Precision grinding of cemented carbide ball valves by resin diamond wheels with different pore-forming agents

-

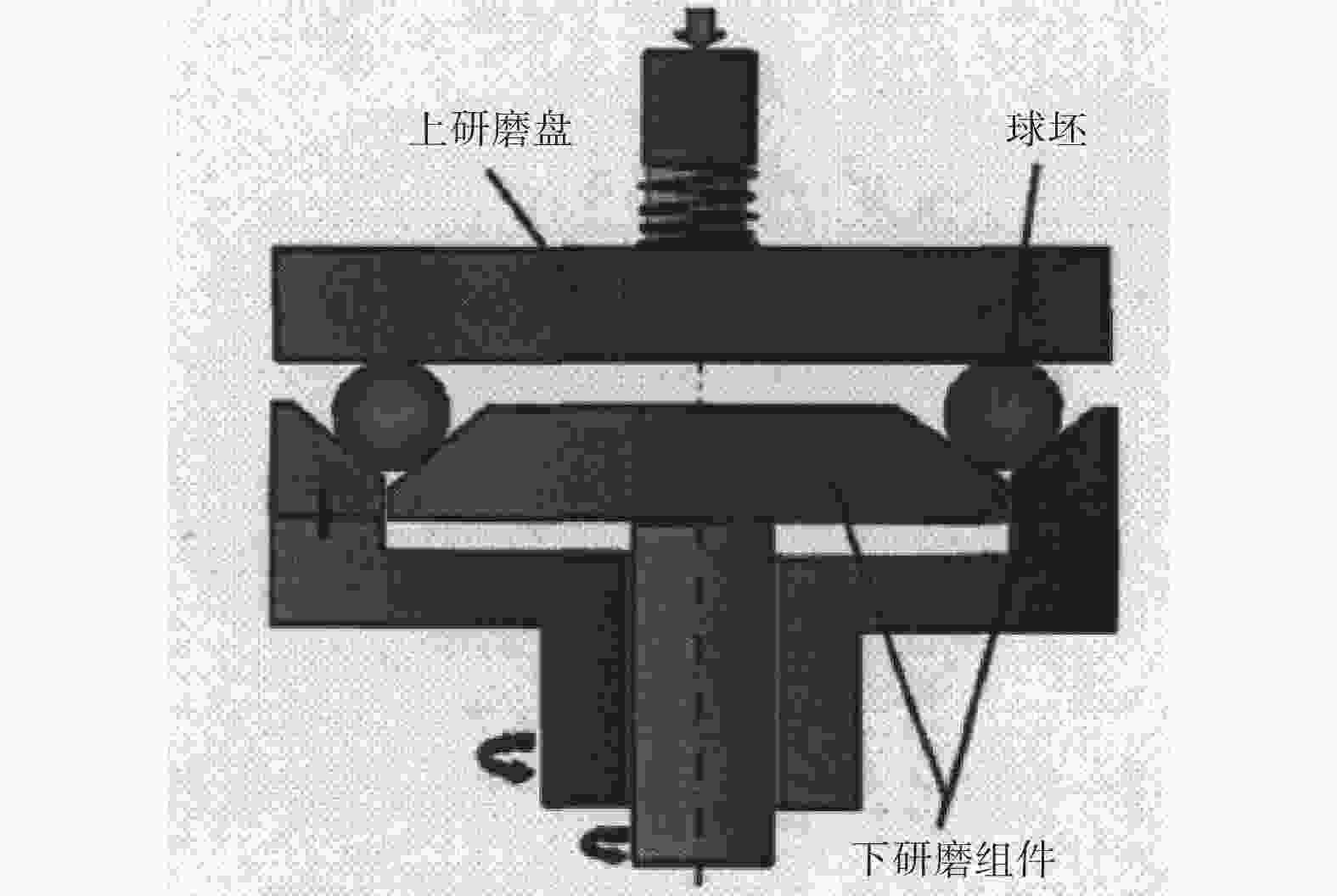

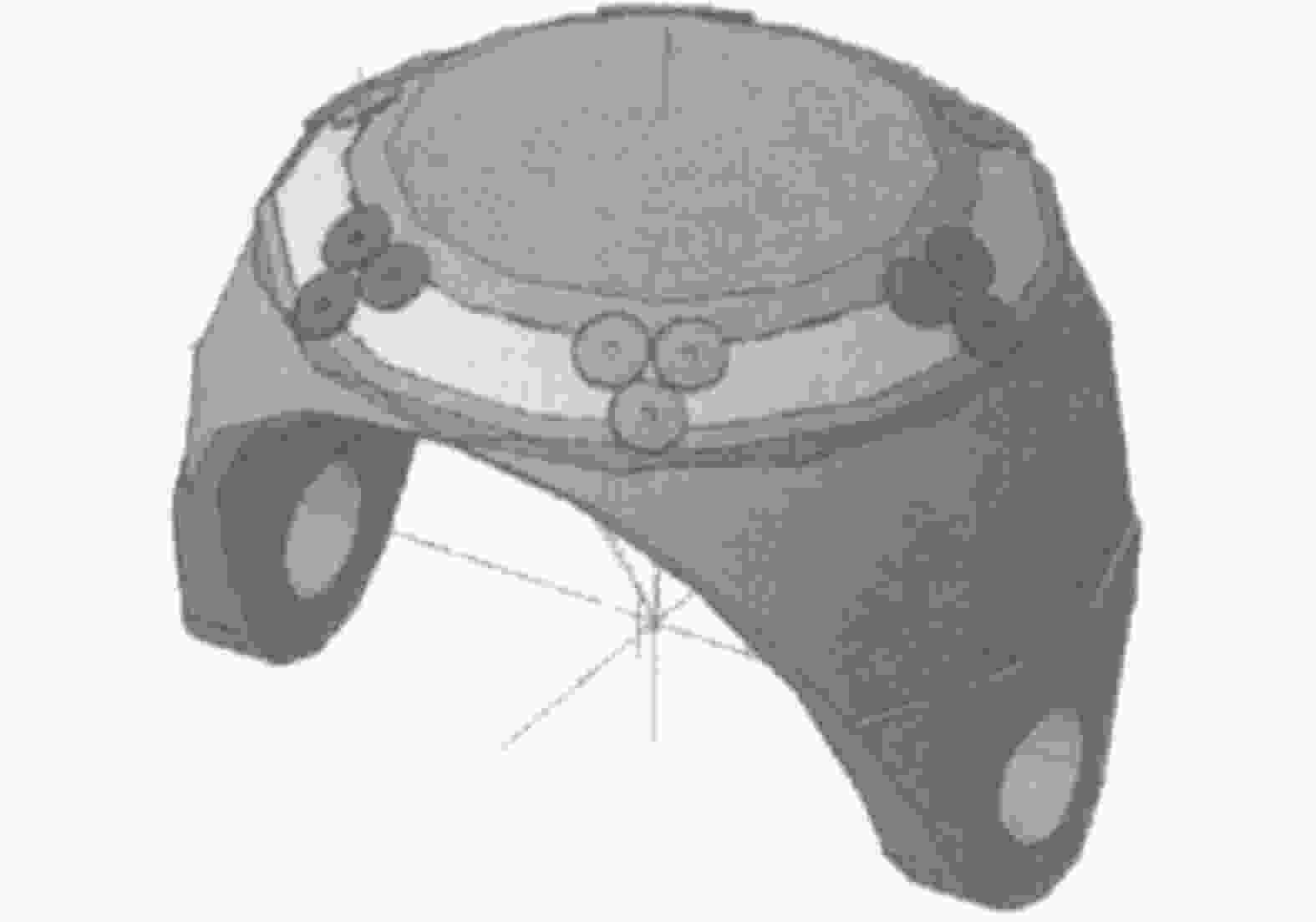

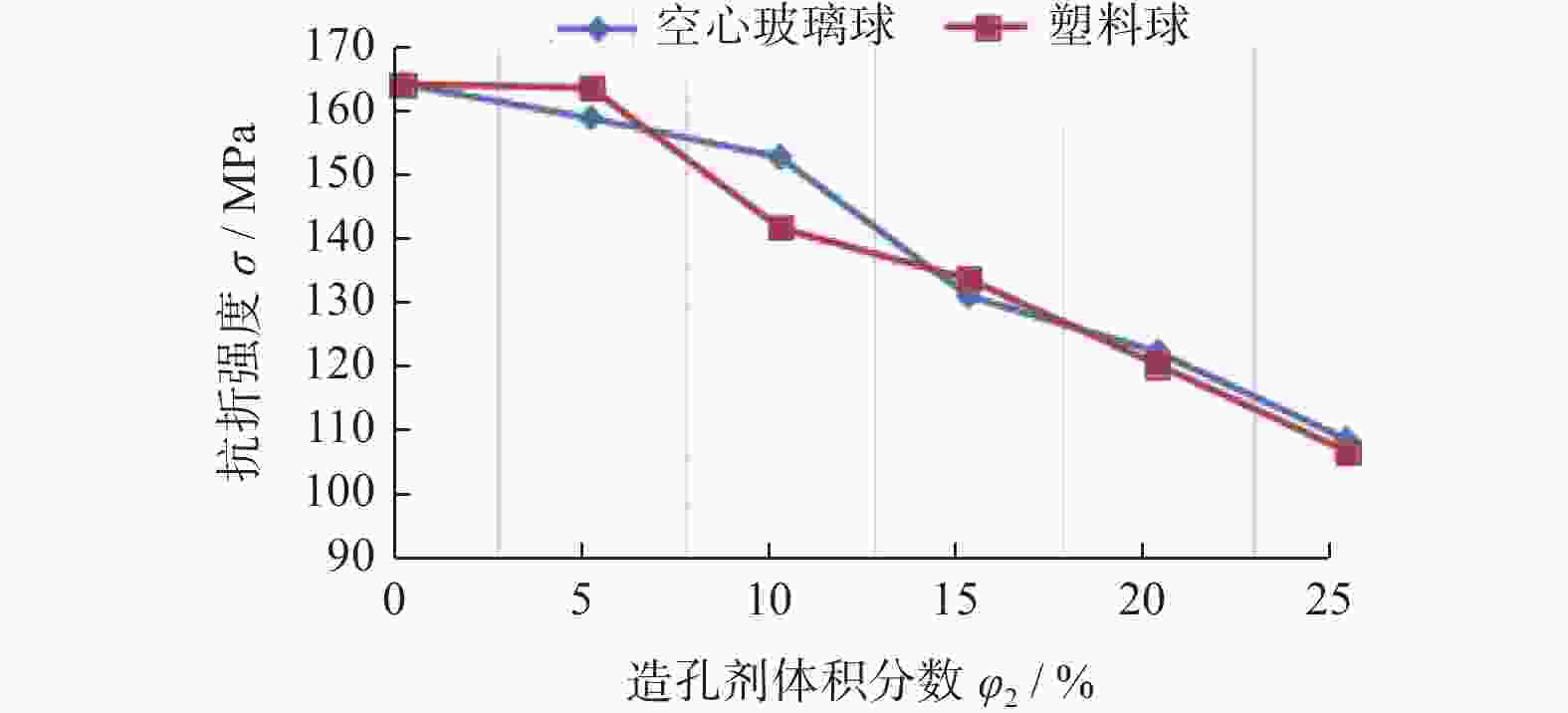

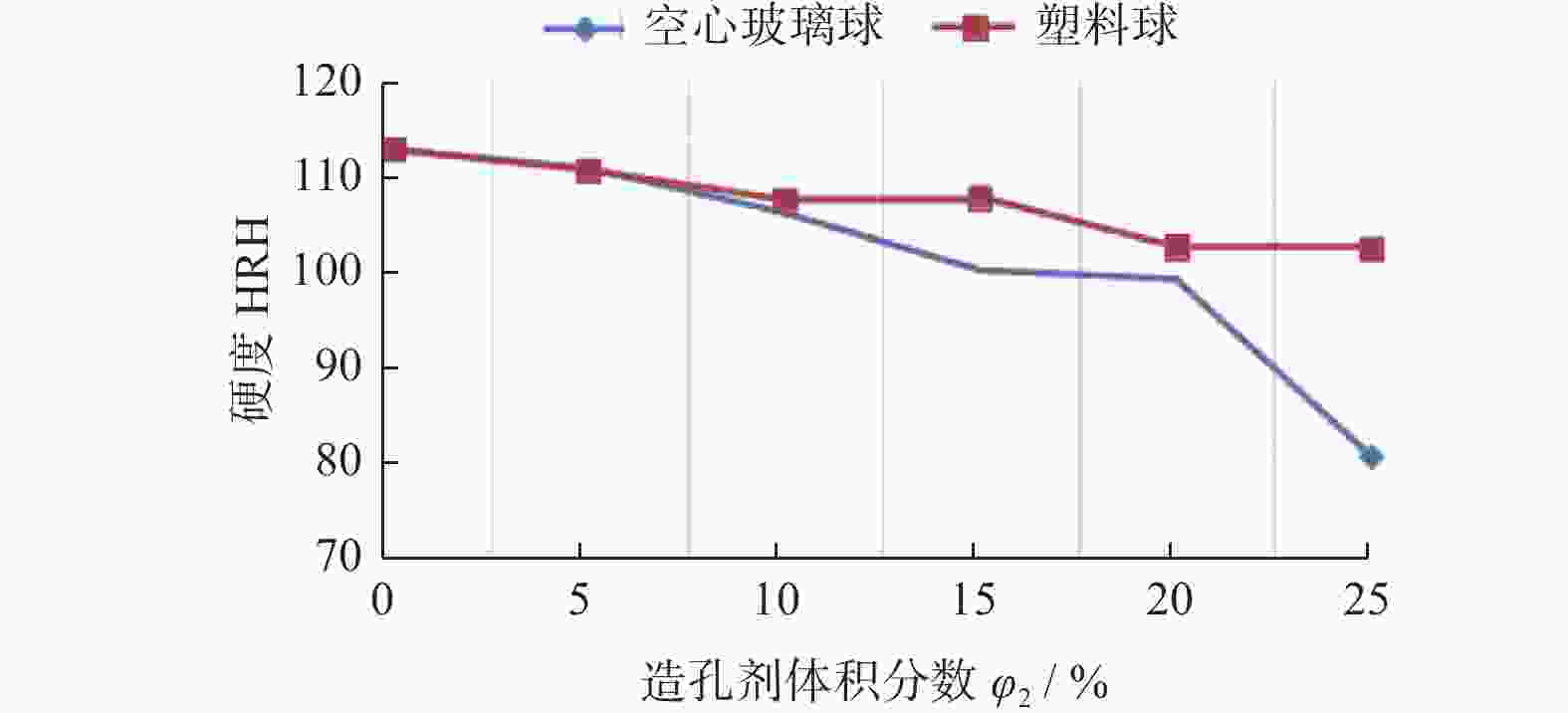

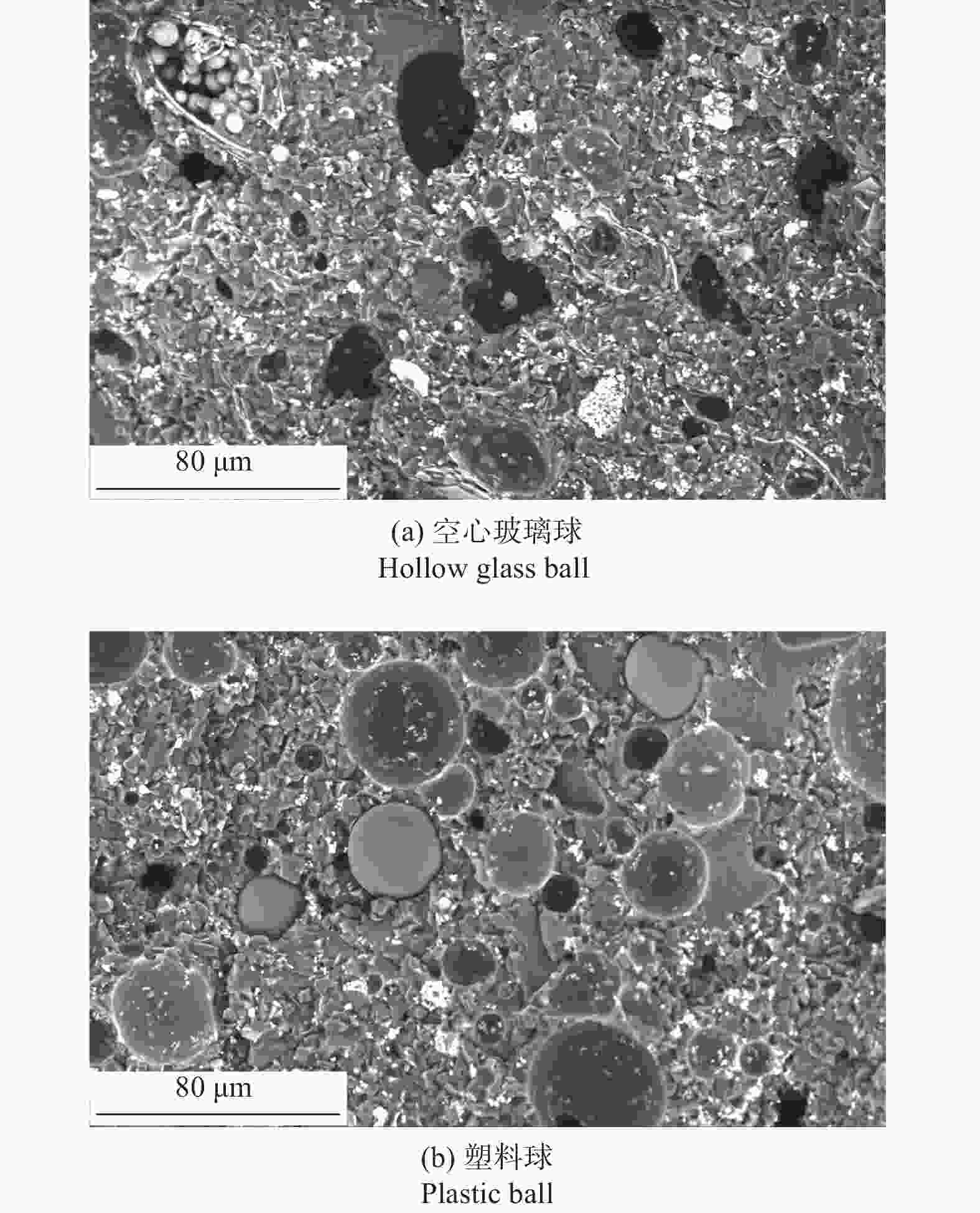

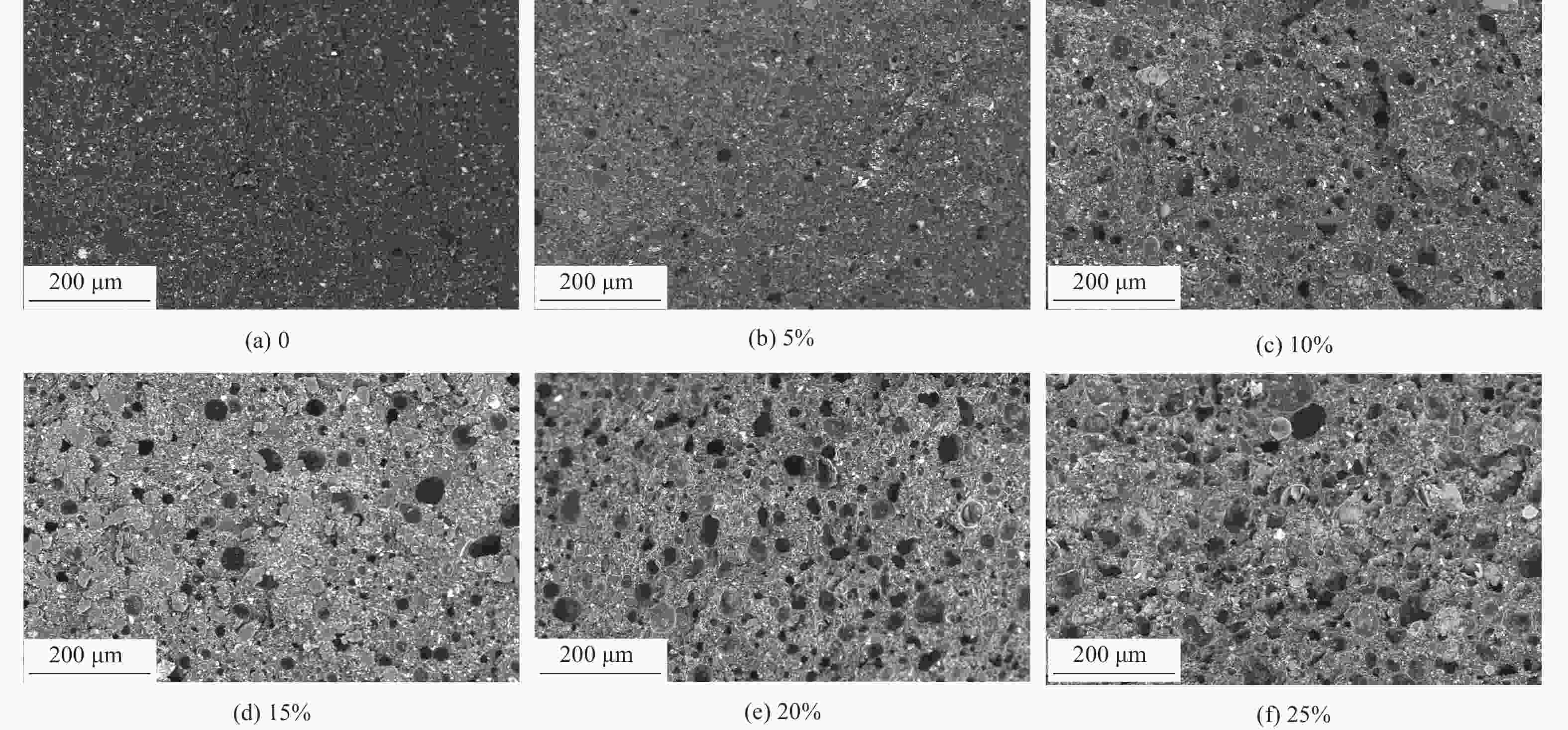

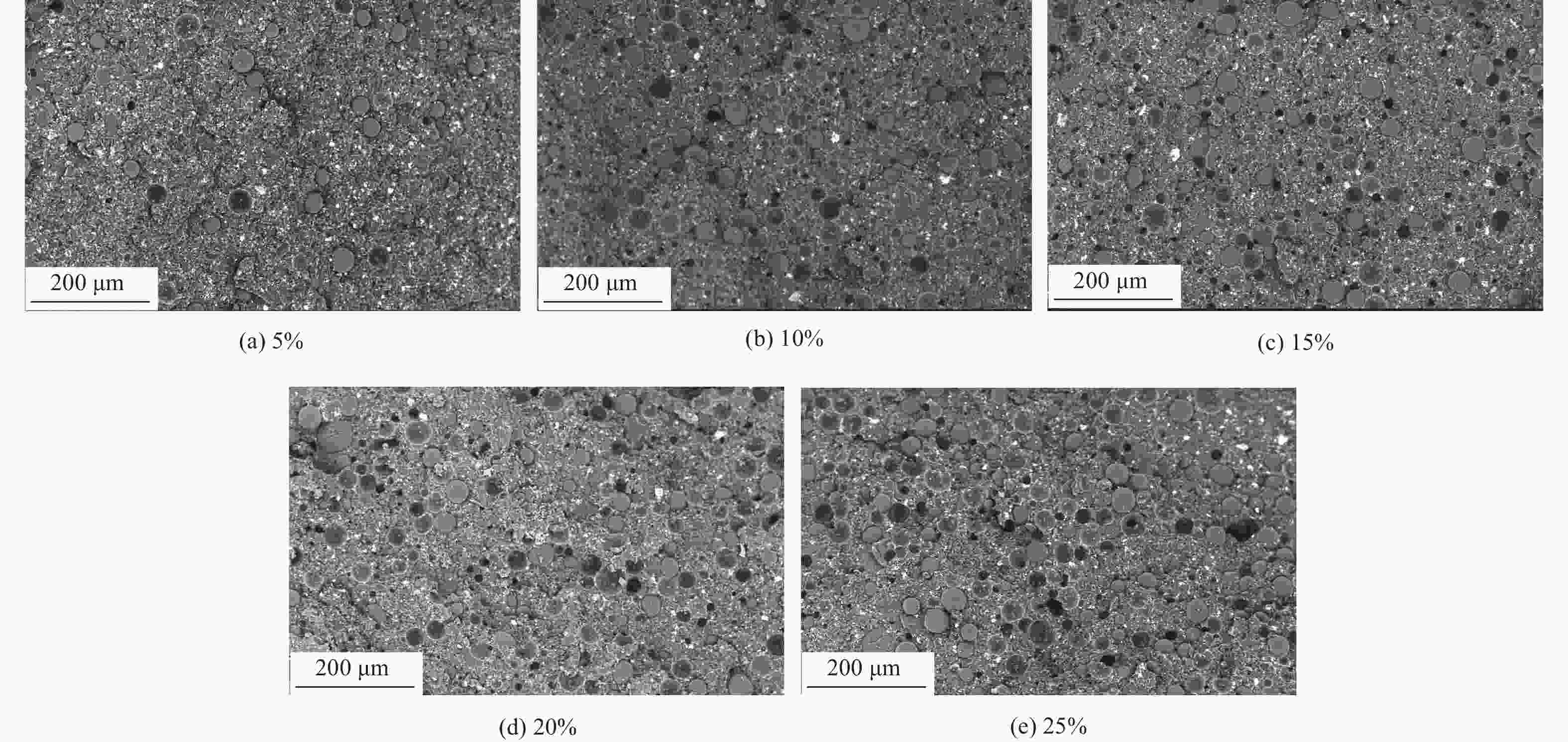

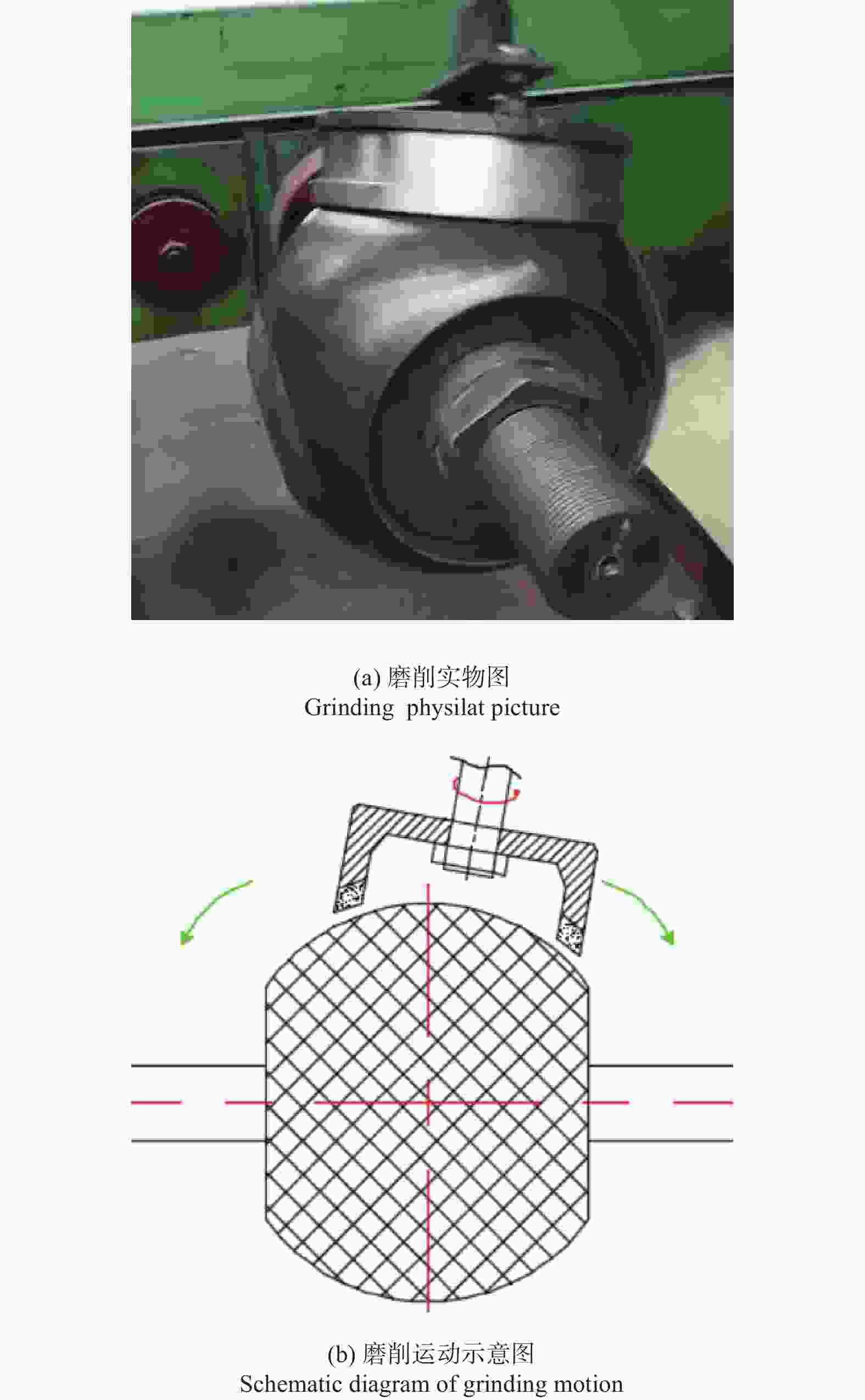

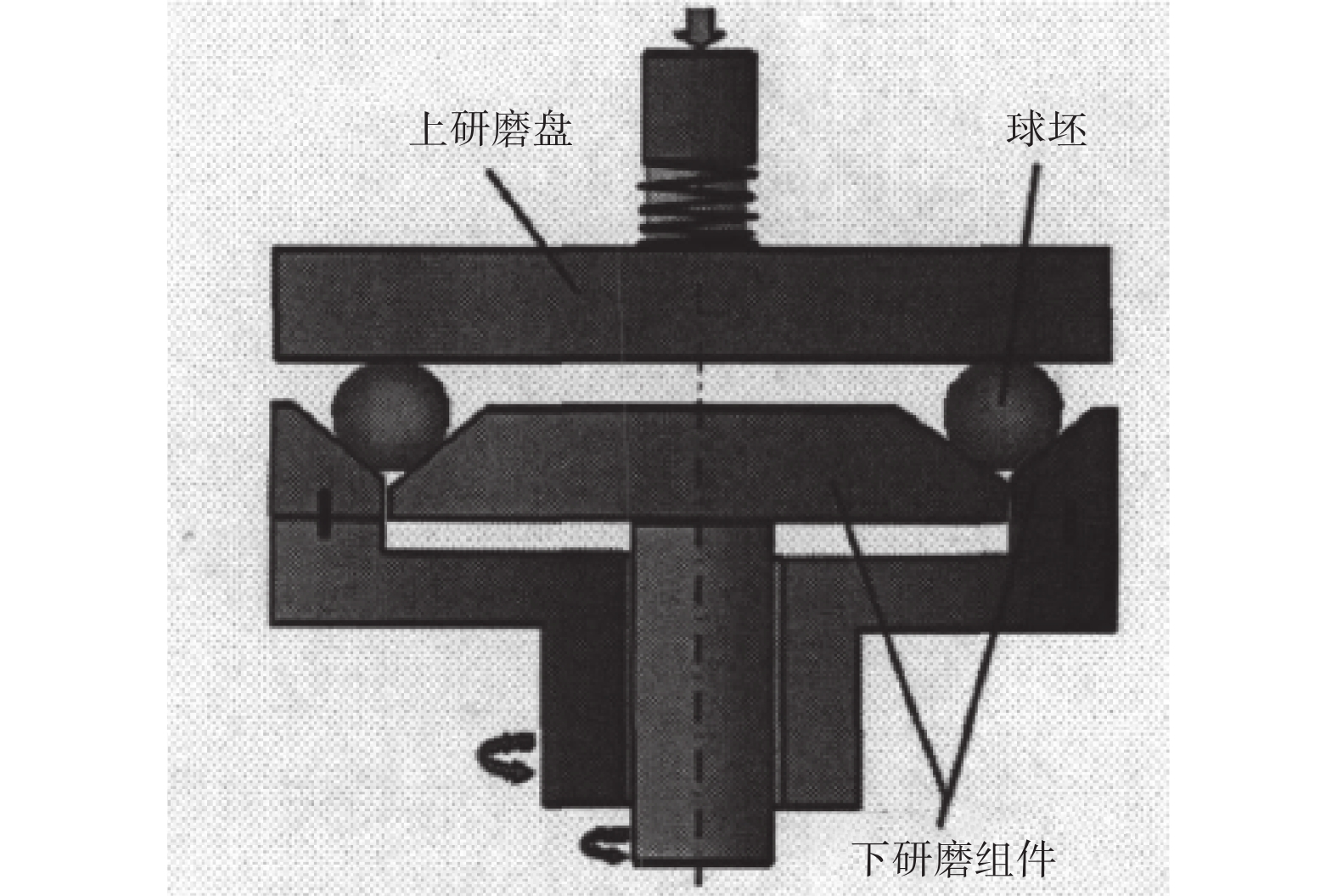

摘要: 为改善硬质合金球阀的加工效果,在树脂金刚石砂轮中引入造孔剂,对其力学性能、微观形貌及磨削性能进行分析,研究空心玻璃球和塑料球造孔剂对树脂金刚石砂轮性能的影响。结果表明:随着造孔剂体积分数增加,树脂砂轮的抗折强度逐渐下降,且2种造孔剂对抗折强度的影响基本一致;砂轮的硬度随造孔剂体积分数的增加亦逐渐下降,但空心玻璃球造孔剂对砂轮硬度的影响显著大于塑料球的;加入造孔剂明显提升了砂轮的锋利性,空心玻璃球体造孔剂体积分数为15%和塑料球造孔剂体积分数为20%的砂轮综合性能最好,且后者的综合性能优于前者的。Abstract: To improve the machining effect of cemented carbide ball valves, pore-forming agents were introduced into resin diamond wheels. The mechanical properties, microstructures, and grinding performances of the wheels were analyzed, and the effects of hollow glass ball pore-forming agent and plastic ball pore-forming agent on the performances of resin diamond wheels were studied. The results show that the bending strength of the grinding wheel decreases gradually with the increase in the content of pore-forming agent, and the influence of the two pore-forming agents on bending strength is basically the same. The hardness of the grinding wheel also decreases with the increase in pore-forming agent content, but the influence of the hollow glass ball pore-forming agent on the hardness of the grinding wheel is significantly greater than that of the plastic ball. The addition of pore-forming agent significantly improves the sharpness of the grinding wheel. The comprehensive performance of the grinding wheels is best when the volume fraction of hollow glass balls is 15% and the volume fraction of plastic balls is 20%, but the latter has better overall performance than the former.

-

表 1 结合剂组分

Table 1. Binder components

成分 体积分数 φ1 / % 酚醛树脂 70 弹性抛光体 10 GC 15 Cr2O3 5 表 2 磨削参数

Table 2. Grinding parameters

参数 类型或取值 砂轮转速 n / (r·min−1) 1 500 单次进给余量 ap / mm 0.005 研磨压力 p / kPa 50 硬质合金球阀球体直径 D / mm 180 球体材质 YG8 球体硬度 HRA 90 表 3 磨削实验结果

Table 3. Grinding test results

造孔剂种类 造孔剂体积分数

φ2 / %磨削功率

P / W工件表面粗糙度

Ra / μm对比样 0 626 0.030 0

空心玻璃球10 495 0.042 0 15 408 0.048 0 20 321 0.090 0

塑料球10 486 0.036 0 15 462 0.041 0 20 386 0.047 2 -

[1] 赖海瑜, 杨志中. 球阀球体研磨装置改进 [J]. 阀门,2006(2):34-35.LAI Haiyu, YANG Zhizhong. The improvement of the grinder for ball of the ball valve [J]. Valve,2006(2):34-35. [2] 尚玉来, 金瑞建, 金克雨, 等. 高温耐磨球阀密封面涂层强化工艺的研究 [J]. 阀门,2022(1):52-57.SHANG Yulai, JIN Ruijian, JIN Keyu, et al. Research on strengthening technology of sealing surface coating of high temperature wear-resistant ball valve [J]. Valve,2022(1):52-57. [3] 苏伟, 颜娟. 高精度硬质合金球阀球体加工工艺研究 [J]. 硬质合金,2021,38(5):351-356.SU Wei, YAN Juan. Research on processing technology of high precision cemented carbide ball of ball valves [J]. Cemented Carbide,2021,38(5):351-356. [4] 张文华, 高兰, 朱剑飞. 固定阀球密度对抽油泵进油的影响 [J]. 石油钻采工艺,2003(Z1):33-35.ZHANG Wenhua, GAO Lan, ZHU Jianfei. Influence of pump, s absorbing oil by density of fixed-valve, s [J]. Oli Drilling & Production Technology,2003(Z1):33-35. [5] 陶嶙, 陶宪之, 杨燕怡, 等. 抽油泵阀球失效分析 [J]. 石油机械,1986(11):10-15.TAO Lin, TAO Xianzhi, YANG Yanyi, et al. Failure analysis of valve balls of sucker rod pumps [J]. China Petroleum Machinery,1986(11):10-15. [6] ZHANG B, UEMATSU T, NAKAJIMA A. High efficiency and precision grinding of Si3N4 ceramic balls aided by magnetic fluid support using diamond wheels [J]. JSME International Journal Series C,1998,41(3):499-505. doi: 10.1299/jsmec.41.499 [7] CHANG F Y, CHILDS T H C. Non-magnetic fluid grinding [J]. Wear,1998,223(1/2):7-12. [8] CHILDS T H C, MOSS D J. Grinding ratio and cost issues in magnetic and non-magnetic fluid grinding [J]. CIRP Annals,2000,49(1):255-261. [9] 孙永安, 李县辉. 国外陶瓷球加工技术及其应用 [J]. 陶瓷学报,2002(2):145-148.SUN Yong’an, LI Xianhui. Machining technology and applications for ceramic balls in abroad [J]. Journal of Ceramics,2002(2):145-148. [10] 黄传真, 杨为清, 艾兴, 等. 新型陶瓷轴承研究的现状与展望 [J]. 中国陶瓷工业,1999(2):27-29.HUANG Chuanzhen, YANG Weiqing, AI Xing, et al. The present situation and future prospect of study on advanced ceramic bearing [J]. China Ceramic Industry,1999(2):27-29. [11] YUAN J L, LV B H, ZHOU Z Z, et al. Parameters optimization on the lapping process for advanced ceramics by applying taguchi method [J]. Materials Science Forum,2006(532/533):487-491. [12] LV B H, YUAN J L, YAO Y X, et al. Research on ultra-precision lapping technology for super-smooth surface of KTP crystal [J]. Key Engineering Material,2006(315/316):284-288. [13] 文灏. 钨钴类硬质合金球行星研磨及其装备研究 [D]. 长沙: 中南大学, 2010.WEN Hao. Research on Planetary grinding and equipment for tungsten [D]. Changsha: Central South University, 2010. [14] 文灏, 刘舜尧. 硬质合金球行星研磨加工技术 [J]. 轴承,2009(11):12-15.WEN Hao, LIU Shunyao. Planetary lapping technology for cemented carbide balls [J]. Bearing,2009(11):12-15. [15] 何文平. 大口径球面阀芯研磨新工艺与新机构设计研究 [J]. 机械科学与技术,2009(5):652-656.HE Wenping. Research on new grinding technology and the device design of large caliber spherical surface valve core [J]. Mechanical Seience and Technology for Aerospace Engineering,2009(5):652-656. [16] 周晓玉. 超细晶粒硬质合金磨削实验研究 [D]. 长沙: 湖南大学, 2013.ZHOU Xiaoyu. The experimental research on grinding of ultra-fine grain cemented carbide [D]. Changsha: Hunan University, 2013. [17] 原一高, 张肖肖, 丁健俊, 等. 磨削参数对超细硬质合金磨削表面粗糙度的影响 [J]. 工具技术,2012,46(5):41-44.YUAN Yigao, ZHANG Xiaoxiao, DING Jianjun, et al. Influence of grinding parameters on ground surface roughness of ultrafine-grained WC-Co cemented carbides [J]. Tool Engineering,2012,46(5):41-44. [18] SHARIF S, RAHIM E A. Performance of coated- and uncoated- carbide tools when drilling titanium alloy Ti-6Al-4V [J]. Journal of Materials Processing Technology,2007,185(1/2/3):72-76. [19] 师超钰, 朱建辉, 冯兵强, 等. 硬质合金磨削加工中树脂和金刚石的影响研究 [J]. 组合机床与自动化加工技术,2017(11):138-140, 144.SHI Chaoyu, ZHU Jianhui, FENG Bingqiang, et al. Experimental research on resins and diamonds influencing grinding performances for cemented carbide [J]. Modular Machine Tool & Automatic Manufacturing Technique,2017(11):138-140, 144. [20] 吴逸涵. WC基硬质合金的性能及其在硬密封球阀的应用研究 [D]. 兰州: 兰州理工大学, 2017.WU Yihan. Performance of WC-based carbide and its application in hard seal ball valves [D]. Lanzhou: Lanzhou University of Technology, 2017. [21] 华建宇, 李林. 硬密封球阀球体研磨装置 [J]. 阀门,2008(2):27-28.HUA Jianyu, LI Ling. Whet device development of small size and hard seal ball valve [J]. Valve,2008(2):27-28. [22] 王吉慧. 浅析金属密封球阀球体加工工艺 [J]. 科技资讯,2019,17(16):34-66.WANG Jihui. Analysis of the processing technology for metal sealed ball valve spheres [J]. Science & Technology Information,2019,17(16):34-66. [23] 史林峰, 韩雪, 郜永娟, 等. 氧化铝空心球对树脂结合剂金刚石磨盘磨削蓝宝石的影响 [J]. 金刚石与磨料磨具工程,2017,37(3):15-18.SHI Linfeng, HAN Xue, GAO Yongjuan, et al. Effect of Al2O3 hollow sphere on properties of resin bond diamond disc in sapphire grinding [J]. Diamond & Abrasives Engineering,2017,37(3):15-18. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS