Effect of nano-scratch speed on removal behavior of single crystal silicon

-

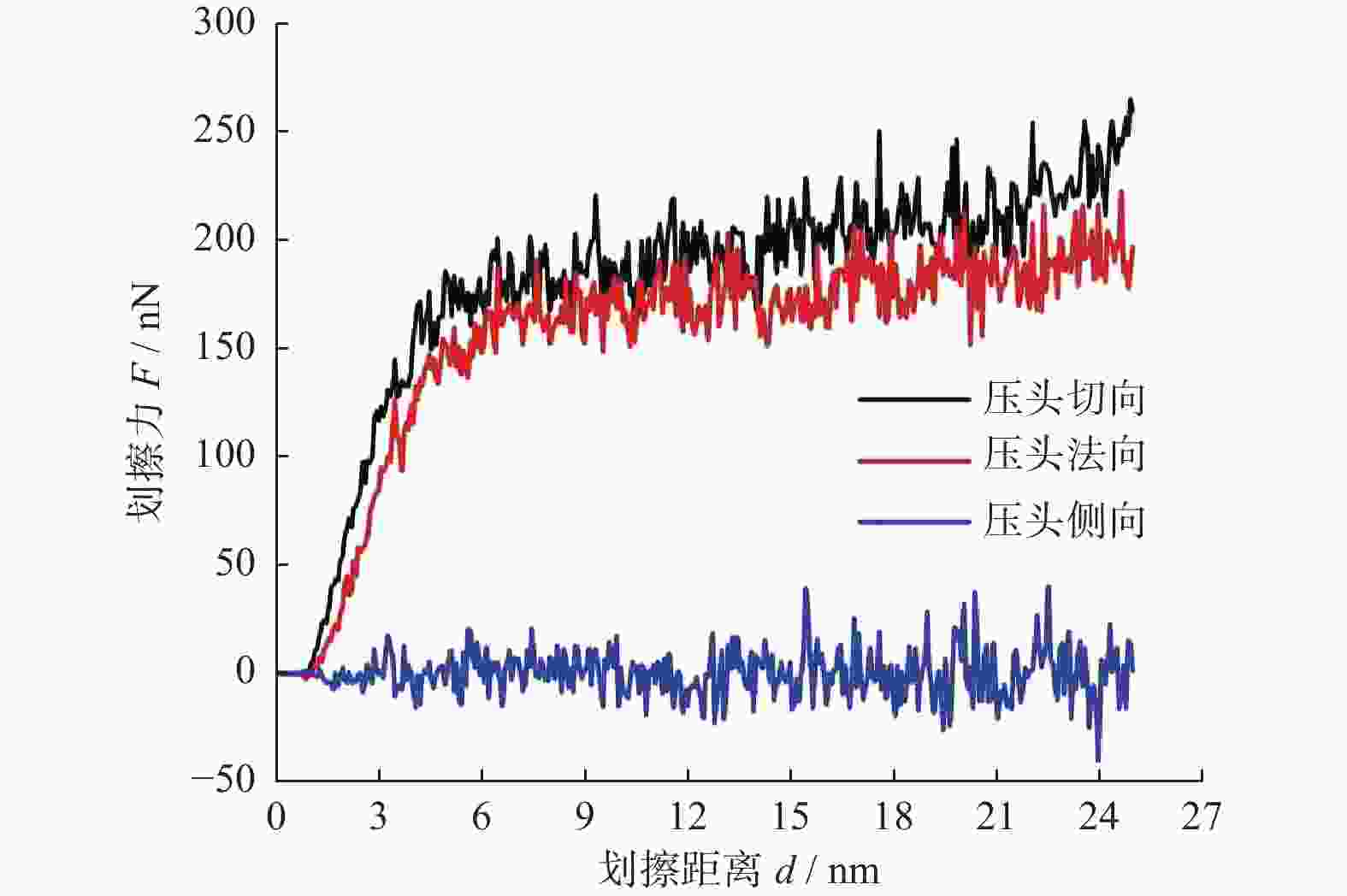

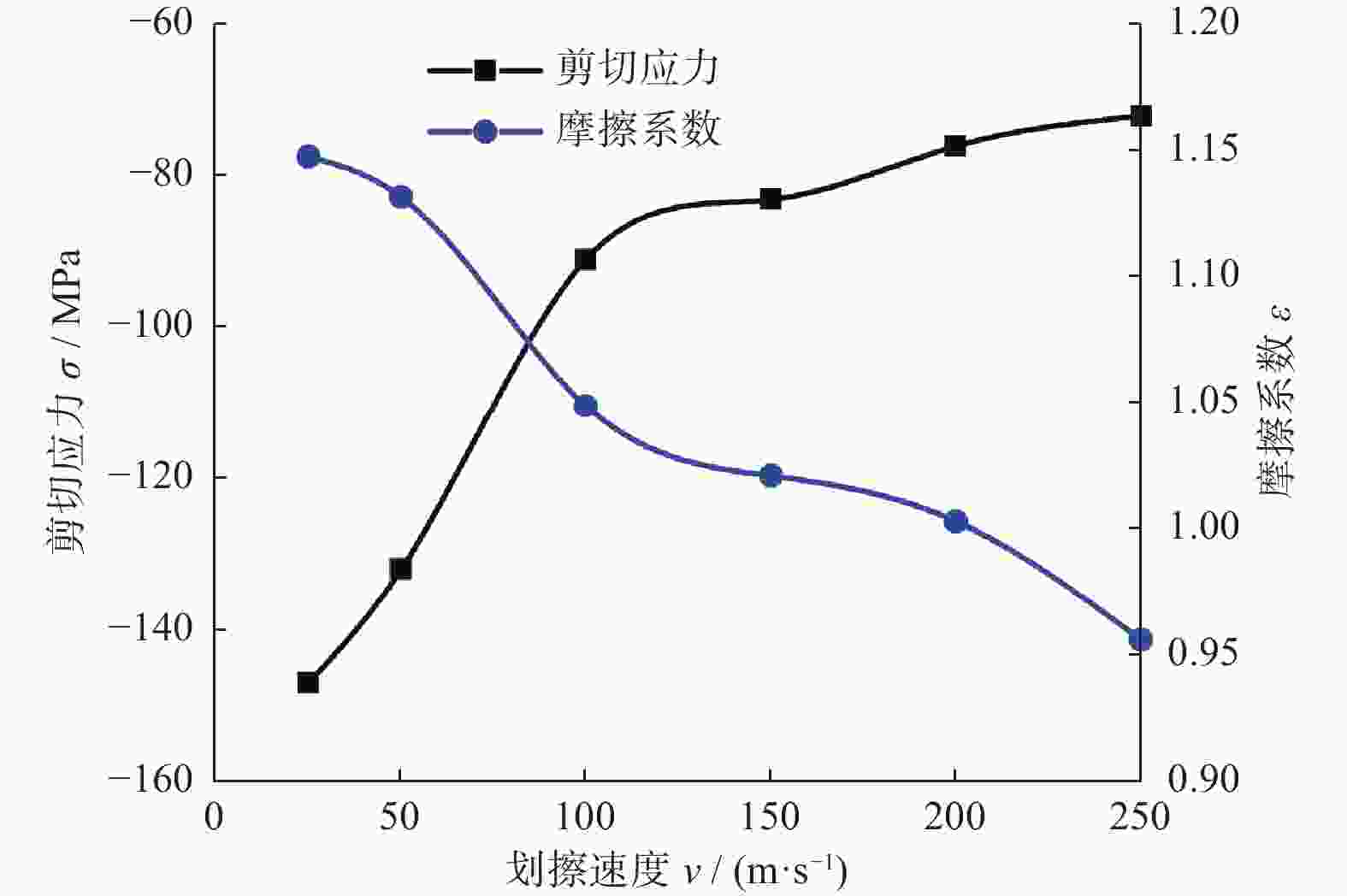

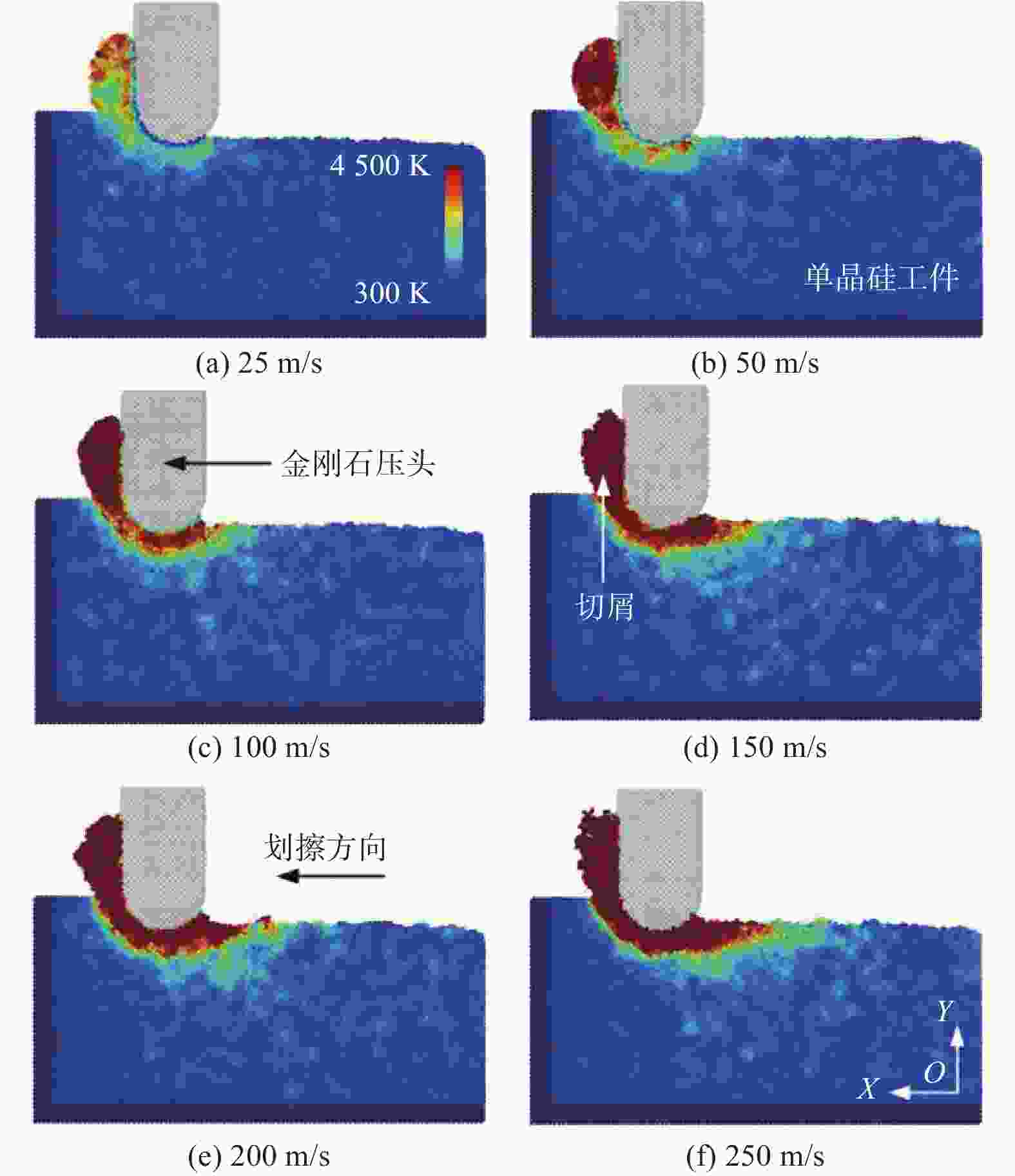

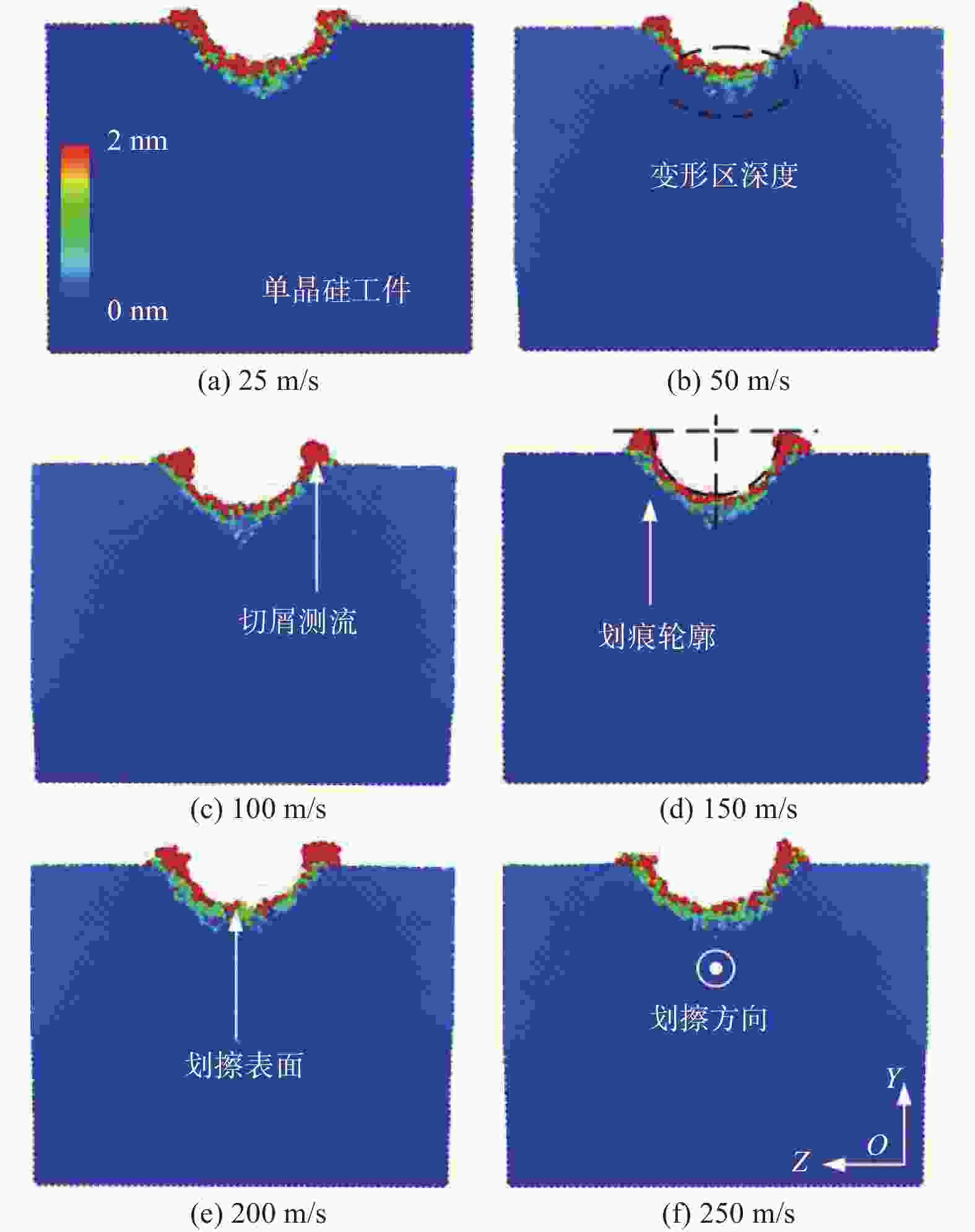

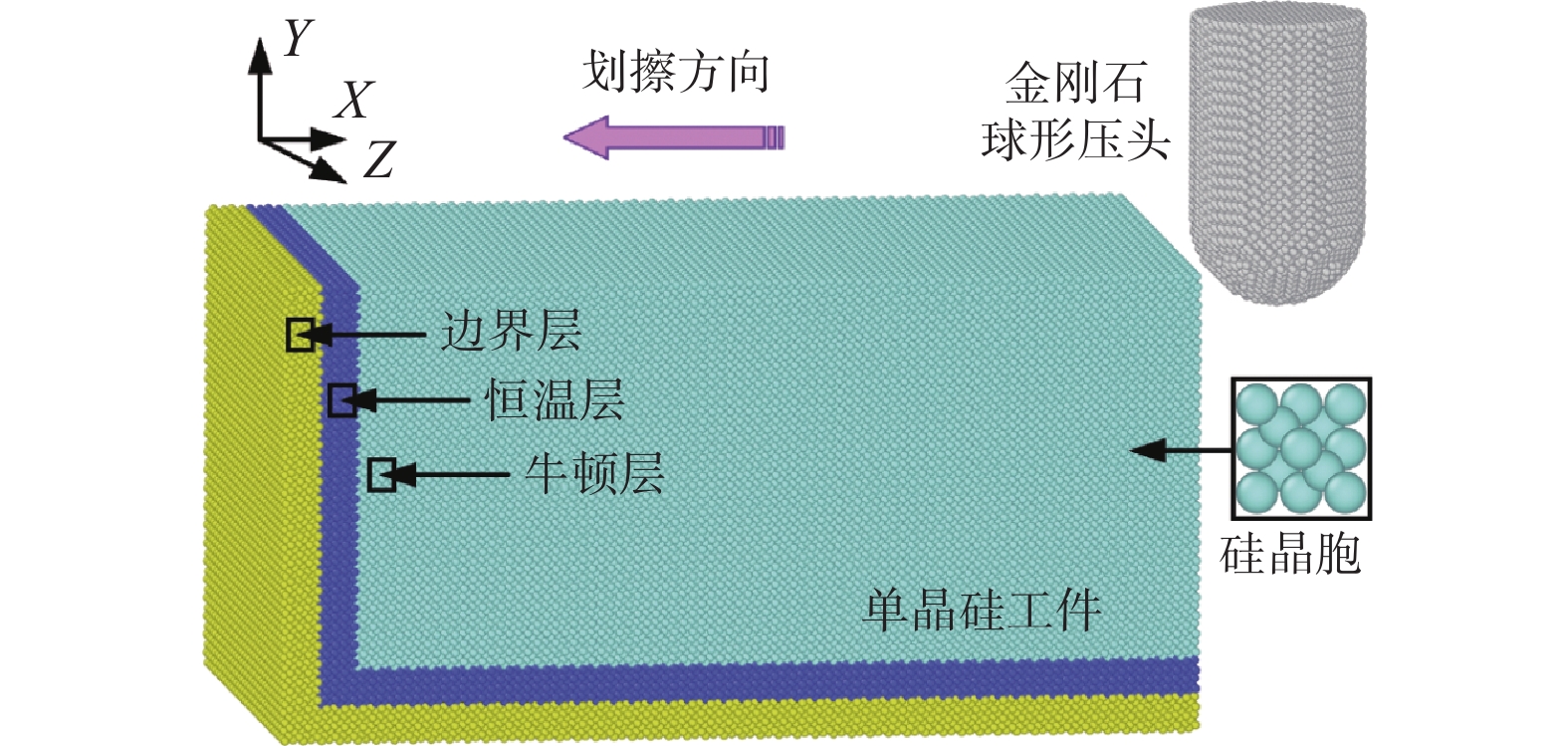

摘要: 单晶硅作为典型的硬脆材料在不同的划擦速度下会有不同的应变率,进而产生不同的材料去除行为,采用分子动力学从应变率角度研究不同划擦速度下材料的变形与去除过程。结果表明:划擦过程中随划擦速度由25 m/s增加到250 m/s,单晶硅的应变率从1.25 × 1010 s−1提高至1.25 × 1011 s−1,其划擦力、剪切应力和摩擦系数减小,划擦温度升高,且划擦表面的轮廓精度和粗糙度随划擦速度的增大而改善。划擦过程中的非晶化和相变是单晶硅纳米尺度变形的主要发生机制,剪切应力减小造成其亚表面损伤层深度由2.24 nm减小到1.89 nm,划擦温度升高导致其表面非晶层深度增加。Abstract: As a typical hard and brittle material, single-crystal silicon exhibits different strain rates at varying scratching speeds, leading to diverse material removal behaviors. Molecular dynamics was used to study the deformation and removal processes of single-crystal silicon at different scratching speeds from the perspective of strain rate. The results show that the strain rate of the material increases from 1.25 × 1010 s−1 to 1.25 × 1011 s−1 as the scratching speed increases from 25 m/s to 250 m/s. At the same time, the scratching parameters, including scratching force, shear stress, and friction coefficient, decrease while the scratching temperature increases. Additionally, the contour accuracy and roughness of the scratch surface improve with increased scratching speeds. Amorphization and phase transformation during the scratching process are the main mechanisms of nanoscale deformation in single-crystal silicon. The depth of the subsurface damage layer decreases from 2.24 nm to 1.89 nm with the increase of shear stress, while the depth of the amorphous layer increases with the rise in scratching temperature.

-

Key words:

- single crystal silicon /

- nano-scratch /

- molecular dynamics /

- scratching speed /

- strain rate

-

表 1 单晶硅纳米划擦的分子动力学参数

Table 1. Molecular dynamics parameters for nano-scratch of single crystal silicon

仿真参数 规格或取值 模型尺寸长 ×

宽 × 高30 nm× 15 nm× 16 nm 原子总数 N / 个 456 982 压头半径 r / nm 2.5 最大划擦距离 dmax / nm 25 初始温度 T / K 297 划擦深度 h / nm 2 划擦速度 v / (m·s−1) 25,50,100,150,200,250 应变率 ε*/s−1 1.25 × 1010,2.50 × 1010,

5.00 × 1010,7.50 × 1010,

1.00 × 1011,1.25 × 1011时间步 t / fs 1 -

[1] 田海兰, 韩涛, 闫少华, 等. 单晶硅纳米磨削亚表面损伤形成机制及其抑制研究 [J]. 制造技术与机床,2023,729(3):24-30.TIAN Hailan, HAN Tao, YAN Shaohua, et al. Study on formation mechanism and suppression of subsurface damage during nano-grinding of monocrystalline silicon [J]. Manufacturing Technology & Machine Tool,2023,729(3):24-30. [2] KANG R K, ZHANG Y, GAO S, et al. High surface integrity fabrication of silicon wafers using a newly developed nonwoven structured grind-polishing wheel [J]. Journal of Manufacturing Processes,2022,77(5):229-239. [3] ZHANG C Y, DONG Z G, YUAN S, et al. Study on subsurface damage mechanism of gallium nitride in nano-grinding [J]. Materials Science in Semiconductor Processing,2021(128):105760. doi: 10.1016/j.mssp.2021.105760 [4] WANG H, KANG R K, BAO Y, et al. Microstructure evolution mechanism of tungsten induced by ultrasonic elliptical vibration cutting at atomic/nano scale [J]. International Journal of Mechanical Sciences,2023(253):108397. doi: 10.1016/j.ijmecsci.2023.108397 [5] LI P H, GUO X G, YUAN S, et al. Effects of grinding speeds on the subsurface damage of single crystal silicon based on molecular dynamics simulations [J]. Applied Surface Science,2021(554):149668. doi: 10.1016/j.apsusc.2021.149668 [6] ZHANG C Y, GUO X G, YUAN S, et al. Effects of initial temperature on the damage of GaN during nanogrinding [J]. Applied Surface Science,2021(556):149771. doi: 10.1016/j.apsusc.2021.149771 [7] 吴珍珍, 刘一扬, 韩涛, 等. 基于分子动力学的GaN纳米磨削亚表面损伤形成机制 [J]. 微纳电子技术, 2022, 59(12): 1368–1374, 1382.WU Zhenzhen, LIU Yiyang, HAN Tao, et al. Formation mechanism of subsurface damage of GaN during nano-grinding based on molecular dynamic [J]. Micronanoelectronic Technology, 2022, 59(12): 1368–1374, 1382. [8] ZHANG C Y, DONG Z G, ZHANG S H, et al. The deformation mechanism of gallium-faces and nitrogen-faces gallium nitride during nanogrinding [J]. International Journal of Mechanical Sciences,2021(214):106888. [9] 张瑜, 康仁科, 高尚, 等. 湿式机械化学磨削单晶硅的软磨料砂轮及其磨削性能 [J]. 机械工程学报,2023,59(3):328-336. doi: 10.3901/JME.2023.03.328ZHANG Yu, KANG Renke, GAO Shang, et al. Development and evaluation of soft abrasive grinding wheel for silicon wafer in wet mechanical chemical Grinding [J]. Journal of Mechanical Engineering,2023,59(3):328-336. doi: 10.3901/JME.2023.03.328 [10] LI C, ZHANG F H, PIAO Y C. Strain-rate dependence of surface/subsurface deformation mechanisms during nanoscratching tests of GGG single crystal [J]. Ceramics International,2019(45):15015-15024. doi: 10.1016/j.ceramint.2019.04.238 [11] WANG H, YANG G L, SU H, et al. Insight into surface formation mechanism during ultrasonic elliptical vibration cutting of tungsten alloy by scratching experiment and molecular dynamics [J]. Tribology International,2024(191):109088. [12] WANG J S, ZHANG X D, FANG F Z, et al. Study on nano-cutting of brittle material by molecular dynamics using dynamic modeling [J]. Computer Material Science,2020(183):109851. doi: 10.1016/j.commatsci.2020.109851 [13] 卢守相, 杨秀轩, 张建秋, 等. 关于硬脆材料去除机理与加工损伤的理性思考 [J]. 机械工程学报,2022,58(15):31-45.LU Souxiang, YANG Xiuxuan, ZHANG Jianqiu, et al. Rational discussion on material removal mechanisms and machining damage of hard and brittle materials [J]. Journal of Mechanical Engineering,2022,58(15):31-45. [14] ZHANG J, HE B, ZHANG B. Failure mode change and material damage with varied machining speeds: A review [J]. International Journal of Extreme Manufacturing,2023(5):022003. doi: 10.1088/2631-7990/acbd6f [15] DONG Z G, WANG H, QI Y N, et al. Effects of minimum uncut chip thickness on tungsten nano-cutting mechanism [J]. International Journal of Mechanical Sciences,2023(237):107790. doi: 10.1016/j.ijmecsci.2022.107790 [16] HU J H, HE Y, LI Z, et al. On the deformation mechanism of SiC under nano-scratching: An experimental investigation [J]. Wear,2023(522):204871. doi: 10.1016/j.wear.2023.204871 [17] 王浩. 氮化硅陶瓷磨削热特性与表面质量研究 [D]. 沈阳: 沈阳建筑大学, 2020.WANG Hao. Study on grinding thermal characteristics and surface quality of silicon nitride ceramics [D]. Shenyang: Shenyang Jianzhu University, 2020. [18] 卞达, 宋恩敏, 倪自丰, 等. 基于响应面法的单晶硅CMP抛光工艺参数优化 [J]. 金刚石与磨料磨具工程,2022,42(6):745-752. doi: 10.13394/j.cnki.jgszz.2022.0081BIAN Da, SONG Enmin, NI Zifeng, et al. Optimization of CMP processing parameters for Si based on response surface method [J]. Diamond & Abrasives Engineering,2022,42(6):745-752. doi: 10.13394/j.cnki.jgszz.2022.0081 [19] 高航, 李睿祺, 许启灏, 等. 金刚石工具加工SiO2f/SiO2复合材料的可行性研究 [J]. 金刚石与磨料磨具工程,2023,43(1):75-81.GAO Hang, LI Ruiqi, XU Qihao, et al. Feasibility study on SiO2f/SiO2 composites processed by diamond tools [J]. Diamond & Abrasives Engineering,2023,43(1):75-81. [20] XIE W K, FANG F Z. Effect of tool edge radius on material removal mechanism in atomic and close-to-atomic scale cutting [J]. Applied Surface Science,2020(504):144451. doi: 10.1016/j.apsusc.2019.144451 [21] 王颖, 苑泽伟, 张幼军. 超精密切削加工的材料去除理论综述 [J]. 机械设计与制造,2022,82(12):147-150, 155. doi: 10.3969/j.issn.1001-3997.2022.12.029WANG Ying, YUAN Zewei, ZHANG Youjun. Review of material removal theory for ultraprecision machining [J]. Machinery Design & Manufacture,2022,82(12):147-150, 155. doi: 10.3969/j.issn.1001-3997.2022.12.029 [22] IRWAN R, HUANG H. Surface and subsurface deformation characteristics of cemented tungsten carbide under nanoscratching [J]. International Journal of Surface Science and Engineering,2013,7(2):122-134. doi: 10.1504/IJSURFSE.2013.0536988 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS