Numerical simulation of bottomhole flow field of PDC bit in horizontal well

-

摘要:

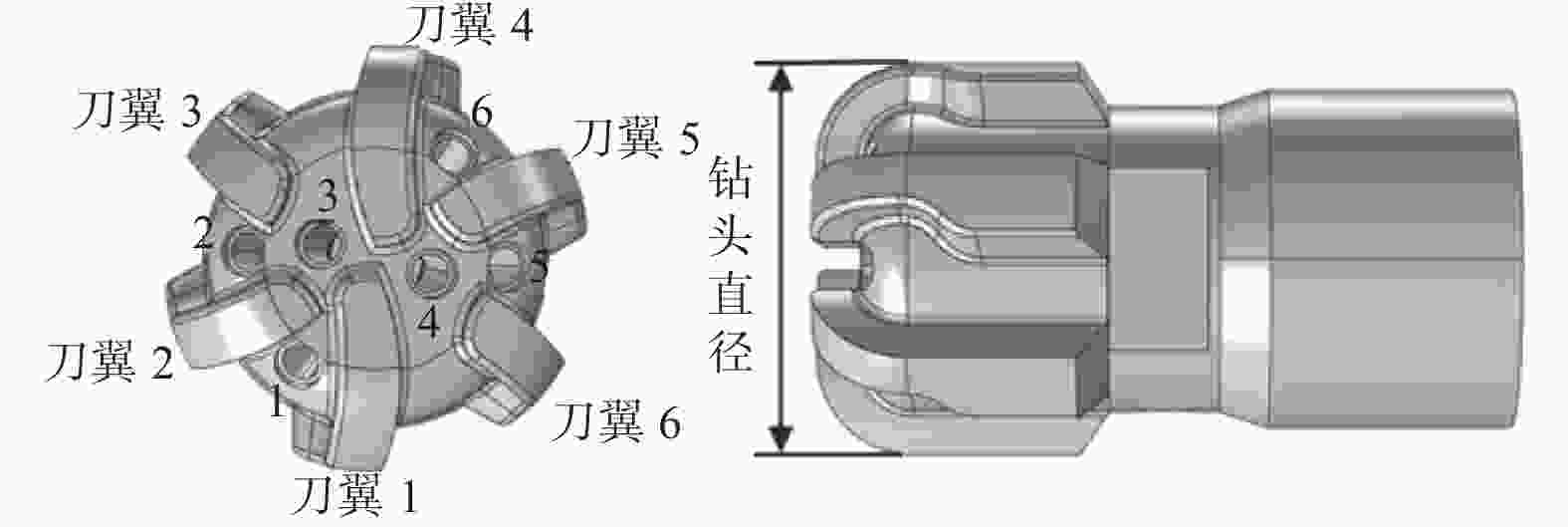

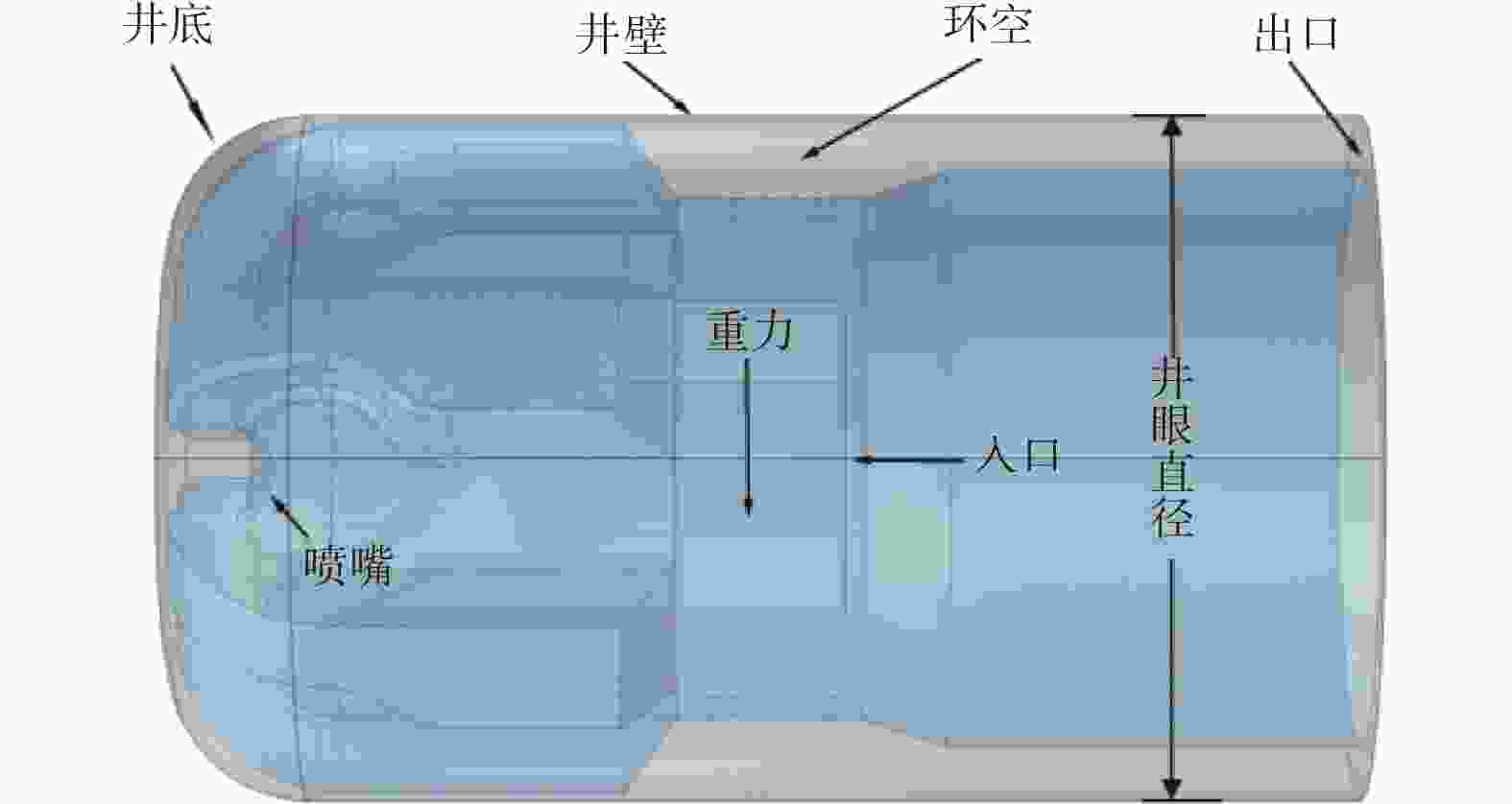

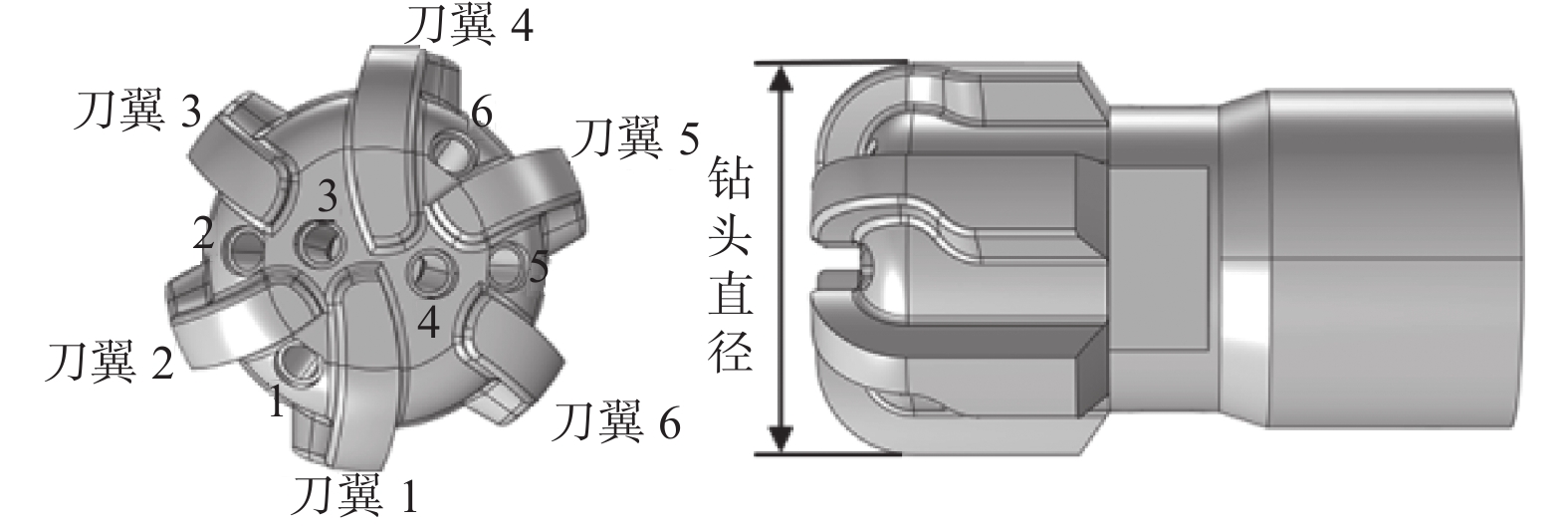

为了解决页岩水平井岩屑运移困难、钻头泥包等问题,提高聚晶金刚石复合片(polycrystalline diamond compact,PDC)PDC钻头在钻井过程中的钻井效率和使用寿命,采用数值模拟方法、低雷诺数k-ԑ湍流模型建立井底的流场模型,对PDC钻头的水力结构在不同钻井液排量、PDC钻头转速和岩屑粒径工况下的井底流场变化和岩屑运动状态进行分析并优化改进。结果表明:重力作用对低排量下的岩屑运动状态影响较大,当钻井液排量增加到一定程度后,岩屑运移效率变化较小;在旋转工况下,钻井液排量和钻头转速不匹配,降低了钻井液的冲刷作用和岩屑运移效率;在一定排量和钻头转速下,钻头转速对大粒径岩屑运移效率的提升作用大于对小粒径岩屑的;在相同的喷嘴面积下,优化后的8喷嘴钻头岩屑运移效率优于6喷嘴钻头的;相比非等径喷嘴组合,等径喷嘴组合的性能表现更均衡。

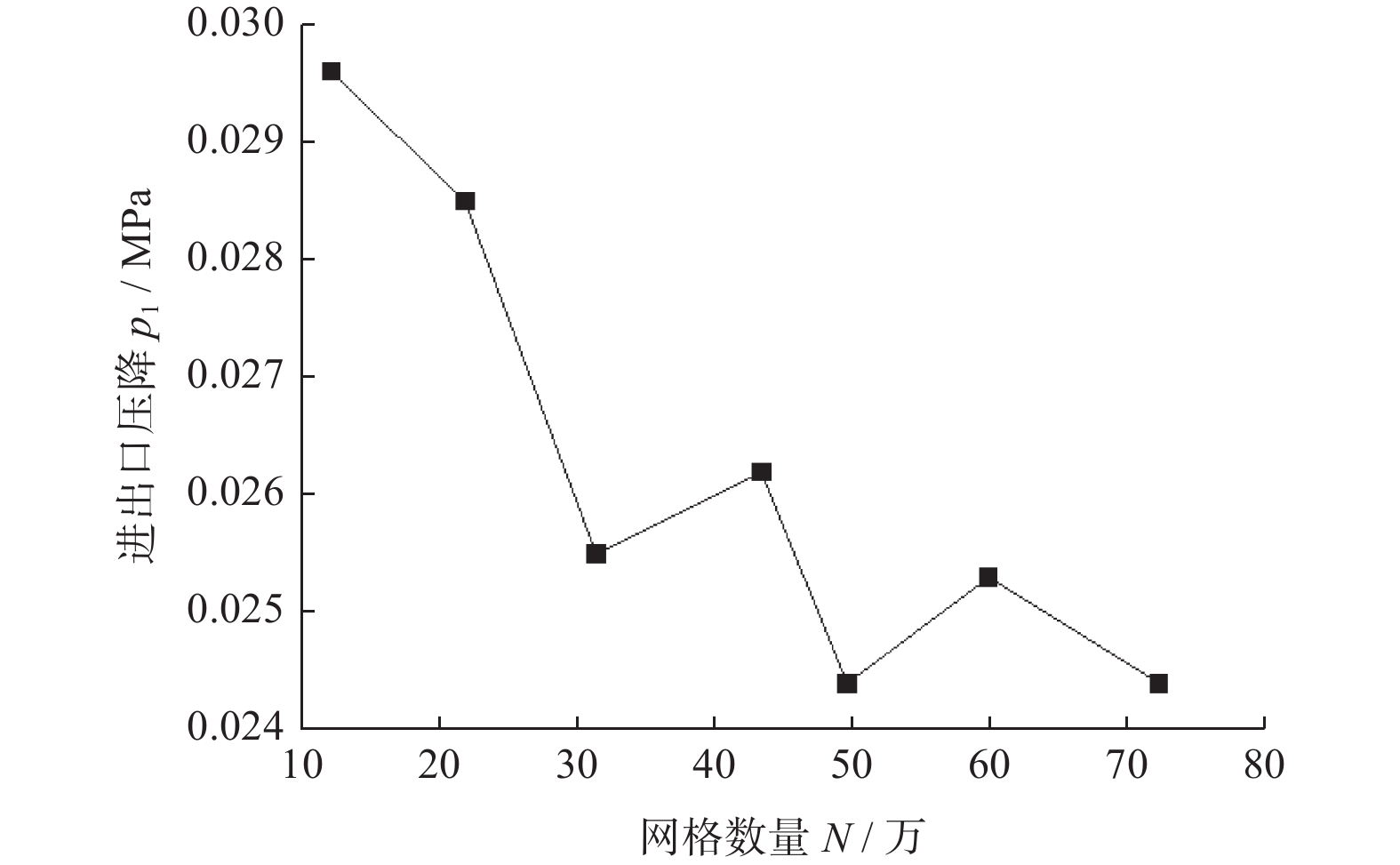

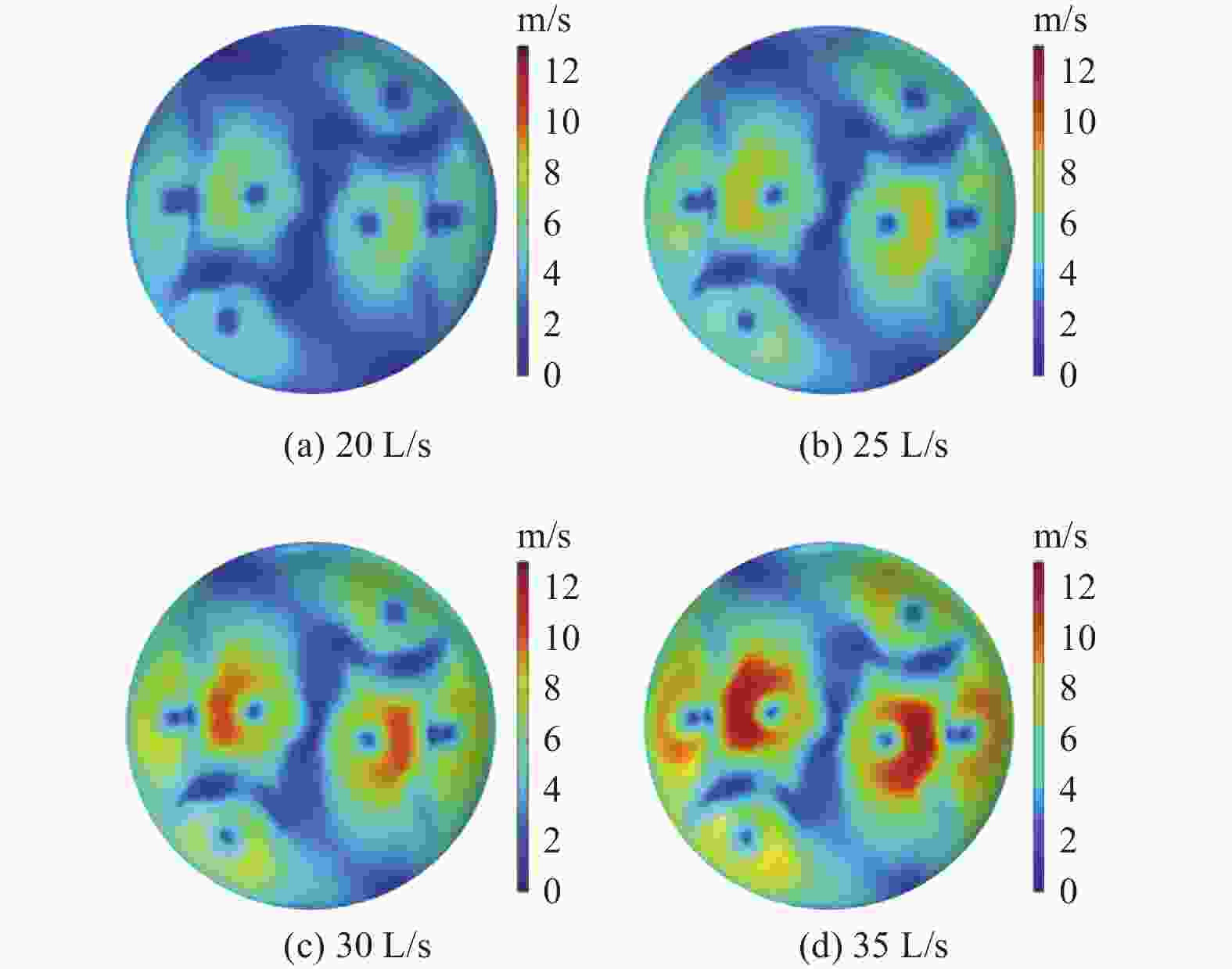

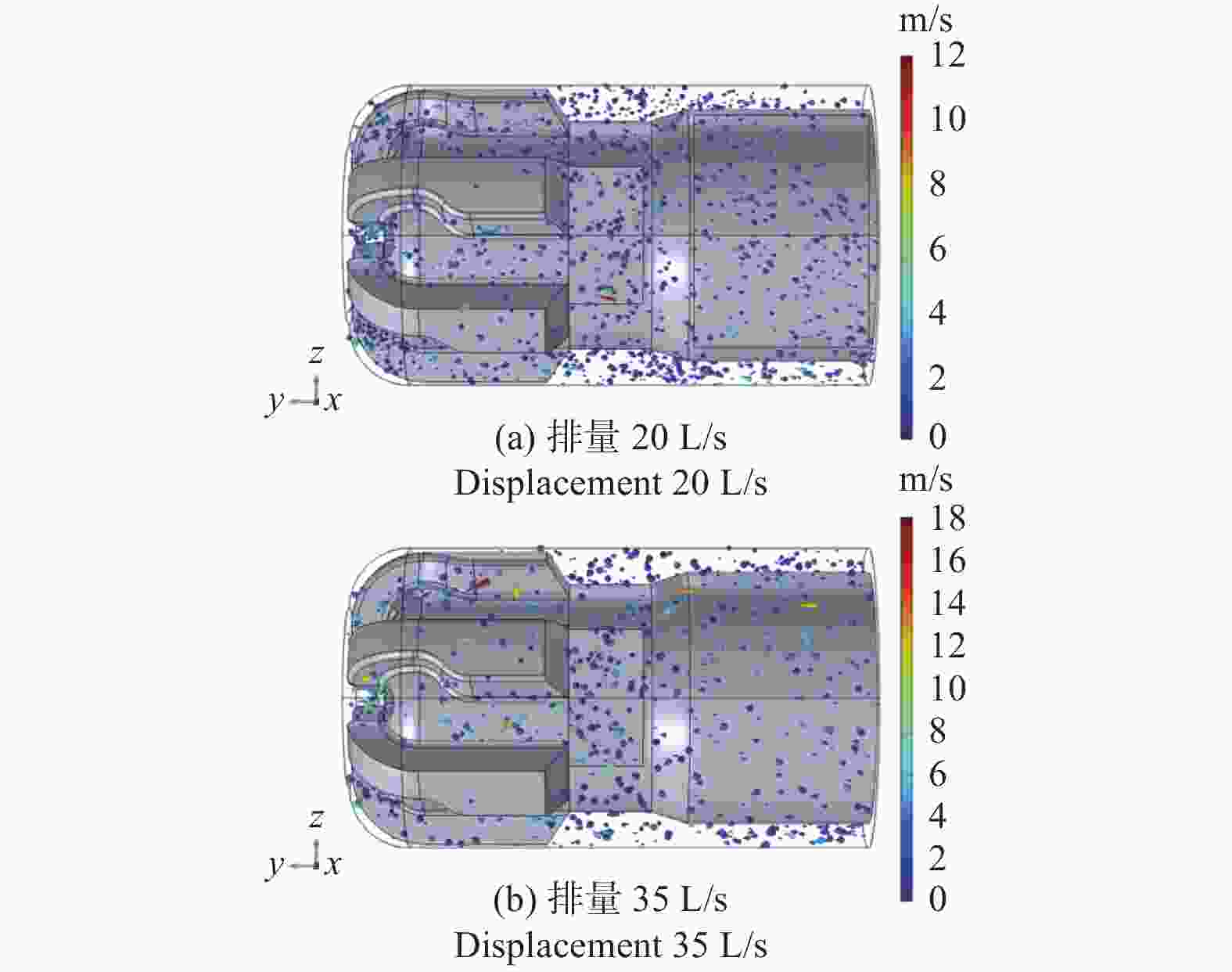

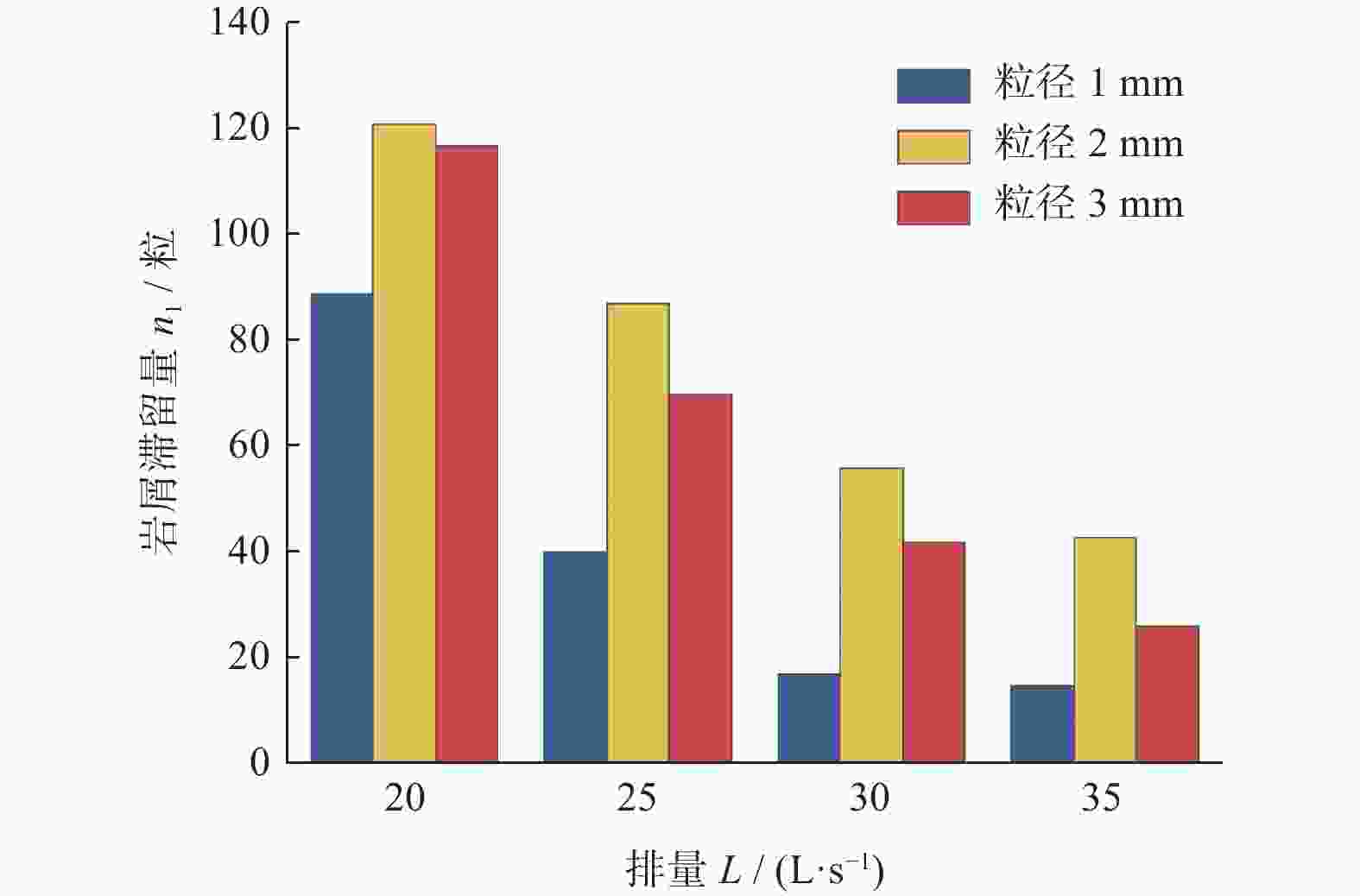

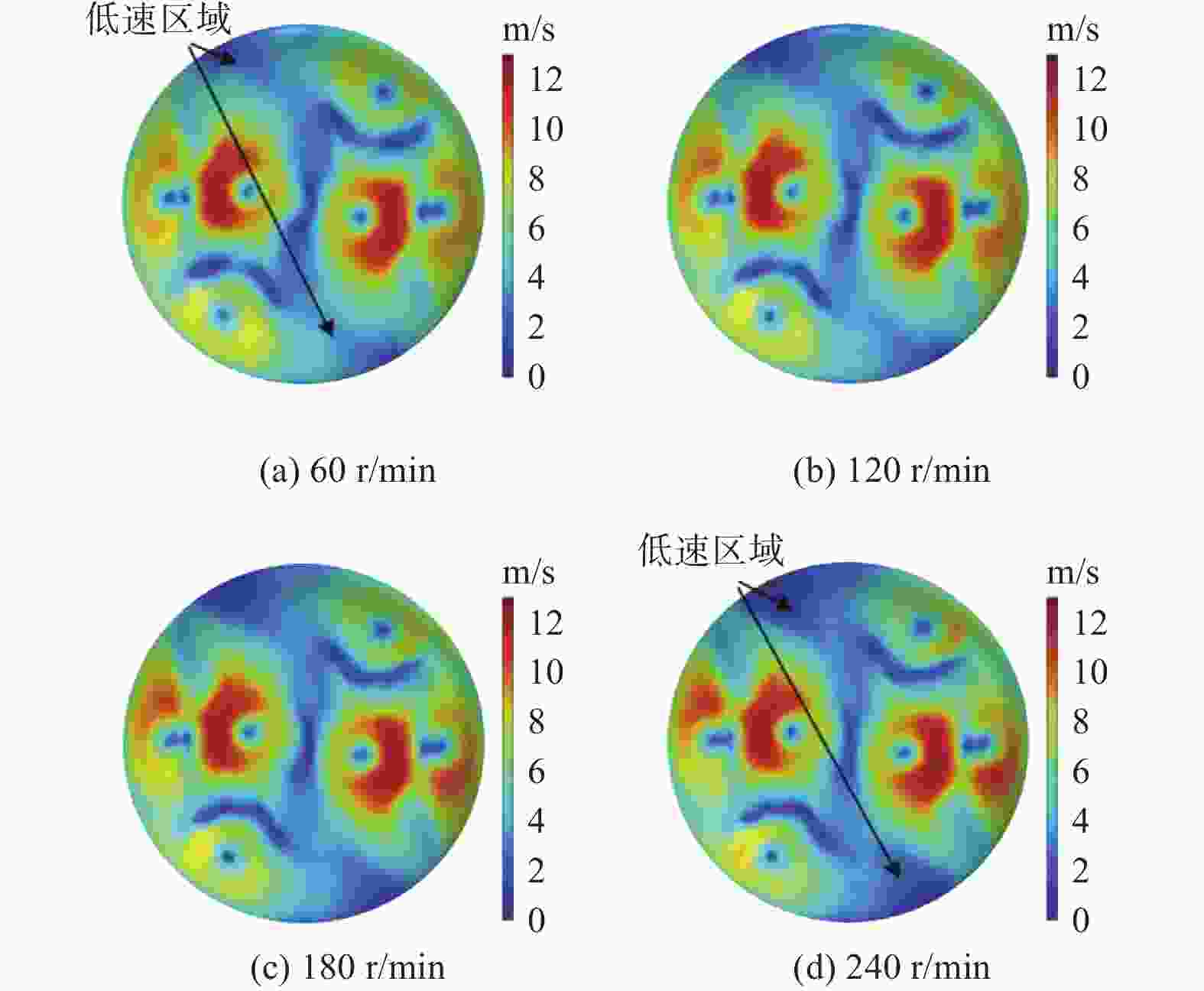

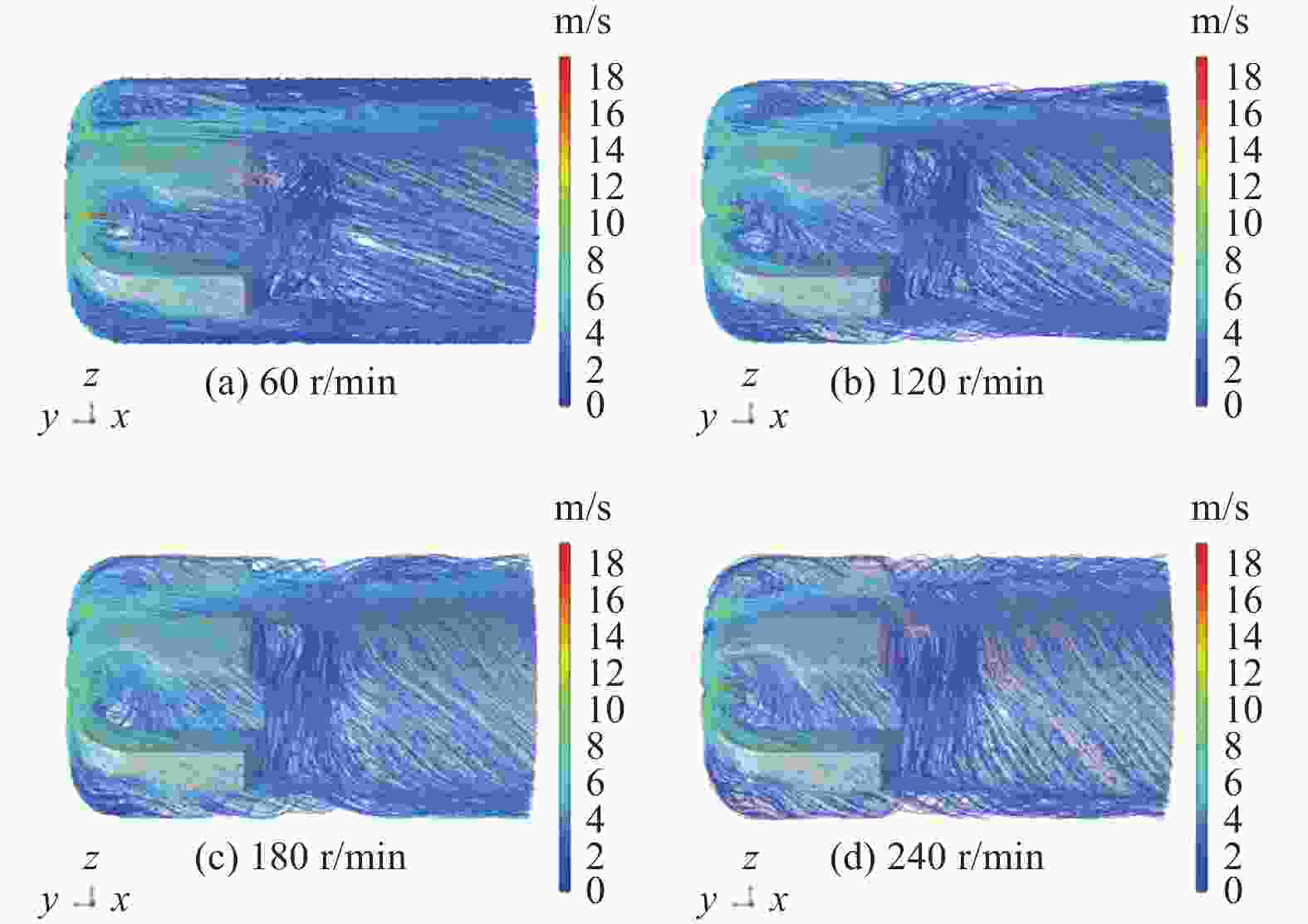

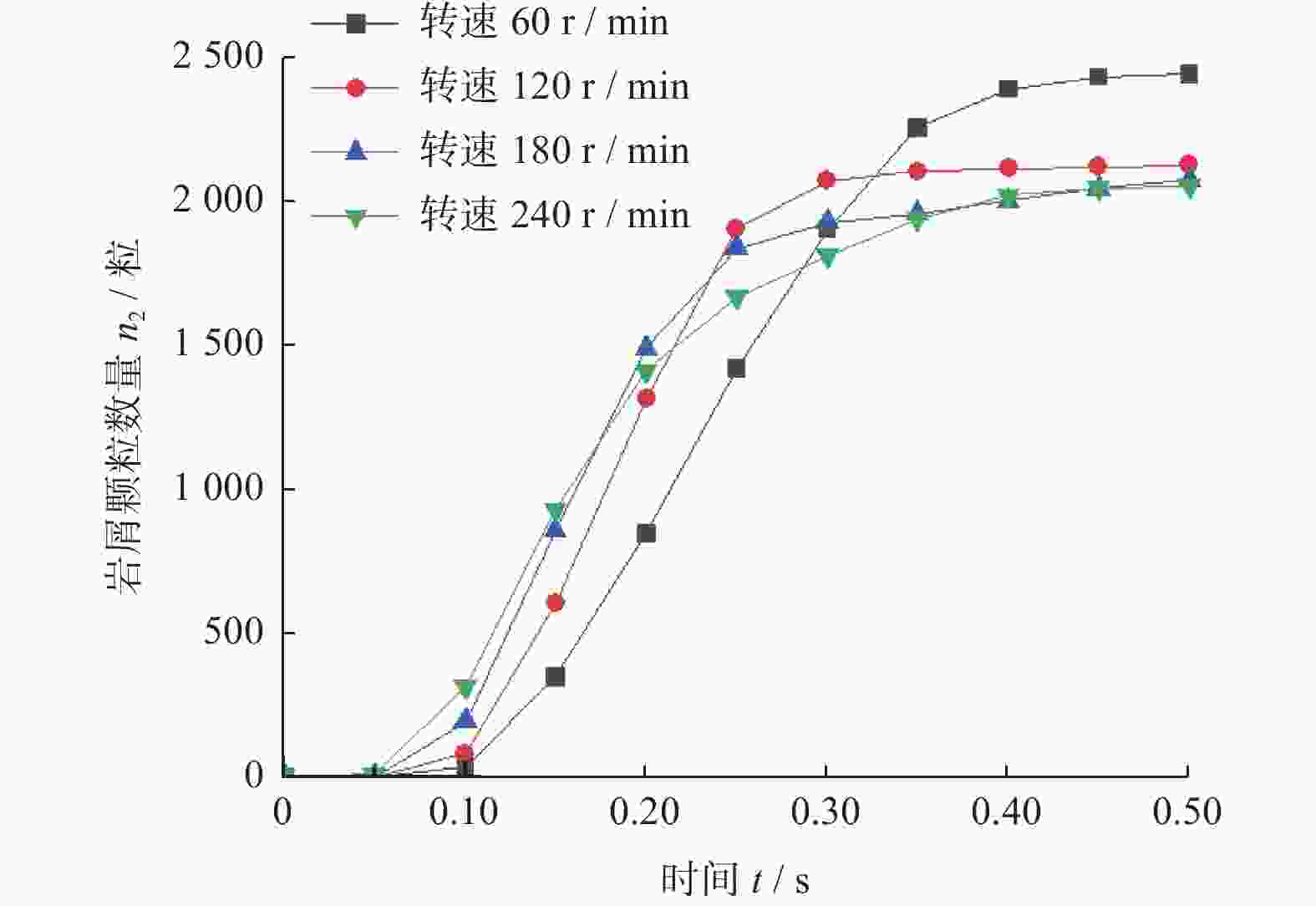

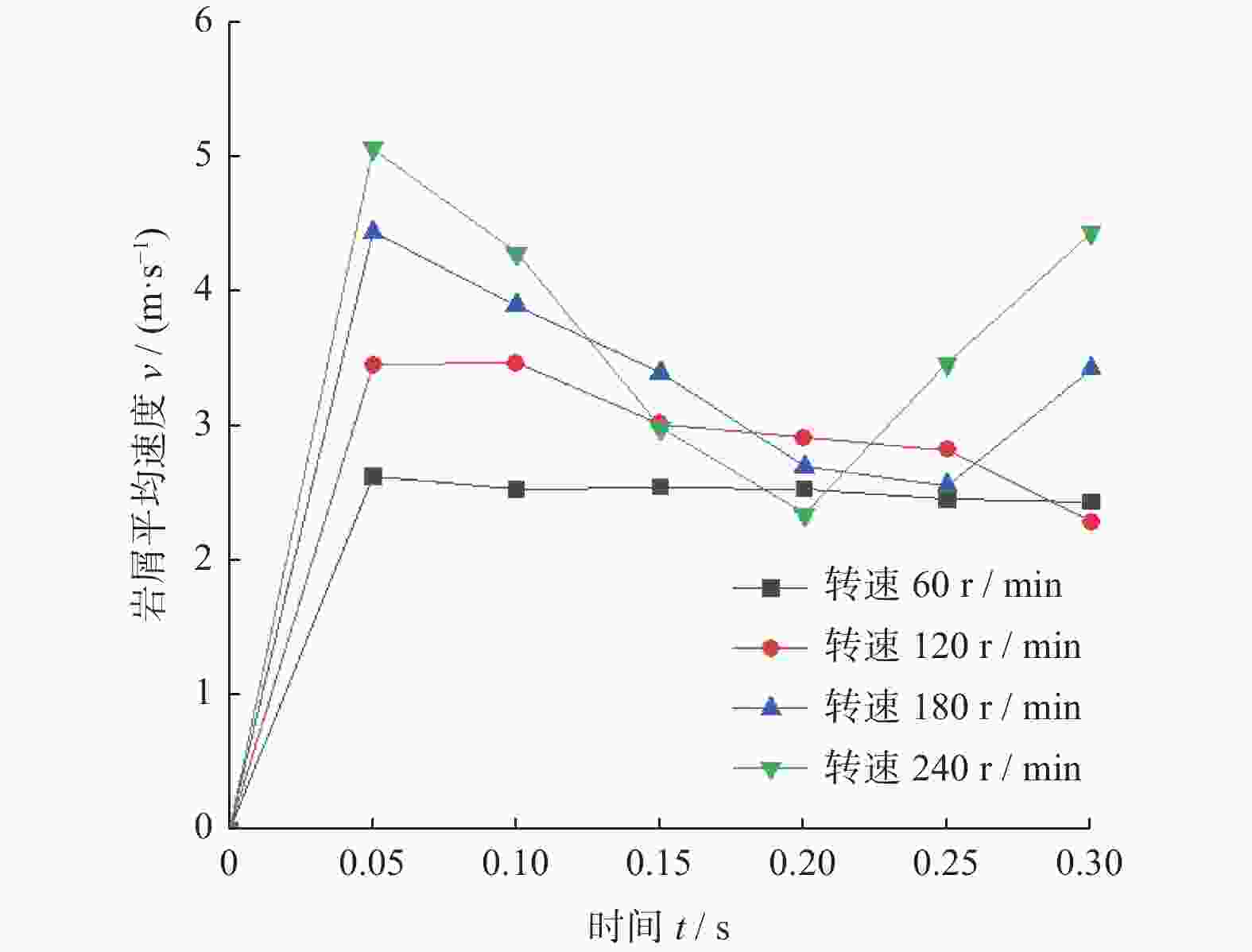

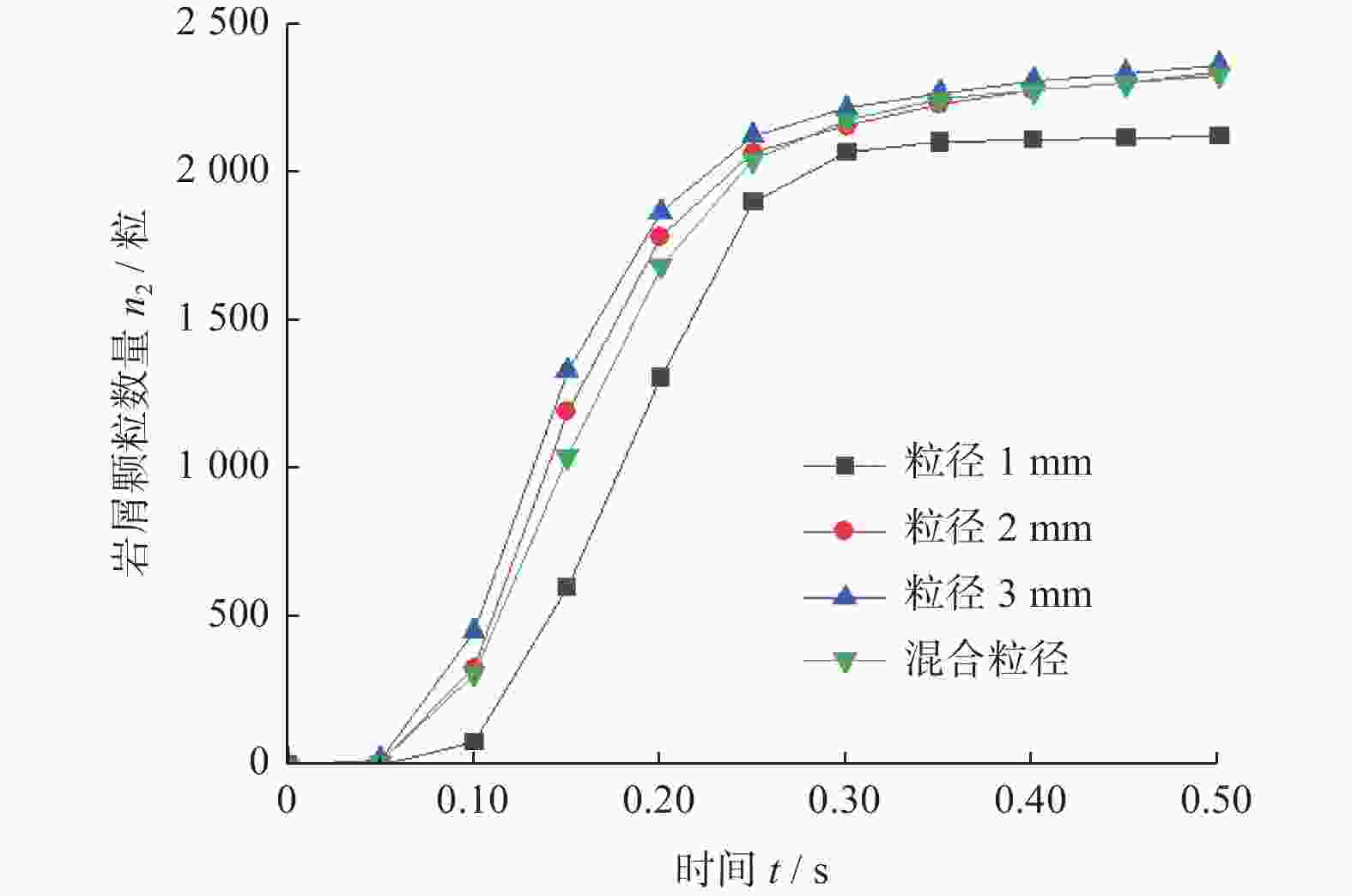

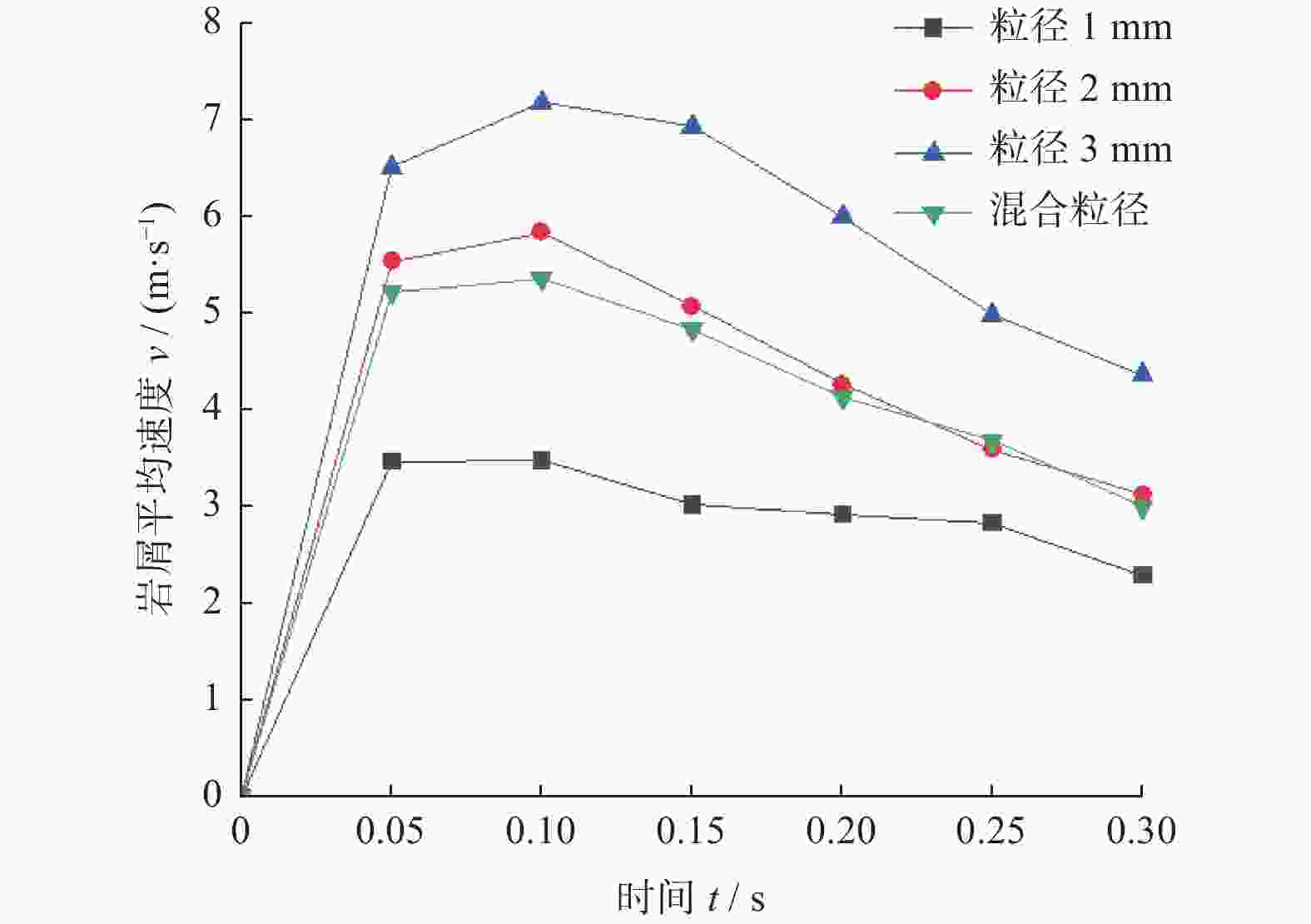

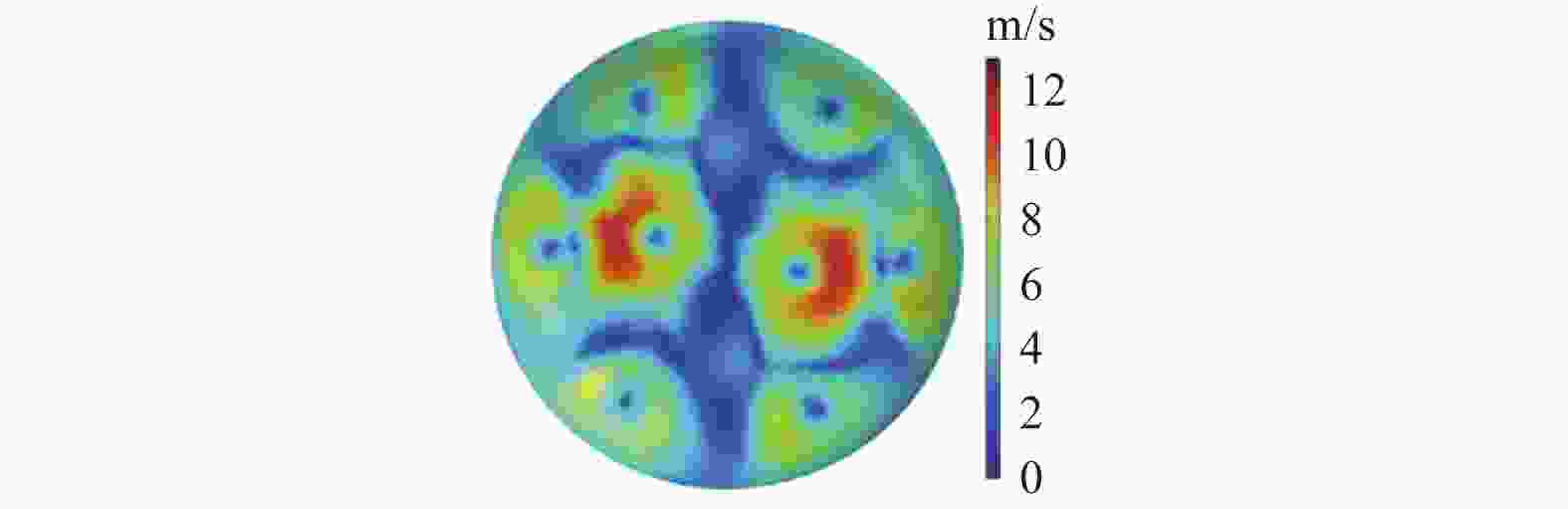

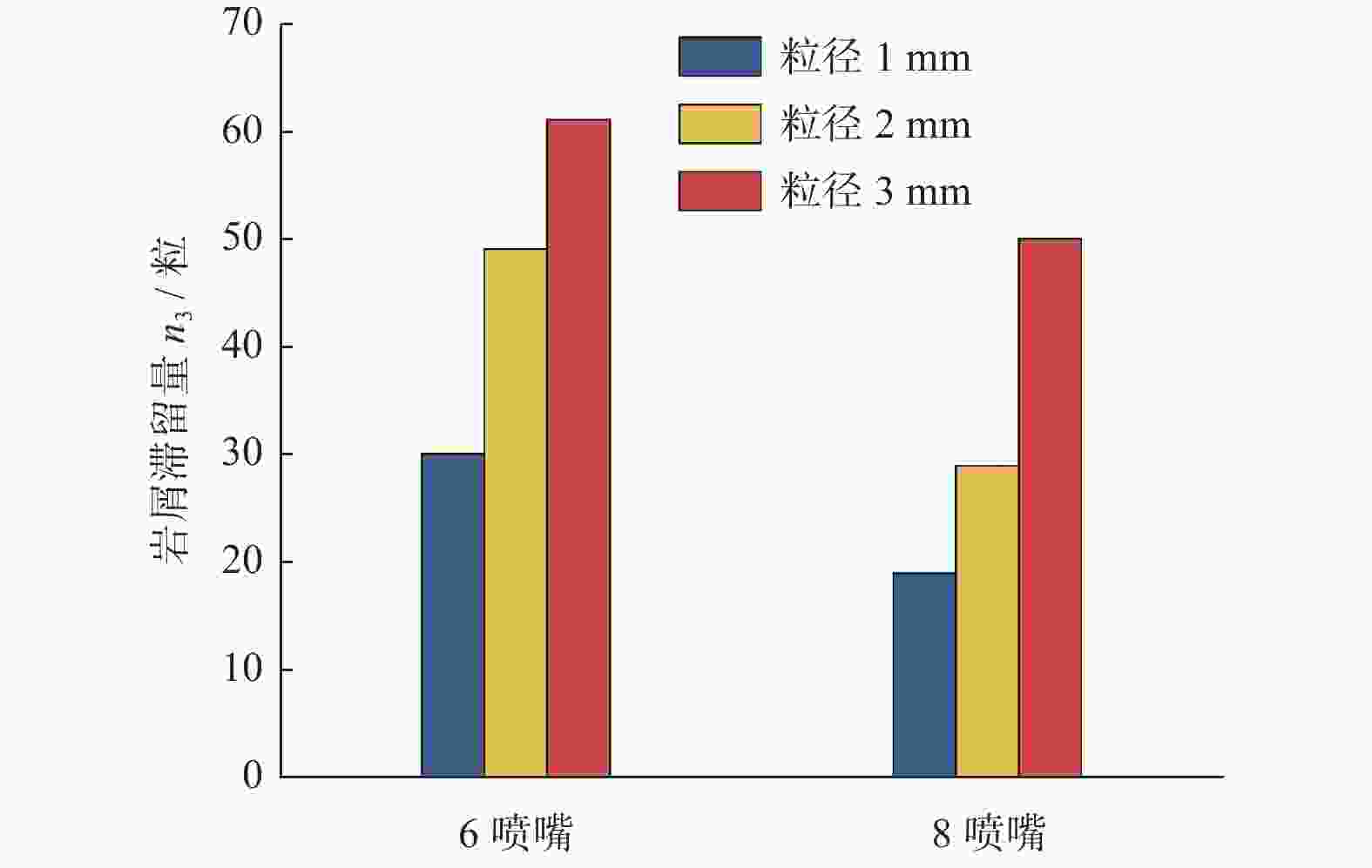

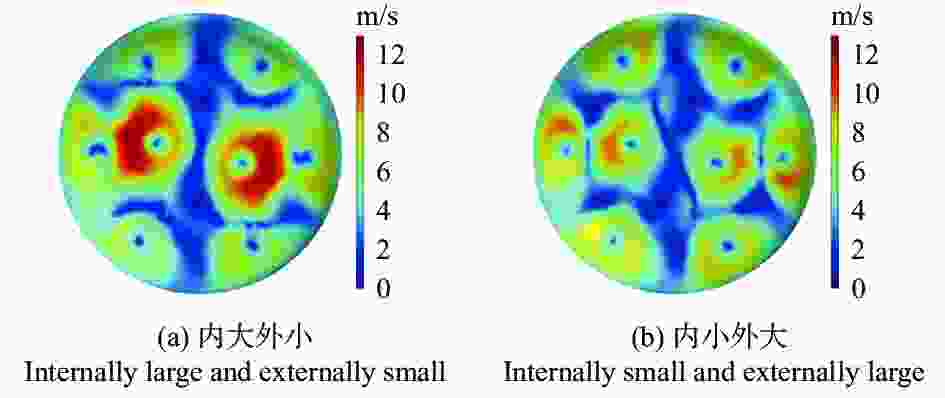

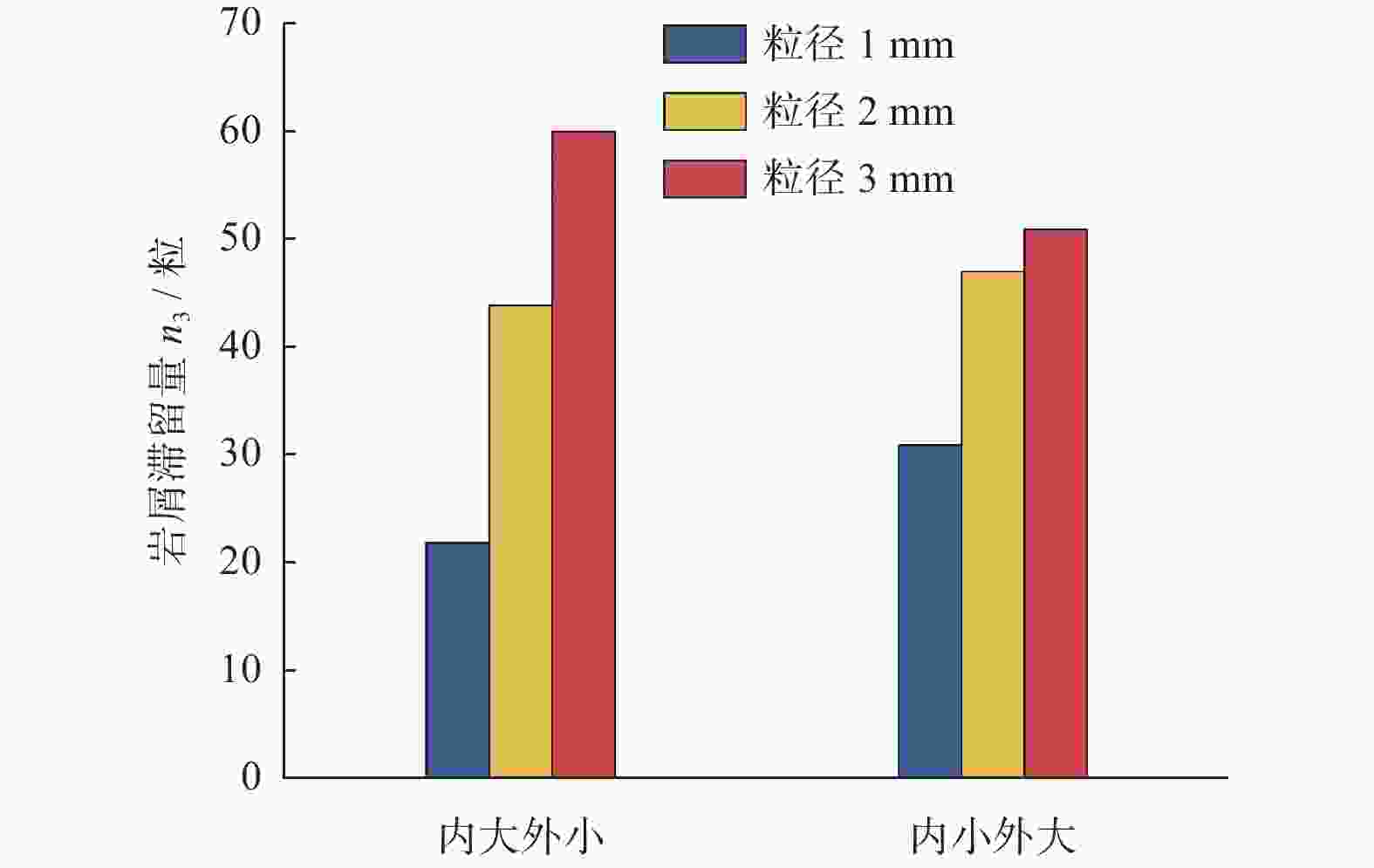

Abstract:Objectives: Horizontal wells can effectively improve the economic benefits of shale oil and gas development. However, as the horizontal section extends, the rock debris transport efficiency of the PDC drill bit gradually decreases, which can lead to bit balling in severe cases. Consequently, it is costly to directly improve the hydraulic structure of PDC bits. This paper uses a multi-physics field coupling numerical simulation method to analyze the influence of the coupling of different drilling process parameters and drill bit structure parameters on the bottom hole flow field and improves the drill bit hydraulic structure to enhance the rock debris transport efficiency of the PDC drill bit. Methods: Using COMSOL multi-physics field coupling simulation software, a geometric model of the bottom hole flow field of the horizontal well was established. The low Reynolds number k-ԑ model was employed to simulate the coupling of fluid flow and particle motion in the fluid, and iterative calculations were performed. The low Reynolds number k-ԑ model could adapt to different Reynolds number regions, especially the influence of molecular viscosity in the viscous bottom layer in the low Reynolds number region on the mixed phase flow. Parameters close to the actual drilling conditions were used to set the boundary conditions of the coupling model, and the grid independence of the coupling model was verified to reduce simulation error. Changes in the bottom hole flow field and the movement of rock debris by the PDC bit in a horizontal well under different drilling fluid displacement, PDC bit rotation speeds, and rock debris particle sizes were analyzed. Results: In the numerical simulation results of the coupling model, the following findings were observed: (1) From the flow velocity distribution diagram on the bottom hole wall, it was observed that the hydraulic energy distribution on the bottom hole wall became more uniform with an increase in displacement. When the displacement is 35 L/s, the flow velocity distribution effect on the bottom hole wall is optimal. However, the low-speed flow area of drilling fluid at the bottom hole cannot be completely eliminated by increasing displacement. In the comparative analysis of the retention of bottom hole rock debris at different displacements, an increase in displacement can reduce the impact of gravity on the cleaning of bottom hole rock debris. However, once the displacement reaches a certain level, the degree of cleaning of bottom hole rock debris changes relatively little. (2) In the lateral drilling fluid flow line at different rotation speeds, the flow rate gradually increases with an increase in rotation speed, causing a significant deviation in the flow state of the drilling fluid. When comparing and analyzing the accumulation of rock debris particles and the average velocity of rock debris particles, it was found that as the drill bit rotation speed increases, the fluctuation of the average velocity of rock debris particles also gradually increases. Although increasing drill rotation speed raises the average velocity of rock debris particles, it does not improve the migration efficiency of rock debris beyond a certain rotation speed. When the rotation speed is 240 r/min, the rock debris migration efficiency is the lowest. (3) In the comparative analysis of the average speeds of different rock debris particles, the farther they are from the bottom of the well, the faster the speed of large-size rock debris decays due to gravity. The speed change of small-size particles is relatively stable, but the average speed of rock debris particles with mixed particle sizes falls in the middle. (4) With roughly the same displacement area, increasing the number of drill bit nozzles from six to eight significantly reduces the amount of rock debris retention. (5) Compared with the equal diameter nozzle combination, the combination of a large inside and small outside nozzle reduces the transport efficiency of large particle rock debris due to the weakening of the drilling fluid flow rate. However, the flow rate in the central area of the combination of a small inside and large outside nozzle is reduced, which fails to form a strong pressure difference, resulting in an overall reduction in rock debris migration efficiency. Conclusions: Increasing the drilling fluid displacement improves the hydraulic energy and the rock debris transport efficiency at the bottom hole wall, but after the displacement increases to a certain level, it has little effect on the change in the degree of rock debris cleanliness at the bottom of the well. The mismatch between the high speed of the drill bit and displacement increases the average speed of the rock debris, but does not improve rock debris transport efficiency. Within a certain range of rock debris particle sizes, gravity has a relatively small impact on larger-size rock debris due to the influence of rotational force and turbulent kinetic energy. The transport efficiency of larger-size rock debris is higher than that of smaller-size rock debris. However, the farther away from the bottom of the well, the greater the impact of gravity on larger-size rock debris, resulting in greater velocity attenuation than that of smaller-size rock debris. According to the bottom hole flow field state under different drilling process parameters, the number of drill bit nozzles increase from six to eight under roughly the same nozzle displacement area, the hydraulic energy distribution is more uniform and the transport efficiency of rock debris improves. Meanwhile, compared to non-equal diameter nozzle combinations, equal diameter nozzle combinations perform more balancedly.

-

Key words:

- horizontal well /

- PDC bit /

- hydraulic structure /

- bottomhole flow field /

- simulation

-

-

[1] 张家希, 于家庆, GALCHENKO R, 等. 北美非常规油气超长水平井优快钻井技术及实例分析 [J]. 钻探工程,2021,48(8):1-11.ZHANG Jiaxi, YU Jiaqing, GALCHENKO R, et al. North America unconventional long lateral well fast-drilling technology with case study [J]. Drilling Engineering,2021,48(8):1-11. [2] 胡德高, 黄文君, 石小磊, 等. 页岩气水平钻井延伸极限预测与参数优化 [J]. 科学技术与工程,2021,21(17):7053-7058.HU Degao, HUANG Wenjun, SHI Xiaolei, et al. Prediction of extension limit and parameter optimization of shale gas horizontal drilling [J]. Science Technology and Engineering,2021,21(17):7053-7058. [3] 刘清友, 朱海燕, 陈鹏举. 地质工程一体化钻井技术研究进展及攻关方向:以四川盆地深层页岩气储层为例 [J]. 天然气工业,2021,41(1):178-188.LIU Qingyou, ZHU Haiyan, CHEN Pengju. Research progress and direction of geology-engineering integrated drilling technology: A case study on the deep shale gas reservoirs in the Sichuan Basin [J]. Natural Gas Industry,2021,41(1):178-188. [4] 胡郁乐, 胡晨, 张恒春, 等. 钻头泥包原因分析及松科二井防泥包钻井液的应用 [J]. 煤田地质与勘探,2020,48(5):254-261.HU Yule, HU Chen, ZHANG Hengchun, et al. Analysis of bit balling and application of the balling-preventing drilling fluid in Well Songke-2 [J]. Coal Geology & Exploration,2020,48(5):254-261. [5] 况雨春, 张锐, 罗金武, 等. 水平井PDC钻头井下颗粒流数值模拟研究 [J]. 石油机械,2019,47(7):36-42.KUANG Yuchun, ZHANG Rui, LUO Jinwu, et al. Numerical simulation of downhole particle flow in horizontal well with PDC bit [J]. China Petroleum Machinery,2019,47(7):36-42. [6] 罗金武, 况雨春, 张锐, 等. 基于CFD-DEM耦合的水平井PDC钻头水力结构研究 [J]. 工程设计学报,2020,27(5):636-644.LUO Jinwu, KUANG Yuchun, ZHANG Rui, et al. Research on hydraulic structure of PDC bit in horizontal well based on CFD-DEM coupling [J]. Chinese Journal of Engineering Design,2020,27(5):636-644. [7] 胡金帅, 张光伟, 陈雨, 等. 基于CFD-DEM耦合的导向钻头井底岩屑运移特性分析 [J]. 中国粉体技术,2022,28(6):37-48.HU Jinshuai, ZHANG Guangwei, CHEN Yu, et al. CFD-DEM coupling-based analysis of rock chip transport characteristics at bottom of rotary-guided drill bit [J]. China Powder Science and Technology,2022,28(6):37-48. [8] MOSLEMI A A, RAHMANI R, GRAHAM R, et al. Hydraulic design of shale drill bit using an integrated numerical and experimental approach: SPE/IADC drilling conference and exhibition [C]// London: SPE/IADC, 2015. [9] 聂欣, 张玉洲, 张童伟, 等. 6种低雷诺数k-ε模型在三维附壁剪切流中的数值模拟与对比分析 [J]. 中国电机工程学报,2017,37(24):7247-7254.NIE Xin, ZHANG Yuzhou, ZHANG Tongwei, et al. Comparative analysis and numerical simulation about six low Reynolds number k-ε models in near-wall shear flow [J]. Proceedings of the CSEE,2017,37(24):7247-7254. [10] ABE K, KONDOH T, NAGANO Y. A new turbulence model for predicting fluid flow and heat transfer in separating and reattaching flows—I. Flow field calculations [J]. International Journal of Heat & Mass Transfer,2016,37(1):139-151. [11] ZHANG F, MISKA S, YU M, et al. A unified transient solid-liquid two-phase flow model for cuttings transport-modelling part [J]. Journal of Petroleum Science & Engineering,2018,166:146-156. [12] 罗金武. 基于CFD-DEM耦合的水平井PDC钻头井底流场研究 [D]. 成都: 西南石油大学, 2018.LUO Jinwu. Research on bottomhole flow field of PDC bit in horizontal well based on CFD-DEM coupling [D]. Chengdu: Southwest Petroleum University, 2018. [13] 赖科, 马欣. 垂直旋转流场中单颗粒运动状态判别及受力分析 [J]. 计算力学学报,2019,36(1):59-64.LAI Ke, MA Xin. Analysis of single particle force and movement condition in vertical rotational flow field [J]. Chinese Journal of Computational Mechanics,2019,36(1):59-64. [14] 范宇, 方永, 吴鹏程, 等. 页岩气钻井岩屑运移规律仿真分析 [J]. 科学技术与工程,2020,20(28):11532-11538.FAN Yu, FANG Yong, WU Pengcheng, et al. Simulation analysis of cuttings migration in shale gas drilling [J]. Science Technology and Engineering,2020,20(28):11532-11538. [15] 汪皖, 马卫国, 王晓蒙. 带旋转管柱连续管钻井岩屑运移研究 [J]. 石油机械,2019,47(5):38-43.WANG Wan, MA Weiguo, WANG Xiaomeng. Research on cuttings transportation in coiled tubing drilling with rotary drillpipe [J]. China Petroleum Machinery,2019,47(5):38-43. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS