Simulation and experimental study on micro-cutting silicon carbide crystal with single grain diamond

-

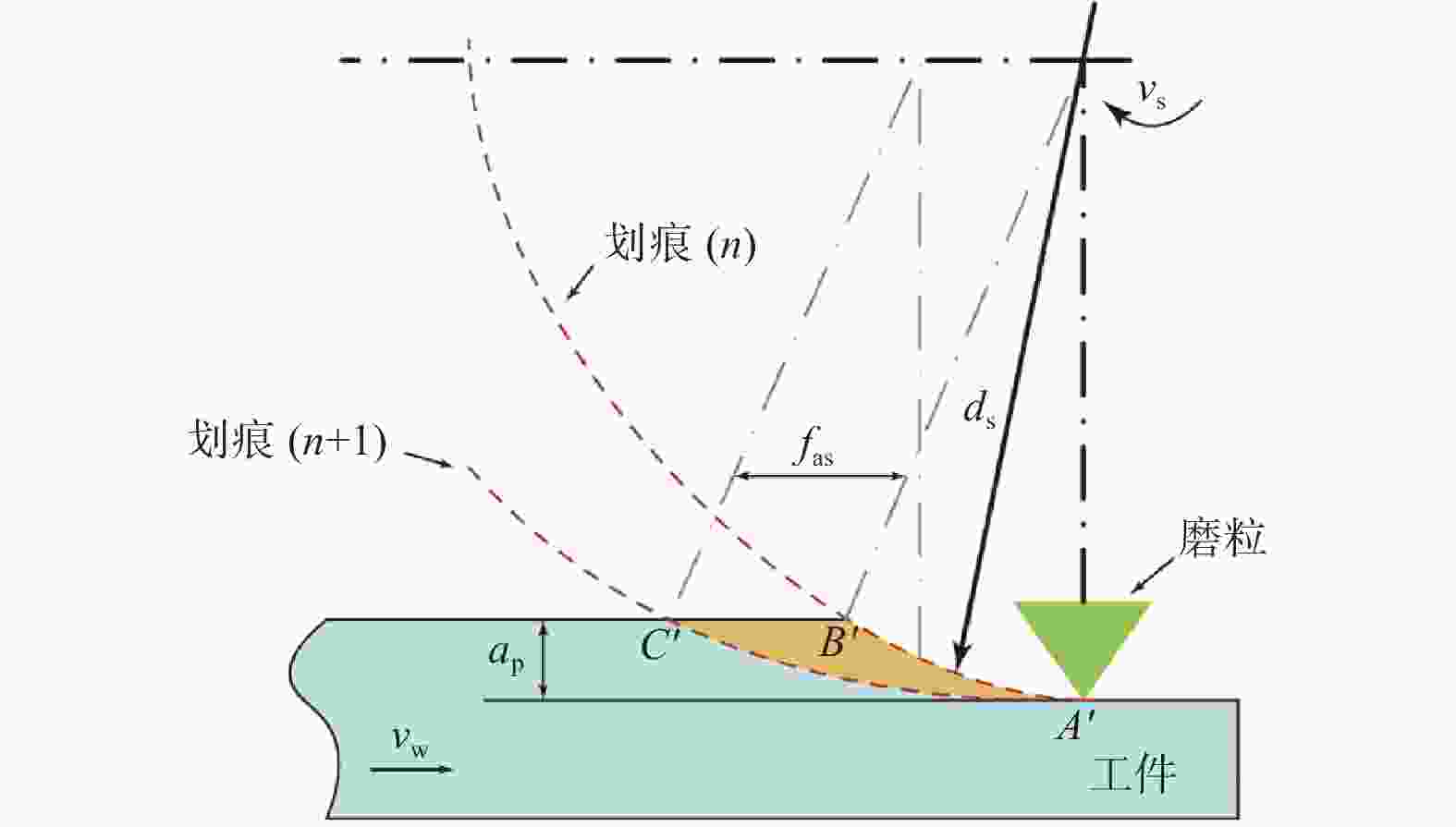

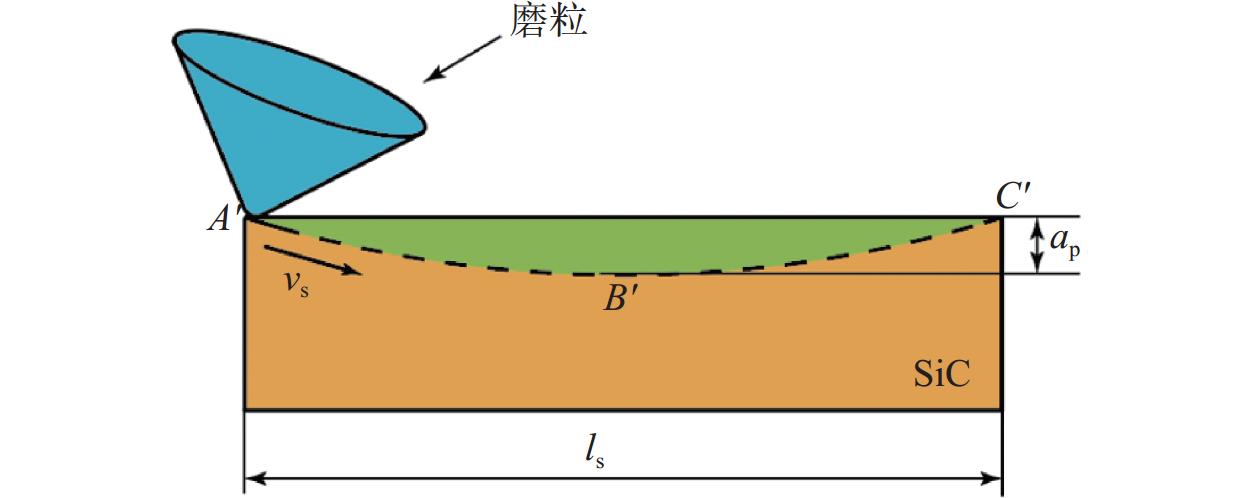

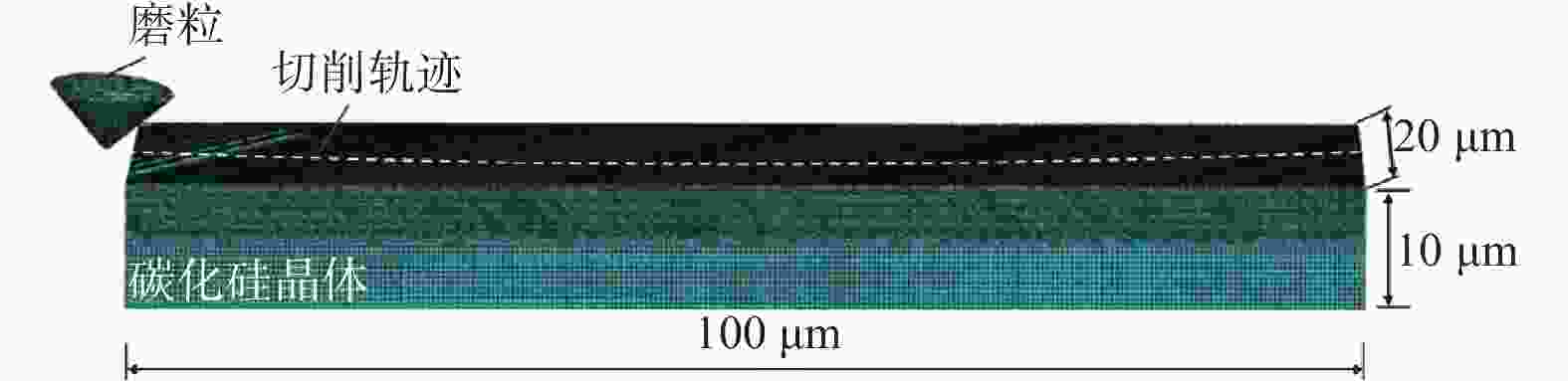

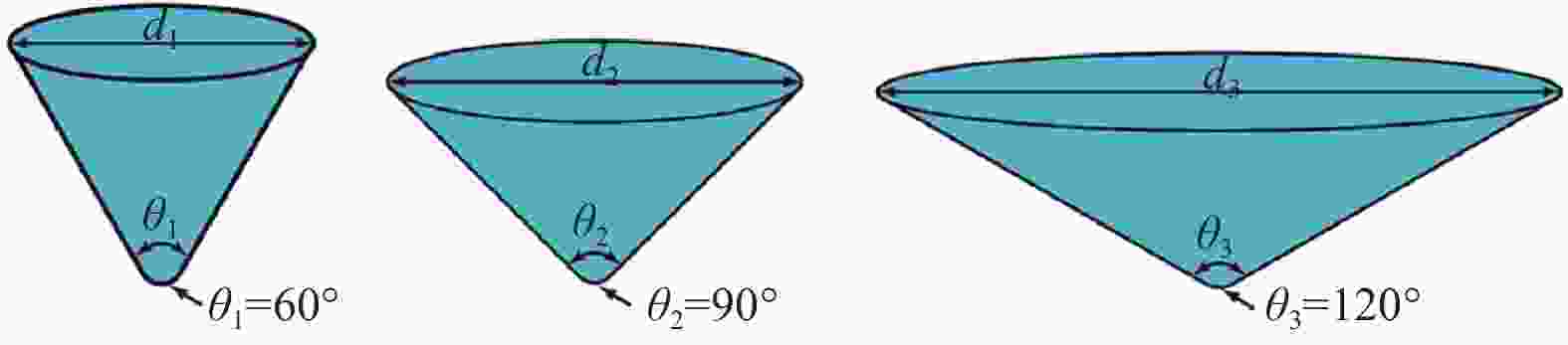

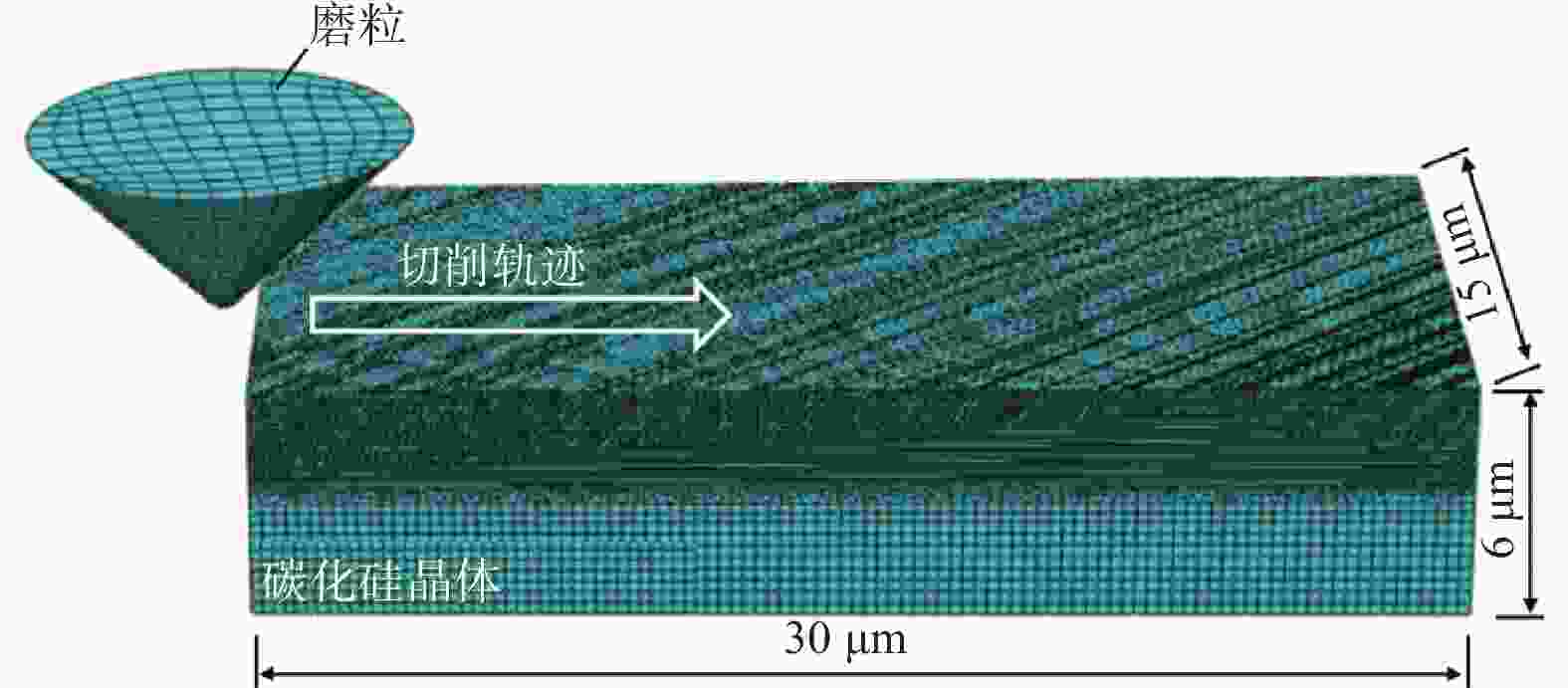

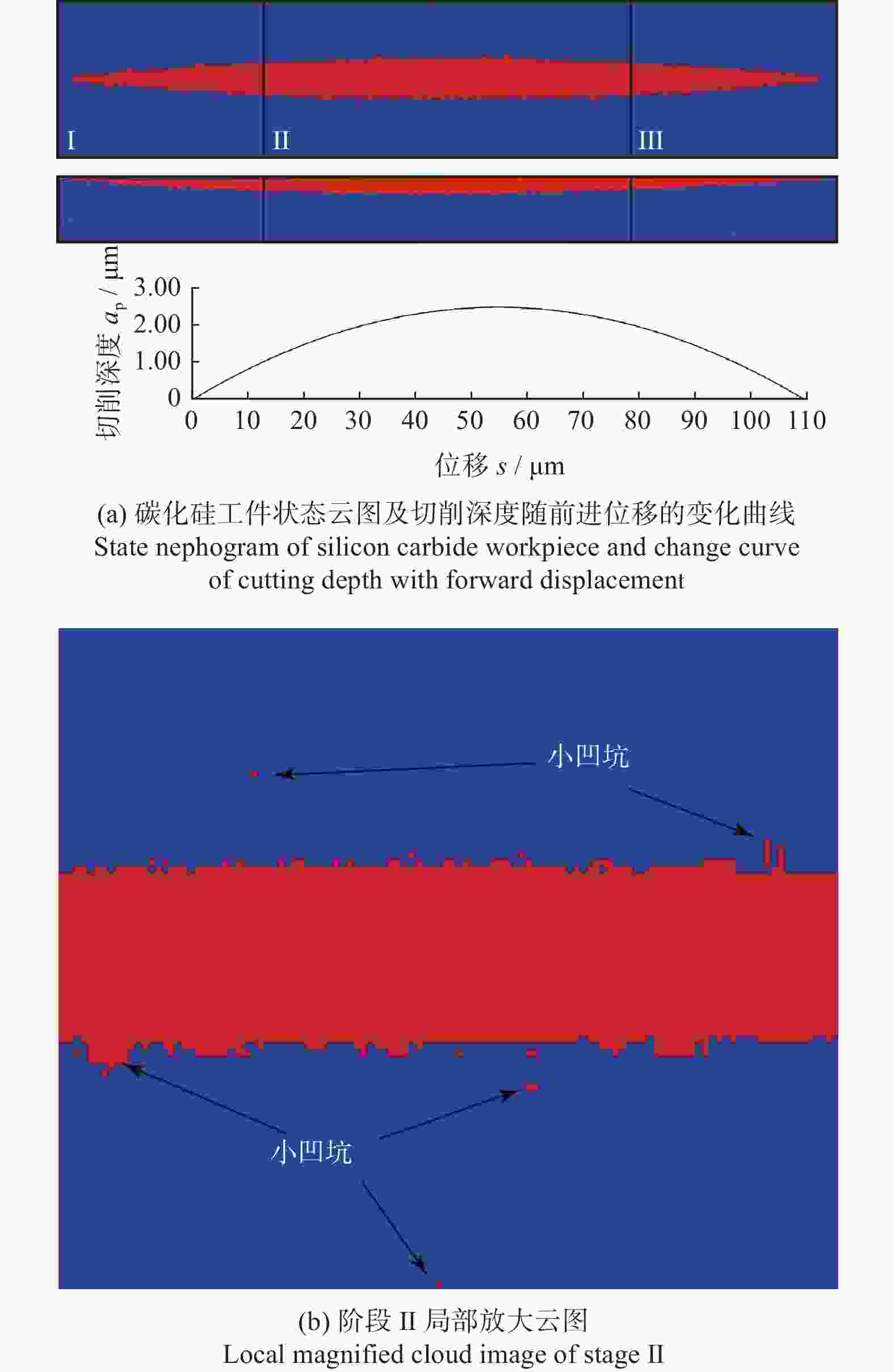

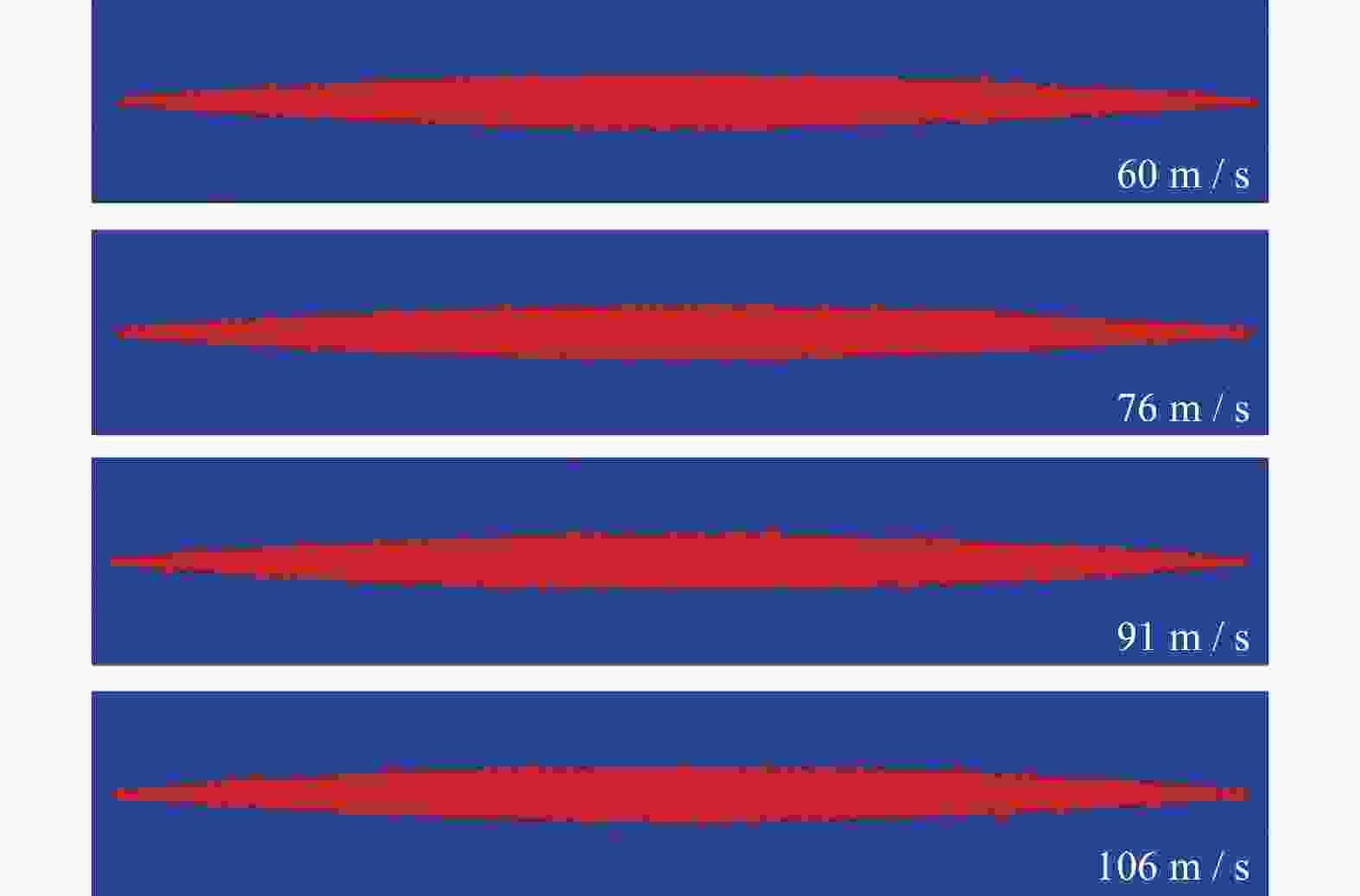

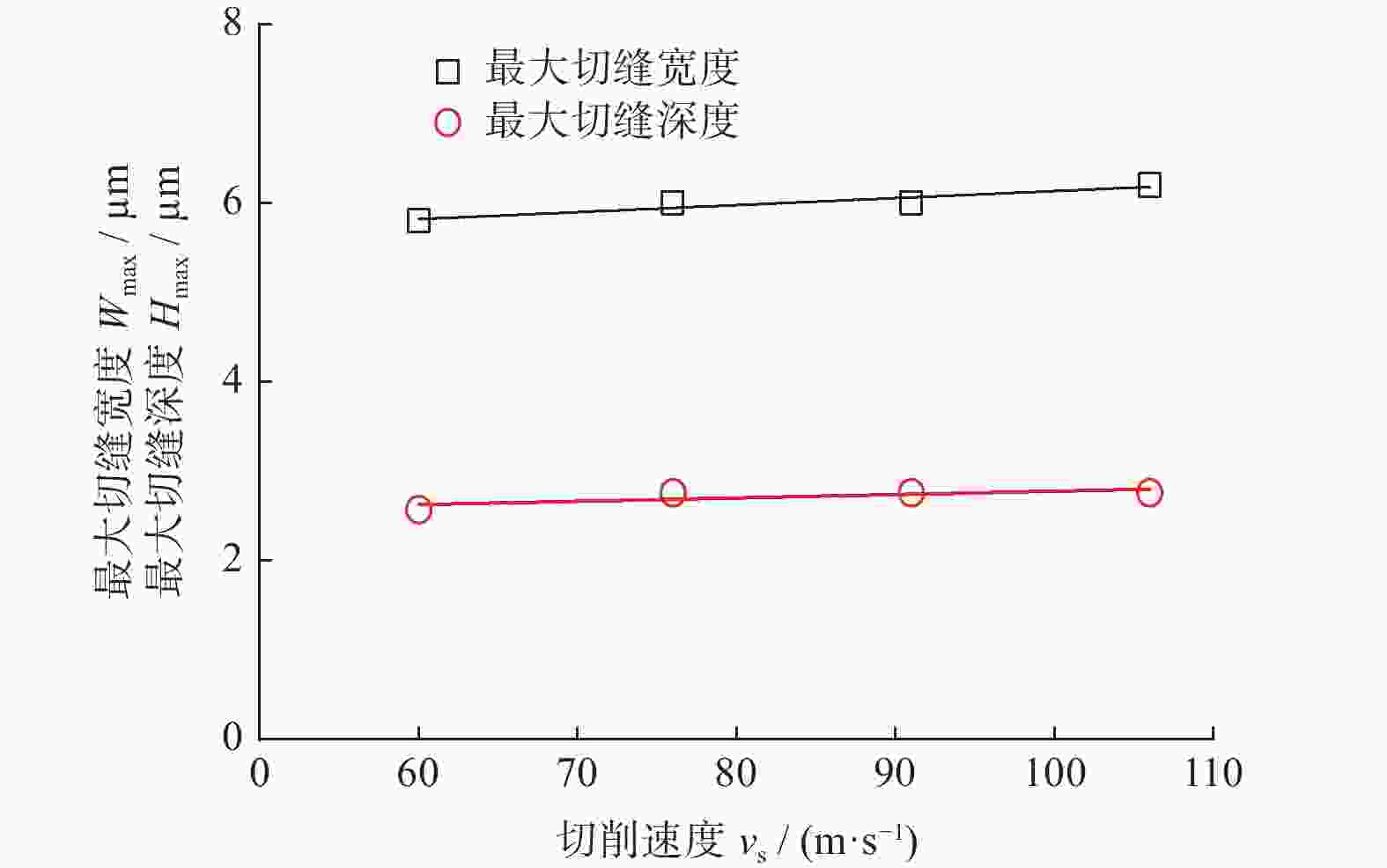

摘要: 采用有限元软件Abaqus建立金刚石锥形磨粒微切削碳化硅晶体的模型,通过预仿真模型确定切削深度和切削速度的选择范围,分析影响切削力的主、次要因素,研究单一切削参数对碳化硅晶体切削效果的影响;并借助赫兹接触理论,验证加载力对摩擦力、切削边缘形貌、切削深度的影响。结果表明:切削深度是影响切削力的显著因素,预仿真模型确定的切削深度不超过1.50 μm;碳化硅晶体切削的最优方案为切削深度取0.50 μm、切削速度取76 m/s、磨料切削刃角度取60°。通过控制切削深度可以提高切削稳定性,且在保证切削质量的前提下适当提高切削速度可以提高切削效率。金刚石探针压入晶体的深度与摩擦系数、摩擦力和切削力呈正相关,获得的碳化硅晶体切削边缘的三维轮廓相对平整、光滑。Abstract:

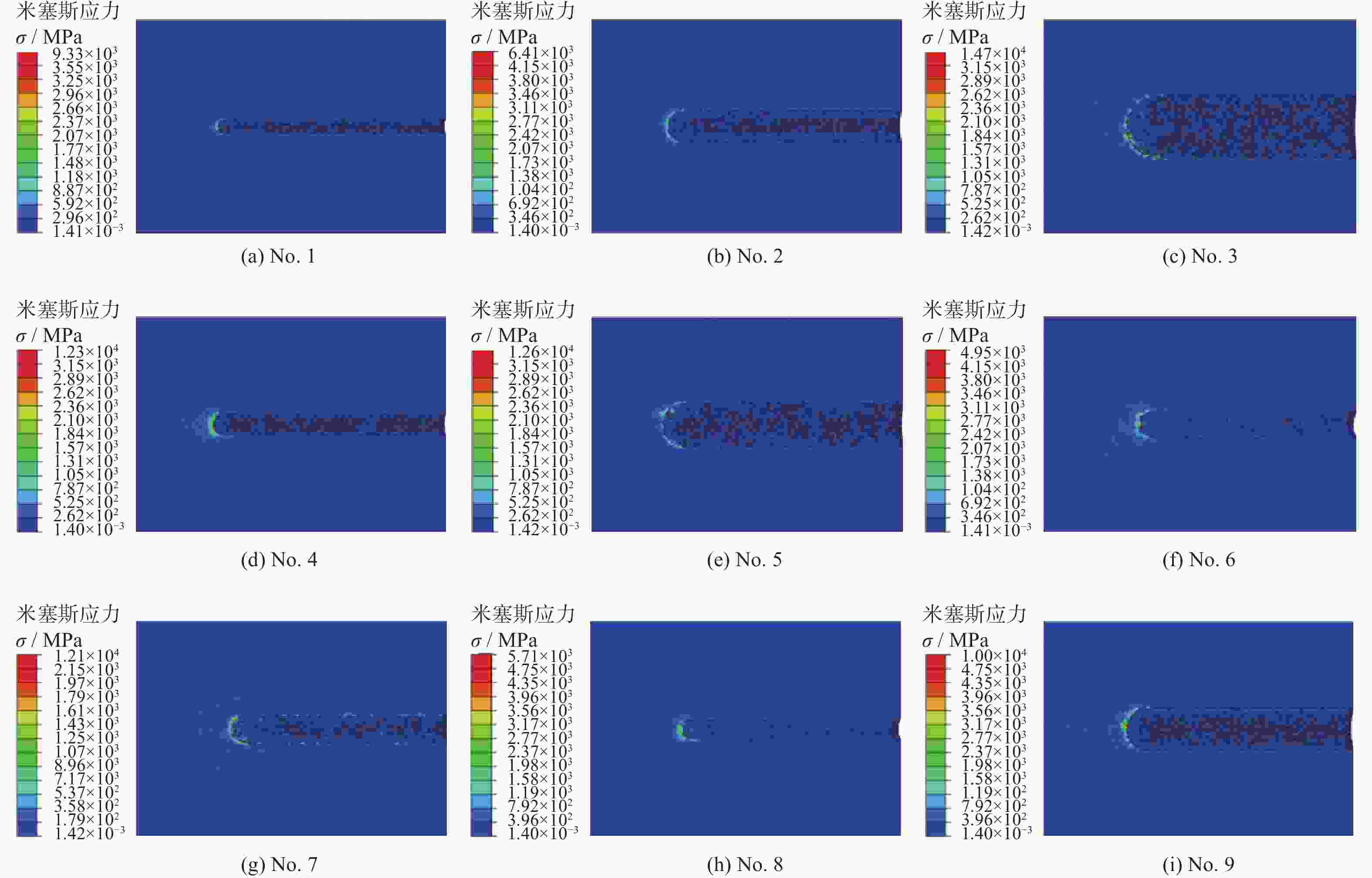

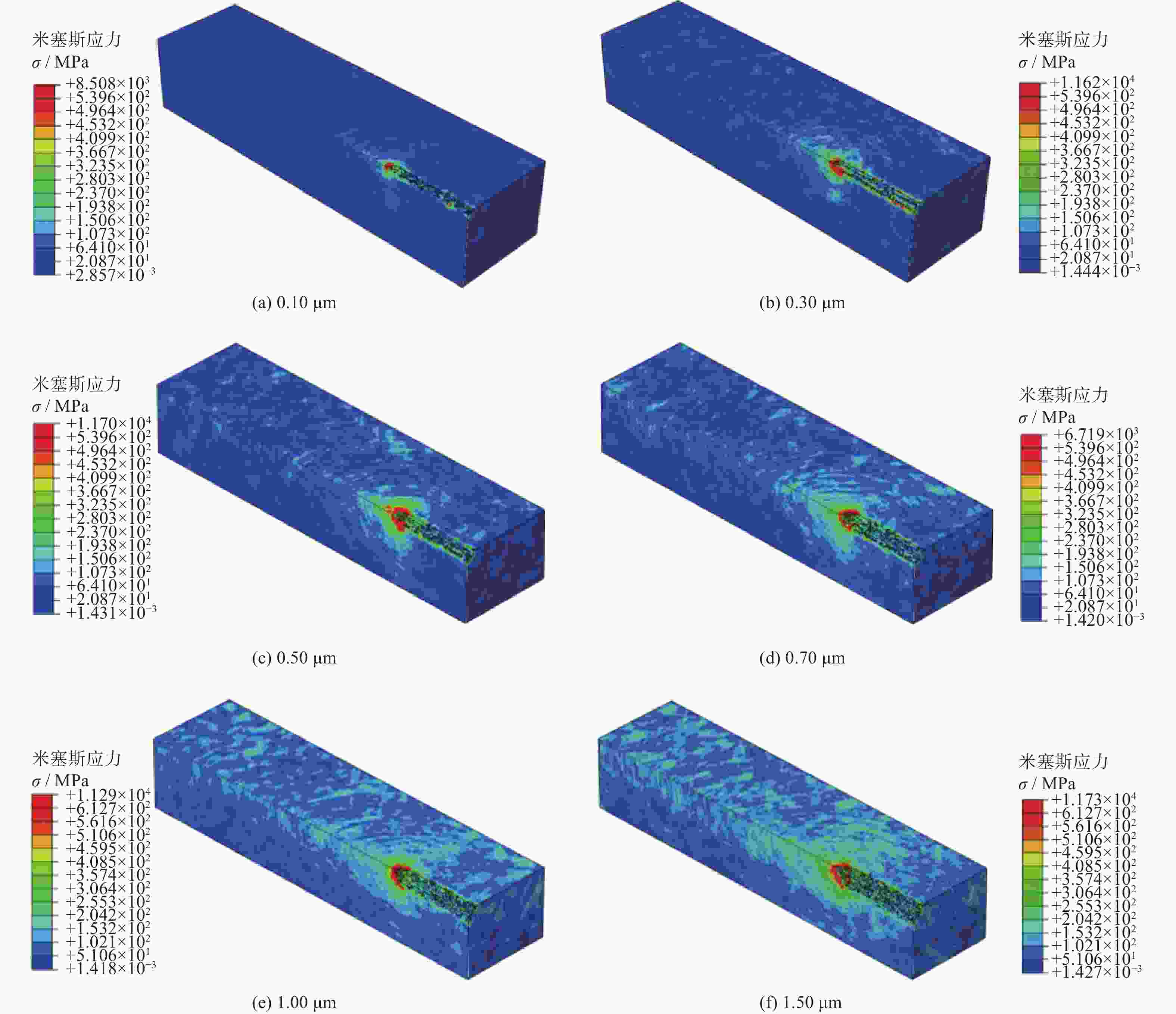

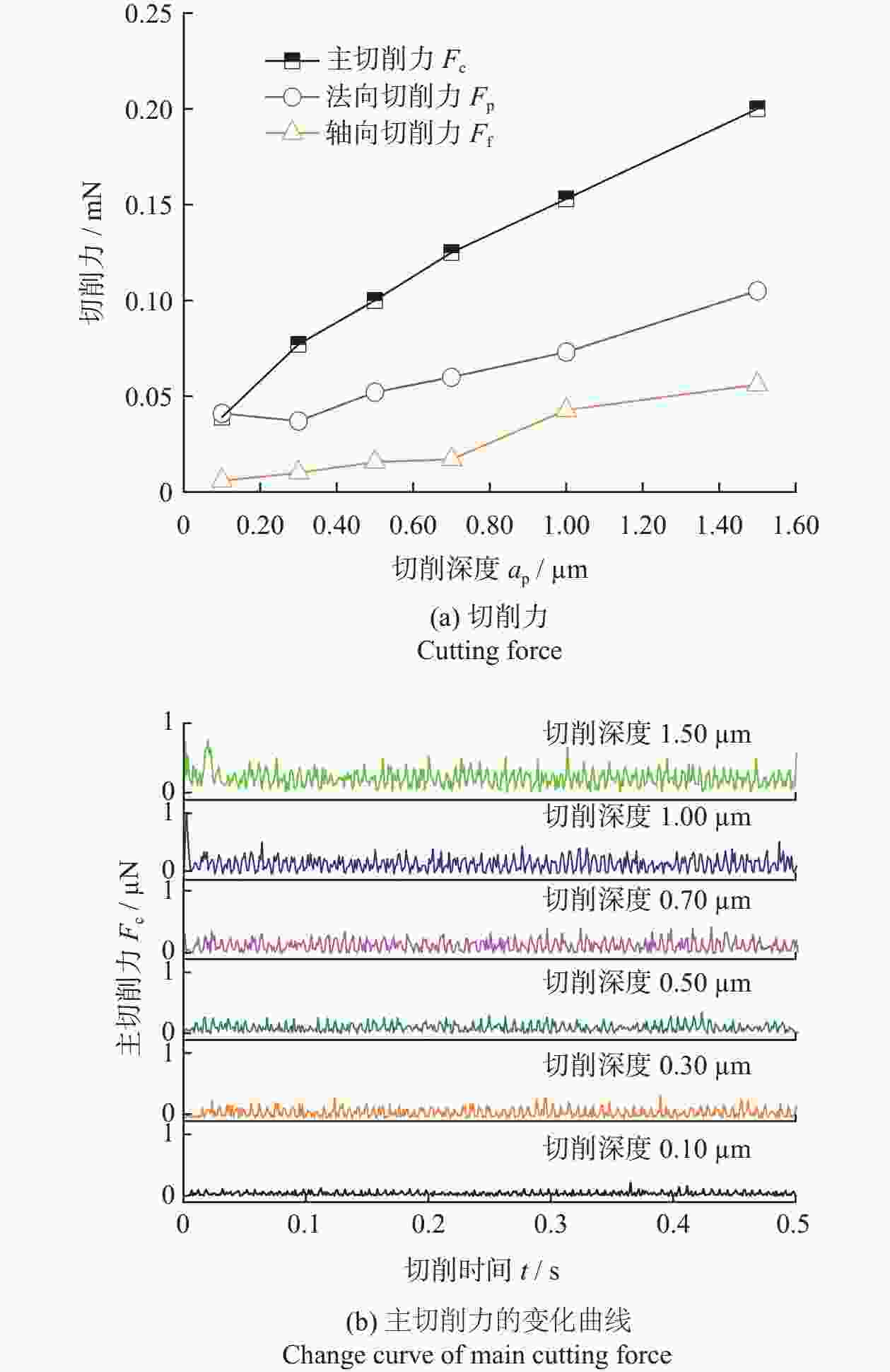

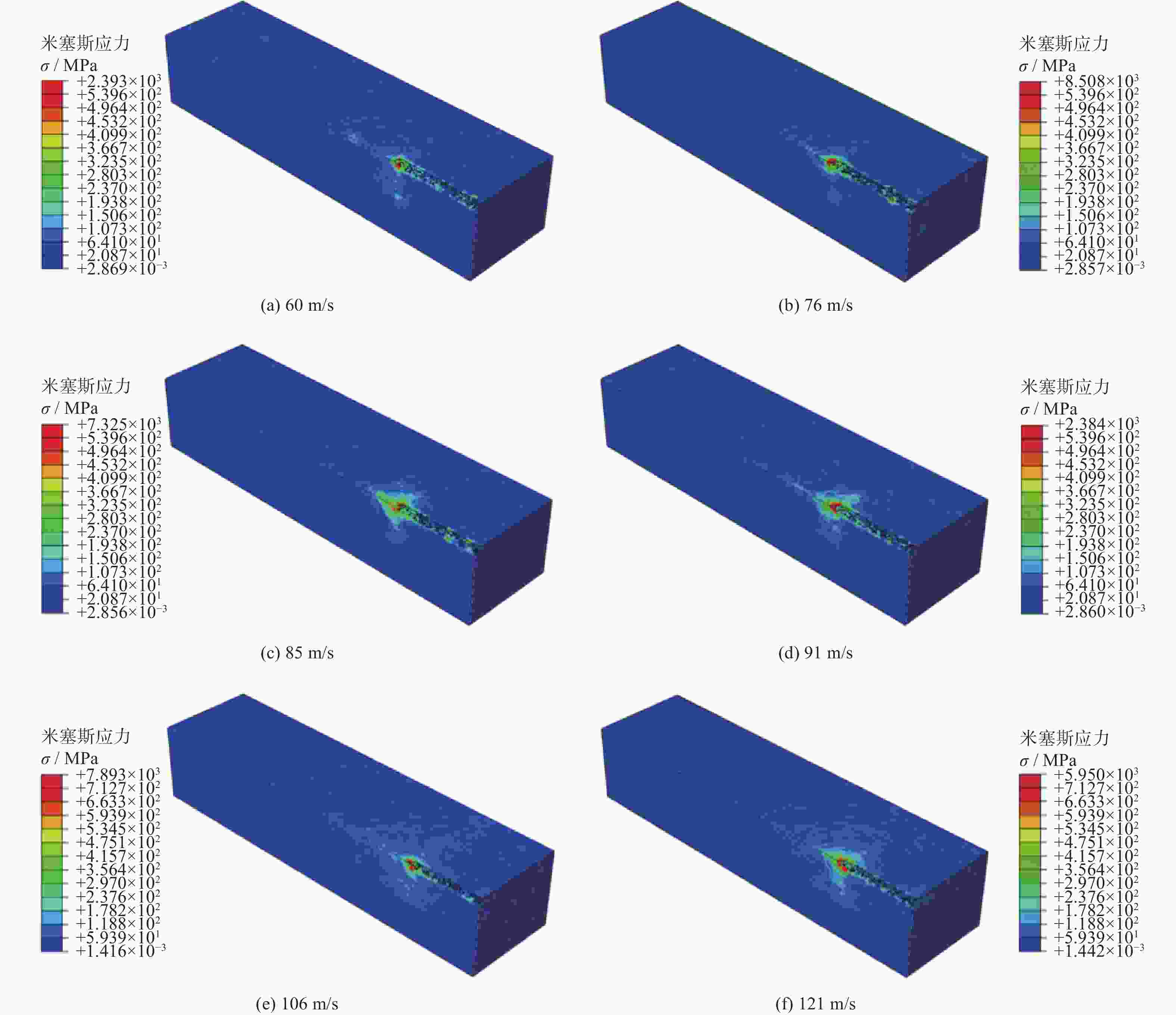

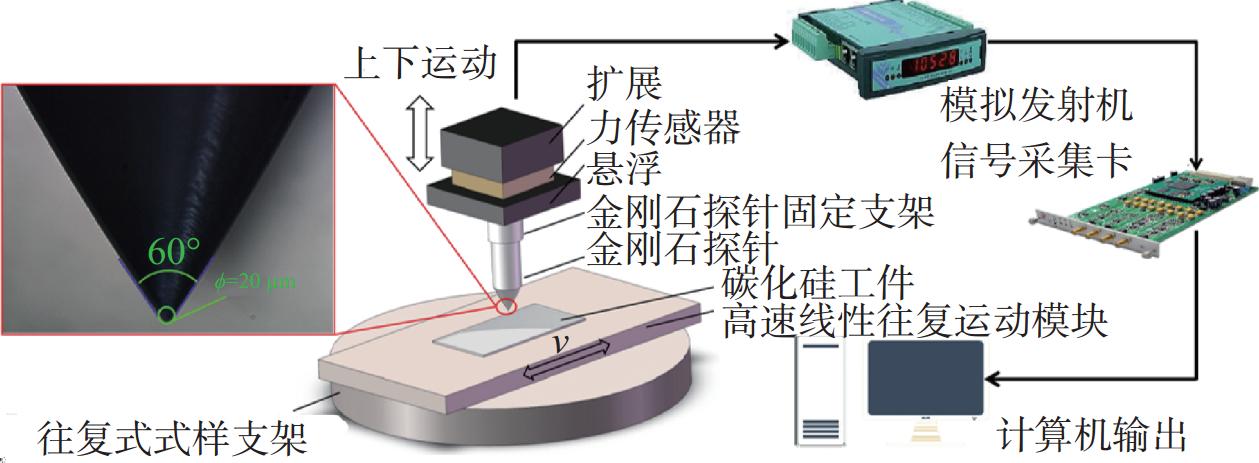

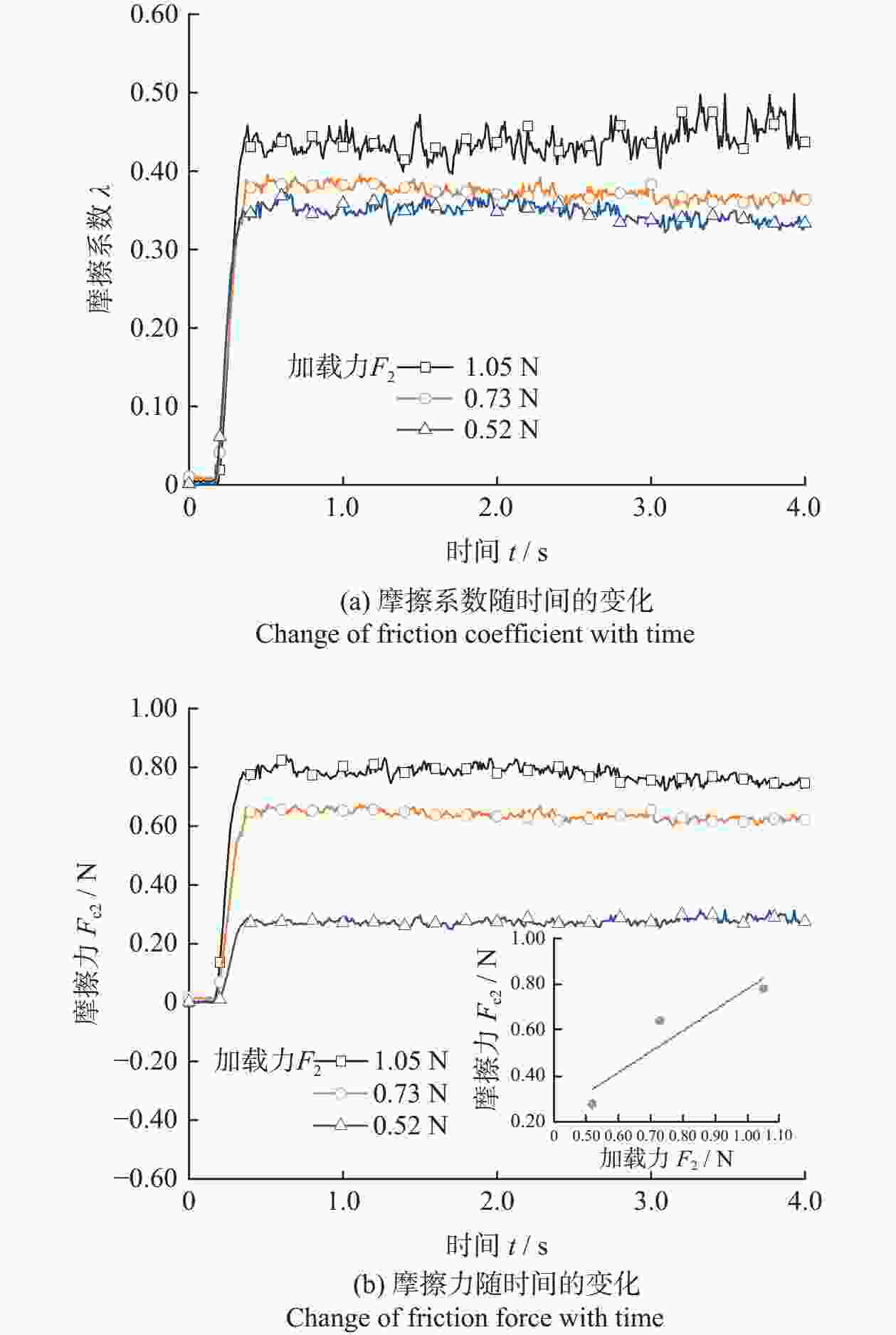

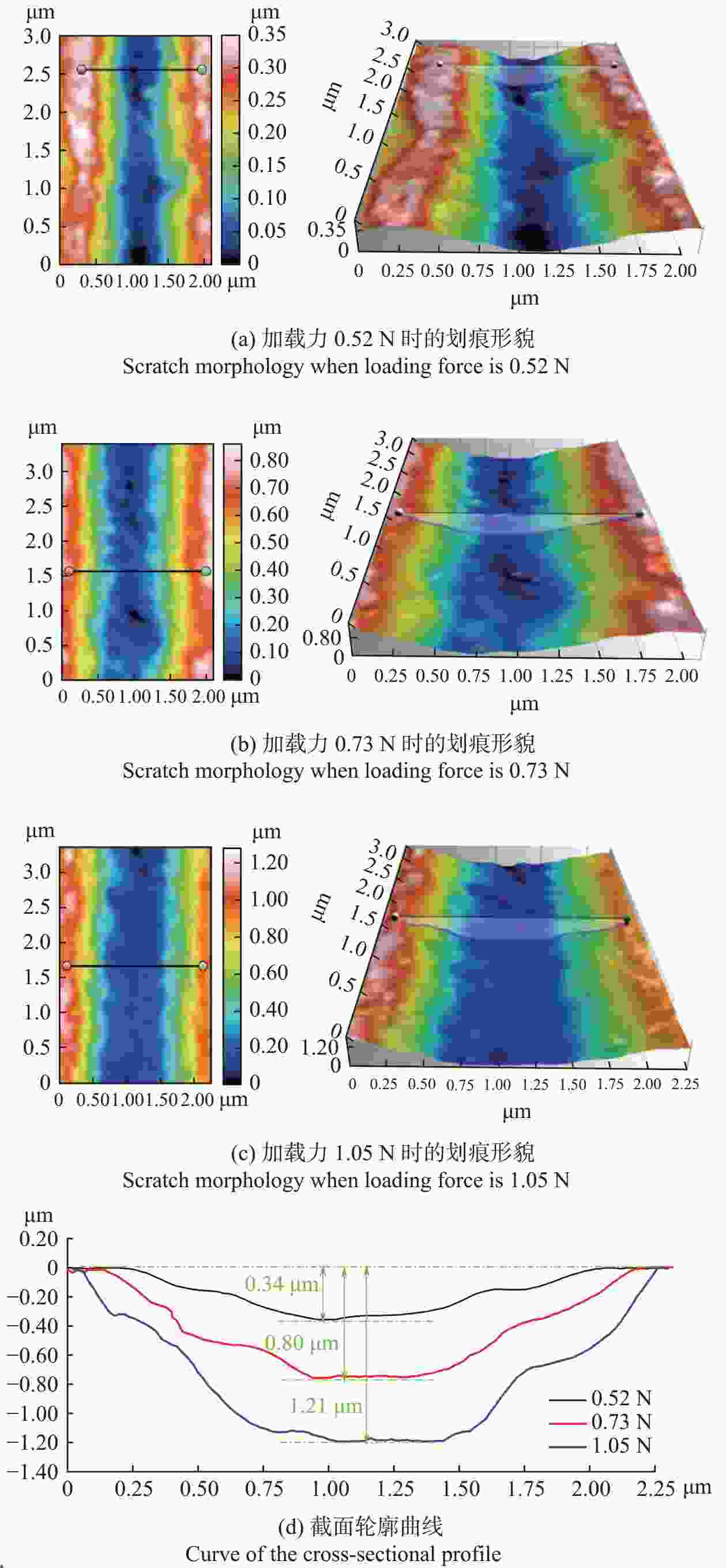

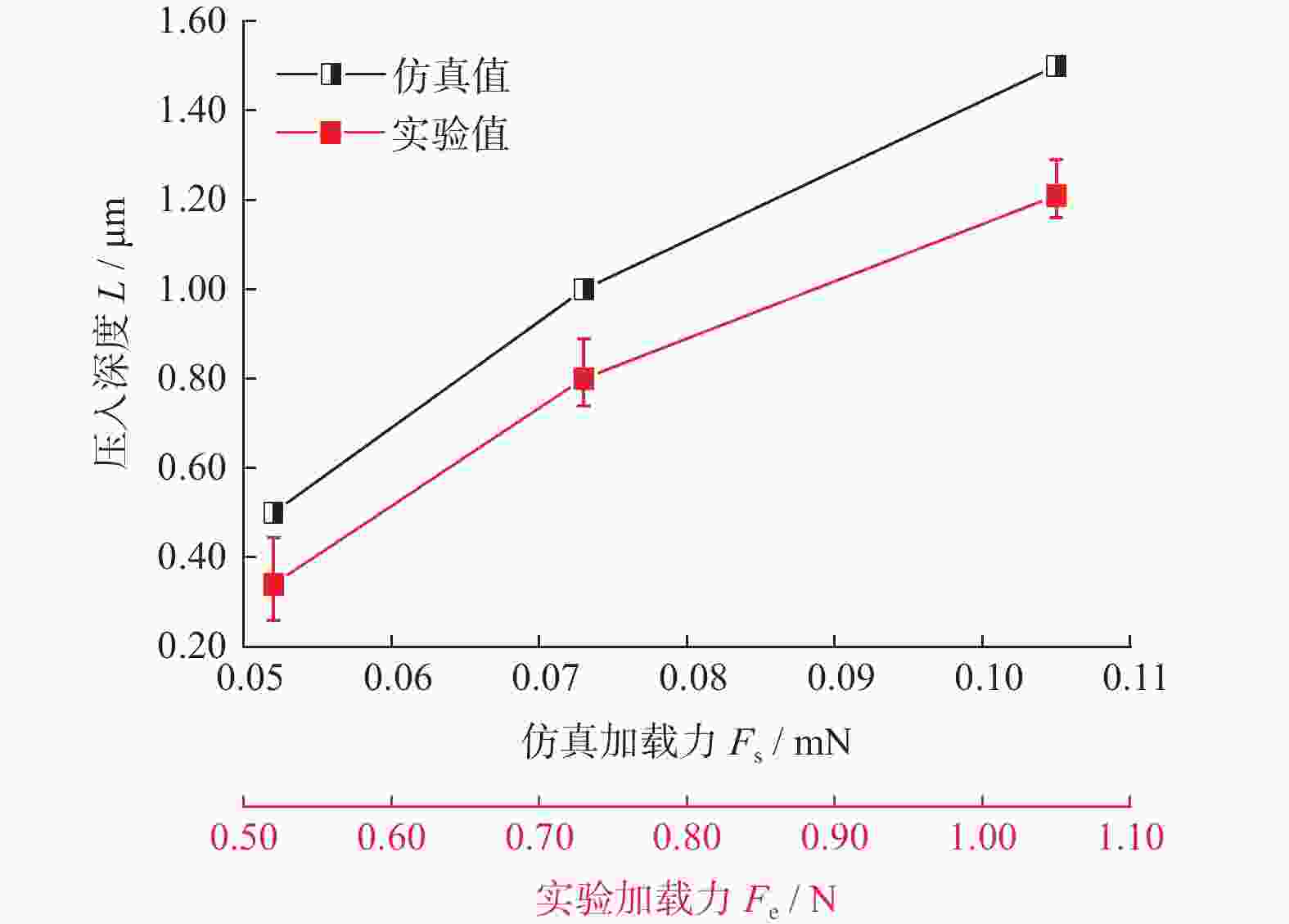

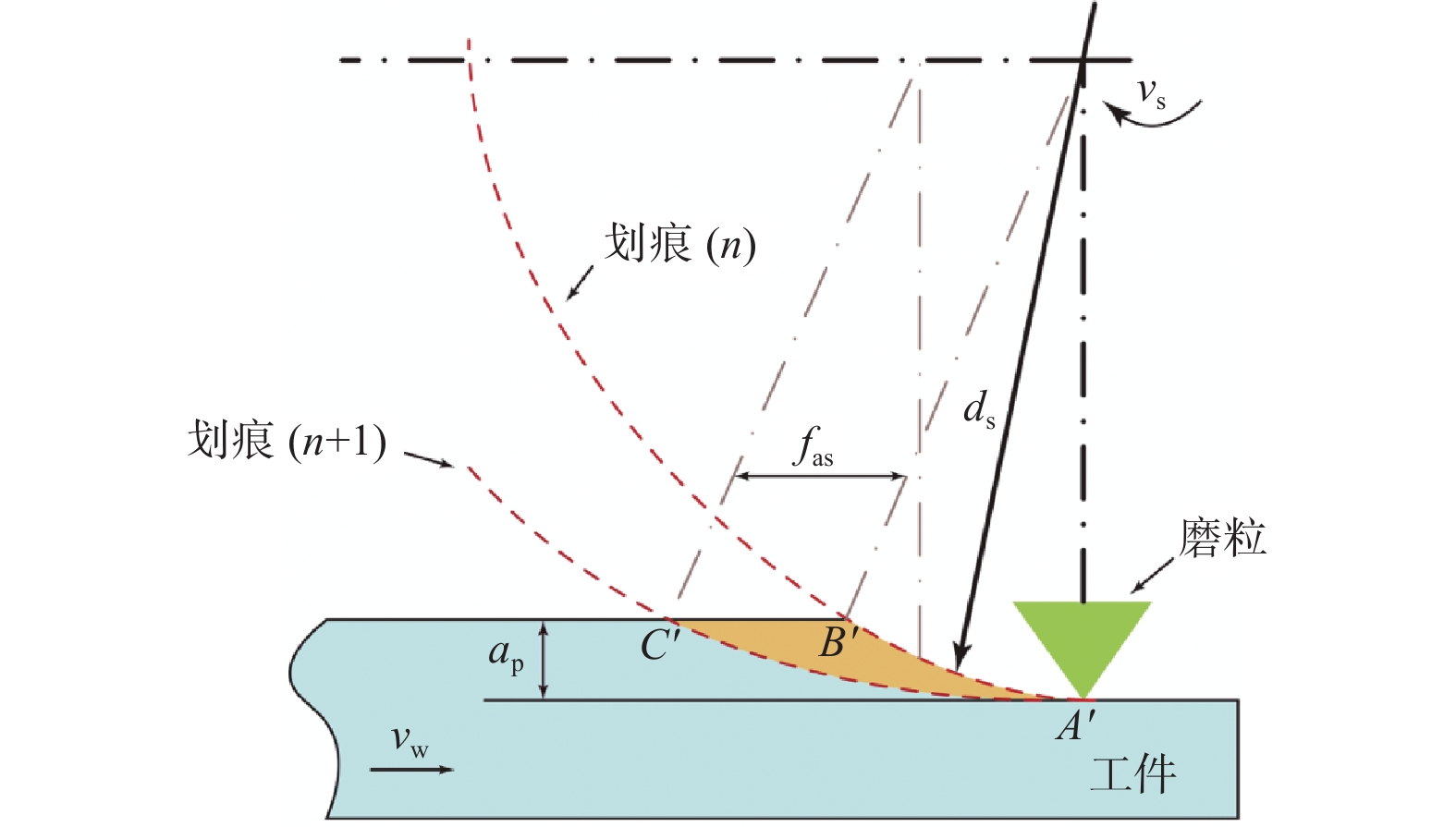

Objectives The hardness of silicon carbide is second only to those of diamond, cubic boron nitride, and boron carbide, making its processing very difficult. Compared with plastic metal materials, the brittle and hard nature of silicon carbide makes it prone to brittle fracture and edge fragmentation during processing, greatly affecting its superior performance. Therefore, it is crucial to carefully select appropriate cutting methods and establish reasonable cutting process conditions. Methods The finite element software Abaqus was used to establish a model of micro-cutting silicon carbide crystal with a diamond conical grain, and the selection range of micro-cutting depth and speed was determined by the pre-simulation model. Then, the main and secondary factors affecting the cutting force were analyzed, and the influence of a single cutting parameter on the cutting effect was studied. In addition, with the help of Hertzian contact stress, the influence of the loading force on the friction force, the morphology of the cutting edge, and the cutting depth was verified by the tip scratching experiment. Results (1) The cutting depth is a crucial factor that greatly impacts the quality of the cutting process. When the cutting depth is less than 1.50 μm, the removal of silicon carbide material primarily occurs through plastic removal. However, when the cutting depth exceeds 1.50 μm, cracks of varying lengths and pits of different sizes gradually form at the cutting edge of the workpiece. As the cutting depth increases, the length of cracks and the number of pits also increase. This type of removal is known as brittle removal. To ensure the integrity of the cutting edge and minimize damage to the silicon carbide workpiece, it is essential to control the cutting depth of the abrasive particles during stages I and III, keeping it below 1.50 μm. (2) Through variance and range analysis of the main cutting force, the relationship between the three factors and the magnitude of the main cutting force is V > W > U, meaning that cutting depth is the most important factor affecting cutting force. The optimal solution V1W1U2 and cutting parameters have been determined, namely a diamond abrasive cutting depth of 0.50 μm, a diamond abrasive cutting edge angle of 60°, and a cutting speed of 76 m/s. Cutting depth is the main factor affecting the magnitude of cutting force, while cutting speed and cutting edge angle are secondary factors. (3) As the cutting depth increases, the affected area surrounding the cut also expands, causing an increase in equivalent stress even in areas where the abrasive particles do not come into contact with the workpiece. This phenomenon is responsible for the development of cutting edge cracks and pits. Additionally, as the cutting depth increases, the main cutting force experiences greater fluctuations. To maintain cutting stability, it is important to control the cutting depth. In the high-speed cutting range of 60-106 m/s, the impact of cutting speed on cutting force is minimal. Therefore, increasing the cutting speed can be an effective method for improving cutting efficiency and ensuring high-quality cuts. For optimal results, a cutting depth of 0.50 μm and a cutting speed of 76 m/s are recommended. (4) The coefficient of friction is not only affected by the properties of the two materials in contact, but also by the depth of the diamond probe pressing into the workpiece. The greater the depth of pressing, the higher the coefficient of friction and the greater the frictional force. The surface of the microgrooves is clear and tidy, with relatively smooth edges. Under the same Hertz contact stress, the simulated depth values and experimental depth values show a consistent trend with the change in loading force. Conclusions Finite element simulation has become a valuable tool for studying the interaction and removal of materials in the precision machining of crystal materials. The purpose of this article is to investigate the removal characteristics of silicon carbide and determine the optimal range of cutting parameters. The study analyzes cutting force, stress distribution, and removal mechanisms, and proposes effective methods for enhancing cutting efficiency. The findings of this research can contribute to improving the smoothness of the cutting edge and reducing subsurface damage to the workpiece. Furthermore, this research has significant implications for understanding the impact of process parameters on cutting accuracy and the removal mechanism of hard and brittle materials during cutting. -

Key words:

- silicon carbide crystal /

- diamond grain /

- diamond tip /

- cutting force /

- cutting edge quality

-

表 1 金刚石和碳化硅的物理性能参数

Table 1. The physical properties of diamond and SiC

材料 密度 ρ' / (kg·m−3) 弹性模量 E / GPa 泊松比 ε 金刚石 3523 1050 0.07 碳化硅 3215 196 0.21 表 2 碳化硅JH-2本构模型参数

Table 2. JH-2 constitutive model parameters of SiC

参数 取值 A 0.96 B 0.35 C 0 M 1.00 N 0.65 表 3 正交试验的因素及水平

Table 3. Factors and level of orthogonal test

水平 切削速度

v / (m·s−1)切削深度

ap / μm磨粒锥角

θ / (°)U V W 1 60 0.5 60 2 76 1.0 90 3 85 1.5 120 表 4 极差分析表

Table 4. Range analysis results

No. U V W 空列 主切削力 Fc / mN 1 1 1 1 1 0.08 2 1 2 2 2 0.39 3 1 3 3 3 0.95 4 2 1 2 3 0.31 5 2 2 3 1 0.52 6 2 3 1 2 0.49 7 3 1 3 2 0.30 8 3 2 1 3 0.43 9 3 3 2 1 0.68 K1 1.42 0.70 1.00 1.29 K2 1.32 1.34 1.38 1.18 K3 1.41 2.12 1.78 1.68 k1 0.47 0.23 0.33 0.43 k2 0.44 0.45 0.46 0.39 k3 0.47 0.71 0.59 0.56 R 0.03 0.47 0.26 0.17 表 5 方差分析结果

Table 5. Variance analysis results

差异源 SS df MS F P-value 显著性 U 0.002 2 0.001 0.08 6.94 V 0.337 2 0.168 13.75 6.94 * W 0.100 2 0.050 4.12 6.94 误差e 0.047 2 0.023 误差eΔ 0.049 4 0.012 总和 0.536 12 -

[1] XUN Q, XUN B Y, LI Z X, et al. Application of SiC power electronic devices in secondary power source for aircraft [J]. Renewable and Sustainable Energy Reviews,2017,70:1336-1342. doi: 10.1016/j.rser.2016.12.035 [2] HE Y, YUAN Z W, TANG M L, et al. Mechanism of chemical and mechanical mutual promotion in photocatalysis-assisted chemical mechanical polishing for single-crystal SiC [J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science,2022,236(24):11464-11478. doi: 10.1177/09544062221117953 [3] CHOI P H, KIM Y P, KIM M S, et al. Side-illuminated photoconductive semiconductor switch based on high purity semi-insulating 4H-SiC [J]. IEEE Transactions on Electron Devices,2021,68(12):6216-6221. doi: 10.1109/TED.2021.3117535 [4] MATSUNAMI H. Fundamental research on semiconductor SiC and its applications to power electronics [J]. Proceedings of the Japan Academy Series B-Physical and Biological Sciences,2020,96(7):235-254. doi: 10.2183/pjab.96.018 [5] KITAHARA H, NODA Y, YOSHIDA F, et al. Mechanical behavior of single crystalline and polycrystalline silicon carbides evaluated by Vickers indentation [J]. Journal of the Ceramic Society of Japan,2001,109(1271):602-606. doi: 10.2109/jcersj.109.1271_602 [6] 魏正义, 高兴军, 邓子龙, 等. 基于ABAQUS的超声椭圆振动车削GH4169的切削性能研究 [J]. 辽宁石油化工大学学报,2021,41(6):67-71. doi: 10.3969/j.issn.1672-6952.2021.06.013WEI Zhengyi, GAO Xingjun, DENG Zilong, et al. Research on cutting performance of GH4169 in ultrasonic ellipticavibration turning based on ABAQUS [J]. Journal of Liaoning Petrochemical University,2021,41(6):67-71. doi: 10.3969/j.issn.1672-6952.2021.06.013 [7] KAMIYA O, TAKAHASHI M, MIYANO Y, et al. Cutting of diamond substrate using fixed diamond grain saw wire [J]. Materials,2022,15(16):5524. doi: 10.3390/ma15165524 [8] YIN Y K, GAO Y F, YANG C F. Sawing characteristics of diamond wire cutting sapphire crystal based on tool life cycle [J]. Ceramics International,2021,47(19):26627-26634. doi: 10.1016/j.ceramint.2021.06.070 [9] ZHANG J G, SUZUKI N, WANG YI L, et al. Fundamental investigation of ultra-precision ductile machining of tungsten carbide by applying elliptical vibration cutting with single crystal diamond [J]. Journal of Materials Processing Technology,2014,214(11):2644-2659. doi: 10.1016/j.jmatprotec.2014.05.024 [10] WANG H J, YANG T. A review on laser drilling and cutting of silicon [J]. Journal of the European Ceramic Society,2021,41(10):4997-5015. doi: 10.1016/j.jeurceramsoc.2021.04.019 [11] CHEN Z J, ZHAO S D, ZHAO Y H. Electrochemical jet-assisted precision grinding of single-crystal SiC using soft abrasive wheel [J]. International Journal of Mechanical Sciences,2021,195:106239. doi: 10.1016/j.ijmecsci.2020.106239 [12] JI S J, LIU LL, ZHAO J, et al. Finite element analysis and simulation about microgrinding of SiC [J]. Journal of Nanomaterials, 2015, 2015: 575398. [13] WEI J H, WANG H J, LIN B, et al. A force model in single grain grinding of long fiber reinforced woven composite [J]. The International Journal of Advanced Manufacturing Technology,2019,100(1/2/3/4):541-52. doi: 10.1007/s00170-018-2719-x [14] GU Y, ZHU W, LIN J, et al. Subsurface damage in polishing process of silicon carbide ceramic [J]. Materials (Basel),2018,11(4):506. doi: 10.3390/ma11040506 [15] GUERRINI G, BRUZZONE A A G, CRENNA F. Single grain grinding: An experimental and FEM assessment [J]. Procedia CIRP,2017,62:287-292. doi: 10.1016/j.procir.2016.07.082 [16] DAI J B, SU H H, HU H, et al. The influence of grain geometry and wear conditions on the material removal mechanism in silicon carbide grinding with single grain [J]. Ceramics International,2017,43(15):11973-11980. doi: 10.1016/j.ceramint.2017.06.047 [17] ZHOU W B, SU H H, DAI J B, et al. Numerical investigation on the influence of cutting-edge radius and grinding wheel speed on chip formation in SiC grinding [J]. Ceramics International,2018,44(17):21451-21460. doi: 10.1016/j.ceramint.2018.08.206 [18] LIU Y, LI B Z, WU C J, et al. Smoothed particle hydrodynamics simulation and experimental analysis of SiC ceramic grinding mechanism [J]. Ceramics International,2018,44(11):12194-12203. doi: 10.1016/j.ceramint.2018.03.278 [19] DU J G, ZHANG H Z, MA J, et al. Simulation and experimental study on single diamond grit of machining SiCp/Al composites [J]. Modern Manufacturing Engineering,2019,26(1):29-40. [20] DUAN N, YU Y Q, WANG W S, et al. SPH and FE coupled 3D simulation of monocrystal SiC scratching by single diamond grit [J]. International Journal of Refractory Metals and Hard Materials,2017,64:279-293. doi: 10.1016/j.ijrmhm.2016.09.016 [21] NGUYEN V T, FANG T H. Material removal and interactions between an abrasive and a SiC substrate: a molecular dynamics simulation study [J]. Ceramics International,2020,46(5):5623-5633. doi: 10.1016/j.ceramint.2019.11.006 [22] LIU Y, LI B Z, KONG L F. Atomistic insights on the nanoscale single grain scratching mechanism of silicon carbide ceramic based on molecular dynamics simulation [J]. AIP Advances,2018,8(3):035109. doi: 10.1063/1.5019683 [23] MENG B B, YUAN D D, XU S L. Study on strain rate and heat effect on the removal mechanism of SiC during nano-scratching process by molecular dynamics simulation [J]. International Journal of Mechanical Sciences,2019,151:724-732. doi: 10.1016/j.ijmecsci.2018.12.022 [24] WU Z H, ZHANG L C, YANG S Y. Effect of abrasive grain position patterns on the deformation of 6H-silicon carbide subjected to nano-grinding [J]. International Journal of Mechanical Sciences,2021,211:106779. doi: 10.1016/j.ijmecsci.2021.106779 [25] ZHOU P, SHI X D, LI J, et al. Molecular dynamics simulation of SiC removal mechanism in a fixed abrasive polishing process [J]. Ceramics International,2019,45(12):14614-14624. doi: 10.1016/j.ceramint.2019.04.180 [26] 凡林, 邓子龙, 高兴军, 等. 基于田口法的微织构PCBN刀具织构参数优化 [J]. 辽宁石油化工大学学报,2021,41(4):71-77. doi: 10.3969/j.issn.1672-6952.2021.04.012FAN Lin, DENG Zilong, GAO Xingjun, et al. Optimization of texture parameters of micro-textured PCBN tool based on taguchi method [J]. Journal of Liaoning Petrochemical University,2021,41(4):71-77. doi: 10.3969/j.issn.1672-6952.2021.04.012 [27] SHIBATA T, FUJII S, MAKINO E, et al. Ductile-regime turning mechanism of single-crystal silicon [J]. Precision Engineering,1996,18(2/3):129-137. [28] CHAI P, LI S J, LI Y. Modeling and experiment of the critical depth of cut at the ductile–brittle transition for a 4H-SiC single crystal [J]. Micromachines,2019,10(6):382. doi: 10.3390/mi10060382 [29] ZHANG B, YIN J F. The ‘skin effect’ of subsurface damage distribution in materials subjected to high-speed machining [J]. International Journal of Extreme Manufacturing,2019,1(1):012007. doi: 10.1088/2631-7990/ab103b [30] ZHANG D Z, ZHAO L, ROY A. Mechanical behavior of silicon carbide under static and dynamic compression [J]. Journal of Engineering Materials and Technology,2019,141(1):011007. doi: 10.1115/1.4040591 [31] TAN Y Q, YANG D M, SHENG Y. Discrete element method (DEM) modeling of fracture and damage in the machining process of polycrystalline SiC [J]. Journal of the European Ceramic Society,2009,29(6):1029-1037. doi: 10.1016/j.jeurceramsoc.2008.07.060 [32] AGARWAL S, RAO P V. Experimental investigation of surface/subsurface damage formation and material removal mechanisms in SiC grinding [J]. International Journal of Machine Tools and Manufacture,2008,48(6):698-710. doi: 10.1016/j.ijmachtools.2007.10.013 [33] WANG X, LI Y Q, XU J K, et al. Comparison and research on simulation models of aluminum-based silicon carbide micro-cutting [J]. International Journal of Advanced Manufacturing Technology,2020,109(1/2):589-605. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS