Comparative experimental study on edge machining of carbide end milling cutter with different tool passivation methods

-

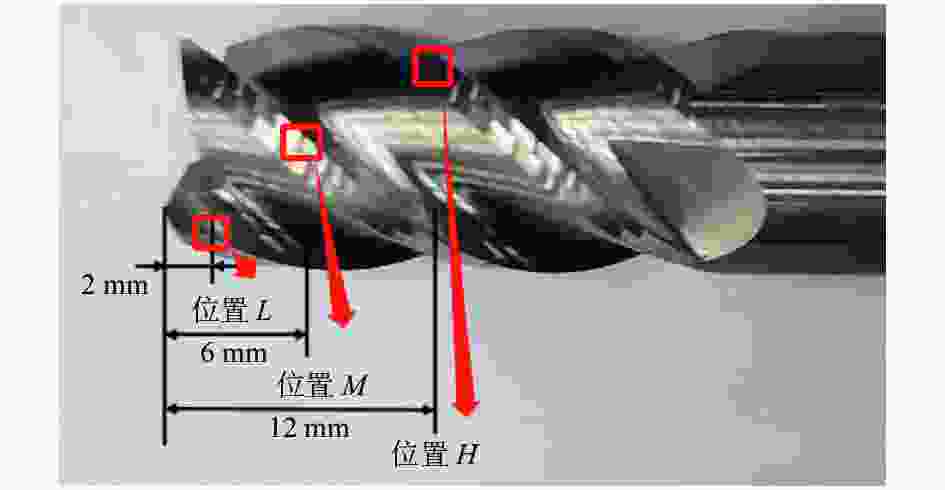

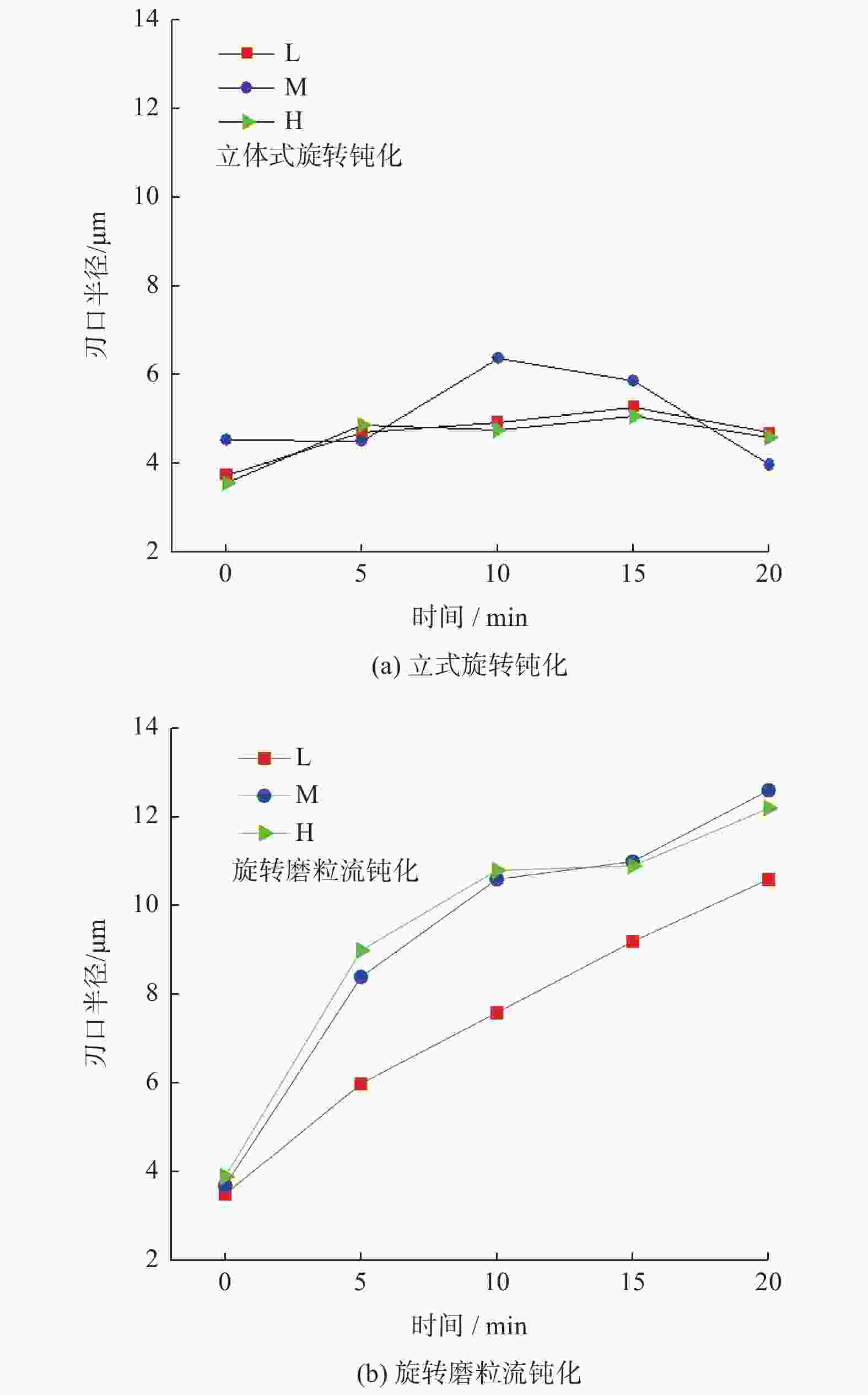

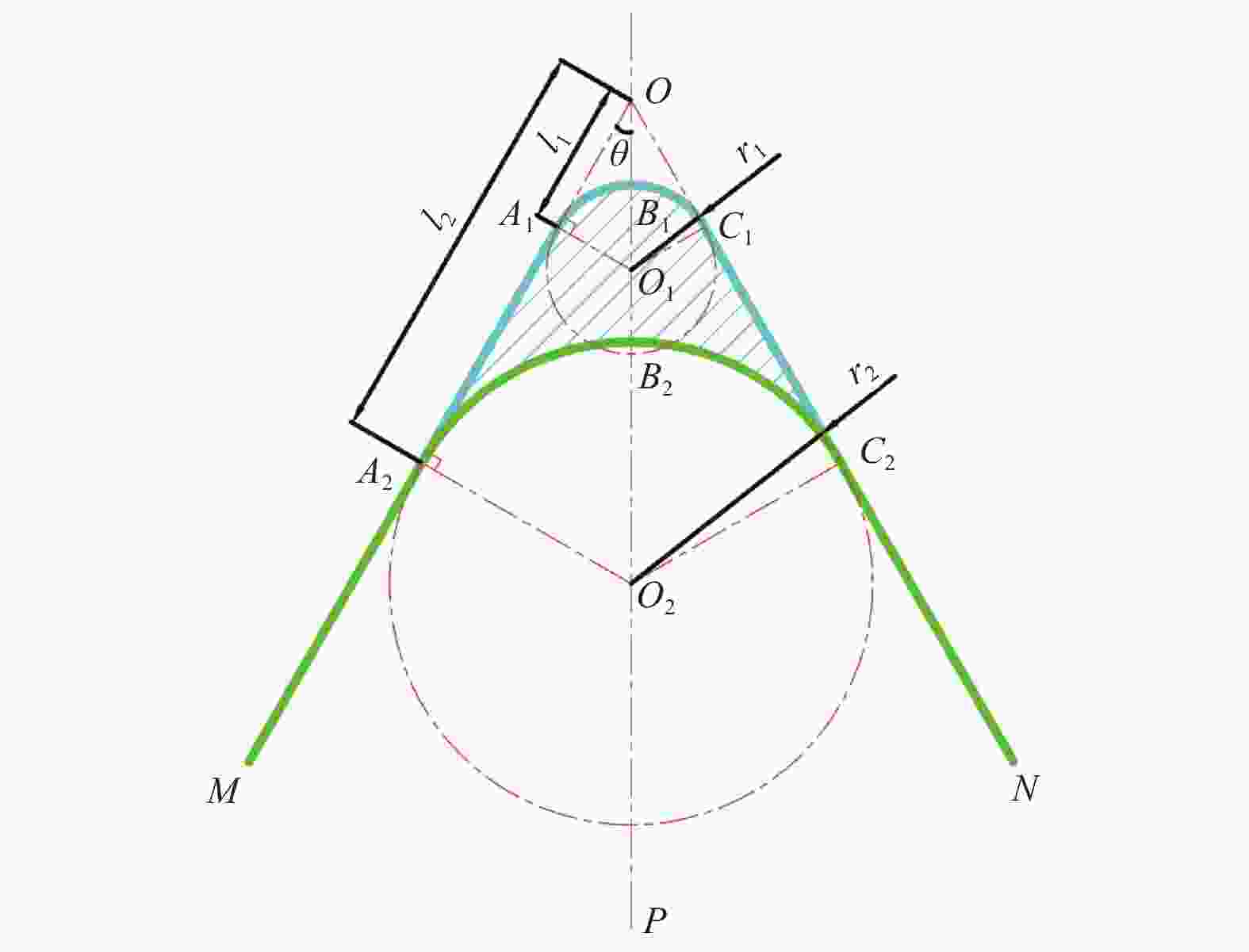

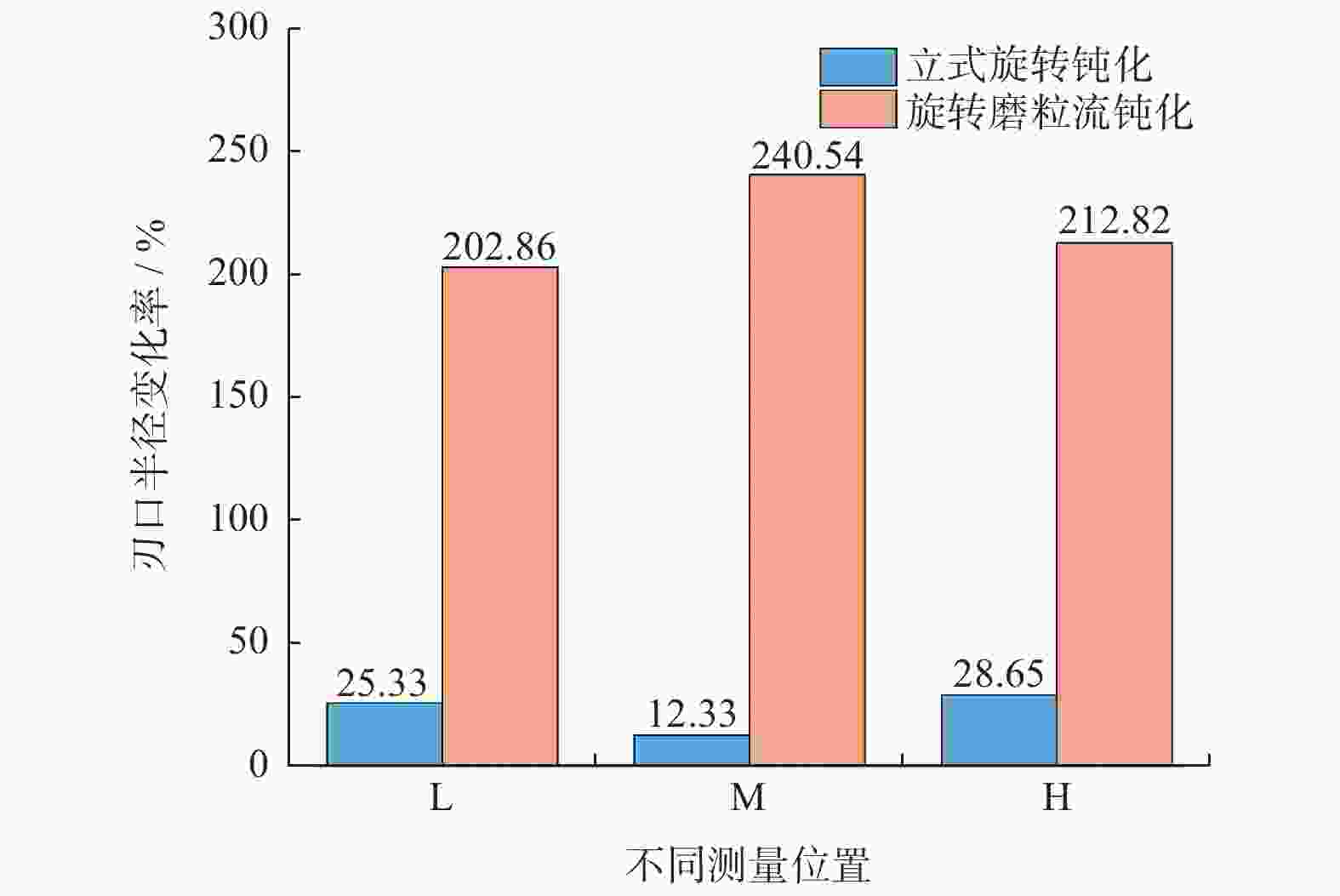

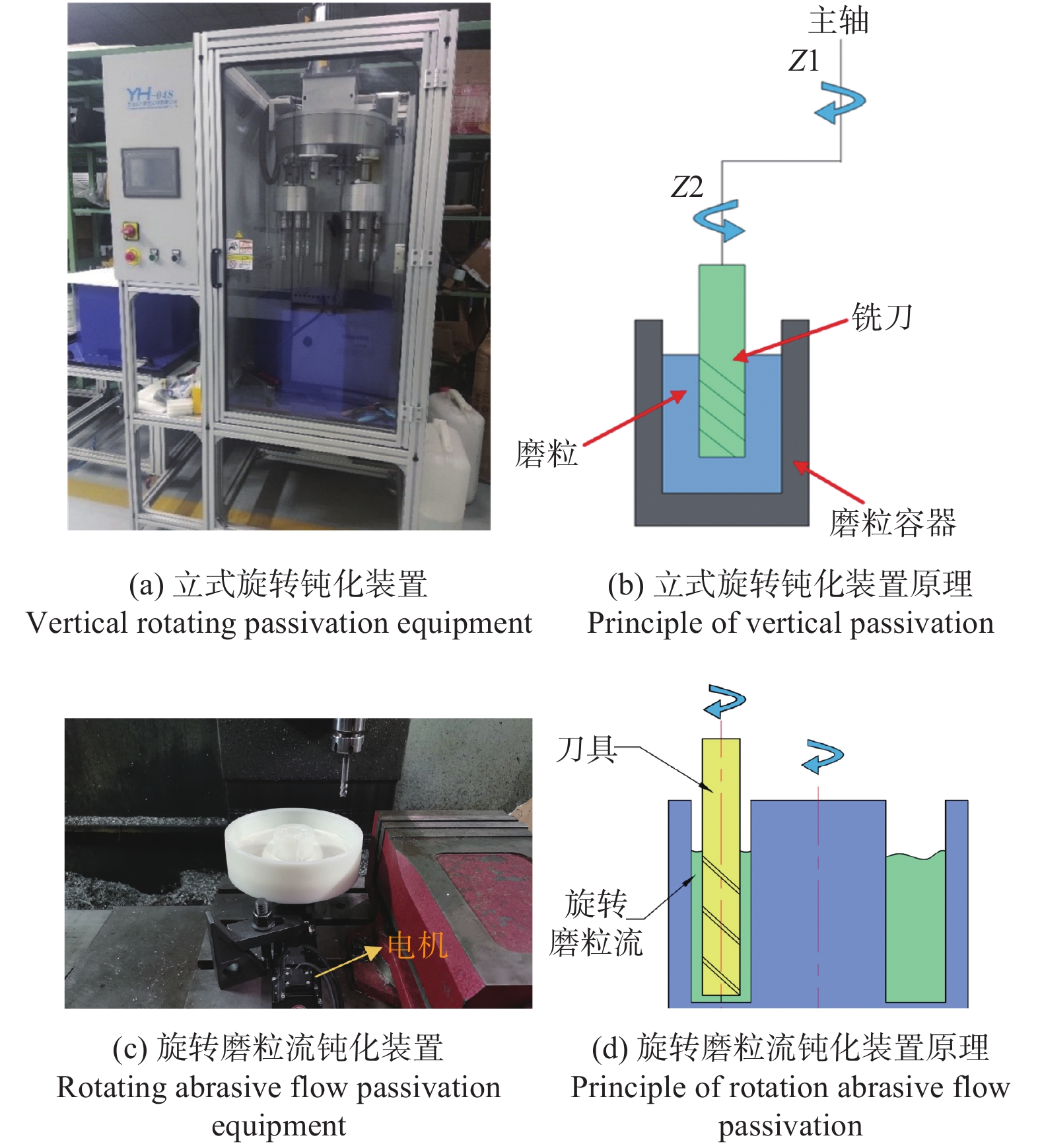

摘要: 为改善刀具性能、提升加工质量,采用旋转磨粒流对刀具钝化。通过对比立式旋转钝化法和旋转磨粒流钝化法钝化硬质合金立铣刀的效果,研究刀具刃口变化规律。试验结果表明:未钝化的刀具刃口半径值最小,且存在很多缺陷,刃型呈尖锐形;立式旋转钝化法得到的刃口半径值变化较小,但刀具刃口缺陷仍然存在,刃型呈不均匀的钝圆形;旋转磨粒流钝化法处理后的刃口半径值变化最大,去除了部分刃口缺陷,刃型呈均匀的钝圆形。旋转磨粒流钝化法不仅可以更好地去除刀具刃口的表面缺陷,同时有着更高的钝化效率以及刃口半径变化率,可以显著提高刀具性能,降低刀具磨损并改善加工质量。Abstract: A tool passivation method called the rotating abrasive flow passivation method is proposed as a means to improve tool performance and processing quality. Experiments were conducted to compare the passivation of a carbide end milling cutter by vertical rotating passivation and rotating abrasive flow passivation, revealing the changing law of the tool edge. The results show that the original tool's edge has the smallest radius, characterized by a sharp edge with numerous defects. After vertical rotating passivation, there is slight change in the edge, but defects persist, and the blade shape remains unevenly blunt and circular. In contrast, As the edge after rotating abrasive flow passivation shows the most significant radius change, with some edge defects removed, resulting in a uniformly blunt circular edge shape. The rotating abrasive flow passivation method can not only eliminates edge defects but also presents higher passivation efficiency and a greater rate of change in the cutting edge radius. This method can significantly enhance tool performance, reduce tool wear, and improve machining quality.

-

Key words:

- tool edge passivation /

- rotary abrasive flow /

- edge radius /

- edge morphology

-

表 1 刀具钝化方式

刀具编号 钝化方式 M1 立式旋转钝化 M2 旋转磨粒流钝化 表 2 硬质合金立铣刀几何参数

刃数

n螺旋角

α0 / (°)后角

αr / (°)刃长

lb / mm刀长

lt / mm直径

dt / mm4 42 12 25 100 10 -

[1] 徐庆. 刃口钝化在刀具优化中的重要性 [J]. 金属加工(冷加工),2018,805(8):59-61. doi: 10.3969/j.issn.1674-1641.2018.08.025XU Qing. The importance of blade passivation in tools optimization [J]. Metal Working (Cold Machining),2018,805(8):59-61. doi: 10.3969/j.issn.1674-1641.2018.08.025 [2] 赵倩, 赖志伟, 刘小杰, 等. 刀具刃口钝化对刀具切削性能影响研究进展 [J]. 硬质合金,2020,37(5):378-389. doi: 10.3969/j.issn.1003-7292.2020.05.008ZHAO Qian, LAI Zhiwei, LIU Xiaojie, et al. Research progress on the influence of tool edge preparation on cutting performance [J]. Cemented Carbide,2020,37(5):378-389. doi: 10.3969/j.issn.1003-7292.2020.05.008 [3] 赵雪峰, 杜宇超, 吴志鹏. 钝化参数对刀具刃口钝圆半径影响的研究 [J]. 机械设计与制造,2020,349(3):131-133, 137. doi: 10.3969/j.issn.1001-3997.2020.03.031ZHAO Xuefeng, DU Yuchao, WU Zhipeng. Research on the influence of the edge preparation parameters on the edge radius [J]. Machinery Design & Manufacture,2020,349(3):131-133, 137. doi: 10.3969/j.issn.1001-3997.2020.03.031 [4] POKORNY P, PATOPRSTY B, VOPAT T, et al. Cutting edge radius preparation [J]. Materials Today:Proceedings,2020,22:212-218. doi: 10.1016/j.matpr.2019.08.090 [5] CHAN J, KOSHY P. Tool edge honing using shear jamming abrasive media [J]. CIRP Annals - Manufacturing Technology,2020,69(1):289-292. doi: 10.1016/j.cirp.2020.04.097 [6] LYU B H, HE Q K, CHEN S H, et al. Experimental study on shear thickening polishing of cemented carbide insert with complex shape [J]. International Journal of Advanced Manufacturing Technology,2019,103:585-595. doi: 10.1007/s00170-019-03600-w [7] WANG W T, BIERMANN D, AßMUT R, et al. Effects on tool performance of cutting edge prepared by pressurized air wet abrasive jet machining (PAWAJM) [J]. Journal of Materials Processing Technology,2020,277:116456. doi: 10.1016/j.jmatprotec.2019.116456 [8] WANG W T, SAIFULIAH K, ASSMUTH R B, et al. Effect of edge preparation technologies on cutting edge properties and tool performance [J]. The International Journal of Advanced Manufacturing Technology,2020,106(5/6):1823-1838. doi: 10.1007/s00170-019-04702-1 [9] SPAN J, KOSHY P, KLOCKE F, et al. Dynamic jamming in dense suspensions: Surface finishing and edge honing applications [J]. CIRP Annals,2017,66(1):321-324. doi: 10.1016/j.cirp.2017.04.082 [10] GE J, LI C, Gao Z, et al. Softness abrasive flow polishing method using constrained boundary vibration [J]. Powder Technology,2021,382:173-187. doi: 10.1016/j.powtec.2020.12.065 [11] 李敏, 吕冰海, 袁巨龙, 等. 剪切增稠抛光的材料去除数学模型 [J]. 机械工程学报,2016,52(7):142-151. doi: 10.3901/JME.2016.07.142LI Min, LÜ Binghai, YUAN Julong, et al. Material removal mathematics model of shear thickening polishing [J]. Journal of Mechanical Engineering,2016,52(7):142-151. doi: 10.3901/JME.2016.07.142 [12] 李敏, 袁巨龙, 吕冰海, 等. Si3N4陶瓷的剪切增稠抛光 [J]. 机械工程学报,2017,53(9):193-200. doi: 10.3901/JME.2017.09.193LI Min, YUAN Julong, LÜ Binghai, et al. Shear-thickening polishing of Si3N4 ceramics [J]. Journal of Mechanical Engineering,2017,53(9):193-200. doi: 10.3901/JME.2017.09.193 [13] LI M, LIU M, RIEMER O, et al. Origin of material removal mechanism in shear thickening-chemical polishing [J]. International Journal of Machine Tools and Manufacture,2021(170):1-19. [14] 李瑞, 李银燕. 磨粒对刀具刃口钝化影响 [J]. 现代机械,2017,197(1):26-29.LI Rui, LI Yinyan. The influence of abrasive on cutting edge dulling [J]. Modern Machinery,2017,197(1):26-29. [15] 游科, 赵雪峰, 袁银, 等. 双磁盘磁力钝化机理与实验研究 [J]. 组合机床与自动化加工技术,2022(10):133-135, 140.YOU Ke, ZHAO Xuefeng, YUAN Yin, et al. Mechanism and experimental study of double disk magnetic preparation [J]. Modular Machine Tool & Automatic Manufacturing Technique,2022(10):133-135, 140. [16] 高航, 郭天博, 彭灿, 等. 丝锥刀具旋转磨粒流去毛刺和钝化抛光技术的研究 [J]. 表面技术,2022,52(3):299-307.GAO Hang, GUO Tianbo, PENG Can, et al. Deburring and passivation polishing technology of tap tool with rotary abrasive flow [J]. Surface Technology,2022,52(3):299-307. [17] 师润平, 韩彦良, 韩春钰. 精切刀具柔性磨粒射流抛光(钝化)工艺研究 [J]. 制造技术与机床,2021,706(4):69-73.SHI Runping, HAN Yanliang, HAN Chunyu. Study on flexible abrasive jet polishing (passivation) process of fine cutting tools [J]. Manufacturing Technology & Machine Tool,2021,706(4):69-73. [18] 杜宇超, 赵雪峰, 何林. 气固两相磨粒流对刀具刃口钝化的数值模拟 [J]. 组合机床与自动化加工技术,2019(5):142-145, 151.DU Yuchao, ZHAO Xuefeng, HE Lin. Numerical simulation of tool edge preparation by gas-solid two-phase abrasive flow [J]. Modular Machine Tool & Automatic Manufacturing Technique,2019(5):142-145, 151. [19] 王林静, 张伟, 干为民, 等. 硬质合金刀具刃口钝化方式对比试验研究 [J]. 工具技术,2013,47(12):25-28. doi: 10.3969/j.issn.1000-7008.2013.12.006WANG Linjing, ZHANG Wei, GAN Weimin, et al. Cemented carbide tool edge passivation contrast experimental research [J]. Tool Engineering,2013,47(12):25-28. doi: 10.3969/j.issn.1000-7008.2013.12.006 [20] 赵雪峰, 杜宇超, 吴志鹏. 基于ABAQUS的磨粒对刀具刃口钝化的分析 [J]. 工具技术,2018,52(8):83-86. doi: 10.3969/j.issn.1000-7008.2018.08.037ZHAO Xuefeng, DU Yuchao, WU Zhipeng. Analysis of tool edge preparation by abrasive based on ABAQUS [J]. Tool Engineering,2018,52(8):83-86. doi: 10.3969/j.issn.1000-7008.2018.08.037 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS