Comparison of erosion resistance of hard and brittle materials processed by low-temperature micro-abrasive gas jet

-

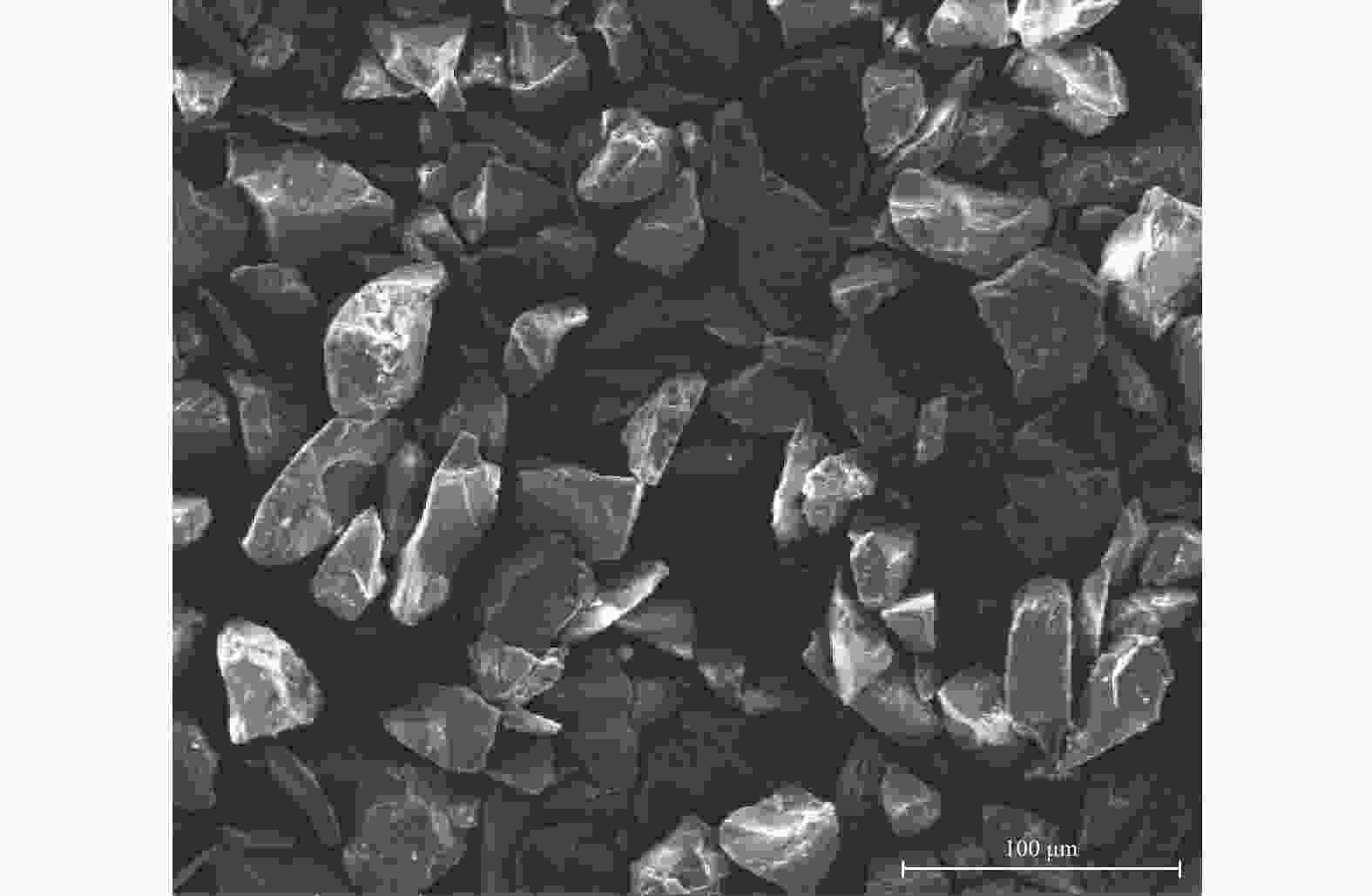

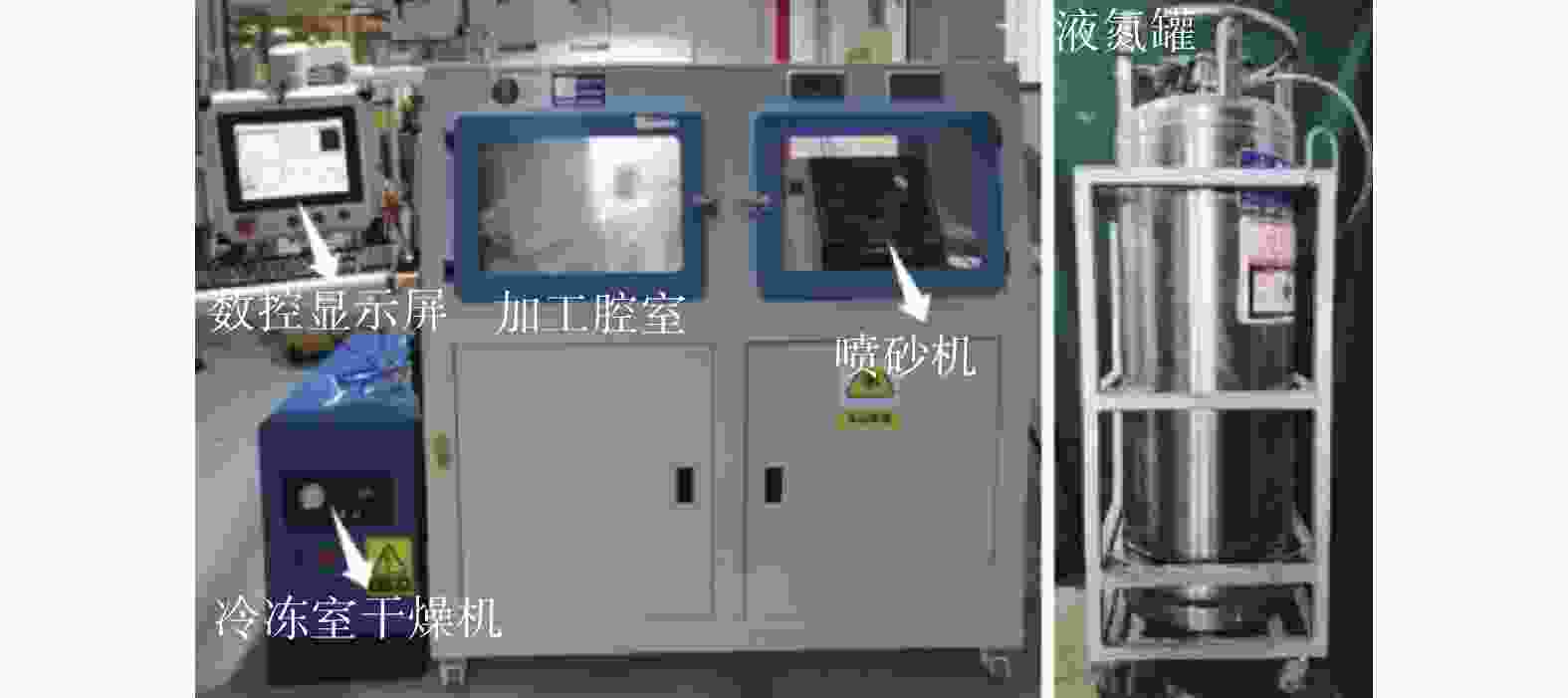

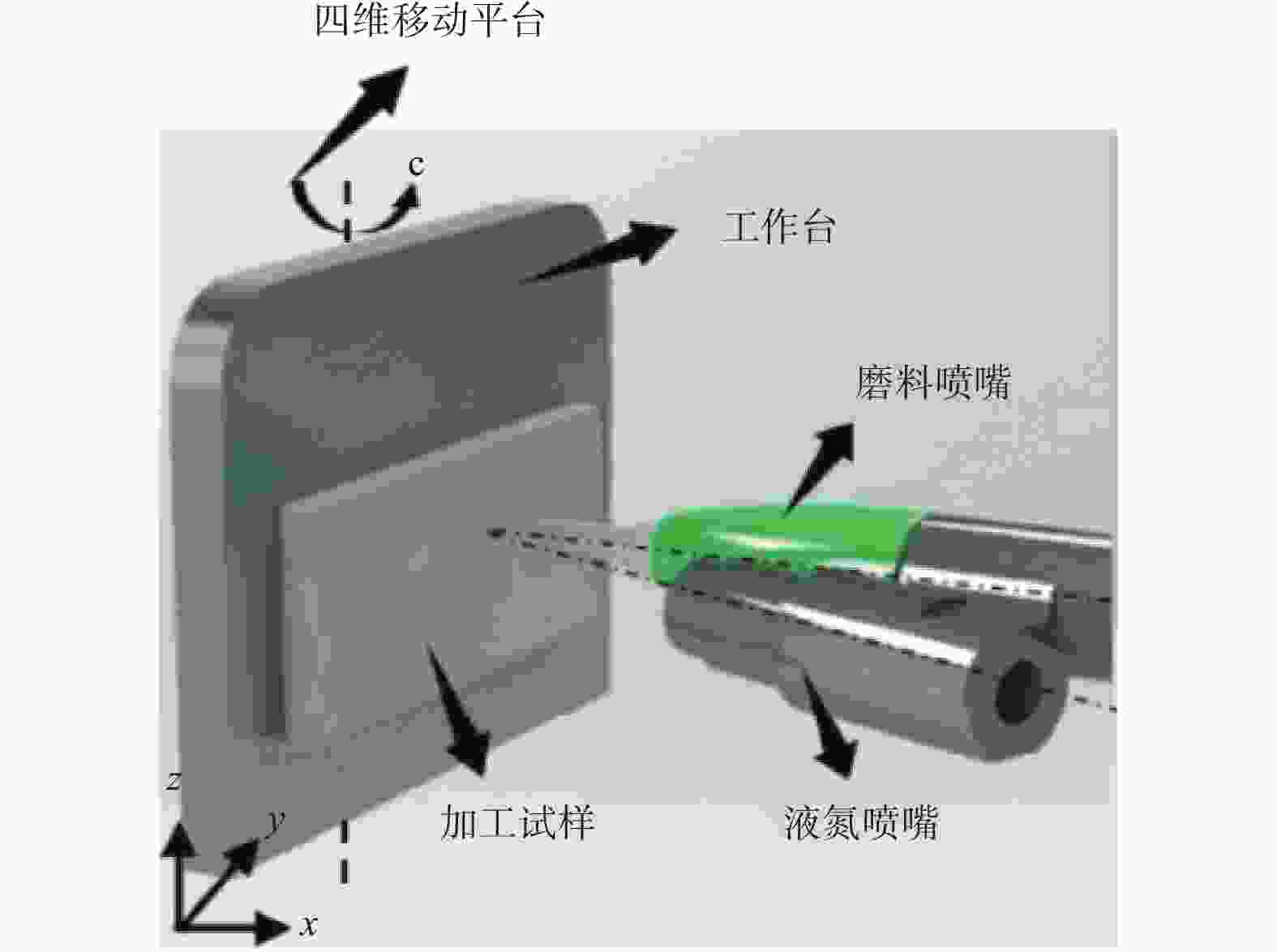

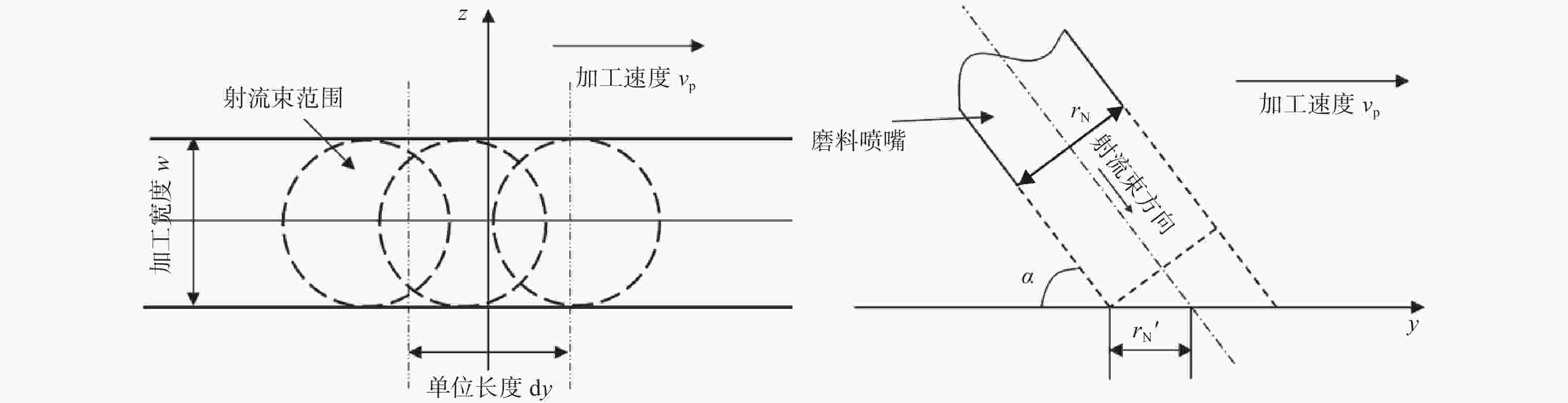

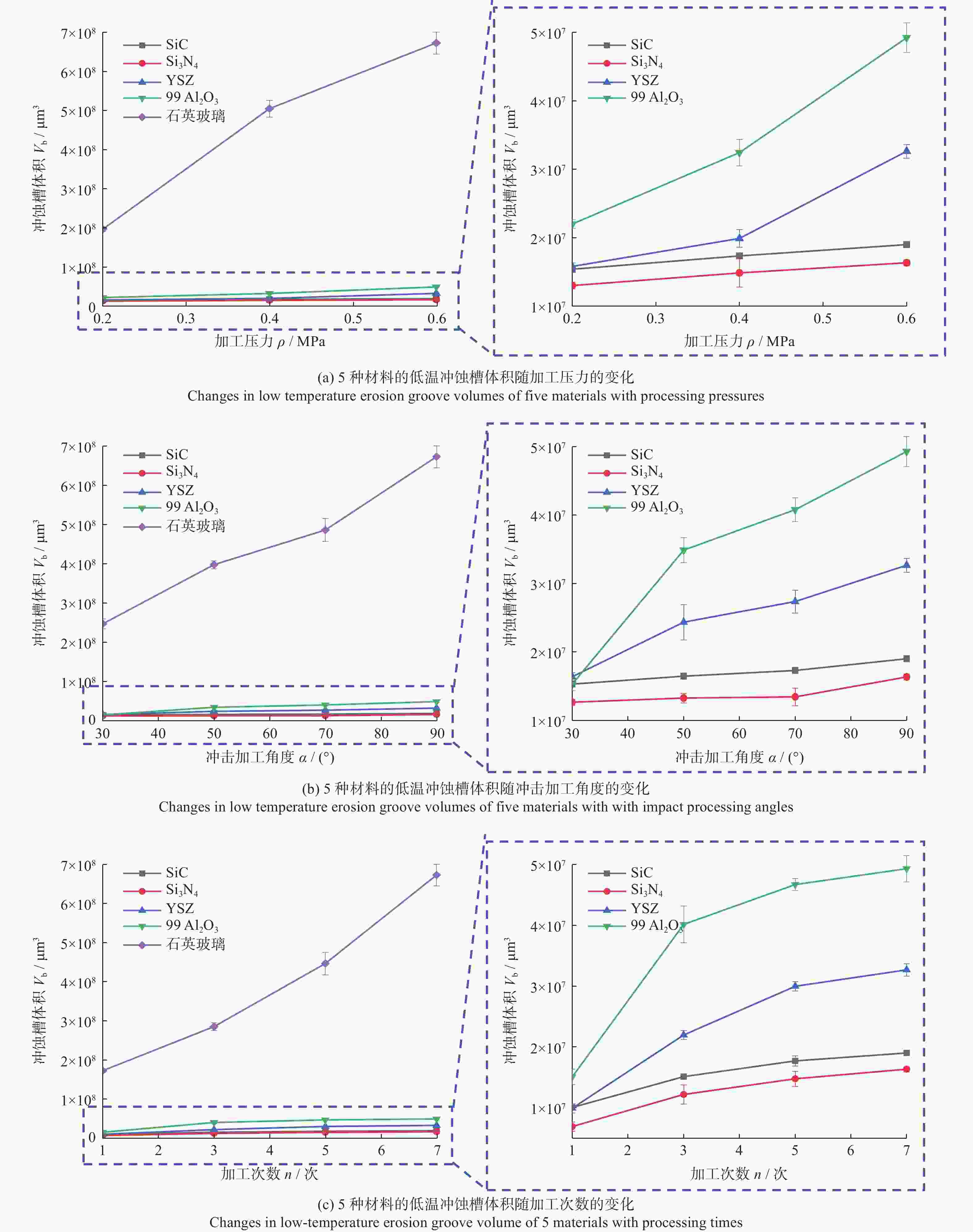

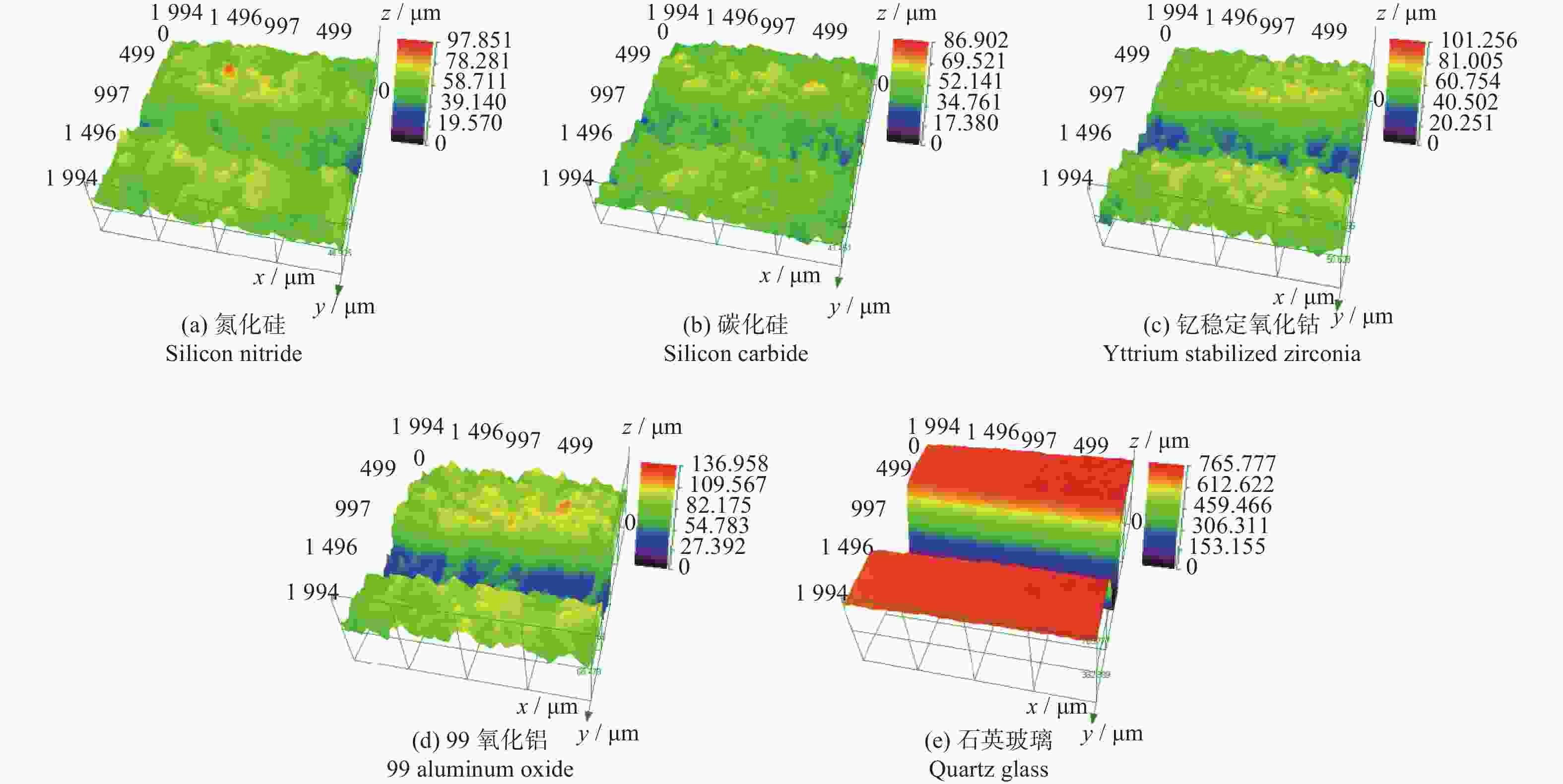

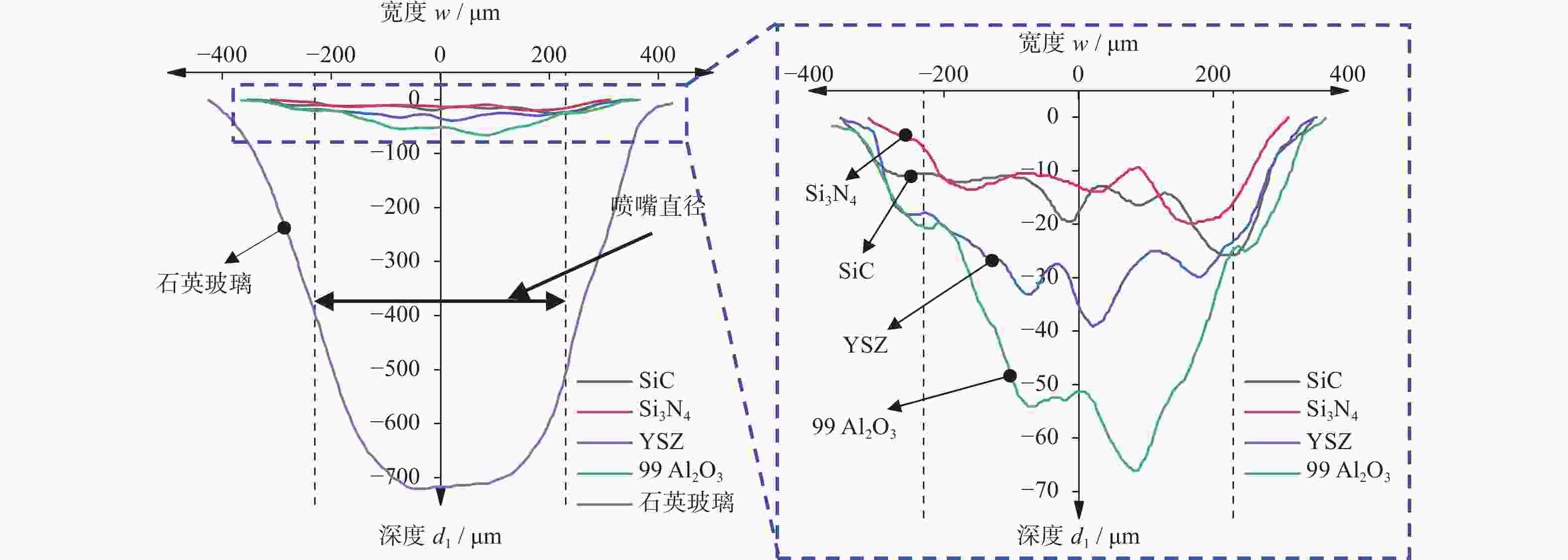

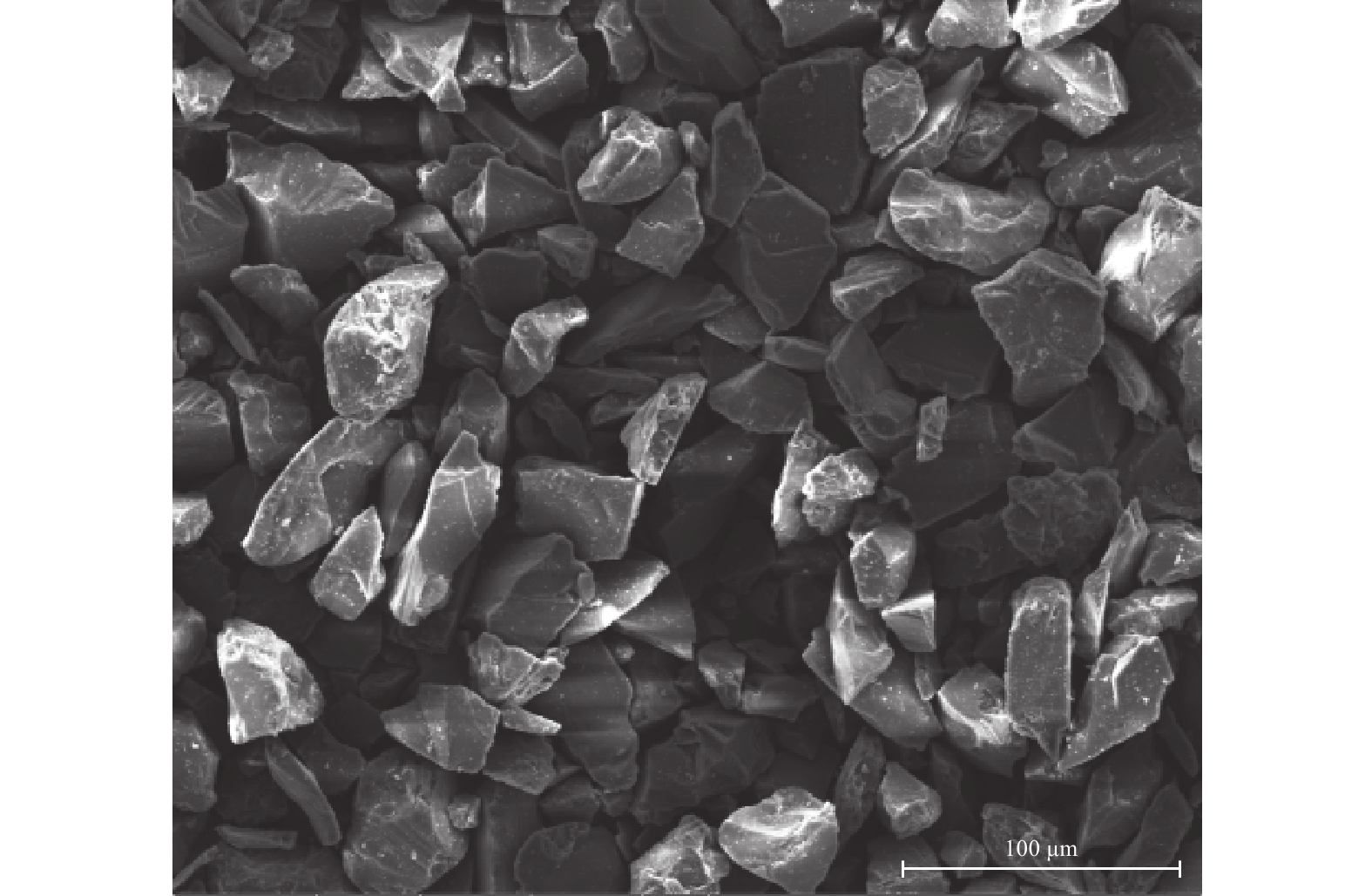

摘要: 低温微磨料气射流加工硬脆材料时,其变脆易被冲蚀去除。对碳化硅(SiC)、氮化硅(Si3N4)、钇稳定氧化锆(YSZ)、99氧化铝(99 Al2O3)、石英玻璃5种硬脆材料进行低温微磨料气射流加工对比实验,探究加工压力、冲击加工角度及加工次数等工艺参数对5种硬脆材料的冲蚀去除率、低温冲蚀槽三维形貌及表面轮廓的影响,优选出低温下耐冲蚀性能良好的硬脆材料。结果表明:随着加工压力和加工次数增加,5种材料的冲蚀去除率都不断增大;随着冲击加工角度变化,5种材料的低温冲蚀槽体积也在变化,并在加工角度为90°的垂直加工角度附近时达到最大;在相同的加工工艺参数下,Si3N4材料的冲蚀去除率最小,其最大低温冲蚀槽深度只有20 μm,SiC材料的与其相差不大,YSZ和99 Al2O3的冲蚀去除率依次增大,但石英玻璃材料的冲蚀去除率最大且远大于其他4种材料的。同时,Si3N4的低温冲蚀槽槽形不明显,且其表面较平整,去除量最小,因而耐冲蚀性能最佳。Abstract: Objectives: During low-temperature micro-abrasive air jet machining, the mechanical properties of materials undergo changes, making the material more prone to brittleness and erosion removal. Comparative experiments were conducted on the low-temperature micro-abrasive air jet machining of hard and brittle materials to investigate their machining performance at low temperatures and to indentify materials with better erosion resistance under such conditions. Methods: Low-temperature micro-abrasive air jet machining comparative experiments were conducted on five materials: silicon carbide (SiC), silicon nitride (Si3N4), yttrium-stabilized zirconia (YSZ), 99% alumina (Al2O3), and quartz glass. First, the materials were pretreated using the same surface treatment method, and a material removal model was established to identify the factors affecting the changes in low-temperature properties. Next, micro-abrasive air jet machining experiments were performed at 77 K to investigate the effects of different process parameters—including machining pressure, impact machining angle, and machining time—on erosion removal rates, low-temperature erosion groove three-dimensional morphology, and surface profiles of the five materials. Finally, the three-dimensional morphology of the low-temperature erosion grooves and the surface profiles of the materials were compared and analyzed to evaluate the erosion resistance of each material during low-temperature machining. Results: The processing performance of the five materials at low-temperatures showed the following trends: (1) As the processing pressure increased, the surface groove volumes of all five materials gradually increased. However, the surface groove volumes of Si3N4 and SiC did not increase significantly. (2) As the impact angle increased, the surface groove volumes of all five materials also gradually increased. The groove volume reached its maximum value when the impact angle approached a vertical processing angle. Si3N4 exhibited the smallest low-temperature erosion groove volume under these conditions. (3) All five materials exhibited increased brittleness at low temperatures, with minimal plastic deformation due to their high hardness. At smaller impact angles, surface material removal was limited, resulting in smaller low-temperature erosion grooves. As the impact angle increased, material removal transitioned from plastic deformation to surface fracture. At the maximum impact angle (90°), the material removal became most evident, and the erosion groove reached their largest volume, exhibiting a typical brittle removal mode. (4) Under the same processing parameters, the erosion removal rates of the five materials increased sequentially. The erosion removal rate of silicon nitride was the smallest, with a maximum low-temperature erosion groove depth of only 20 μm. Silicon carbide's erosion removal rate was similar to that of silicon nitride material, but the erosion removal rate of quartz glass material was the highest, considerably exceeding that of the other four materials. (5) As the number of machining cycles increased, the surface groove volumes for all five materials also gradually increased. (6) The groove shape formed on the surface of silicon nitride was not obvious, consisting mainly of small pits that could not form complete microchannels. Additionally, the surface of silicon nitride remained relatively flat, with minimal material removal, resulting in the smallest depth of the low-temperature erosion grooves. (7) After the erosion processing, quartz glass formed an obvious "U"-shaped groove, which could be clearly observed under a microscope. In contrast, the grooves of the other four materials had no fixed shape and appeared relatively flat. Upon magnification, small "U"-shaped grooves and similar "V"-shaped grooves were observed locally on the surfaces of the four materials, indicating that the morphological changes during erosion processing were relatively complex. Conclusions: The low-temperature micro-abrasive air jet machining comparative experiment was used to analyze the material erosion removal rates, three-dimensional morphology, and surface profiles of low-temperature erosion grooves. Among the five hard and brittle materials tested, silicon nitride material exhibited the smallest erosion groove volume, the lowest erosion removal rate, and the highest erosion resistance. These findings provide a foundation for future research into low-temperature micro-abrasive air jet technology for masks.

-

Key words:

- hard-brittle materials /

- low-temperature /

- abrasive air jet /

- erosion resistance /

- erosion removal rate

-

材料名称 抗弯强度

σ / MPa断裂韧性

KIC / (MPa·m1/2)石英玻璃 61.2 0.8 YSZ 646.0 7.5 99 Al2O3 370.0 5.3 Si3N4 930.0 6.8 SiC 500.0 5.5 表 2 实验中固定的加工参数

Table 2. Fixed processing parameters in the experiment

实验参数 类型或取值 气射流喷嘴直径 dN / μm 460 液氮射流喷嘴直径 d2 / mm 3 气射流和液氮喷嘴夹角 θ1 / (°) 10 实验气体 干燥的压缩空气 液氮压力 p1 / MPa 0.2 试样表面温度 T / K 77 磨料粒径 d50 / μm 25 磨料种类 Al2O3 加工速度 vp / (mm·s−1) 5 加工距离 d / mm 2 表 3 全因子实验的参数设计

Table 3. Parameter design of full factor experiment

实验参数 水平数 取值 冲击加工角度 α / (°) 4 30,50,70,90 加工压力 p / MPa 3 0.2,0.4,0.6 加工次数 n / 次 4 1,3,5,7 -

[1] ZARAGOZA-GRANADOS J, GALLARDO-HERNÁNDEZ E A, VITE-TORRES M, et al. Erosion behaviour of AISI 310 stainless steel at 450 °C under turbulent swirling impinging jets [J]. Wear,2019,426/427:637-642. doi: 10.1016/j.wear.2019.01.076 [2] DE LA ROSA SEDANO C S, VITE-TORRES M, GALLARDO-HERNÁNDEZ M A, et al. Effect of tangential velocity on erosion of ASTM A-106 grade B steel pipe under turbulent swirling impinging jet [J]. Tribology International,2017,113:500-506. doi: 10.1016/j.triboint.2017.01.011 [3] ZHANG M, LI D, KANG Y, et al. Experimental study on the rock erosion performance of a pulsed abrasive supercritical CO2 jet [J]. Journal of Petroleum Science and Engineering,2021,201:108489. doi: 10.1016/j.petrol.2021.108489 [4] 汤张喆. 伺服零件交叉孔磨粒流去毛刺技术研究 [D]. 南京: 南京航空航天大学, 2021.TANG Zhangzhe. Research on abrasive honing deburring technology of servo parts intersecting holes [D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2021. [5] 杨博均, 魏木孟, 姚敬华, 等. 基材不同除锈处理工艺对涂层性能影响的优劣对比研究 [J]. 中国涂料,2022,37(8):70-74. doi: 10.13531/j.cnki.china.coatings.2022.08.014YANG Bojun, WEI Mumeng, YAO Jinghua, et al. A comparative study on the effects of different substrate derusting processes on coatings properties [J]. China Coatings,2022,37(8):70-74. doi: 10.13531/j.cnki.china.coatings.2022.08.014 [6] AVCI H I, CAKIR O. Abrasive water-jet applications in 6 mm flat glass cuttings [J]. Materials Today: Proceedings,2023,80(1):104-109. doi: 10.1016/j.matpr.2022.10.252 [7] CHEN C, LIU Y, TANG J, et al. Effect of nozzle pressure ratios on the flow and distribution of abrasive particles in abrasive air jet machining [J]. Powder Technology,2022,397:117114. doi: 10.1016/j.powtec.2022.117114 [8] 李全来. 微磨料气射流成形加工表面粗糙度的研究 [J]. 机械工程师,2014(12):7-10. doi: 10.3969/j.issn.1002-2333.2014.12.003LI Quanlai. Surface roughness analysis on micro abrasive air jet forming technology [J]. Mechanical Engineer,2014(12):7-10. doi: 10.3969/j.issn.1002-2333.2014.12.003 [9] SCHÜLER M, DADGAR M, HERRIG T. Influence of abrasive properties on erosion in waterjet machining [J]. Procedia CIRP,2021,102:375-380. doi: 10.1016/j.procir.2021.09.064 [10] 钱炳坤, 孙玉利, 张桂冠, 等. 低温微磨料气射流加工PDMS传热仿真及实验研究 [J]. 南京航空航天大学学报,2022,54(1):163-171. doi: 10.16356/j.1005-2615.2022.01.019QIAN Bingkun, SUN Yuli, ZHANG Guiguan, et al. Heat transfer simulation and experimental research of cryogenic micro-abrasive air jet machining PDMS [J]. Journal of Nanjing University of Aeronautics and Astronautics,2022,54(1):163-171. doi: 10.16356/j.1005-2615.2022.01.019 [11] HU Y, DAI Q, HUANG W, et al. Tapered mask and its effect on the fluid flow and machining efficiency of a multiphase jet [J]. Journal of Manufacturing Processes,2020,50(4):467-474. doi: 10.1016/j.jmapro.2020.01.006 [12] 胡焰. 基于气液固混合的磨料射流加工系统及实验研究 [D]. 南京: 南京航空航天大学, 2019.HU Yan. Abrasive jet processing system based on gas-liquid-solid mixing and experimental study [D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2019. [13] NAKANISHI Y, NAKASHIMA Y, HEIDE D V E. Microstructuring glass surfaces using a combined masking and microslurry-jet machining process [J]. Precision Engineering,2021,67:172-177. doi: 10.1016/j.precisioneng.2020.09.018 [14] BELLOY E, THURRE S, WALCKIERS E, et al. The introduction of powder blasting for sensor and microsystem applications [J]. Sensors & Actuators A: Physical,2020,84(3):330-337. doi: 10.1016/S0924-4247(00)00390-3 [15] 王学亮, 王瑞国, 刘立艳, 等. 几种常见耐磨耐冲击材料的综合性能对比分析 [J]. 山东工业技术,2020(4):46-52. doi: 10.16640/j.cnki.37-1222/t.2020.04.006WANG Xueliang, WANG Ruiguo, LIU Liyan, et al. Comprehensive performance analysis of some wear-resisting and impact resistant materials [J]. Journal of Shandong Industrial Technology,2020(4):46-52. doi: 10.16640/j.cnki.37-1222/t.2020.04.006 [16] 陈娟. 低温下氧化物陶瓷的微观结构、断裂机理与性能研究 [D]. 北京: 清华大学, 2016.CHEN Juan. Research on the microstructure and fracture mechanism of oxide structural ceramics at cryogenic temperatures [D]. Beijing: Tsinghua University, 2016. [17] 钱炳坤, 孙玉利, 张桂冠, 等. 低温微磨料气射流加工微流道专用机床 [J]. 南京航空航天大学学报,2021,53(1):93-100. doi: 10.16356/j.1005-2615.2021.01.010QIAN Bingkun, SUN Yuli, ZHANG Guiguan, et al. Micro-channel special machine tool for cryogenic micro-abrasive air jet machining [J]. Journal of Nanjing University of Aeronautics and Astronautics,2021,53(1):93-100. doi: 10.16356/j.1005-2615.2021.01.010 [18] 刘旭, 孙玉利, 张桂冠, 等. 液氮射流冲击冷却聚二甲基硅氧烷的温度场仿真和实验研究 [J]. 中国机械工程,2022,33(18):2161-2171. doi: 10.3969/j.issn.1004-132X.2022.18.002LIU Xu, SUN Yuli, ZHANG Guiguan, et al. Simulation and experimental research about temperature fields of PDMS cooled by liquid nitrogen jet impingement [J]. China Mechanical Engineering,2022,33(18):2161-2171. doi: 10.3969/j.issn.1004-132X.2022.18.002 [19] SLIKKERVEER P J, BOUTEN P C P, VELD F H, et al. Erosion and damage by sharp particles [J]. Wear,1998,217(2):237-250. doi: 10.1016/S0043-1648(98)00187-2 [20] ZHANG G, SUN Y, GAO H, et al. PDMS material embrittlement and its effect on machinability characteristics by cryogenic abrasive air-jet machining [J]. Journal of Manufacturing Processes,2021,67:116-127. doi: 10.1016/j.jmapro.2021.04.057 [21] TARODIYA R, LEVY A. Surface erosion due to particle-surface interactions - A review [J]. Powder Technology,2021,387:527-555. doi: 10.1016/j.powtec.2021.04.055 [22] RICARDO G, SOMMERFELD M. Experimental evaluation of surface roughness variation of ductilematerials due to solid particle erosion [J]. Advanced Powder Technology,2020,31(9):3790-3816. doi: 10.1016/j.apt.2020.07.023 [23] ZHANG G, SUN Y L, GAO H, et al. A theoretical and experimental investigation of particle embedding and erosion behaviour of PDMS in micro-abrasive air-jet machining [J]. Wear,2021(486/487):204118. doi: 10.1016/j.wear.2021.204118 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS