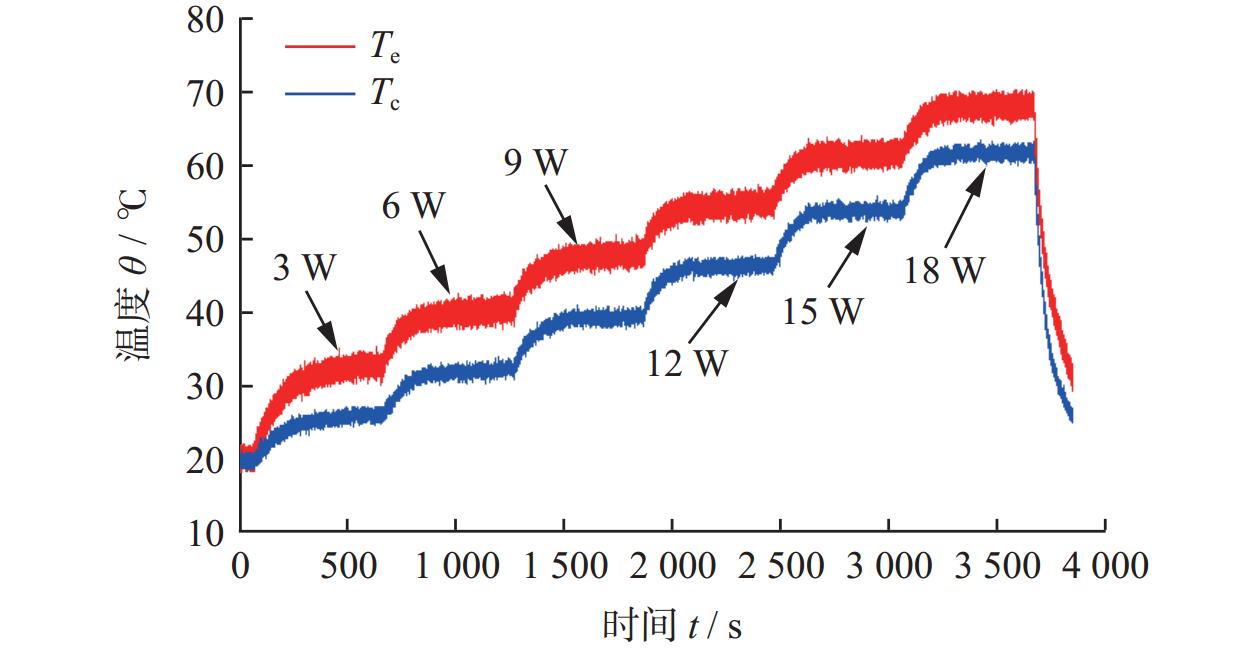

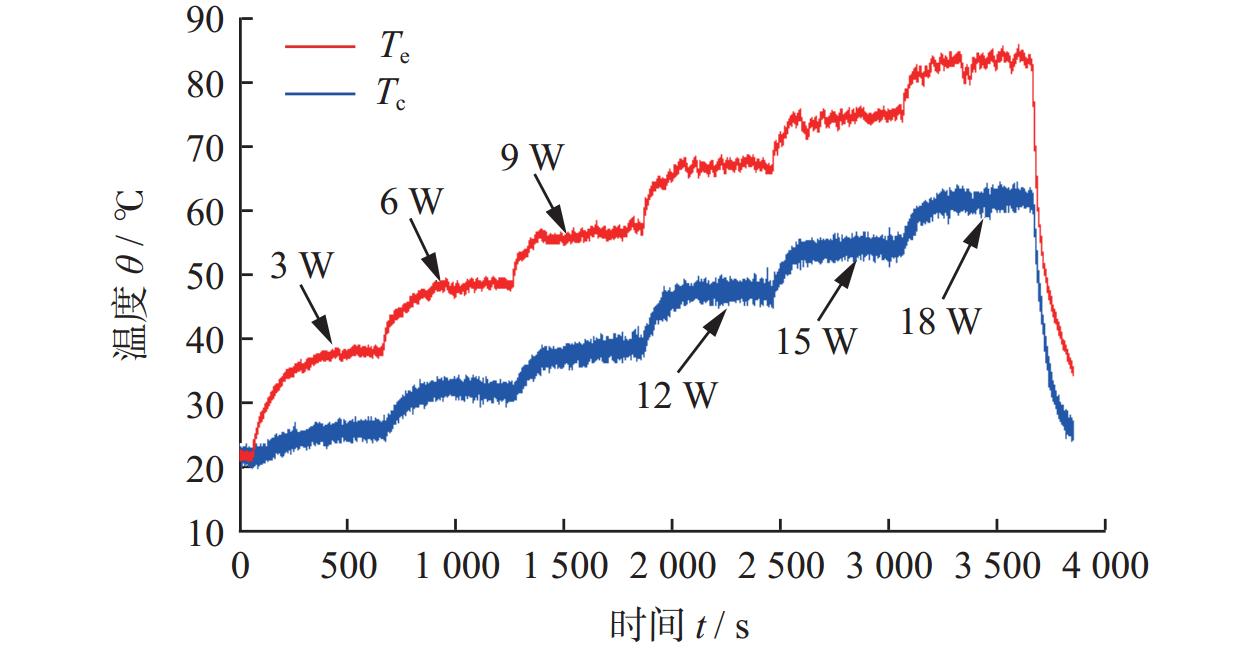

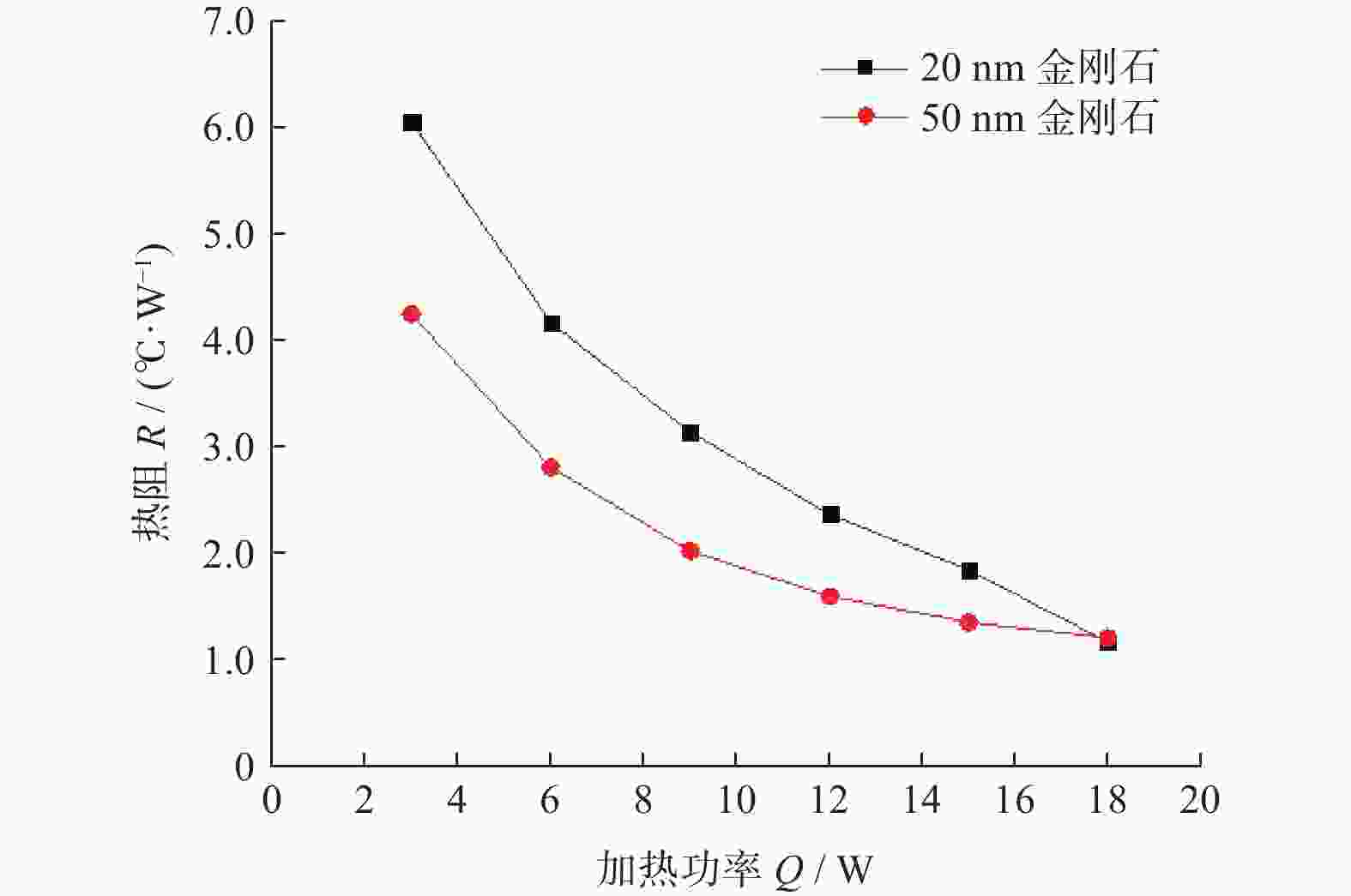

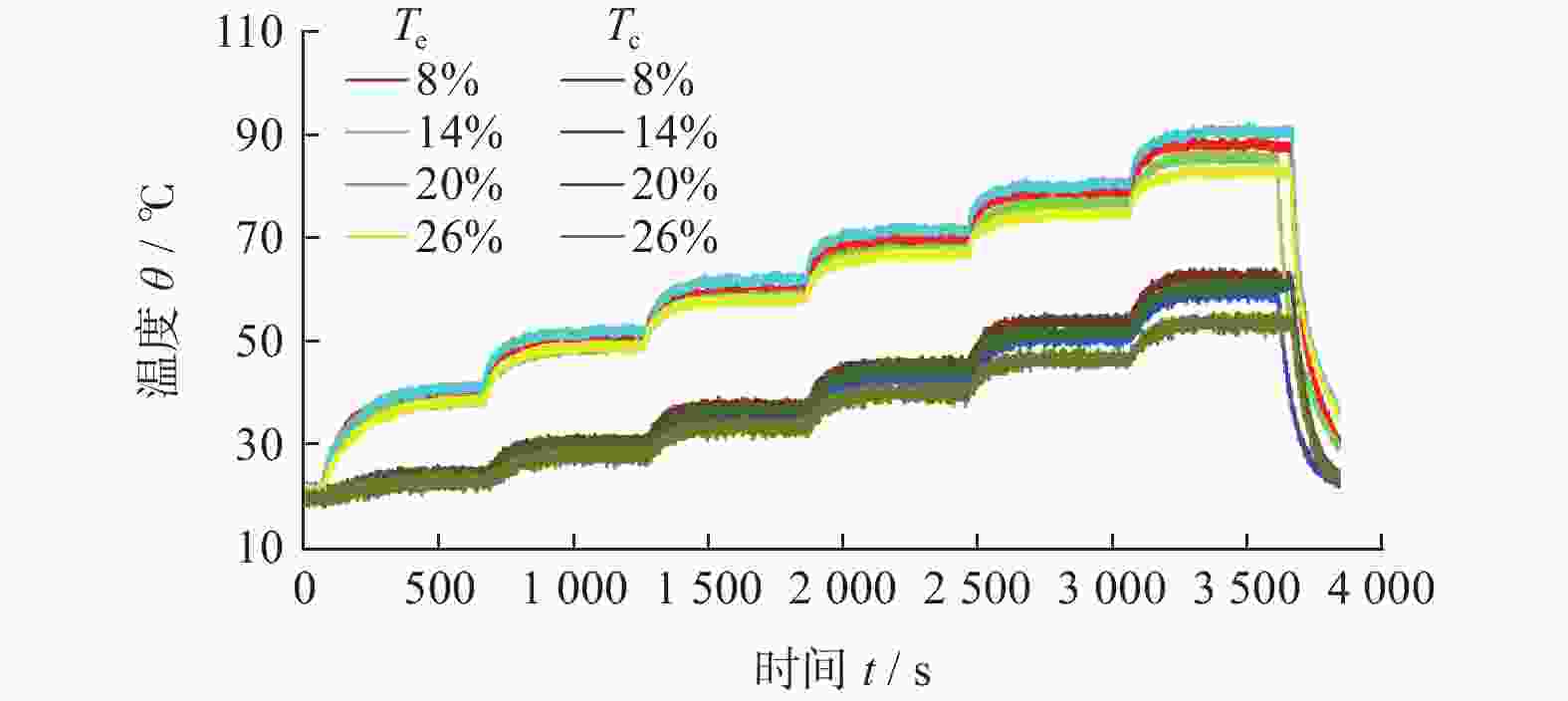

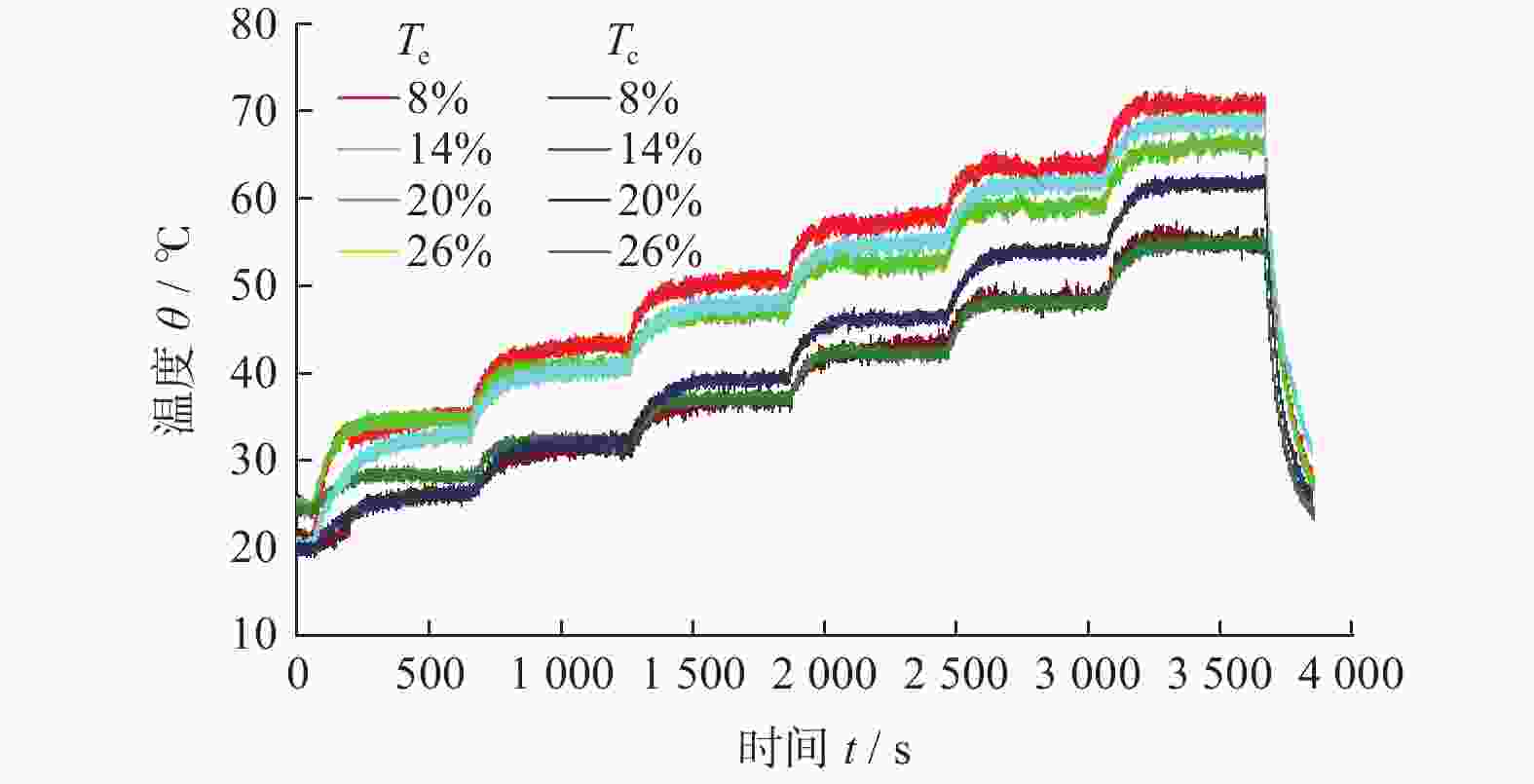

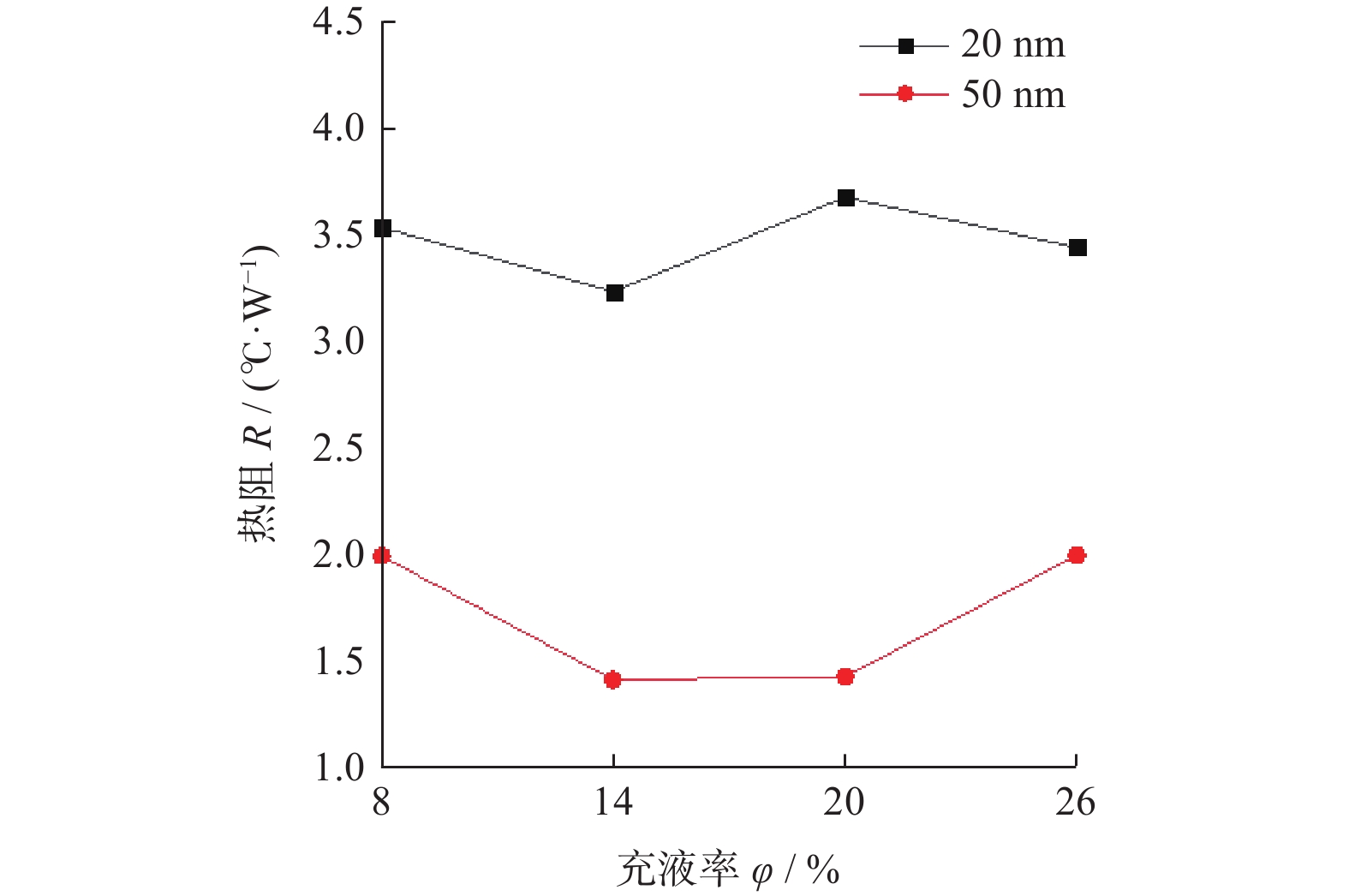

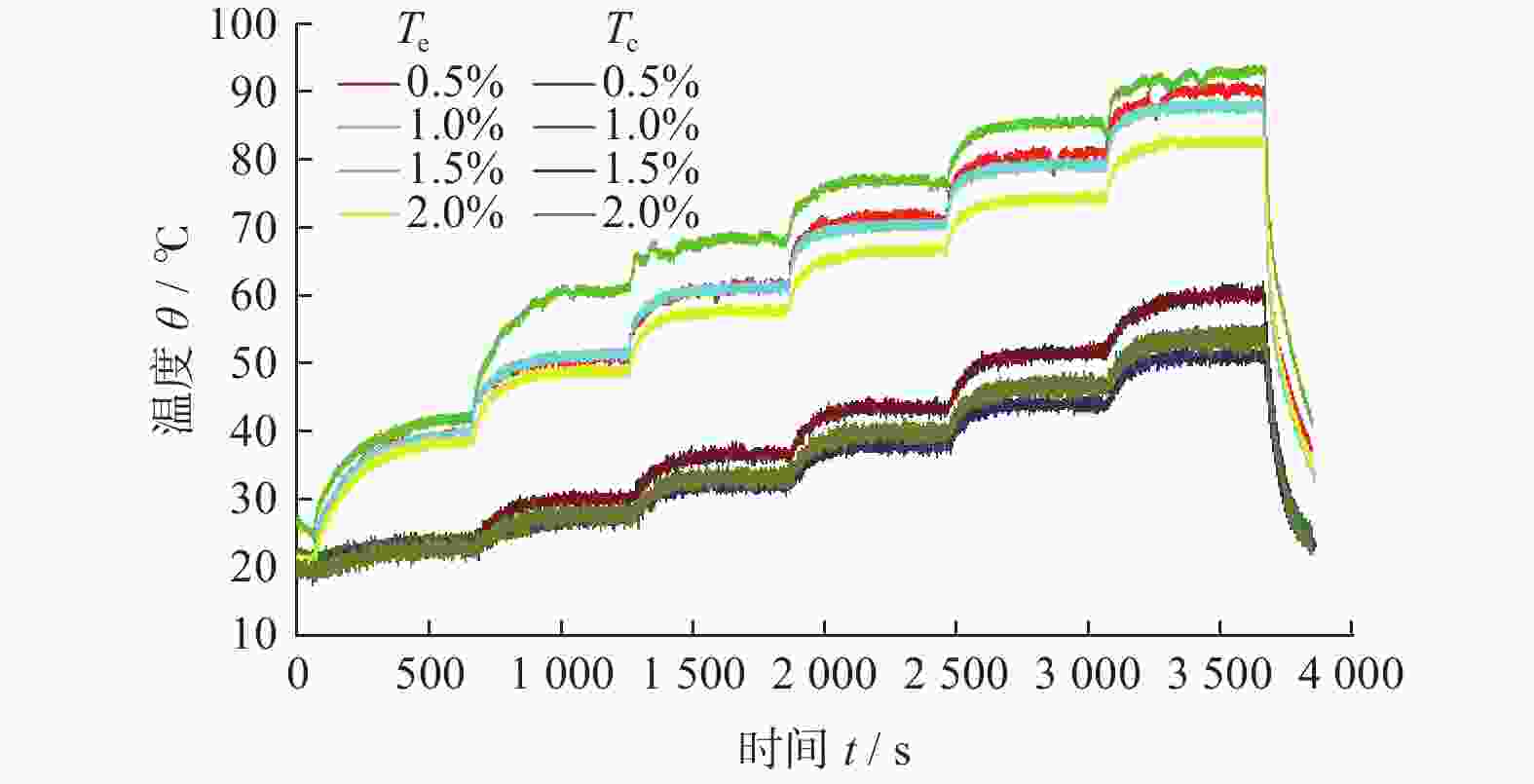

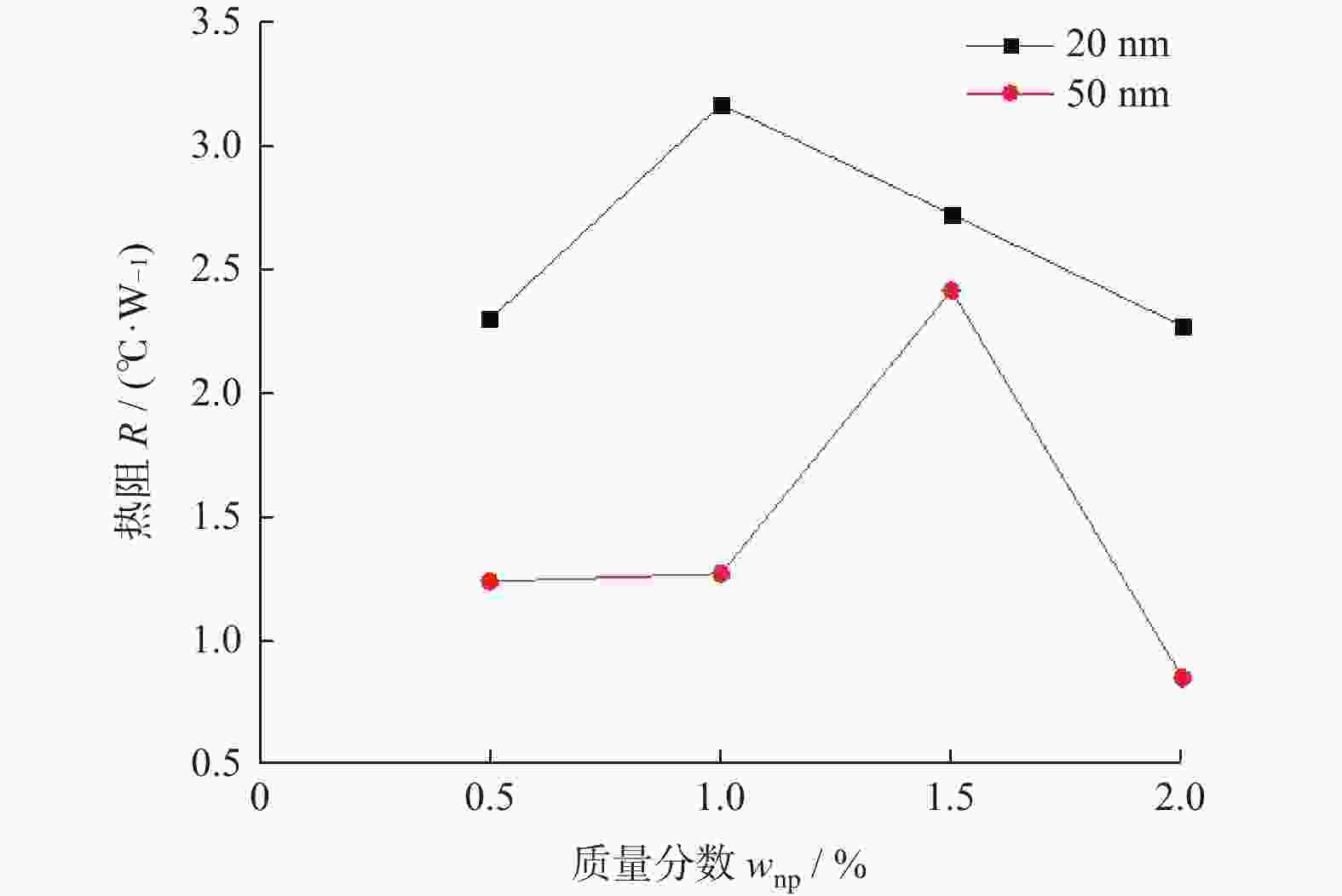

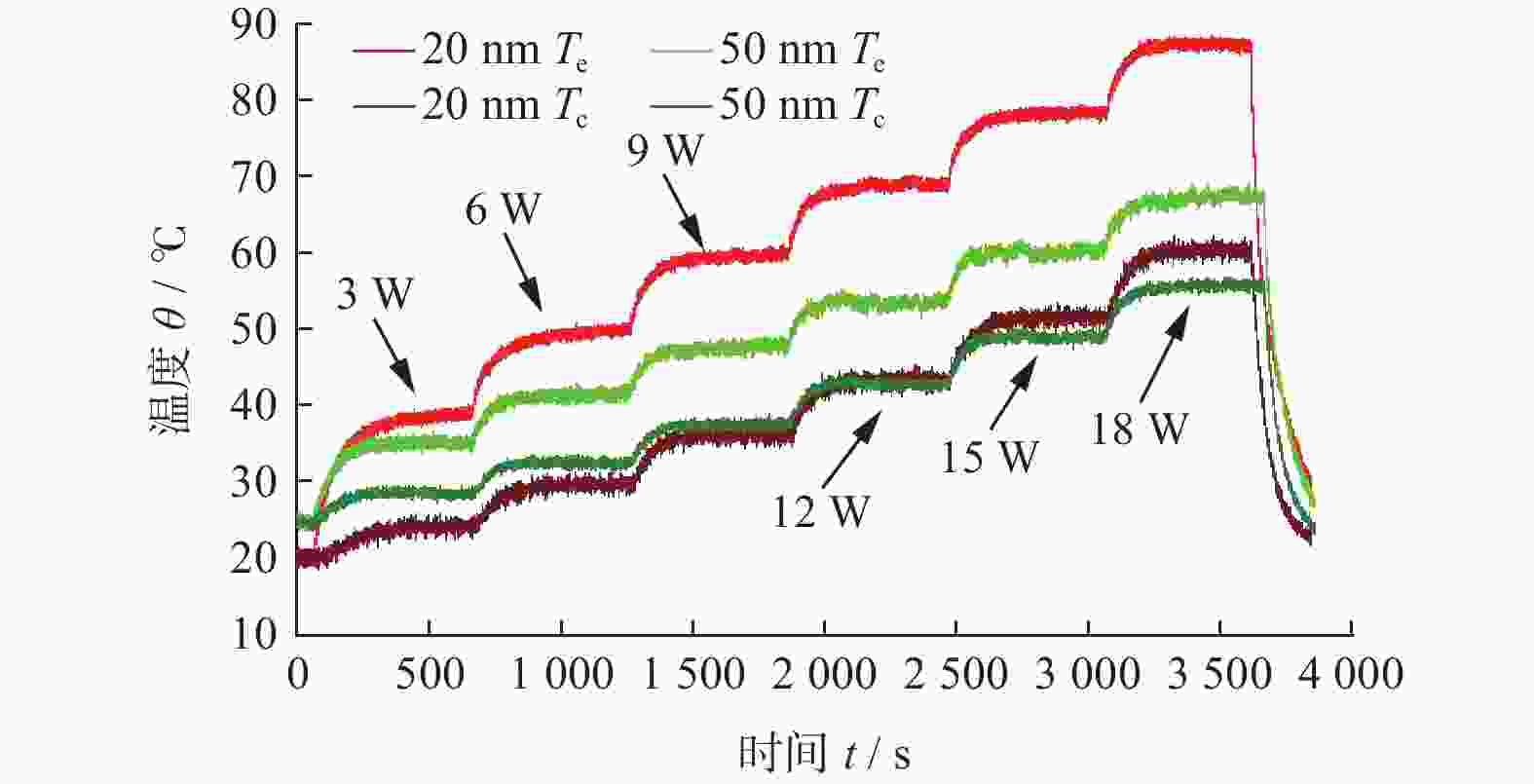

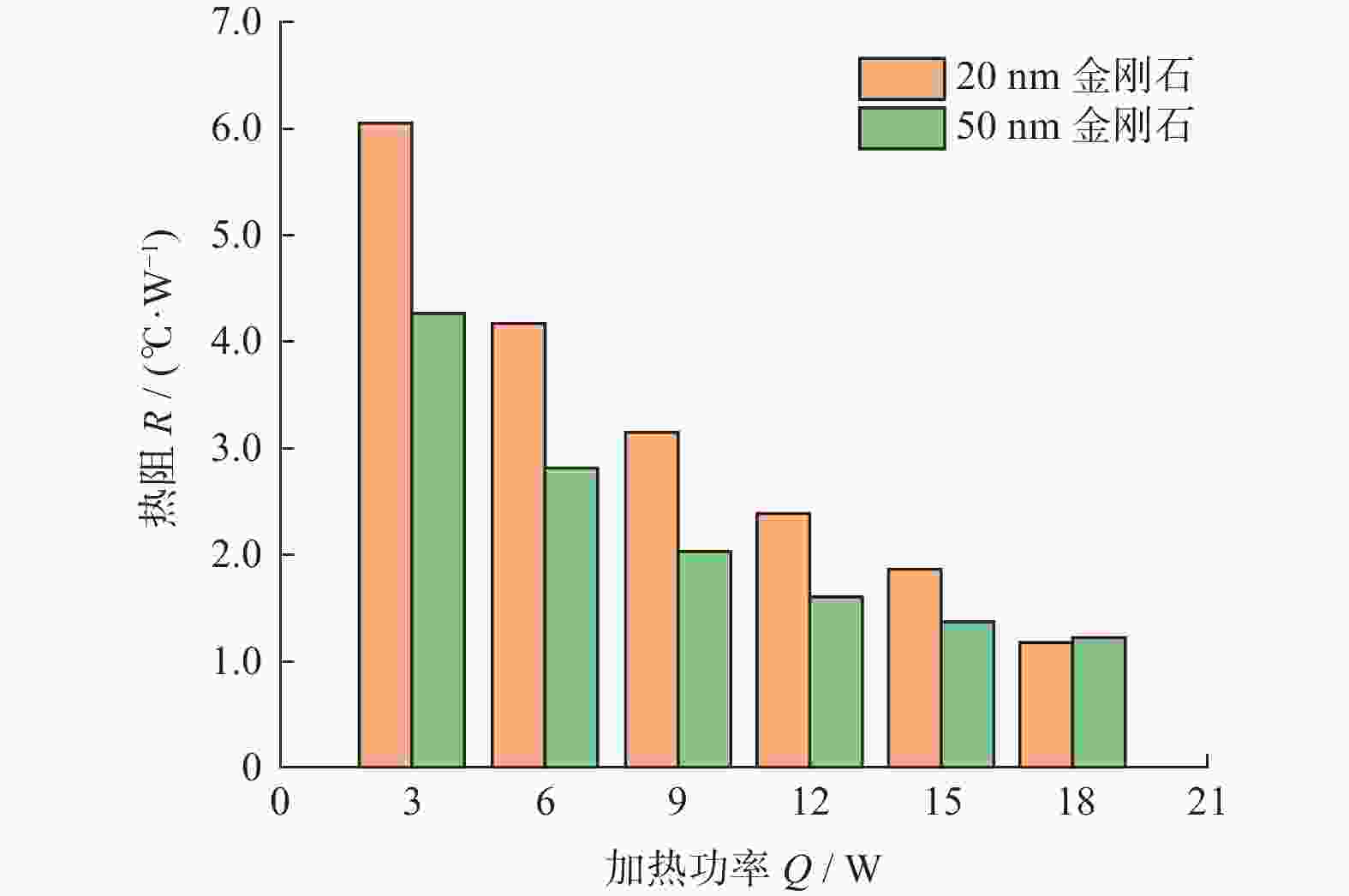

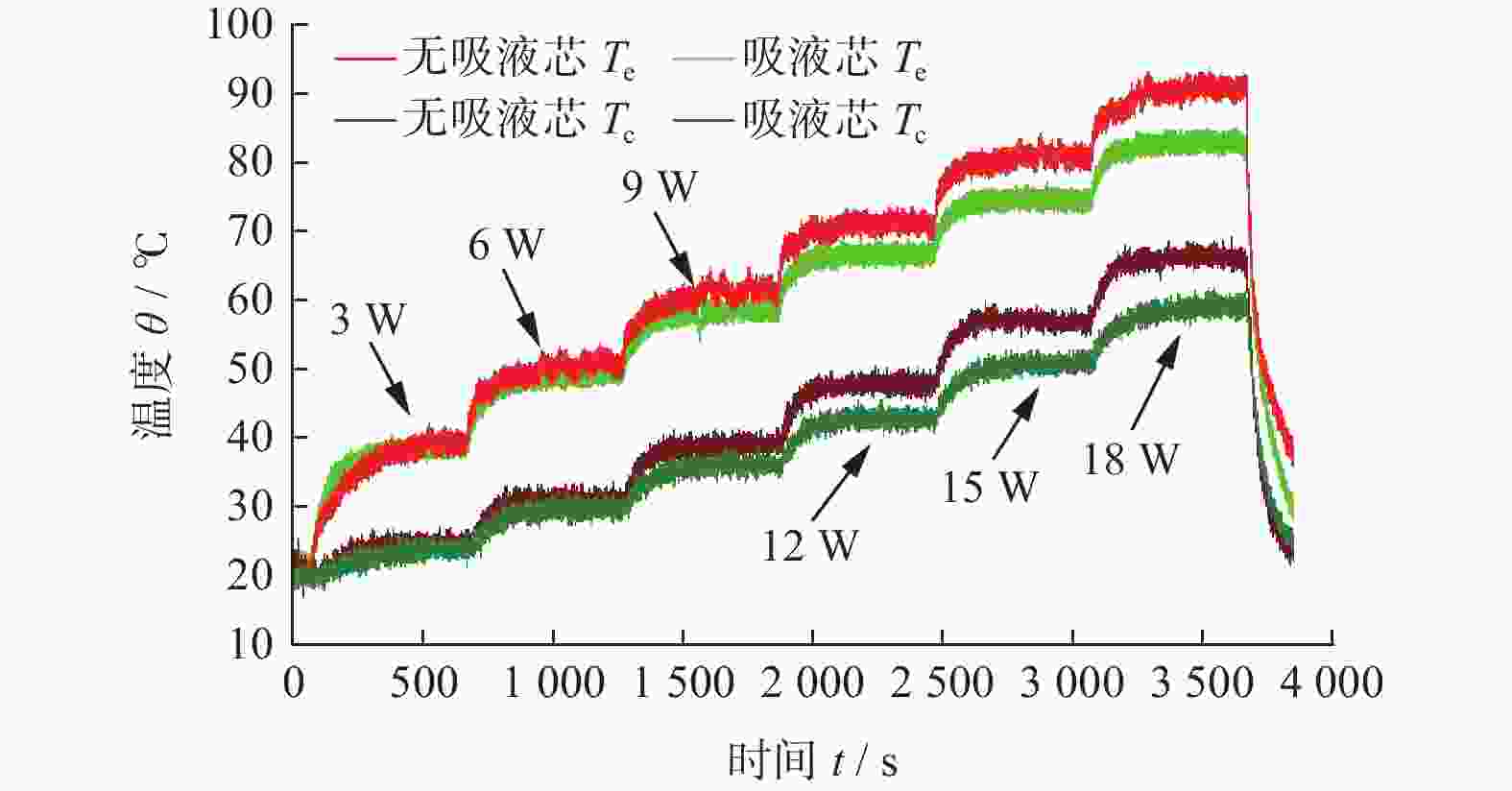

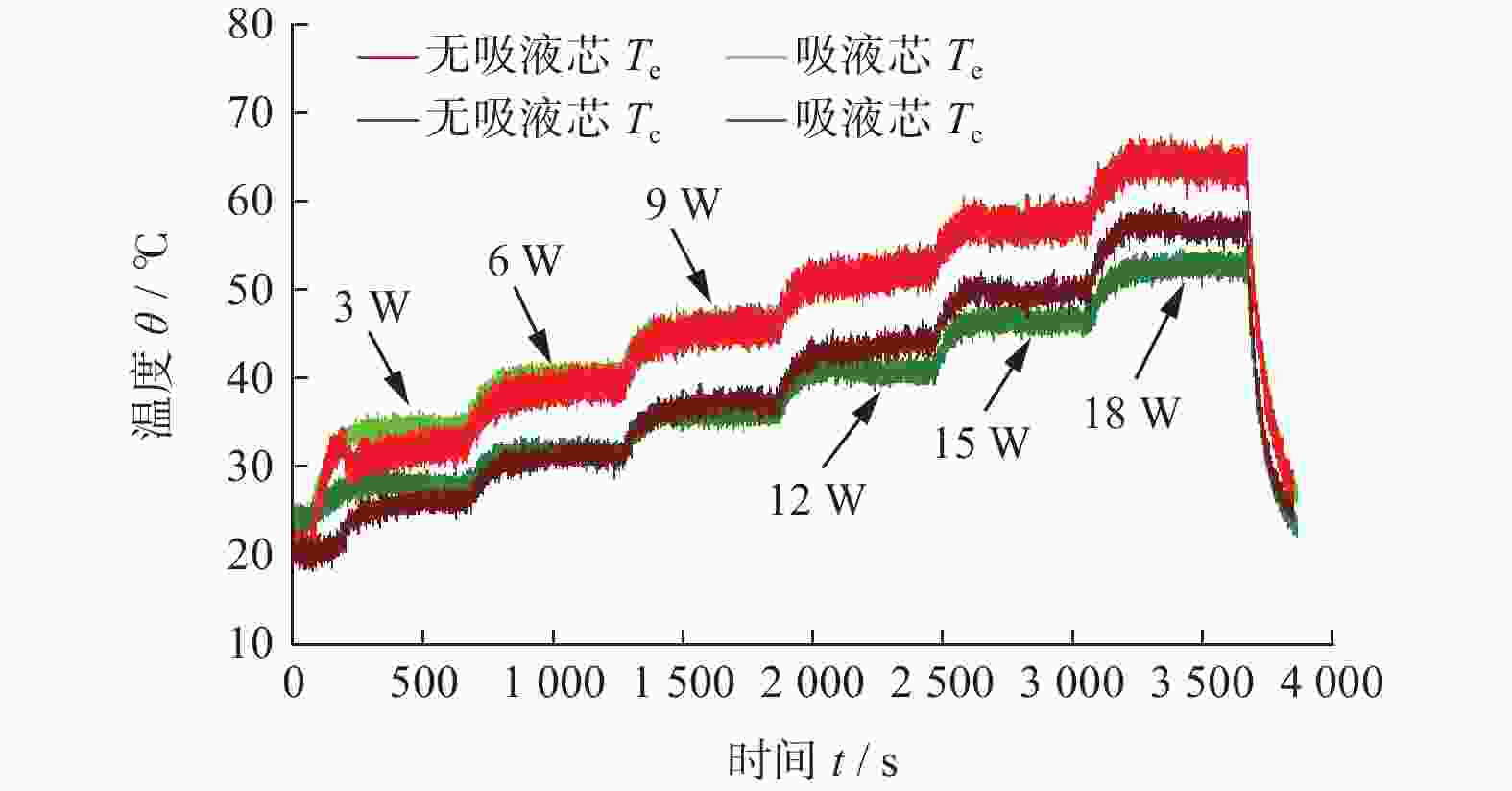

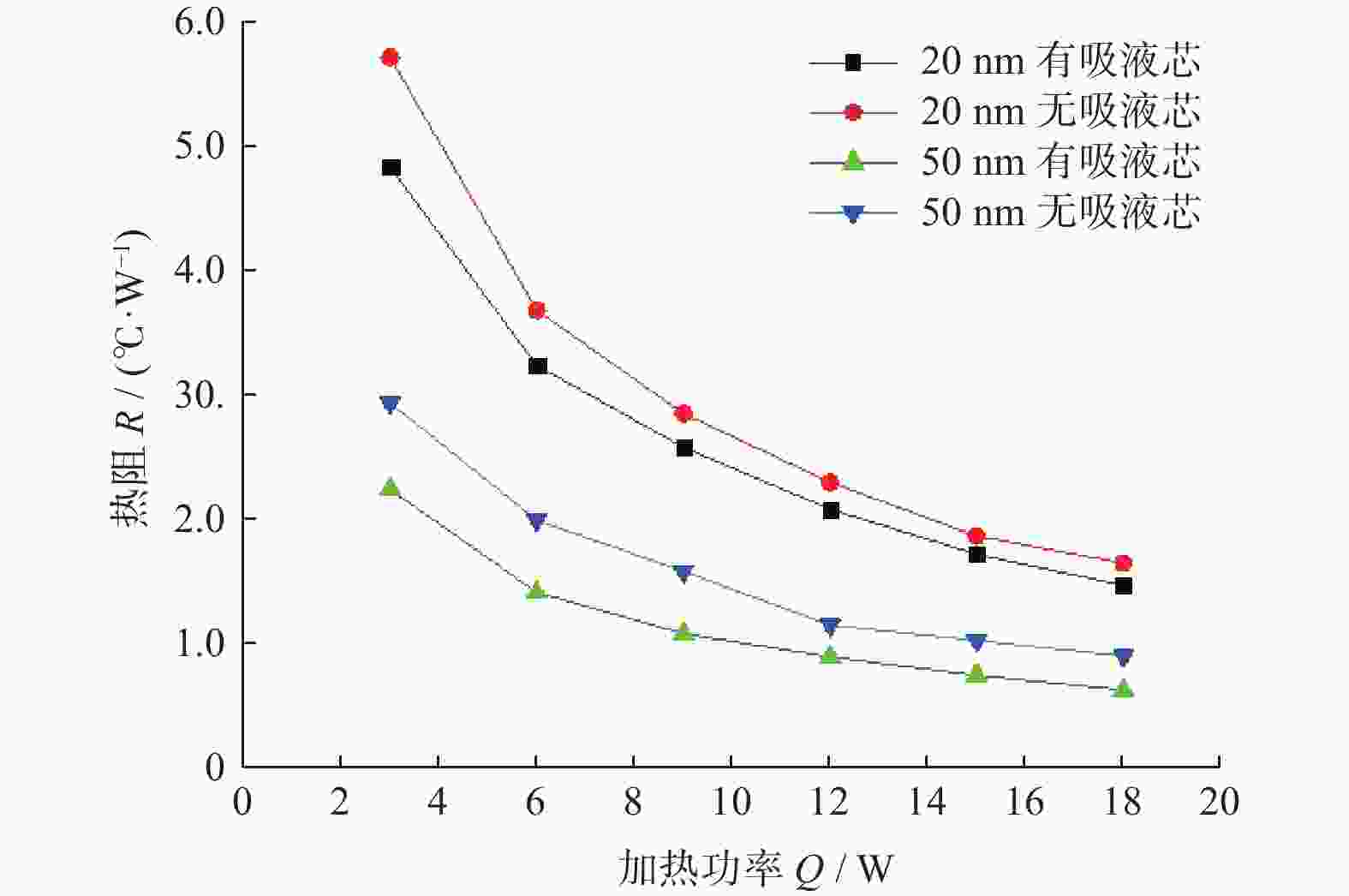

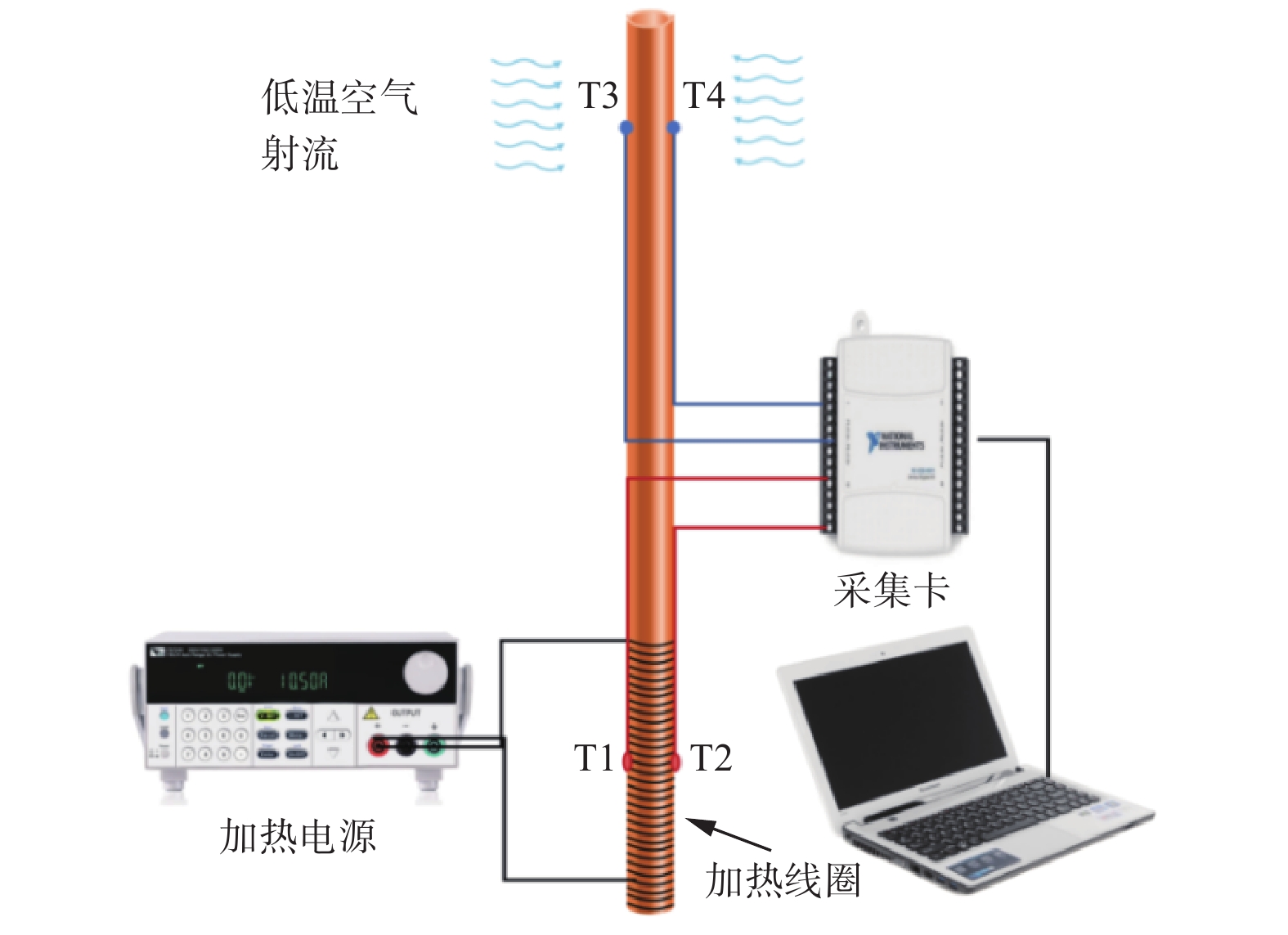

摘要: 热管是通过工质在管内的气液相态变化实现热量高效传递的换热元件,其中重力热管具有结构简单、工作稳定、成本低廉等优势,被广泛应用于工业生产的各个换热场合,尤其在节能、新能源的开发和利用方面发挥了显著的作用。本文中基于金刚石纳米流体开展重力热管的换热特性研究,探索特定条件下重力热管的最优工作参数。研究不同的纳米颗粒质量分数(0.5%~2.0%)、充液率(8%~26%)、纳米颗粒粒径(20和50 nm)、电源加热功率(3~18 W)和有无吸液芯等对金刚石纳米流体重力热管换热性能的影响,结果表明:当纳米颗粒质量分数为2.0%时,重力热管换热性能最佳,总热阻相比最大值降低28.4%~64.7%;当充液率为14%时,换热性能最好,总热阻相比最大值降低6.1%~8.5%;当选用粒径为50 nm的金刚石纳米流体时,重力热管换热性能整体优于20 nm的;当电源加热功率提高时,换热性能随之提升;当选用吸液芯重力热管时,其换热性能整体优于无吸液芯重力热管的换热性能。Abstract: Objectives: With the development of modern processing technology, heat accumulation has become an urgent processing problem that needs to be solved. A heat pipe is a heat exchange element that efficiently transfers heat through the gas-liquid phase change of the working fluid inside the pipe. Gravity heat pipe have advantages such as simple structure, stable operation, and low cost, and are widely used in various heat exchange scenarios in industrial production. They have played a significant role in energy conservation, the development and utilization of new energy, and in strengthening heat exchange during processing. This article prensents experimental research on diamond nanofluids, exploring the influence of different parameters on the heat transfer performance of diamond nanofluid gravity heat pipes, laying a foundation for the research and application of heat pipe technology in heat dissipation during machining processes such as drilling, milling, and grinding. Methods: The evaporation section is heated using a DC power supply and thermal resistance wire. K-type thermocouples and temperature acquisition cards are used to record the temperature of the evaporation and condensation sections of the gravity heat pipe. The influence of heating power, filling rate, nanofluid concentration, and nanoparticle size on the heat transfer performance of the gravity heat pipe is analyzed using thermal resistance R as an indicator. Results: The heat transfer performance of gravity heat pipes is investigated under a power range of 3-18 W, while maintaining a filling rate of 20% and a nanoparticle concentration of 1%. The results show that as the heating power increases, the temperatures of the evaporation and the condensation sections gradually increase, while the rise time gradually shortenes. The temperature difference between the evaporation and condensation sections shows a decreasing trend. When the heating power increases for the same concentration and filling rate of nanoparticles, the total thermal resistance shows a decreasing trend, but the magnitude of the decrease continues to decrease. Keeping the concentration of nanoparticles at 2% and the heating power at 6 W, the heat transfer performance of gravity heat pipes is investigated under conditions of filling rates of 8%, 14%, 20%, and 26%. The results show that the overall temperature of the 20 nm diamond nanofluid is higher than those of other filling rates at a 20% filling rate, while the overall temperature at a 26% filling rate is lower than at other filling rates. The overall temperature at a 26% filling rate is higher than at other filling rates. With the same mass fraction and heating power, as the filling rate increases, the total thermal resistance shows a trend of first decreasing and then increasing, with the minimum value of the total thermal resistance appearing at a filling rate of 14%. By maintaining a filling rate of 26% and a heating power of 12 W, the heat transfer performance of gravity heat pipes under 0.5%, 1.0%, 1.5%, and 2.0% mass fraction conditions is investigated. The results show that the overall temperature of 20 nm diamond nanofluid heat pipes is the highest at a 1% mass fraction, while the overall temperature is lower at a 2.0% mass fraction. The hot-end temperature of 50 nm diamond nanofluid heat pipes is the highest at a 1.5% mass fraction, and the cold-end temperature is the lowest. At a mass fraction of 2.0%, there is a situation where the hot-end temperature is lower and the cold-end temperature is higher. With the same filling rate and heating power, as the mass fraction increases, the total thermal resistance first increases and then decreases. At a mass fraction of 2.0%, the minimum total thermal resistance will appears. In addition, for diamond nanofluids with different particle sizes, there is a trend of heat transfer capacity decreasing first and then improving with increasing mass fraction. Maintaining a filling rate of 14% and a mass fraction of 2.0%, the heat transfer performance of gravity heat pipes with particle sizes of 20 nm and 50 nm was investigated. The total thermal resistance of 50 nm diamond nanofluid gravity heat pipes was always lower than that of 20 nm diamond nanofluid gravity heat pipes. However, as the heating power increases, the advantage of 50 nm diamond nanofluid gravity heat pipes tends to weaken. Maintaining a liquid filling rate of 14% and a mass fraction of 2.0%, the heat transfer performance of gravity heat pipes with and without a liquid absorbing core was investigated. The total thermal resistance of gravity heat pipes with suction cores is lower than that of heat pipes without suction cores, but as the heating power increases, the advantage tends to weaken. Conclusions: When the mass fraction is 2.0%, gravity heat pipes have the best heat transfer performance, with a total thermal resistance increase of approximately 28.4%-64.7% compared to the maximum value. When the filling rate is 14%, the heat transfer performance is the best, and the total thermal resistance decreases by about 6.1%-8.5% compared to the maximum value. When using diamond nanofluids with a particle size of 50 nm, the overall heat transfer performance of gravity heat pipes is better than that of 20 nm. When the heating power of the power supply increases, the heat exchange performance also improves. When using a gravity heat pipe with a liquid absorbing core, its overall heat transfer performance is better than that of a gravity heat pipe without a liquid absorbing core.

-

Key words:

- gravity heat pipe /

- heat transfer coefficient /

- thermal resistance /

- diamond nanofluid

-

表 1 换热试验参数

Table 1. Heat transfer test parameters

参数 取值 加热功率 Q / W 3,6,9,12,15,18 充液率 φ / % 8,14,20,26 纳米颗粒质量分数 ωnp / % 0.5,1.0,1.5,2.0 纳米颗粒粒径 rnp / nm 20,50 环境温度 θ' / ℃ 20 热管直径 d / mm 8 -

[1] 陈家绪. 重力热管传热特性的数值模拟与实验研究及热管式空预器优化设计 [D]. 太原: 太原理工大学, 2022.CHEN Jiaxu. Numerical simulation and experimental research on heat transfer characteristics of gravity heat pipes and optimization design of heat pipe air preheaters [D]. Taiyuan: Taiyuan University of Technology, 2022. [2] 于涛. 重力热管的制造及传热性能测试 [D]. 济南: 山东大学, 2008.YU Tao. Manufacturing and heat transfer performance testing of gravity heat pipes [D]. Jinan: Shandong University, 2008. [3] 郭浩, 彭家略, 尤天伢,等. 工质对重力热管壁温与传热特性的影响 [J]. 工程热物理学报,2021,42(11):2893-2898.GUO Hao, PENG Jialue, YOU Tianya, et al. Effect of working fluids on wall temperature and heat transfer characteristics of gravity heat pipe [J]. Journal of Engineering Thermophysics,2021,42(11):2893-2898. [4] 韩振兴, 王冬骁, 王飞,等. 重力热管冷凝段运行特征的可视化实验研究 [J]. 化工学报,2014,65(8):2934-2939. doi: 10.3969/j.issn.0438-1157.2014.08.012HAN Zhenxing, WANG Dongxiao, WANG Fei, et al. Visual experimental study on operation characteristics of condensation segment of gravity-assisted heat pipe [J]. Journal of Chemical Engineering,2014,65(8):2934-2939. doi: 10.3969/j.issn.0438-1157.2014.08.012 [5] 金志浩, 陈玉润, 韩振南. 氧化石墨烯-水重力热管传热性能实验研究 [J]. 化学工程,2022,50(12):38-41,71. doi: 10.3969/j.issn.1005-9954.2022.12.008JIN Zhihao, CHEN Yurun, HAN Zhennan. Experimental study on heat transfer performance of graphene oxide-water gravity heat pipe [J]. Chemical Engineering (China),2022,50(12):38-41,71. doi: 10.3969/j.issn.1005-9954.2022.12.008 [6] 杨文斌, 杨峻. SiO2-乙醇纳米流体重力热管传热性能的试验研究 [J]. 当代化工,2019,48(12):2962-2966. doi: 10.3969/j.issn.1671-0460.2019.12.067YANG Wenbin, YANG Jun. Experimental research on heat transfer performance of SiO2-ethanol nanofluid gravity heat pipe [J]. Contemporary Chemical,2019,48(12):2962-2966. doi: 10.3969/j.issn.1671-0460.2019.12.067 [7] GOU X, ZHANG Q Y, LI Y M, et al. Experimental research on the thermal performance and semi-visualization of rectangular flat micro-grooved gravity heat pipes [J]. Energies,2018,11(9):2480. doi: 10.3390/en11092480 [8] SUDHAN S A L, SOLOMON A B, SUNDER S. Heat transport limitations and performance enhancement of anodized grooved heat pipes charged with ammonia under gravity and anti-gravity condition [J]. Applied Thermal Engineering,2022,200:117633. doi: 10.1016/j.applthermaleng.2021.117633 [9] 刘时安. 螺旋吸液芯热管传热性能的实验研究 [D]. 天津: 河北工业大学, 2018.LIU Shian. Experimental research on heat transfer performance of heat pipe with spiral liouid suction core [D]. Tianjin: Hebei University of Technology, 2018. [10] 郭威. 基于丝网型吸液芯的平板热管传热特性实验研究[D]. 大连: 大连理工大学, 2022.GUO Wei. Experimental study on heat transfer characteristics of flat plate heat pipe based on mesh type liquid absorbing core [D]. Dalian: Dalian University of Technology, 2022. [11] 仲宁波. 仿叶脉复合吸液芯柔性超薄平板热管制备及性能研究 [D]. 哈尔滨: 哈尔滨工业大学, 2022.ZHONG Ningbo. Preparation and performance study of a flexible ultra-thin plate heat pipe with a leaf like vein composite suction core [D]. Harbin: Harbin Institute of Technology, 2022. [12] WU S C, CHEN S K , XIAO N H, et al. Thermo-hydrodynamic performance of tubular pulsating heat pipes with integral sintered powder wicks [J]. International Communications in Heat and Mass Transfer,2023,141:106573. doi: 10.1016/j.icheatmasstransfer.2022.106573 [13] ZHAO Z G, PENG G H , ZHANG Y H , et al. Heat transfer performance of flat micro-heat pipe with sintered multi-size copper powder wick [J]. Case Studies in Thermal Engineering,2023,42:102720. doi: 10.1016/j.csite.2023.102720 [14] ZHAO J, JI Y, YUAN D Z, et al. Structural effect of internal composite wick on the anti-gravity heat transfer performance of a concentric annular high-temperature heat pipe [J]. International Communications in Heat and Mass Transfer,2022,139:106404. doi: 10.1016/j.icheatmasstransfer.2022.106404 [15] 李万杰. 纳米流体热管砂轮强化传热试验与仿真研究[D]. 南京:南京航空航天大学, 2021.LI Wanjie. Experimental and simulation study on enhanced heat transfer of nanofluid heat pipe grinding wheel [D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2021. [16] 宫玉英, 赵蔚琳, 朱保杰,等. SiO2-水纳米流体热管传热性能的实验研究 [J]. 化工机械,2013,40(3):302-305,405. doi: 10.3969/j.issn.0254-6094.2013.03.007GONG Yuying, ZHAO Weilin, ZHU Baojie, et al. Experimental study on heat transfer performance of heat pipes for SiO2-water nanofluid [J]. Chemical Engineering & Machinery,2013,40(3):302-305,405. doi: 10.3969/j.issn.0254-6094.2013.03.007 [17] JIANG W T, DING G L, PENG H, et al. Experimental and model research on nanorefrigerant thermal conductivity [J]. HVAC & R Research,2009,15(3):651-669. doi: 10.1080/10789669.2009.10390855 [18] 史继媛. GO纳米流体热物性能及在热管中应用的研究 [D].济南: 济南大学, 2017.SHI Jiyuan. Research on the thermophysical properties of GO nanofluid and its application in heat pipes [D]. Jinan: Jinan University, 2017. [19] 林清宇, 刘鹏辉, 石卫军, 等. 纳米颗粒粒径对内置扭带螺旋管传热特性的影响 [J]. 当代化工,2017,46(5):905-908. doi: 10.13840/j.cnki.cn21-1457/tq.2017.05.031LIN Qingyu, LIU Penghui, SHI Weijun, et al. Effect of nanoparticle size on heat transfer characteristics of helical tube with twisted tape [J]. Contemporary Chemical Industry,2017,46(5):905-908. doi: 10.13840/j.cnki.cn21-1457/tq.2017.05.031 [20] 徐正基, 杨峻. 石墨烯纳米片-水纳米流体重力热管的传热性能实验研究 [J]. 化工机械,2020,47(6):751-758. doi: 10.3969/j.issn.0254-6094.2020.06.005XU Zhengji, YANG Jun. Experimental study of heat transfer performance of gravity heat tube using graphene nanoplatelet-water nanofluids [J]. Chemical Machinery,2020,47(6):751-758. doi: 10.3969/j.issn.0254-6094.2020.06.005 [21] 陆鑫, 杨峻. SiO2-DW纳米流体重力热管传热性能试验研究 [J]. 现代化工,2015,35(11):145-147. doi: 10.16606/j.cnki.issn0253-4320.2015.11.036LU Xin, YANG Jun. Heat transfer characteristics of SiO2-DW nanofluid gravity heat pipe [J]. Modern Chemical Industry,2015,35(11):145-147. doi: 10.16606/j.cnki.issn0253-4320.2015.11.036 [22] 刘振华, 杨雪飞. 纳米流体在回路型重力热管中的沸腾传热特性 [J]. 上海交通大学学报,2011,45(6):890-894. doi: 10.16183/j.cnki.jsjtu.2011.06.021LIU Zhenhua, YANG Xuefei. Boiling heat transfer characteristics of nanofluids in a thermosyphon loop [J]. Journal of Shanghai Jiao Tong University,2011,45(6):890-894. doi: 10.16183/j.cnki.jsjtu.2011.06.021 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS