Experimental study on tangential vibration assisted abrasive flow finishing of circular tubes

-

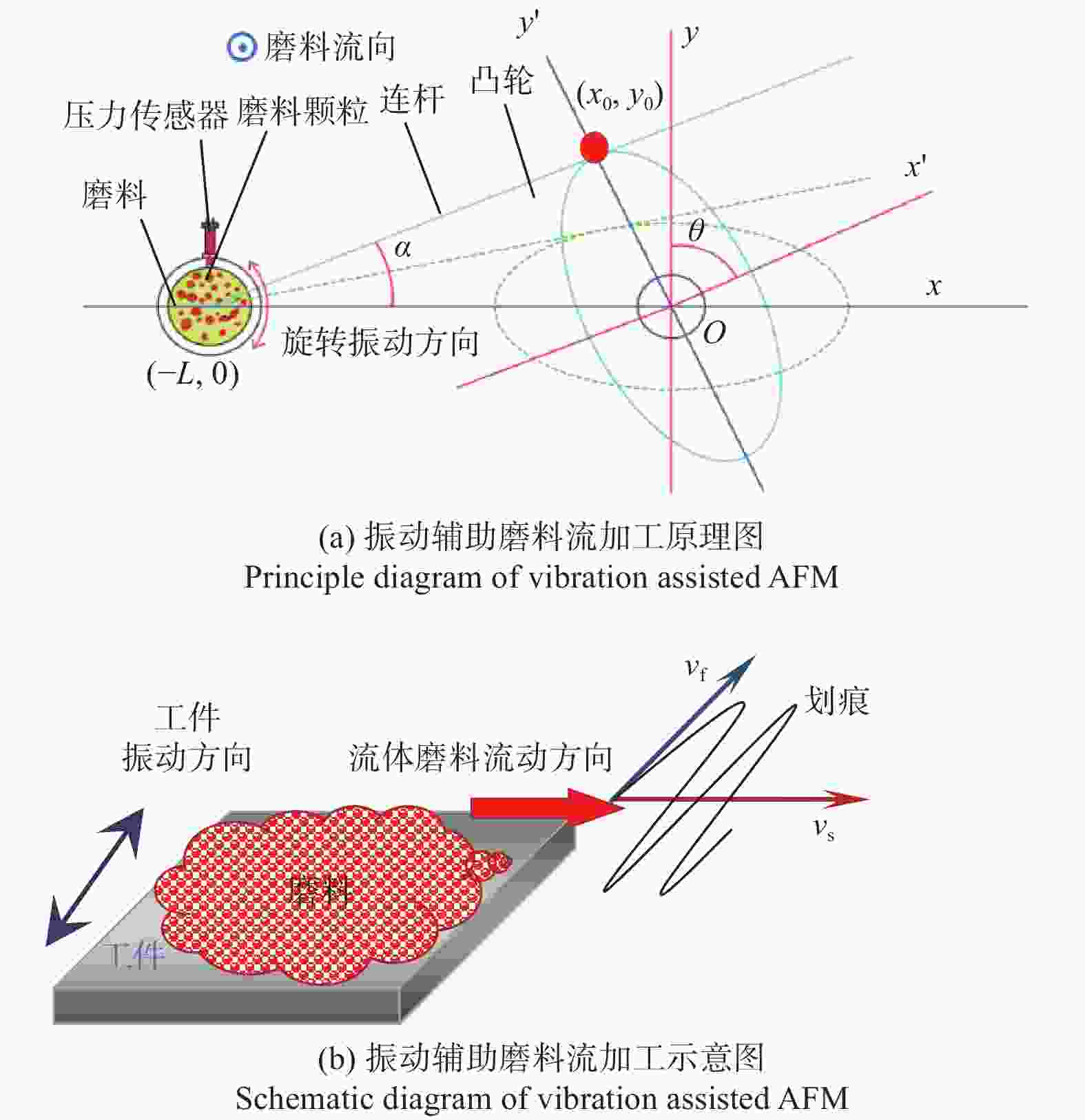

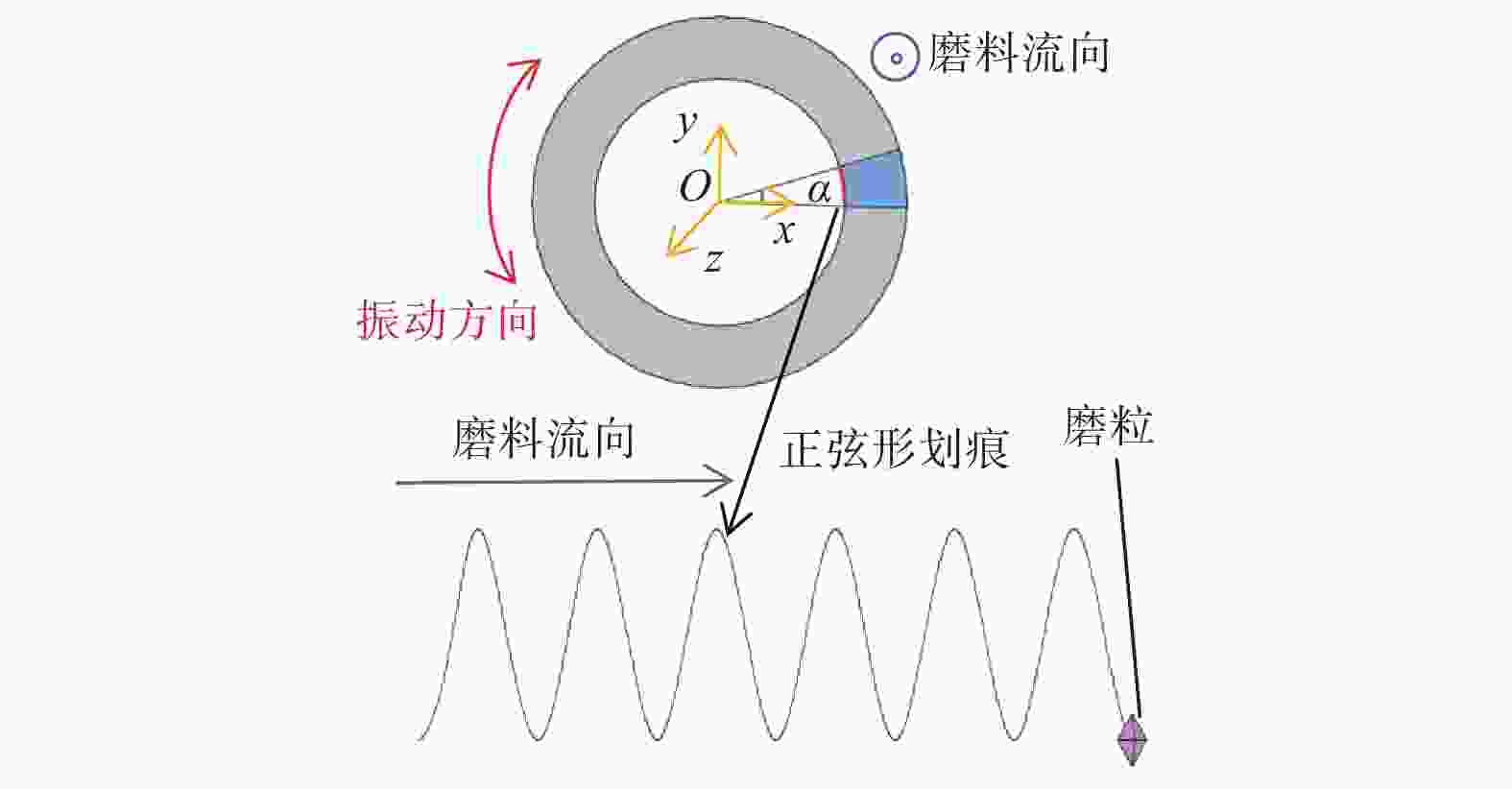

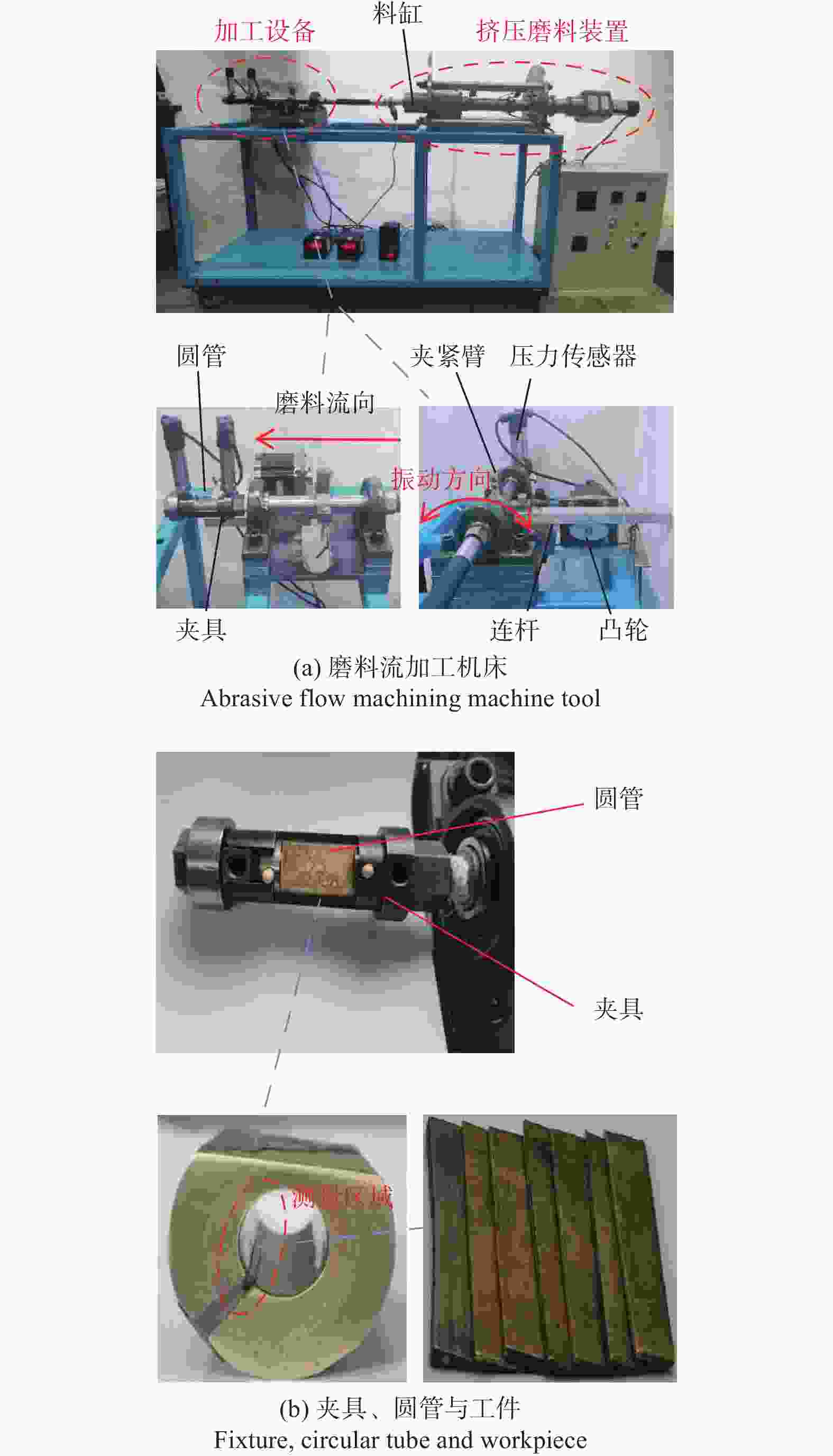

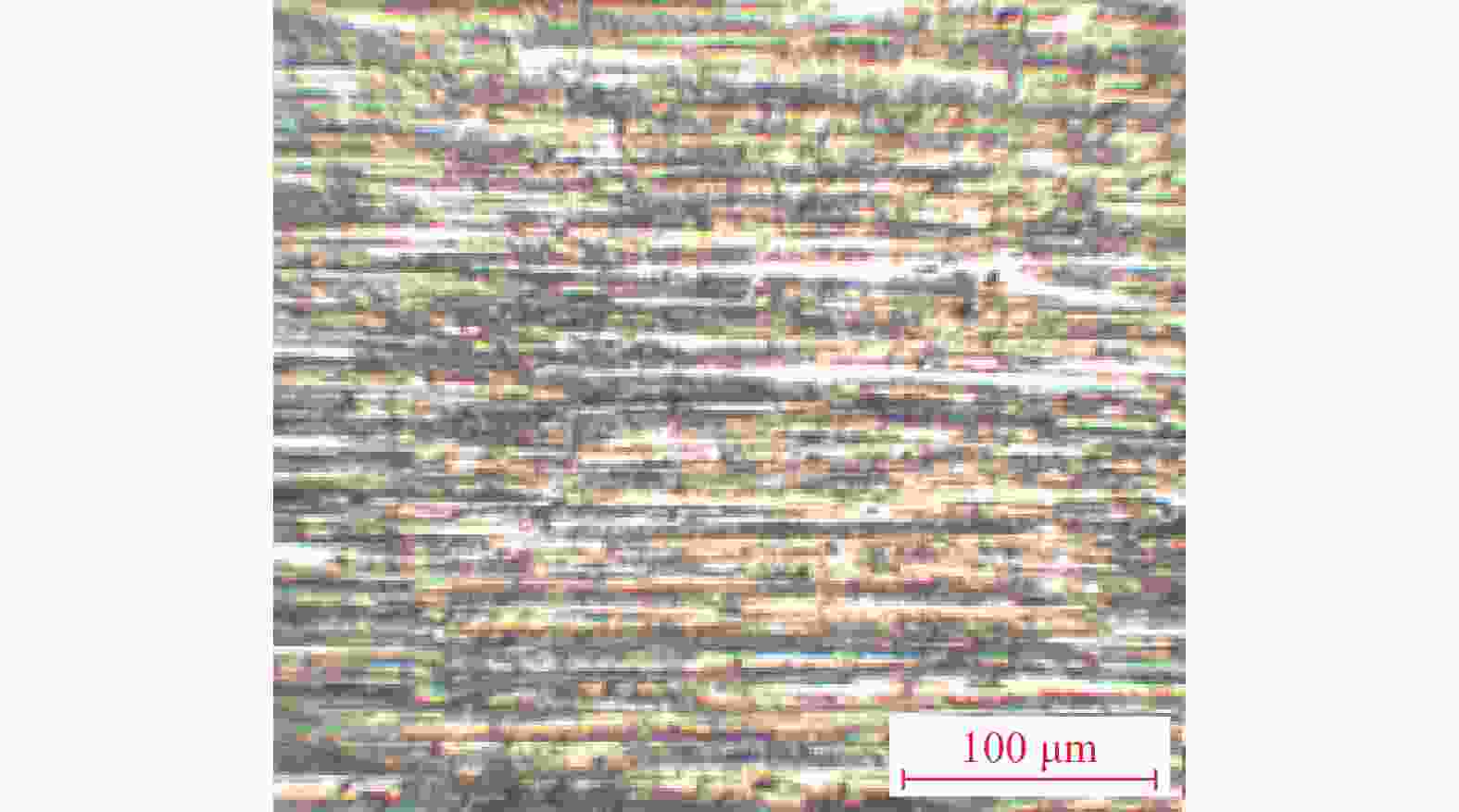

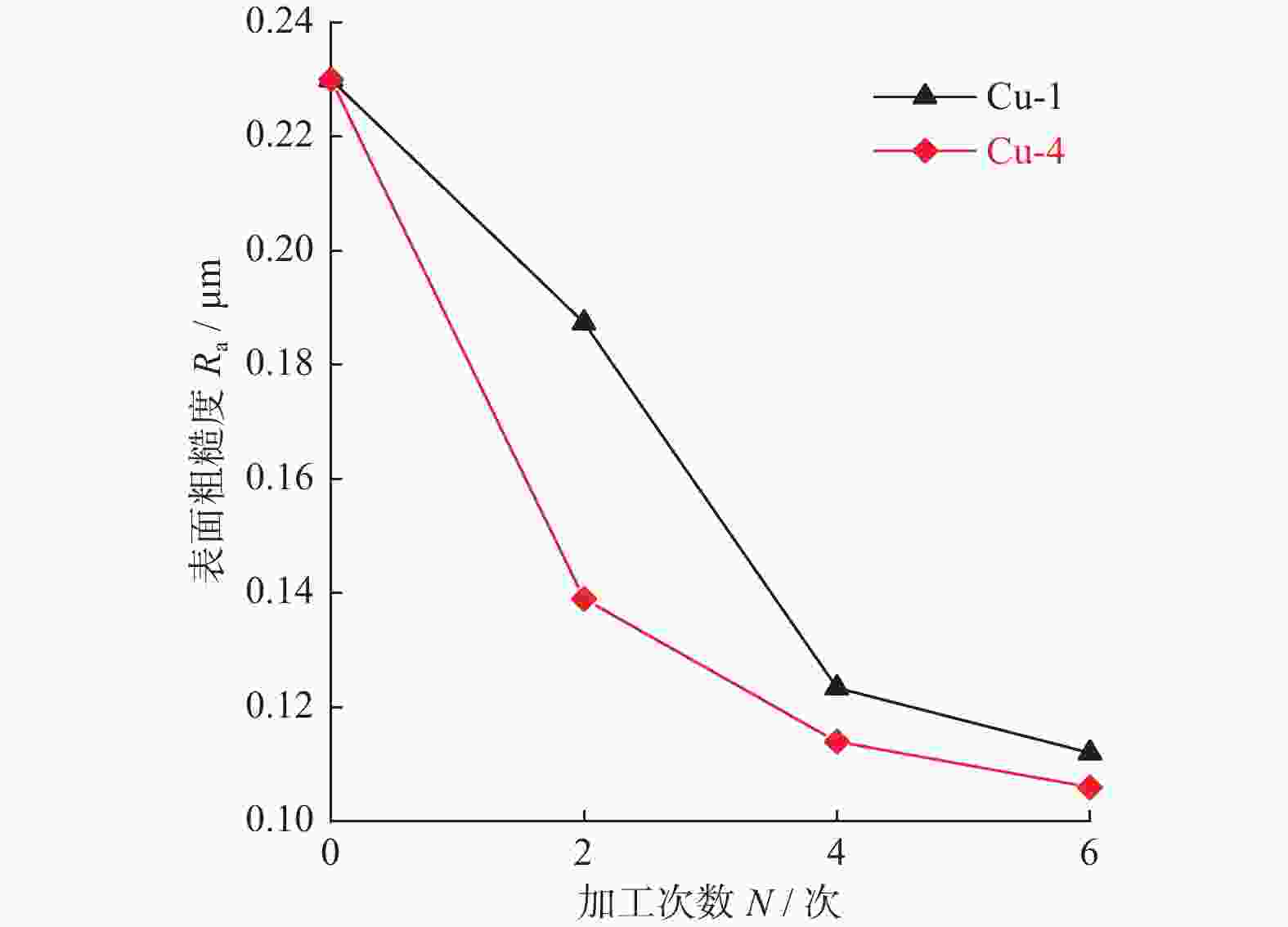

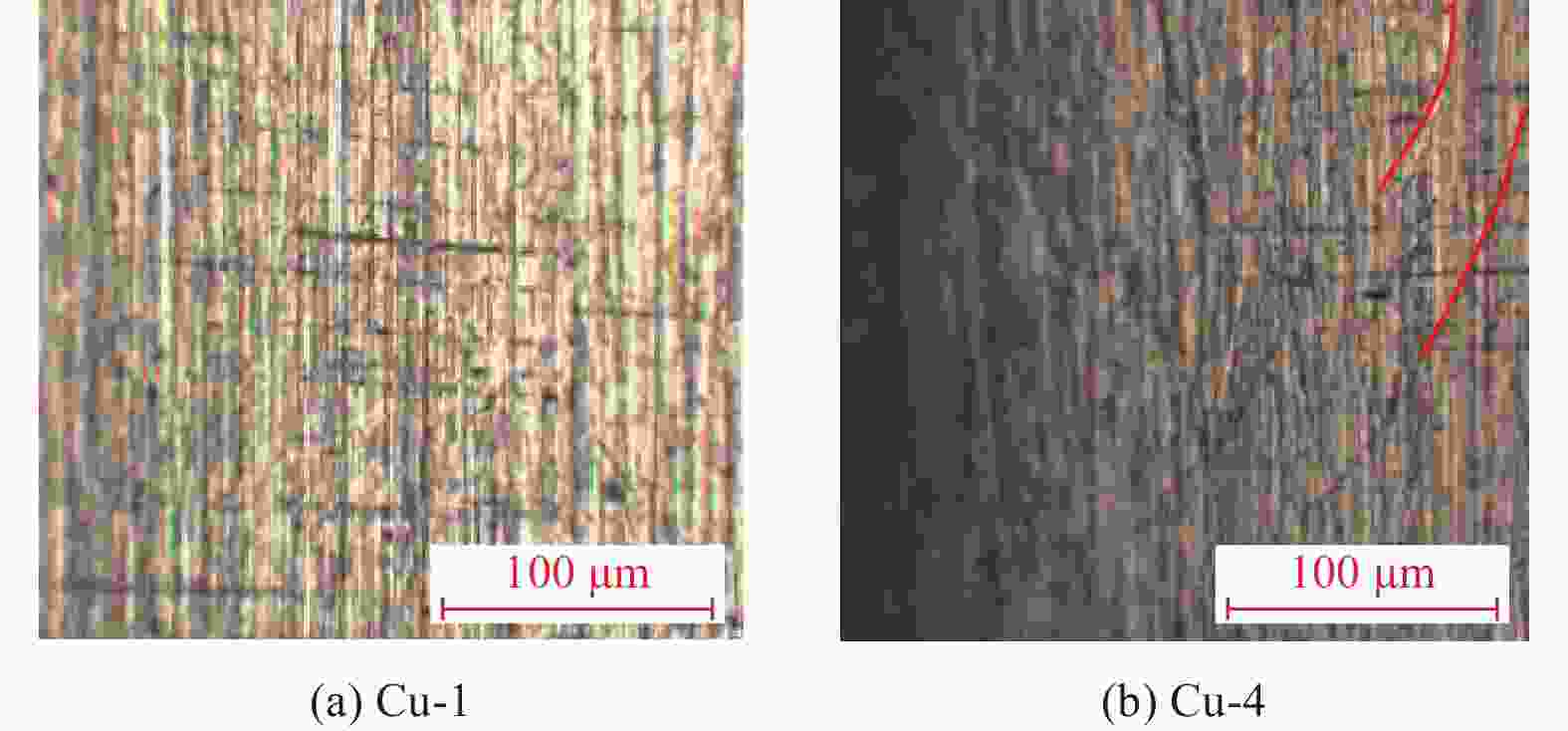

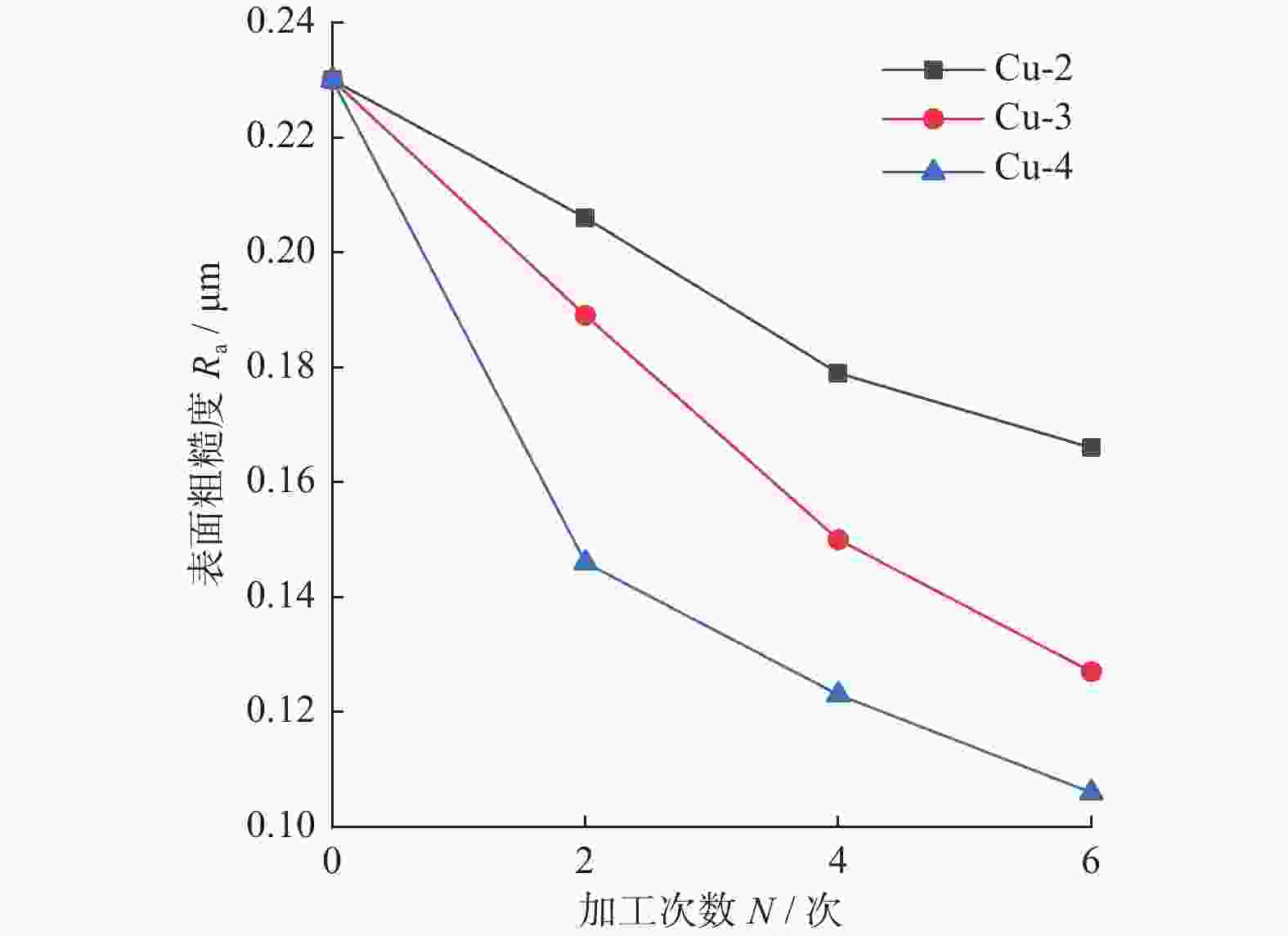

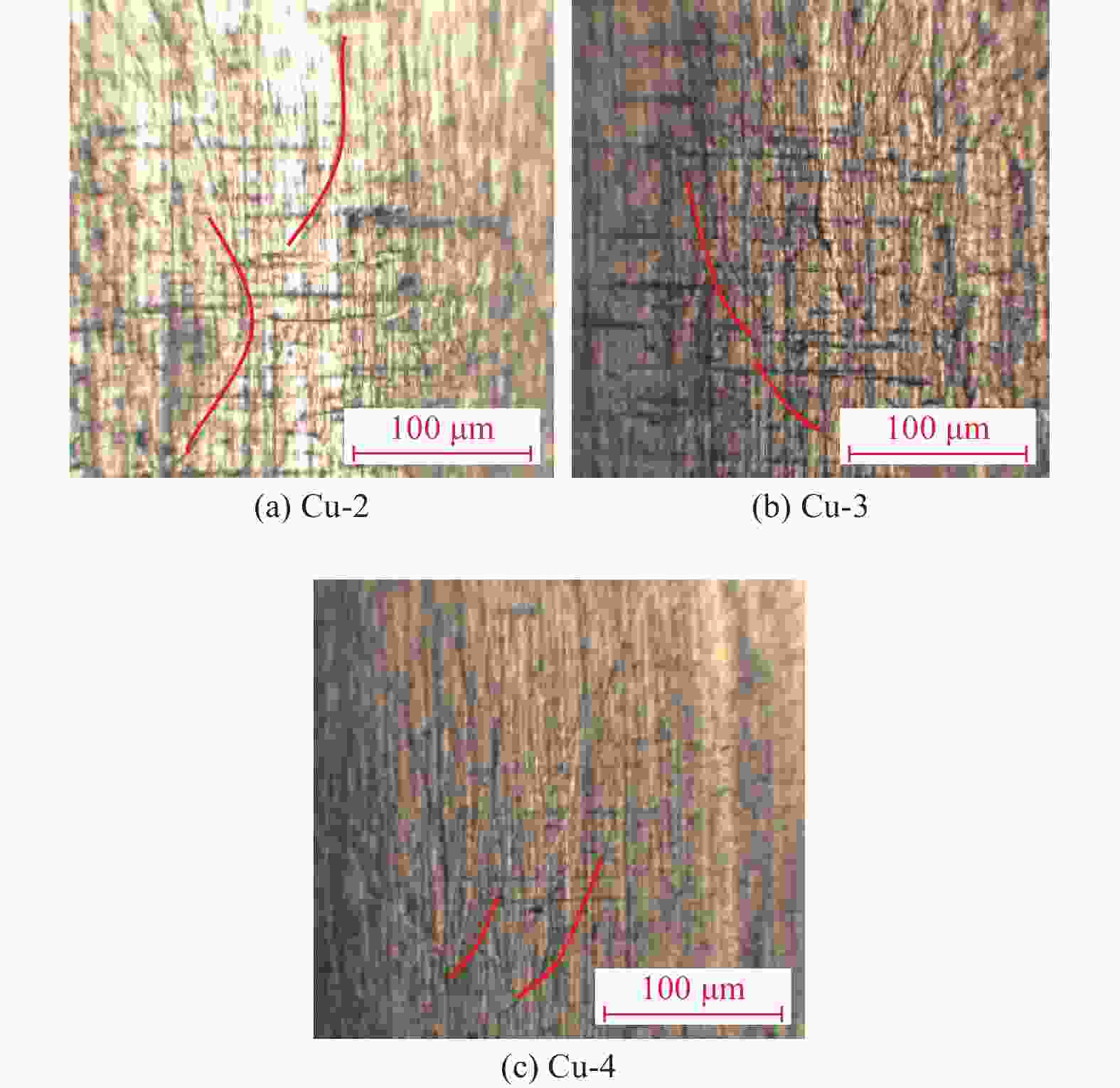

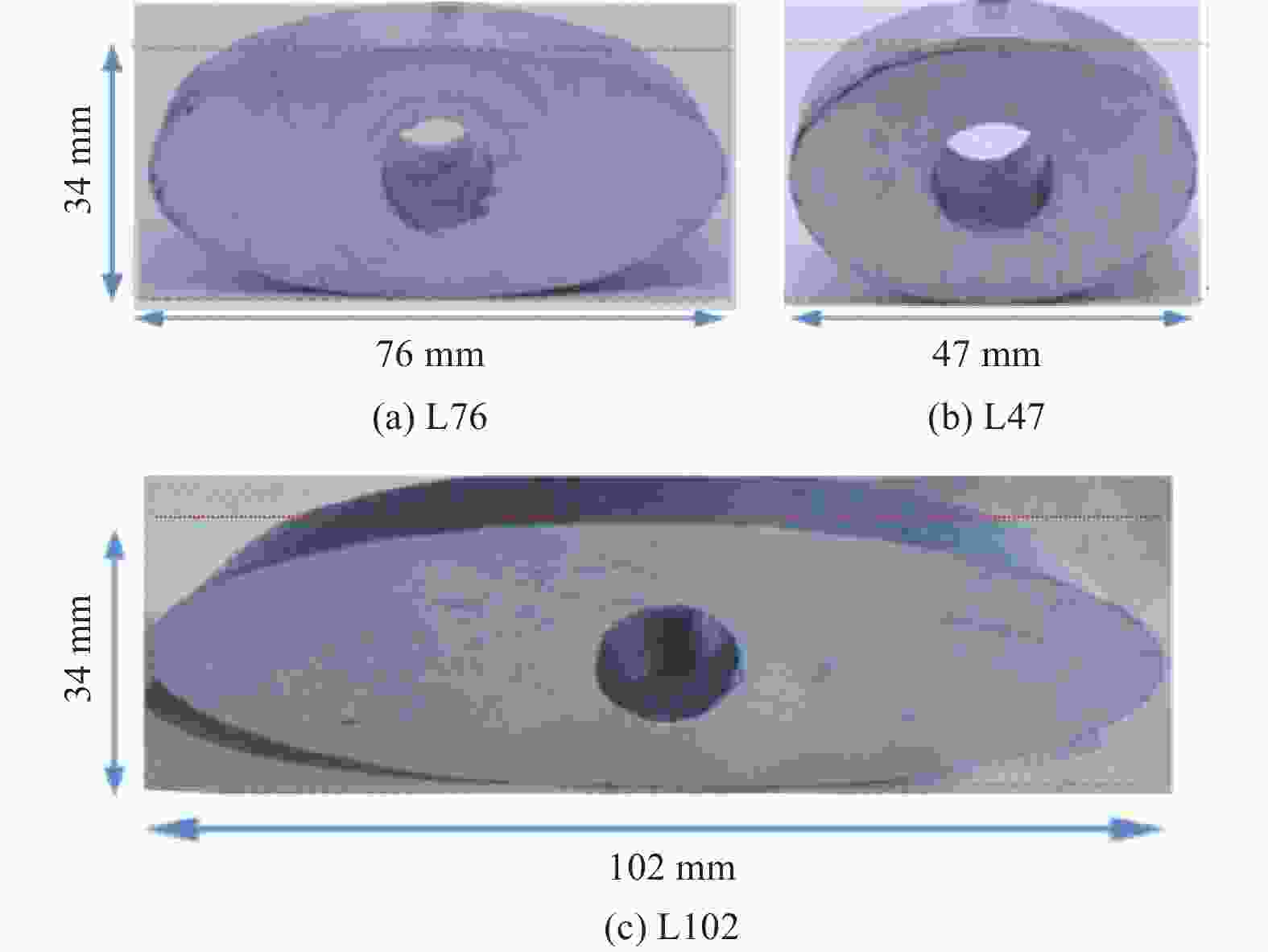

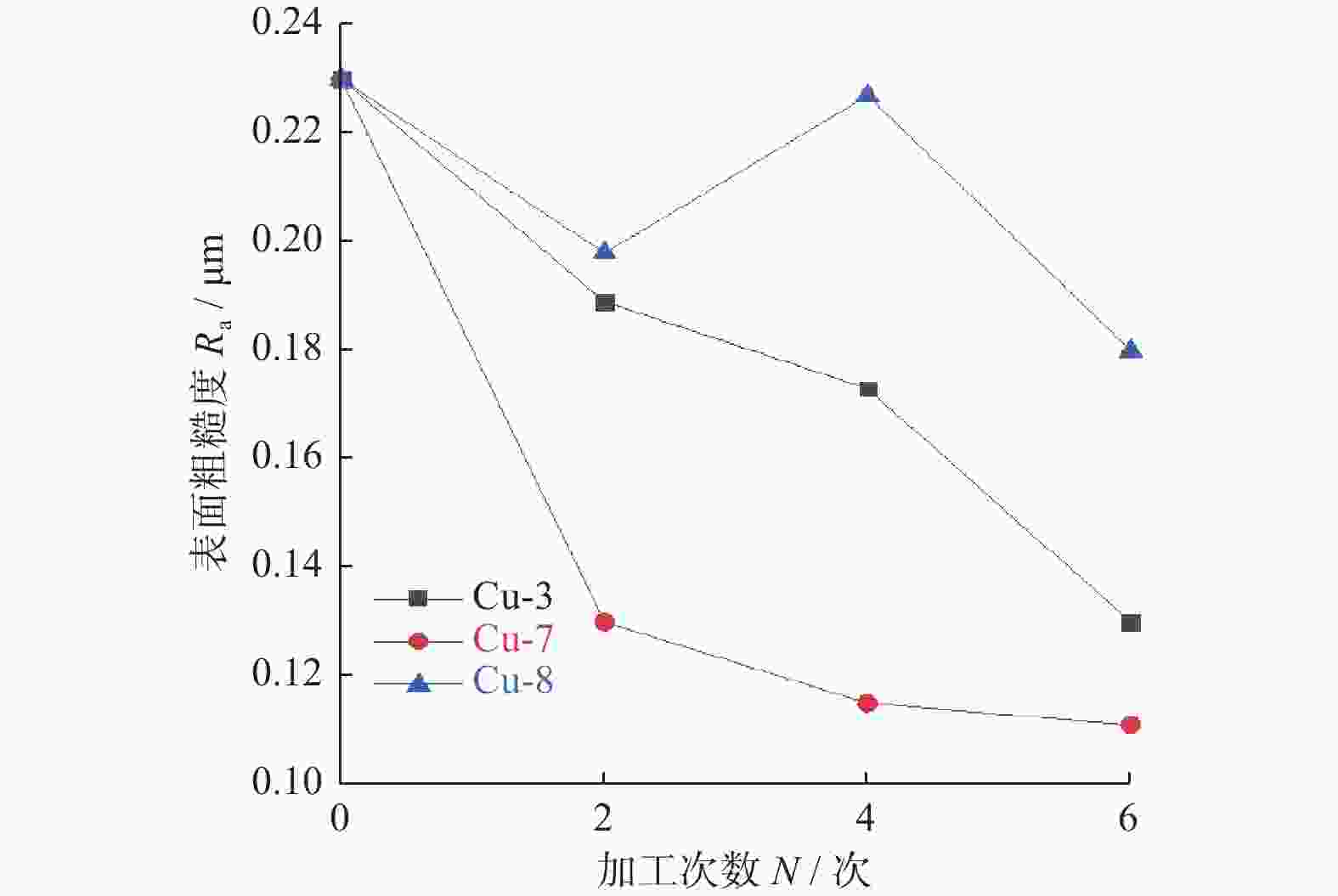

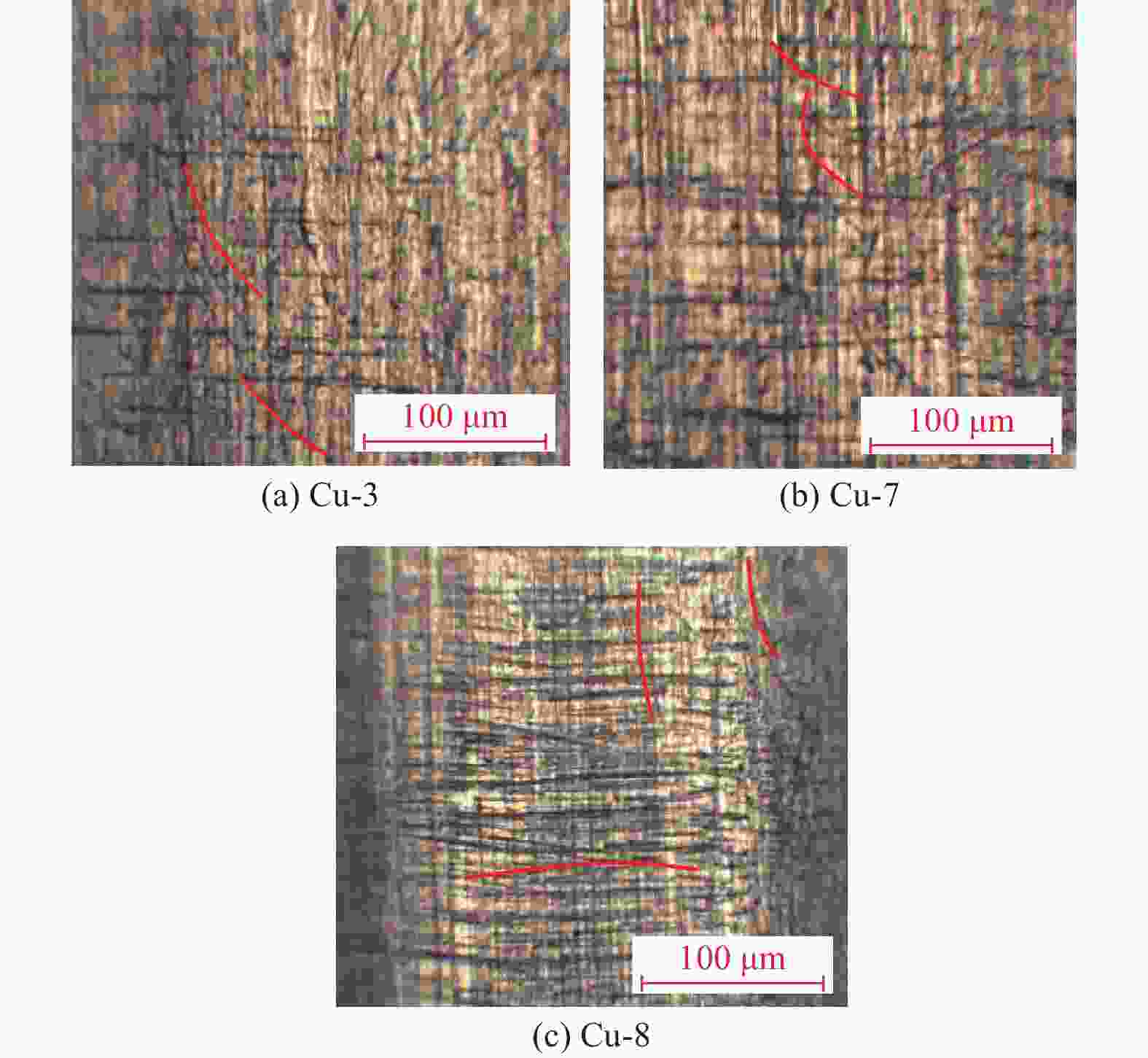

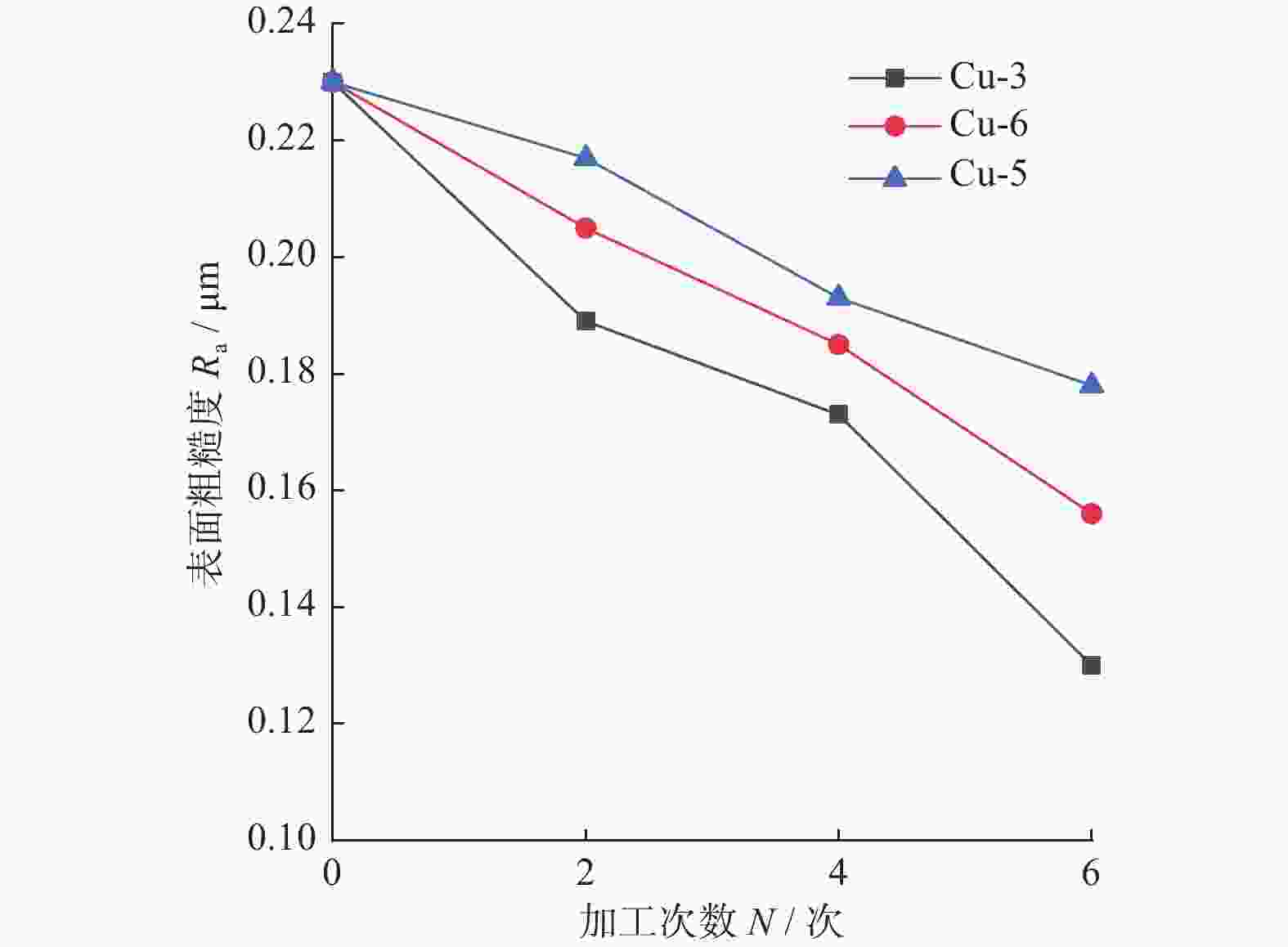

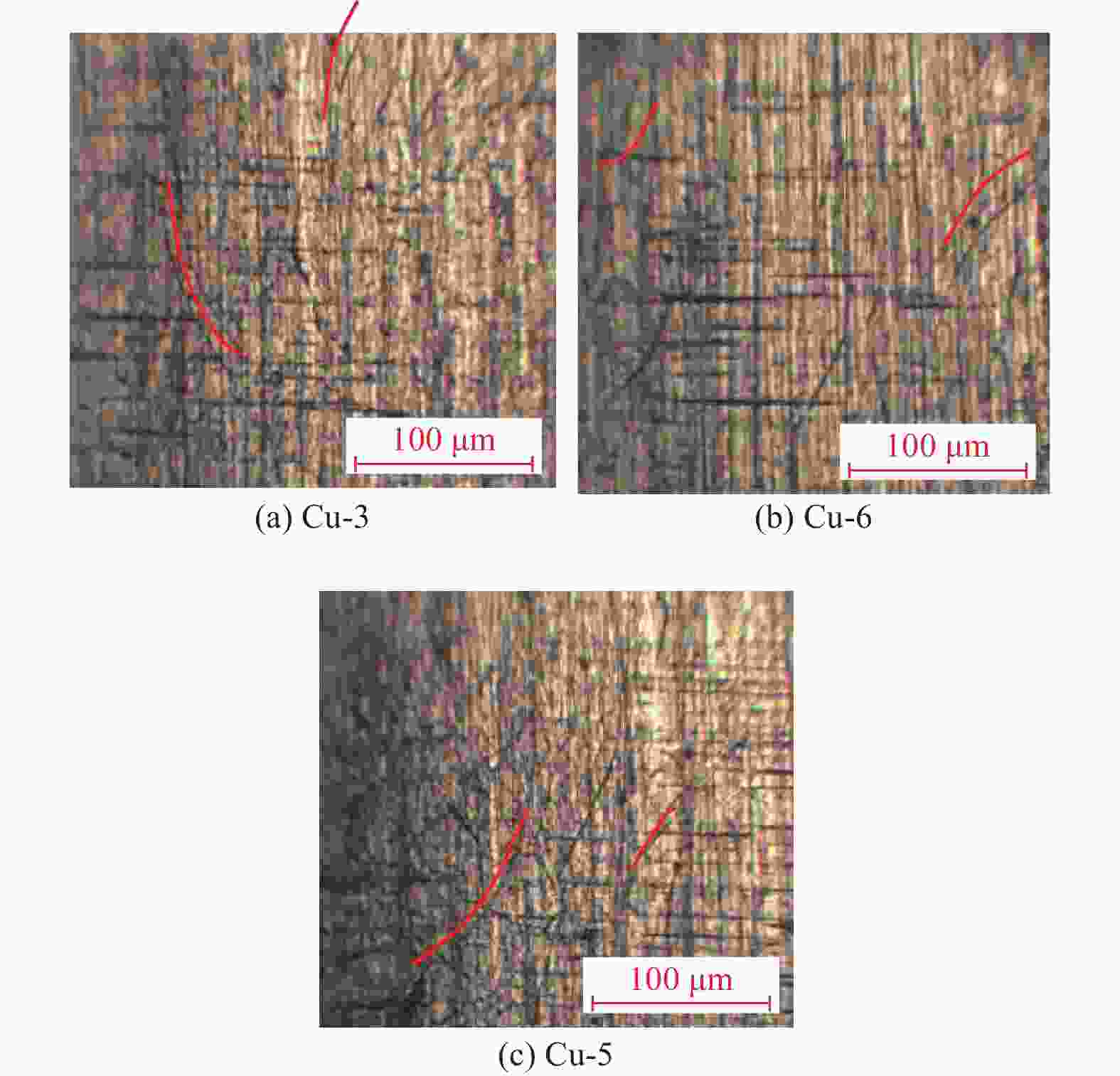

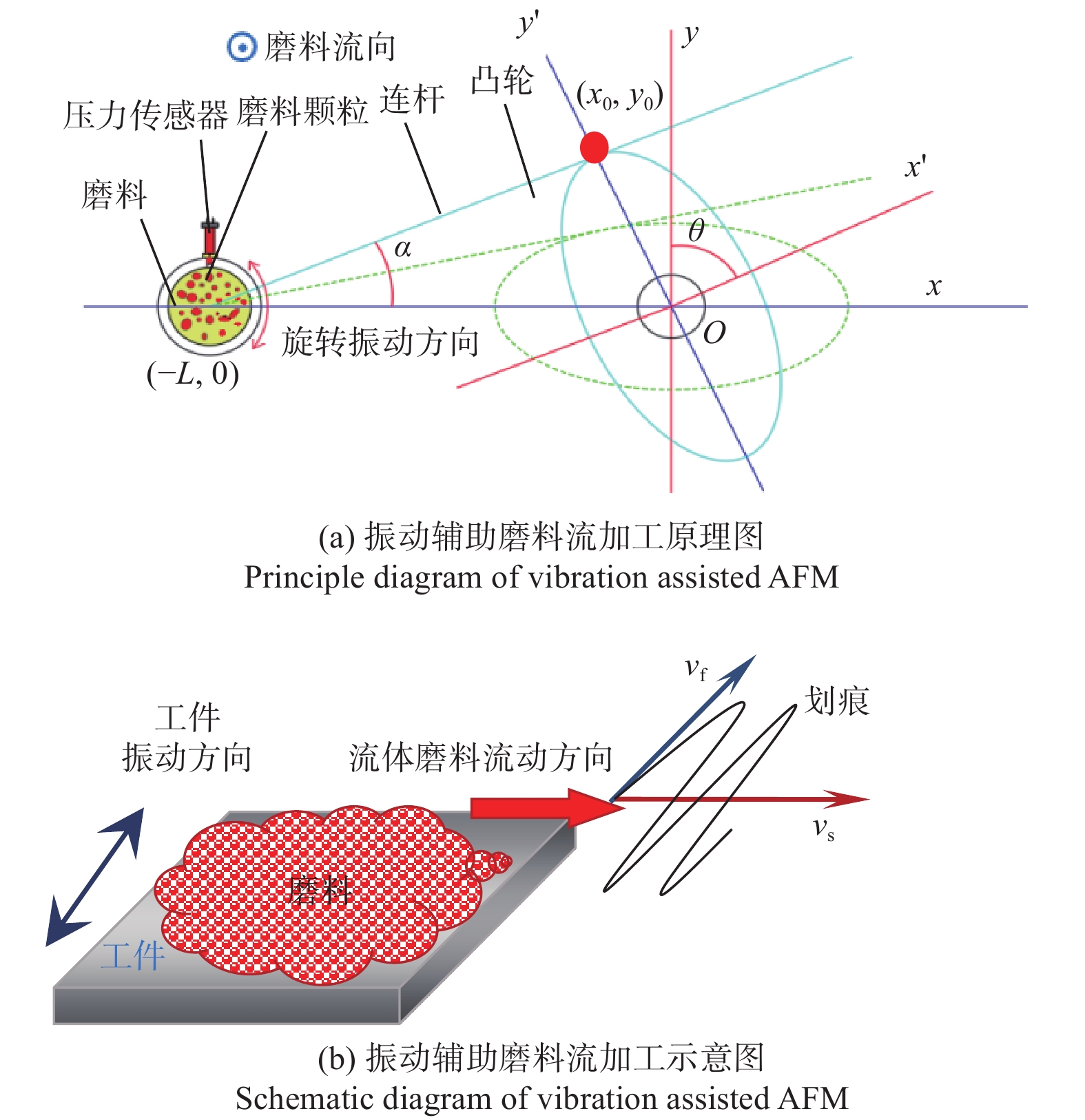

摘要: 传统磨料流加工技术在加工孔道内壁、形状复杂的工件时,工件表面在各个方向上的加工质量不均匀。在传统磨料流加工中加入振动辅助,使工件表面形成波浪形加工轨迹,以提高工件表面质量和材料去除效率。分析振动辅助加工原理和磨粒对工件表面的划痕作用,搭建振动辅助磨料流加工试验平台,研究磨料流速、振幅、频率对工件表面粗糙度与表面形貌的影响。结果表明:与传统磨料流加工相比,振动辅助磨料流加工使磨粒在工件表面的切削路径变长,形成交叉划痕,工件表面粗糙度降低;振动频率越高,磨粒与工件表面间的微切削长度越长,工件的表面粗糙度越低;磨料流速增大,磨粒对工件表面的切削效果增强,表面粗糙度下降的幅度更大。Abstract: Objectives: When the traditional abrasive flow machining (AFM) technology is used to process workpieces with complex shapes and inner walls of the tunnels, the machining quality of the workpiece surface tends to be uneven in each directions. To address this, the vibration assistance is added to traditional abrasive flow machining, forming a wavy machining track on the workpiece surface. This technique generates interwoven scratch textures, reduces the roughness value of the workpiece surface in all directions, and improves the surface quality and material removal efficiency converging the surface roughness. Methods: By rotating a cam to drive a connecting rod, vibration is induced in a round tube, altering the flow field distribution characteristics of the fluid abrasive and the mode of abrasive phase movement. This enables a new relative movement between the fluid abrasive and the workpiece surface. The principle of vibration-assisted machining and the scratching effect of abrasive particles on the workpiece surface were analyzed. At the same time, different frequencies and amplitudes were achieved by varying the motor speed and adjusting the long and short half-axes of the elliptical cam. A test platform for vibration-assisted abrasive flow machining was built to study the effects of abrasive flow rate, amplitude, and frequency on workpiece surface roughness and topography. Results: (1) After 2, 4, and 6 processing cycles without vibration, the surface roughness of the Cu-1 workpiece was reduced to 0.187, 0.123, and 0.112 μm, respectively. After 2, 4 and 6 processing cycles with vibration, the surface roughness of the Cu-4 workpiece decreased from an initial 0.230 μm to 0.139, 0.114, and 0.106 μm, respectively. The surface roughness of the workpiece polished with vibration was lower than that without vibration. At the same time, under non-vibration conditions, the transverse fringes of the original surface of Cu-1 after machining remained visible, although its surface roughness were significantly reduced. When Cu-4 was processed for 6 times under vibration condition, the transverse stripes on the original Cu-4 surface were almost completely removed, and some fine circular scratches appeared, resulting in a relatively ideal machining surface. (2) The cam speed directly corresponded to vibration frequency, higher cam speeds resulted in higher frequencies. When the Cu-2 workpiece was machined at a cam speed of 150 r/min, its surface roughness decreased slowly and steadily. At the cam speed of 225 r/min, the Cu-3 workpiece was experienced a longer micro-cutting length between abrasive particles and the workpiece, resulting in lower surface roughness compared to those of Cu-2. When Cu-4, polished at a higher cam speed, these appeared a significant reduction in surface roughness, decreasing to 0.166, 0.130. and 0.106 μm in the order of Cu-2 > Cu-3 > Cu-4. Higher cam speeds produced more scratches on the workpiece surface under the same flow rate, leading to longer arc scratches and smaller curvature radii. (3) When Cu-3, Cu-7 and Cu-8 workpieces were processed for the same times with three different cam sizes, the surface roughness of Cu-3 slowly reduced to 0.130 μm with L76 cam. The Cu-7 was machined with L47 cam at lower amplitude and relatively stable vibration, had lower surface roughness of 0.111 μm, which was lower than that of Cu-3. The Cu-8 was machined with L102 cam, the connecting rod swings greatly, the vibration was extremely unstable, and the surface roughness of the workpiece changed little. The L76 cam had the larger and more intense amplitude on Cu-3, and the curvature radius of the scratch formed by the machining was larger, and the direction angle of the scratches formed by the abrasive particles on the Cu-3 surface was closer to the original direction angle of scratches of the workpiece. The vibration amplitude of the L47 cam was small, and the scratch amplitude on the Cu-7 workpiece was smaller, and the cutting condition was more stable and the surface roughness was lower. However, the machining of Cu-8 by L102 cam destroyed the surface morphology of the workpiece. (4) The abrasive flow rates for the Cu-3, Cu-6 and Cu-5 workpieces were 38, 28, and 19 mm/s, respectively. After processing, the surface roughness were 0.130, 0.156, and 0.178μm, respectively. Under the same vibration machining conditions, the higher the abrasive flow rate, the lower the workpiece surface roughness, and the relationship between the surface roughness of each workpiece after machining was Cu-5 > Cu-6 >Cu-3. Moreover, there were scratches on the workpiece surface with a certain angle from the original scratches, and the relationship between the curvature radius of the scratch on the surface of the workpiece was Cu-3 > Cu-6 > Cu-5. Conclusions: Compared with traditional abrasive flow machining, vibration-assisted abrasive flow machining extends the cutting path of abrasive particles on the workpiece surface, forming cross scratches and reducing the surface roughness of the workpiece. The higher the vibration frequency, the longer the micro-cutting length between abrasive particles and the workpiece surface, the lower the surface roughness of the workpiece. With the increase of abrasive flow rate, the cutting effect of the abrasive particles on the workpiece surface is enhanced, leading to greater reductions in surface roughness.

-

表 1 磨料流加工试验方案

Table 1. Experimental scheme of abrasive flow machining

方案编号 凸轮规格 凸轮转速

n / (r·min−1)磨料流速

v / (mm·s−1)工件编号 加工次数 是否振动 加工前表面

粗糙度Ra /μm1 L76 0 38 Cu-1 6 否 0.230 2 L76 150 38 Cu-2 6 是 0.230 3 L76 225 38 Cu-3 6 是 0.230 4 L76 300 38 Cu-4 6 是 0.230 5 L76 225 19 Cu-5 6 是 0.230 6 L76 225 28 Cu-6 6 是 0.230 7 L47 225 38 Cu-7 6 是 0.230 8 L102 225 38 Cu-8 6 是 0.230 -

[1] SWAM S, HARISH K, SANTOSH K, et al. A systematic review on recent advancements in abrasive flow machining (AFM) [J]. Materials today:Proceedings,2022,56:60-96. [2] JONES A R, HULLl J B. Ultrasonic flow polishing [J]. Ultrasonics,1998,36(1/2/3/4/5):97-101. [3] LIU D F, YAN R M, CHEN T. Material removal model of ultrasonic elliptical vibration-assisted chemical mechanical polishing for hard and brittle materials [J]. The International Journal of Advanced Manufacturing Technology,2017,92(1//2/3/4):81-99. [4] GUDIPADU V, SHARMA A K, SINGH N. Simulation of mediabehaviour in vibration assisted abrasive flow machining [J]. Simulation Modelling Practice & Theory,2015,51:1-13. [5] 李道朋, 傅波, 庄文敏. 换能器阵列型超声抛光机理及声场仿真和实验研究 [J]. 西安交通大学学报,2020,54(2):24-34.LI Daopeng, FU Bo, ZHUANG Wenmin. Ultrasonic polishing mechanism and simulative and experimental sound field researches on transducer array [J]. Journal of Xi'an Jiaotong University,2020,54(2):24-34. [6] VENKATESH G, SHARMA A K, KUMAR P. On ultrasonic assisted abrasive flow finishing of bevel gears [J]. International Journal of Machine Tools and Manufacture,2015,89:29-38. doi: 10.1016/j.ijmachtools.2014.10.014 [7] 张宇超, 董志国, 雷鸿博, 等. 超声振动辅助软性磨料流喷孔光整加工研究 [J]. 组合机床与自动化加工技术,2021(7):165-169. doi: 10.13462/j.cnki.mmtamt.2021.07.038ZHANG Yuchao, DONG Zhiguo, LEI Hongbo, et al. Study on ultrasonic vibration-assisted soft abrasive flow machining of nozzle hole [J]. Modular Machine Tool & Automatic Manufacturing Technique,2021(7):165-169. doi: 10.13462/j.cnki.mmtamt.2021.07.038 [8] 张忠伟. 超声振动辅助微细磨料水射流切割技术研究[D]. 济南: 山东大学, 2014.ZHANG Zhongwei. Study on ultrasonic vibration-assisted micro abrasive waterjet cutting [D]. Jinan: Shandong University, 2014. [9] 吕哲. 超声振动辅助磨料水射流抛光冲蚀机理与工艺技术研究 [D]. 济南: 山东大学, 2015.LV Zhe. A study of the erosion mechanisms and processing technology for ultrasonic vibration assisted abrasive waterjet polishing [D]. Jinan: Shandong University, 2015. [10] 张宇超. 振动辅助磨料流圆管精密抛光机理与工艺研究 [D] . 太原: 太原理工大学, 2022.ZHANG Yuchao. Research on the mechanism and technology of vibration-assisted abrasive flow for precision polishing of circular tubes [D]. Taiyuan: Taiyuan University of Technology, 2022. [11] SCHVLER M, DADGAR M, HERRIG T, et al. Influence of abrasive properties on erosion in waterjet machining [J]. Procedia CIRP,2021,102:1-17. doi: 10.1016/j.procir.2021.09.001 [12] WANG T, CAO X, WANG C, et al. Numerical simulation of herringbone gear abrasive flow machining [J]. Vibroengineering Procedia,2022,47:110-123. [13] 段泽斌, 轧刚, 董志国, 等. 可控倒锥角微孔磨料流加工成形研究 [J]. 机械设计与制造, 2018(3): 116-119.DUAN Zebin, YA Gang, DONG Zhiguo, et al. Controlled abrasive flow machining forming inverted cone angle microporous [J]. Machinery Design & Manufacture, 2018(3): 116-119. [14] 王昌盛. 微晶陶瓷磨料砂轮磨削20CrMnTi齿轮时的划擦机理研究 [D]. 济南: 山东大学, 2017.WANG Changsheng. Study on scratch mechanism of gear grinding on 20CrMnTi steel with microcrystalline ceramic abrasive wheel [D]. Jinan: Shandong University, 2017. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS