Experimental evaluation of grinding zirconia ceramics with leaf vein bionic fractal textured diamond grinding wheel

-

摘要:

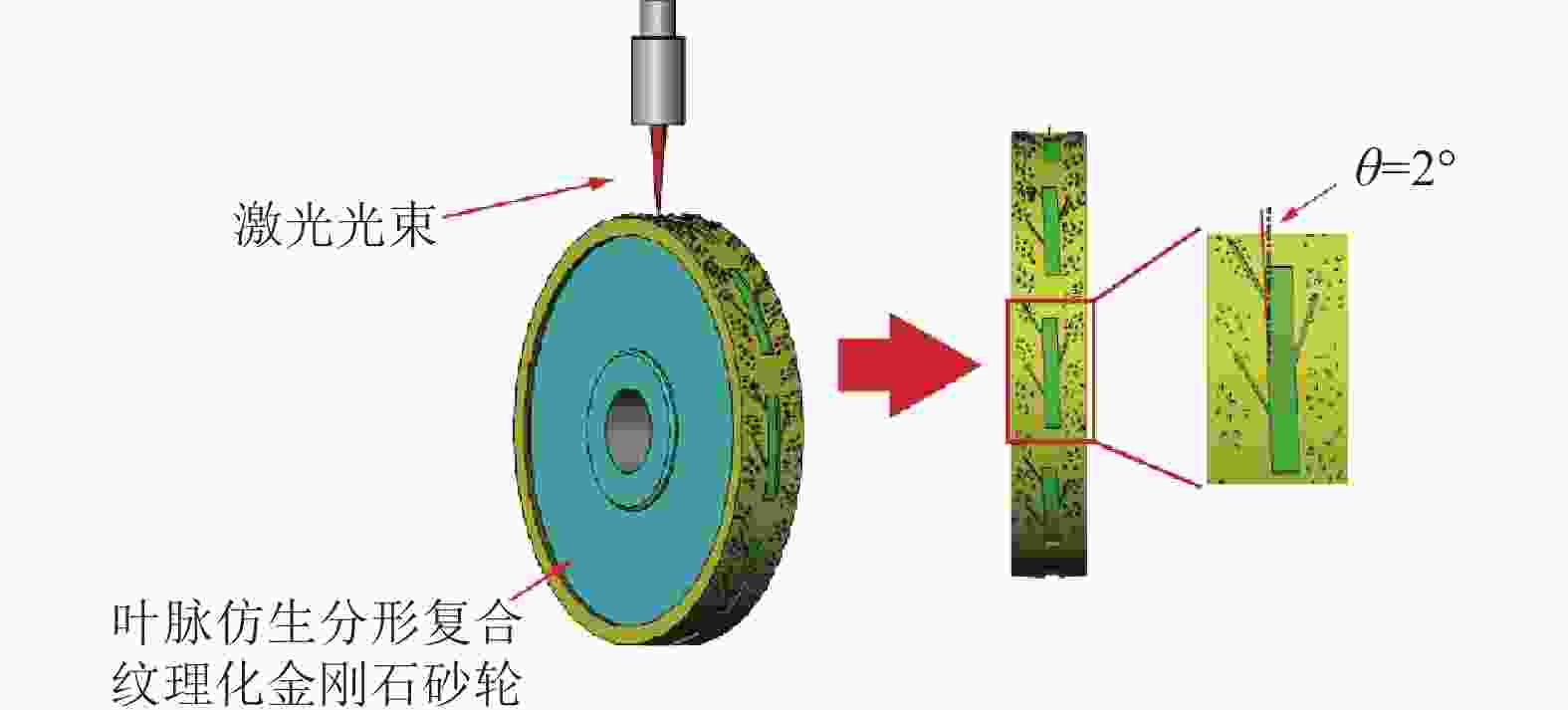

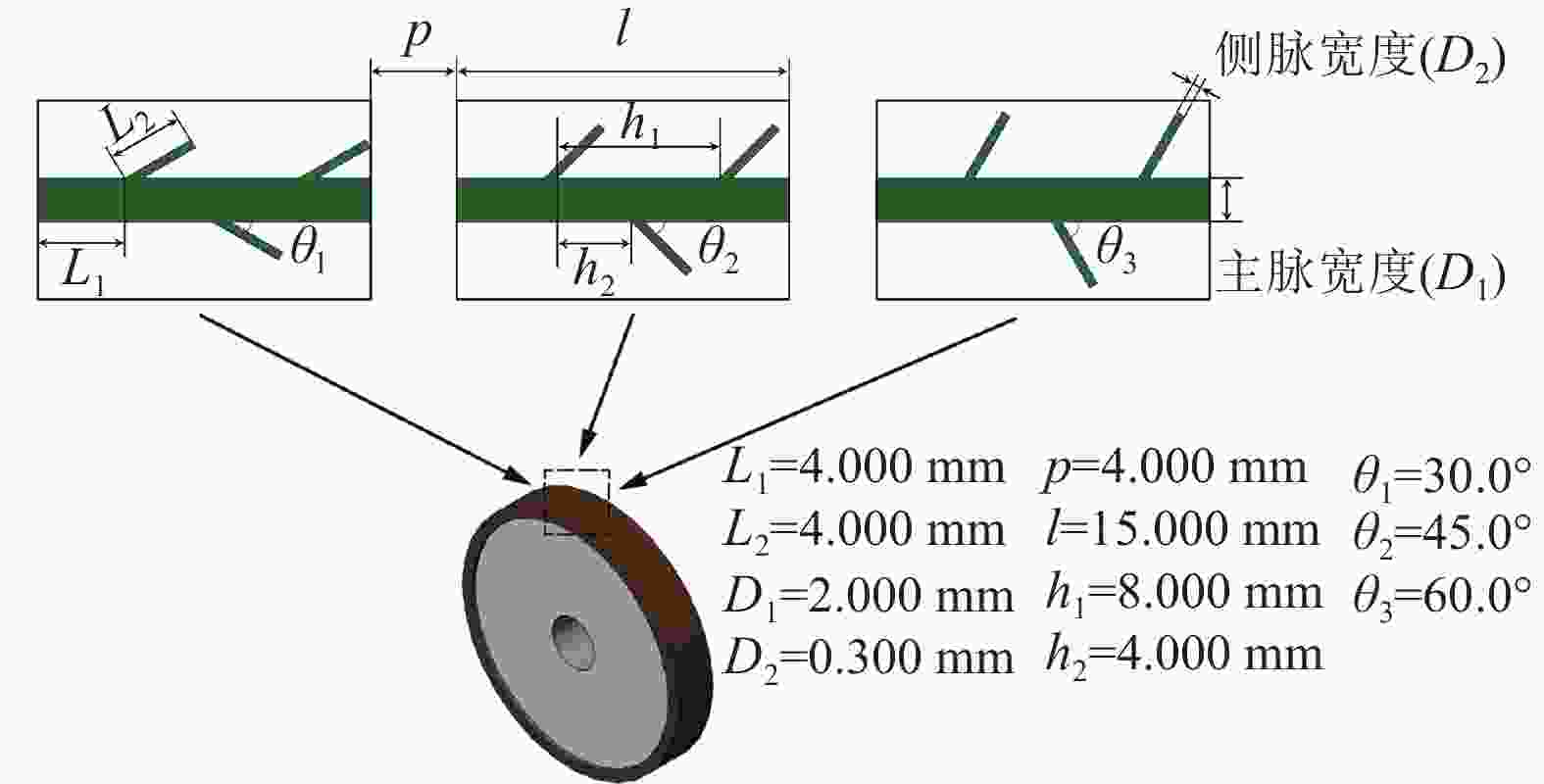

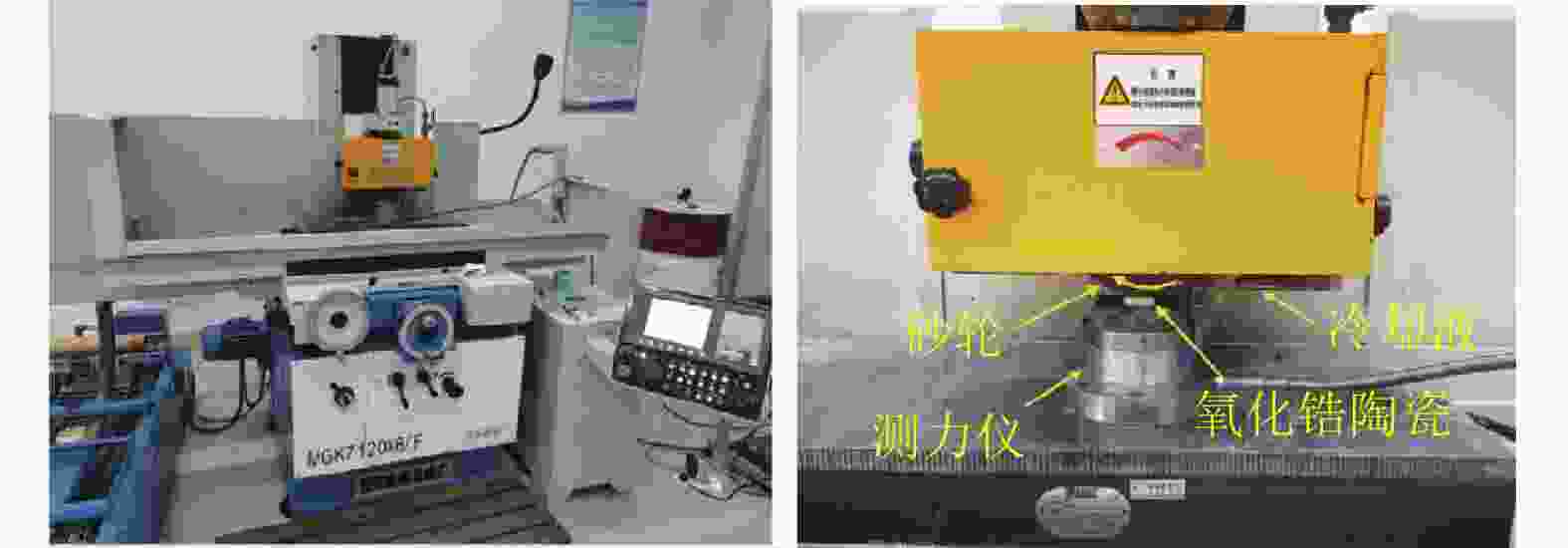

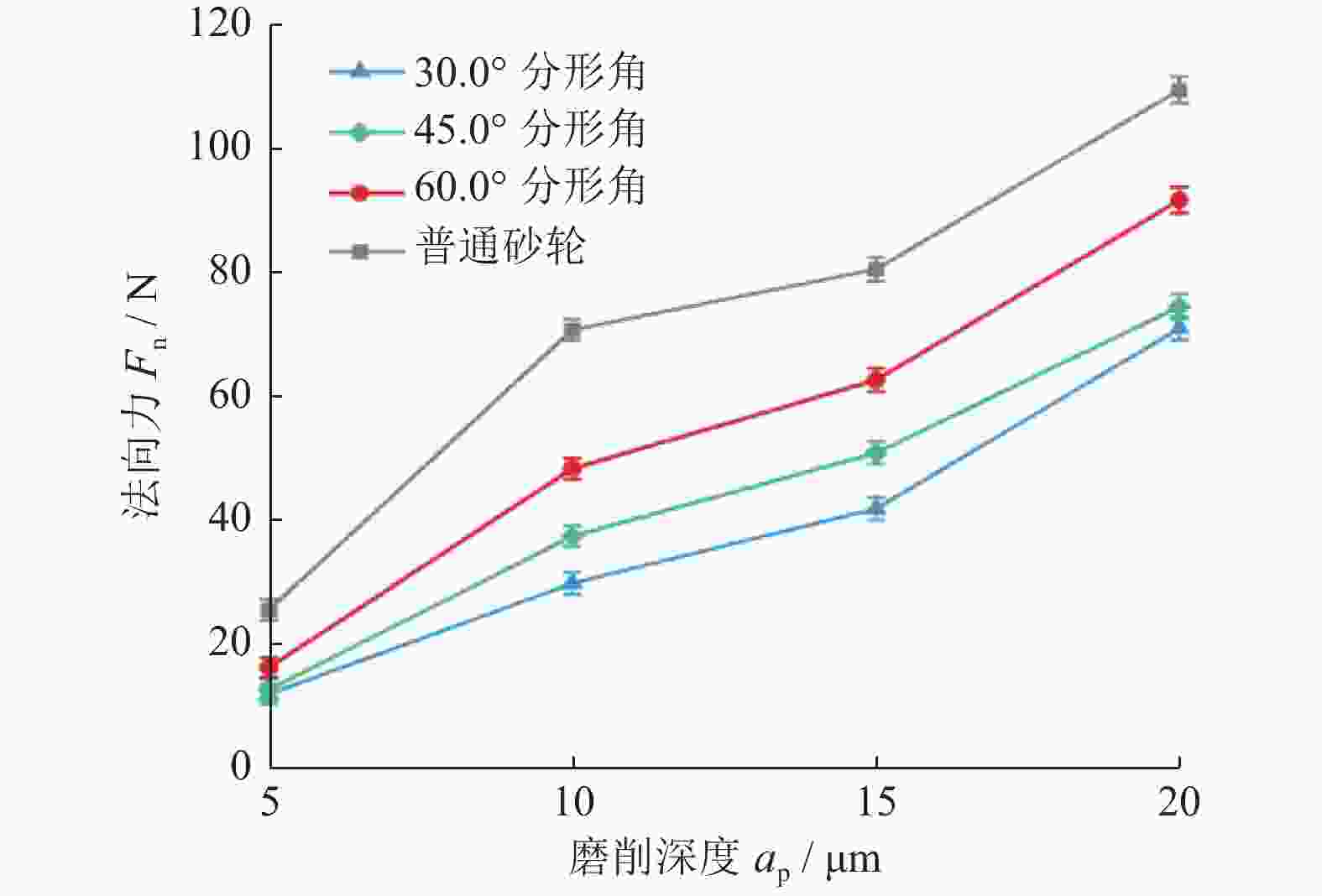

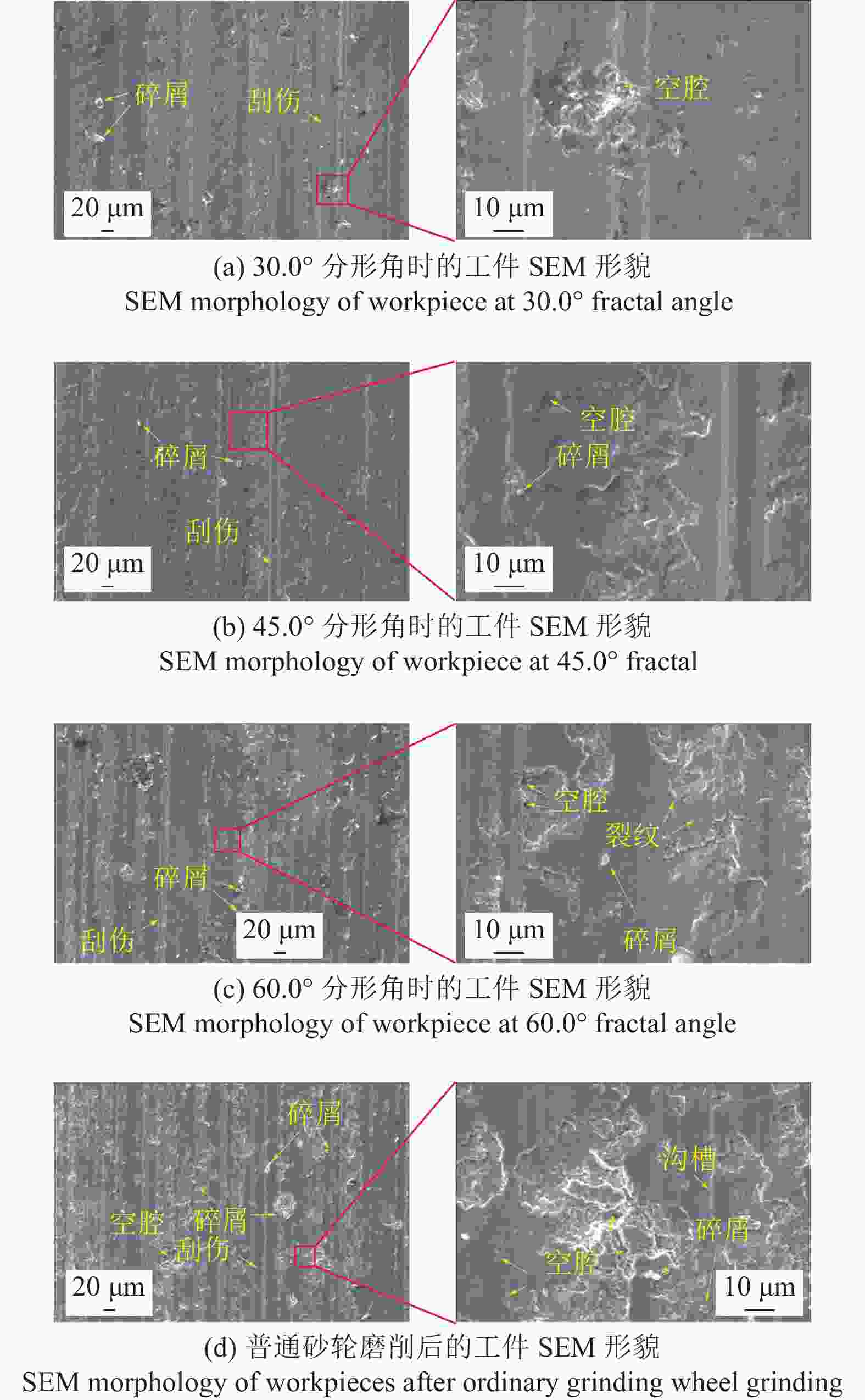

针对氧化锆陶瓷在传统砂轮磨削过程中存在的磨削力大、加工质量较差等问题,根据叶脉分形结构在减阻导流与散热传质方面的优异性能,建立叶脉分形角模型,设计30.0°、45.0°和60.0° 3种不同分形角度的叶脉仿生分形纹理化金刚石砂轮,对比分析原始砂轮与3种仿生分形砂轮对氧化锆陶瓷磨削表面粗糙度Ra、磨削力和磨削力比的影响。结果表明:仿生分形砂轮比原始砂轮具有更好的磨削性能;与原始砂轮相比,仿生分形砂轮的法向磨削力降低了12.7%~55.8%,切向磨削力降低了8.1%~40.3%,且其对表面粗糙度Ra影响不明显;当分形角为30.0°时,获得的磨削力比最小值为1.4~3.0,表面粗糙度Ra最小值为1.824 μm。

Abstract:To address the challenges of high grinding force and poor processing quality in grinding zirconia ceramics with traditional grinding wheels, this study explores the use of leaf vein bionic fractal textured diamond grinding wheels. These wheels, designed with fractal angles of 30.0°, 45.0°, and 60.0°, leverage the leaf vein bionic fractal texture's capabilities in reducing drag, guiding flow, heat dissipation, and mass transfer. The effects of the original grinding wheel and the three types of bionic fractal grinding wheels on the surface roughness (Ra), grinding force, and grinding force ratio of zirconia ceramics were compared and analyzed. The results show that the bionic fractal grinding wheels outperform the original grinding wheel. Specifically, compared to the original grinding wheel, the normal grinding force of the bionic fractal grinding wheel is reduced by 12.7% to 55.8%, and the tangential grinding force is reduced by 8.1% to 40.3%. The bionic fractal grinding wheels have not obvious effects on the surface roughness Ra. When the fractal angle is 30.0°, the minimum grinding force ratio is 1.4 to 3.0, and the minimum surface roughness Ra is 1.824 μm.

-

Key words:

- leaf vein fractal texture /

- fractal angle /

- laser texturing /

- zirconia ceramics /

- grinding performance

-

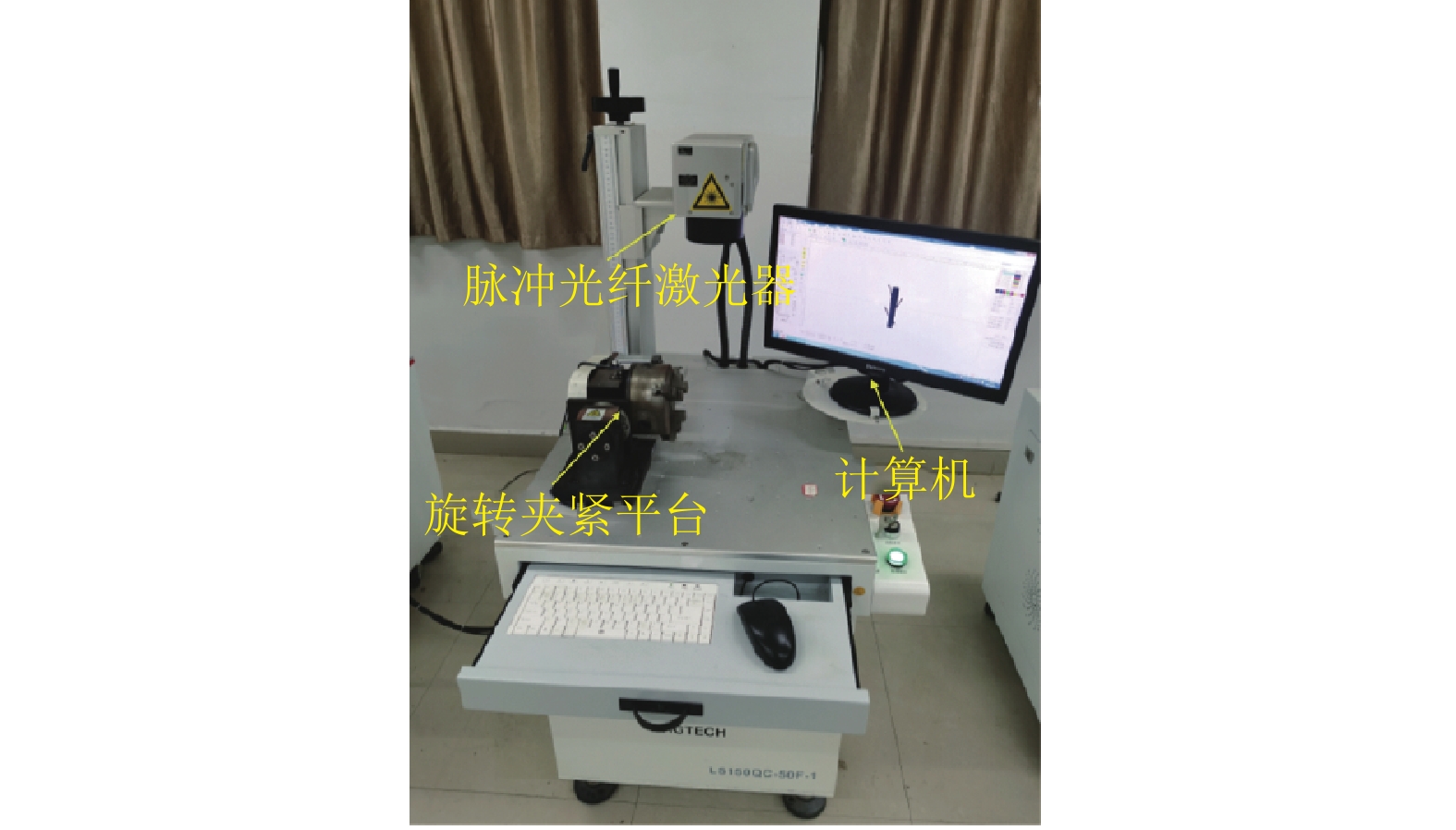

表 1 烧蚀宏观主脉与侧脉的激光参数

Table 1. Laser parameters for ablation of main and side veins

参数 主脉 侧脉 焦距 f / mm 105 105 光斑直径 df / μm 60 60 激光功率 Pavg / W 23 19 脉冲频率 fp / kHz 25 25 扫描速度 Vs / (mm·s−1) 2 100 2 100 扫描次数 N 33 30 表 2 青铜结合剂金刚石砂轮参数

Table 2. Bronze bond diamond grinding wheel parameters

参数 类型或取值 砂轮型号 SDC120N100B 砂轮直径 D / mm 180 内孔直径 d / mm 32 砂轮宽度 W / mm 20 磨粒层厚度 h / mm 5 磨粒基本颗粒尺寸 D50 / μm 70~130 磨粒浓度φ / % 75 磨粒 金刚石 表 3 氧化锆陶瓷材料的机械特征

Table 3. Mechanical characteristics of zirconia ceramic materials

氧化锆陶瓷 取值 密度 ρ / (kg·m−3) 5.7 × 103 弹性模量 E / GPa 200 硬度 H / GPa 12 断裂韧性 EIC / (MPa·m1/2) 8 表 4 磨削试验参数

Table 4. Grinding test parameters

磨削参数 类型或取值 砂轮速度 V / (m·s−1) 35 工件进给速度 Vf / (m·min−1) 2 磨削深度 ap / μm 5, 10, 15, 20 磨削方式 顺磨 磨削液 W20水基冷却液 -

[1] 张云龙. SiC/SiC复合材料微孔激光--化学复合加工技术研究 [D]. 山东: 青岛理工大学, 2022ZHANG Yunlong. Research on microporous laser-chemical composite processing technology for SiC/SiC composite materials [D]. Shandong: Qingdao University of Technology, 2022. [2] 廖燕玲, 张凤林, 李凯江, 等. 微结构砂轮对不同陶瓷的磨削性能 [J]. 金刚石与磨料磨具工程,2022,42(3):290-299. doi: 10.13394/j.cnki.jgszz.2021.0204LIAO Yanling, ZHANG Fenglin, LI Kaijiang, et al. Grinding performance of micro-texured grinding wheel on different ceramic materials [J]. Diamond and Abrasives Engineering,2022,42(3):290-299. doi: 10.13394/j.cnki.jgszz.2021.0204 [3] PANG J Z, JI X, NIU Y, et al. Experimental investigation of grinding force and materialremoval mechanism of laser-structured zirconia ceramics [J]. Micromachines,2022,13(5):710. doi: 10.3390/mi13050710 [4] DENG H, WU X S, YUCHI G Z, et al. Research on laser preparation and grinding performance of hydrophilic structured grinding wheels [J]. Ceramics International,2023,49(5):7649-7661. doi: 10.1016/j.ceramint.2022.10.240 [5] ALI S M, JONHNSIN N N, MADHAVADAS V, et al. Investigation on the effect of grinding wheel for grinding of AISI D3 tool steel under different conditions [J]. Engineering Research Express,2022,4(4):045036. doi: 10.1088/2631-8695/aca956 [6] MA Z L, WANG Q H, CHEN H, et al. Surface prediction in laser-assisted grinding process considering temperature-dependent mechanical properties of zirconia ceramic [J]. Journal of Manufacturing Processes,2022,80:491-503. [7] CHEN Z, ZHANG X H, WEN D D, et al. Improved grinding performance of SiC using an innovative bionic vein-like structured grinding wheel optimized by hydrodynamics [J]. Journal of Manufacturing Processes,2023(101):195-207. doi: 10.1016/j.jmapro.2023.06.010 [8] ZHANG X H, KANG Z X, LI S, et al. Grinding force modelling for ductile-brittle transition in laser macro-micro-structured grinding of zirconia ceramics [J]. Ceramics International,2019,45(15):18487-18500. doi: 10.1016/j.ceramint.2019.06.067 [9] MA Z L, WANG Z, WANG X Z, et al. Effects of laser-assisted grinding on surface integrity of zirconia ceramic [J]. Ceramics International,2020,46(1):921-929. doi: 10.1016/j.ceramint.2019.09.051 [10] ZHANG X H, LI S, KANG Z X, et al. Experimental investigations on the impact of different laser macro-structured diamond grinding wheels on alumina ceramic [J]. The International Journal of Advanced Manufacturing Technology,2018(96):5-8. [11] WEN D D, WAN LL, ZHANG X H, et al. Grinding performance evaluation of SiC ceramic by bird feather-like structure diamond grinding wheel [J]. Journal of Manufacturing Processes,2023(95):382-391. doi: 10.1016/j.jmapro.2023.04.024 [12] BUTLER-SMITH P W, AXINTE D A, DAINE M. Ordered diamond micro-arrays for ultraprecision grinding—An evaluation in Ti-6Al-4V [J]. International Journal of Machine Tools and Manufacture. 2010, 51 (1): 54-66. [13] WALTER C, KOMISCHKE T, KUSTER F, et al. Laser-structured grinding tools—Generation of prototype patterns and performance evaluation [J]. Journal of Materials Processing Technology,2014,214(4):951-961. doi: 10.1016/j.jmatprotec.2013.11.015 [14] WALTER C, KOMISCHKE T, WEINGARTNER E, et al. Structuring of CBN grinding tools by ultrashort pulse laser ablation [J]. Procedia CIRP,2014(14):31-36. doi: 10.1016/j.procir.2014.03.093 [15] YU H Y, LU Y S, WANG J. Study on wear of the grinding wheel with an abrasive phyllotactic pattern [J]. Wear,2016(358/359):89-96. [16] LI S, YUCHI G Z, ZHANG X H, et al. Grinding behavior of biomimetic fractal-branched silicon carbide ceramic inspired from leaf-vein structure [J]. Ceramics International,2022,48(13):18212-18223. doi: 10.1016/j.ceramint.2022.03.080 [17] ANTONIO F M. Constructal branching design for fluid flow and heat transfer [J]. International Journal of Heat and Mass Transfer,2018(122):204-211. doi: 10.1016/j.ijheatmasstransfer.2018.01.095 [18] UYLINGS H B M. Optimization of diameters and bifurcation angles in lung and vascular tree structures [J]. Bulletin of Mathematical Biology,1977,39(5):509-520. doi: 10.1016/S0092-8240(77)80054-2 [19] DENG H, CHEN G, HE J, et al. Online, efficient and precision laser profiling of bronze-bonded diamond grinding wheels based on a single-layer deep-cutting intermittent feeding method [J]. Optics and Laser Technology,2016(80):41-50. doi: 10.1016/j.optlastec.2015.12.021 [20] MURRAY C D. The physiological principle of minimum work: I. The vascular system and the cost of blood volume [J]. Proceedings of the National Academy of Sciences of the United States of America,1926,12(3):207-214. [21] MURRAY C D. The physiological principle of minimum work applied to the angle of branching of arteries [J]. The Journal of General Physiology,1926,9(6):835-841. doi: 10.1085/jgp.9.6.835 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS