Simulation experimental on material removal mechanism of ITO conductive glass by single abrasive

-

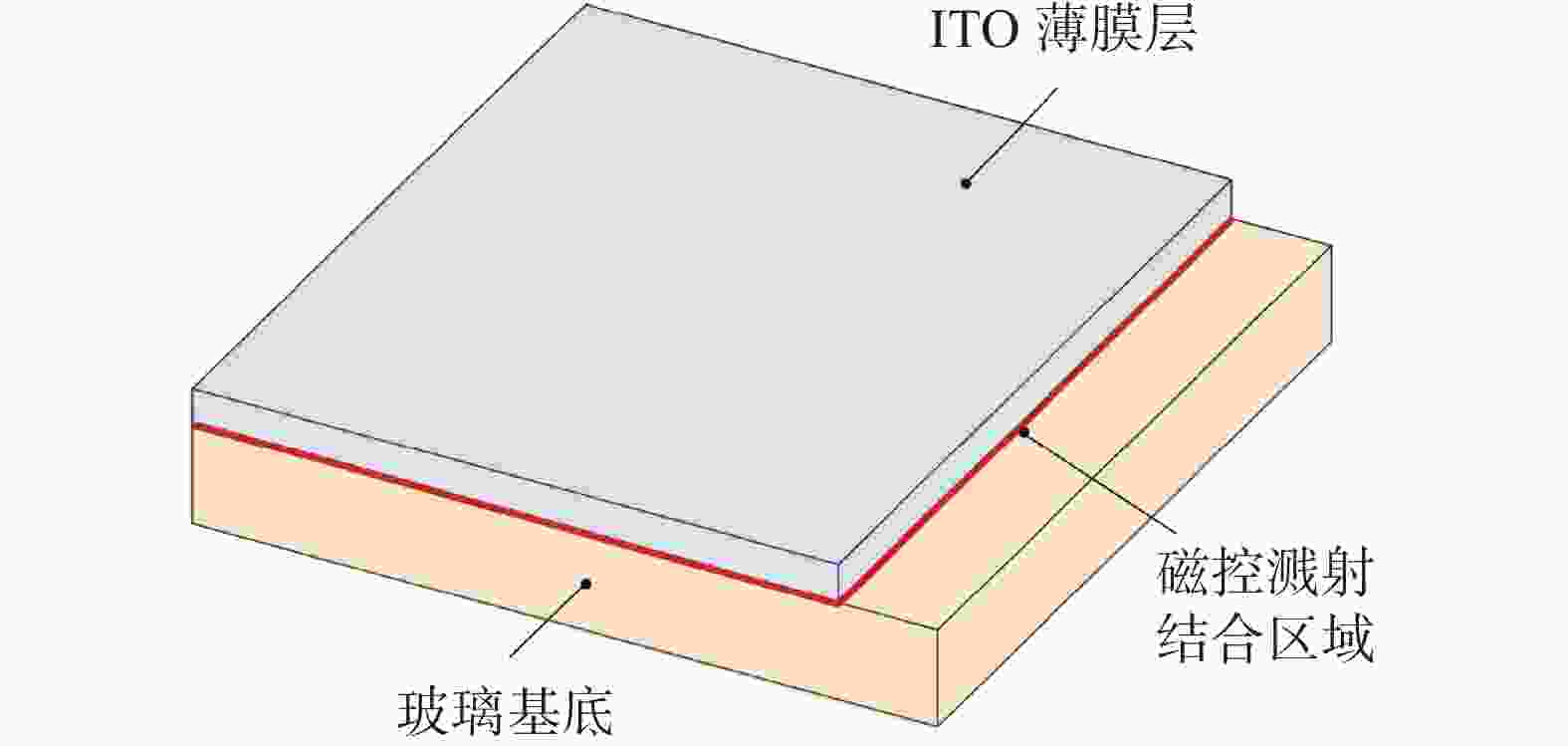

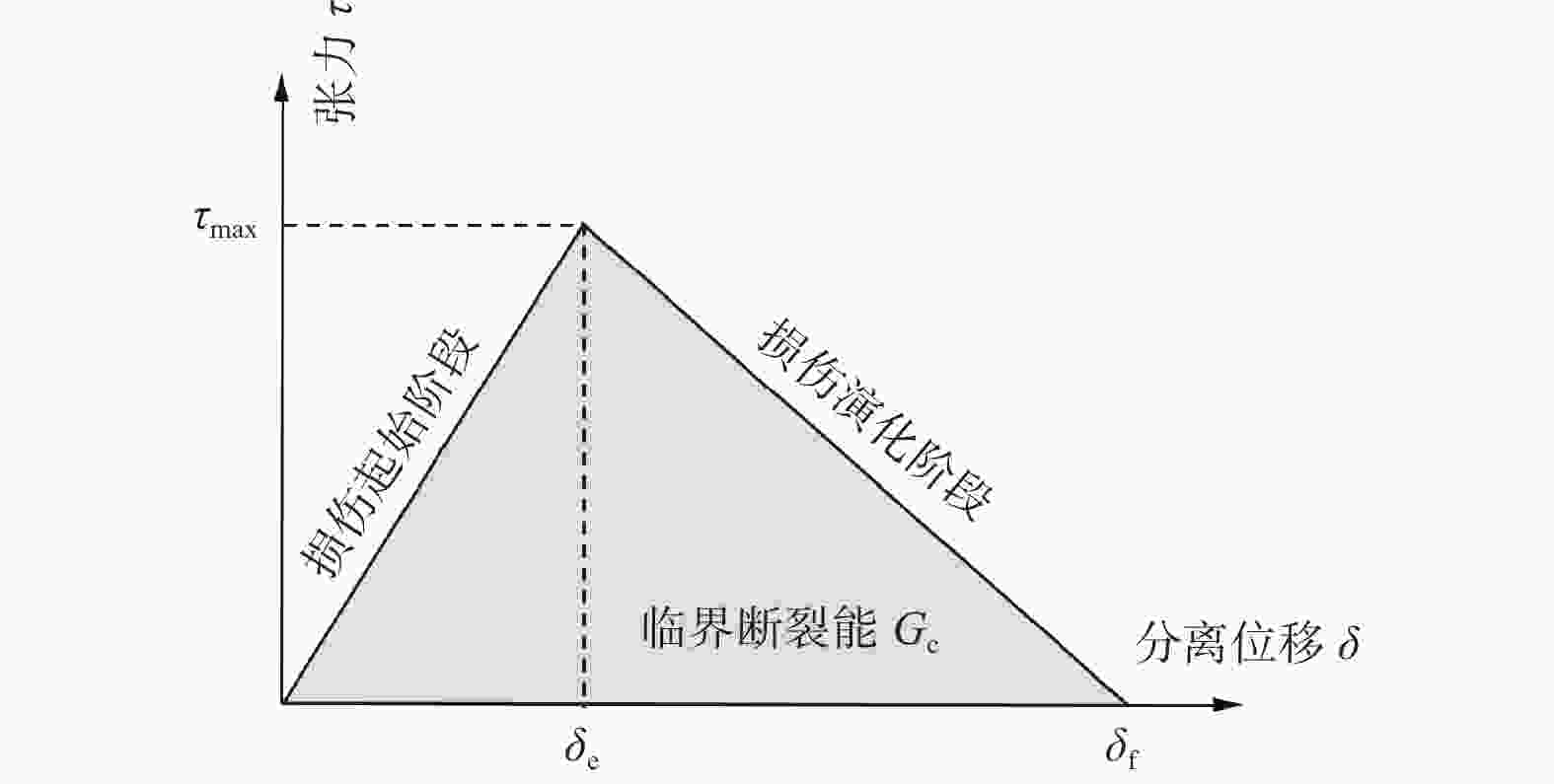

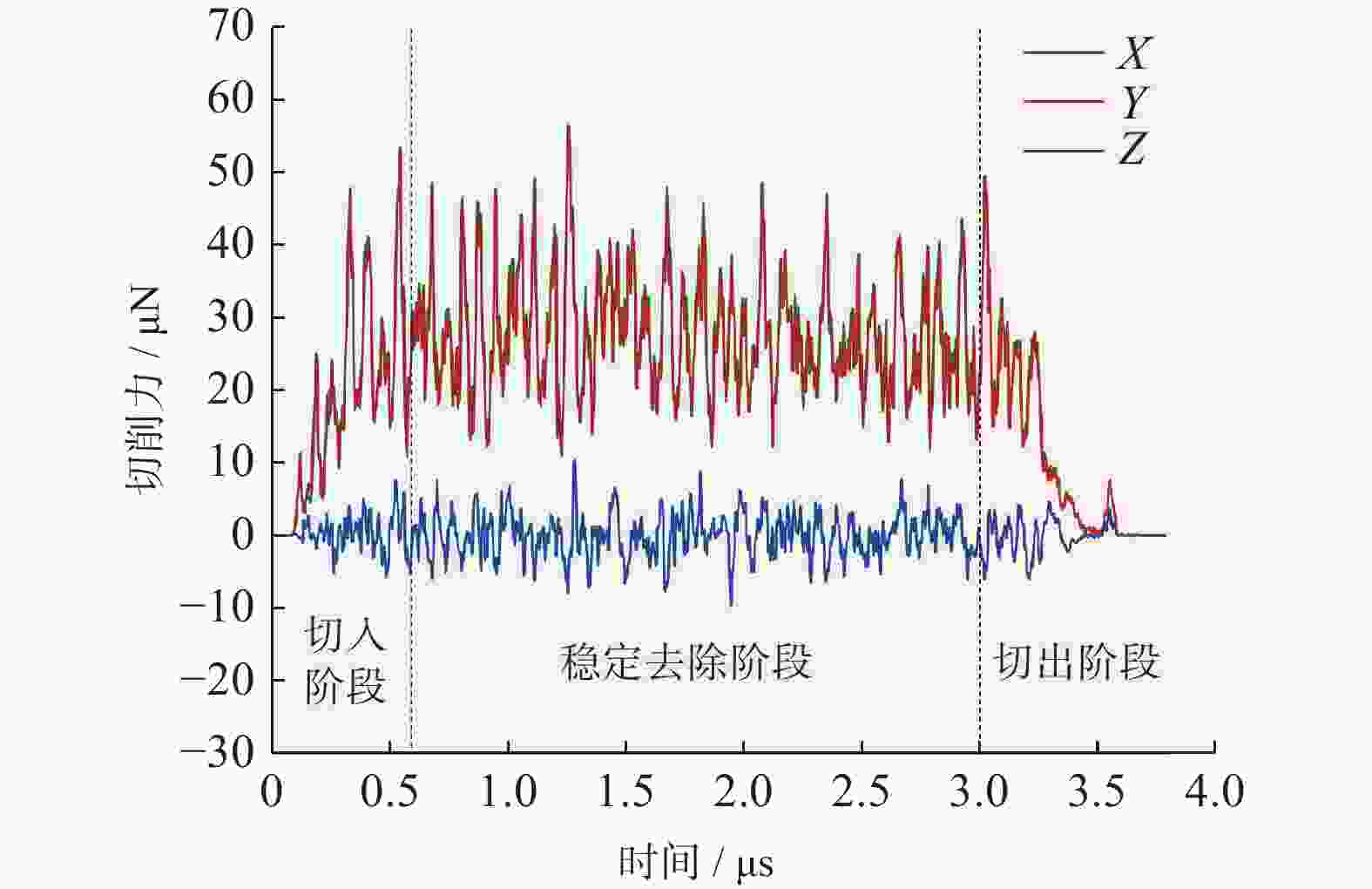

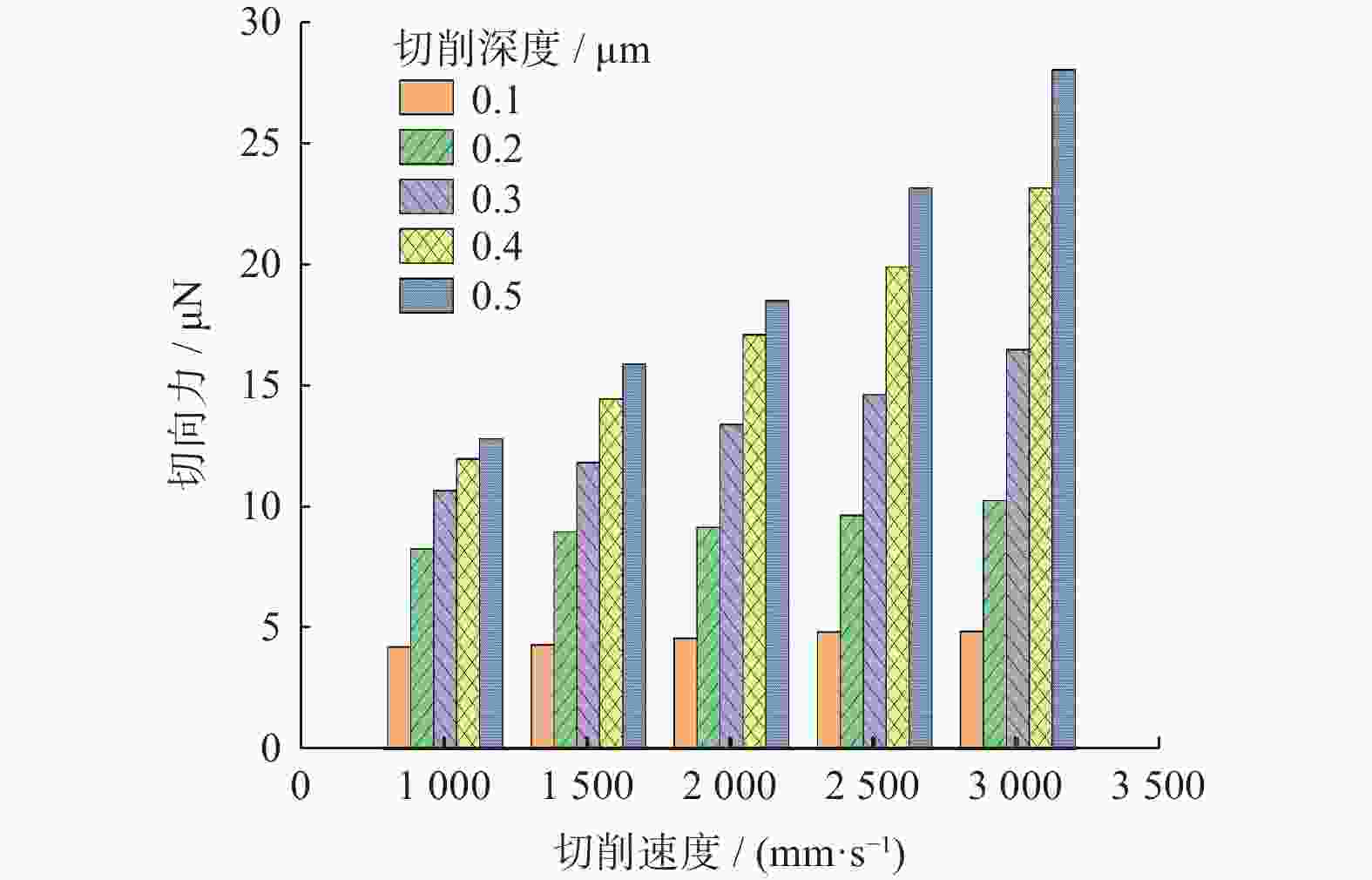

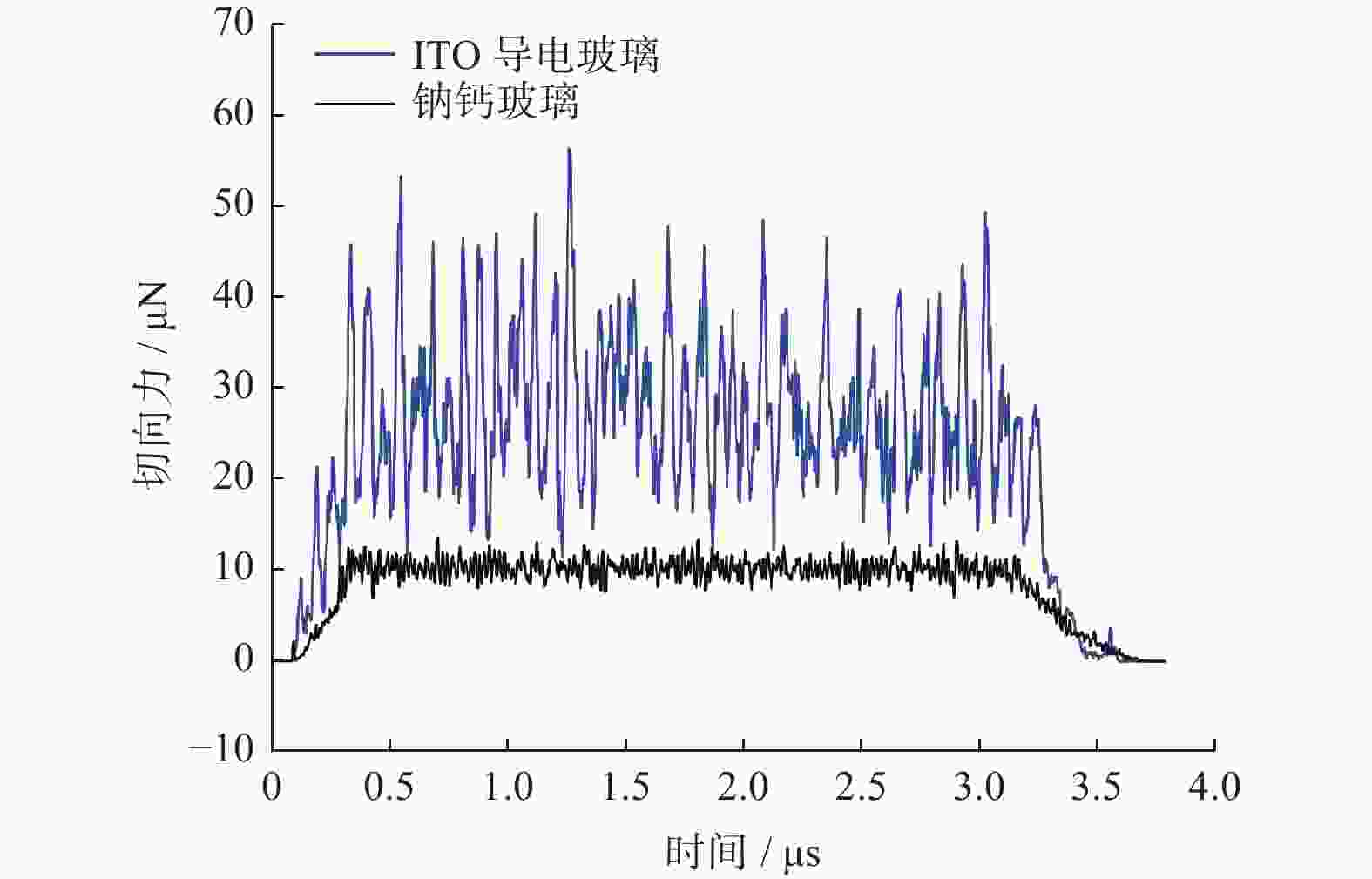

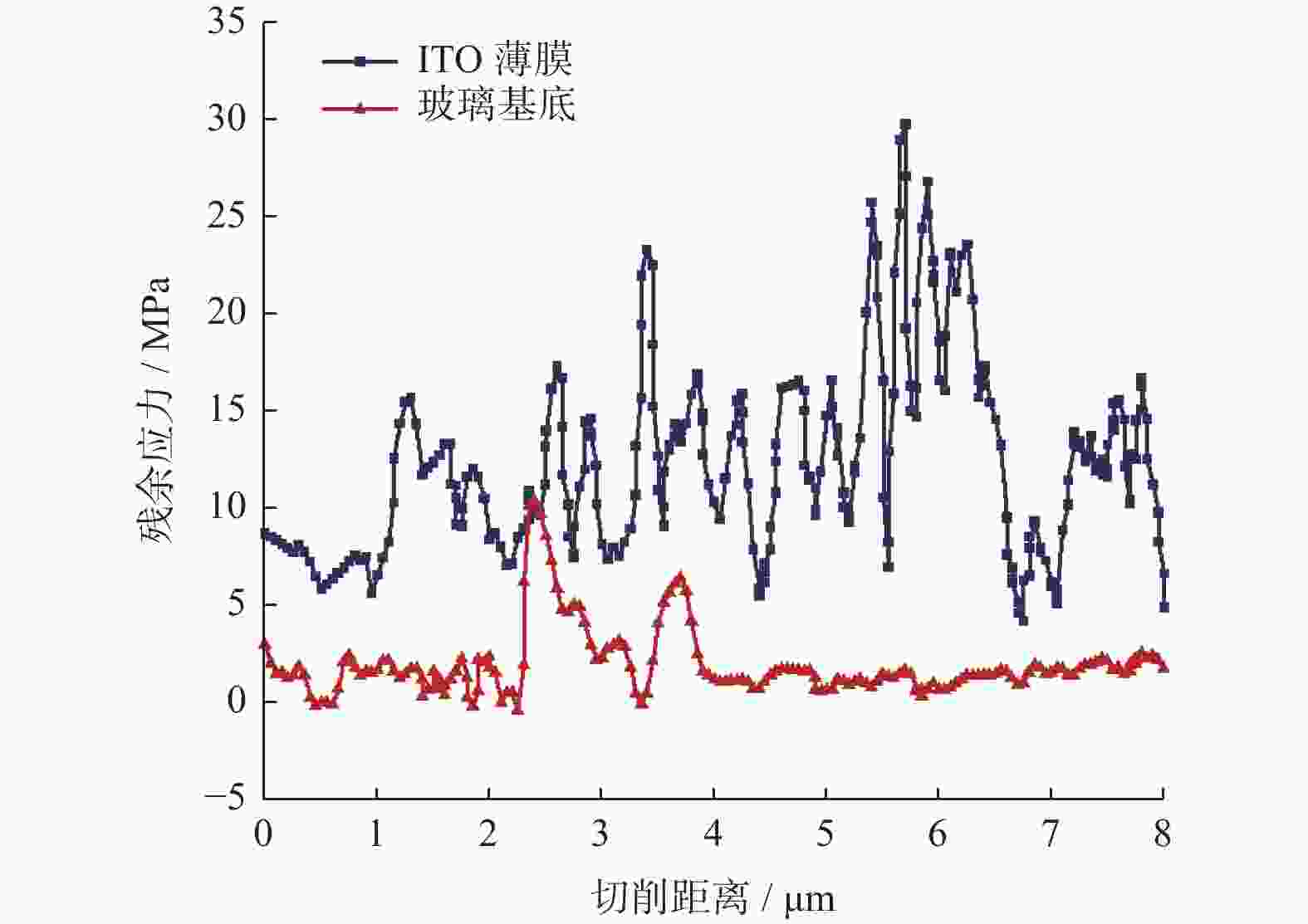

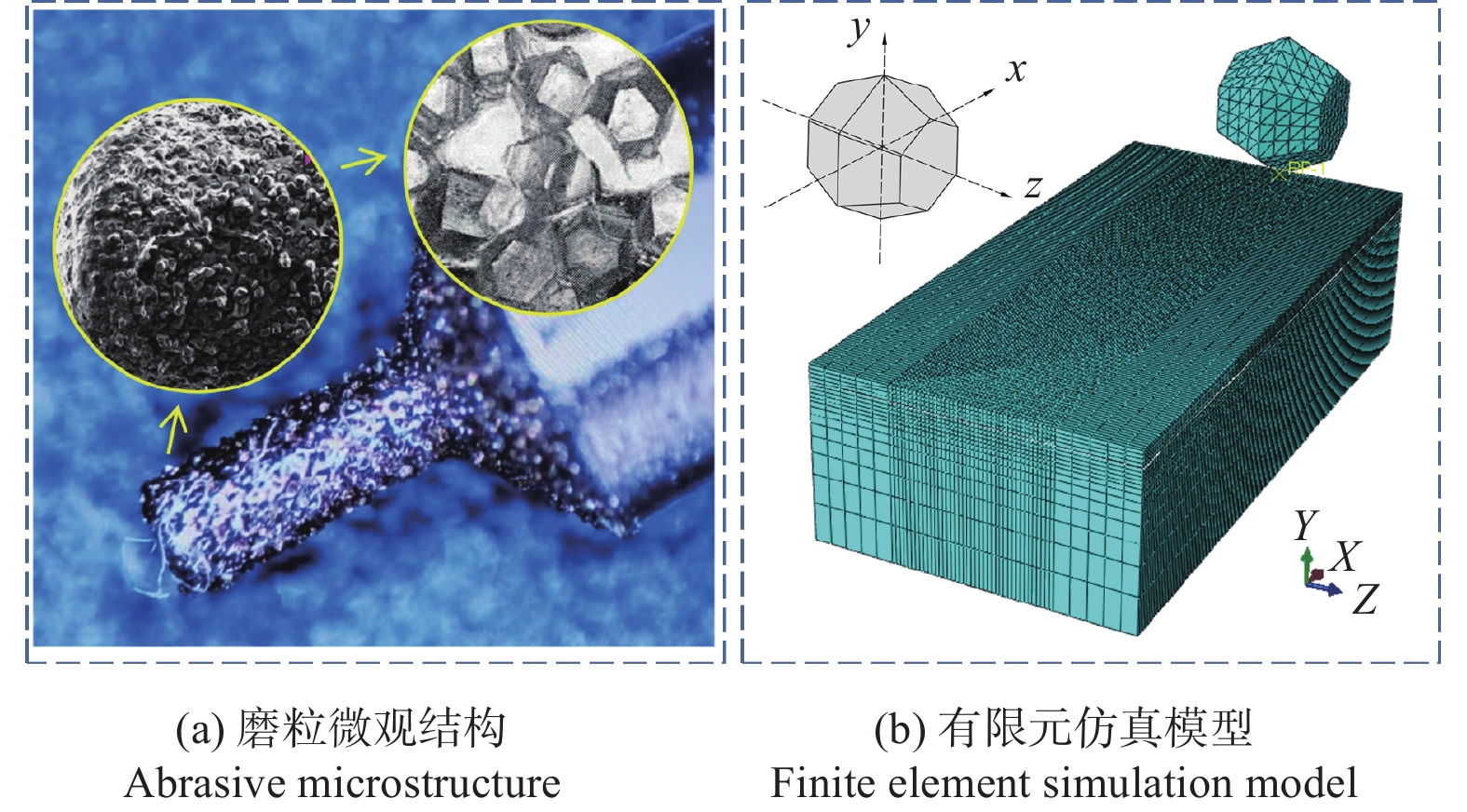

摘要: 为研究氧化铟锡(indium tin oxide,ITO)导电玻璃材料的去除机理,采用单磨粒对材料进行切削仿真,建立了ITO导电玻璃的材料模型,根据加工表面形貌、应力和切削力情况分析了材料去除机理,之后研究了切削参数对切削力和残余应力的影响,并与钠钙玻璃进行对比分析。结果表明:在磨粒的切削过程中,材料的去除受ITO薄膜层、玻璃基底和内聚力接触行为的共同影响,会产生分层、通道开裂和层间断裂等失效形式;随着磨粒的进给,切削力在一定范围内波动,且呈现上升、稳定、降低的变化,同时磨粒的切削力与切削速度和切削深度呈正相关;薄膜上残余应力相比玻璃基底,数值更大且波动更剧烈;当切削深度接近ITO薄膜厚度时,薄膜的存在对磨粒切削行为的影响显著。Abstract: To study the removal mechanism of ITO conductive glass materials, this paper uses a single abrasive particle to simulate the cutting process of the materials and establishes a material model for ITO glass. Based on the analysis of processed surface morphology, stress, and cutting force, the material removal mechanism of ITO glass is examined. Additionally, the influence of cutting parameters on cutting force and residual stress is studied and compared with soda-lime glass. The results show that during the cutting process of abrasive particle, material removal is influenced by the ITO film layer, the glass substrate, and cohesive contact behavior, leading to failure forms such as delamination, channel cracking, and interlayer fracture. With the feed of the abrasive particle, the cutting force fluctuates within a certain range, exhibiting a pattern of growth, stability, and decrease. The cutting force of the abrasive particle is positively correlated with both cutting speed and cutting depth. Compared to the glass substrate, the residual stress on the ITO film is larger and fluctuates more dramatically. The presence of the ITO film significantly influences cutting behavior, especially when the cutting depth approaches the thickness of the ITO film.

-

Key words:

- ITO conductive glass /

- material removal mechanism /

- cutting force /

- residual stress

-

表 1 玻璃基底JH-2模型参数

Table 1. JH-2 model parameters for glass substrate

参数 取值 参数 取值 密度ρ/ (kg·m−3) 2 530 强

度

常

量A 0.71 剪切模量G/ MPa 2 690 B 0.178 损伤

常量D1 0.043 C 0.018 33 D2 0.85 M 1 FS 1.0 N 0.61 状态

方程K1 43.2 T/ MPa 27.8 K2 −67.2 HEL/ MPa 5 950 K3 153.2 PHEL/ MPa 2 920 BATE 1 SFmax/ MPa 0.5 EPSO/ s−1 0.001 表 2 ITO薄膜的材料属性

Table 2. Material properties of ITO films

参数 数值 密度ρ/ (kg·m−3) 6 800 弹性模量E/ GPa 116 泊松比 0.35 抗拉强度$ {\text{σ}}_{\text{t}} $/ MPa 293 断裂能$ {\text{G}}_{\text{f}}^{\text{I}} $/ (J·m−2) 36.3 -

[1] THIRUMOORTHI M, PRAKASH J T J. Structure, optical and electrical properties of indium tin oxide ultra thin films prepared by jet nebulizer spray pyrolysis technique [J]. Journal of Asian Ceramic Societies,2016,4(1):124-132. doi: 10.1016/j.jascer.2016.01.001 [2] LEWIS B G, PAINE D C. Applications and processing of transparent conducting oxides [J]. Mrs Bulletin,2000,25(8):22-27. doi: 10.1557/mrs2000.147 [3] HENGST C, MENZEL S B, RANE G K, et al. Mechanical properties of ZTO, ITO, and a-Si: H multilayer films for flexible thin film solar cells [J]. Materials,2017,10(3):245. doi: 10.3390/ma10030245 [4] OH S J, KWON J H, LEE S, et al. Unveiling the annealing-dependent mechanical properties of freestanding indium tin oxide thin films [J]. Acs Applied Materials & Interfaces,2021,13(14):16650-16659. [5] WANG Z X, WANG S B, WANG J R, et al. Mechanical performance of ITO/Ag/ITO multilayer films deposited on glass substrate by RF and DC magnetron sputtering [J]. Ceramics International,2021,47(22):31442-31450. doi: 10.1016/j.ceramint.2021.08.020 [6] JUNG H S, EUN K, KIM Y T, et al. Experimental and numerical investigation of flexibility of ITO electrode for application in flexible electronic devices [J]. Microsystem Technologies,2017,23(6):1961-1970. [7] ZIAEI S, WU Q, FITCH J, et al. Channel cracking and interfacial delamination of indium tin oxide (ITO) nano-sized films on polyethylene terephthalate (PET) substrates: experiments and modeling [J]. Experimental Mechanics,2019,59(5):703-712. doi: 10.1007/s11340-019-00534-y [8] TIAN X, XIONG S, ZHANG Y, et al. Simulation of thermal stress in ion beam sputtered Ta2O5/SiO2 multilayer coatings on different substrates by finite element analysis [J]. Surface and Coatings Technology,2019(362):225-233. [9] QIU Y, JIN Y, ZHAO H, et al. Physical properties of ITO thin films prepared by ion-assisted electron beam evaporation[C]// International Symposium on Optoelectronic Technology and Application, 2014(9295): 929505. [10] LEE K Y, CHOI G W, KIM Y J, et al. Chemical mechanical polishing characteristics of ITO thin film prepared by RF magnetron sputtering [J]. Journal of the Korean Physical Society,2012,60(3):388-392. doi: 10.3938/jkps.60.388 [11] CHEN L, CAO K Q, LIU J K, et al. Surface birefringence of regular periodic surface structures produced on glass coated with an indium tin oxide film using a low-fluence femtosecond laser through a cylindrical lens [J]. Optics Express,2020,28(20):30094-30106. doi: 10.1364/OE.402037 [12] TAN S, LONG S, YAO X, et al. An improved material model for loading-path and strain-rate dependent strength of impacted soda-lime glass plate [J]. Journal of Materials Research and Technology,2021(15):1905-1919. [13] CHEN J, BULL S J. Assessment of the toughness of thin coatings using nanoindentation under displacement control [J]. Thin Solid Films,2006,494(1/2):1-7. [14] HARPER P W, HALLETT S R. Cohesive zone length in numerical simulations of composite delamination [J]. Engineering Fracture Mechanics,2008,75(16):4774-4792. doi: 10.1016/j.engfracmech.2008.06.004 [15] 黄水泉, 高尚, 黄传真, 等. 脆性材料磨粒加工的纳米尺度去除机理 [J]. 金刚石与磨料磨具工程,2022,42(3):257-267,384.HUANG Shuiquan, GAO Shang, HUANG Chuanzhen, et al. Nanoscale removal mechanisms in abrasive machining of brittle solids [J]. Diamond & Abrasives Engineering,2022,42(3):257-267,384. [16] 葛培琪, 陈自彬, 王沛志. 单晶硅切片加工技术研究进展 [J]. 金刚石与磨料磨具工程,2020,40(4):12-18.GE Peiqi, CHEN Zibin, WANG Peizhi. Review of monocrystalline silicon slicing technology [J]. Diamond & Abrasives Engineering,2020,40(4):12-18. [17] WAN L, LI L, DENG Z, et al. Thermal-mechanical coupling simulation and experimental research on the grinding of zirconia ceramics [J]. Journal of Manufacturing Processes,2019(47):41-51. [18] HSU J S, LEE C C, WEN B J, et al. Experimental and simulated investigations of thin polymer substrates with an indium tin oxide coating under fatigue bending loadings [J]. Materials,2016,9(9):720. doi: 10.3390/ma9090720 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS