Wear prediction of micro-grinding tool based on GA-BP neural network

-

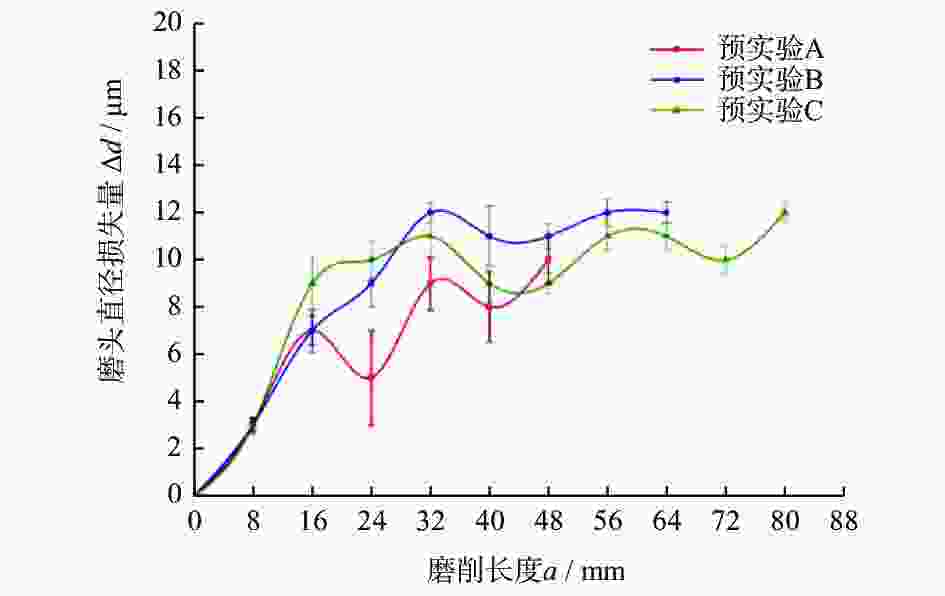

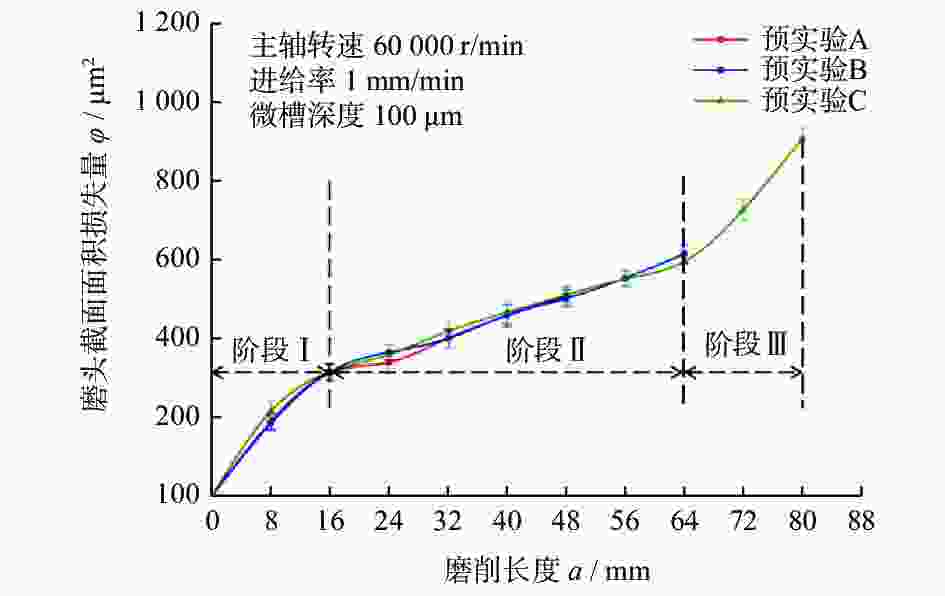

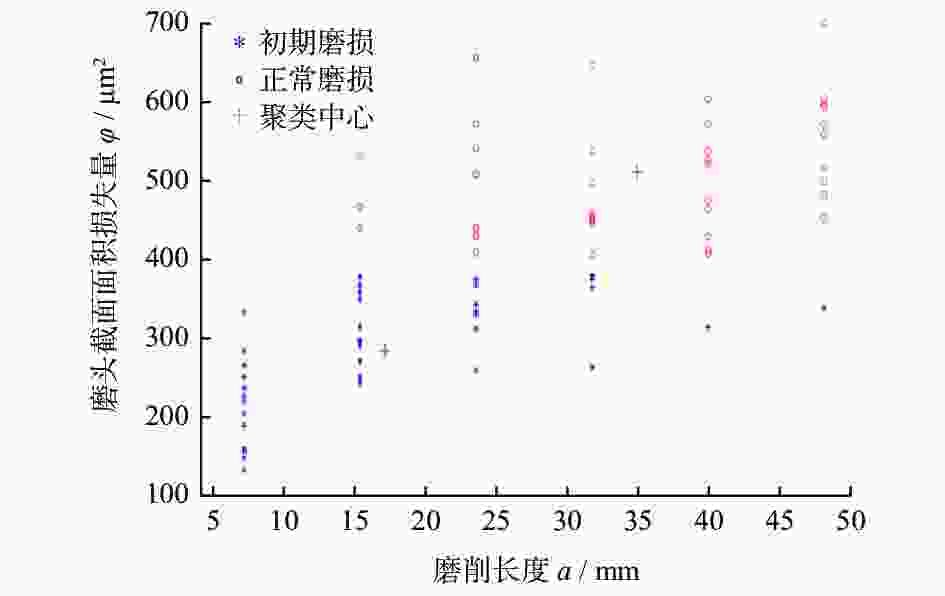

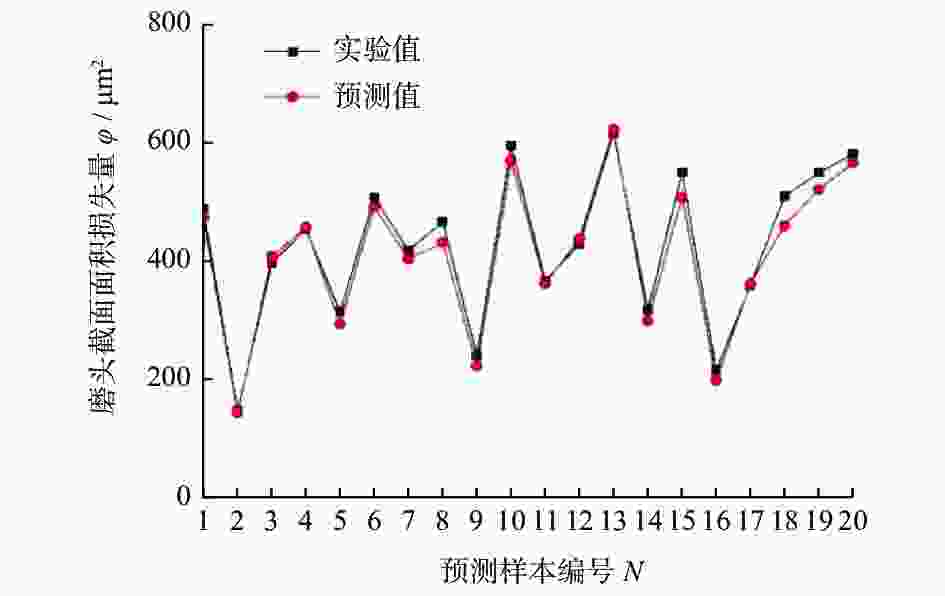

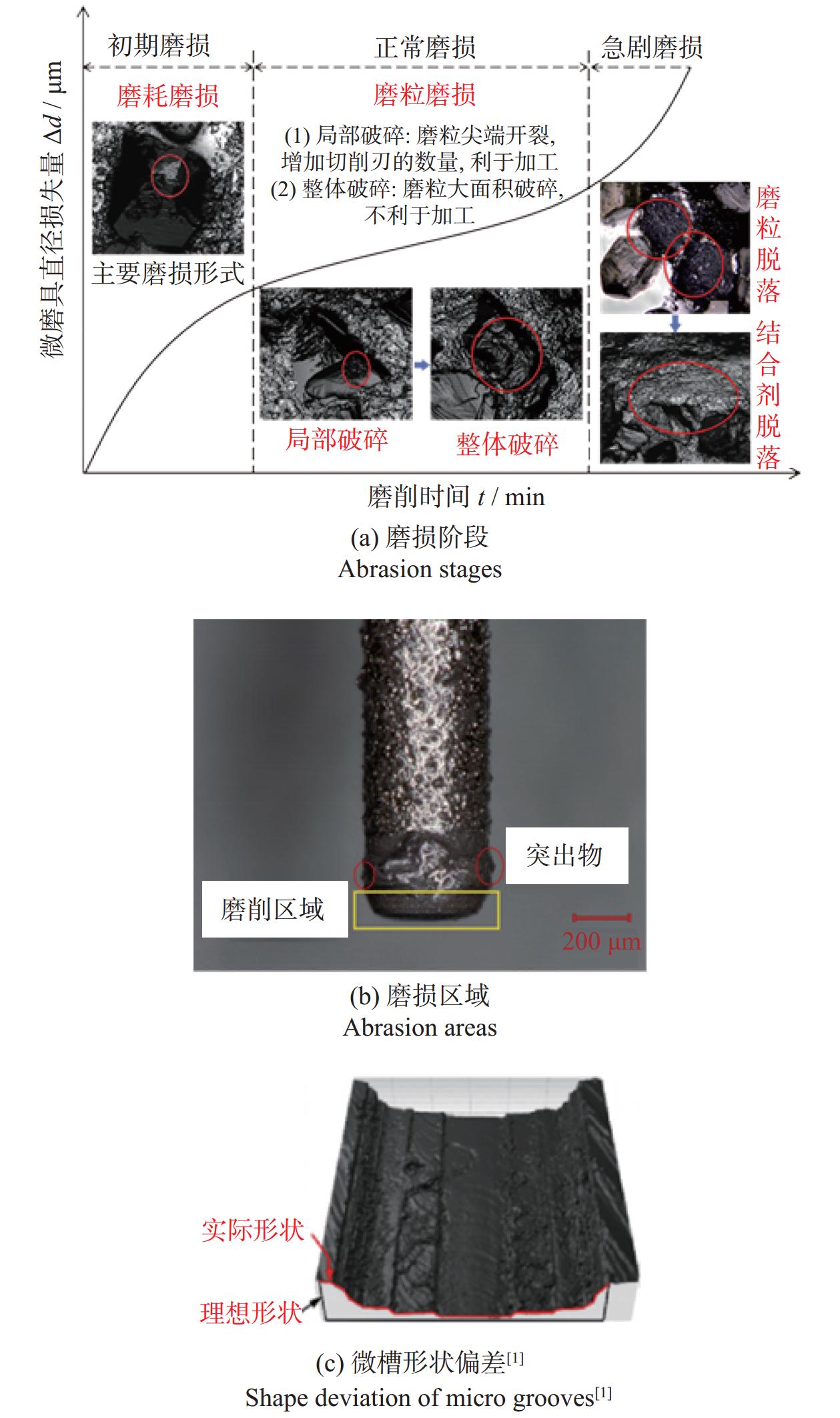

摘要: 为提高硬脆材料微结构的加工效率和精度,需要预测微磨具的不确定性磨损。基于微磨具在位视觉磨损检测和聚类分析,提出基于遗传算法的反向神经网络(genetic algorithm back propagation,GA-BP)模型。选取微磨具磨头截面面积损失量为指标,以表征微磨具不确定性磨损特征。利用K-均值聚类算法划分微磨具磨损状态阶段。最后构建以主轴转速、进给率、微槽深度、磨削长度和微磨具初始截面面积为输入层神经元,以磨头截面面积损失量预测值为输出层的GA-BP神经网络模型。设计不同工艺参数条件下的单晶硅微槽微细磨削实验,基于自搭建的机器视觉系统在位测量微磨具的磨头截面面积磨损量。将实验测得的微磨具磨损量作为训练数据,与传统高斯过程回归预测模型对比,验证GA-BP神经网络模型的有效性和准确性。结果表明,GA-BP神经网络模型能够实现不同工艺参数和不同磨削长度下的微磨具磨损预测,比传统高斯过程回归预测模型具有更高预测精度,平均误差精度达到5%,可以实现微磨具磨损阶段状态预测。Abstract: An intelligent tool wear prediction model has been proposed for the micro-grinding tool, optimized using a genetic algorithm (GA) based BP neural network. The GA-BP prediction model is applied with in-situ tool wear detection to obtain training set data and combines cluster analysis to divide the tool wear stages. To represent the uncertainty in wear characteristics, the loss of cross-sectional area of the micro-grinding tool has been selected as an index to evaluate tool wear loss. The K-means clustering algorithm is used to cluster and analyze the tool wear stages under different process parameters. The GA-BP neural network includes five neurons in the input layer: rotating speed, feed rate, cutting depth, grinding length, and the initial cross-sectional area of the tool. The output layer neuron predicts the loss of the tool's cross-sectional area. To validate the method, a series of micro-grinding experiments were performed under different parameters for the micro-groove array of monocrystalline silicon. The loss of the tool's cross-sectional area was measured by a self-made visual inspection system, providing learning samples for the prediction model. The predicted results of the GA-BP neural network model were compared with the traditional Gaussian process regression method. The results show that the GA-BP neural network model can correctly predict tool wear loss and identify wear stages under different process parameters and grinding lengths. It has higher prediction accuracy during the self-learning process, with an average error of 5% .

-

Key words:

- micro-grinding tools /

- wear prediction /

- GA-BP neural network /

- cluster analysis

-

表 1 微磨具磨头直径

Table 1. Diameter of micro-grinders

微槽数 预实验A dA / μm 预实验B dB / μm 预实验C dC / μm 0 414 423 413 1 411 421 410 2 407 416 404 3 409 414 403 4 405 411 402 5 406 412 404 6 404 412 404 7 - 411 402 8 - 411 402 9 - - 403 10 - - 401 表 2 微磨具磨头截面面积

Table 2. Cross-sectional area of micro-grinders

微槽数 预实验A SA / μm2 预实验B SB / μm2 预实验C SC / μm2 0 35099.90 36334.72 35005.37 1 34911.55 36150.37 34790.47 2 34787.20 36019.83 34690.84 3 34760.29 35969.66 34646.12 4 34699.21 35934.75 34586.85 5 34642.48 35875.12 34538.49 6 34591.21 35832.94 34494.86 7 - 35780.94 34454.13 8 - 35720.22 34409.41 9 - - 34275.97 10 - - 34096.34 表 3 工艺实验参数表

Table 3. Processing parameters

组号 主轴转速n / (r·min−1) 进给率vf / (mm·min−1) 微槽深度h / μm 1 20000 1.0 100 2 40000 1.0 100 3 60000 1.0 100 4 80000 1.0 100 5 100000 1.0 100 6 60000 0.4 100 7 60000 0.7 100 8 60000 1.3 100 9 60000 1.6 100 10 60000 1.0 50 11 60000 1.0 80 12 60000 1.0 150 13 60000 1.0 200 14 60000 1.0 250 15 60000 0.5 200 表 4 不同隐含层节点数的网络模型误差精度

Table 4. Error accuracy of network model with different number of hidden layer nodes

隐含层节点数 N 均方误差 4 0.0126 5 0.0111 6 0.0070 7 0.0045 8 0.0020 9 0.0061 10 0.0085 11 0.0062 12 0.0031 -

[1] AURICH J C, KIRSCH B, SETTI D, et al. Abrasive processes for micro parts and structures [J]. CIRP Annals-Manufacturing Technology,2019,68:653-676. doi: 10.1016/j.cirp.2019.05.006 [2] PARK H W, LIANG S Y. Force modeling of micro-grinding incorporating crystallographic effects [J]. International Journal of Machine Tools and Manufacture,2008,48(15):1658-1667. doi: 10.1016/j.ijmachtools.2008.07.004 [3] 李伟, 周志雄, 尹韶辉, 等. 微细磨削技术及微磨床设备研究现状分析与探讨[J]. 机械工程学报, 2016, 52(17): 10-19. doi: 10.3901/JME.2016.17.010LI Wei, ZHOU Zhixiong, YIN Shaohui, et al. Research status analysis and review of micro-grinding technology and micro-grinding machines[J]. Journal of Mechanical Engineering, 2016, 52(17): 10-19. doi: 10.3901/JME.2016.17.010 [4] REN Y, LI C, LI W, et al. Study on micro-grinding quality in micro-grinding tool for single crystal silicon [J]. Journal of Manufacturing Processes,2019,42:246-256. doi: 10.1016/j.jmapro.2019.04.030 [5] LI W, REN Y, LI C, et al. Investigation of machining and wear performance of various diamond micro-grinding tools [J]. International Journal of Advanced Manufacturing Technology,2020,106(3):921-935. doi: 10.1007/s00170-019-04610-4 [6] 温雪龙, 巩亚东, 程军, 等. 电镀金刚石微磨具磨损机理分析与试验研究 [J]. 机械工程学报,2015,51(11):177-185. doi: 10.3901/JME.2015.11.177WEN Xuelong, GONG Yadong, CHENG Jun, et al. Mechanism analysis and experimental research on wear of electroplated diamond micro-grinding tool [J]. Journal of Mechanical Engineering,2015,51(11):177-185. doi: 10.3901/JME.2015.11.177 [7] KIRSCH B, BOHLEY M, ARRABIYEH P A, et al. Application of ultra-small micro grinding and micro milling tools [J]. Micromachines,2017,8(9):261. doi: 10.3390/mi8090261 [8] LI X, LIU X, YUE C, et al. Systematic review on tool breakage monitoring techniques in machining operations [J]. International Journal of Machine Tools & Manufacture,2022,176:103882. doi: 10.1016/j.ijmachtools.2022.103882 [9] 刘献礼, 李雪冰, 丁明娜, 等. 面向智能制造的刀具全生命周期智能管控技术 [J]. 机械工程学报,2021,57(10):196-219. doi: 10.3901/JME.2021.10.196LIU Xianli, LI Xuebing, DING Mingna, et al. Intelligent management and control technology of cutting tool life-cycle for intelligent manufacturing [J]. Journal of Mechanical Engineering,2021,57(10):196-219. doi: 10.3901/JME.2021.10.196 [10] NOURI M, FUSSELL B K, ZINITI B L, et al. Real-time tool wear monitoring in milling using a cutting condition independent method [J]. International Journal of Machine Tools and Manufacture,2015,89:1-13. doi: 10.1016/j.ijmachtools.2014.10.011 [11] MEI Y, YU Z, YANG Z. Experimental investigation of correlation between attrition wear and features of acoustic emission signals in single-grit grinding [J]. The International Journal of Advanced Manufacturing Technology,2017,93(5):2275-2287. doi: 10.1007/s00170-017-0687-1 [12] XIE Z, LI J, LU Y. An integrated wireless vibration sensing tool holder for milling tool condition monitoring [J]. International Journal of Advanced Manufacturing Technology,2018,95(5):2885-2896. doi: 10.1016/j.measurement.2021.109038 [13] GARCIA-ORDAS M T, ALEGRE E, GONZALEZ-CASTRO V, et al. A computer vision approach to analyze and classify tool wear level in milling processes using shape descriptors and machine learning techniques [J]. International Journal of Advanced Manufacturing Technology,2017,90(5):1947-1961. doi: 10.1007/s00170-016-9541-0 [14] MIKOLAJCZYK T, NOWICKI K, KLODOWSKI A, et al. Neural network approach for automatic image analysis of cutting edges wear [J]. Mechanical Systems and Signal Processing,2017,88(5):100-110. doi: 10.1016/j.ymssp.2016.11.026 [15] XU L, NIU M, ZHAO D, et al. Methodology for the immediate detection and treatment of wheel wear in contour grinding [J]. Precision Engineering,2019,60:405-412. doi: 10.1016/j.precisioneng.2019.09.006 [16] LI L, AN Q. An in-depth study of tool wear monitoring technique based on image segmentation and texture analysis [J]. Measurement,2016,79:44-52. doi: 10.1016/j.measurement.2015.10.029 [17] KONG D, CHEN Y, LI N. Gaussian process regression for tool wear prediction [J]. Mechanical systems and signal processing,2018,104:556-574. doi: 10.1016/j.ymssp.2017.11.021 [18] 刘强. 刀具磨损的偏最小二乘回归分析与建模 [J]. 北京航空航天大学学报,2000,26(4):457-460. doi: 10.3969/j.issn.1001-5965.2000.04.023LIU Qiang. Pratial least squares regressive analysis and modeling for tool wear [J]. Journal of Beijing University of Aeronautics and Astronautics,2000,26(4):457-460. doi: 10.3969/j.issn.1001-5965.2000.04.023 [19] 张锴锋, 袁惠群, 聂鹏. 基于广义维数与优化BP神经网络的刀具磨损量预测 [J]. 东北大学学报(自然科学版),2013,34(9):1292-1295. doi: 10.3969/j.issn.1005-3026.2013.09.018ZHANG Kaifeng, YUAN Huiqun, NIE Peng. Prediction of tool wear based on generalized dimensions and optimized BP neural network [J]. Journal of Northeastern University (Natural Science),2013,34(9):1292-1295. doi: 10.3969/j.issn.1005-3026.2013.09.018 [20] LI J, LU J, CHEN C, et al. Tool wear state prediction based on feature-based transfer learning [J]. International Journal of Advanced Manufacturing Technology,2021,113(11):3283-3301. doi: 10.1007/s00170-021-06780-6 [21] 史珂铭, 邹益胜, 刘永志, 等. 一种不同工艺条件下刀具磨损状态多类域适应迁移辨识方法 [J]. 中国机械工程,2022,33(15):1841-1849. doi: 10.3969/j.issn.1004-132X.2022.15.010SHI Keming, ZOU Yisheng, LIU Yongzhi, et al. A multi class domain adaptive transfer identification method for tool wear states under different processing conditions [J]. China Mechanical Engineering,2022,33(15):1841-1849. doi: 10.3969/j.issn.1004-132X.2022.15.010 [22] 何彦, 凌俊杰, 王禹林, 等. 基于长短时记忆卷积神经网络的刀具磨损在线监测模型 [J]. 中国机械工程,2020,31(16):1959-1967. doi: 10.3969/j.issn.1004-132X.2020.16.008HE Yan, LING Junjie, WANG Yulin, et al. In-process tool wear monitoring model based on LSTM-CNN [J]. China Mechanical Engineering,2020,31(16):1959-1967. doi: 10.3969/j.issn.1004-132X.2020.16.008 [23] 万鹏, 李迎光, 刘长青, 等. 基于域对抗门控网络的变工况刀具磨损精确预测方法 [J]. 航空学报,2021,42(10):524879.WAN Peng, LI Yingguang, LIU Changqing, et al. Method for accurate prediction of tool wear under varying cutting conditions based on domain adversarial gating neural network [J]. Acta Aeronautica et Astronautica Sinica,2021,42(10):524879. [24] MINH H L, SANG T T, ABDEL W M, et al. A new metaheuristic optimization based on K-means clustering algorithm and its application to structural damage identification [J]. Knowledge-Based Systems,2022,251:109189. doi: 10.1016/j.knosys.2022.109189 [25] YANG Y, LIAO Q, WANG J, et a. Application of multi-objective particle swarm optimization based on short-term memory and K-means clustering in multi-modal multi-objective optimization [J]. Engineering Applications of Artificial Intelligence,2022,112:104866. doi: 10.1016/j.engappai.2022.104866 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS