Online recognition of contour error of diamond roller

-

摘要:

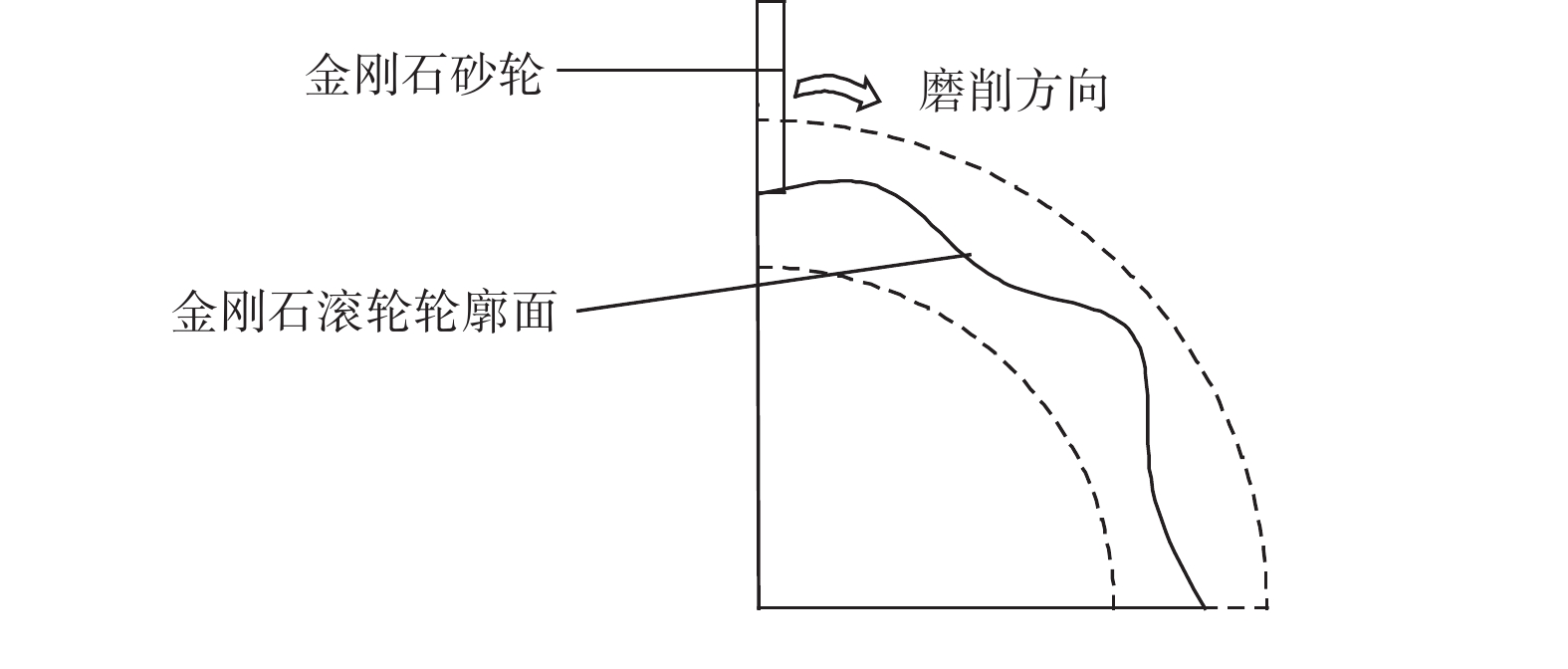

金刚石滚轮形面的修形技术是制造金刚石滚轮的关键技术之一,常采用金刚石砂轮磨削法对其进行精密修形,修形后的轮廓圆度误差是考量滚轮修形合格与否的重要指标。目前的轮廓圆度检测方法是人工停机取下滚轮并放置于轮廓仪上进行,极大地增加了滚轮制作的时间和成本。为此,对在五轴加工机床上的金刚石滚轮,沿其轮廓面横向磨削修形时产生的振动信号,提出基于小波包系数和随机森林的在线检测方法并对其轮廓修形状态进行识别,在修形进行状态时的识别准确率为93.3%,具有实际应用价值。

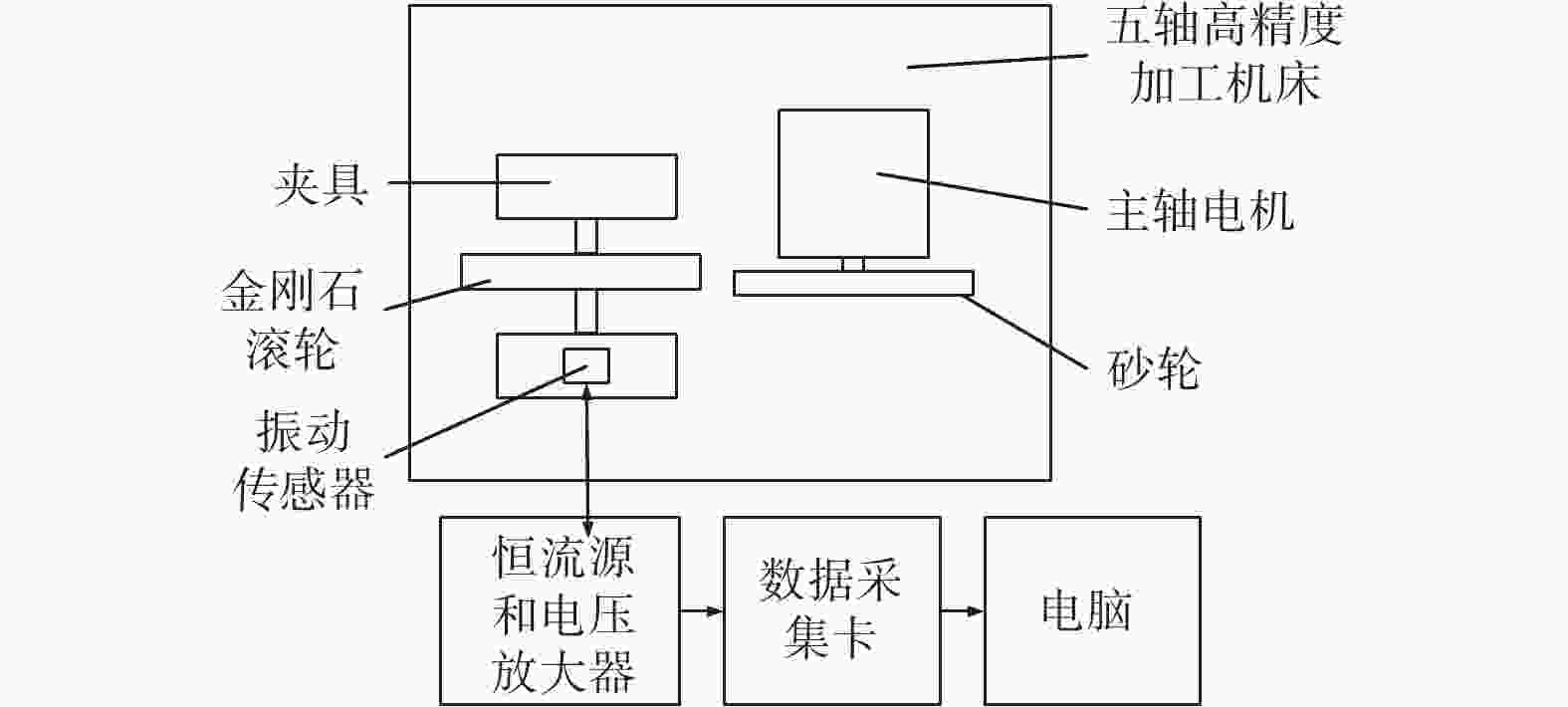

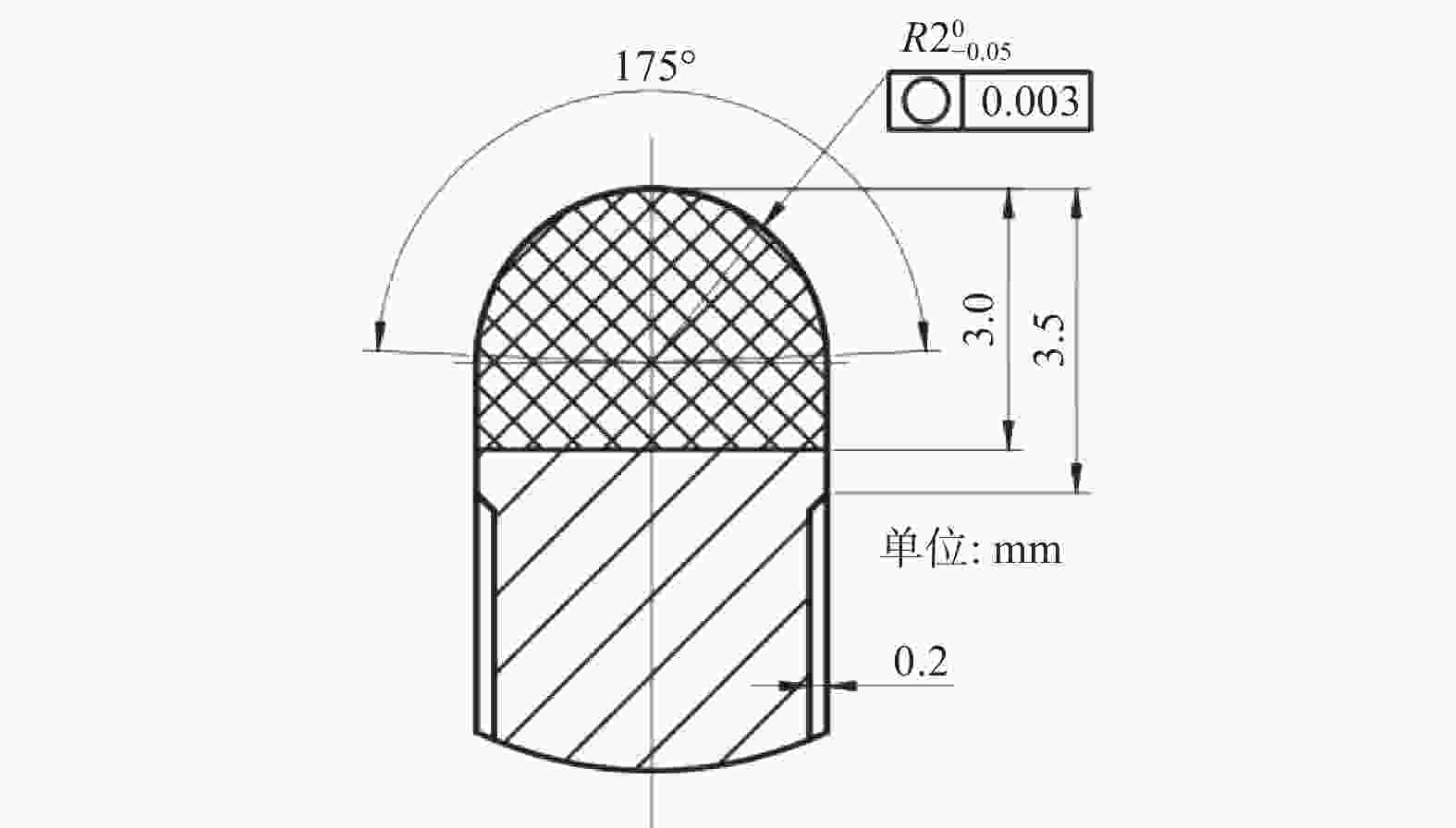

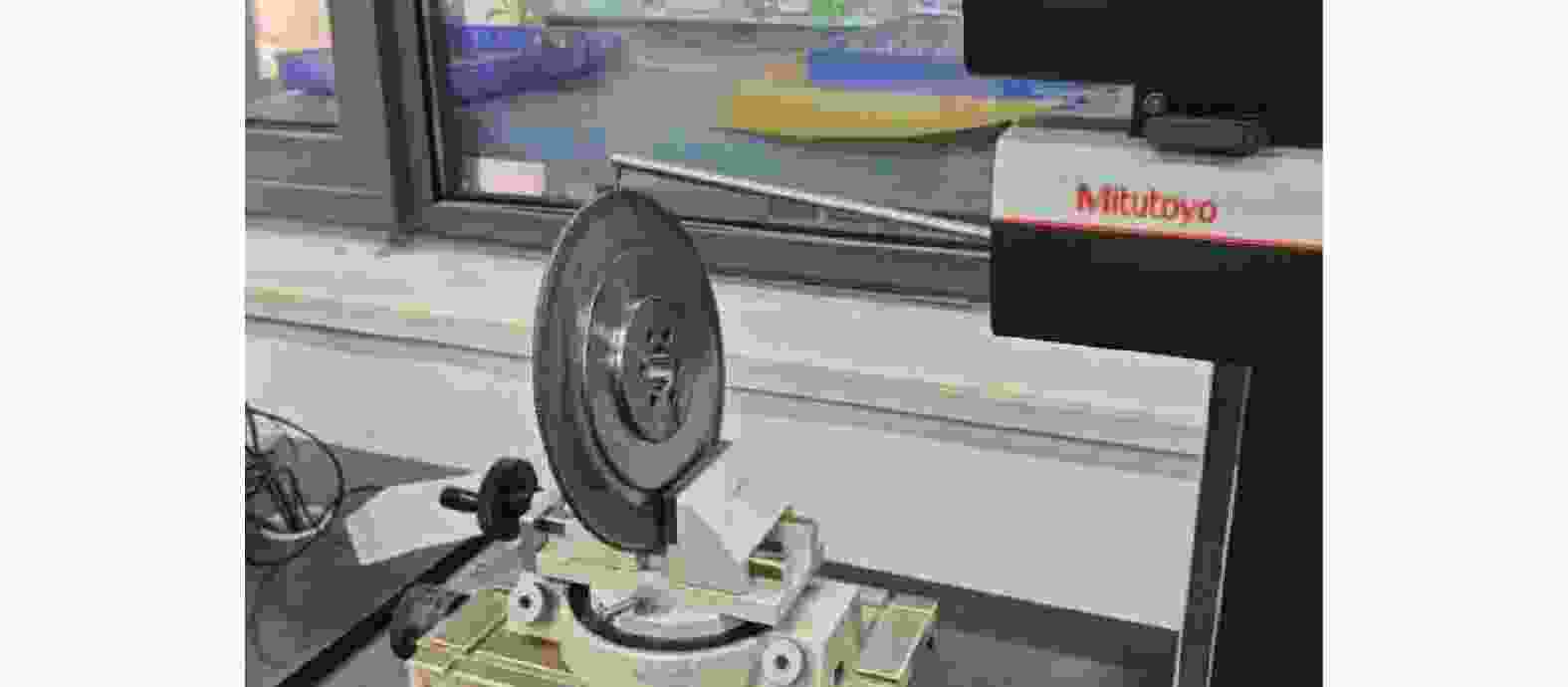

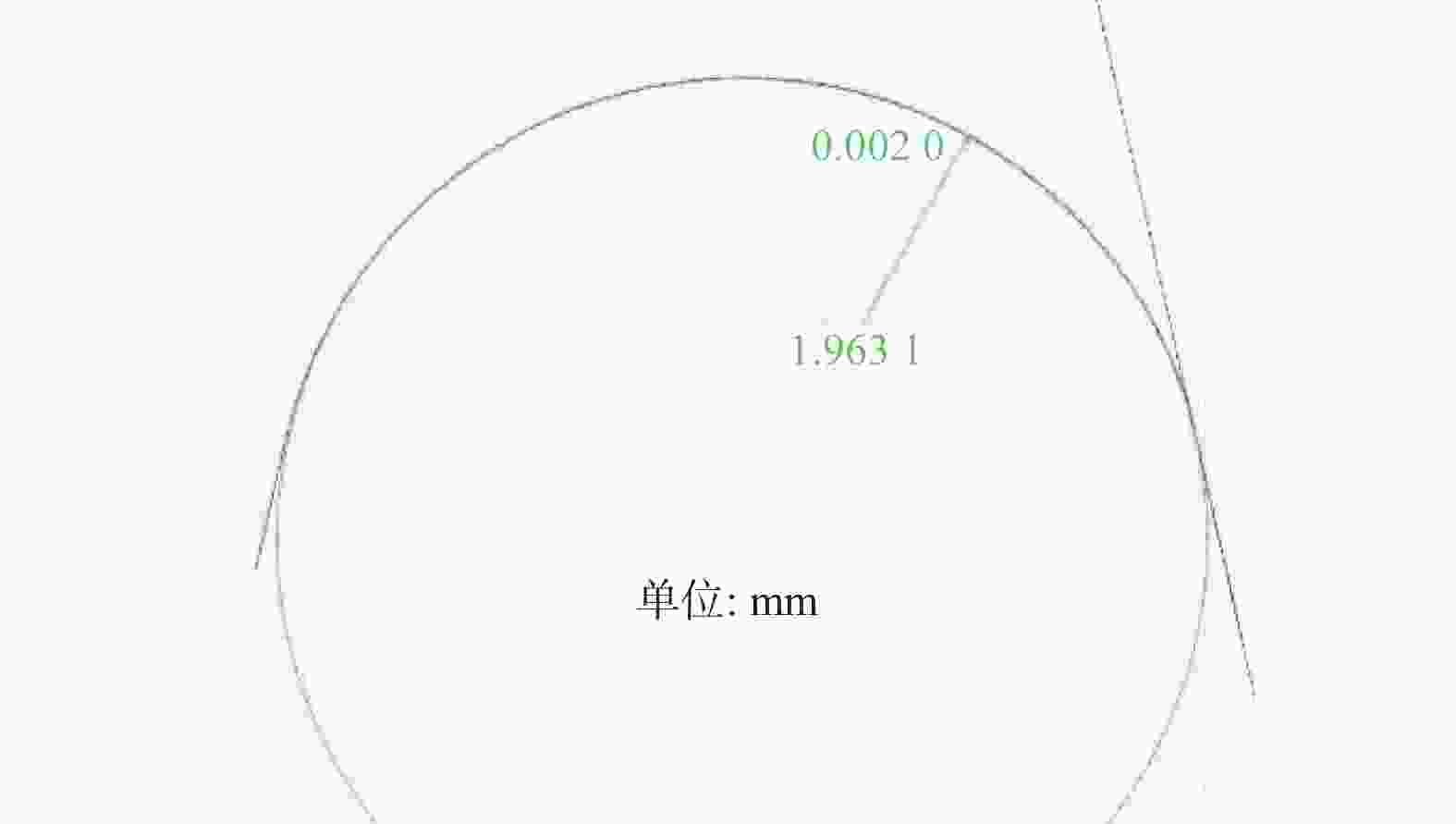

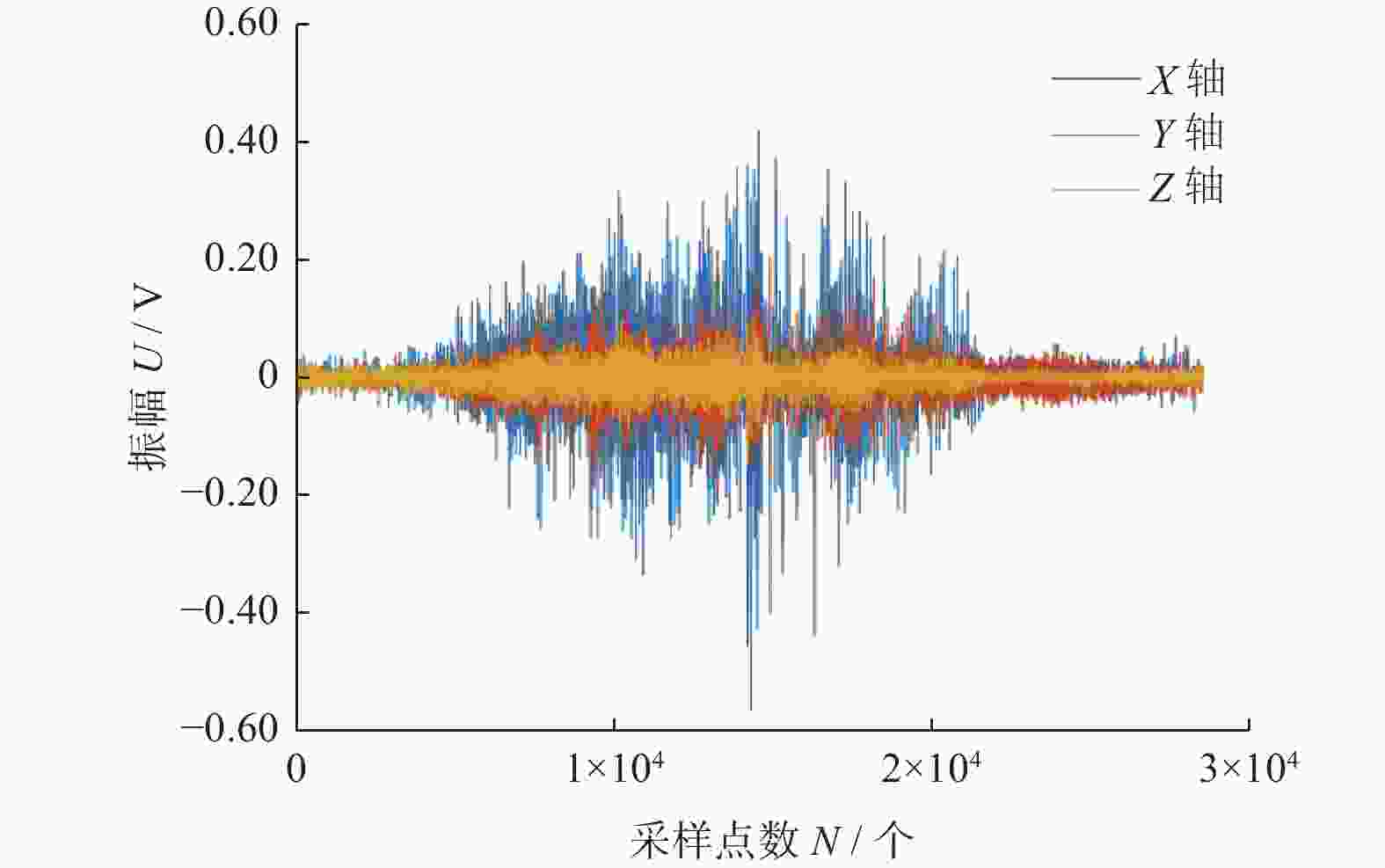

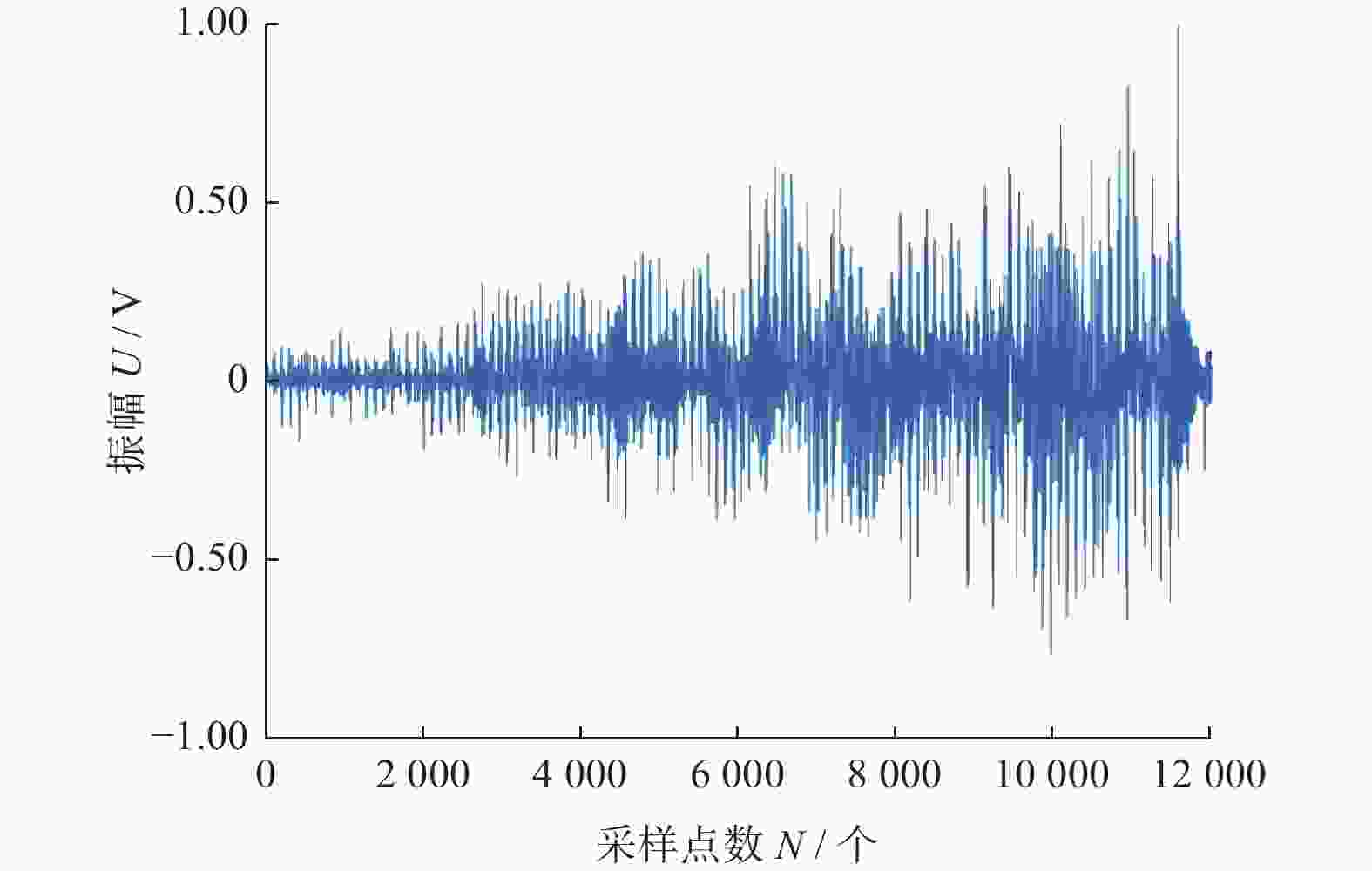

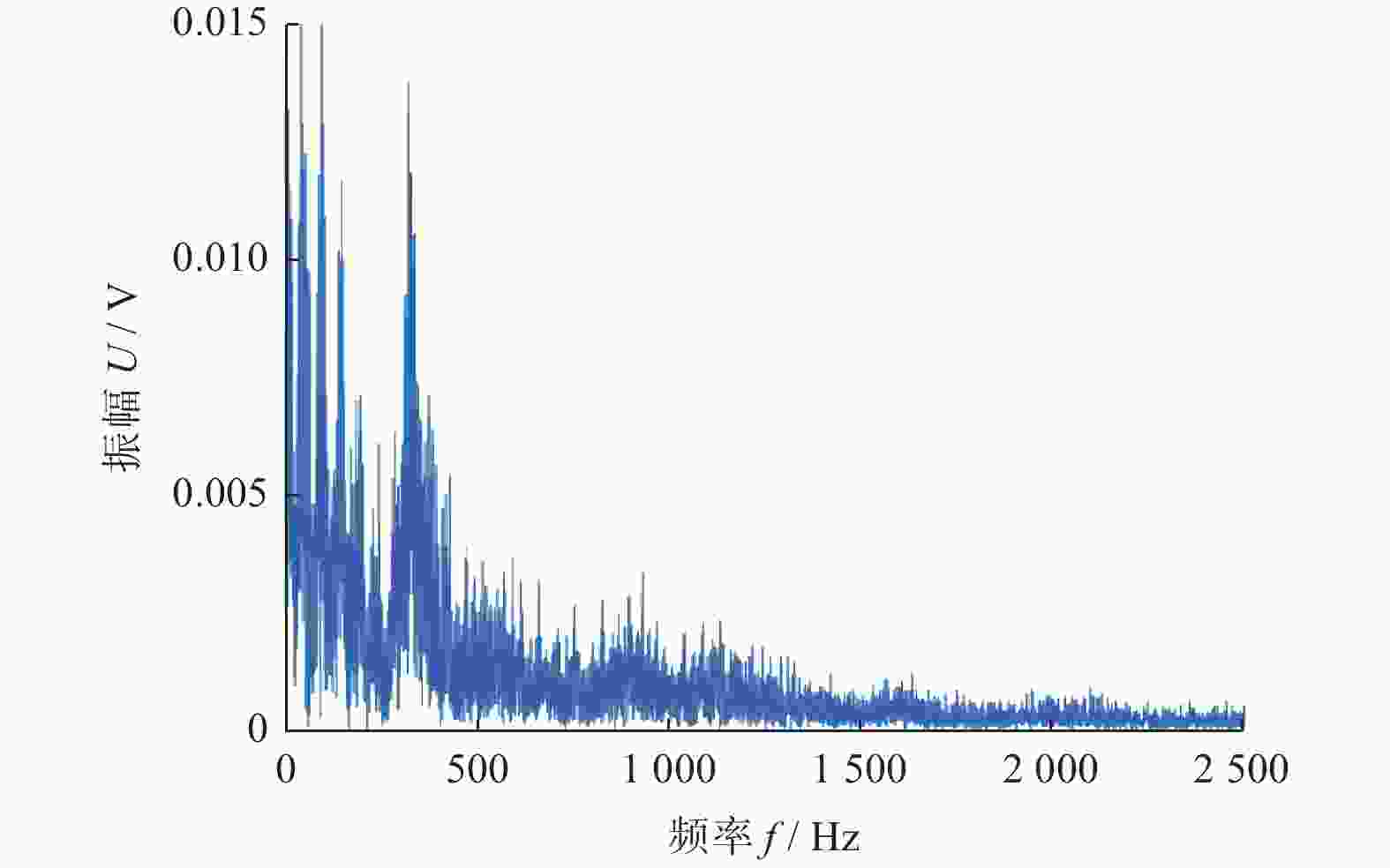

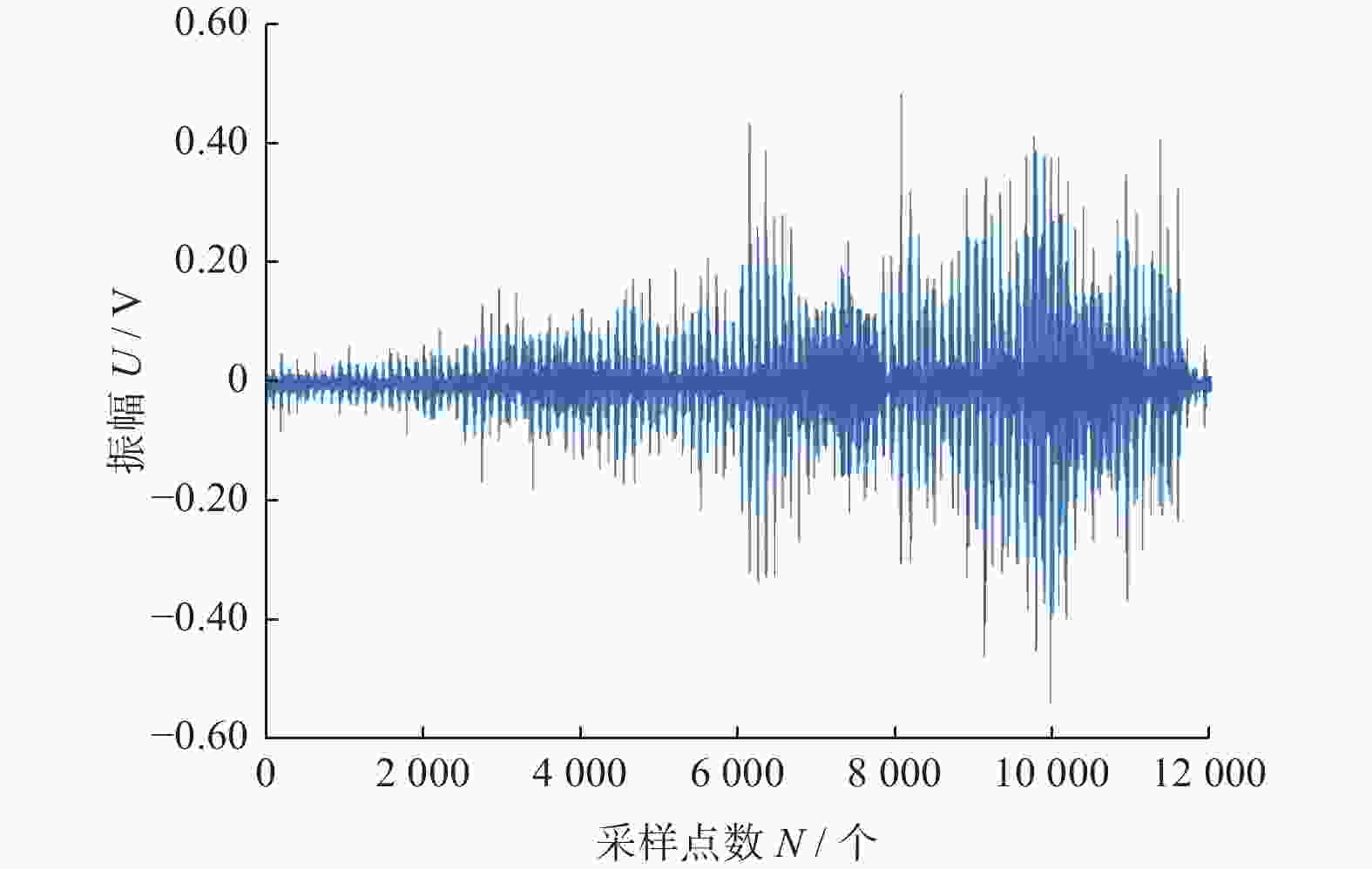

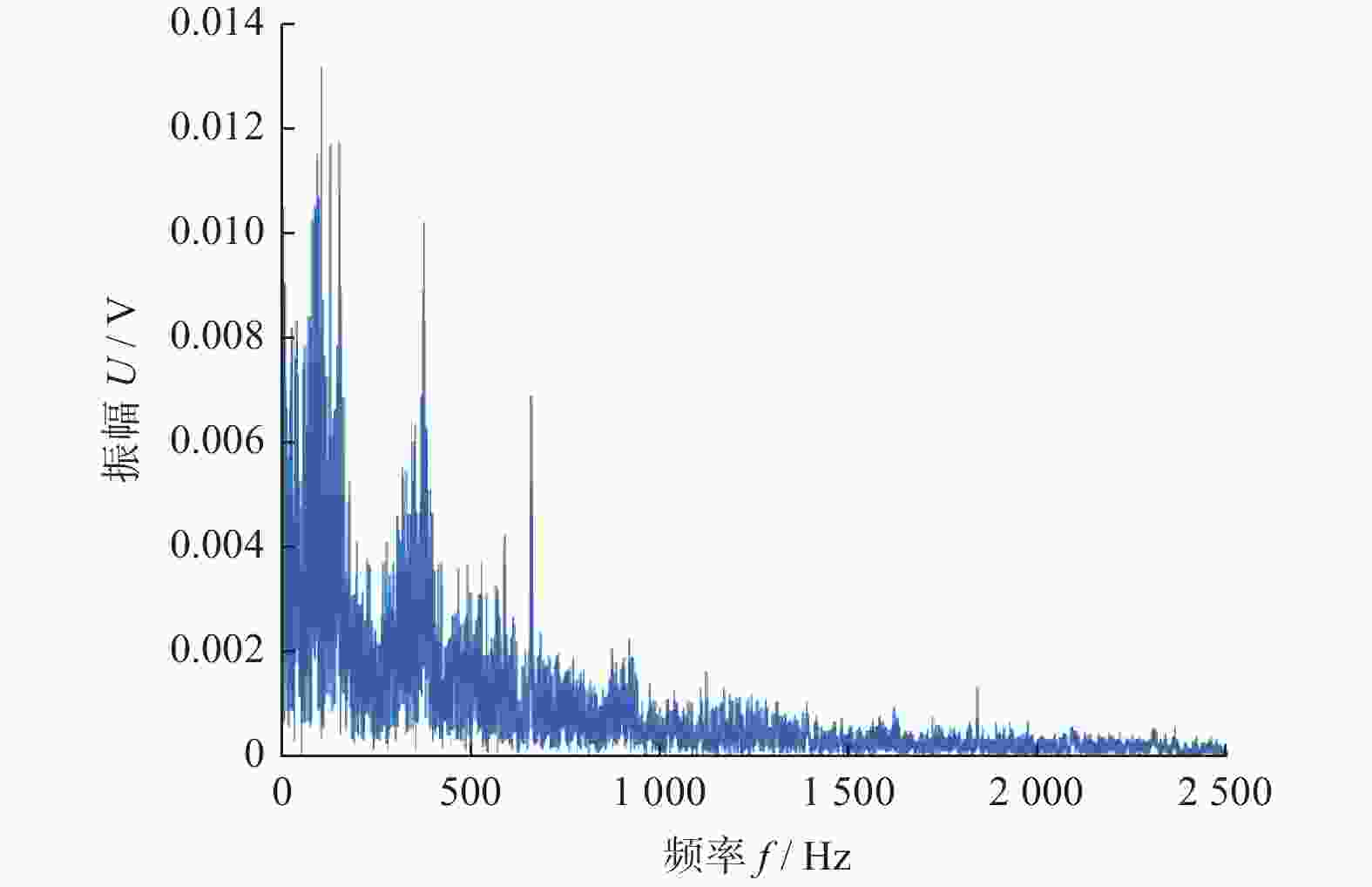

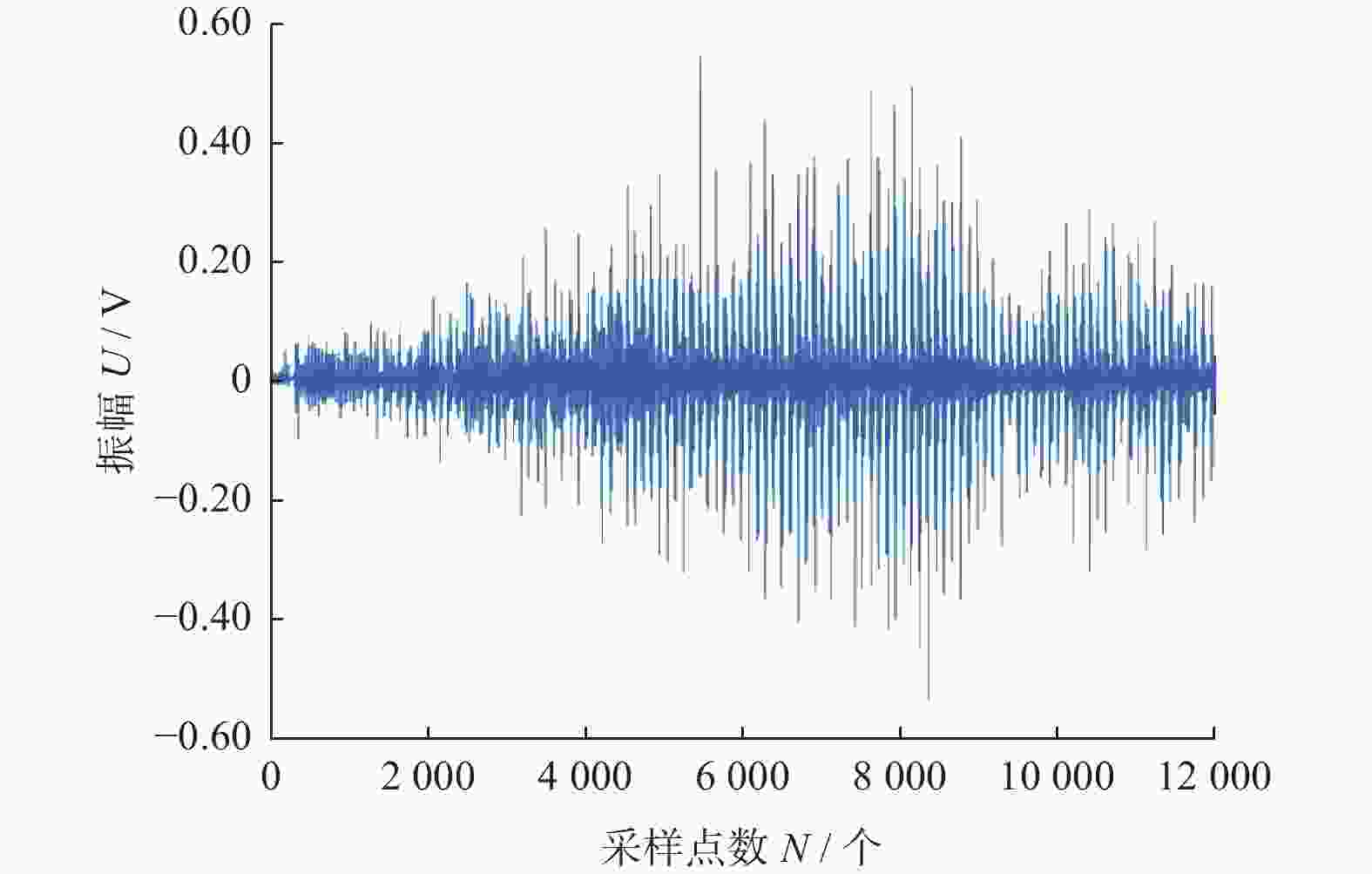

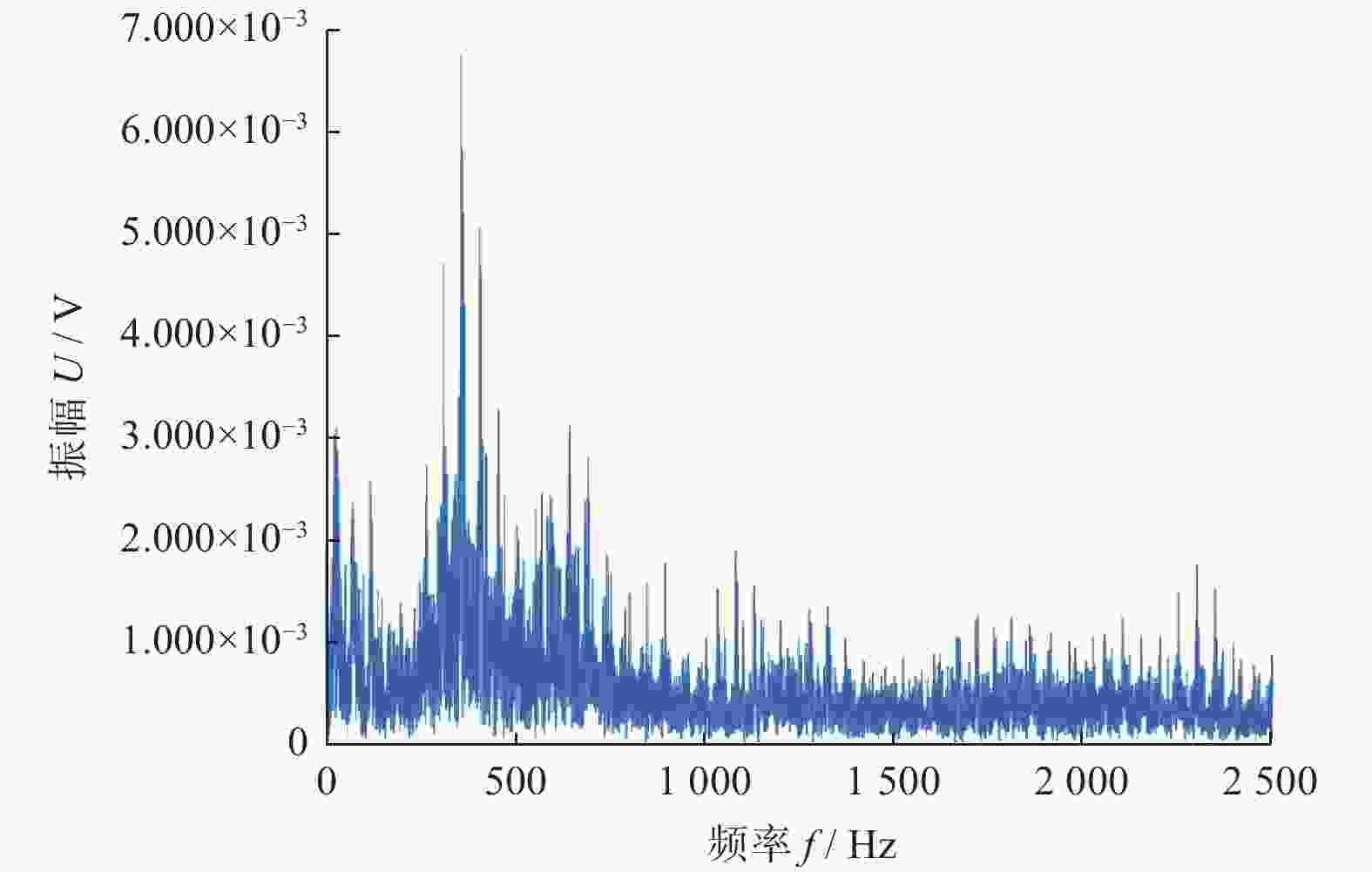

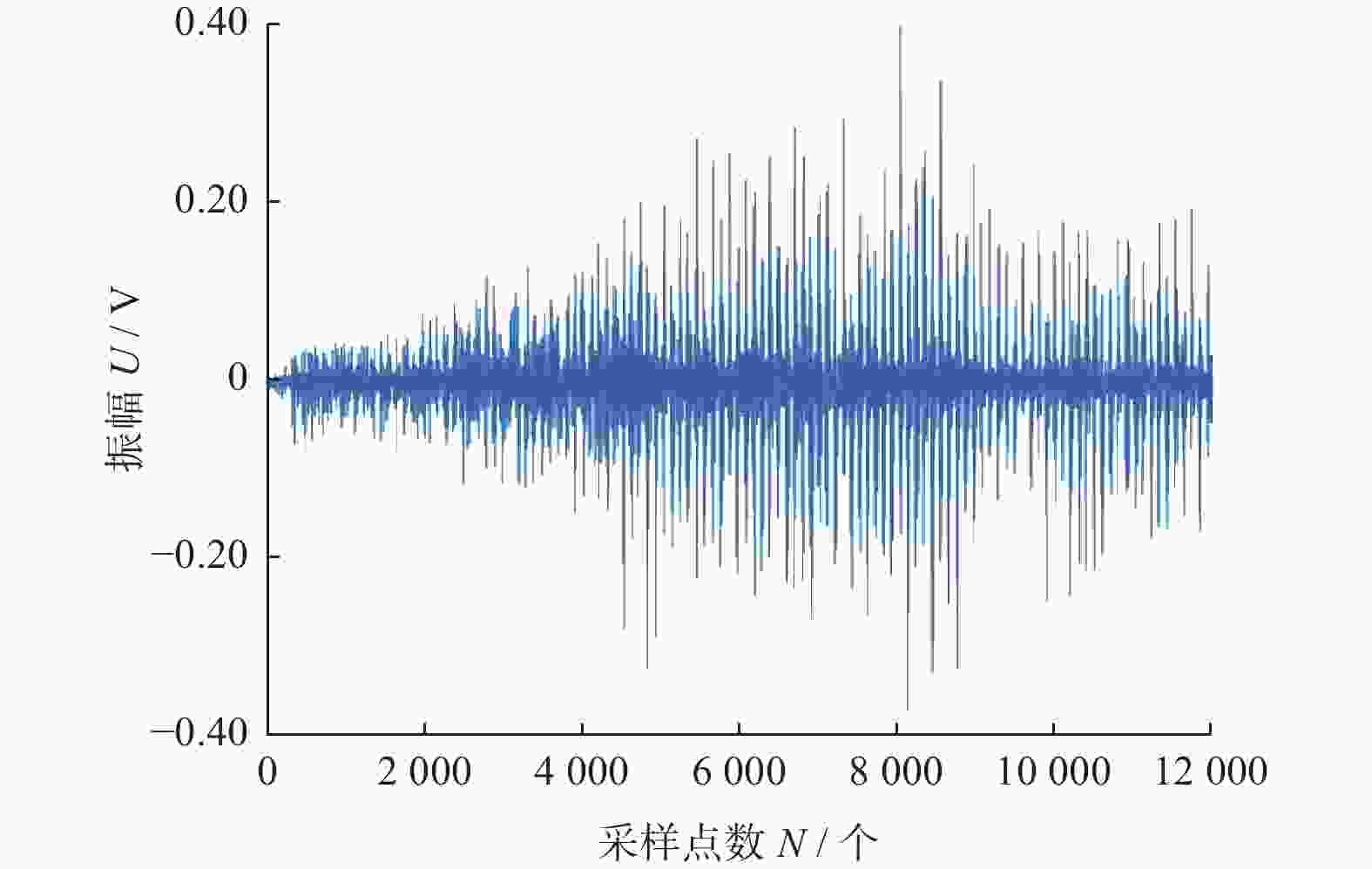

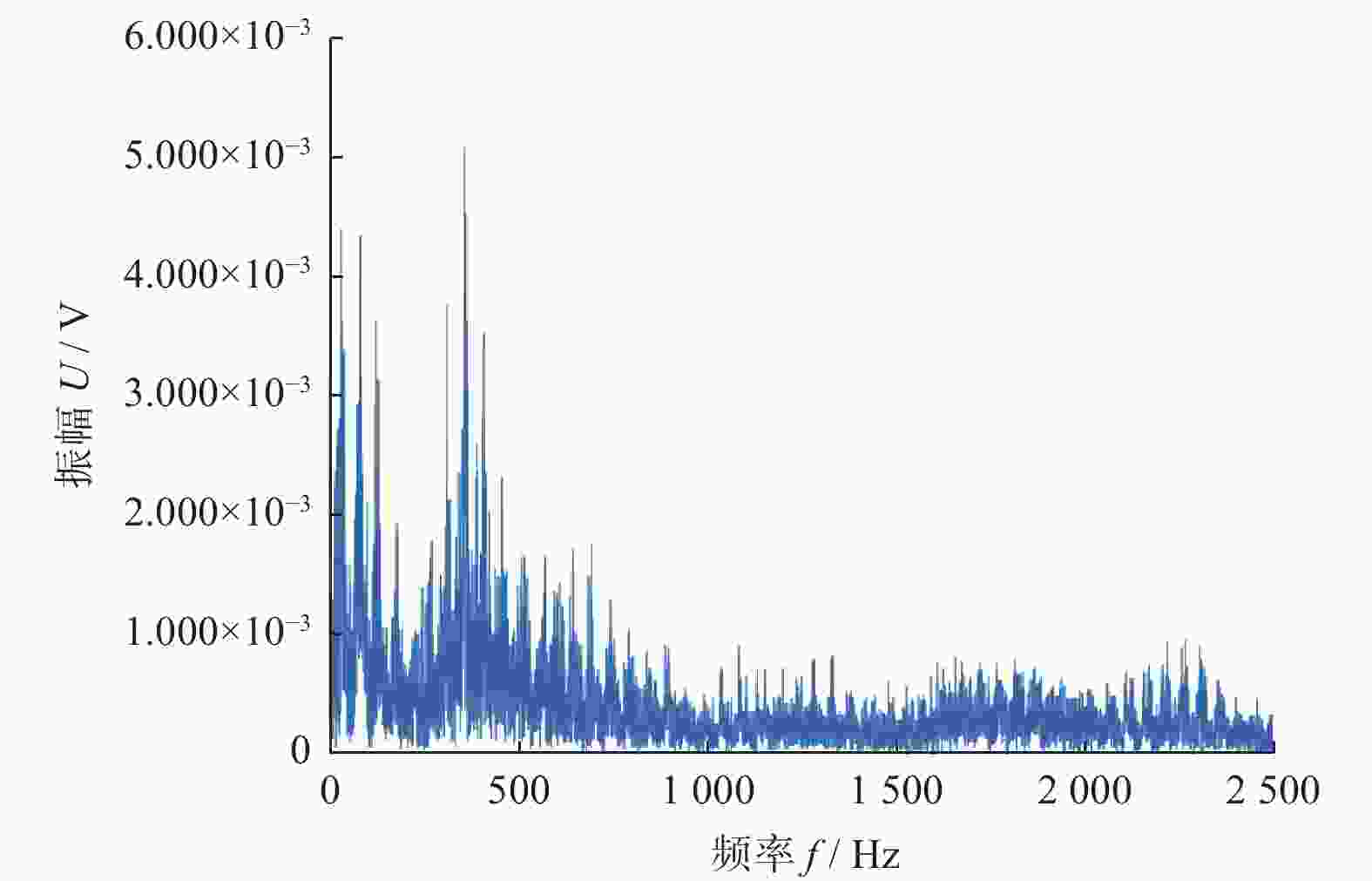

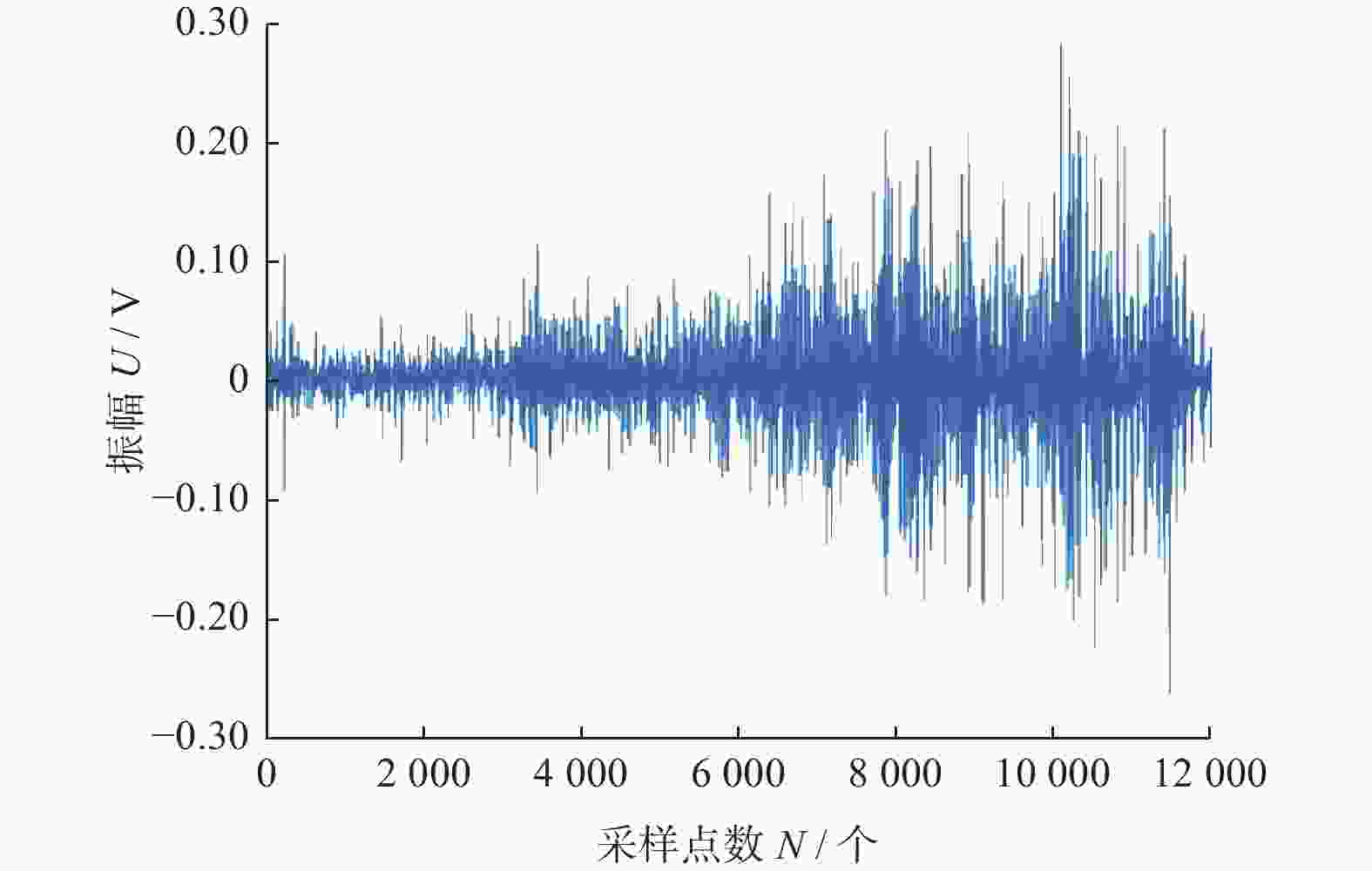

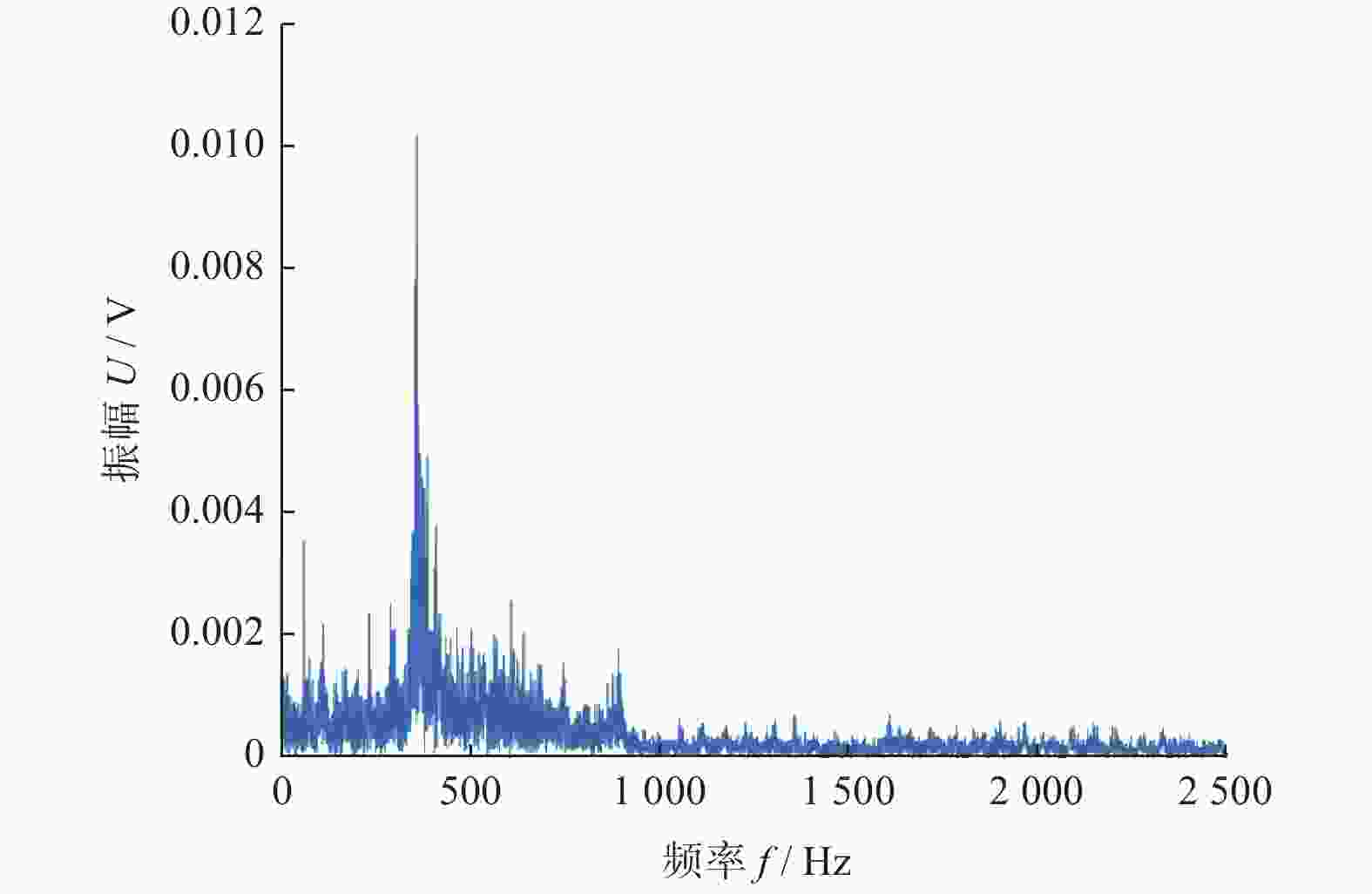

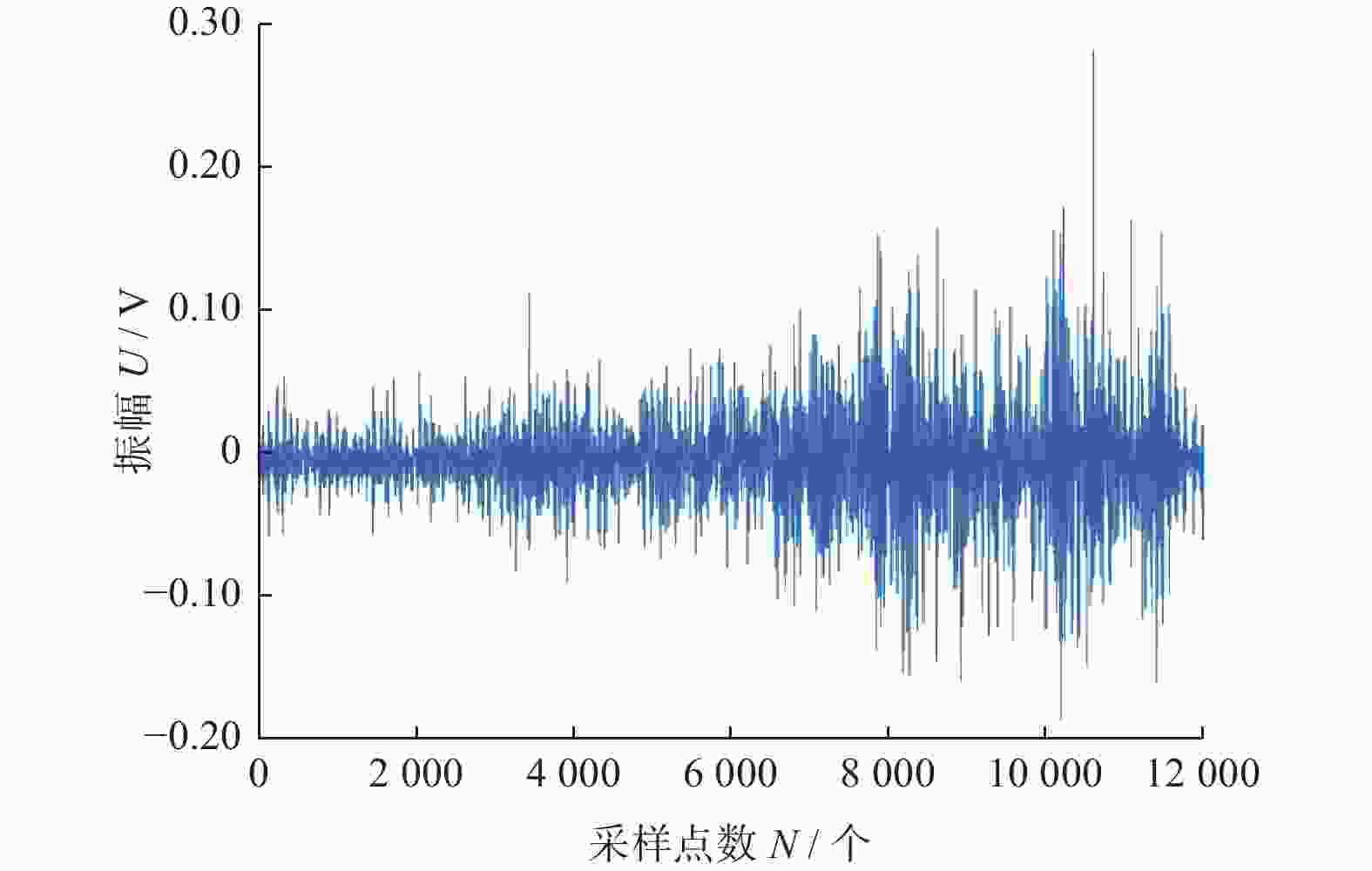

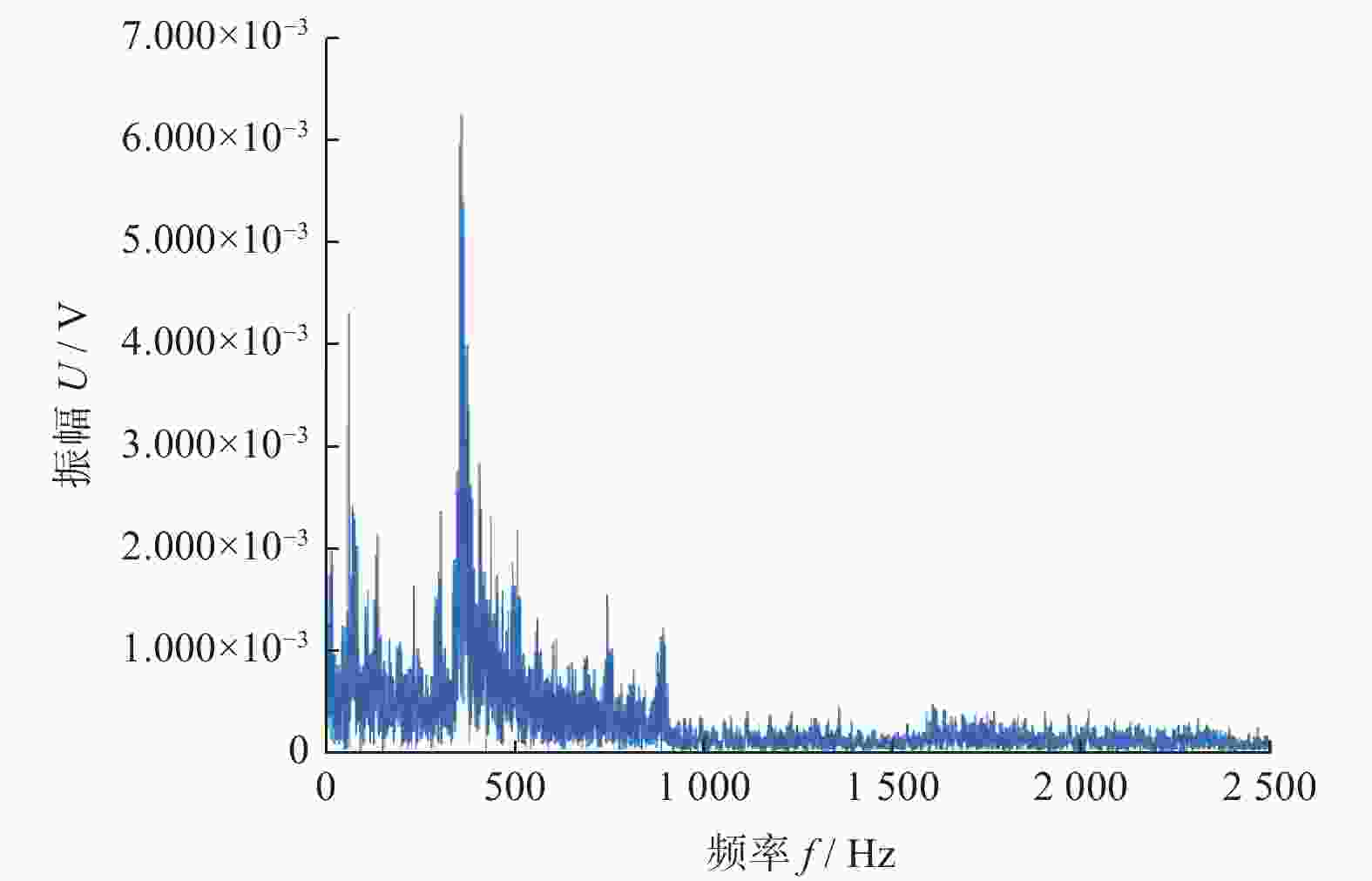

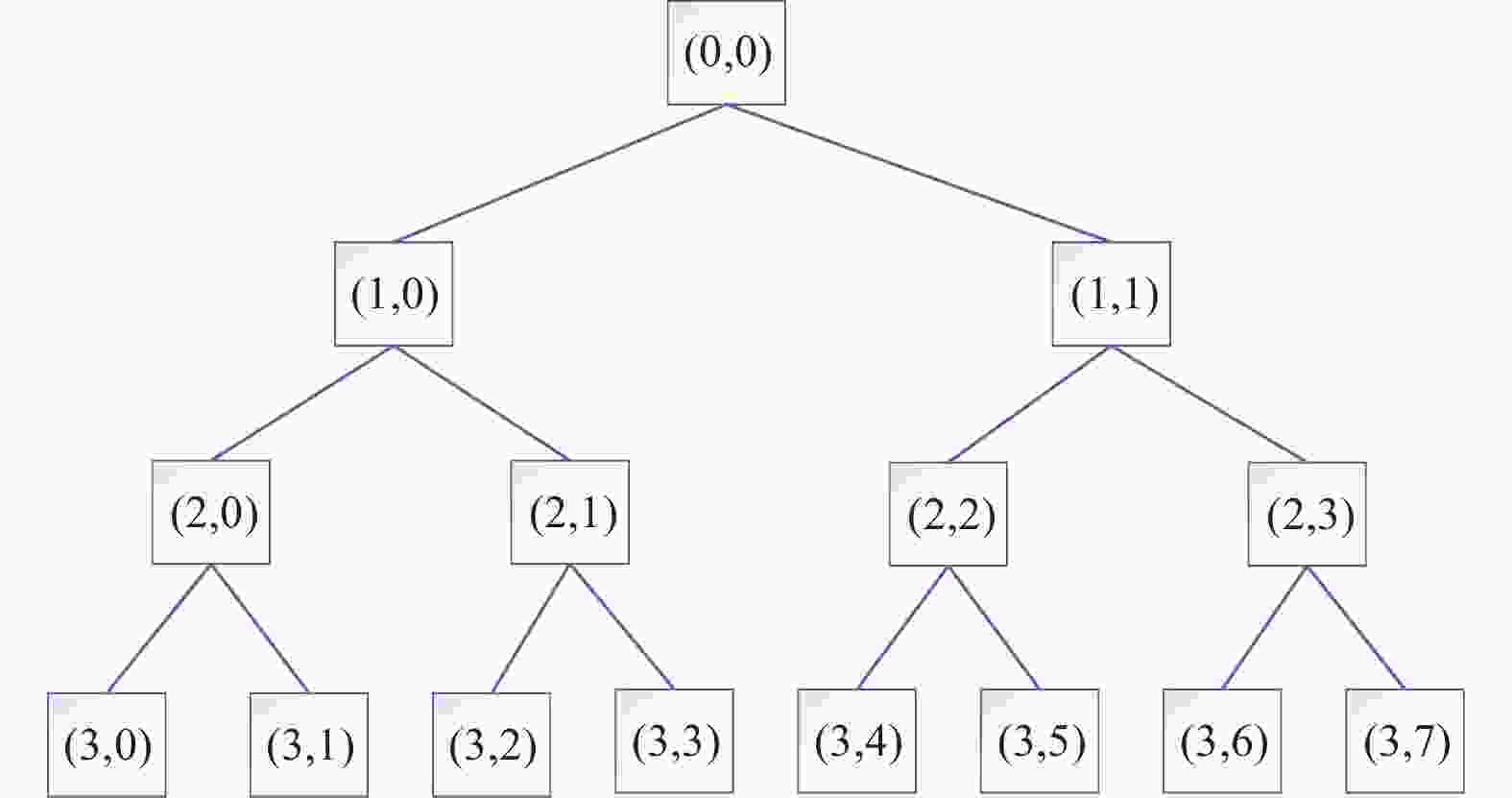

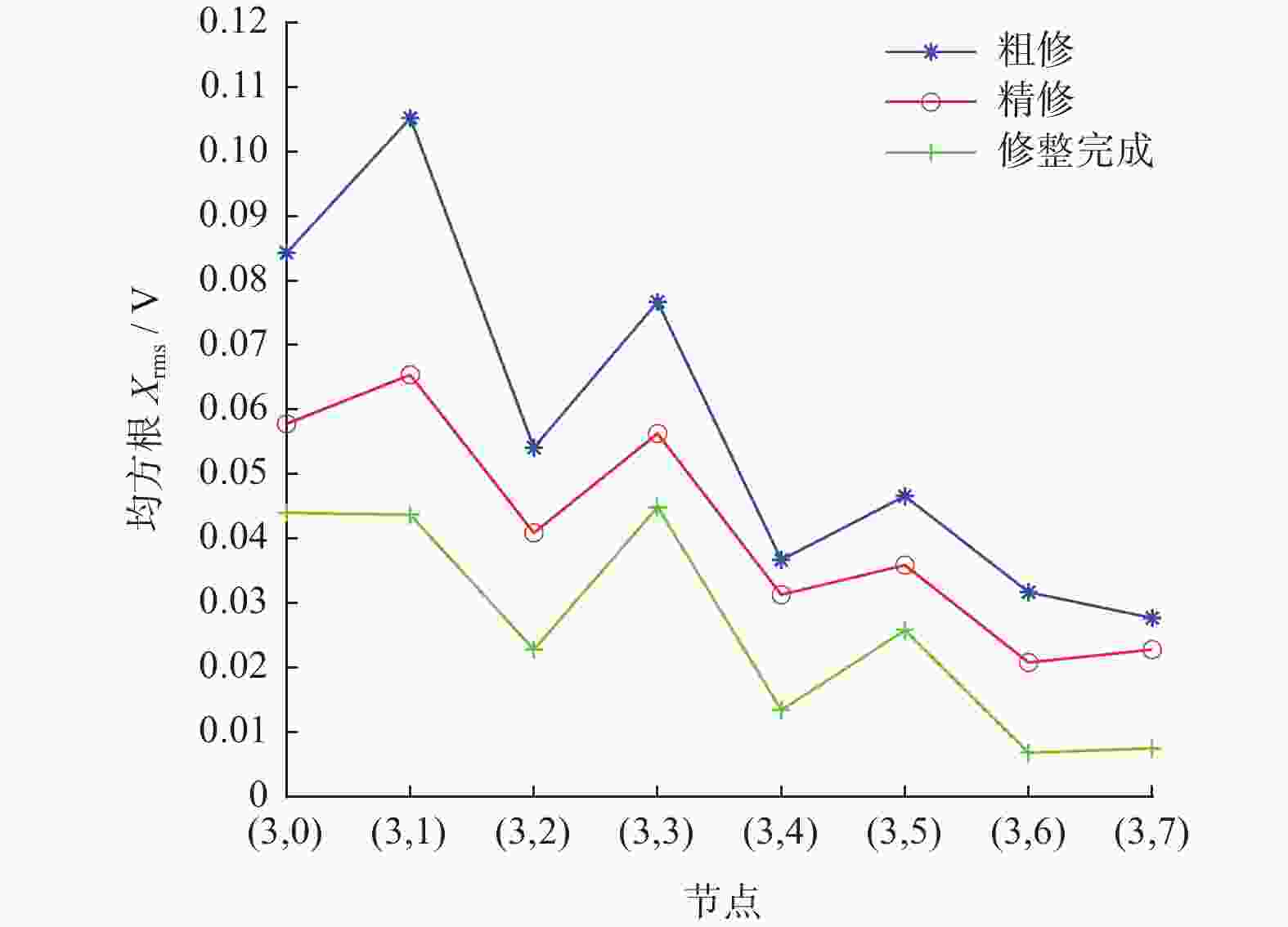

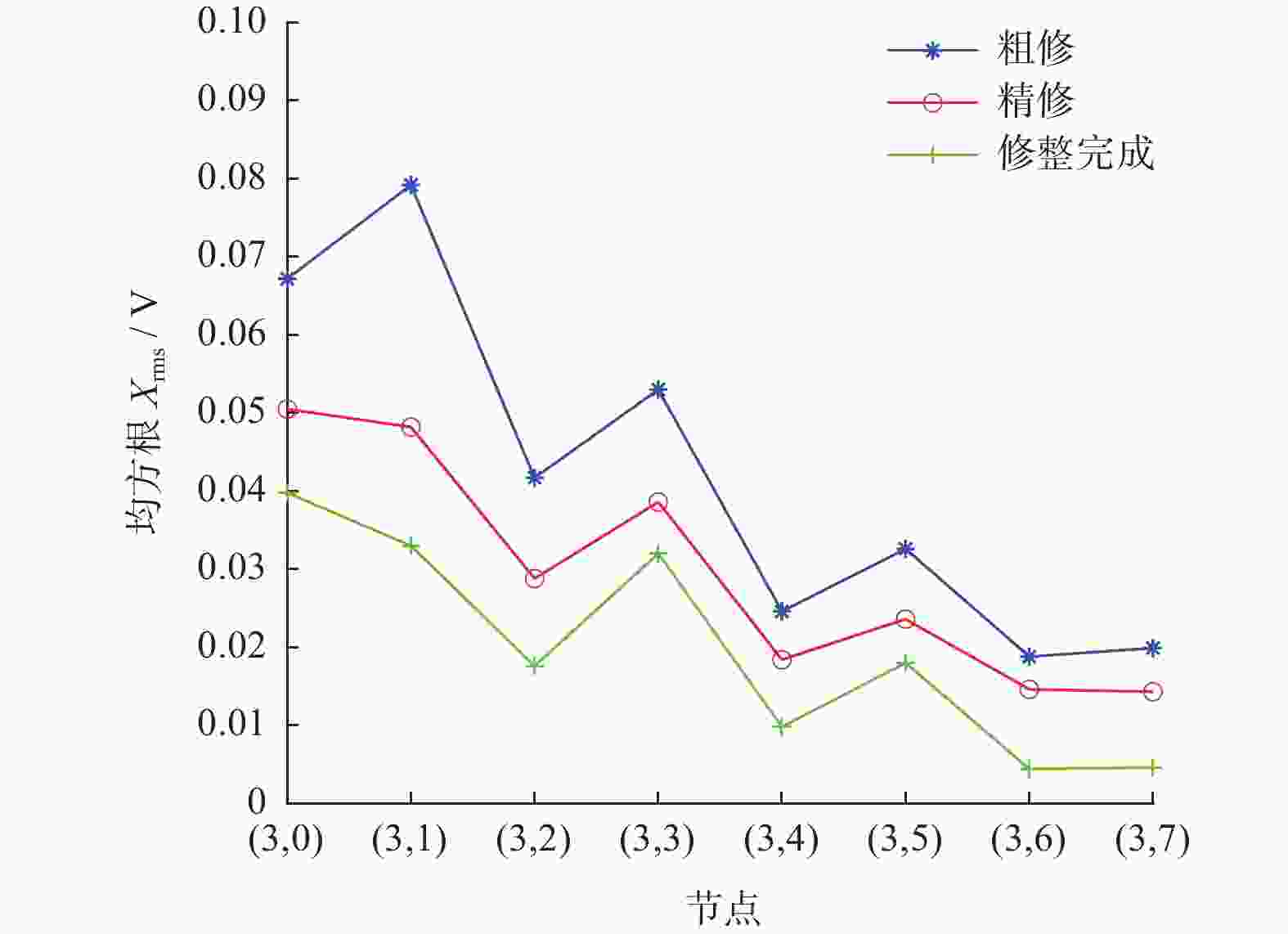

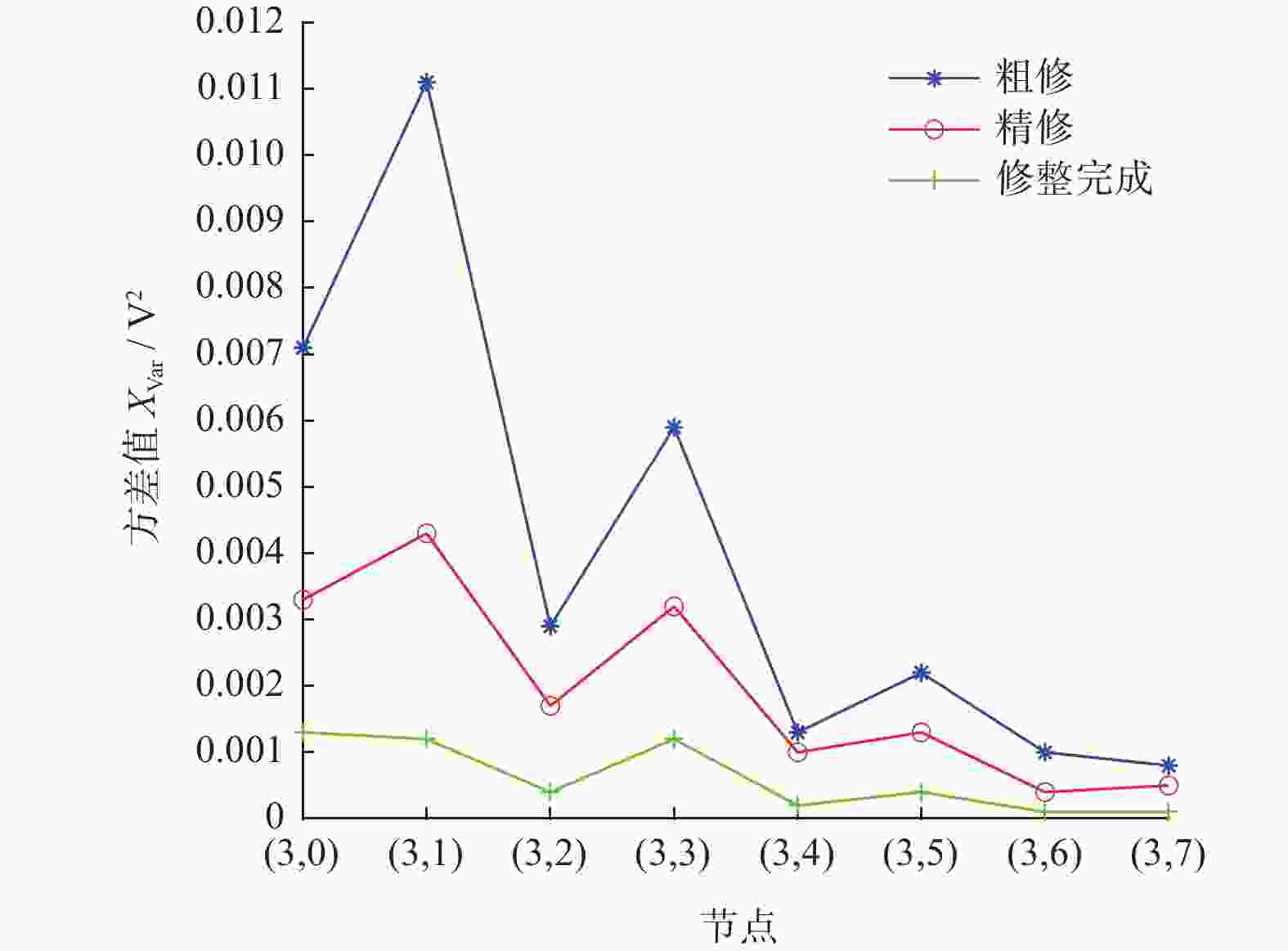

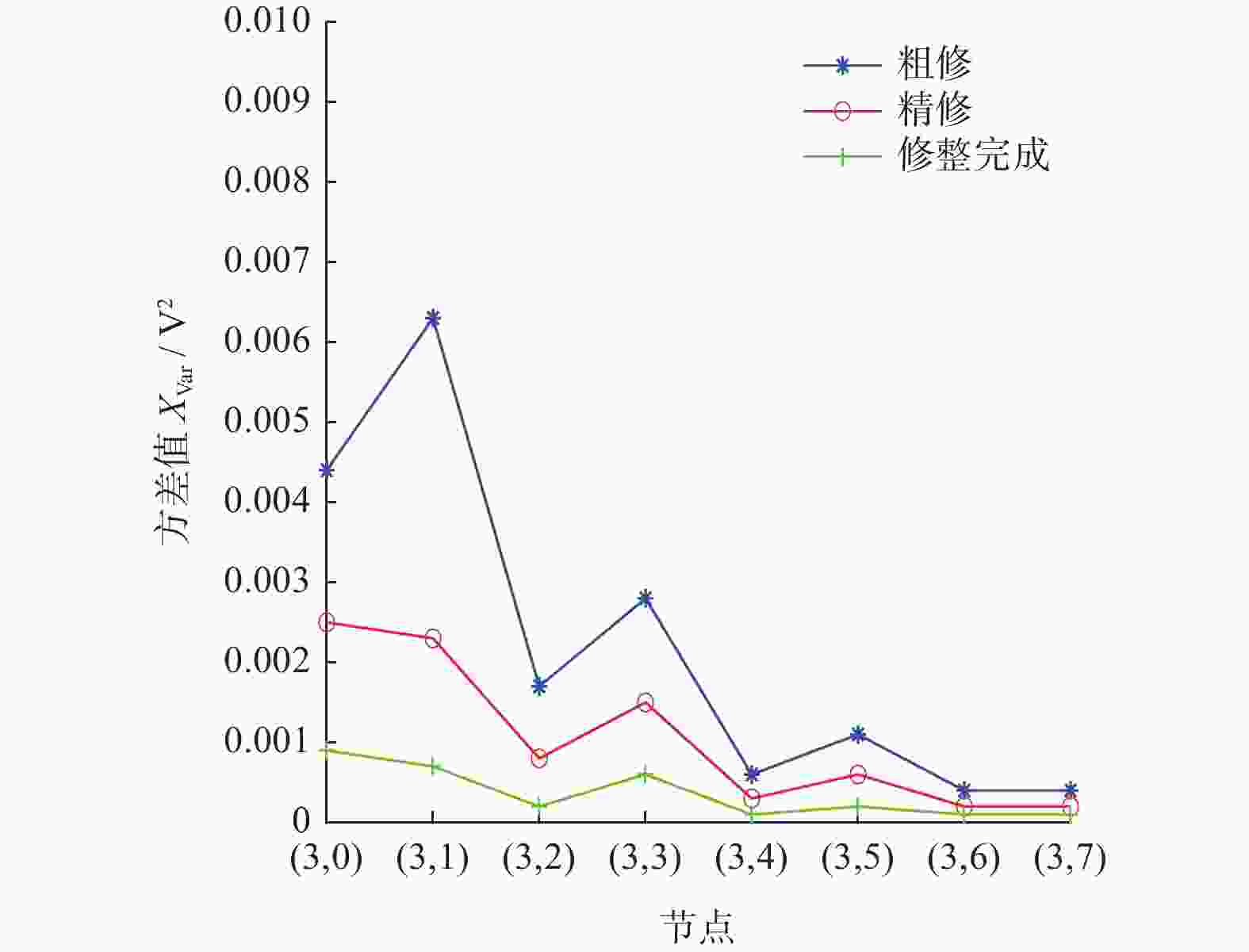

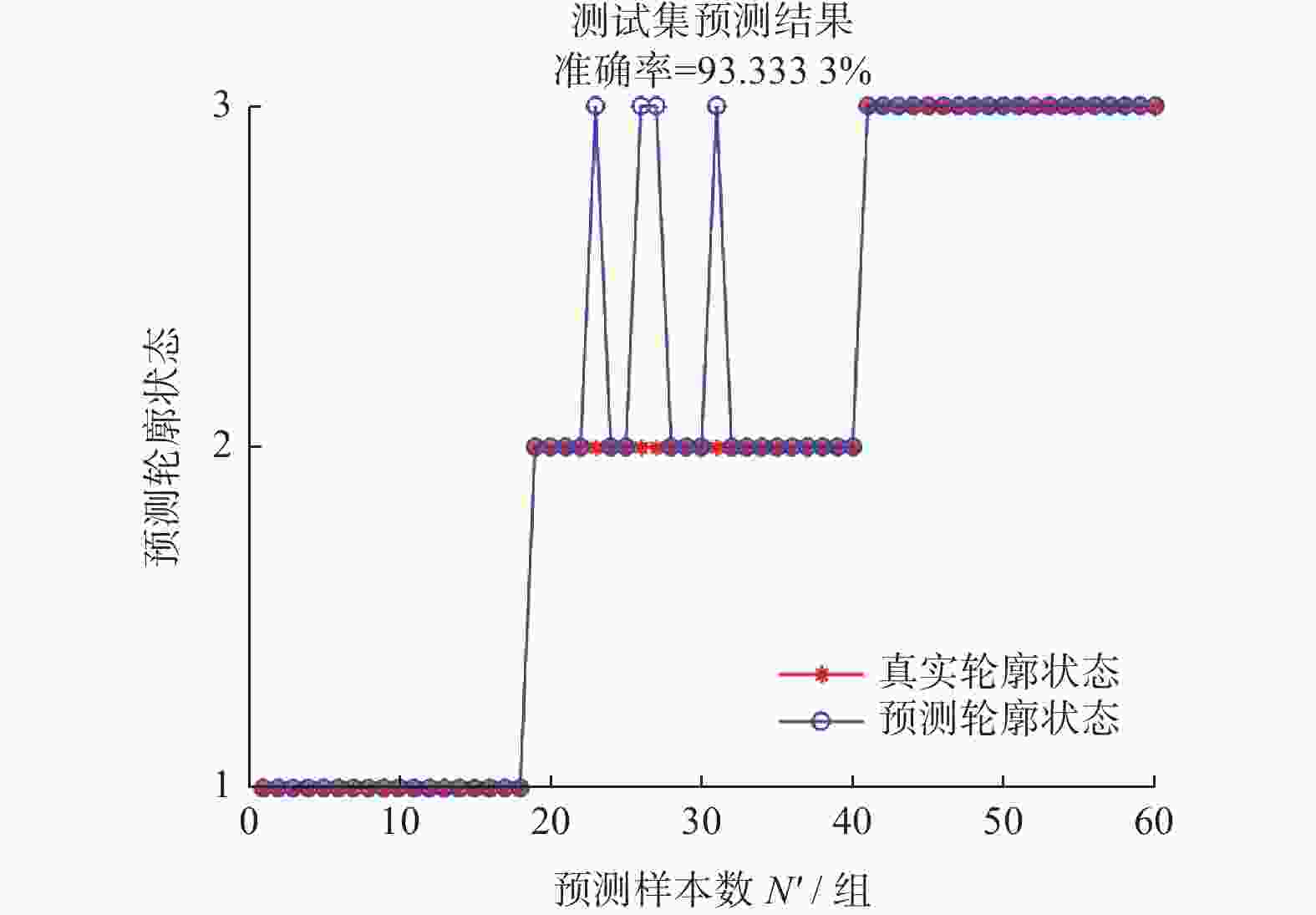

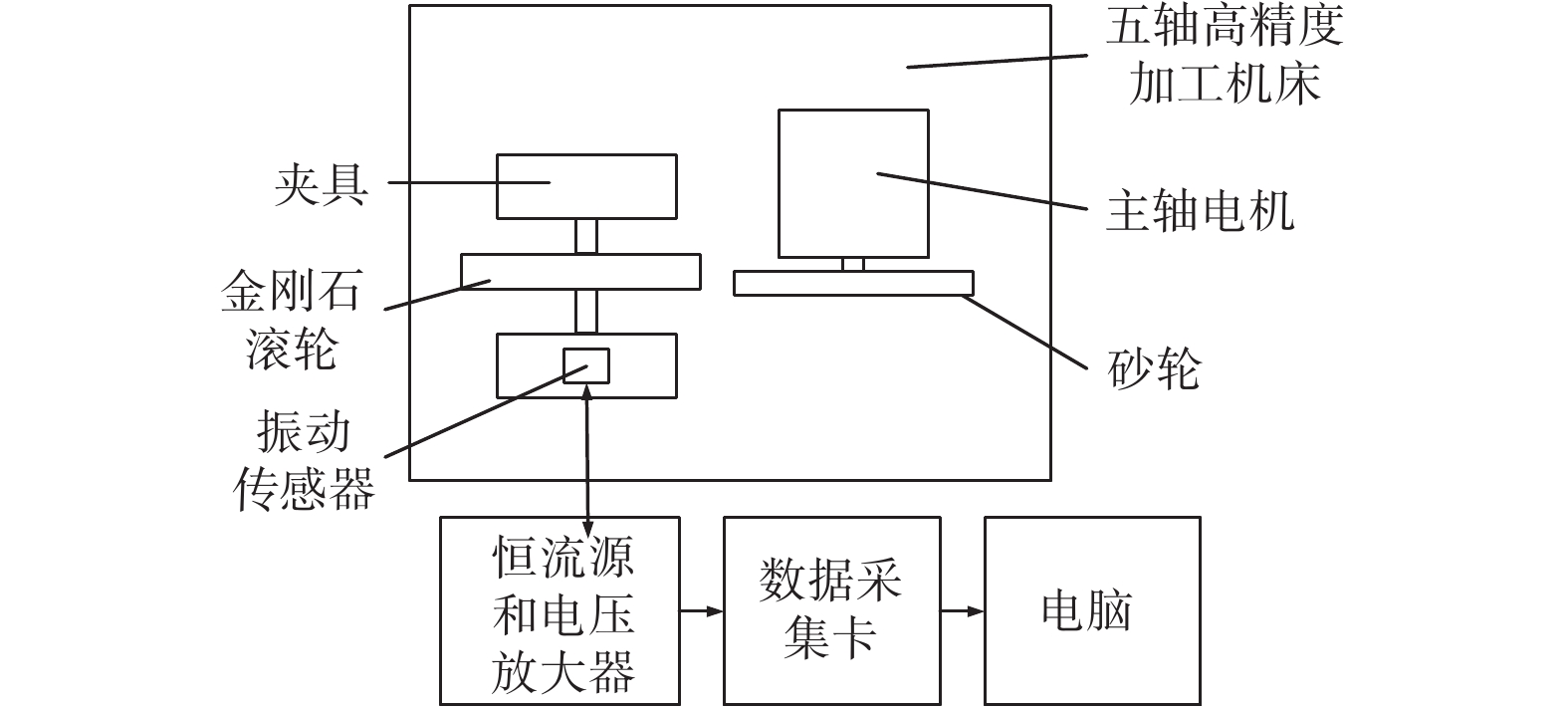

Abstract:Objectives: With the development of the manufacturing industry, precision grinding has become an indispensable part of the high-end manufacturing field. As a key tool for precision grinding, the surface reshaping technology of diamond rollers is one of the critical technologies for making diamond rollers. Currently, the diamond grinding wheel grinding method is commonly used for diamond roller precision reshaping. In the process of precision reshaping, the surface profile of the diamond roller is an important indicator for assessing its reshaping quality. However, in the current reshaping detection, the workers often stop the machine to remove the rollers and place them on the profiler, which greatly increases the time and the cost of roller reshaping. Therefore, to improve the efficiency of diamond roller reshaping, a method based on sensors to monitor the state of contour reshaping during the process of diamond roller reshaping is explored. Methods: To realize online monitoring and discrimination of the diamond roller contour reshaping state, the diamond roller grinding monitoring platform was first built according to the structure of the GC-X3 machine tool, and LabVIEW was used to read and save the signals collected by the acquisition card. Secondly, the diamond rollers with different contour reshaping states were processed by the GC-X3 machine tool, and the signals with different reshaping states collected by the computer were analyzed in time and frequency domains. The wavelet packet decomposition method was used to decompose the signals according to the characteristics of time and frequency domains, and the signals of different nodes obtained after decomposition were calculated and compared to identify and determine the characteristic values of the signals. Finally, the machine learning method was used to establish the recognition model of the diamond roller contour reshaping state. The model is based on the mapping relationship between the characteristic values of the vibration signals and the contour reshaping state to realize the intelligent recognition of the contour reshaping state of the diamond roller. Results: After preprocessing the signal, it can be observed through the time and the frequency domains that the maximum amplitudes of the X and Y axis vibration signals decrease with the improvement of the roller profile accuracy. The amplitudes of the X and Y axis vibration signals during rough trimming are 1.00 and 0.50 V, respectively. The amplitudes of the X and Y axis vibration signals during fine trimming are 0.50 and 0.40 V, respectively. The amplitudes of X and Y axis vibration signals at the completion of trimming are 0.29 and 0.27 V respectively, and the main frequencies of signals at the completion of rough, fine, and finishing are all distributed within 1 000 Hz. The root mean square and the variance of wavelet packet coefficients mainly occur at nodes (3,0) to (3,3), and as the grinding accuracy increases, the root mean square and the variance of wavelet packet coefficients decrease gradually. When rough trimming diamond rollers with diamond grinding wheels, the roundness error value of the roller profile is larger than that after fine trimming and the completion of trimming, resulting in a larger local grinding allowance. A large number of abrasive particles from the diamond grinding wheel come into contact with the roller, which increases the material removal amount of the diamond roller, the grinding force also increases, and the resulting vibration also increases accordingly. During the fine trimming process, the roundness error of the roller contour is reduced, so that the diamond wheel cutting the diamond roller allowance is reduced, the removal amount is also reduced, the grinding force is reduced, and the vibration generated is also reduced. At the same time, the root mean square and the variance of the wavelet packet coefficients in the completion of trimming decrease correspondingly as the roundness error value of the roller profile decreases. As the trend and fluctuation of the root mean square and the variance of the wavelet packet coefficients in the X and Y axes are generally consistent, the root mean square and the variance of the wavelet packet coefficients in the direction of the X-axis are selected as the feature vectors for the classification of experimental data. The wavelet packet is used to decompose the X-axis signal, and the variance and the root mean square of each node are calculated to obtain 16 characteristic values of the vibration signal. There is a mapping relationship between these characteristic values and the reshaping state of the roller, and the random forest algorithm is used to classify the vibration signals based on these 16 characteristic values, and the recognition accuracy reaches 93.3%. Conclusions: The contour reshaping of the diamond roller is the key to the production of diamond rollers. In the process of roller machining, the method combining sensor monitoring and machine learning models is used to judge the reshaping state of the diamond roller. The method can be used to identify the modified state of the diamond roller profile, reduce the number of roller disassemblies and roller profile detections, and improve the processing efficiency.

-

Key words:

- diamond roller /

- vibration signal /

- wavelet packet coefficients /

- online recognition /

- random forest

-

表 1 修形参数

Table 1. Trimming parameters

参数 类型或取值 滚轮直径 $ {D}_{1}\;\mathrm{m}\mathrm{m} $ 180 滚轮轮廓面CVD金刚石覆盖率P / % 50 CVD金刚石的长 (mm)× 高 (mm) × 厚 (mm) 4.2 × 2.4 × 0.8 滚轮CVD层宽度 $ {W}_{1}\;/\;\mathrm{ }\mathrm{m}\mathrm{m} $ 4.2 滚轮结合剂 J 砂轮直径 $ {D}_{2}\;/\;\mathrm{ }\mathrm{m}\mathrm{m} $ 200 砂轮中金刚石粒度代号 120/140 砂轮磨削层宽度 $ {W}_{2}\;/\;\mathrm{ }\mathrm{m}\mathrm{m} $ 5 砂轮中金刚石浓度 $ C\;/\;\mathrm{\%} $ 120 砂轮结合剂 V 砂轮转速 $ {n}_{1}\;/\;\mathrm{ }(\mathrm{r}·{\mathrm{m}\mathrm{i}\mathrm{n}}^{-1}) $ 1 000 滚轮转速 $ {n}_{2}\;/\;\mathrm{ }(\mathrm{r}·{\mathrm{m}\mathrm{i}\mathrm{n}}^{-1}) $ 60 纵向走刀转速 n3 / $ (\mathrm{r}·{\mathrm{m}\mathrm{i}\mathrm{n}}^{-1}) $ 6.8 砂轮进给量 $s\;/\;\text{μ} {\rm{m}}$ 4 表 2 样本圆度误差值

Table 2. Sample roundness error value

序号 圆度误差值 δ / μm 类别 序号 圆度误差值 δ / μm 类别 序号 圆度误差值 δ / μm 类别 1 30.6 1 101 9.8 2 201 1.9 3 2 25.1 1 102 8.6 2 202 1.8 3 ··· ··· ··· ··· ··· ··· ··· ··· ··· 99 19.8 1 199 9.6 2 299 1.9 3 100 23.2 1 200 7.3 2 300 1.9 3 表 3 小波包系数均方根值(V)

Table 3. Root mean square values of wavelet packet coefficients(V)

序号 (3,0) (3,1) (3,2) (3,3) (3,4) (3,5) (3,6) (3,7) 1 0.19005 0.10357 0.05747 0.07636 0.02990 0.04077 0.03106 0.02824 2 0.11971 0.05844 0.03135 0.04132 0.01610 0.02264 0.01641 0.01468 3 0.17662 0.06918 0.03955 0.05730 0.01994 0.03044 0.02503 0.02581 ··· ··· ··· ··· ··· ··· ··· ··· ··· 298 0.04174 0.02949 0.01774 0.04162 0.00908 0.02311 0.01275 0.01649 299 0.04435 0.02950 0.01910 0.04323 0.00979 0.02405 0.01361 0.01725 300 0.04370 0.03123 0.01961 0.04595 0.00993 0.02565 0.01435 0.01772 表 4 小波包系数方差值(V2)

Table 4. Variance values of wavelet packet coefficients(V2)

序号 (3,0) (3,1) (3,2) (3,3) (3,4) (3,5) (3,6) (3,7) 1 0.03580 0.01073 0.00330 0.00583 0.00089 0.00166 0.00096 0.00080 2 0.01371 0.00342 0.00098 0.00171 0.00026 0.00051 0.00027 0.00022 3 0.03118 0.00479 0.00157 0.00328 0.00040 0.00093 0.00063 0.00067 ··· ··· ··· ··· ··· ··· ··· ··· ··· 298 0.00166 0.00147 0.00041 0.00323 0.00011 0.00105 0.00016 0.00026 299 0.00146 0.00128 0.00041 0.00268 0.00011 0.00085 0.00019 0.00033 300 0.00191 0.00204 0.00058 0.00487 0.00017 0.00160 0.00018 0.00024 -

[1] 宋月清, 刘一波. 人造金刚石工具手册 [M]. 北京: 冶金工业出版社, 2014.SONG Yueqing, LIU Yibo. Handbook of synthetic diamond tools [M]. Beijing: Metallurgical Industry Press, 2014. [2] 蔡恩磊, 王立平, 孙丽荣, 等. 基于多过程信号的轧辊磨削表面粗糙度智能预测 [J]. 机电工程,2022,39(10):1462-1469.CAI Enlei, WANG Liping, SUN Lirong, et al. Intelligent prediction of surface roughness in roller grinding based on multi-process signals [J]. Mechanical and Electrical Engineering,2022,39(10):1462-1469. [3] 王素华, 徐小健, 于飞, 等. 基于振动特征优选和极限学习机的滚动轴承故障诊断 [J]. 深圳大学学报(理工版),2023,40(4):504-512.WANG Suhua, XU Xiaojian, YU Fei, et al. Fault diagnosis of rolling bearing based on vibration feature optimization and extreme learning machine [J]. Journal of Shenzhen University (Science and Engineering),2023,40(4):504-512. [4] 迟玉伦, 吴耀宇, 江欢, 等. 基于模糊神经网络与主成分分析的磨削表面粗糙度在线预测 [J]. 计量学报,2022,43(11):1389-1397. doi: 10.3969/j.issn.1000-1158.2022.11.01CHI Yulun, WU Yaoyu, JIANG Huan, et al. On-line prediction of grinding surface roughness based on fuzzy neural network and principal component analysis [J]. Acta Metrologica Sinica,2022,43(11):1389-1397. doi: 10.3969/j.issn.1000-1158.2022.11.01 [5] 郭力, 龙华, 王艺, 等. 基于卷积神经网络对磨削表面粗糙度声发射智能预测 [J]. 精密制造与自动化,2022(4):9-13.GUO Li, LONG Hua, WANG Yi, et al. Acoustic emission intelligent prediction of grinding surface roughness based on convolution neural network [J]. Precision Manufacturing and Automation,2022(4):9-13. [6] 黄双云, 武利冲. 基于小波包分析和BP神经网络的滚动轴承故障诊断研究 [J]. 煤矿机械,2023,44(7):157-160.HUANG Shuangyun, WU Lichong. Research on rolling bearing fault diagnosis based on wavelet packet analysis and BP neural network [J]. Coal Mine Machinery,2023,44(7):157-160. [7] 杜福嘉, 黄康, 郭跃楠. 小波包和模糊熵特征融合的轴承故障诊断 [J]. 机械设计与制造, 2023(10): 285-290.DU Fujia, HUANG Kang, GUO Yuenan. Bearing fault diagnosis based on feature fusion of wavelet packet and fuzzy entropy [J]. Machinery Design and Manufacturing, 2023(10): 285-290. [8] PLAZA E G, LOPEZ P J N. Application of the wavelet packet transform to vibration signals for surface roughness monitoring in CNC turning operations [J]. Mechanical Systems and Signal Processing,2018,98:902-919. doi: 10.1016/j.ymssp.2017.05.028 [9] XIAO J Q, LUO Z H. Time-frequency characteristics of vibration signals analysis for large instantaneous impact mill rolling based on wavelet packet [J]. Advanced Materials Research,2013(834/835/836):1061-1064. [10] 全国磨料磨具标准化技术委员会. 超硬磨料制品 金刚石修整滚轮: JB/T 10040-2017 [S]. 北京: 机械工业出版社, 2017.National Abrasive Standardization Technical Committee. Superabrasive products: Diamond dressing rollers: JB/T 10040-2017 [S]. Beijing: China Machine Press, 2017. [11] 孔玲军. MATLAB小波分析超级学习手[M]. 北京: 人民邮电出版社, 2014.KONG Lingjun. MATLAB super learning handbook for wavelet analysis [M]. Beijing: People's Posts and Telecommunications Press, 2014. [12] 葛飞, 卫鑫, 董鹏, 等. 基于小波包能量变化率的钢桁架损伤识别研究 [J]. 天津城建大学学报,2023,29(2):101-107. doi: 10.1007/s12209-022-00349-4GE Fei, WEI Xin, DONG Peng, et al. Research on damage identification of steel truss based on wavelet packet energy change rate [J]. Journal of Tianjin Chengjian University,2023,29(2):101-107. doi: 10.1007/s12209-022-00349-4 [13] Araújo L R R, Ariya S, Keuton D A, et al. Wavelet-based estimation method for online condition monitoring of dc-link capacitors of distributed energy resources [J]. International Journal of Electrical Power and Energy Systems, 2023, 151(卷): 109141.ARAÚJO L R R, ARIYA S, KEUTON D A, et al. Wavelet-based estimation method for online condition monitoring of Dc-link capacitors of distributed energy resources [J]. International Journal of Electrical Power and Energy Systems,2023,151:109141. [14] 王贝伦. 机器学习 [M]. 南京: 东南大学出版社, 2021.WANG Beilun. Machine learning [M]. Nanjing: Southeast University Press, 2021. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS