Preparation of diamond coated floating core head and its application in copper pipe production

-

摘要:

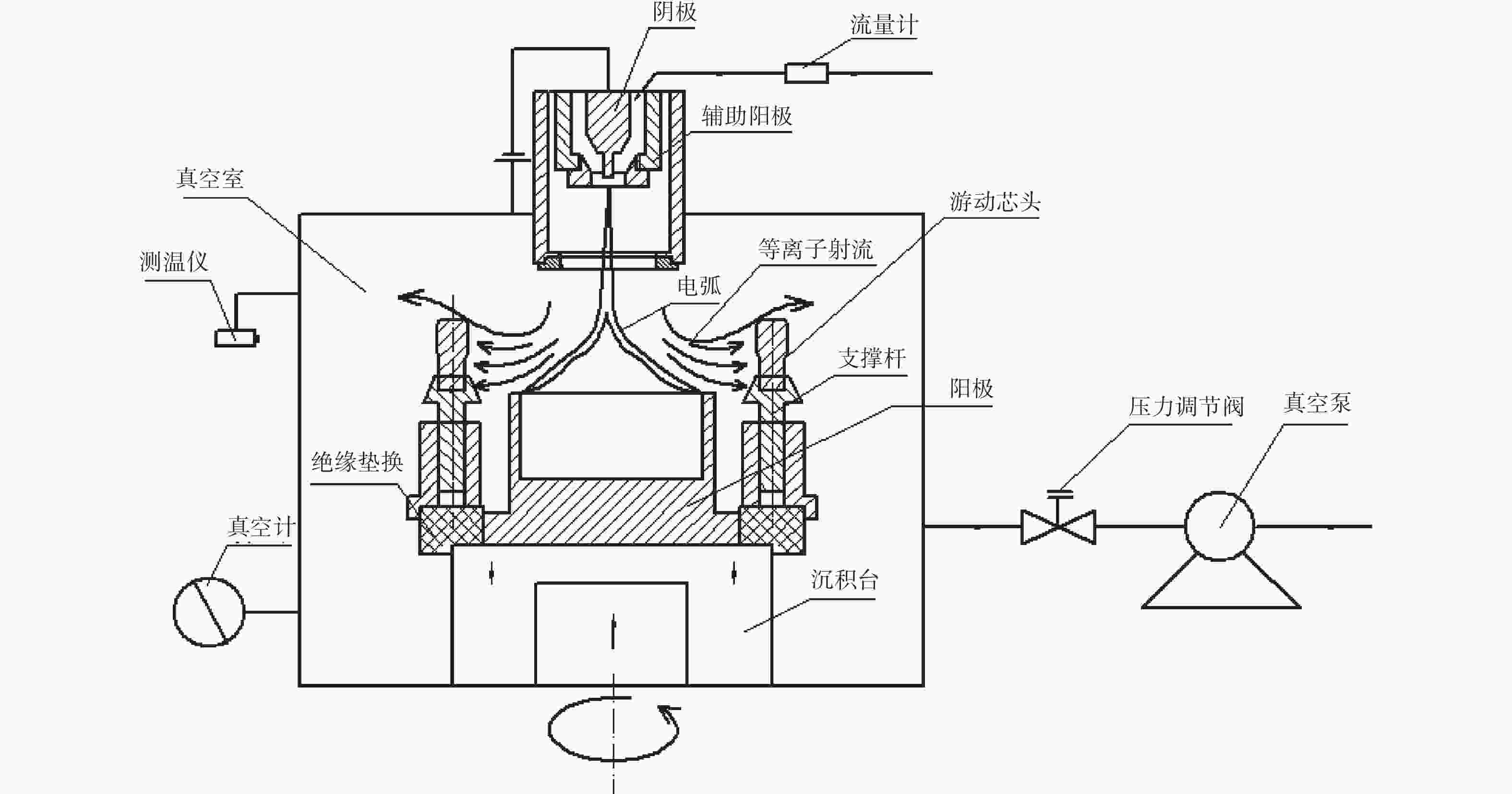

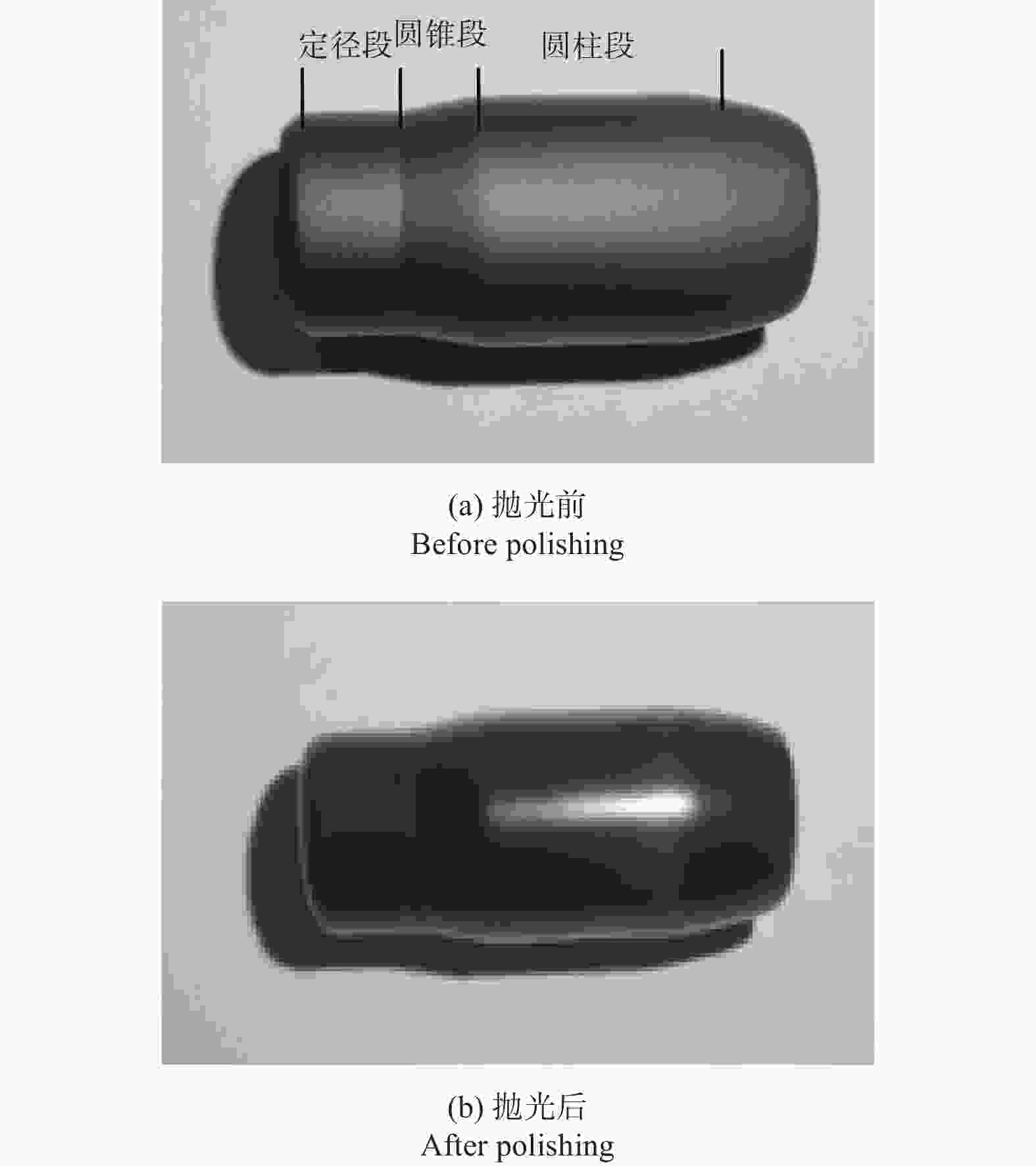

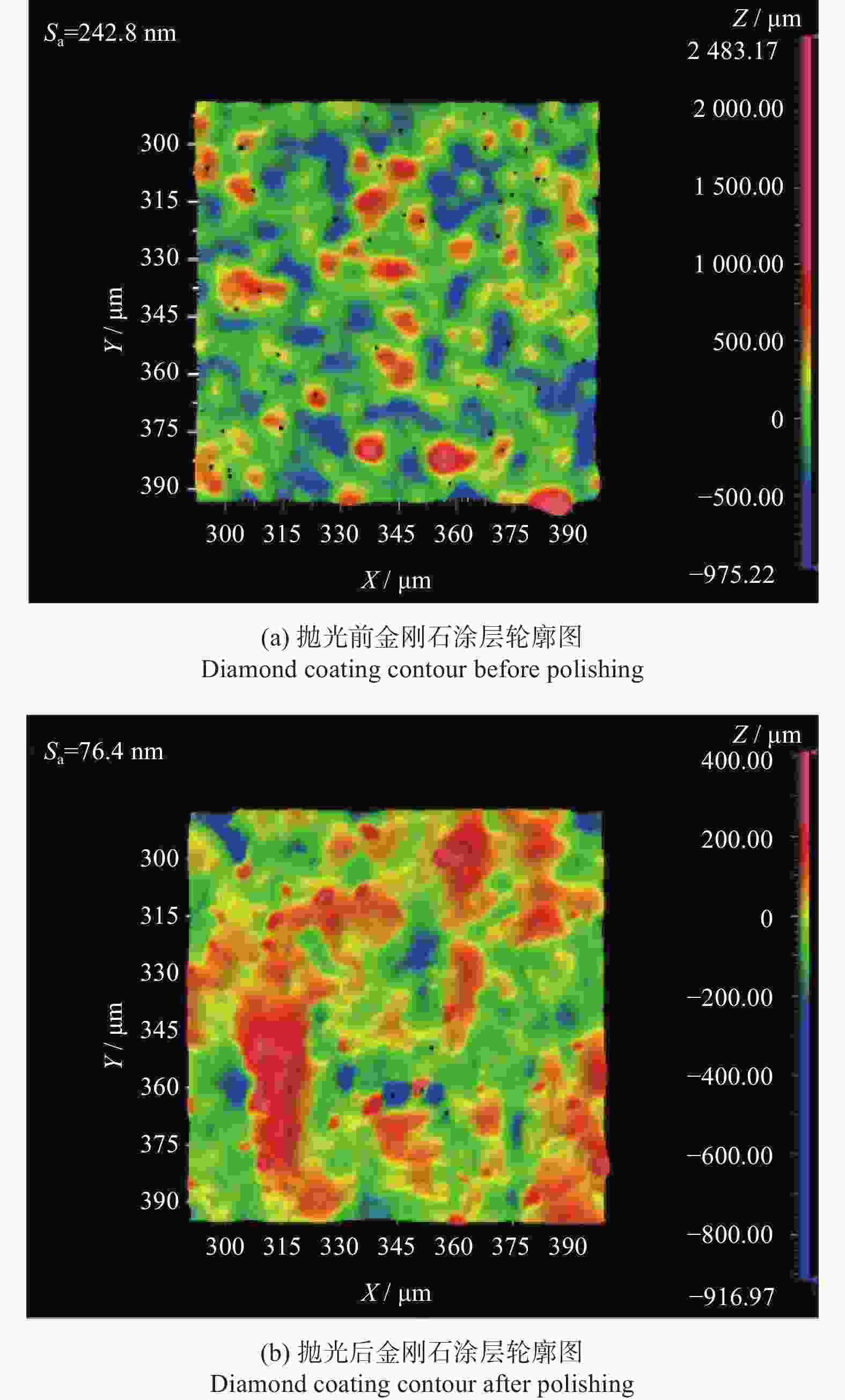

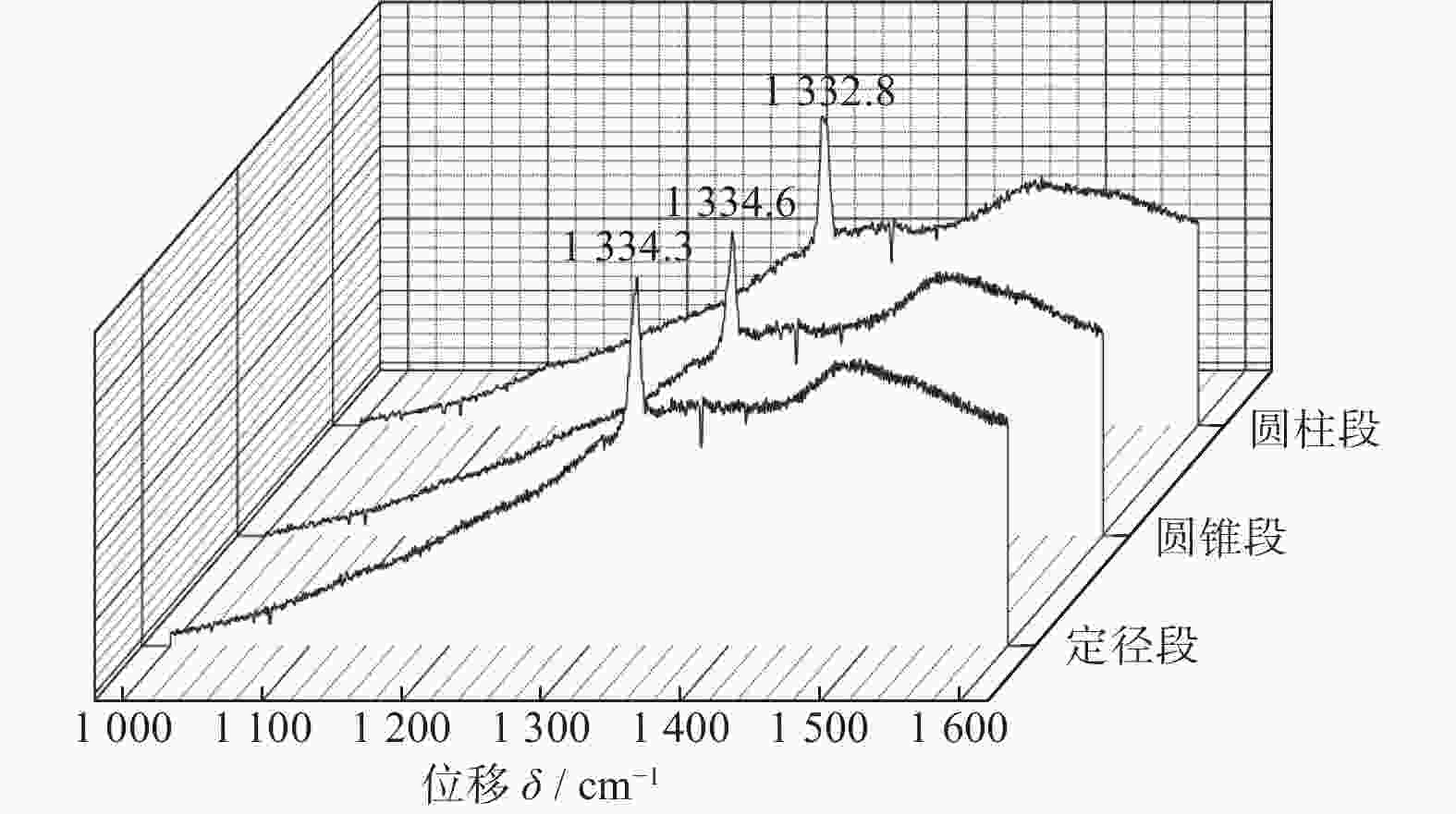

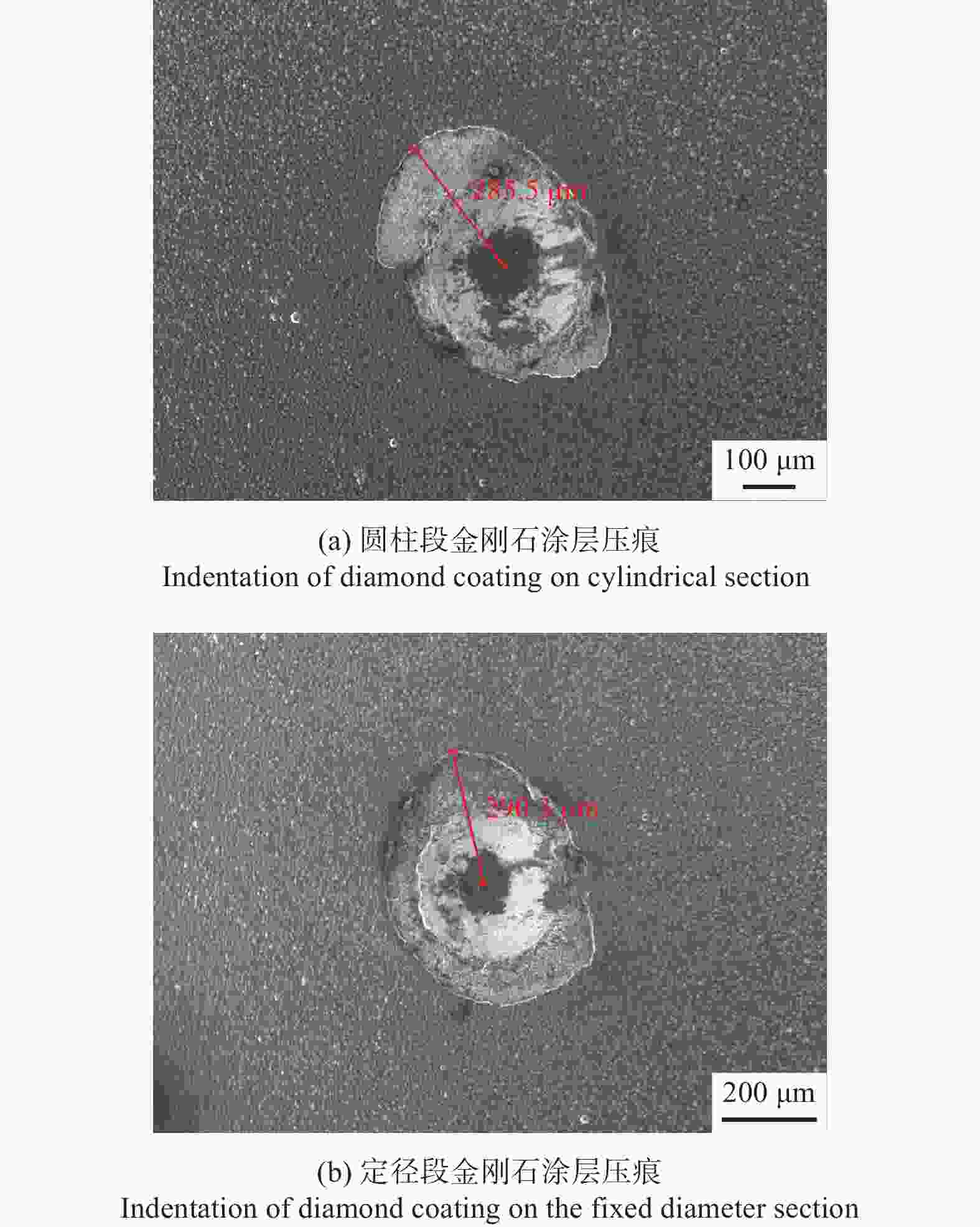

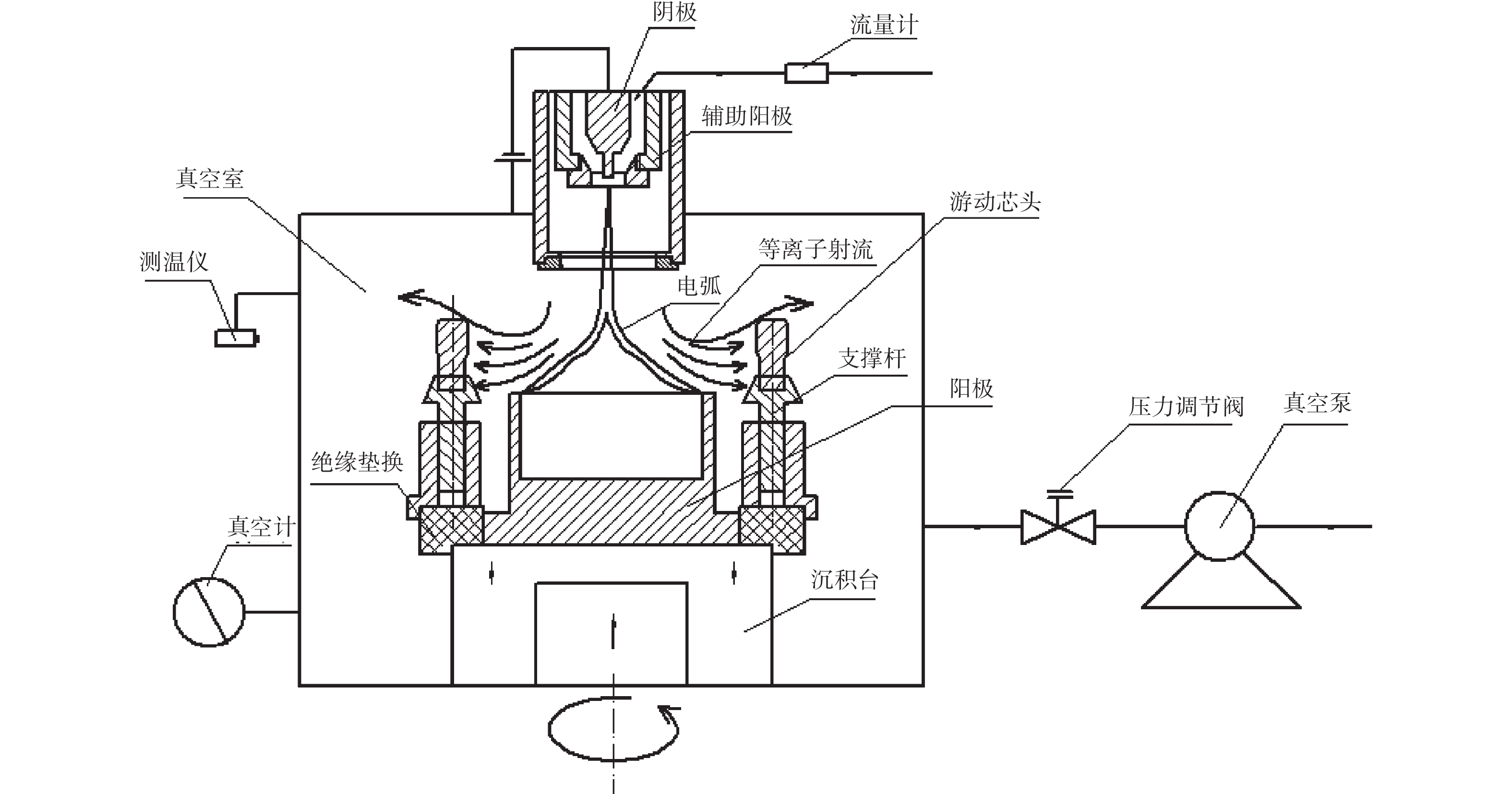

通过沉积方式和旋转装置设计,采用直流电弧等离子体喷射法在硬质合金游动芯头表面均匀沉积金刚石涂层,并利用白光干涉仪、扫描电子显微镜、Raman光谱仪和压痕法对涂层的表面粗糙度、形貌、质量均匀性和膜–基附着力等进行测试分析。结果表明:金刚石涂层抛光后的表面平均粗糙度Sa为76.4 nm,金刚石涂层脱落位置到压痕中心的平均距离为287.9 μm,且各位置的金刚石涂层厚度均匀性和质量均较好。将制备的金刚石涂层游动芯头应用于高精度精密铜管生产线中,与硬质合金游动芯头对比,其在降低劳动强度、保证铜管一致性和延长芯头使用寿命方面都有显著效果。

-

关键词:

- 铜管 /

- 直流电弧等离子体喷射法 /

- 游动芯头 /

- 金刚石涂层

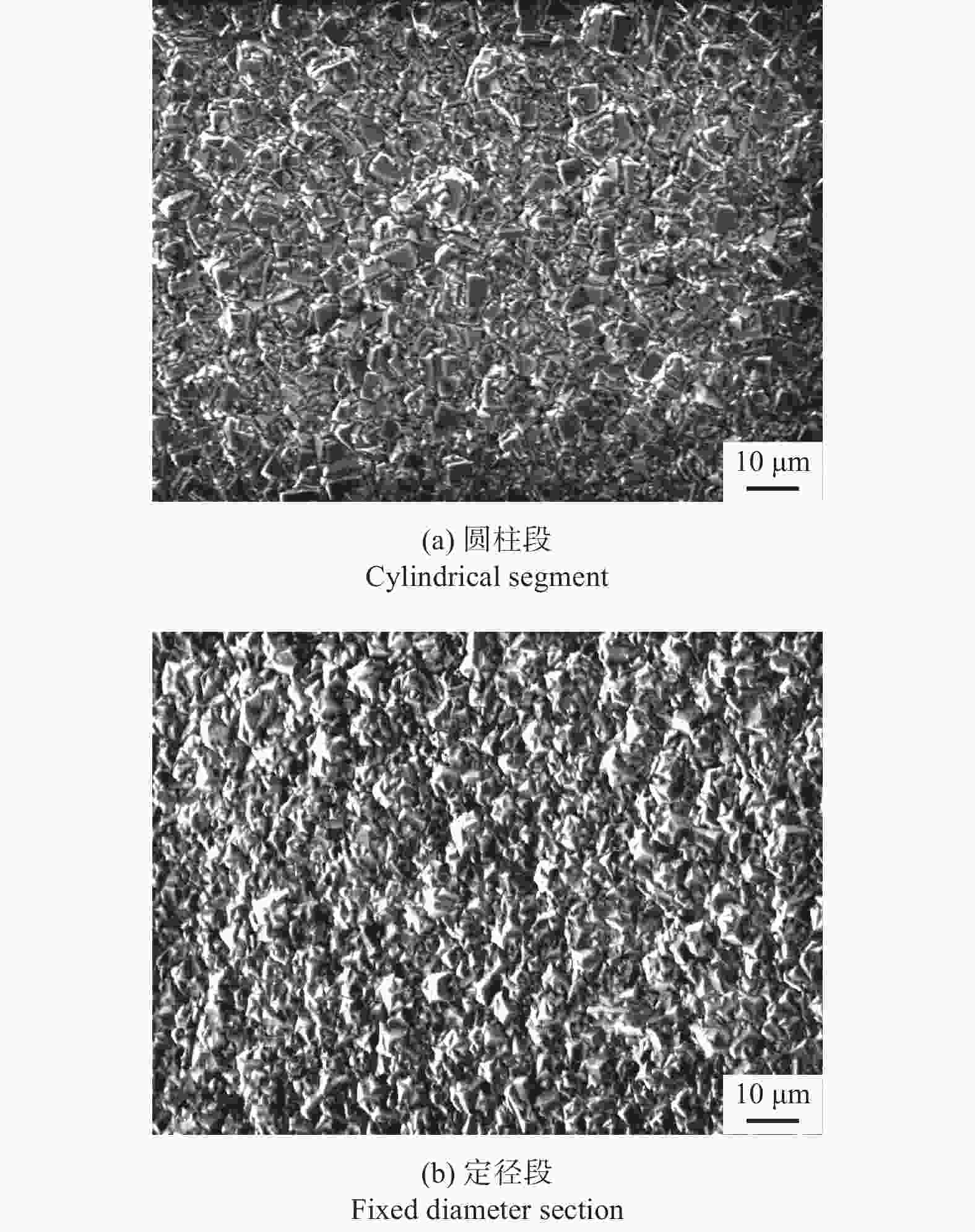

Abstract:Objectives: In the refrigeration industry, thin-walled copper tubes are crucial heat exchange devices, and during their drawing production process, the floating core head plays a significant role in the quality of the copper tubes. With the rapid development of chemical vapor deposition(CVD) diamond coating technology and its wide application in the field of molds, the DC arc plasma injection method is used to produce diamond-coated floating core heads to improve the quality of copper tube drawing and extend the service life of floating core heads. Methods: Using a deposition method and a rotating device design, the diamond coating was uniformly deposited on the surface of cemented carbide floating core heads by the DC arc plasma injection method. The surface roughness, morphology, mass uniformity, and film-base adhesion of the coating were tested and analyzed using a white light interferometer, scanning electron microscope, Raman spectrometer, and indentation method. The prepared diamond-coated floating core head was applied to a high-precision copper pipe production line, and the application effect was compared with that of a traditional cemented carbide floating core head. Results: SEM and Raman spectrum analysis showed that the diamond coating quality at each position of the floating core head was superior. The average thickness of the diamond in the cylindrical section of the floating core head was 13.3 μm, and in the fixed diameter section, it was 13.7 μm. At a room temperature of 20 ℃ and a relative humidity of 40%, with a filtering cutoff wavelength of 250 μm and a scanning area of 100 μm × 100 μm, the average surface roughness (Ra) of the polished diamond coating was 76.4 nm. Under the indentation test condition of loading to 1 000 N and holding constant force for 3 seconds at a fixed loading rate of 20.0 N/s, the average distance from the diamond coating shedding position to the indentation center was 287.9 μm. The prepared diamond-coated floating core head was then applied to the high-precision copper pipe production line. Compared with the cemented carbide floating core head, the following findings were observed: (1) Due to the excellent finish and self-lubrication characteristics of the diamond coating, the maintenance frequency of the floating core head decreased from once per frame to once every 20 frames, reducing labor intensity significantly. (2) Due to the excellent wear resistance of the diamond coating, the size of the fixed diameter section of the core head remained constant, ensuring that the wall thickness of the copper tube did not vary, therefore improving product consistency. (3) The service life of the diamond-coated floating core head was about 15 times that of the cemented carbide core head. Conclusions: The DC arc plasma injection method can uniformly deposit high quality diamond coating on the surface of cemented carbide floating core heads, reducing labor intensity effectively, ensuring consistency in copper tube production, and extending the service life of the core head in practical applications. Others: With the continuous progress of DC arc plasma jet deposition diamond coating technology, the quality of diamond-coated floating core heads will further improve. Diamond coatings can gradually be applied to various internal molds, such as fixed core heads and threaded cores. When used with diamond coated outer molds, these internal molds can replace traditional cemented carbide molds, reducing mold costs and labor costs, and improving the drawing quality of pipes significantly. This approach will help achieve the goal of reducing costs and increasing the efficiency in the copper, aluminum, stainless steel and other related industries.

-

Key words:

- copper pipe /

- DC arc plasma jet method /

- floating core head /

- diamond coating

-

表 1 不同位置的金刚石涂层厚度

Table 1. Diamond coating thickness at different positions

测量位置 金刚石涂层厚度 h / μm 1 2 3 平均值 圆柱上段

圆柱下段

定径段13

12

1512

14

1215

14

1413.3

13.3

13.7表 2 2种游动芯头的测试结果

Table 2. Two kinds of floating core head test results

参数 硬质合金

游动芯头金刚石涂层

游动芯头维护频次 n / (次·框-1) 1 1/20 游动芯头定径段缩径量 H1 / (μm·t−1) 1.46 0 铜管壁厚增加量 H2 / (μm·t−1) 2.92 0 使用寿命 L / t 7 100 -

[1] 唐伟东, 张士宏, 林涛, 等. 游动芯头拉拔模具失效分析 [J]. 材料科学与工艺,2012,20(3):109-116.TANG Weidong, ZHANG Shihong, LIN Tao, et al. Die failure analysis of tube drawing with floating plugs [J]. Materials Science and Technology,2012,20(3):109-116. [2] SAWAMIPHAKDI K, LAHOTI G D, GUNASEKERA J S, et al. Development of utility programs for a cold drawing process [J]. Journal of Materials Processing Technology,1998,80/81:392-397. doi: 10.1016/S0924-0136(98)00118-6 [3] 唐伟东. 游动芯头拉拔模具摩擦磨损及其优化 [D]. 北京: 中国科学院大学, 2012.TANG Weidong. Research on friction and wear of die in tube drawing with floating plug and its optimization [D]. Beijing: University of Chinese Academy of Sciences, 2012. [4] 郭建超, 张雄文, 靳士昌, 等. 电弧法CVD金刚石膜热学性能影响因素分析 [J]. 标准科学,2023(S1):195-199.GUO Jianchao, ZHANG Xiongwen, JIN Shichang, et al. Analysis of influence factor about thermal properties of CVD diamond films by DC arc plasma method [J]. Standard Science,2023(S1):195-199. [5] 方向阳. 直流电弧等离子体喷射CVD金刚石膜的制备工艺探讨 [J]. 宁夏工程技术,2002(3):246-249.FANG Xiangyang. Discussion on the manufacturing technic of the direct current arc plasma jet on CVD diamond film [J]. Ningxia Engineering Technology,2002(3):246-249. [6] 耿传文, 赵鹏, 张晓东, 等. 金刚石薄膜在第一壁材料表面的应力研究 [J]. 表面技术,2022,51(10):243-249, 320.GENG Chuanwen, ZHAO Peng, ZHANG Xiaodong, et al. The stress of diamond films on the surface of the first wall material [J]. Surface Technology,2022,51(10):243-249, 320. [7] 崔玉明, 李国华, 董旺, 等. 高压及超高压电缆金属护套金刚石涂层模具制备与应用 [J]. 电线电缆,2021(5):36-40.CUI Yuming, LI Guohua, DONG Wang, et al. Preparation and application of diamond coating drawing die for metal sheath of high voltage and ultra-high voltage cable [J]. Wire & Cable,2021(5):36-40. [8] 李国华, 姜龙, 郭辉, 等. 一种环状工件内壁沉积金刚石涂层的方法 : CN111676463A [P]. 2020-09-18.LI Guohua, JIANG Long, GUO Hui, et al. Method for depositing diamond coating on inner wall of annular workpiece: CN111676463A [P]. 2020-09-18. [9] 崔玉明, 李国华, 姜龙. 直流电弧等离子体喷射法制备金刚石涂层拉拔模具 [J]. 金刚石与磨料磨具工程,2019,39(6):25-29.CUI Yuming, LI Guohua, JIANG Long. Diamond coated drawing die prepared by direct current arc plasma jet method [J]. Diamond & Abrasives Engineering,2019,39(6):25-29. [10] 吕反修. 金刚石膜制备与应用 [M]. 北京: 科学出版社, 2014.LYU Fanxiu. Diamond film preparation and application [M]. Beijing: Science Press, 2014. [11] 阎研, 张树霖, 郝少康, 等. CVD金刚石膜中1145 cm−1拉曼峰的研究 [J]. 光散射学报,2004,16(2):131-135.YAN Yan, ZHANG Shulin, HAO Shaokang, et al. Study of 1145 cm−1 raman peak of CVD diamond film [J]. Chinese Journal of Light Scattering,2004,16(2):131-135. [12] BOPPART H, VAN STRAATEN J, SILVERA I F. Raman spectra of diamond at high pressures [J]. Physical Review B, 1985, 32(2): 1423-1425. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS