Physical and chemical characterization of the surface and removal process of silicon carbide ceramics by femtosecond laser processing

-

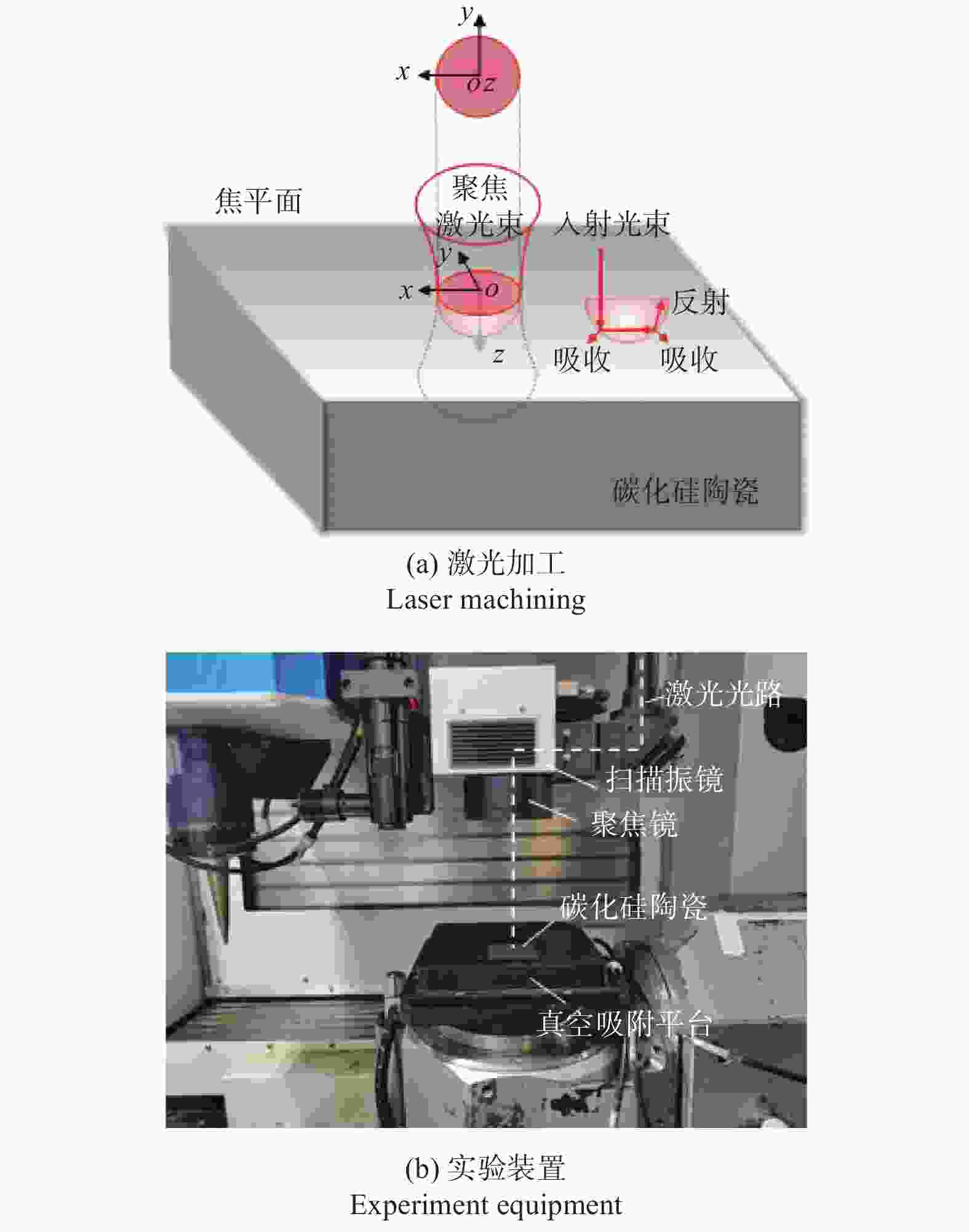

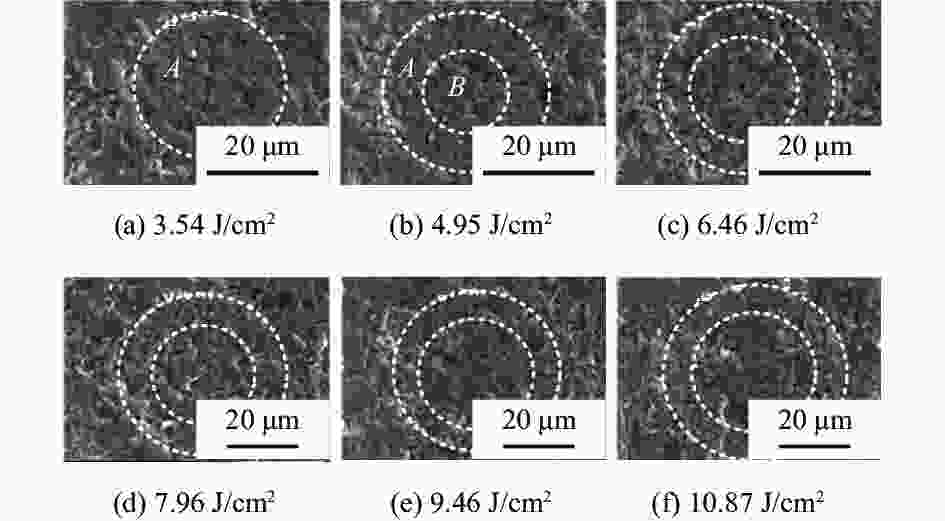

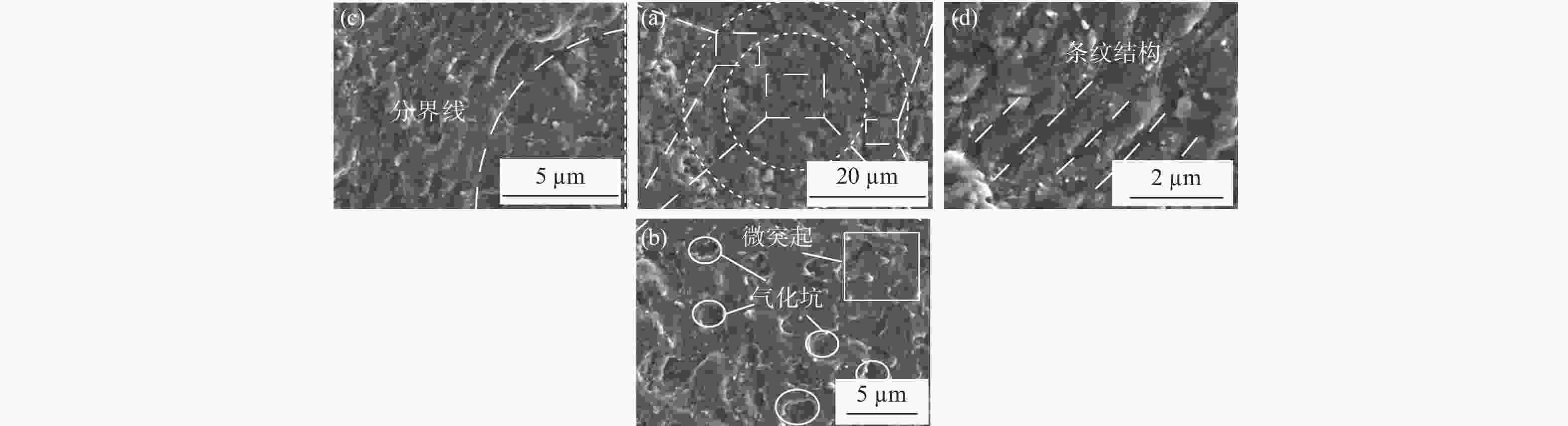

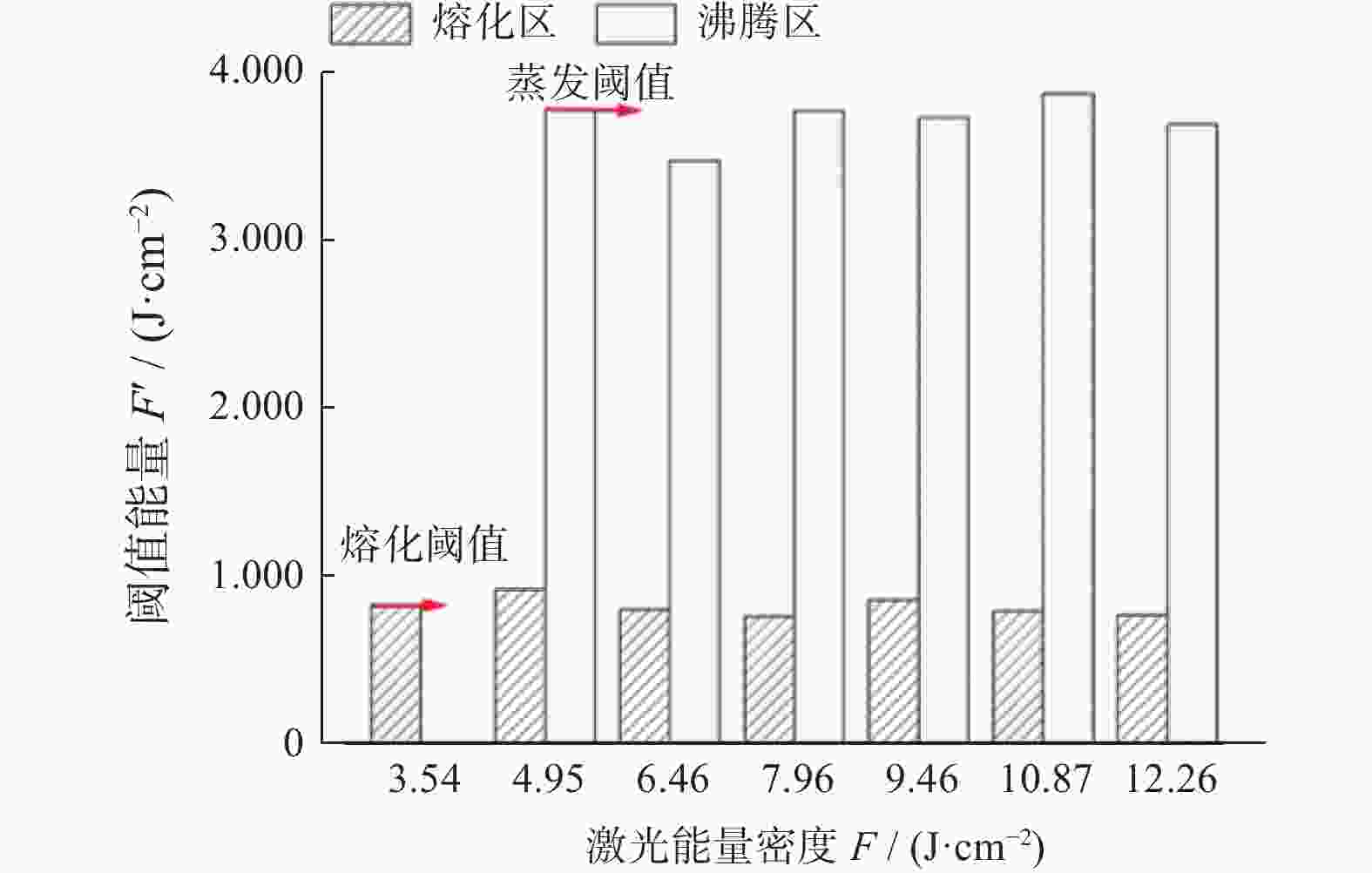

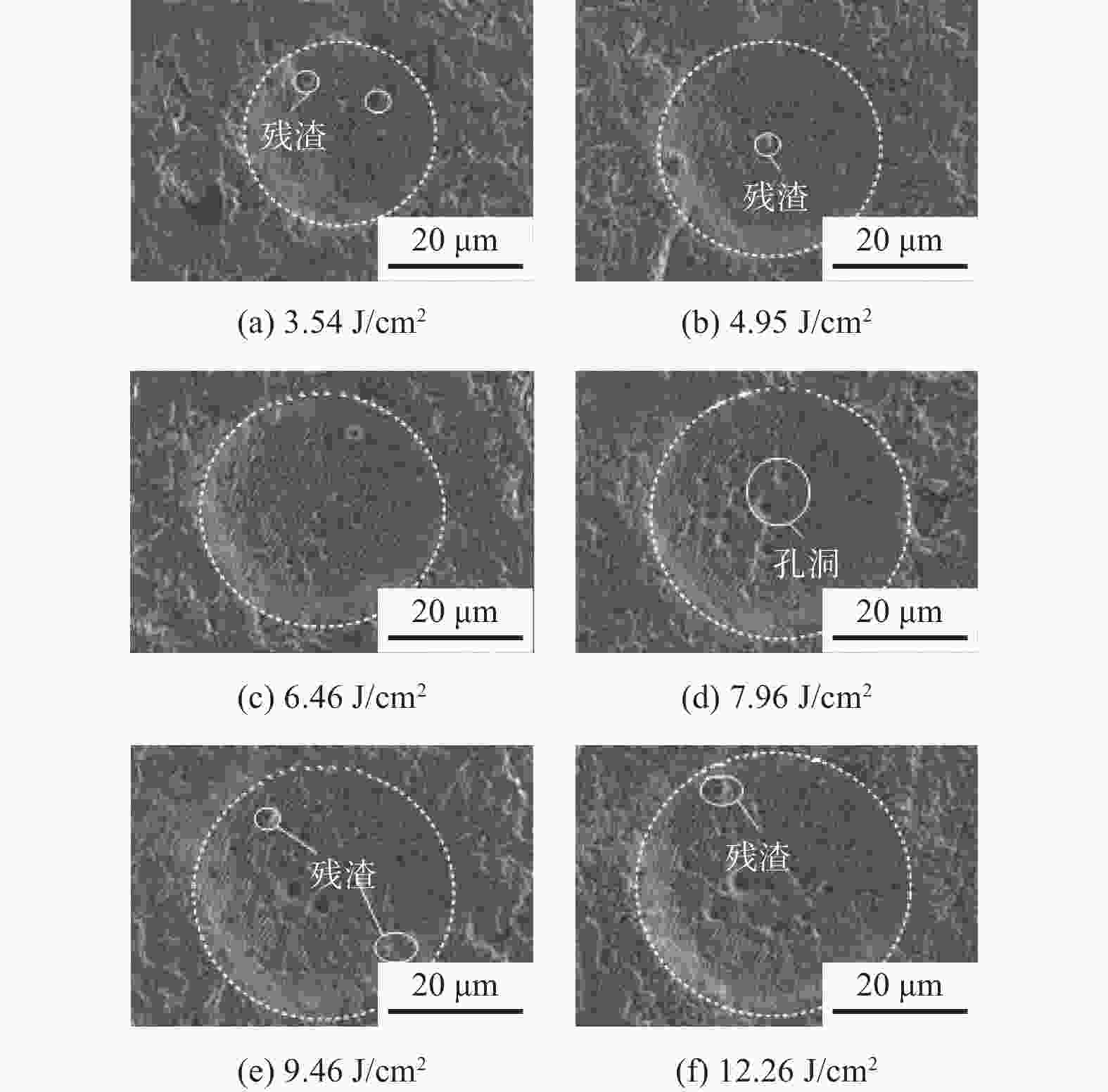

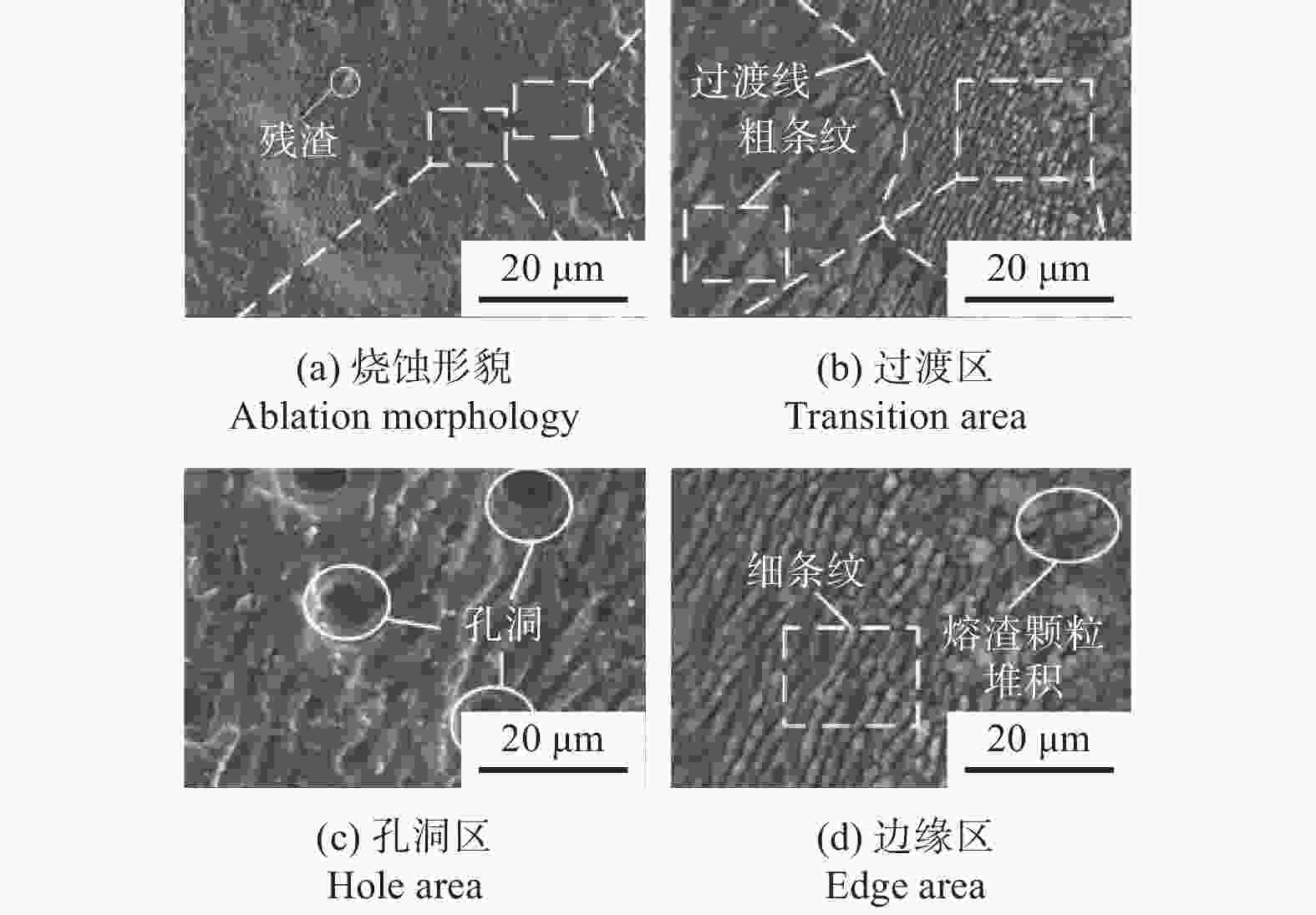

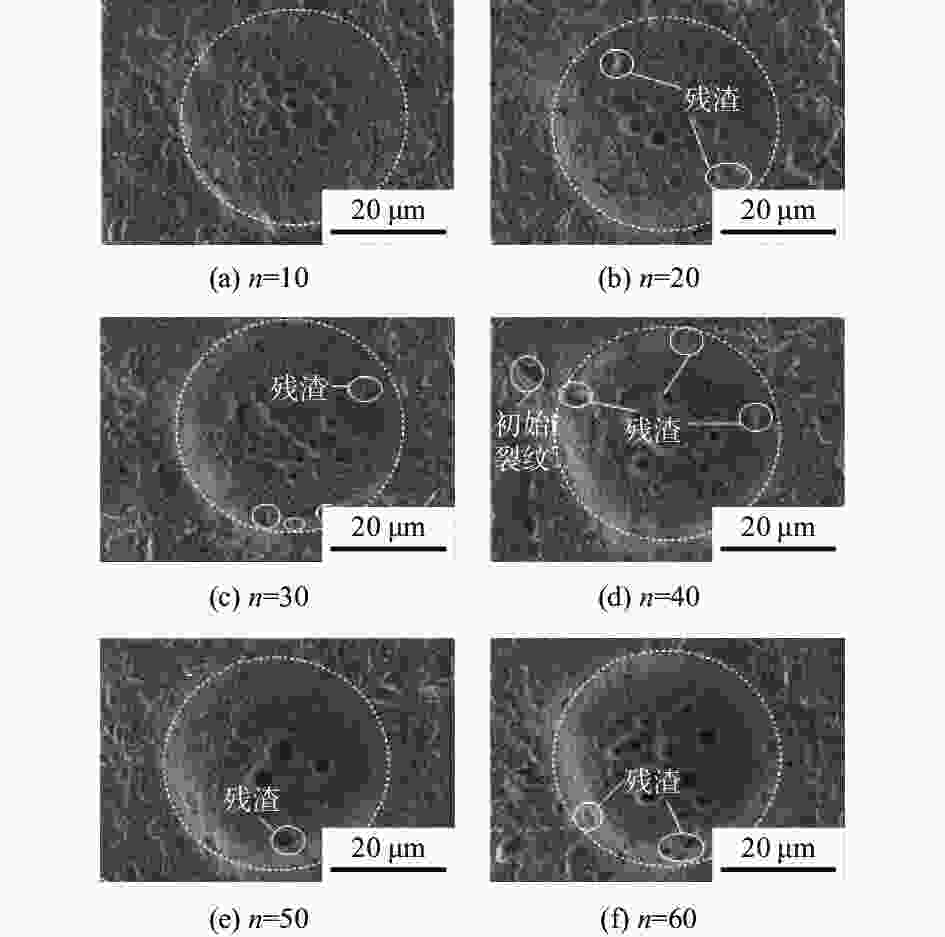

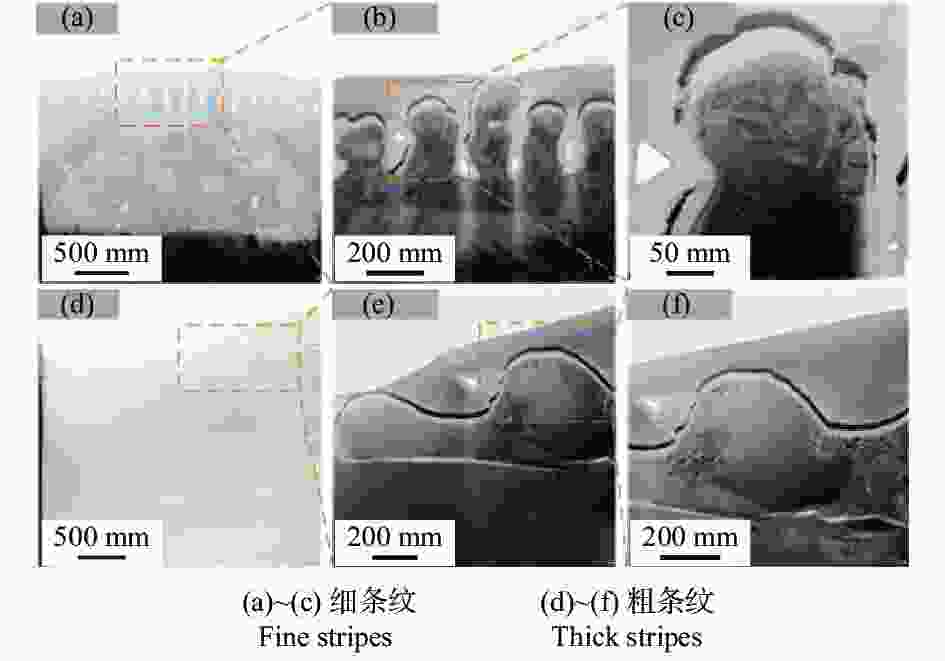

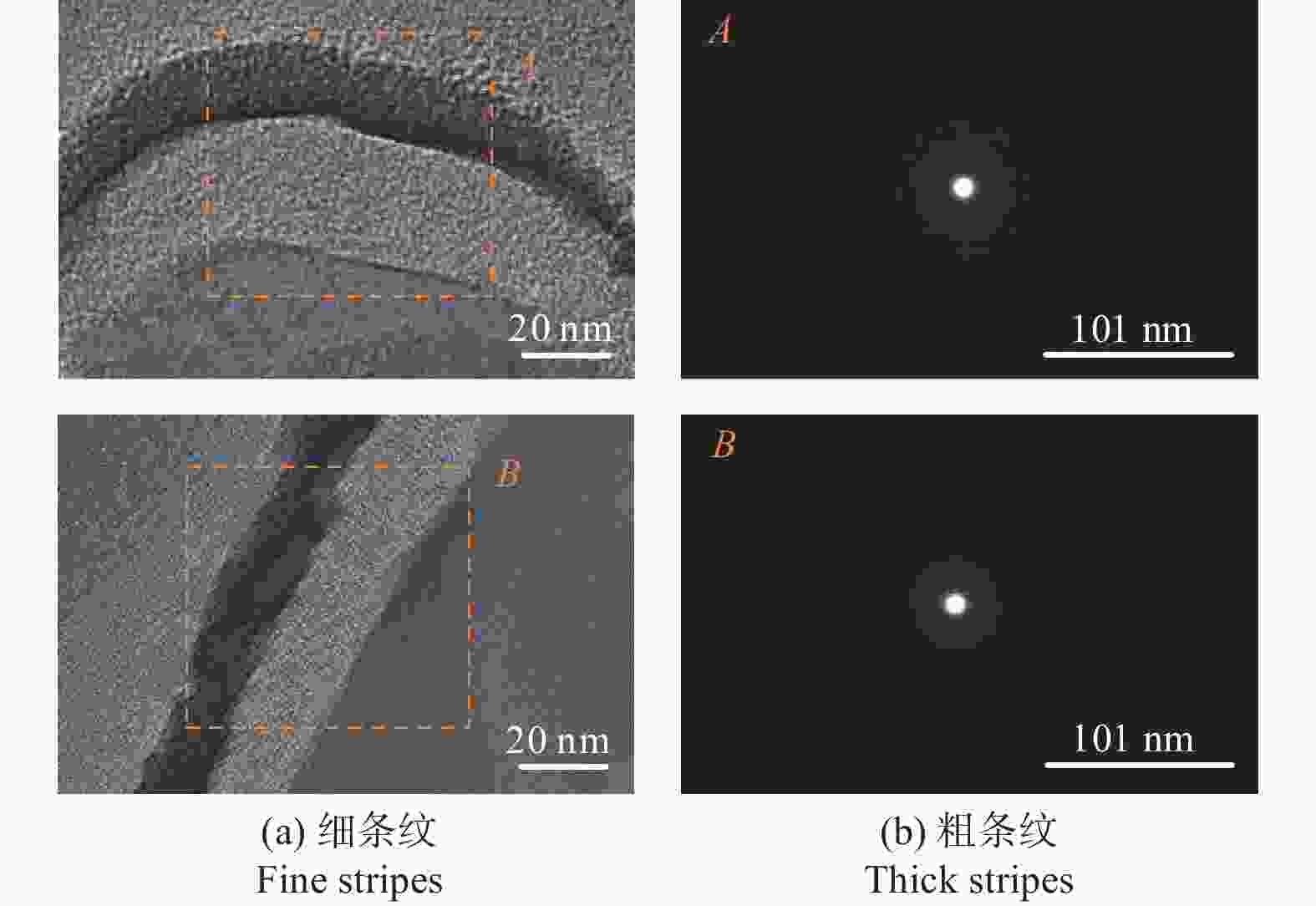

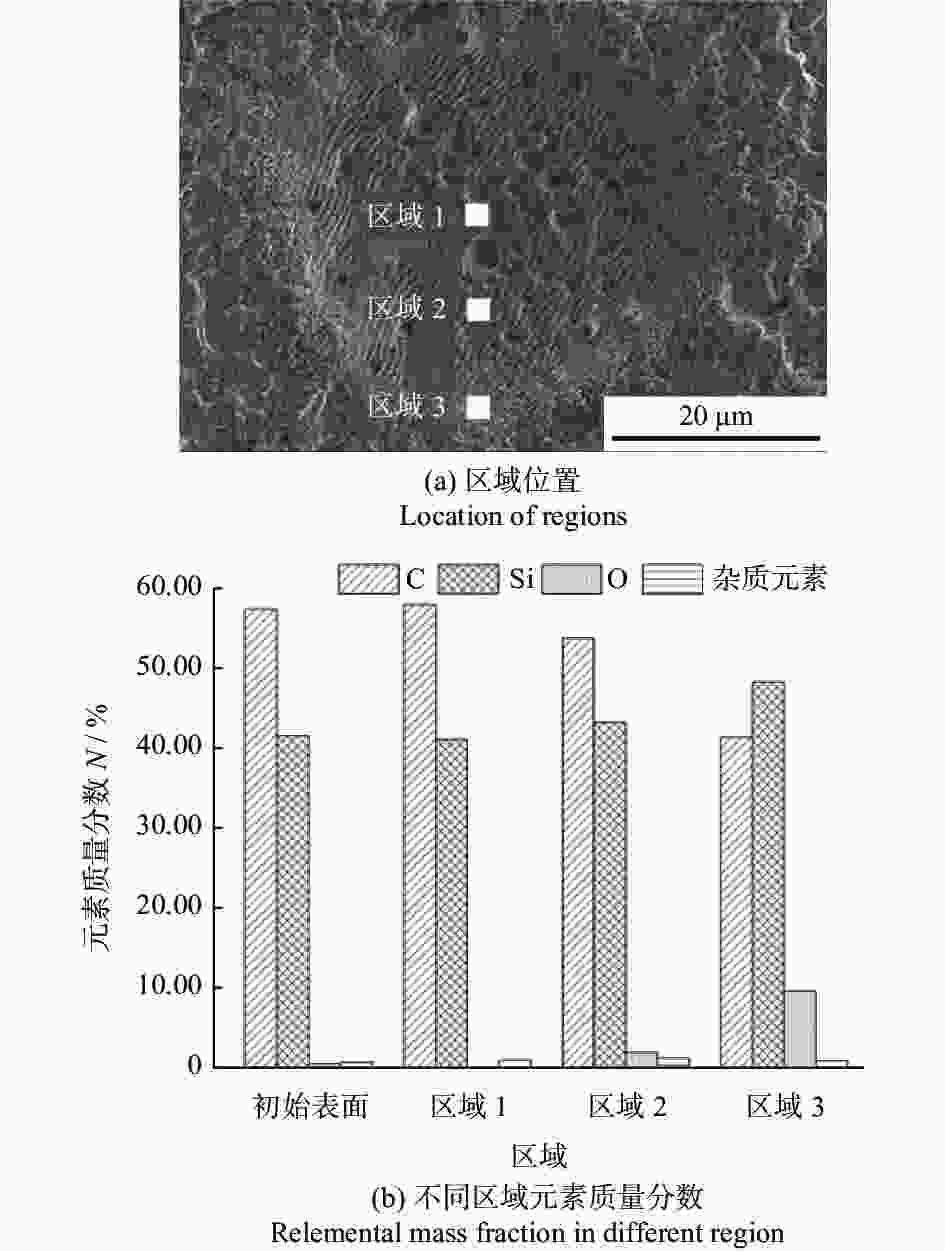

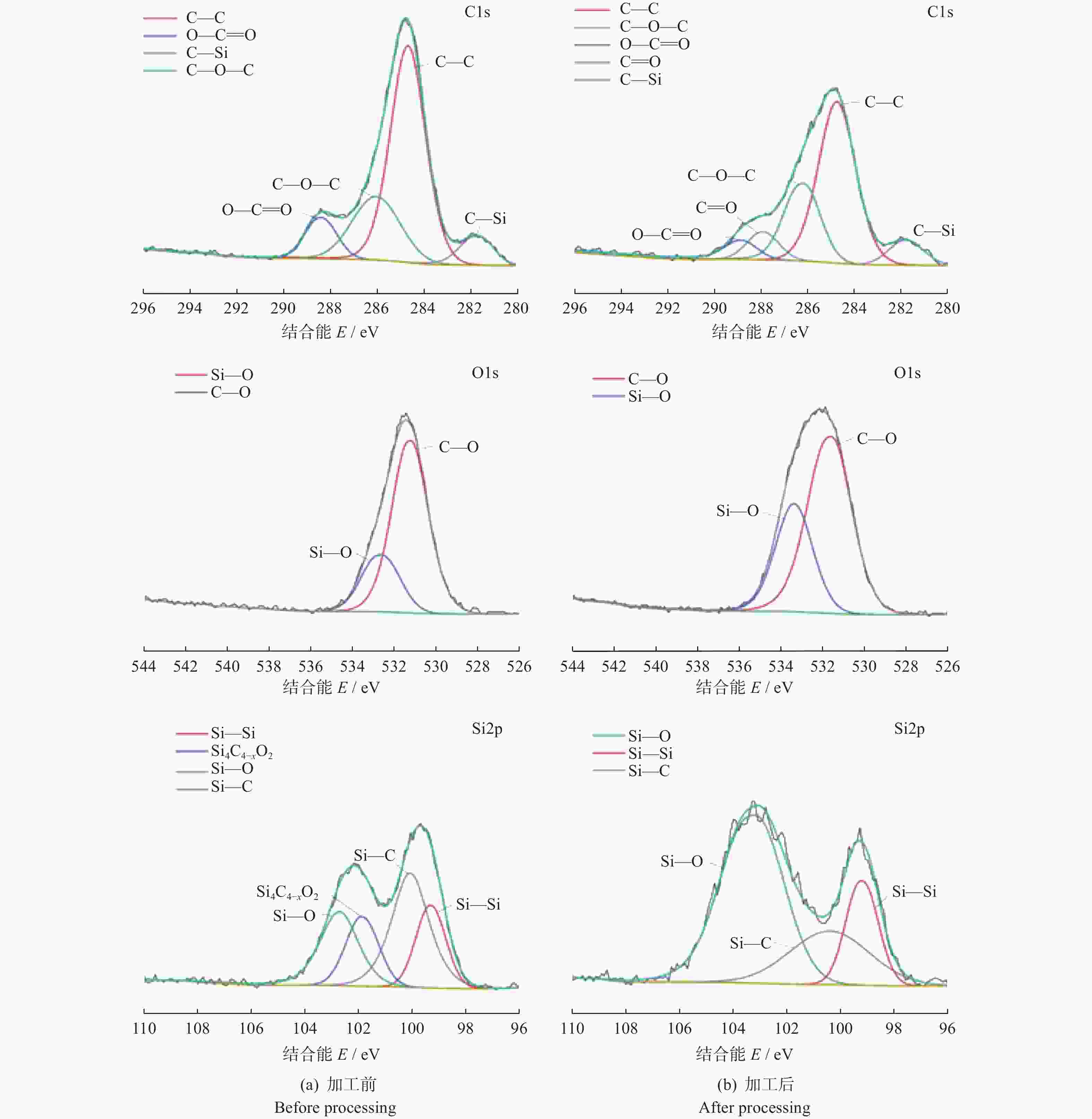

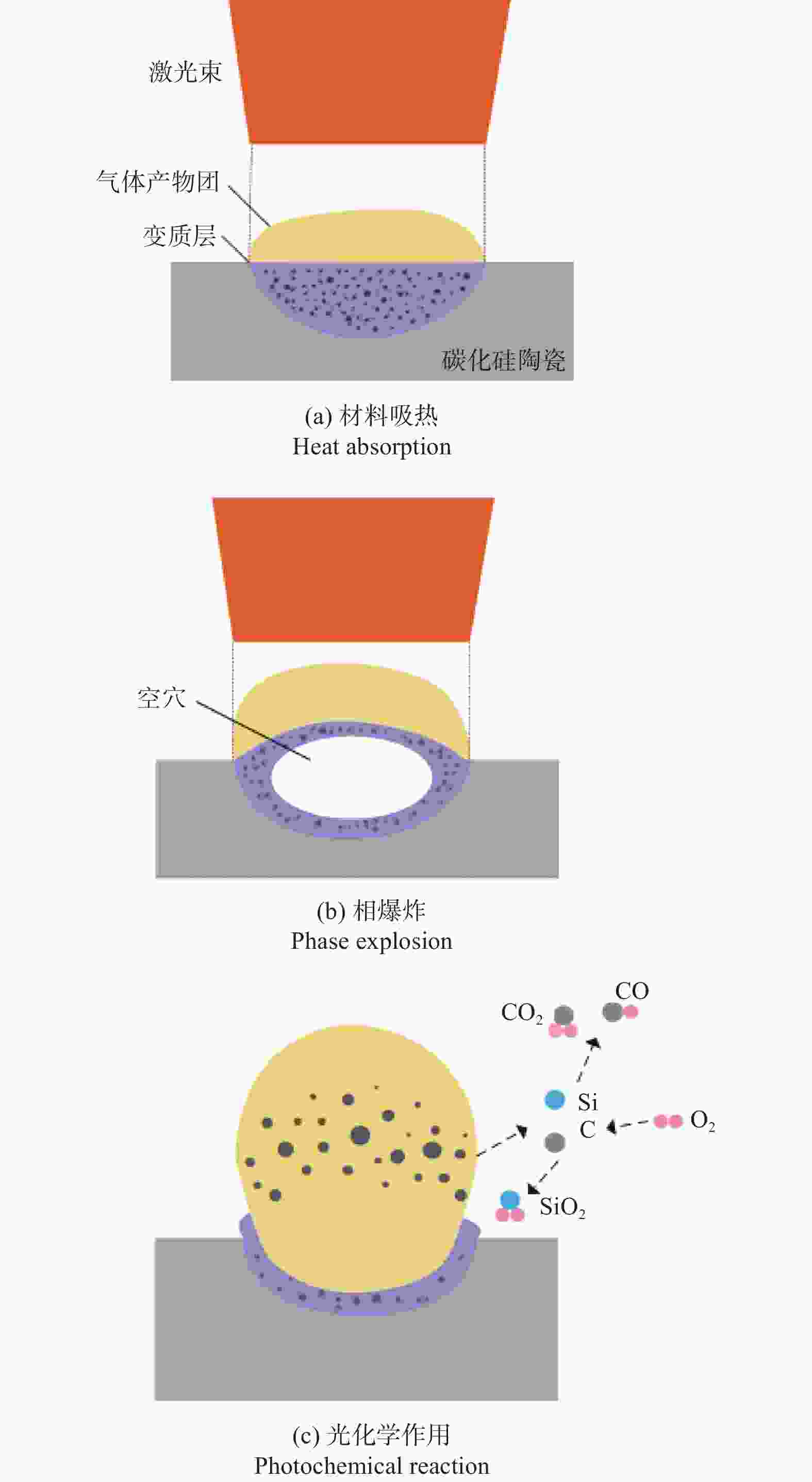

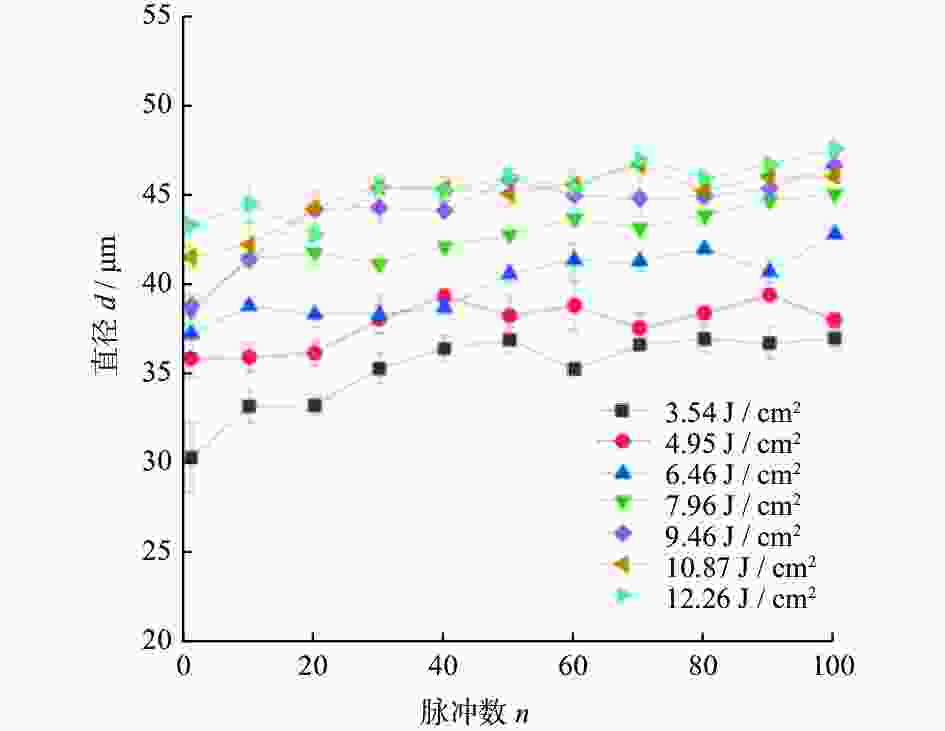

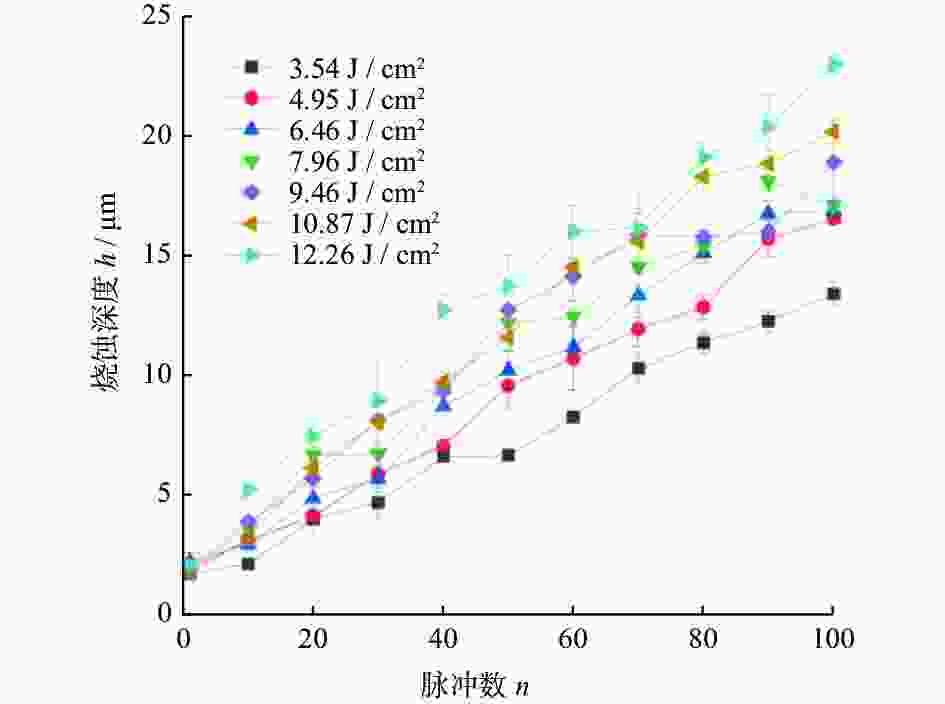

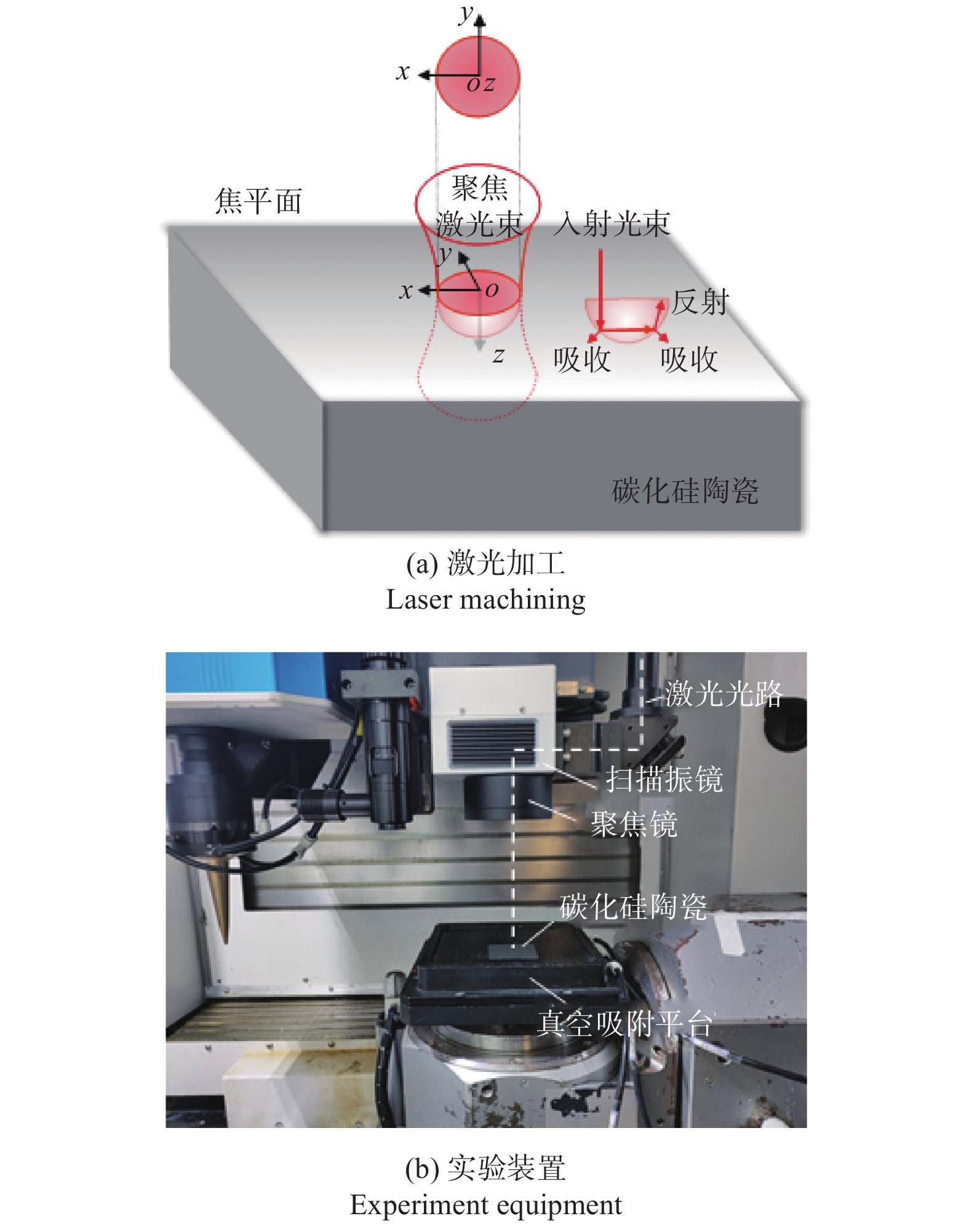

摘要: 硬脆材料超快激光加工可有效抑制加工损伤,是碳化硅陶瓷精密加工的重要手段。采用飞秒激光,在不同能量密度和脉冲数下对碳化硅陶瓷进行加工,探究激光参数对其表面形貌特征、化学组分和微孔加工的影响,分析表面微观结构的演变规律和材料去除过程。结果表明:单脉冲加工碳化硅陶瓷表面形成沸腾区和熔化区,计算得到形成特征区的阈值能量分别为3.779、0.860 J/cm2;碳化硅陶瓷的去除过程是光热作用和光化学作用先后作用的结果,在温度较高的中心区域的作用机制是材料的蒸发作用,其他低温区域则是材料的热分解和氧化;微孔直径和烧蚀深度随着能量密度和脉冲数量的增大而增大。本研究从材料物理化学特性变化角度进一步完善了碳化硅陶瓷飞秒激光加工机理,为碳化硅陶瓷零部件的精密无损伤加工应用提供理论参考。Abstract: Objectives : Silicon carbide ceramics, as a typical hard and brittle material, are difficult to process, with challenges such as low efficiency, significant tool wear, and poor surface quality during processing. Ultrafast laser processing can effectively inhibit the processing damage, which is an important method for the precision processing of silicon carbide ceramics. However, existing research on femtosecond laser processing of silicon carbide primarily focuses on the laser ablation characteristics of the material. The specific removal process of the material, in relation to the composition distribution and laser ablation mechanism, is still lacking in the relevant research. This paper analyzes the microstructure of the surface of silicon carbide ceramics processed by femtosecond laser pulses and its evolution law. It reveals the material removal process by examining the changes in chemical components in the ablation area, further improving the femtosecond laser processing mechanism of silicon carbide ceramics from the perspective of changes in material's physicochemical properties. Methods : Under the premise of a fixed laser repetition frequency, the silicon carbide ceramics were processed by varying the laser energy density and the number of pulses. The changes in the physical and chemical properties of silicon carbide were observed and analyzed. A field emission scanning electron microscope was used to observe the microscopic morphology of the processed surface, while a matching energy spectrum analyzer was used to analyze the composition of the processed area. Additionally, X-ray photoelectron spectroscopy was employed to detect the chemical components of the surface before and after processing. A field emission transmission electron microscope was used to detect the cross-sectional morphology of the microstructure. An OLS4100 confocal laser microscope was used to scan the three-dimensional morphology of the micropores formed by the pulsed processing, measuring the diameter and depth of the micropores. The diameter and depth of the micropores were measured. Results : It was found that when femtosecond laser processing silicon carbide ceramics with a single pulse at low energy density, the surface of the processed ceramic was slightly ablated, forming a melting characteristic zone. At high energy density, localized high temperatures were generated in the central processed area, reaching the boiling point of the material, leading to the boiling of the material and the formation of a boiling characteristic zone. Simultaneously, due to the relatively lower energy in the edge area, the material melted, forming a melting characteristic zone. The surface morphology of the boiling region mainly consisted of gasification pits and micro-projectile structures formed by gasification, while the morphology of the melting region was not obvious, with the local appearance of unclear contours of a periodic stripe structure. Using the radius of the feature area and the Gaussian laser intensity function, the evaporation and melting thresholds for the formation of the boiling and melting zones were calculated to be 3.779 J/cm2 and 0.860 J/cm2, respectively. Under the influence of multi-pulse laser processing, the morphology of the processed area was primarily striped when the laser energy was between the melting and evaporation thresholds, with coarse stripe structures in the central area and fine stripe structures in the edge area. The center region produced coarse streaks, and fine streaks were produced in the edge region. When the laser energy exceeded the evaporation threshold, the central region's structural appeared as a hole structure formed by vaporization, followed by the formation of concentric coarse and fine stripe structures extending to the edge region. As the laser energy density and the number of pulses increased, the micropore diameter and ablation depth exhibited an increasing trend, with the micropore diameter leveling off after an energy density of 9.46 J/cm2 and 50 pulses. Phase explosion performed a shielding effect on oxygen and material oxidation reactions; due to the decreasing distribution of laser energy and temperature from the center to the edge of the laser beam, the extent of the phase explosion decreased. In the central region, oxygen in the air did not center the material, while in the middle to the edge regions, exposure to oxygen increased, resulting in an increasing trend in oxygen content from the center to the edge. Meanwhile, through transmission and compositional analysis, it was found that the material subjected to laser action produced a metamorphic layer in the depth direction, showing a distribution pattern of an oxide layer-C-rich layer-silicon carbide matrix. Conclusions : This article investigates the ablation mechanism of silicon carbide ceramics processed by femtosecond laser. In terms of the removal process, laser removal of silicon carbide ceramics is a process in which photothermal and photochemical effects act sequentially. The laser beam irradiates the surface of the material, and the absorbed energy causes an internal temperature rise, accelerating atomic movement. As the energy continues to increase, it leads to a plasma phase explosion of the material, which jets outward, allowing oxygen from the air to react chemically within the material, completing the removal process. In terms of pulse processing, two characteristic regions, boiling and melting, are formed in the ablation region under the action of a Gaussian beam when processing with a single pulse. The evaporation threshold and the melting threshold of the characteristic region are 3.779 J /cm2 and 0.860 J/cm2, respectively. During multi-pulse processing, when the laser energy is between the melting and the boiling thresholds, the generation of structural defects in the hole structure can be avoided. The temperature of the ablation region decreases from the center of the laser beam to the edge region. In the high-temperature area, the material removal mechanism is primarily direct evaporation of the matrix, while in the low-temperature region, it is the thermal decomposition of the material and the oxidation reaction. This results in the formation of microstructures in the ablation region that are consistent from the center to the edge during multi-pulse processing.

-

Key words:

- SiC ceramics /

- femtosecond laser /

- ablation characteristics /

- removal process /

- micropores

-

图 3 飞秒激光单脉冲加工碳化硅陶瓷的特征区及形貌特征

(a) 沸腾区; (b) 沸腾区形貌特征; (c) 熔化区; (d) 熔化区形貌特征

Figure 3. Characteristic zone of silicon carbide ceramics processed by single pulse of femtosecond laser and morphological characteristics

(a) Boiling zone; (b) Morphological characteristics of boiling zone; (c) Melting zone; (d) Morphological characteristics of melting zone

-

[1] 李辰冉, 谢志鹏, 康国兴, 等. 国内外碳化硅陶瓷材料研究与应用进展 [J]. 硅酸盐通报,2020,39(5):1353-1370. doi: 10.16552/j.cnki.issn1001-1625.2020.05.001LI Chenran, XIE Zhipeng, KANG Guoxing, et al. Research and application progress of SiC ceramics: A review [J]. Bulletin of the Chinese Ceramic Society,2020,39(5):1353-1370. doi: 10.16552/j.cnki.issn1001-1625.2020.05.001 [2] WILLANDER M, FRIESEL M, WAHAB Q, et al. Silicon carbide and diamond for high temperature device applications [J]. Journal of Materials Science:Materials in Electronics,2006,17:1-25. [3] NASLAIN R, GUETTE A, REBILLAT F, et al. Boron-bearing species in ceramic matrix composites for long-term aerospace applications [J]. Journal of Solid State Chemistry,2004,177(2):449-456. doi: 10.1016/j.jssc.2003.03.005 [4] AMSELLEM W, SARVESTANI H Y, PANKOV V, et al. Deep precision machining of SiC ceramics by picosecond laser ablation [J]. Ceramics International,2023,49(6):9592-9606. doi: 10.1016/j.ceramint.2022.11.129 [5] GOEL S. The current understanding on the diamond machining of silicon carbide [J]. Journal of Physics D:Applied Physics,2014,47(24):243001. doi: 10.1088/0022-3727/47/24/243001 [6] QU S, GONG Y, YANG Y, et al. Surface topography and roughness of silicon carbide ceramic matrix composites [J]. Ceramics International,2018,44(12):14742-14753. doi: 10.1016/j.ceramint.2018.05.104 [7] LIN Q, FAN Z J, WANG W, et al. The effect of spot overlap ratio on femtosecond laser planarization processing of SiC ceramics [J]. Optics & Laser Technology,2020,129:106270. [8] 赵清亮, 姜涛, 董志伟, 等. 飞秒激光加工SiC的烧蚀阈值及材料去除机理 [J]. 机械工程学报,2010,46(21):172-177. doi: 10.3901/JME.2010.21.172ZHAO Qingliang, JIANG Tao, DONG Zhiwei, et al. Ablation threshold and material removal mechanisms of SiC processed by femtosecond laser [J]. Journal of Mechanical Engineering,2010,46(21):172-177. doi: 10.3901/JME.2010.21.172 [9] 李卫波. 飞秒激光抛光碳化硅陶瓷材料的工艺过程研究[D]. 哈尔滨: 哈尔滨工业大学, 2011.LI Weibo. Research on femtosecond laser purse polishing of silicon carbide ceramic material [D]. Harbin: Harbin Institute of Technology, 2010 [10] DONG Y Y, MOLIAN P. Femtosecond pulsed laser ablation of 3CSiC thin film on silicon [J]. Applied Physics A,2003,77:839-846. doi: 10.1007/s00339-003-2103-y [11] 李俭国. 超快激光诱导碳化硅表面改性机理研究[D]. 广州: 广东工业大学, 2020.LI Jianguo. Study on mechanism of ultra-fast laser induced modification of silicon carbide[D]. Guangzhou: Guangdong University of Technology, 2020 [12] 李晓宇, 孙会来, 赵方方, 等. 飞秒激光加工SiC模型参数优化设计研究 [J]. 激光与红外,2016,46(8):948-952.LI Xiaoyu, SUN Huilai, ZHAO Fangfang, et al. Research on parameters optimization design of femtosecond laser machining SiC model [J]. Laser & Infrared,2016,46(8):948-952. [13] 王金舵. 超短脉冲激光与碳化硅相互作用研究 [J]. 科技创新与应用,2022,12(22):79-82+86.WANG Jinduo. A study of the interaction between ultrashort pulse laser and silicon carbide [J]. Technology Innovation and Application,2022,12(22):79-82+86. [14] SHI H, SONG Q, HOU Y, et al. Investigation of structural transformation and residual stress under single femtosecond laser pulse irradiation of 4H–SiC [J]. Ceramics International,2022,48(17):24276-24282. doi: 10.1016/j.ceramint.2022.03.063 [15] ŽEMAITIS A, GAIDYS M, BRIKAS M, et al. Advanced laser scanning for highly-efficient ablation and ultrafast surface structuring: Experiment and model [J]. Scientific Reports,2018,8(1):17376. doi: 10.1038/s41598-018-35604-z [16] VARLAMOVA O, COSTACHE F, REIF J, et al. Self-organized pattern formation upon femtosecond laser ablation by circularly polarized light [J]. Applied Surface Science,2006,252(13):4702-4706. doi: 10.1016/j.apsusc.2005.08.120 [17] HIKAGE H, NOSAKA N, MATSUO S. High-spatial-frequency periodic surface structures on steel substrate induced by subnanosecond laser pulses [J]. Applied Physics Express,2017,10(11):112701. doi: 10.7567/APEX.10.112701 [18] ZHANG Q, WANG C, LIU Y, et al. Picosecond laser machining of deep holes in silicon infiltrated silicon carbide ceramics [J]. Journal of Wuhan University of Technology-Mater. Sci. Ed.,2015,30(3):437-441. doi: 10.1007/s11595-015-1167-9 [19] READY J F. Effects due to absorption of laser radiation [J]. Journal of Applied Physics,1965,36(2):462-468. doi: 10.1063/1.1714012 [20] DENG H, UEDA M, YANANURA K. Characterization of 4H-SiC (0001) surface processed by plasma-assisted polishing[J]. International Journal of Advanced Manufacturing Technology, 2014, 72:156-159. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS