Study on manufacturing process constraint of feature structures of diamond composite materials fabricated by selective laser melting

-

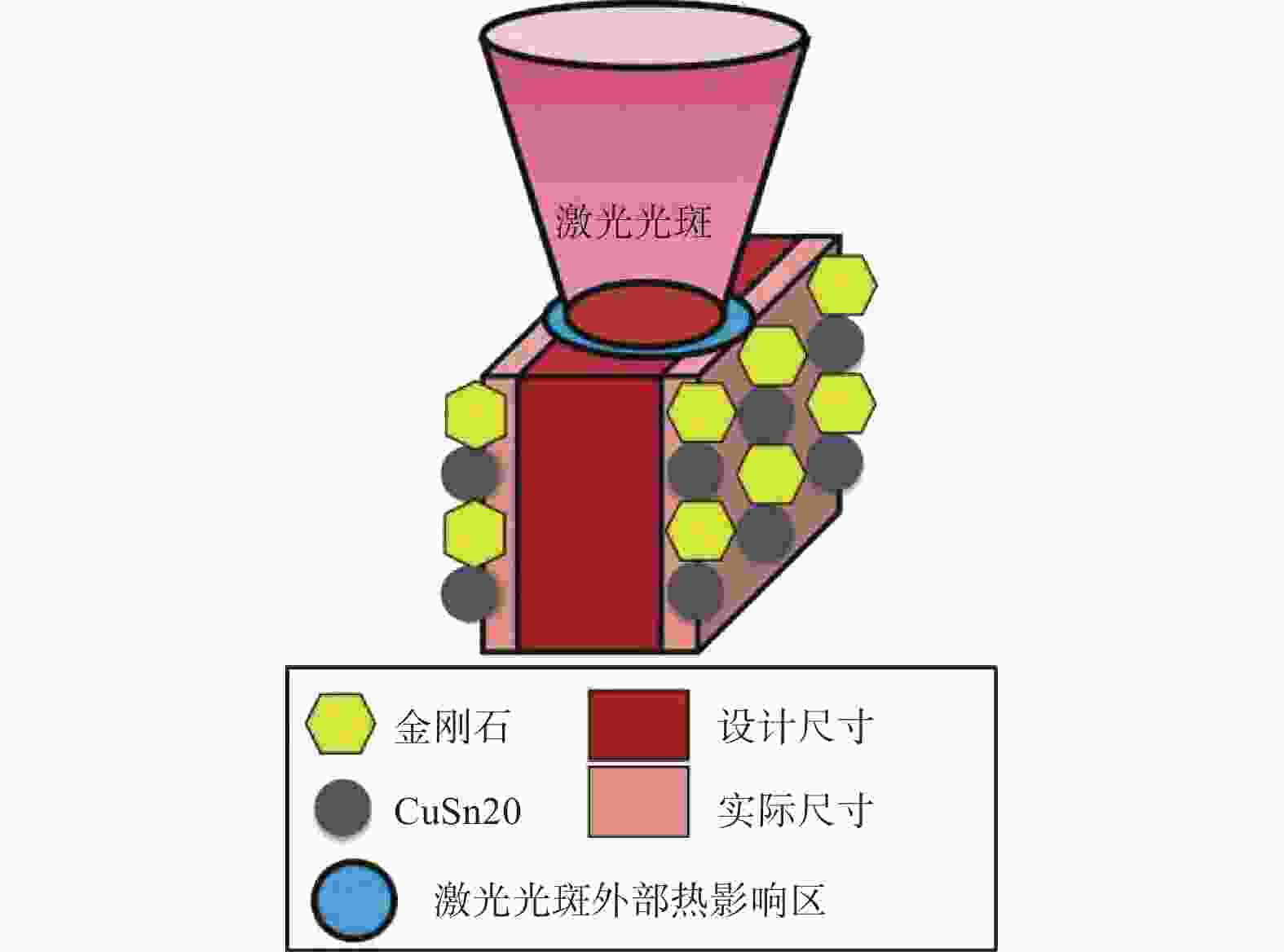

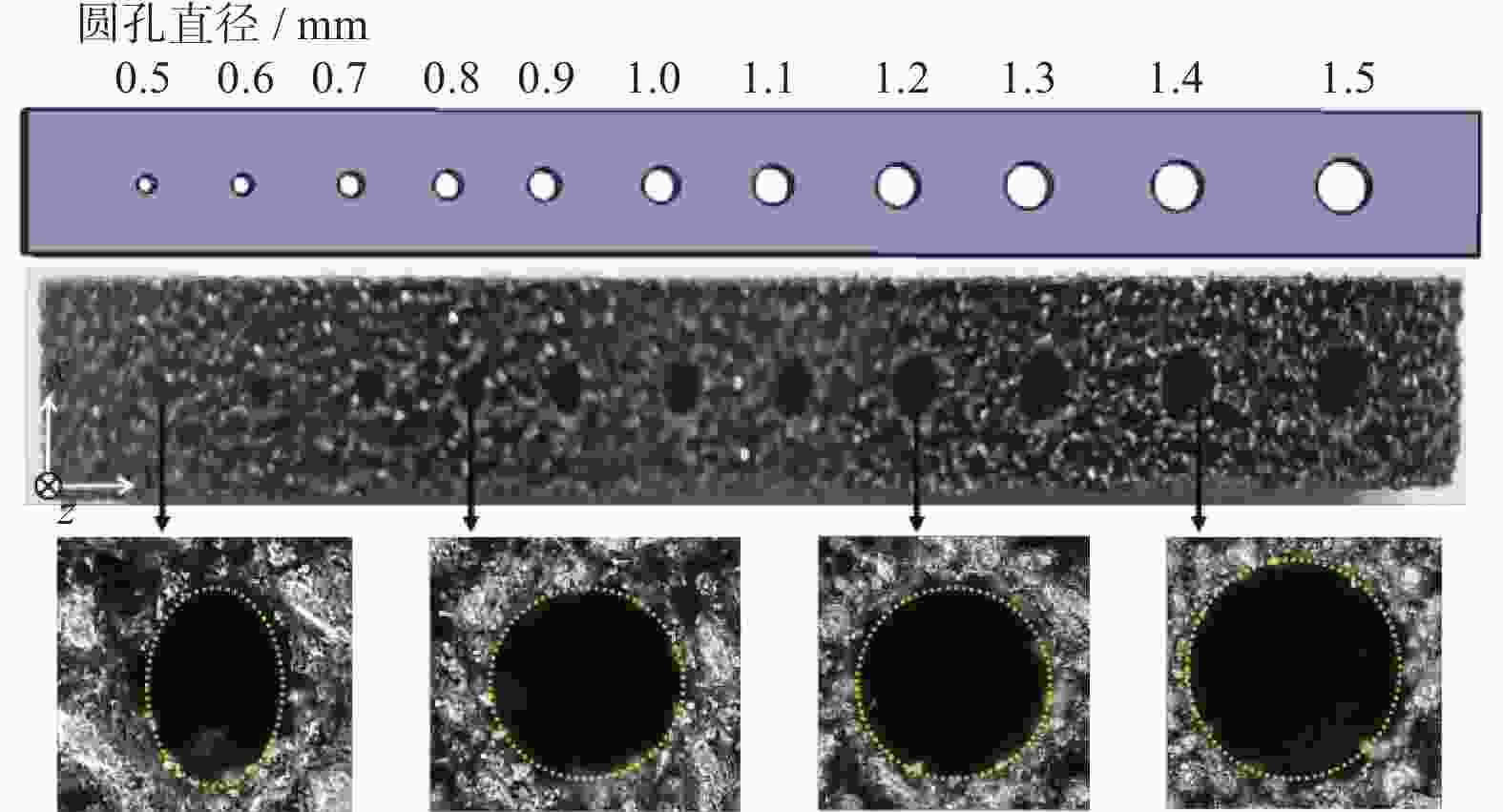

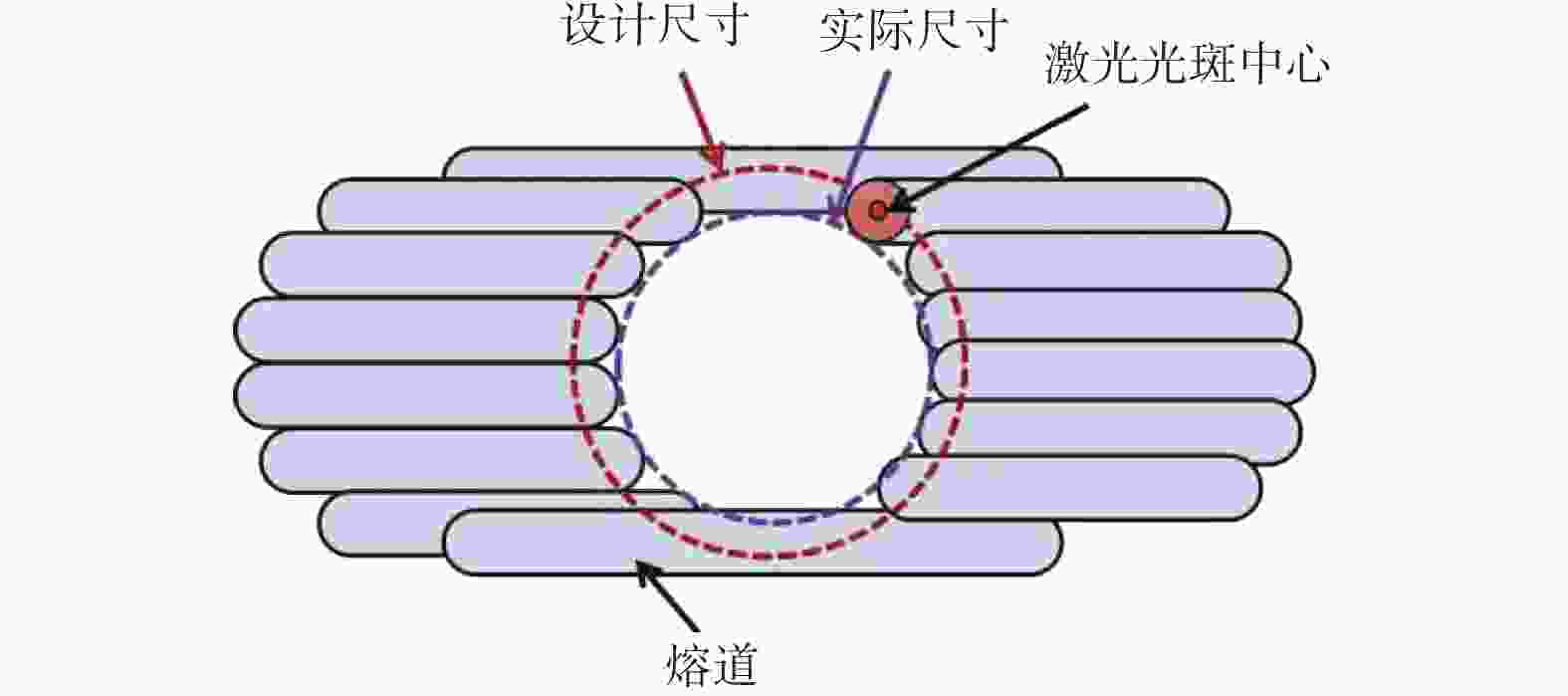

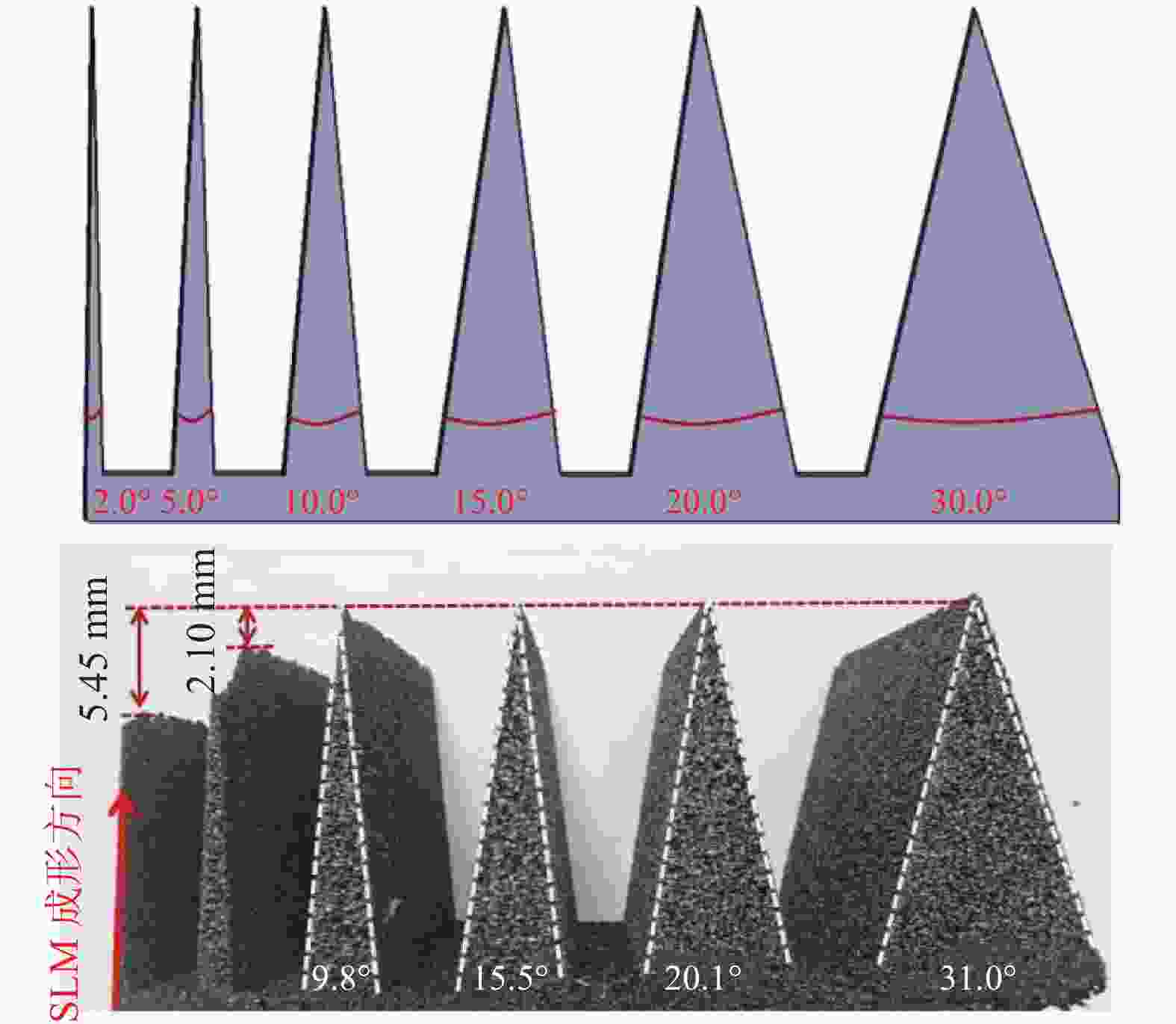

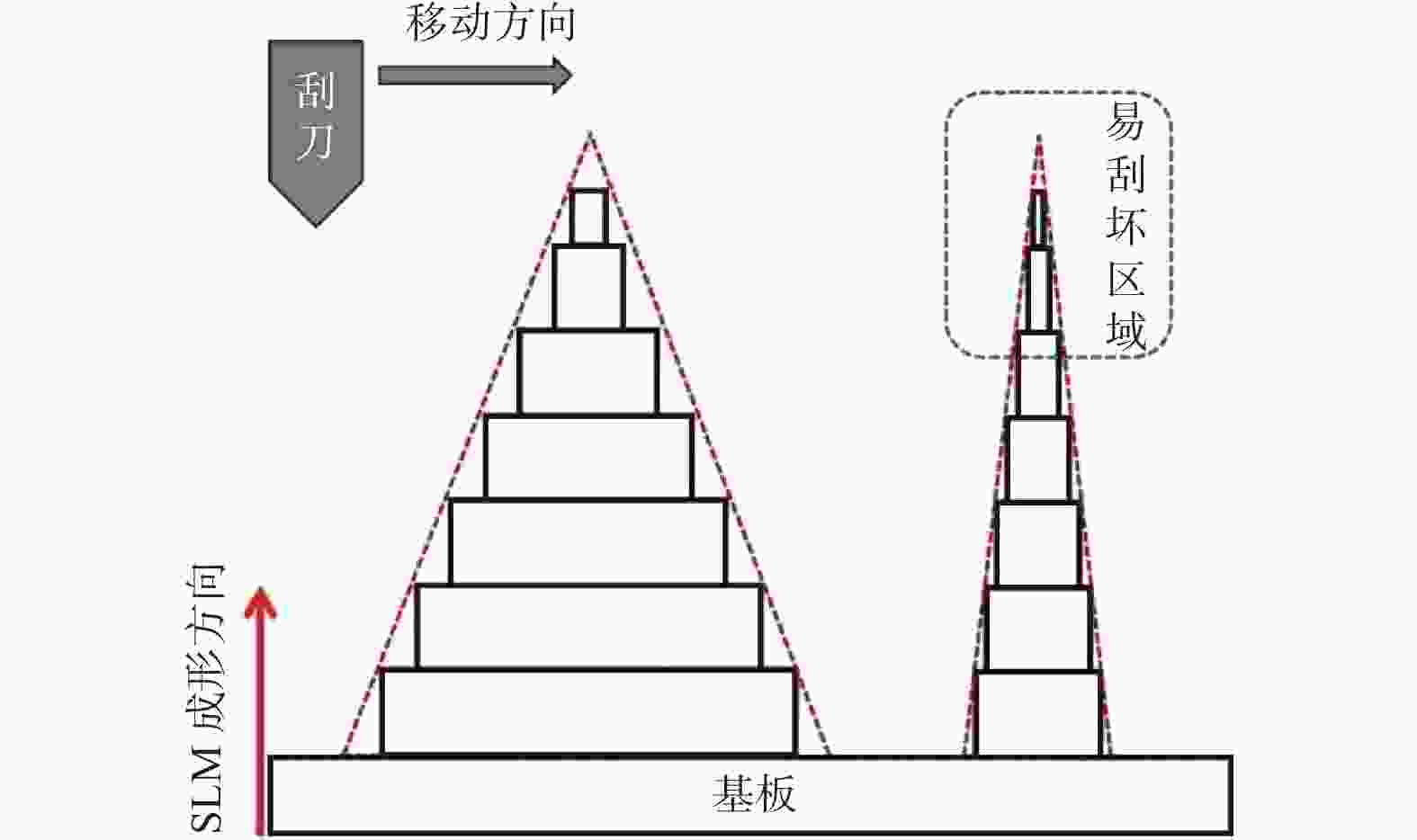

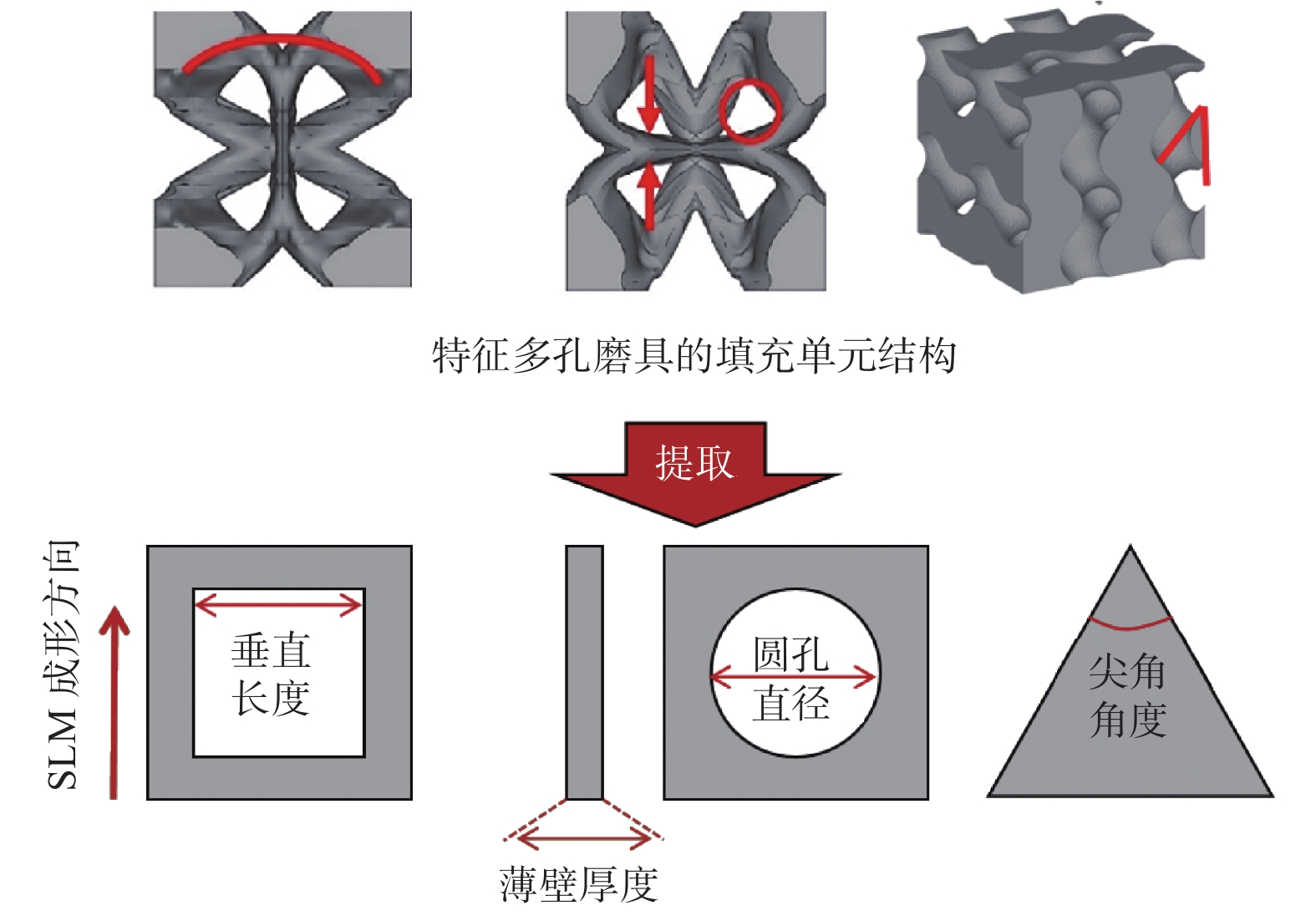

摘要: 多孔金刚石磨具是一种能在磨削加工过程中提供容屑和冷却液流通空间的新型工具,激光选区熔化(selective laser melting,SLM)成形技术是制造多孔金刚石磨具的有效手段。受激光增材制造的光斑尺寸约束、逐层成形等技术特征的影响,所设计的多孔金刚石磨具难以精准成形,因此有必要对金刚石复合材料特征几何结构的可成形性进行研究。基于SLM125HL设备,以CuSn20/金刚石复合材料为研究对象,采用SLM成形技术成形了不同成形方向、不同尺寸的悬垂结构、薄壁、圆孔和尖角等特征几何结构,并对其可成形性、成形误差及产生原因进行分析。结果表明:金刚石复合材料悬垂结构的最佳可成形尺寸为1.00~2.00 mm,薄壁结构的最小可成形尺寸为0.70 mm;垂直于成形方向的圆孔结构的最小可成形直径尺寸为0.50 mm,平行于成形方向的圆孔结构的最佳成形直径尺寸为1.00~4.00 mm;尖角结构的可成形角度需>10°。这些特征几何结构的成形误差主要受激光对复合粉末的热吸附、激光光斑热影响区扩散以及复合粉末的弱支撑等作用影响。

-

关键词:

- 激光选区熔化 /

- CuSn20/金刚石复合材料 /

- 特征几何结构 /

- 工艺约束

Abstract: Porous diamond grinding tools are a new type tools that can provide a space for chip holding and coolant flowing during the grinding process. selective laser melting (SLM) is an effective method for manufacturing porous diamond grinding tools. However, due to the limitations of spot size and layer by layer fabricating process in SLM process, the designed porous diamond tools are difficult to be manufactured accurately. Therefore, it is necessary to study the formability of diamond composite materials feature geometry structures. Based on CuSn20/diamond composites, a series of feature structures such as overhang structures, thin-walled, holes, and sharp angle structures with different fabricating directions and sizes were fabricated by SLM technology. The formability, forming errors, and causes of these structures are analyzed. The results show that the optimal formable length of the overhang structure is 1.0~2.0 mm; The minimum formable size of thin wall structures is 0.70 mm; The minimum formable diameter size of hole structures perpendicular to the fabricating direction is 0.50 mm; The optimal forming diameter size for circular hole structures parallel to the fabricating direction is 1.00~4.00 mm; The formable angle of sharp angle structures should be greater than 10°. The forming error of feature structures is mainly affected by the thermal adsorption of laser on composite powder, the diffusion of laser spot heat affected zone, and the weak support of composite powder. This work provide a certain technical reference for the design and additive manufacturing of complex diamond tools. -

表 1 实验材料属性

Table 1. Properties of materials

材料 主要成分 平均粒径 / μm 金刚石 C 40~50 CuSn20合金 Cu,Sn 17~53 表 2 特征几何结构成形工艺参数

Table 2. SLM parameters of feature geometric structures

参数名称 数值 激光功率 / W 200 扫描速度 / (mm·s−1) 1 600 层厚 / μm 40 扫描间距 / mm 0.12 光斑直径 / μm 80 表 3 悬垂方孔结构边长尺寸测量

Table 3. Side length measurements of square hole structures

设计边长 / mm 水平边长 / mm 相对误差 / % 竖直边长 / mm 相对误差 / % 0.50 1.00 1.01 1.00 0.89 −11.00 2.00 2.02 1.00 1.71 −14.50 3.00 2.98 −0.67 2.83 −5.67 4.00 4.15 3.75 3.72 −7.00 5.00 5.00 0.00 4.54 −9.20 6.00 6.05 0.83 5.54 −7.67 7.00 7.05 0.71 6.37 −9.00 8.00 7.99 −0.13 7.42 −7.25 表 4 薄壁结构厚度尺寸测量

Table 4. Thickness measurements of square hole structures

设计厚度 / mm 成形厚度 / mm 相对误差 / % 0.50 0.60 0.70 0.68 −2.86 0.80 0.81 1.25 0.90 0.91 1.11 1.00 1.02 2.00 1.10 1.11 0.91 1.20 1.21 0.83 1.30 1.30 0 1.40 1.41 0.71 表 5 垂直于成形方向圆孔结构直径尺寸测量

Table 5. Diameter measurements of hole structures perpendicular to the building direction

设计直径 / mm 成形直径 / mm 相对误差 / % 0.50 0.46 −8.00 0.60 0.55 −8.33 0.70 0.69 −1.43 0.80 0.74 −7.5 0.90 0.83 −7.78 1.00 0.95 −5.00 1.10 1.04 −5.45 1.20 0.14 −6.92 1.30 1.21 −4.62 1.40 1.37 −2.14 1.50 1.46 −2.67 表 6 平行于成形方向圆孔结构直径尺寸测量

Table 6. Diameter measurements of hole structures parallel to the building direction

设计直径 / mm 成形直径 / mm 相对误差 / % 0.50 1.00 0.94 −6.00 2.00 2.01 0.50 3.00 2.98 −0.67 4.00 3.97 −0.75 5.00 4.97 −0.60 6.00 5.97 −0.50 7.00 6.98 −0.29 8.00 7.95 −0.63 表 7 尖角结构的角度测量

Table 7. Angle measurements of sharp angle structures

设计角度 / (°) 成形角度 / (°) 相对误差 / % 2.0 5.0 10.0 9.8 −2.0 15.0 15.5 3.3 20.0 20.1 0.5 30.0 31.0 3.3 -

[1] 轩闯, 向刚强, 廖燕玲, 等. 半导体加工用金刚石工具现状 [J]. 超硬材料工程,2021,33(1):41-49. doi: 10.3969/j.issn.1673-1433.2021.01.008XUAN Chuang, XIANG Gangqiang, LIAO Yanling, et al. Current status of diamond tools for semiconductor processing industry [J]. Superhard Material Engineering,2021,33(1):41-49. doi: 10.3969/j.issn.1673-1433.2021.01.008 [2] 吴燕平, 燕青芝. 金属结合剂金刚石工具研究进展 [J]. 金刚石与磨料磨具工程,2019,39(2):37-45.WU Yanping, YAN Qingzhi. Research progress of metal bond diamond tools [J]. Diamond & Abrasives Engineering,2019,39(2):37-45. [3] XU H, LIAO C J, WENG Q M. Experimental study on porous metal bonded diamond grinding wheels - the selection of porosity inducers and agglomeration’s parameter [J]. Advanced Materials Research,2011(415/416/417):594-597. [4] LIU Z, LIAO X, FU W, et al. Microstructures and bonding strength of synthetic diamond brazed by near-eutectic Ag–Cu–in–Ti filler alloy [J]. Materials Science and Engineering: A,2020(790):139711. [5] 吴颖. 电镀金刚石工具的应用现状及改进研究 [J]. 热加工工艺,2015,44(18):18-21.WU Ying. Application status and improved research of electroplated diamond tools [J]. Hot Working Technology,2015,44(18):18-21. [6] YUAN L, GU D, LIN K, et al. Electrically actuated shape recovery of NiTi components processed by laser powder bed fusion after regulating the dimensional accuracy and phase transformation behavior [J]. Chinese Journal of Mechanical Engineering: Additive Manufacturing Frontiers,2022,1(4):100056. doi: 10.1016/j.cjmeam.2022.100056 [7] 王建宇, 黄国钦. 金刚石磨粒工具增材制造技术现状及展望 [J]. 金刚石与磨料磨具工程,2022,42(3):307-316.WANG Jianyu, HUANG Guoqin. Status and prospect of additive manufacturing technology for diamond abrasive tools [J]. Diamond and Abrasive Engineering,2022,42(3):307-316. [8] TIAN C, LI X, ZHANG S, et al. Porous structure design and fabrication of metal-bonded diamond grinding wheel based on selective laser melting (SLM) [J]. International Journal of Advanced Manufacturing Technology,2019,100(5/6/7/8):1451-1462. [9] MA Q, PENG Y, CHEN Y, et al. Quantitative investigation of thermal evolution and graphitisation of diamond abrasives in powder bed fusion-laser beam of metal-matrix diamond composites [J]. Virtual and Physical Prototyping,2023,18(1):e2121224. doi: 10.1080/17452759.2022.2121224 [10] TIAN C, LI X, ZHANG S, et al. Study on design and performance of metal-bonded diamond grinding wheels fabricated by selective laser melting (SLM) [J]. Materials & Design,2018(156):52-61. [11] LI X, WANG C, TIAN C, et al. Digital design and performance evaluation of porous metal-bonded grinding wheels based on minimal surface and 3D printing [J]. Materials & Design,2021(203):109556. [12] PENG Y, REN J, JIA C, et al. Structural design and mechanical properties of porous structured diamond abrasive tool by selective laser melting [J]. Ceramics International,2023,49(4):6508-6521. doi: 10.1016/j.ceramint.2022.10.136 [13] TIAN C, LI X, LI H, et al. The effect of porosity on the mechanical property of metal-bonded diamond grinding wheel fabricated by selective laser melting (SLM) [J]. Materials Science and Engineering: A,2019(743):697-706. [14] GAN J, GAO H, WEN S, et al. Simulation, forming process and mechanical property of Cu-Sn-Ti/diamond composites fabricated by selective laser melting [J]. International Journal of Refractory Metals and Hard Materials,2020(87):105144. [15] LIN K, YUAN L, GU D. Influence of laser parameters and complex structural features on the bio-inspired complex thin-wall structures fabricated by selective laser melting [J]. Journal of Materials Processing Technology,2019(267):34-43. [16] WANG D, MAI S, XIAO D, et al. Surface quality of the curved overhanging structure manufactured from 316-L stainless steel by SLM [J]. International Journal of Advanced Manufacturing Technology,2016,86(1/2/3/4):781-792. [17] GU D D, MEINERS W, WISSENBACH K. Laser additive manufacturing of metallic components: materials, processes and mechanisms [J]. International Materials Reviews,2012,57(3):133-164. doi: 10.1179/1743280411Y.0000000014 [18] CHEN H Y, GU D D, XIONG J P, et al. Improving additive manufacturing processability of hard-to-process overhanging structure by selective laser melting [J]. Journal of Materials Processing Technology,2017(250):99-108. [19] 徐仰立, 曹玄扬, 李婷婷, 等. 激光增材制造Ti6Al4V点阵结构的抗压吸能特性 [J]. 稀有金属材料与工程,2022,51(7):2536-2544.XU Yangli, CAO Xuanyang, LI Tingting, et al. Compressive energy absorption characteristics of Ti6Al4V lattice structure manufactured by laser additive manufacturing [J]. Rare Metal Materials and Engineering,2022,51(7):2536-2544. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS