Energy consumption modeling and parameter optimization of tower combined diamond circular saw blade

-

摘要: 为准确预测塔形组合式金刚石圆盘锯在荒料锯切过程中的功率,以组合锯切系统中单锯片的单磨粒平均未变形切屑厚度为媒介,建立了锯切功率的参数模型,并对其进行修正,提出一种少样本快速预测模型,通过锯切实验测量不同参数组合下的锯切功率,采用多元线性回归方法拟合数据以获取可靠的模型系数。最后以锯切参数为优化变量,以锯切比能和锯切时间最小为优化目标建立优化模型,并采用改进粒子群算法对模型进行优化求解。试验结果表明,参数模型充分解释了各锯切参数对锯切功率的影响,能够准确预测不同锯片组合方式下的锯切功率,改进的粒子群算法有较高的优化性能,使用优化后的参数能够显著降低锯切功率。

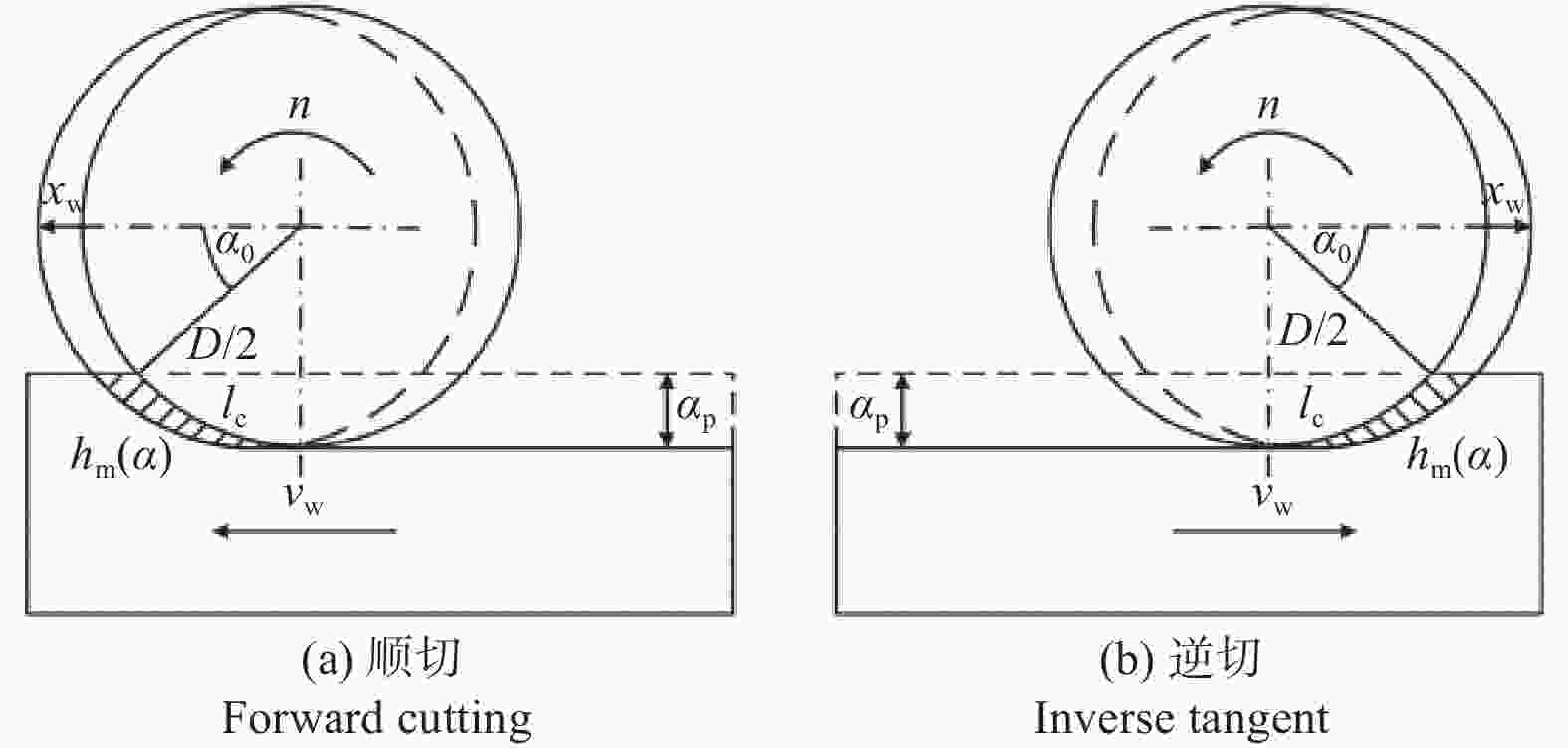

-

关键词:

- 塔形组合式金刚石圆盘锯 /

- 能耗模型 /

- 平均未变形切屑厚度 /

- 参数优化

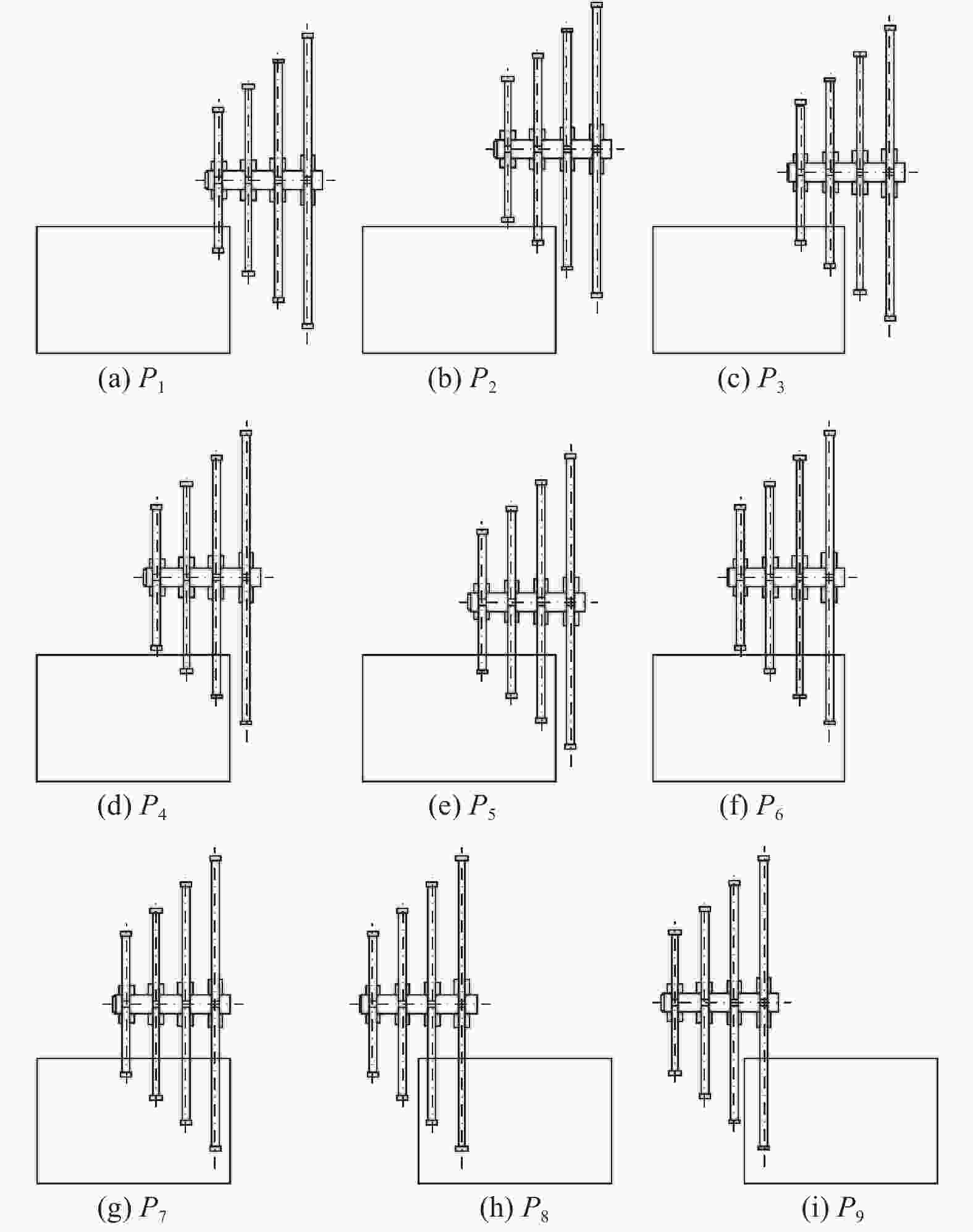

Abstract: To precisely forecast the power of a tower combined diamond circular saw blade during material sawing, a model for sawing power was established using the average thickness of an undeformed chip from a single grinding grain of an individual saw blade within the combination saw as a medium. This model was then refined to enhance accuracy. A fast and accurate prediction model, requiring only a small number of samples, was developed. Sawing power was measured through various parameter combinations via sawing experiments, and model coefficients were obtained by fitting the data using multivariate linear regression techniques. An optimization model was subsequently established, with sawing parameters as optimization variables. The objectives of this model were to minimize sawing specific energy and reduce sawing time. An optimized particle swarm algorithm was adopted to solve the model. The experimental results reveal that the parameter model can comprehensively elucidate the influence of various sawing parameters on sawing power, with the model accurately forecasting the sawing power under different saw blade combinations. The improved particle swarm algorithm demonstrates strong optimization performance, with optimized parameters contributing to significant reductions in sawing power. -

表 1 锯切参数组合

Table 1. Sawing parameter combination

参数 取值 转速 n / (r·min−1) 380,395,410 进给速度 vw / (m·min−1) 3.45,4.45,5.45 锯切深度 ap / mm 4,6,8 表 2 锯切能耗测量结果

Table 2. Measurement results of sawing energy consumption

编号 转速 n /

(r·min−1)进给速度

vw / (m·min−1)锯切

深度

ap / mm后3片组合

锯切功率

P6 / kW4片组合

锯切功率

P7 / kW1 380 3.45 4 12.74 15.20 2 380 4.45 4 15.66 17.33 3 380 5.45 4 18.89 21.56 4 380 3.45 6 16.22 19.11 5 380 4.45 6 19.50 22.92 6 380 5.45 6 22.59 27.04 7 380 3.45 8 19.72 22.74 8 380 4.45 8 22.97 26.97 9 380 5.45 8 26.81 31.96 10 395 3.45 4 13.29 15.57 11 395 4.45 4 15.74 18.84 12 395 5.45 4 18.90 22.87 13 395 3.45 6 16.93 19.58 14 395 4.45 6 19.69 23.32 15 395 5.45 6 23.44 27.52 16 395 3.45 8 19.59 22.80 17 395 4.45 8 23.31 27.73 18 395 5.45 8 27.84 32.62 19 410 3.45 4 13.51 16.58 20 410 4.45 4 15.96 19.29 21 410 5.45 4 18.91 22.42 22 410 3.45 6 16.84 19.79 23 410 4.45 6 19.78 23.99 24 410 5.45 6 23.47 27.94 25 410 3.45 8 19.83 23.32 26 410 4.45 8 23.59 28.35 27 410 5.45 8 28.38 35.44 表 3 P6模型拟合系数

Table 3. Fitting coefficients of the P6 model

系数 Beta1 Beta2 Sig VIF kcp6 0.144 <0.001 K6 0.248 0.033 x 0.543 <0.001 1.000 a 0.078 0.055 <0.001 1.000 b 0.204 0.655 <0.001 1.000 c −0.210 0.750 <0.001 1.000 R2 99.4% <0.001 DW 2.355 RMSE 0.017 表 4 P7模型拟合系数

Table 4. Fitting coefficients of the P7 model

系数 Beta1 Beta2 Sig VIF kcp7 0.171 <0.001 K7 0.027 <0.001 x 0.543 <0.001 1.000 a −0.312 0.109 <0.001 1.000 b 0.228 0.660 <0.001 1.000 c −0.205 0.737 <0.001 1.000 R2 99.0% <0.001 DW 1.808 RMSE 0.022 表 5 P6模型对比分析

Table 5. Comparative analysis of the P6 model

编号 转速 n

/ (r·min−1)进给速度vw /

(m·min−1)锯切深度ap / mm P预测 / kW P实测 / kW η / % 1 370 3.45 8 18.97 18.40 3.10 2 385 4.45 6 19.80 20.97 5.58 3 400 5.45 4 18.61 19.29 3.53 表 6 P7模型对比分析

Table 6. Comparative analysis of the P7 model

编号 转速 n

/ (r·min−1)进给速度vw /

(m·min−1)锯切深度ap / mm P预测 / kW P实测 / kW η / % 1 370 3.45 8 21.53 23.25 7.40 2 385 4.45 6 22.94 24.03 4.54 3 400 5.45 4 21.95 22.95 4.35 表 7 优化结果对比分析

Table 7. Comparative analysis of optimization results

编号 方案 转速

n / (r·min−1)进给速度

vw / (m·min−1)锯切深度

ap / mmF 1 LPSO 378.78 6.22 8.22 0.043 NPSO 371.82 5.49 8.96 0.038 2 LPSO 375.24 5.91 8.54 0.039 NPSO 370.30 6.18 8.27 0.037 3 LPSO 378.16 5.69 8.69 0.043 NPSO 372.39 5.38 9.07 0.038 表 8 优化解与经验解对比分析

Table 8. Comparative analysis of optimal solution and empirical solution

方法 转速

n / (r·min−1)进给速度vw / (m·min−1) 锯切深度

ap / mm锯切比能

SEC / (kJ·cm−3)加工时间

T / min优化 370.30 6.18 8.27 0.695 9.783 经验 410.00 5.45 8.00 0.757 11.468 -

[1] TURCHETTA S. Cutting force and diamond tool wear in stone machining [J]. The International Journal of Advanced Manufacturing Technology,2012,61(5):441-448. [2] POLINI W, TURCHETTA S. Force and specific energy in stone cutting by diamond mill [J]. International Journal of Machine Tools and Manufacture,2004,44(11):1189-1196. doi: 10.1016/j.ijmachtools.2004.04.001 [3] 黄国钦, 徐西鹏. 基于锯切弧区切向力分布的功率消耗模型 [J]. 机械工程学报,2011,47(21):170-176. doi: 10.3901/JME.2011.21.170HUANG Guoqin, XU Xipeng. Establishment of power model for circular sawing based on tangential force distribution at the contact zone [J]. Chinese Journal of Mechanical Engineering,2011,47(21):170-176. doi: 10.3901/JME.2011.21.170 [4] HUANG G, ZHANG M, HUANG H, et al. Estimation of power consumption in the circular sawing of stone based on tangential force distribution [J]. Rock Mechanics and Rock Engineering,2018,51(4):1249-1261. doi: 10.1007/s00603-017-1380-2 [5] 张昆, 田业冰, 丛建臣, 等. 基于动态惯性权重粒子群算法的磨削低能耗加工方法 [J]. 金刚石与磨料磨具工程,2021,41(1):71-75.ZHANG Kun, TIAN Yebing, CONG Jianchen, et al. Reduce grinding energy consumption by modified particle swarm optimization based on dynamic inertia weigh [J]. Diamond & Abrasives Engineering,2021,41(1):71-75. [6] 陈行政, 李聪波, 吴磊, 等. 面向能耗的多刀具孔加工刀具直径及工艺参数集成优化模型 [J]. 机械工程学报,2018,54(15):221-231. doi: 10.3901/JME.2018.15.221CHEN Xingzheng, LI Congbo, WU Lei, et al. Integrating optimization of cutter diameter and cutting parameters for energy-aware multi-tool hole machining [J]. Chinese Journal of Mechanical Engineering,2018,54(15):221-231. doi: 10.3901/JME.2018.15.221 [7] 黄国钦, 黄辉, 郭桦, 等. 串珠绳锯切花岗石过程中锯切参数对锯切力和能耗的影响 [J]. 机械工程学报,2009,45(3):234-239. doi: 10.3901/JME.2009.03.234HUANG Guoqin, HUANG Hui, GUO Hua, et al. Influences of sawing parameters on forces and energy in wire sawing of granite [J]. Journal of Mechanical Engineering,2009,45(3):234-239. doi: 10.3901/JME.2009.03.234 [8] KONSTANTY J. Theoretical analysis of stone sawing with diamonds [J]. Journal of Materials Processing Technology,2002,123(1):146-154. doi: 10.1016/S0924-0136(02)00071-7 [9] LI K, LIAO W. Modelling of ceramic grinding processes part I. Number of cutting points and grinding forces per grit [J]. Journal of Materials Processing Technology,1997,65(1/2/3):1-10. [10] ZHOU J, WANG K, ZHANG J, et al. Rock breakage and tools performance during rock processing by multidiameter combination saw with different diameters [J]. Rock Mechanics and Rock Engineering,2022,55(7):4459-4476. doi: 10.1007/s00603-022-02824-9 [11] 周京国. 塔形组合式金刚石圆锯片锯切特性研究[D]. 济南: 山东大学, 2022.ZHOU Jingguo. Sawing performance of tower combined diamond circular saw blade[D]. Jinan: Shandong University, 2022. [12] 帅茂杭, 熊国江, 胡晓, 等. 基于改进多目标骨干粒子群算法的电力系统环境经济调度 [J]. 控制与决策,2022,37(4):997-1004.SHUAI Maohang, XIONG Guojiang, HU Xiao, et al. Economic emission dispatch of power system based on improved bare-bone multi-objective particle swarm optimization algorithm [J]. Control and Decision Making,2022,37(4):997-1004. [13] 陈贵敏, 贾建援, 韩琪. 粒子群优化算法的惯性权值递减策略研究 [J]. 西安交通大学学报,2006(1):53-56,61.CHEN Guimin, JIA Jianyuan, HAN Qi. Study on the strategy of decreasing inertia weight in particle swarm optimization algorithm [J]. Journal of Xi'an Jiaotong University,2006(1):53-56,61. [14] 贾会群, 魏仲慧, 何昕, 等. 基于改进粒子群算法的路径规划 [J]. 农业机械学报,2018,49(12):371-377.JIA Huiqun, WEI Zhonghui, HE Xin, et al. Path Planning Based on Improved Particle Swarm Optimization Algorithm [J]. Journal of Agricultural Machinery,2018,49(12):371-377. [15] 毛开富, 包广清, 徐驰. 基于非对称学习因子调节的粒子群优化算法 [J]. 计算机工程,2010,36(19):182-184.MAO Kaifu, BAO Guangqing, XU Chi. Particle swarm optimization algorithmbasedon non-symmetric learning factor adjusting [J]. Computer Engineering,2010,36(19):182-184. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS