Surface defects in ultrasonic vibration assisted cutting of TiCp/TC4 with PCD tool

-

摘要:

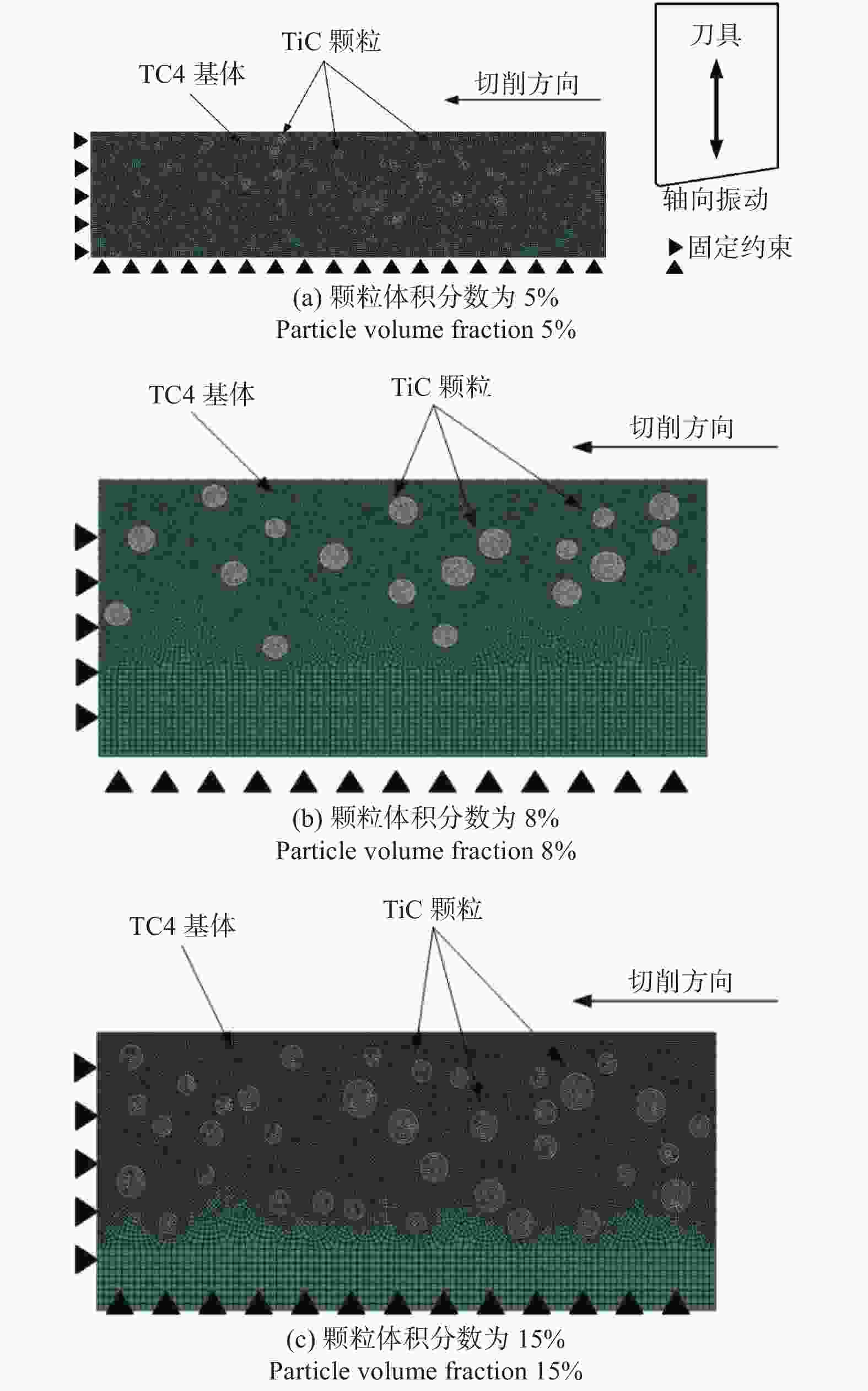

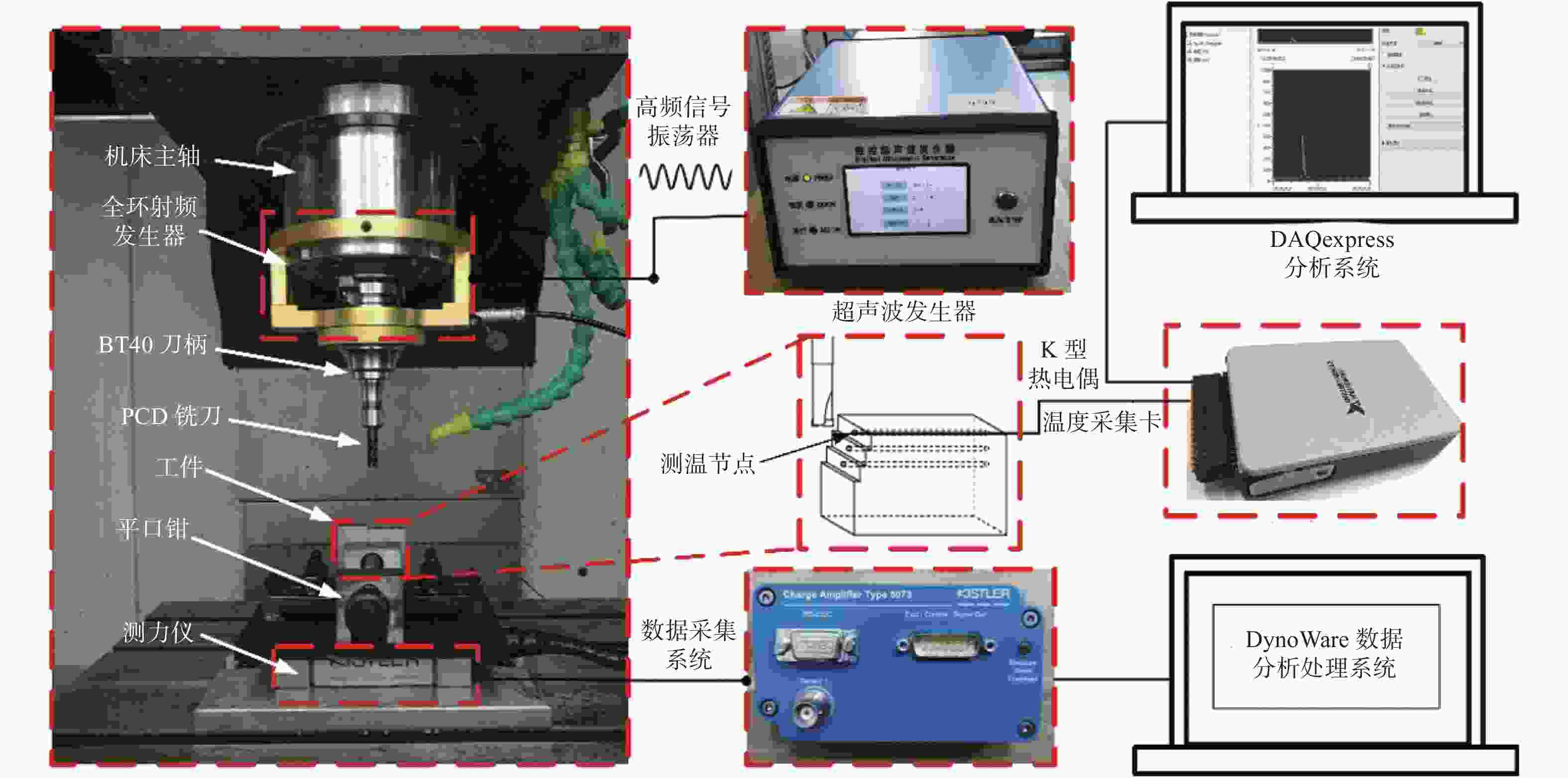

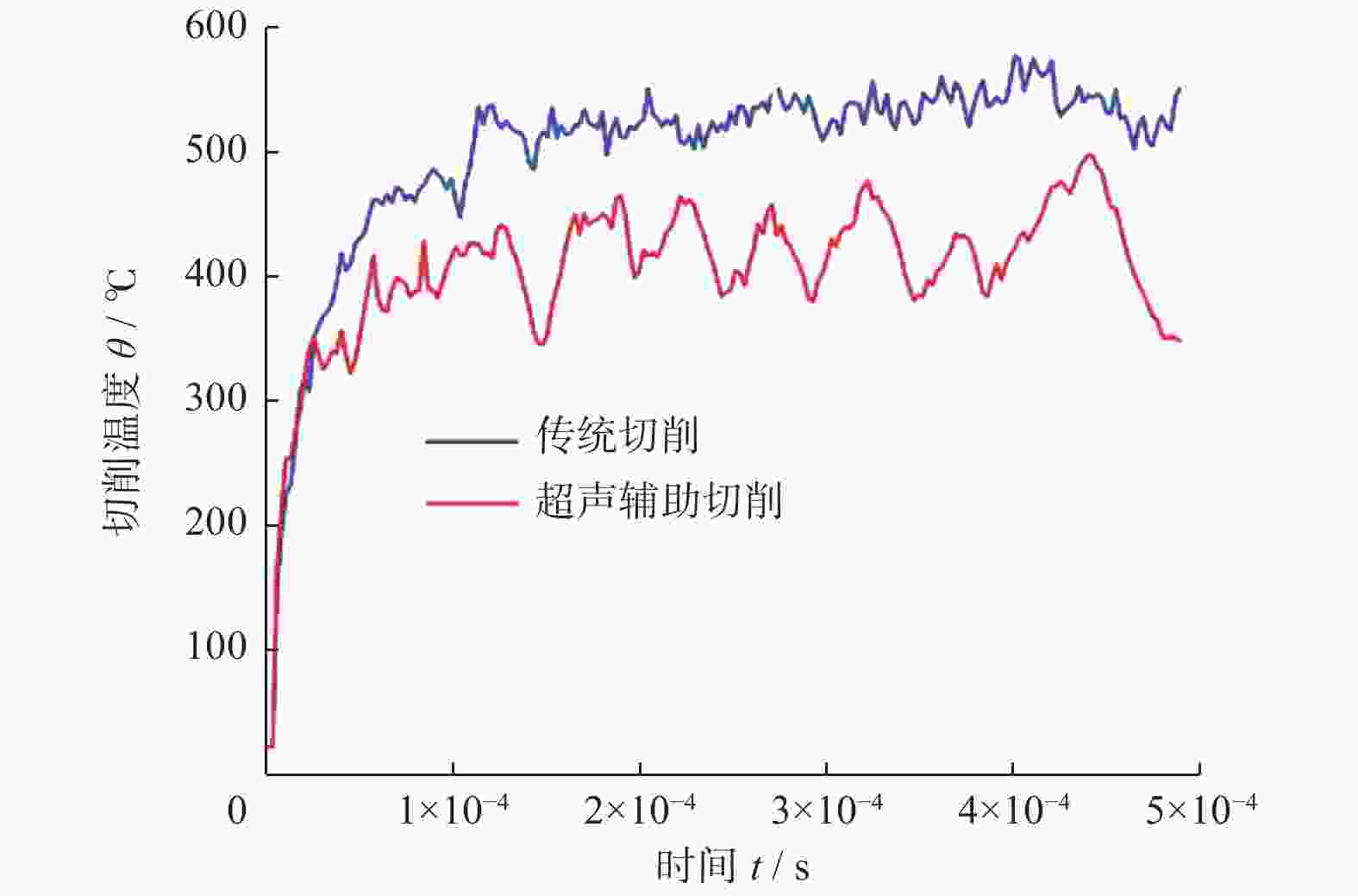

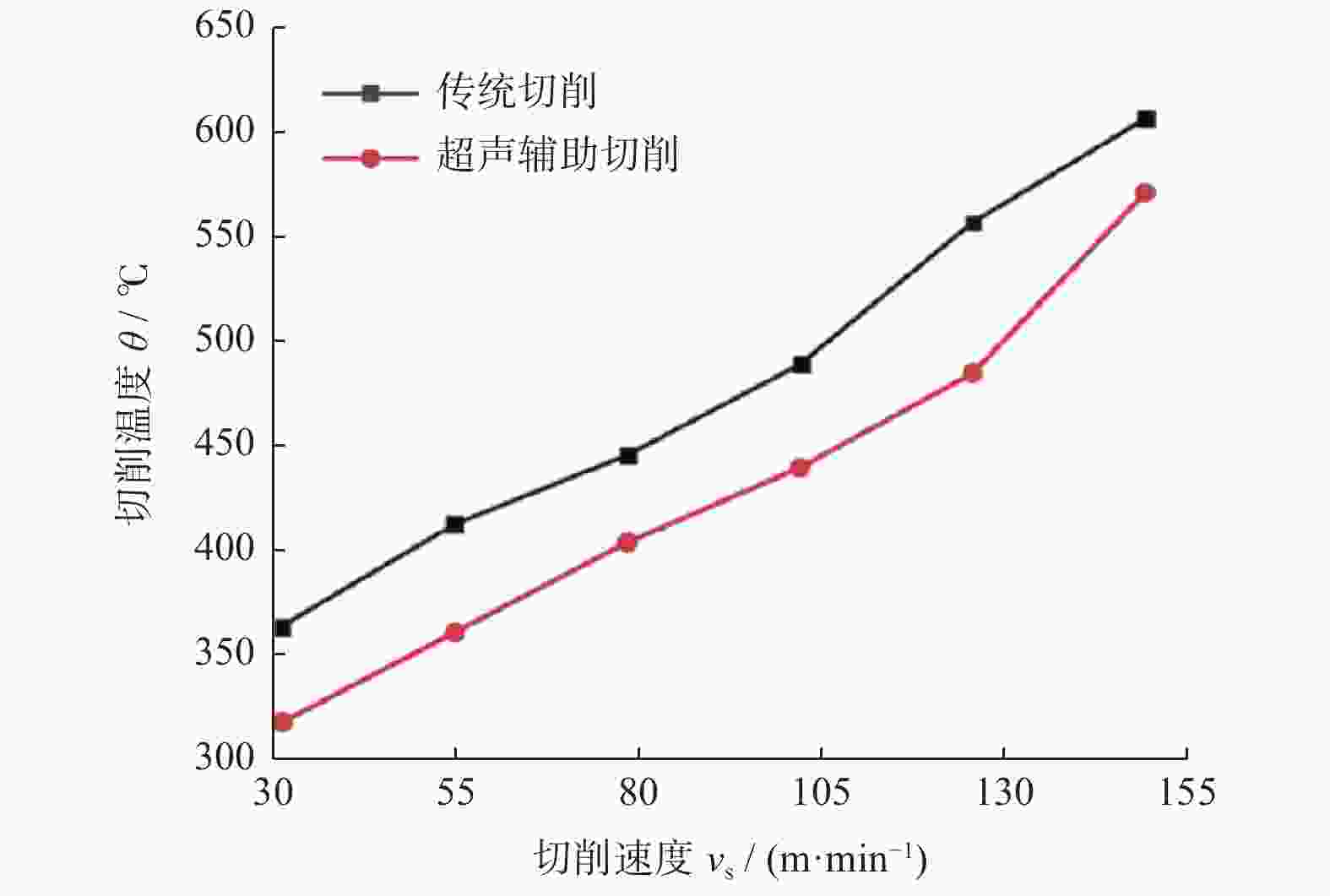

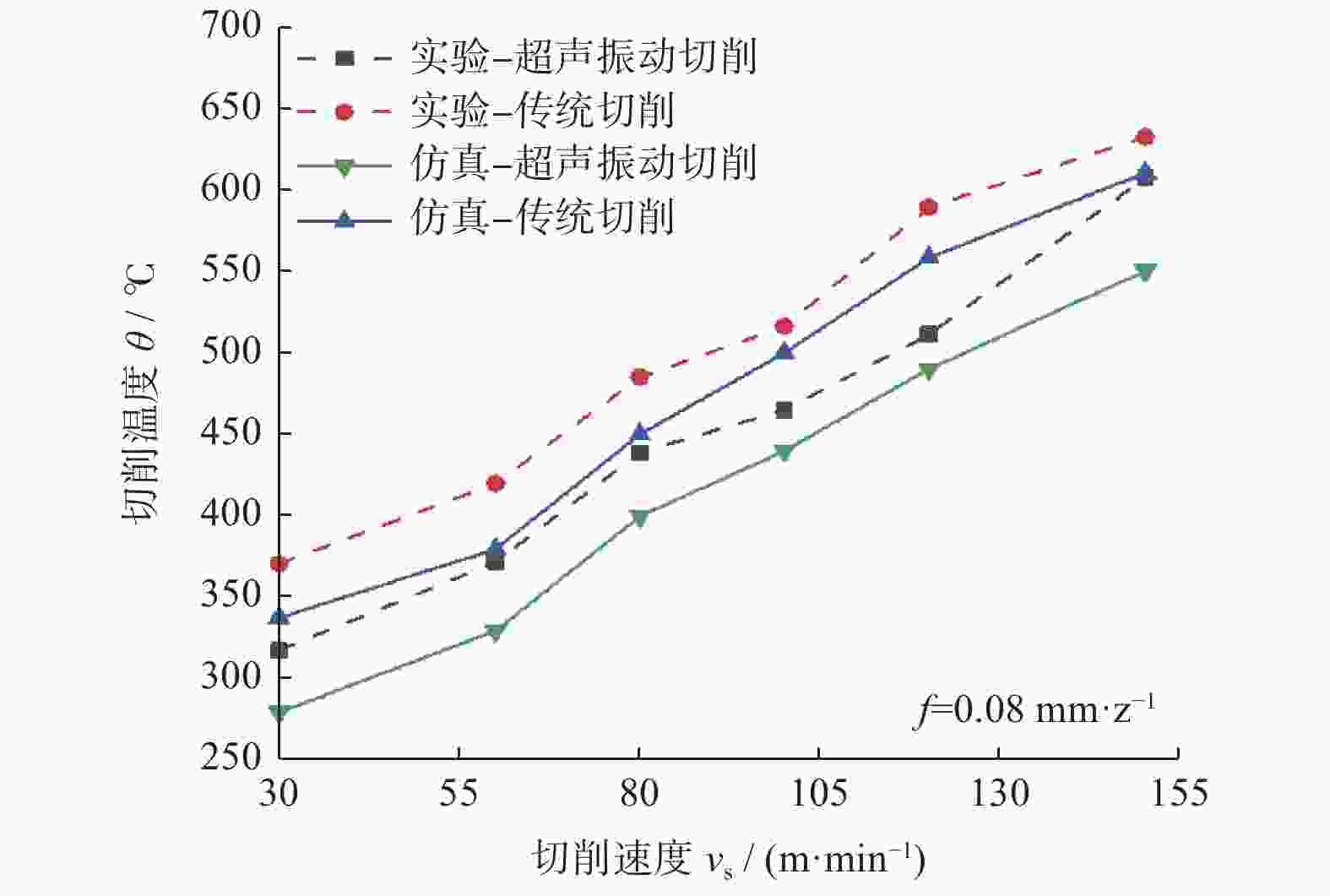

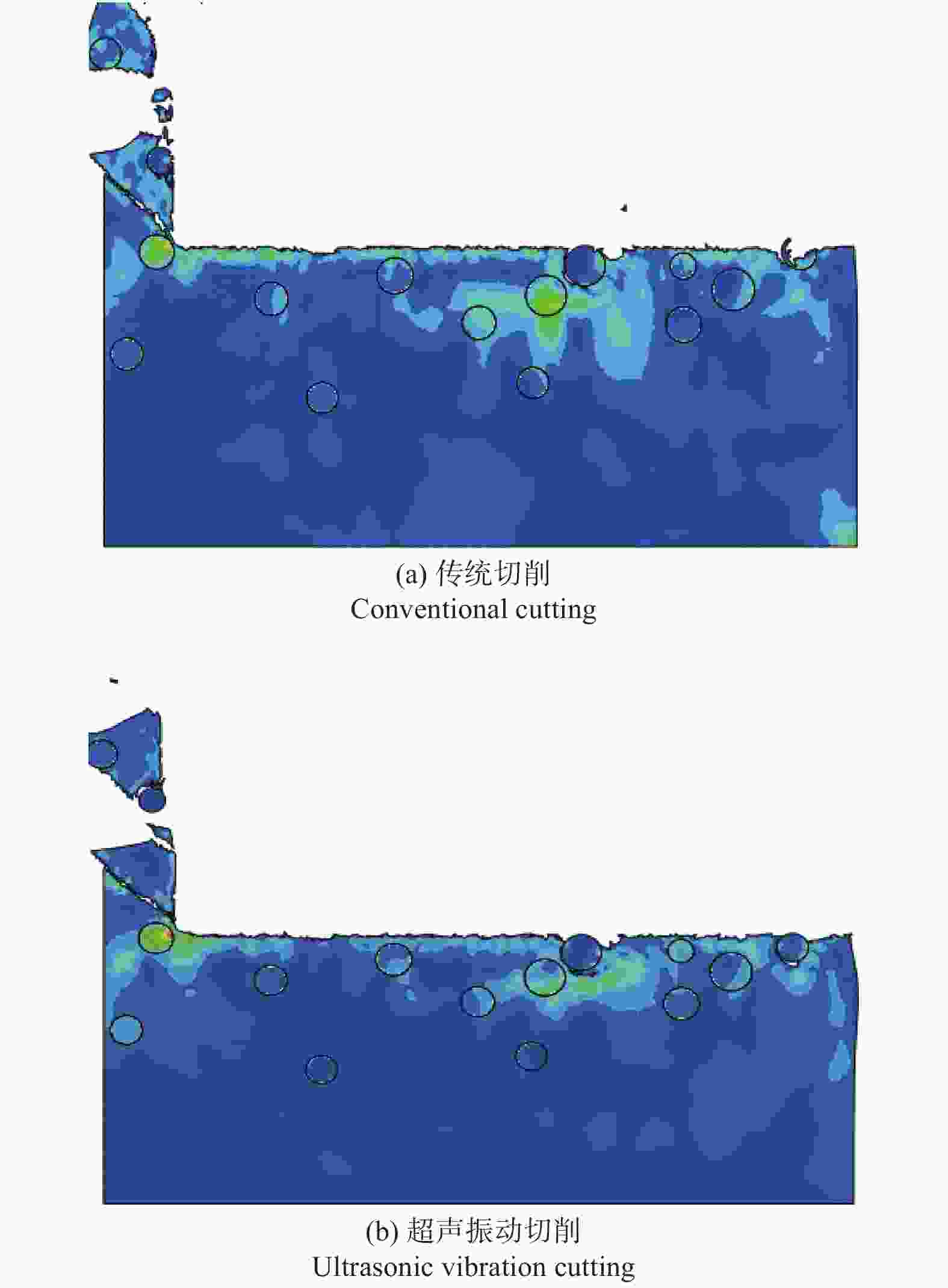

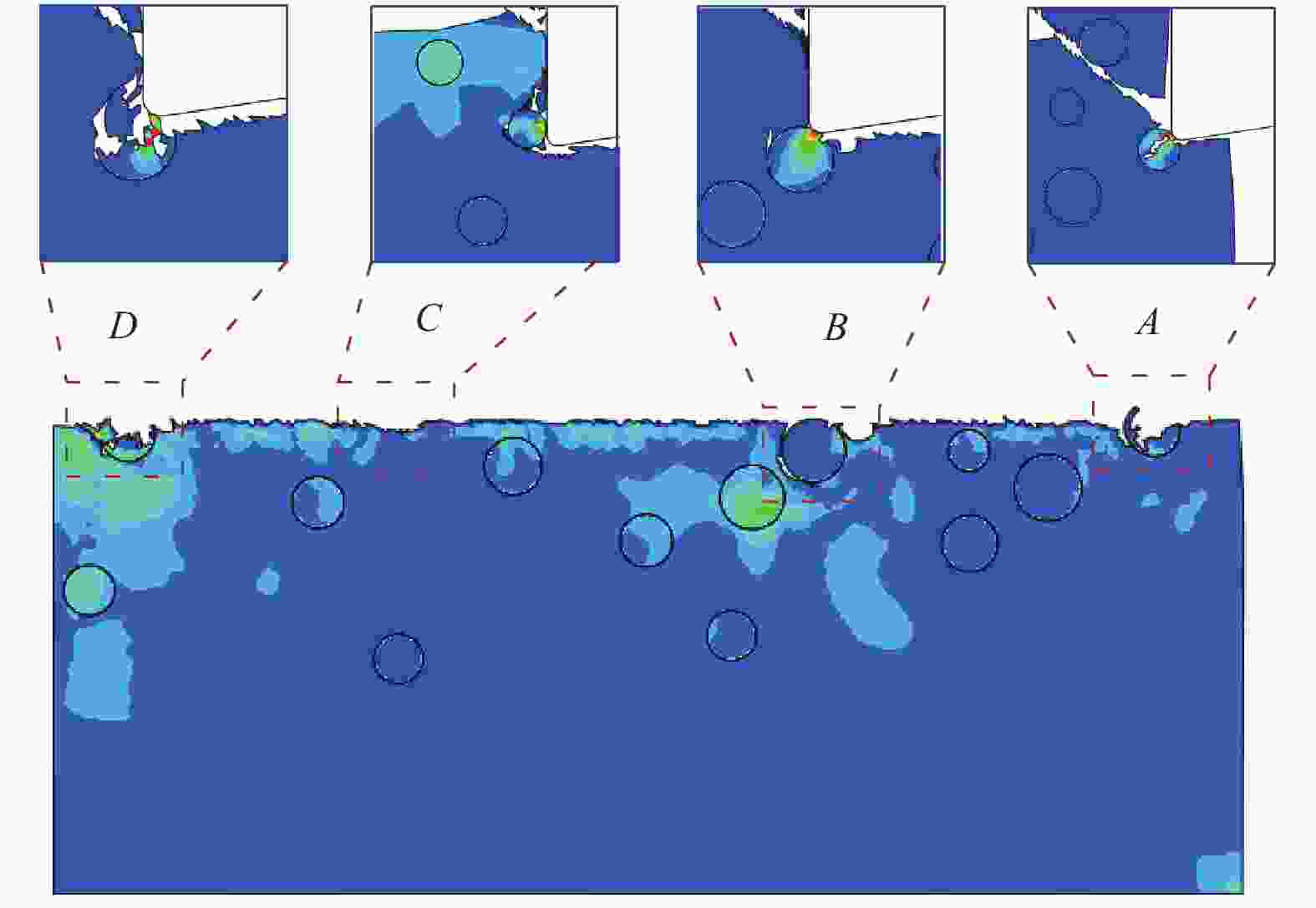

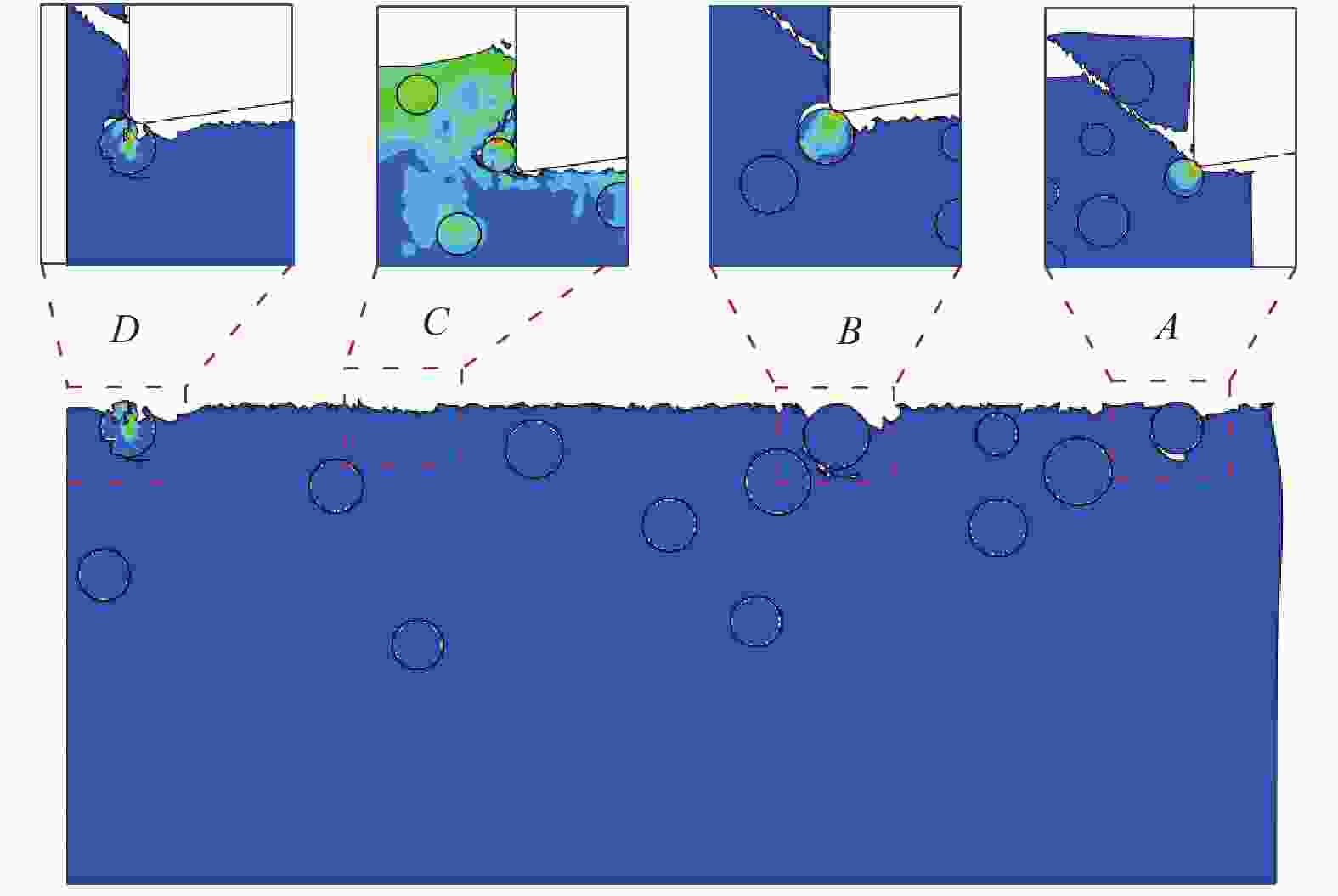

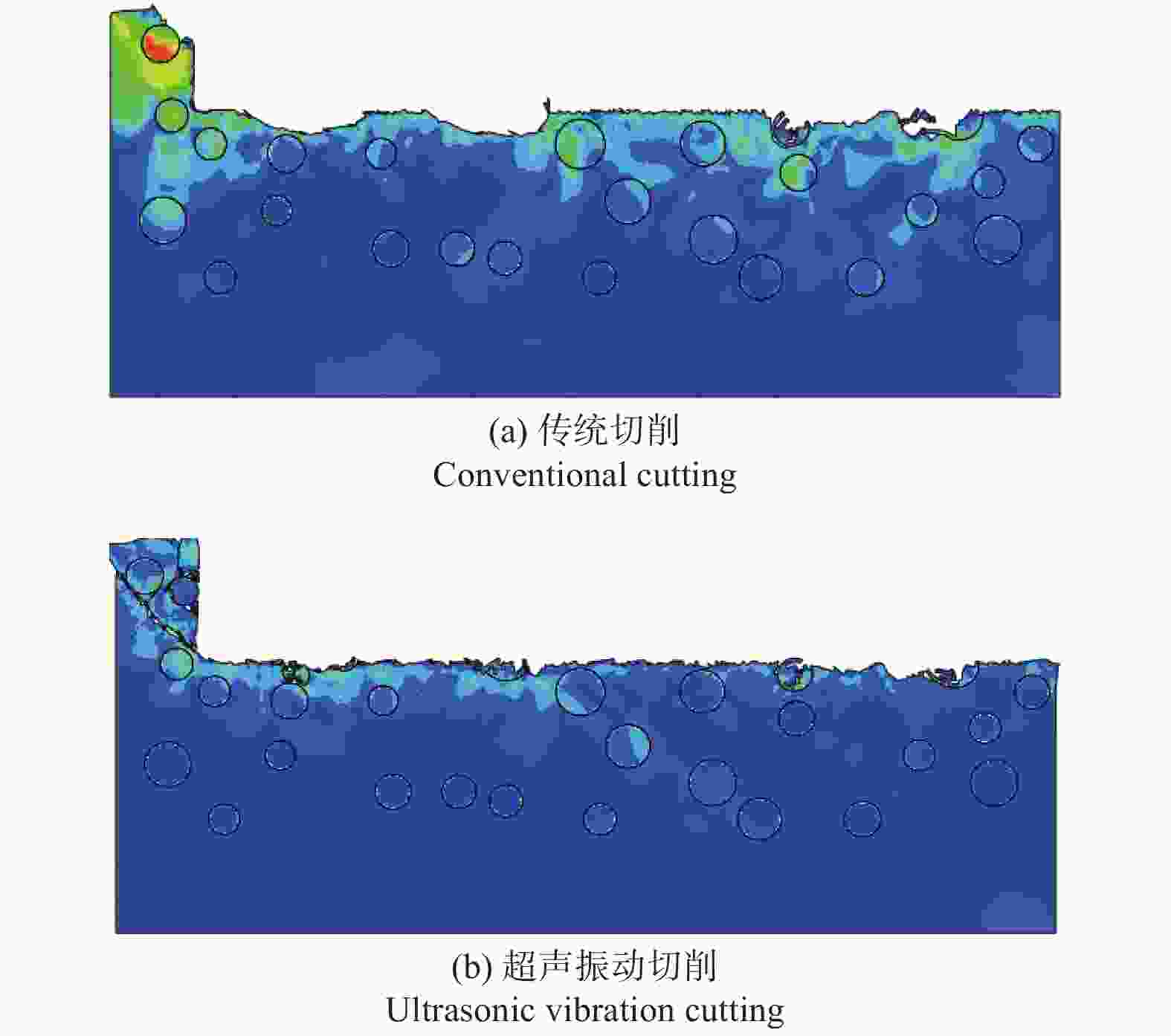

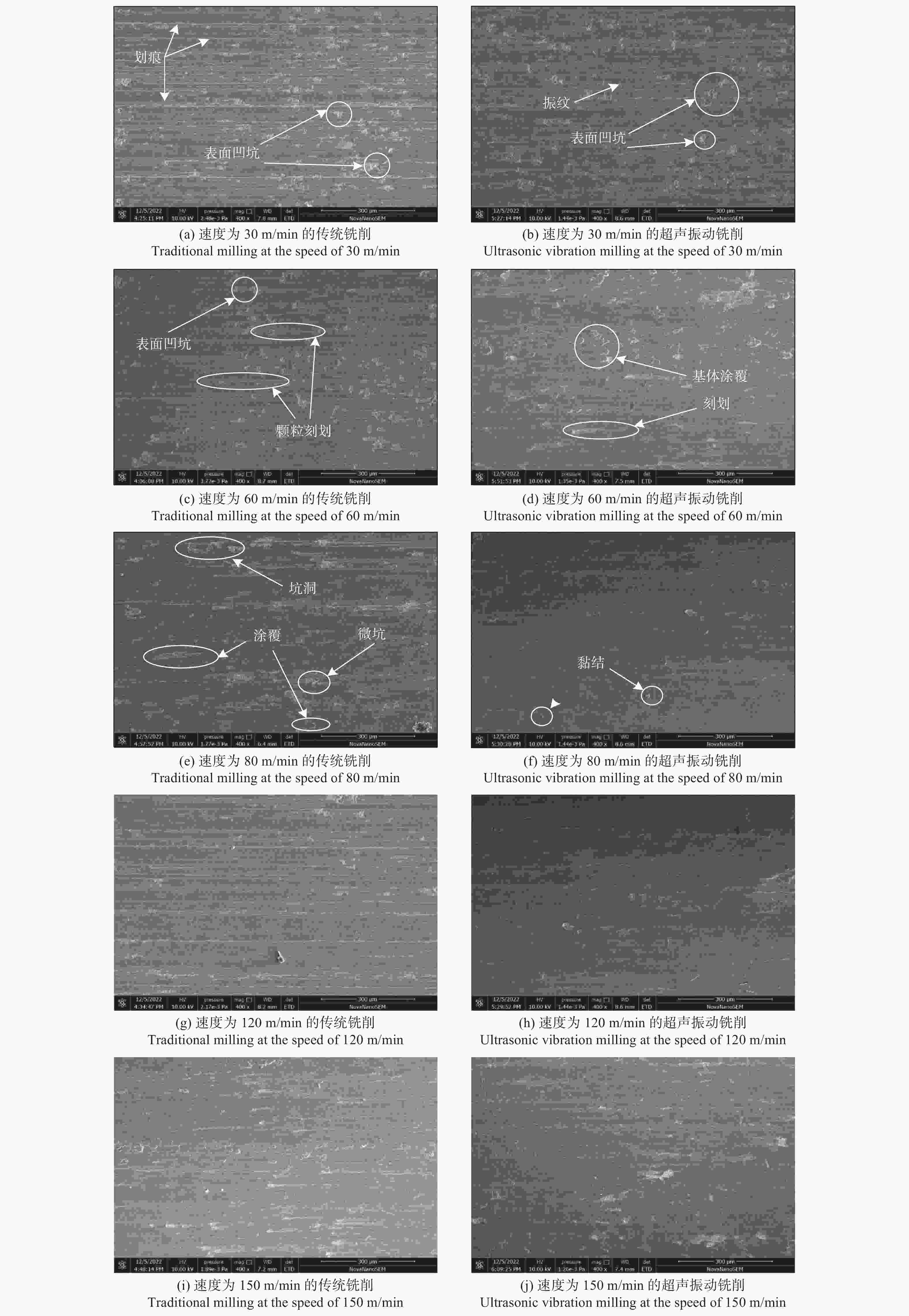

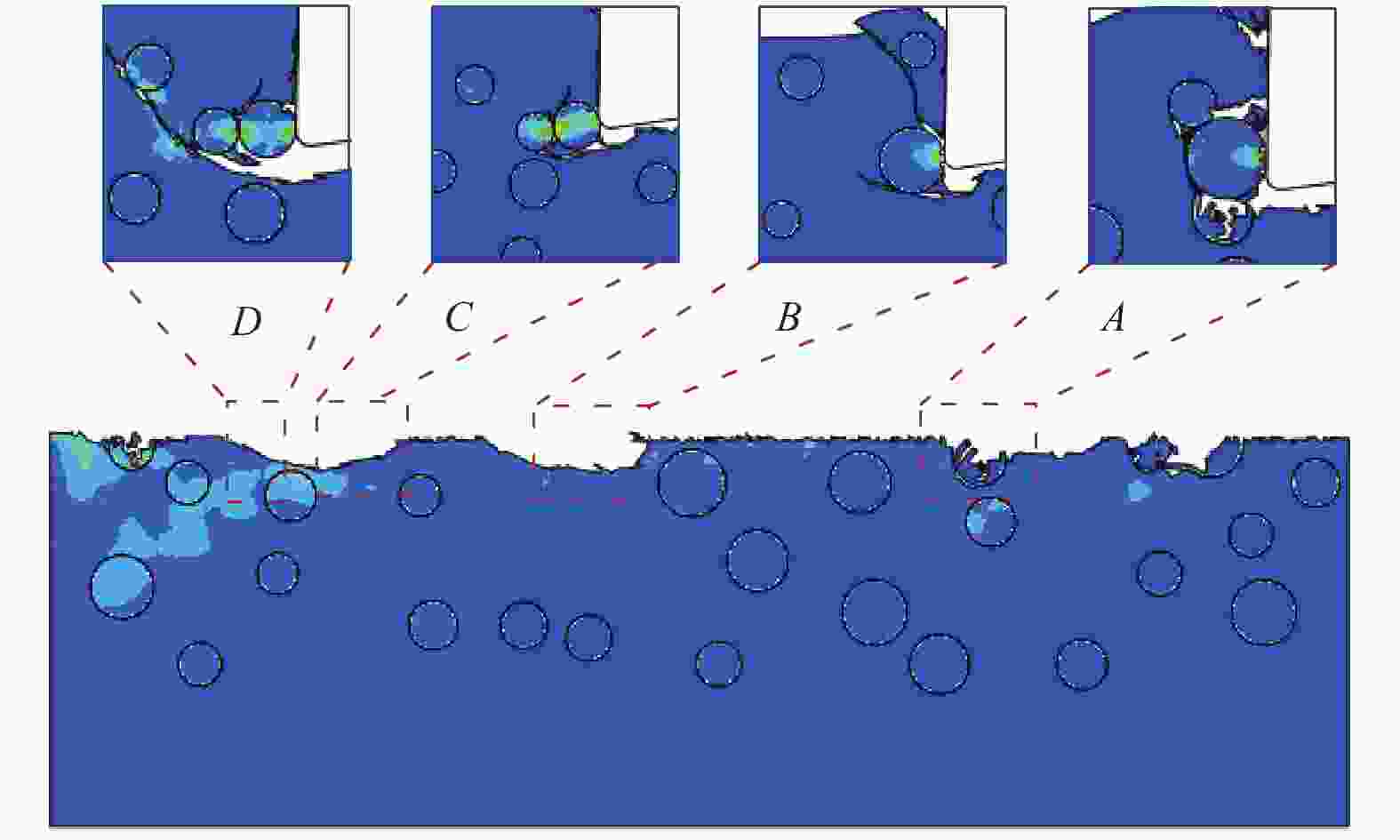

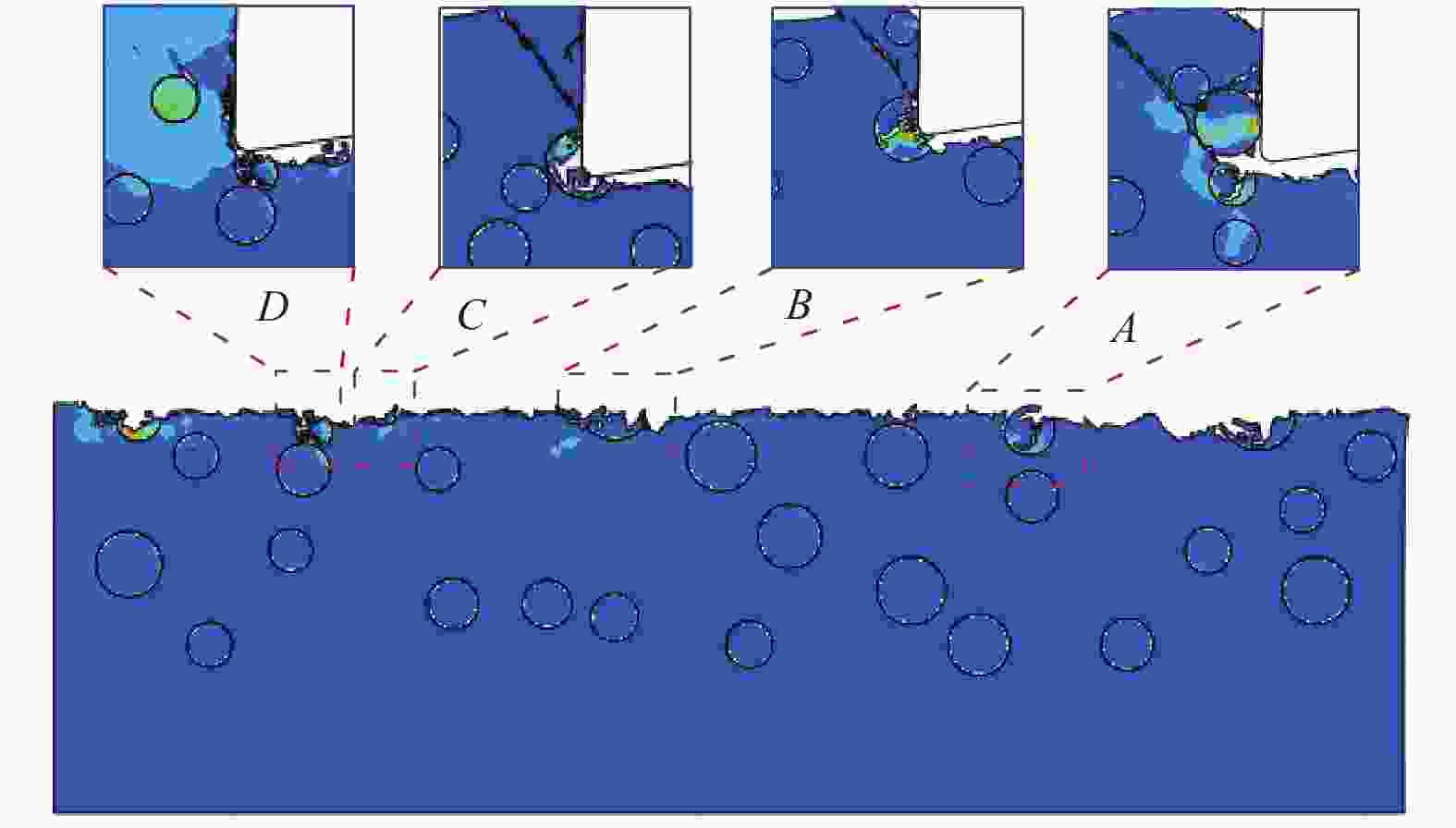

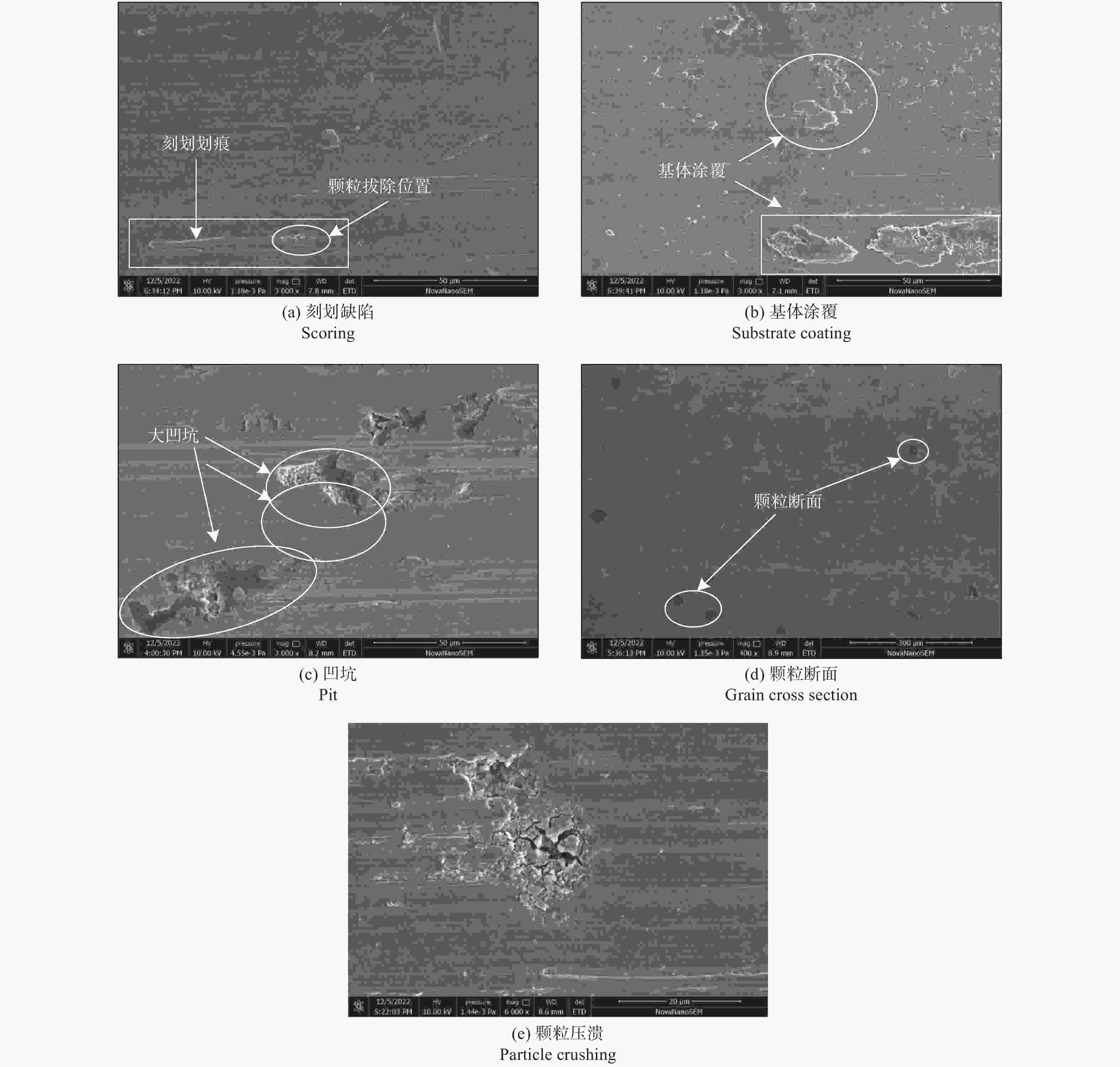

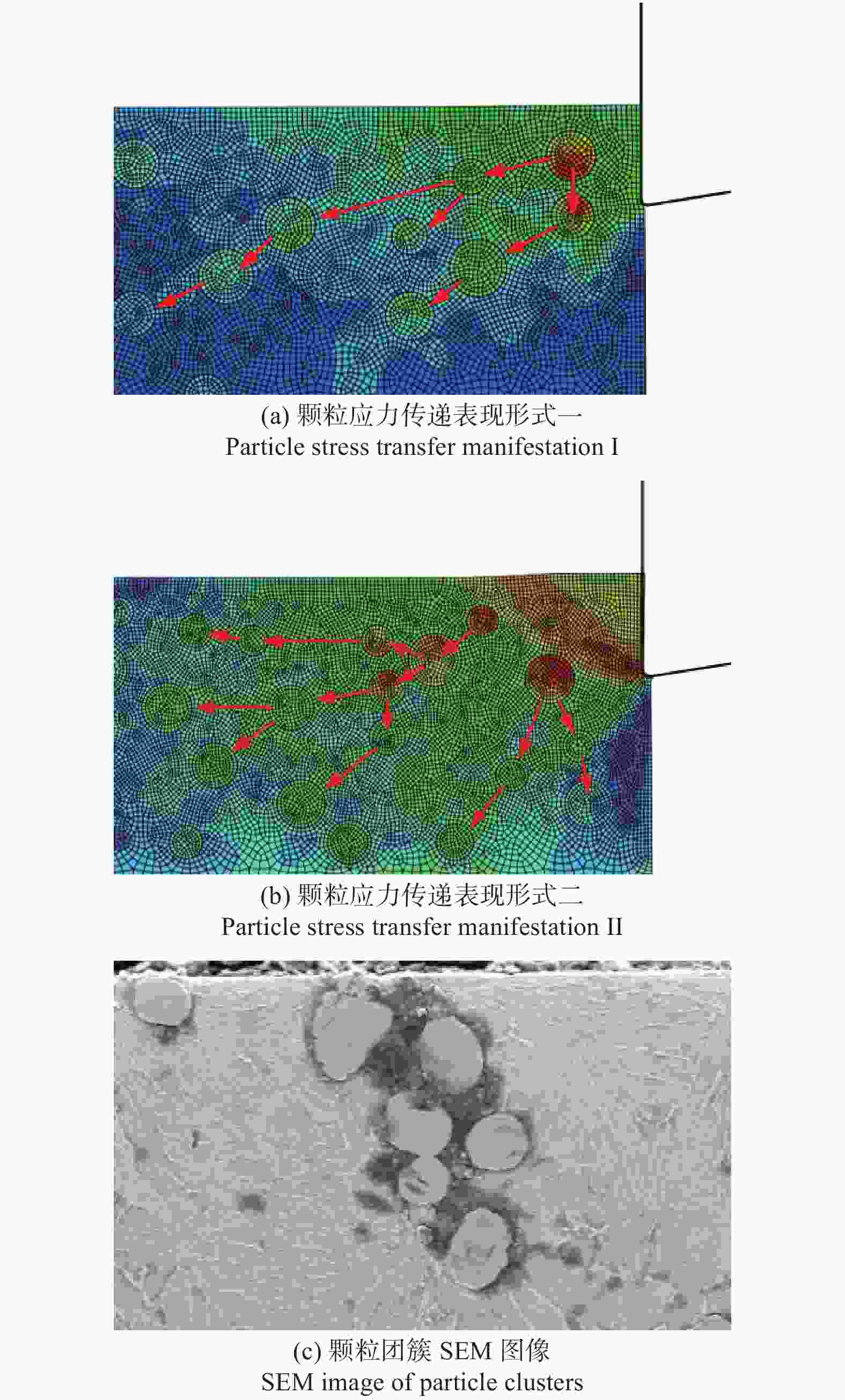

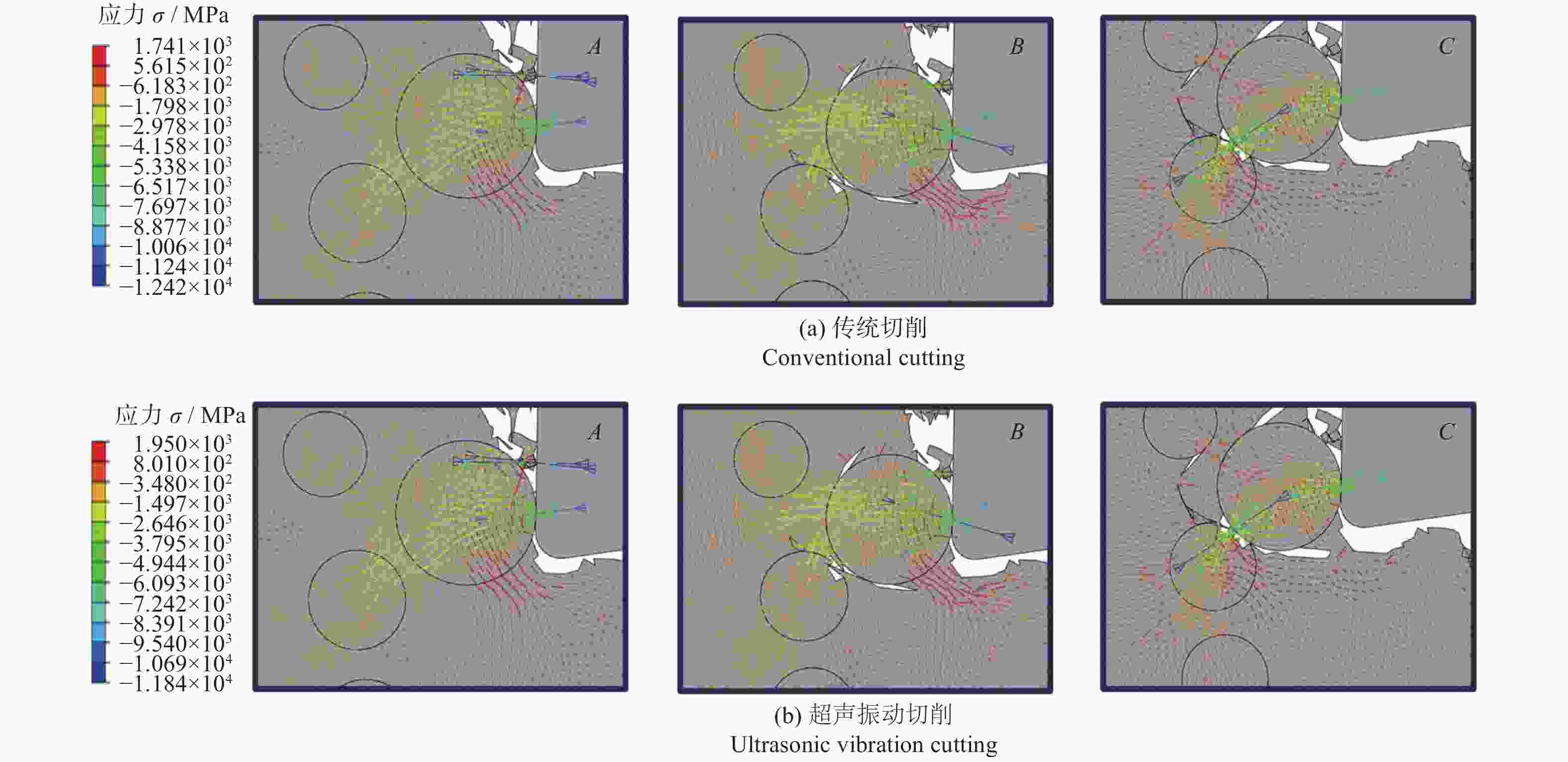

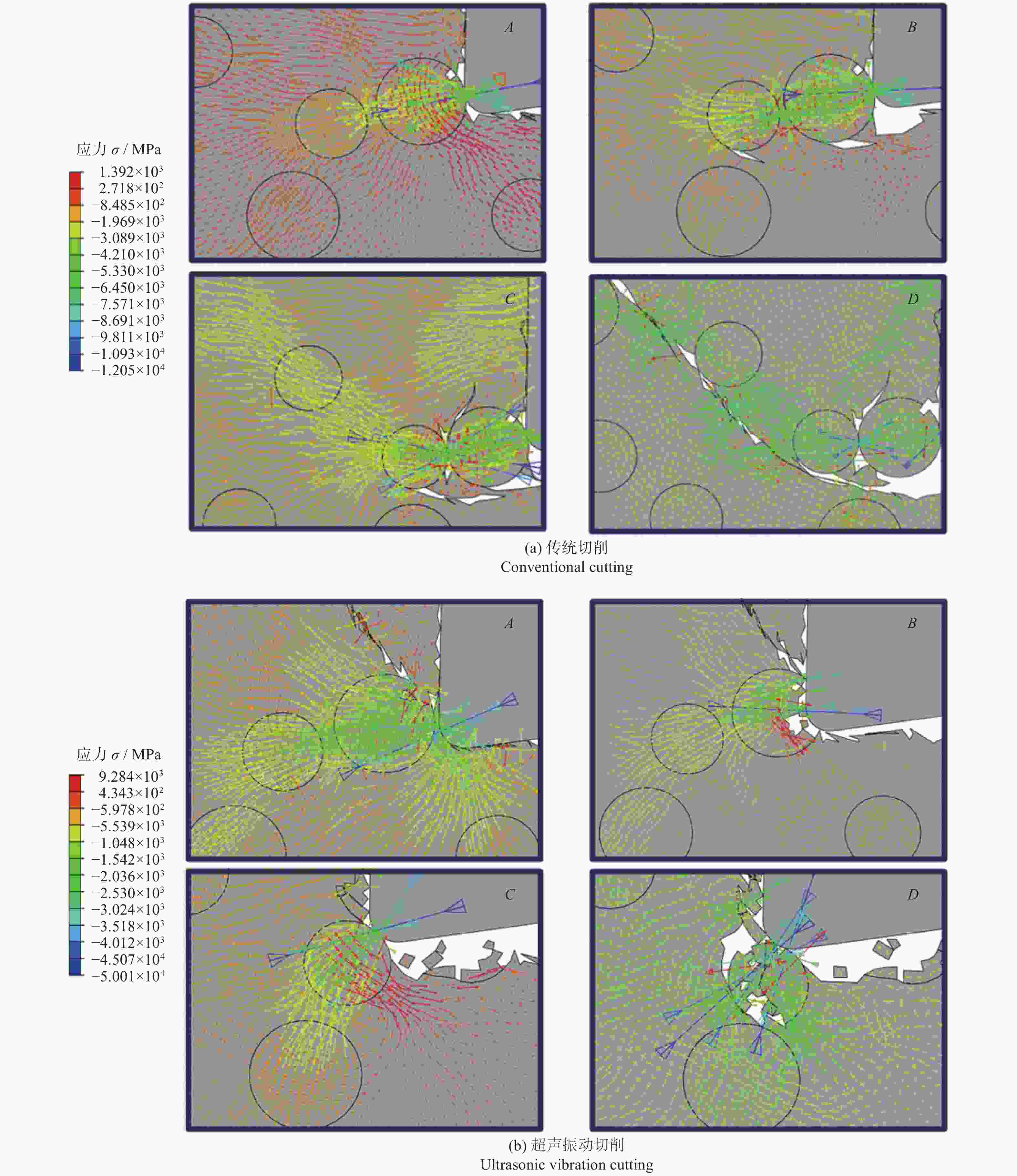

研究微观角度下PCD刀具超声振动辅助切削TiCp/TC4时,超声振动对材料表面缺陷的影响。基于ABAQUS/Explicit有限元软件,建立PTMCs二维切削微观非均质模型,开展不同体积分数下的多颗粒切削仿真;并采用仿真和实验相结合的方法,分析切削速度对切削温度变化的影响规律,阐述TiCp/TC4在切削过程中的颗粒受力破碎过程,讨论同体积分数的TiCp/TC4切削表面缺陷的表现形式。结果表明:超声振动切削时,切削温度始终较低,TiCp/TC4表面缺陷表现形式多为颗粒切断和颗粒突起;且超声振动能有效阻断颗粒与基体间的应力持续传递,使应力优先在颗粒间传递,减小了基体变形,促使颗粒破碎,提升材料表面加工质量,同时验证实验结果与仿真结果相符。

Abstract:To investigate the microscopic influence of ultrasonic vibration on the surface flaws of particle-reinforced titanium matrix composites TiCp/TC4 during cutting with ultrasonic vibration of PCD tools. A two-dimensional cutting microscopic non-homogeneous model for TiCp/TC4 was established using ABAQUS/Explicit finite element software, and different volume fractions of the multi-particle cutting simulation were performed to analyze the changing rule of cutting speed on cutting temperature using a combination of simulation and experimental methods, to elaborate the particle force crushing process of PTMCs during the cutting process, and to discuss the defect manifestation. The results show that ultrasonic vibration cutting, the cutting temperature is always lower, the surface defects are mostly particle cut off and particle protrusion, and ultrasonic vibration can effectively block the stress between the particle and the substrate continues to transfer, so that the stress is prioritized in the transmission between the particles, reducing substrate deformation, prompting the particles to break first, and improving the surface. The experimental results were validated to be consistent with the simulation results.

-

Key words:

- titanium matrix composites /

- ultrasonic vibration /

- PCD tool /

- finite element simulation

-

表 1 工件材料的性能参数

Table 1. Performance parameters of the workpiece material

材料性能 TC4 TiC 密度ρ / (kg·m−3) 4510 4390 泊松比 μ 0.34 0.18 弹性模量 E / GPa 110 470 导热系数 k / [W·(m·K)−1] 5.708 17.200 比热容 c / [J·(kg·K)−1] 457.2 568.0 表 2 切削参数

Table 2. Cutting parameters

切削参数 数值 切削速度 vs / (m·min−1) 100 每齿进给量 f1 / (mm·z−1) 0.08 切削深度 ap / mm 3 振幅 A / μm 3 超声频率 f / kHz 20 -

[1] MA Z Y, TJONGS C, GEN L. In-situ Ti-TiB metal-matrix composite prepared by a reactive pressing process [J]. Scripta Materialia,2000,42(4):367-373. doi: 10.1016/S1359-6462(99)00354-1 [2] NI D R, GENG L, ZHANG J, et al. Effect of B4C particle size on microstructure of in situ titanium matrix composites prepared by reactive processing of Ti-B4C system [J]. Scripta Materialia,2006,55(5):429-432. doi: 10.1016/j.scriptamat.2006.05.024 [3] LU W, ZHANG G, ZHANG X, et al. Microstructural characterization of TiB in in situ synthesized titanium matrix composites prepared by common casting technique [J]. Journal of Alloys and Compounds,2001,327(1):240-247. [4] 韩远飞, 邱培坤, 孙相龙, 等. 非连续颗粒增强钛基复合材料制备技术与研究进展 [J]. 航空制造技术,2016,510(15):62-74.HAN Yuanfei, QIU Peikun, SUN Xianglong, et al. Progress and fabrication technology on discontinuously reinforced titanium matrix composites [J]. Aeronautical Manufacturing Technology,2016,510(15):62-74. [5] 黄陆军, 耿林. 非连续增强钛基复合材料研究进展 [J]. 航空材料学报,2014,34(4):126-138.HUANG Lujun, GENG Lin. Progress on discontinuously reinforced titanium matrix composites [J]. Journal of Aeronautical Materials,2014,34(4):126-138. [6] 吕维洁. 原位自生钛基复合材料研究综述 [J]. 中国材料进展,2010,9(4):41-48.LU Weijie. An overview on the research of in-situ titanium matrix composites [J]. Materials China,2010,9(4):41-48. [7] 赵波. 超声加工技术的研究现状和发展方向简介 [J]. 金刚石与磨料磨具工程,2020,40(1):1-4.ZHAO Bo. The research status and development direction of ultrasonic machining technology are introduced [J]. Diamond & Abrasives Engineering,2020,40(1):1-4. [8] ABD HALIM N F H, ASCROFT H, BARNES S. Analysis of tool wear, cutting force, surface roughness and machining temperature during finishing operation of ultrasonic assisted milling (UAM) of carbon fibre reinforced plastic (CFRP) [J]. Procedia Engineering,2017,184:185-191. doi: 10.1016/j.proeng.2017.04.084 [9] BREHL D E, DOW T A. Review of vibration-assisted machining [J]. Precision engineering,2008,32(3):153-172. doi: 10.1016/j.precisioneng.2007.08.003 [10] ZHANG J, CUI T, GE C, et al. Review of micro/nano machining by utilizing elliptical vibration cutting [J]. International Journal of Machine Tools and Manufacture,2016,106:109-126. doi: 10.1016/j.ijmachtools.2016.04.008 [11] MAUROTTO A, MUHAMMAD R, ROY A, et al. Enhanced ultrasonically assisted turning of a β-titanium alloy [J]. Ultrasonics,2013,53(7):1242-1250. doi: 10.1016/j.ultras.2013.03.006 [12] TABATABAEI S, BEHBAHANI S, MIRIAN S. Analysis of ultrasonic assisted machining (UAM) on regenerative chatter in turning [J]. Journal of Materials Processing Technology,2013,213(3):418-425. doi: 10.1016/j.jmatprotec.2012.09.018 [13] NATH C, RAHMAN M, NEO K S. Machinability study of tungsten carbide using PCD tools under ultrasonic elliptical vibration cutting [J]. International Journal of Machine Tools and Manufacture,2009,49(14):1089-1095. doi: 10.1016/j.ijmachtools.2009.07.006 [14] 牛秋林, 高航, 张深圳, 等. 超声振动辅助铣削SiCp/Al复合材料表面质量与切屑形貌实验研究 [J]. 工具技术,2022,56(4):12-17.NIU Qiulin, GAO Hang, ZHANG Shenzhen, et al. Ultrasonic vibration assisted milling SiCp/Al experimental study on surface quality and chip morphology of composite materials [J]. Tool Engineering,2022,56(4):12-17. [15] 马超, 张建华, 陶国灿. 超声振动辅助铣削加工钛合金表面摩擦磨损性能研究 [J]. 表面技术,2017,46(8):115-119.MA Chao, ZHANG Jianhua, TAO Guocan. Study on surface friction and wear properties of titanium alloy in ultrasonic vibration assisted milling [J]. Surface Technology,2017,46(8):115-119. [16] 高泽, 张德远, 李哲, 等. 高速超声椭圆振动铣削腹板表面质量研究 [J]. 机械工程学报,2019,55(7):249-256. doi: 10.3901/JME.2019.07.249GAO Ze, ZHANG Deyuan, LI Zhe, et al. Research on surface quality of titanium alloy webs via high-speed ultrasonic elliptical vibration milling [J]. Journal of Mechanical Engineering,2019,55(7):249-256. doi: 10.3901/JME.2019.07.249 [17] ABAQUS Inc. Abaqus/CAE user’s guide 6.14 [EB/OL]. [2023-06-15]. http://130.149.89.49:2080/v6.14/index.html. [18] 李征, 刘斌, 丁文锋, 等. 颗粒增强钛基复合材料磨削试验与仿真研究 [J]. 航空制造技术,2023,66(05):63-67.LI Zheng, LIU Bin, DING Wenfeng, et al. Grinding test and simulation study of particle reinforced titanium matrix composites [J]. Aeronautical Manufacturing Technology,2023,66(05):63-67. [19] ZHOU L, HUANG T S, WANG D, et al. Finite element and experimental studies of the cutting process of SiCp/Al composites with PCD tools [J]. The International Journal of Advanced Manufacturing Technology, 2011, 52(5-8). [20] CHEN G, REN C, YANG X, et al. Finite element simulation of high-speed machining of titanium alloy (Ti–6Al–4V) based on ductile failure model [J]. The International Journal of Advanced Manufacturing Technology, 2011, 56(9-12). [21] SHUI X, ZHANG Y, WU Q. Mesoscopic model for SiCP/Al composites and simulation on the cutting process [J]. Applied Mechanics and Materials, 2014, 2943(487-487). [22] 武永祥. SiCp/Al复合材料切削仿真研究与实验验证 [D]. 哈尔滨: 哈尔滨工业大学, 2017.WU Yongxiang. SiCp/Al simulation research and experimental verification of composite cutting [D]. Harbin: Harbin Institute of Technology, 2017. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS