Prediction of subsurface microcrack depth of brittle materials based on co-training SVR

-

摘要:

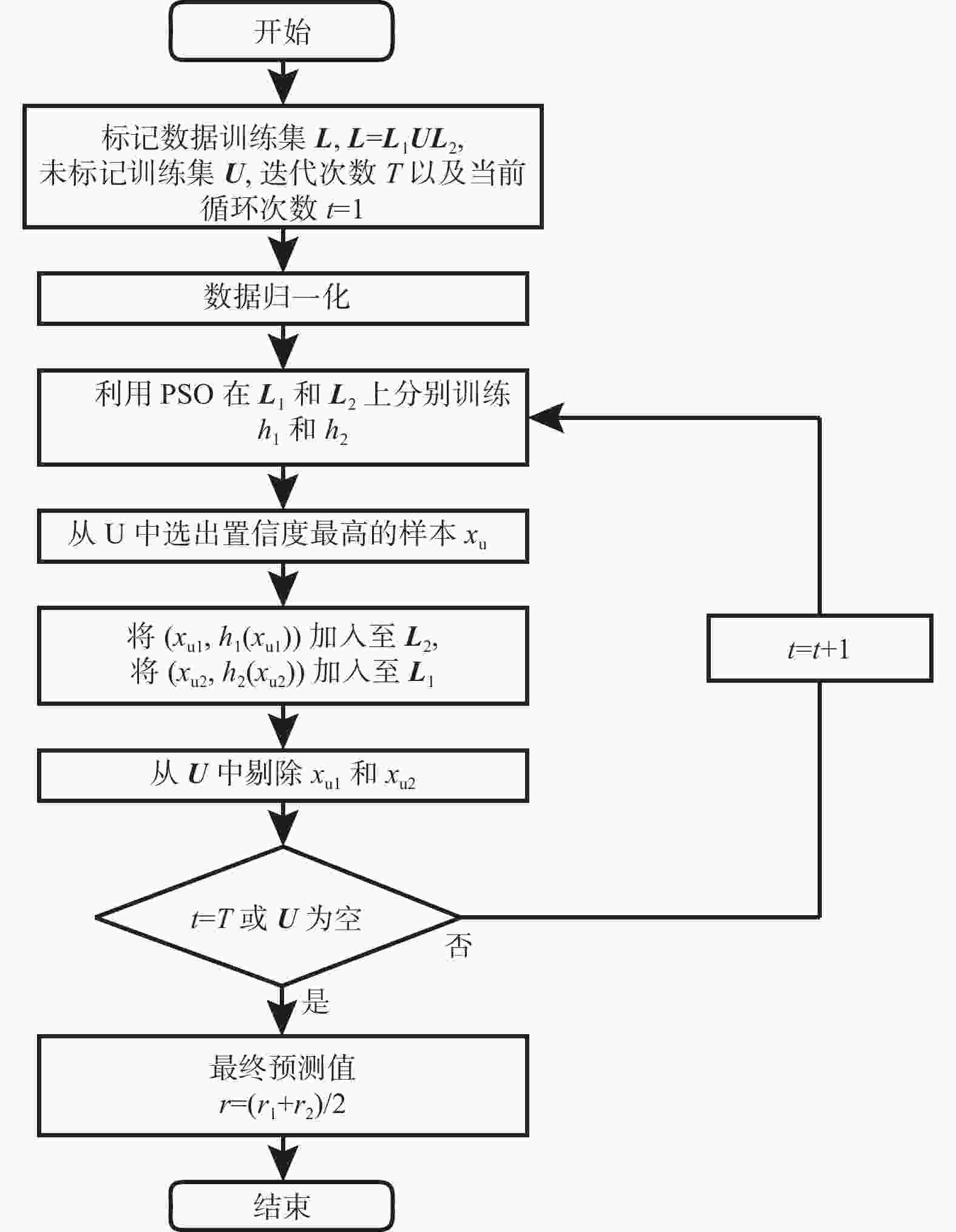

为克服固结磨料研磨脆性材料的亚表面微裂纹深度有效样本数不足的困境,实现其准确预测,采用协同训练SVR构建预测模型,对比不同标记训练集划分方法对测试集均方误差的影响;后以监督学习PSO-SVR模型为对照,比较二者的预测性能;最后以标记训练集未包含的脆性材料微晶玻璃和氟化钙为加工对象,进行工件的研磨及角度抛光法裂纹深度检测实验,并将检测的4组亚表面微裂纹深度值与协同训练SVR模型的预测值对比。结果表明:分开划分法下的协同训练SVR模型具有更小的均方误差;相比于PSO-SVR模型,协同训练SVR模型的均方误差和平均绝对百分比误差分别减小9%和17%,且其对4组验证实验的预测误差在1.2%~13.8%。表明协同训练SVR模型,可较为准确地预测固结磨料研磨脆性材料的亚表面微裂纹深度。

Abstract:[OBJECTIVES] Brittle materials, characterized by low fracture toughness, are susceptible to subsurface damages such as microcracks during grinding processes. This damage can adversely affect the performance and lifespan of the components. Precise measurement of the depth of subsurface microcracks is crucial for selecting appropriate machining allowance in subsequent processes. While current methods for measuring subsurface microcracks have limitation, machine learning models show significant potential in predicting machining quality of brittle materials. However, these models often require extensive labeled data, which is difficult to obtain in practice, thus limiting their learning capabilities. To address the challenge of limited effective samples for analyzing subsurface microcrack depths in brittle materials ground with fixed abrasives, this study proposes a collaborative training approach for a Support Vector Regression (SVR) model,tailored for small datasets, capable of accurately predicting microcrack depth caused by grinding different brittle materials.

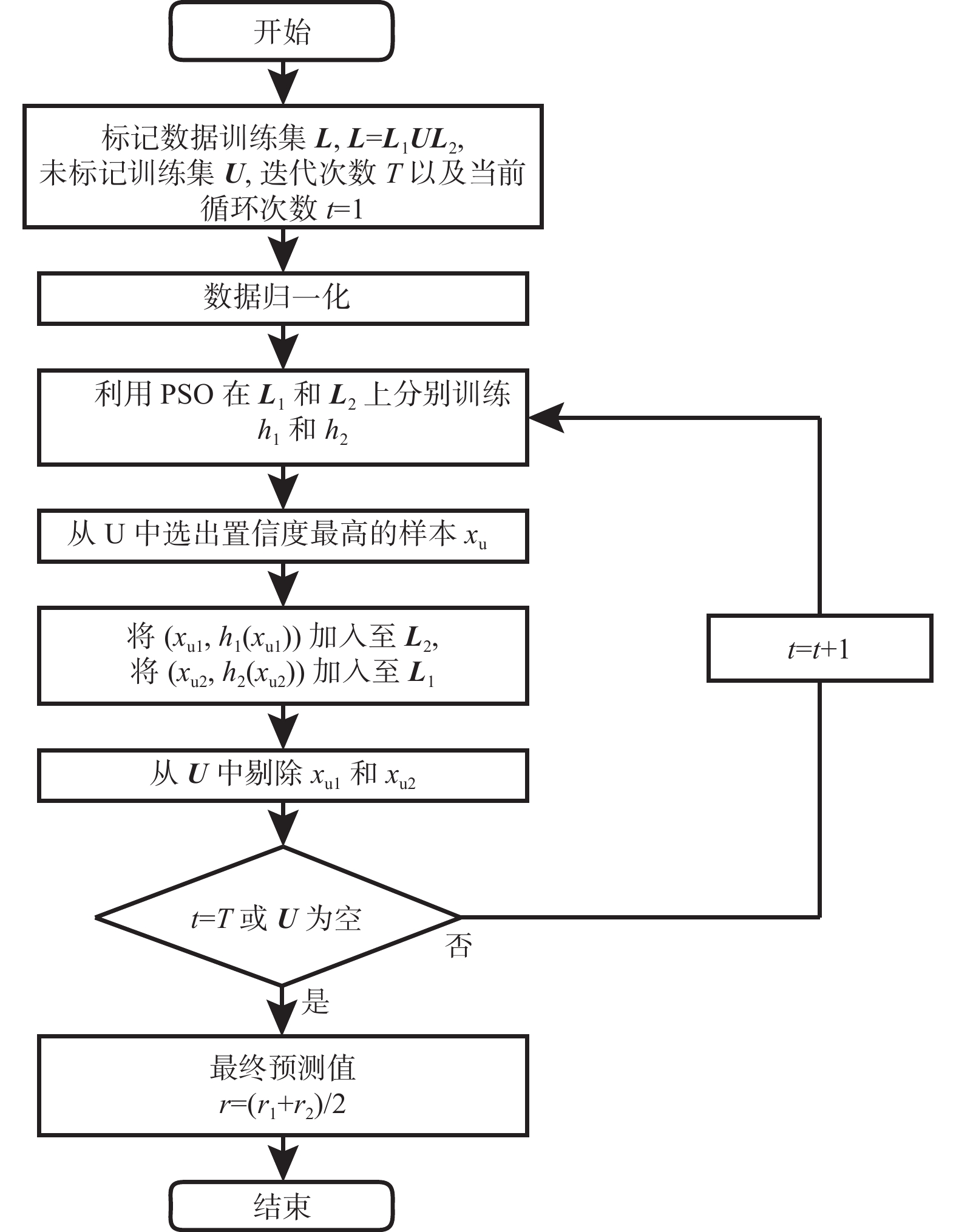

[METHODS] This study employed the SVR model as the foundational learner, with inputs including Mohs hardness, elastic modulus, fracture toughness of the brittle materials, diamond abrasive grain size and grinding pressure. The output was the depth of subsurface microcracks resulting from grinding. Integrating semi-supervised and supervised learning concepts, the study developed both a collaborative training SVR model and a PSO-SVR model. The model’s predictive performances were assessed using mean square error (MSE) and mean absolute percentage error (MAPE). Further, the impact of various labeled training set partitioning strategies on the MSE of the test set was examined using the collaborative training SVR model. The study also compared the predictive performances of the collaborative training SVR model and the PSO-SVR model under separate dataset partitioning strategies. Finally, the study validated the models through grinding and angle polishing experiments to measure subsurface microcrack depths in materials not included in the training set, evaluating the collaborative training SVR model's predictive accuracy against experimental results.

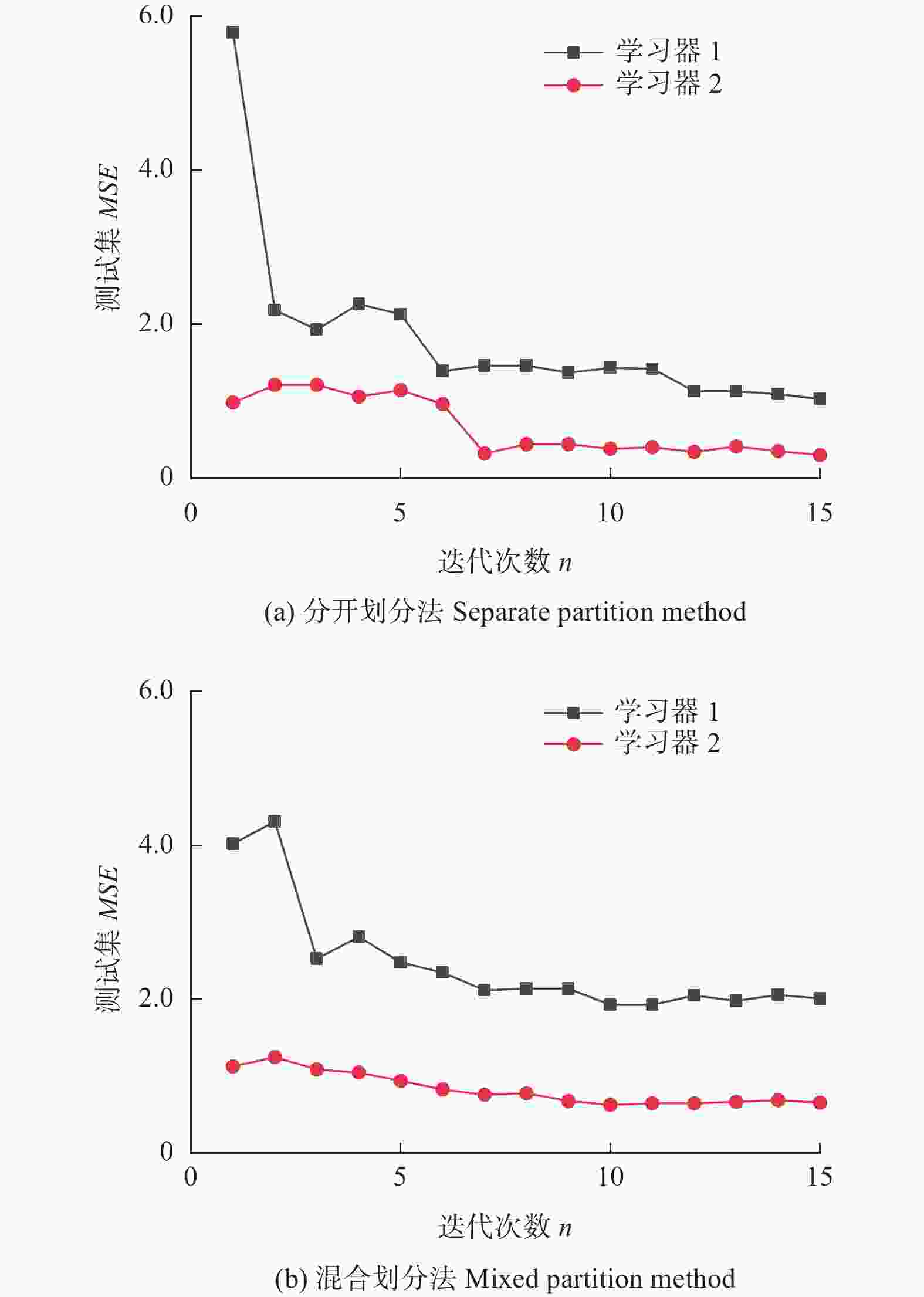

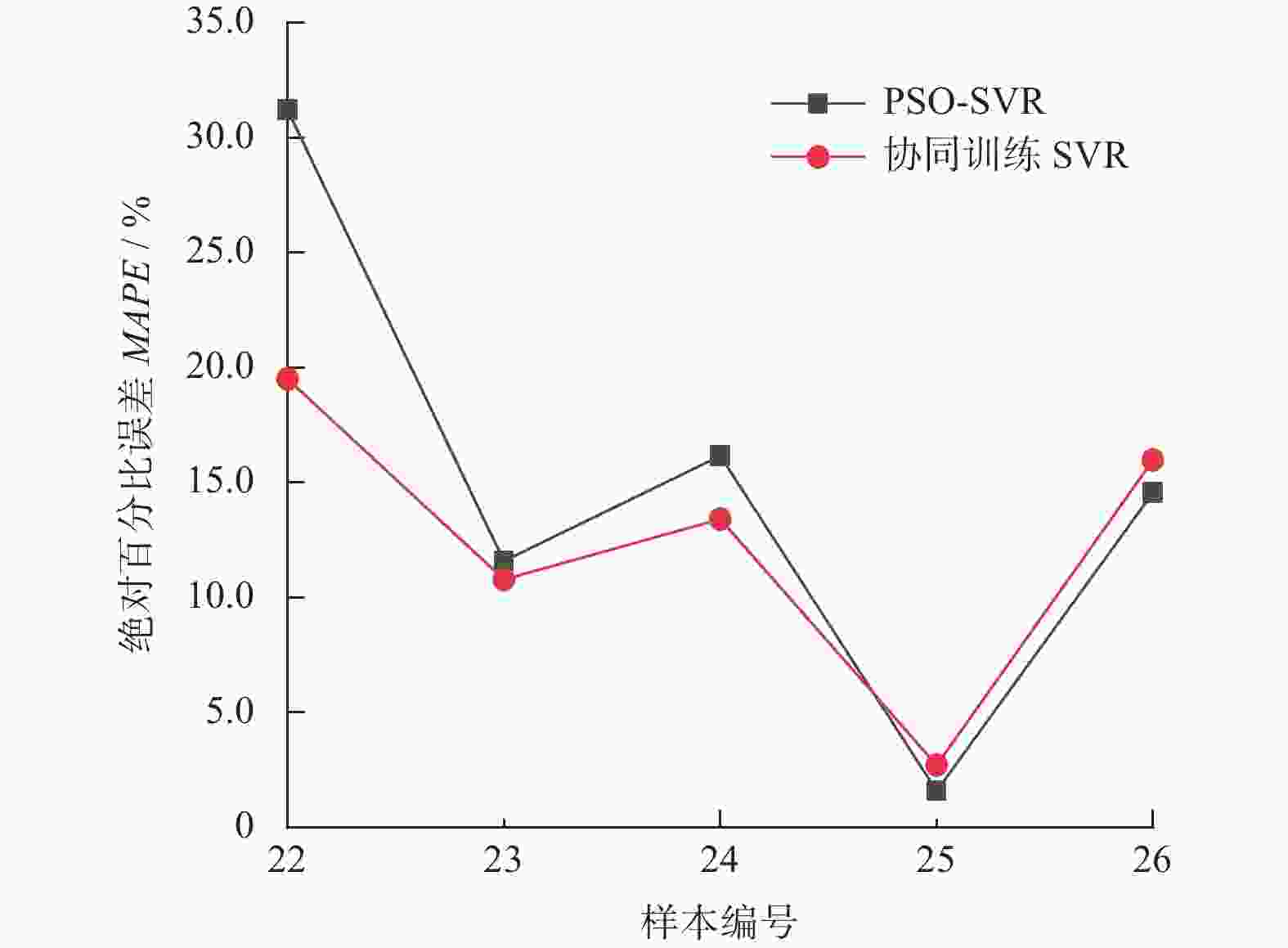

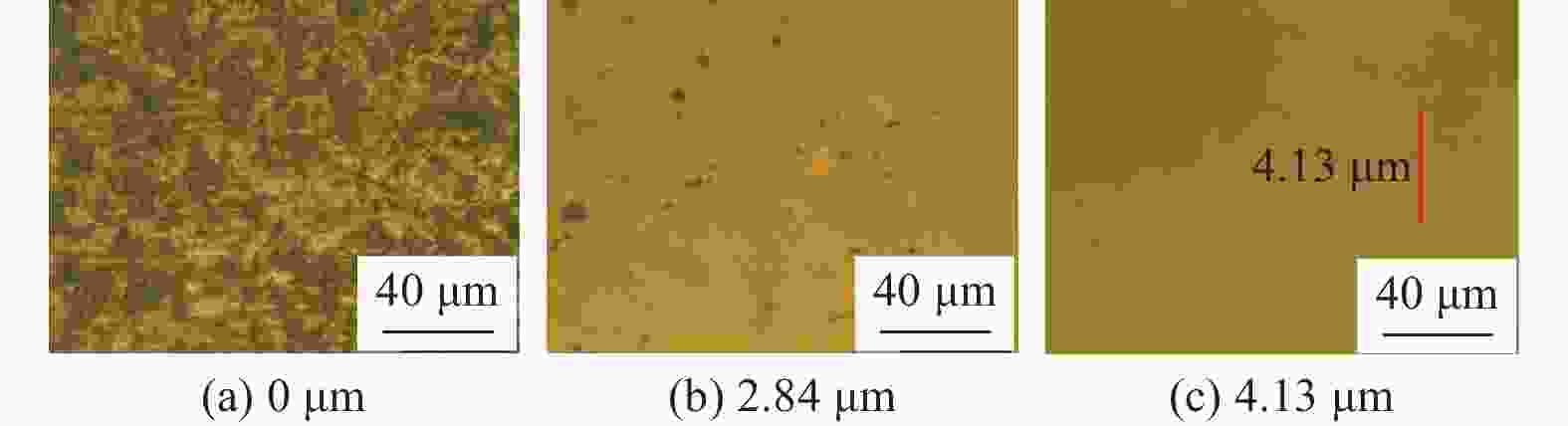

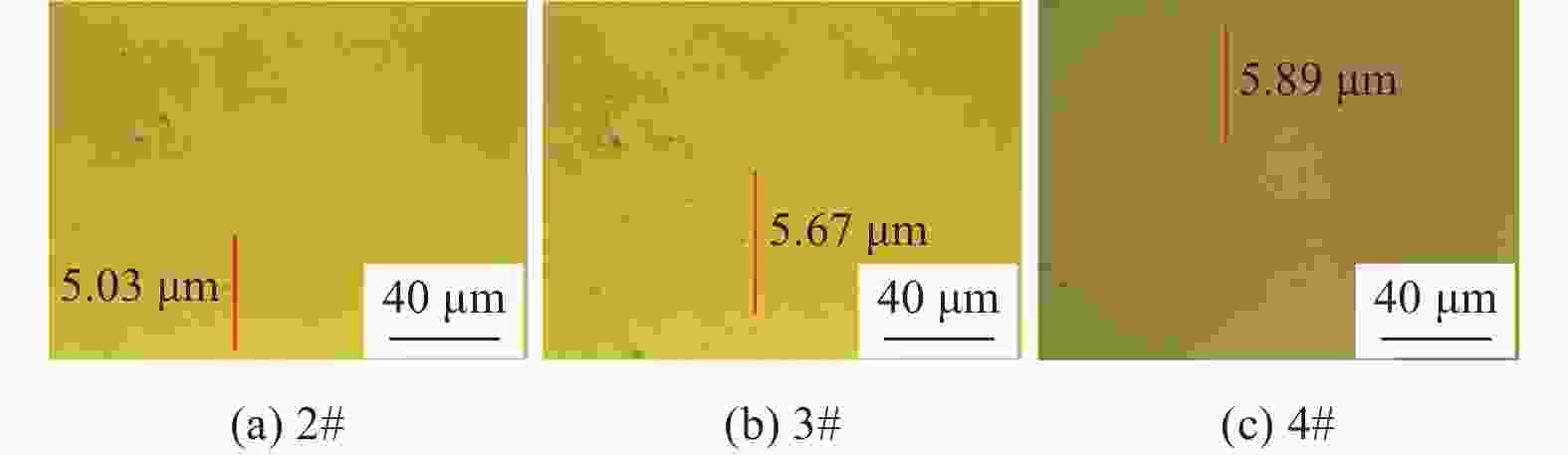

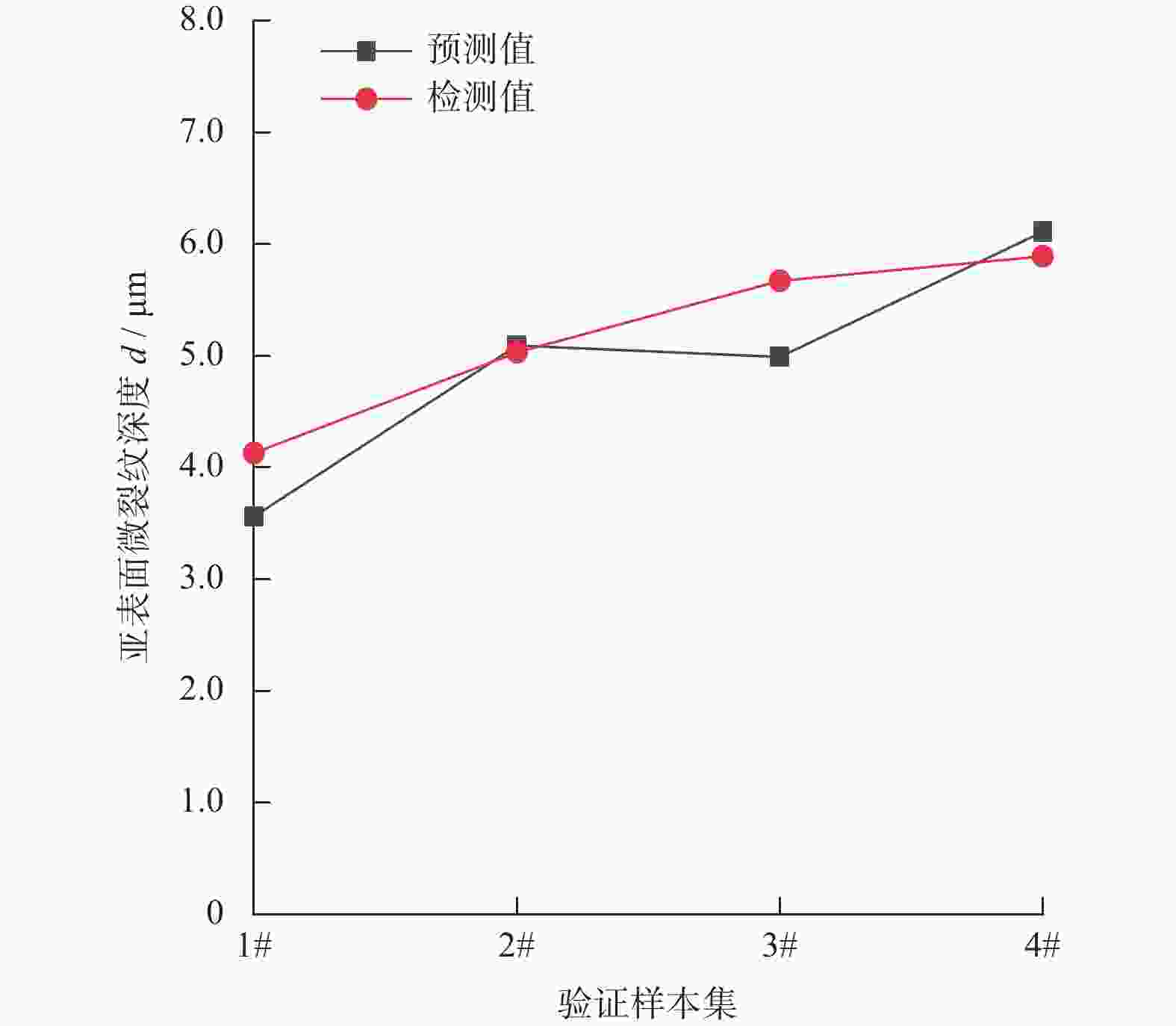

[RESULTS] When using separate dataset partitioning strategies, the initial MSE values of the two learners in the collaborative SVR model were 5.79 and 0.98, ultimately converging to 1.15 and 0.35, respectively. For mixed dataset partitioning strategy, the initial MSE values were 4.02 and 1.13, converging to 2.0 and 0.70, respectively. When predicting small dataset, the collaborative training SVR model demonstrated a reduction in MSE and MAPE by 9% and 17%, respectively, outperforming the PSO-SVR model. The collaborative model provided more reliable and stable predictions for both individual test samples and entire test sets. The measured subsurface microcrack depths in glass-ceramics and calcium fluoride under different processing conditions were 4.13, 5.03, 5.67, and 5.89 μm, with prediction errors ranging from 1.2% to 13.8%, averaging at 7.7%, which was significantly lower than the test set’s average prediction error of 12.5%.

[CONCLUSION] Dividing the labeled dataset using both separate and mixed partitioning methods can reduce the MSE of the collaborative training SVR model on the test set, with the separate method achieving smaller MSEs and superior outcomes. Compared to the supervised learning PSO-SVR model, the collaborative training SVR model demonstrates smaller MSE and MAPE values, with more stable prediction errors. The close agreement between the experimentally measured subsurface microcrack depths and the model's predictions underscores its robust generalization capability, confirming the model's ability to provide accurate and stable predictions of subsurface microcrack depths in various brittle materials after grinding.

-

表 1 亚表面微裂纹深度训练样本集

Table 1. Subsurface microcrack depth training sample set

样本

编号输入参数 输出参数 材料种类 莫氏硬度

M弹性模量

E / GPa断裂韧性

KIC / (MPa·m1/2)磨粒粒径

D50 / μm研磨压力

p / kPa亚表面微裂纹深度

d / μm1 K9玻璃 7.0 61.0 0.70 40 7.10 3.62 2 K9玻璃 7.0 61.0 0.70 28 7.10 2.91 3 石英玻璃 7.5 70.0 0.75 70 10.37 14.42 4 石英玻璃 7.5 70.0 0.75 30 10.37 6.45 5 石英玻璃 7.5 70.0 0.75 5 10.37 1.36 6 镁铝尖晶石 8.2 190.0 1.44 30 10.37 7.12 7 镁铝尖晶石 8.2 190.0 1.44 50 10.37 10.73 8 铌酸锂 5.0 195.0 0.70 14 15.00 1.73 9 硫化锌 3.0 85.5 1.06 5 20.00 2.02 10 蓝宝石 9.0 380.0 3.50 28 28.00 4.98 11 K9玻璃 7.0 61.0 0.70 20 7.10 1.17 12 石英玻璃 7.5 70.0 0.75 50 10.37 9.94 13 镁铝尖晶石 8.2 190.0 1.44 70 10.37 14.95 14 镁铝尖晶石 8.2 190.0 1.44 5 10.37 1.81 15 铌酸锂 5.0 195.0 0.70 28 15.00 5.53 16 铌酸锂 5.0 195.0 0.70 25 12.50 4.82 17 铌酸锂 5.0 195.0 0.70 14 12.50 1.34 18 硫化锌 3.0 85.5 1.06 15 20.00 3.98 19 硫化锌 3.0 85.5 1.06 30 20.00 8.27 20 蓝宝石 9.0 380.0 3.50 50 28.00 7.53 21 蓝宝石 9.0 380.0 3.50 14 28.00 2.84 表 2 亚表面微裂纹深度测试样本集

Table 2. Subsurface microcrack depth test sample set

样本

编号输入参数 输出参数 材料种类 莫氏硬度

M弹性模量

E / GPa断裂韧性

KIC / (MPa·m1/2)磨粒粒径

D50 / μm研磨压力

p / kPa亚表面微裂纹深度

d / μm22 石英玻璃 7.5 70.0 0.75 14 10.37 3.59 23 镁铝尖晶石 8.2 190.0 1.44 14 10.37 3.71 24 铌酸锂 5.0 195.0 0.70 28 7.10 3.28 25 硫化锌 3.0 85.5 1.06 25 20.00 6.27 26 蓝宝石 9.0 380.0 3.50 65 28.00 10.64 表 3 部分未标记数据集

Table 3. Partial unlabeled data set

材料

种类输入参数 莫氏硬度

M弹性模量

E / GPa断裂韧性

KIC / (MPa·m1/2)磨粒粒径

D50 / μm研磨压力

p / kPaYAG晶体 8.5 280.0 1.04 20 21.00 氧化镓 5.5 200.0 0.85 40 10.00 单晶硅 7.0 187.0 0.82 28 7.10 单晶锗 6.0 115.0 0.56 28 21.00 表 4 模型评价指标

Table 4. Evaluation metrics of the models

评价指标 PSO-SVR 协同训练SVR MSE 0.8265 0.7525 MAPE / % 15.0 12.5 表 5 验证样本集

Table 5. Validation sample set

实验

编号材料种类 输入参数 莫氏硬

度 M弹性模量

E / GPa断裂韧性

KIC /

(MPa·m1/2)磨粒粒径

D50 / μm研磨压力

p / kPa1# 微晶玻璃 6.5 90.0 0.90 20 10.00 2# 微晶玻璃 6.5 90.0 0.90 20 20.00 3# 微晶玻璃 6.5 90.0 0.90 28 10.00 4# 氟化钙 4.0 187.0 0.82 20 20.00 表 6 研磨工艺参数

Table 6. Lapping process parameters

参数类型 取值 微晶玻璃 氟化钙 磨料垫转速 n1 / (r·min−1) 85 85 工件转速 n2 / (r·min−1) 80 80 研磨液流量 Q / (mL·min−1) 60 60 研磨时间 t0 / min 15 5 表 7 角度抛光工艺参数

Table 7. Angle polishing process parameters

参数类型 取值 微晶玻璃 氟化钙 抛光压力 p1 / kPa 10 15 磨料垫转速 n3 / (r·min−1) 85 85 工件转速 n4 / (r·min−1) 80 80 聚氨酯抛光时间 t1 / min 30 10 绒布抛光时间 t2 / min 40 40 表 8 腐蚀液及腐蚀条件

Table 8. Corrosion liquids and corrosion conditions

材料种类 腐蚀液

(质量比)腐蚀时间

t3 / min腐蚀温度

θ / ℃微晶玻璃 HF∶NH4F=1∶20 4 20 氟化钙 浓硫酸 5 20 -

[1] 王建彬, 马睿, 江本赤, 等. 固结磨料研磨单晶蓝宝石亚表面微裂纹的预测 [J]. 表面技术,2020,49(6):345-351.WANG Jianbin, MA Rui, JIANG Benchi, et al. Prediction of subsurface damage for fixed abrasive lapping single crystal sapphire [J]. Surface Technology,2020,49(6):345-351. [2] 张羽斐, 王子琨, 胡伟栋, 等. 固结磨料研磨硫化锌的亚表面微裂纹预测分析 [J]. 红外与激光工程,2022,51(5):390-398.ZHANG Yufei, WANG Zikun, HU Weidong, et al. Prediction analysis of subsurface damage of work-part ZnS in fixed abrasive lapping [J]. Infrared and Laser Engineering,2022,51(5):390-398. [3] 戴子华, 朱永伟, 李军, 等. 固结磨料研磨K9玻璃亚表面微裂纹层深度测量方法研究 [J]. 金刚石与磨料磨具工程,2014,34(5):6-12.DAI Zihua, ZHU Yongwei, LI Jun, et al. Comparison of different methods to measure the subsurface damage depth of K9 glass lapped by fixed abrasive polishing pad [J]. Diamond & Abrasives Engineering,2014,34(5):6-12. [4] 朱永伟, 李信路, 王占奎, 等. 光学硬脆材料固结磨料研磨中的亚表面微裂纹预测 [J]. 光学精密工程,2017,25(2):367-374. doi: 10.3788/OPE.20172502.0367ZHU Yongwei, LI Xinlu, WANG Zhankui, et al. Subsurface damage prediction in consolidated abrasive grinding of optical hard and brittle materials [J]. Optics and Precision Engineering,2017,25(2):367-374. doi: 10.3788/OPE.20172502.0367 [5] 徐志强, 尹韶辉, 姜胜强, 等. 在线电解修整磨削与化学机械抛光相结合的蓝宝石基片组合加工技术 [J]. 中国机械工程,2018,29(11):1310-1315.XU Zhiqiang, YIN Shaohui, JIANG Shengqiang, et al. ELID grinding and CMP compound processing technology for sapphire substrates [J]. China Mechanical Engineering,2018,29(11):1310-1315. [6] TROST M, HERFFURTH T, SCHMITZ D, et al. Evaluation of subsurface damage by light scattering techniques [J]. Applied Optics,2013,52(26):65-79. [7] 王春慧. 光学表面亚表层微裂纹检测技术研究 [D]. 西安: 西安工业大学, 2010.WANG Chunhui. Study on optical subsurface damage evaluation technology [D]. Xi′an: Xi′an Technological University, 2010. [8] 王宁昌, 姜峰, 黄辉, 等. 脆性材料亚表面微裂纹检测研究现状和发展趋势 [J]. 机械工程学报,2017,53(9):170-179. doi: 10.3901/JME.2017.09.170WANG Ningchang, JIANG Feng, HUANG Hui, et al. Research stats and development trend of subsurface damage detection of brittle materials [J]. Journal of Mechanical Engineering,2017,53(9):170-179. doi: 10.3901/JME.2017.09.170 [9] 郭继通, 郑方志, 徐成宇, 等. 基于遗传算法和神经网络的软脆工件研磨加工工艺智能决策系统 [J]. 表面技术,2020,49(4):23-29.GUO Jitong, ZHENG Fangzhi, XU Chengyu, et al. Intelligent decision system for lapping process of soft and brittle workpiece based on genetic algorithm and neural network [J]. Surface Technology,2020,49(4):23-29. [10] 张任, 胥芳, 陈教料, 等. 基于PSO-RBF神经网络的锂离子电池健康状态预测 [J]. 中国机械工程,2016,27(21):2975-2981.ZHANG Ren, XU Fang, CHEN Jiaoliao, et al. Li-ion battery SOH prediction based on PSO-RBF neural network [J]. China Mechanical Engineering,2016,27(21):2975-2981. [11] 严建文, 钟小虎, 范煜, 等. 基于整群抽样和支持向量回归模型的高功率半导体激光器剩余使用寿命预测 [J]. 中国机械工程,2021,32(13):1523-1529.YAN Jianwen, ZHONG Xiaohu, FAN Yu, et al. RUL prediction of high-power semiconductor lasers based on cluster sampling and SVR model [J]. China Mechanical Engineering,2021,32(13):1523-1529. [12] TU E, ZHANG Y, ZHU L, et al. A graph-based semi-supervised k nearest-neighbor method for nonlinear manifold distributed data classification [J]. Information Sciences,2016,367/368:673-688. doi: 10.1016/j.ins.2016.07.016 [13] SHI Y, YAO K, CHEN H, et al. Semi-supervised slot tagging in spoken language understanding using recurrent transductive support vector machines: 2015 IEEE workshop on automatic speech recognition & understanding [C]. Scottsdale: IEEE, 2016. [14] ZHAN Y Z, CHEN Y B. Co-training semi-supervised active learning algorithm with noise filter [J]. Pattern Recognition & Artificial Intelligence,2009,22(5):750-755. [15] ZHOU Z H, LI M. Semi-supervised regression with co-training style algorithm [J]. IEEE Trans on Knowledge and Data Engineering,2007,19(11):1479-1493. doi: 10.1109/TKDE.2007.190644 [16] 李东, 黄道平, 刘乙奇. 基于协同训练的半监督异构自适应软测量建模方法的研究 [J]. 化工学报,2020,71(5):2128-2138.LI Dong, HUANG Daoping, LIU Yiqi. Research on semi-supervised heterogeneous adaptive co-training soft-sensor model [J]. CIESC Journal,2020,71(5):2128-2138. [17] 鲁娟, 张振坤, 吴智强, 等. 基于支持向量机的蠕墨铸铁表面粗糙度预测 [J]. 表面技术,2020,49(2):339-346.LU Juan, ZHANG Zhenkun, WU Zhiqiang, et al. Prediction of surface roughness for compacted graphite cast iron based on support vector machine [J]. Surface Technology,2020,49(2):339-346. [18] 苏晓云, 汪建新, 辛李霞. 基于神经网络的铣削大理石表面粗糙度预测模型 [J]. 表面技术,2020,71(5):2128-2138.SU Xiaoyun, WANG Jianxin, XIN Lixia. Neural network-based prediction model for surface roughness of milled marble [J]. Surface Technology,2020,71(5):2128-2138. [19] 王建彬. 固结磨料研磨蓝宝石工件的材料去除机理及工艺研究 [D]. 南京: 南京航空航天大学, 2015.WANG Jianbin. Material removal mechanism and process research of lapping sapphire by fixed abrasive [D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2015. [20] 朱楠楠, 朱永伟, 李军, 等. 铌酸锂晶体的研磨亚表面微裂纹深度 [J]. 光学精密工程,2015,23(12):3387-3394. doi: 10.3788/OPE.20152312.3387ZHU Nannan, ZHU Yongwei, LI Jun, et al. Subsurface damage depth of lithium niobate crystal in lapping [J]. Optics and Precision Engineering,2015,23(12):3387-3394. doi: 10.3788/OPE.20152312.3387 [21] 王占奎, 朱永伟, 李信路, 等. 固结磨料研磨镁铝尖晶石的平均切深和亚表面微裂纹行为 [J]. 硅酸盐学报,2017,45(3):402-409.WANG Zhankui, ZHU Yongwei, LI Xinlu, et al. Average cutting depth and subsurface damage of spinel induced by lapping with fixed abrasive pad [J]. Journal of the Chinese Ceramic Society,2017,45(3):402-409. [22] 高平. 光学玻璃研磨加工后亚表面微裂纹研究 [D]. 南京: 南京航空航天大学, 2012.GAO Ping. Study on subsurface damage of optical glass after lapping [D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2012. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS