| [1] |

DOI T, MARINESCU I D, KUROKAWA S. Advances in CMP polishing technologies [M]. Amsterdam: Elsevier, 2012, 15-19.

|

| [2] |

MARINESCU I D,DOI T, UHLMANN E. Handbook of ceramics grinding and polishing (2nd edition) [M]. Amsterdam: Elsevier, 2015, 275-315.

|

| [3] |

MARINESCU I D, UHLMANN EDOI T. Handbook of ceramics lapping and polishing [M]. New York: CRC Press (Taylor & Francis Group), 2006, 341-477.

|

| [4] |

DOI T. Details of semiconductor CMP technology [M]. Tokyo: Kogyo Chosakai Publishing Co., 2001, 13-38.

|

| [5] |

ITRS 2005 Edition. http://strj-jeita.elisasp.net/pdf_ws_2005nendo/9A_WS2005IRC_Ishiuchi.pdf

|

| [6] |

TAGAMI M. Metallization challenges in 3D flash memory [C]// The Planarization and CMP Technical Committee, The Japan Society for Precision Engineering. 2022 Proceedings of Meeting of Planarization CMP Committee. Tokyo: [s.n.], 2023: 109.

|

| [7] |

CHEN R, LI Y C, CAI J M, et al. Atomic level deposition to extend Moore's law and beyond [J]. International Journal of Extreme Manufacturing,2020(2):022002.

|

| [8] |

NAKAMURA S, MUKAI T, SENOH M, et al. Thermal annealing effects on P-type Mg-doped GaN films [J]. Japanese Journal of Applied Physics,1992,31(2B):L139. doi: 10.1143/JJAP.31.L139

|

| [9] |

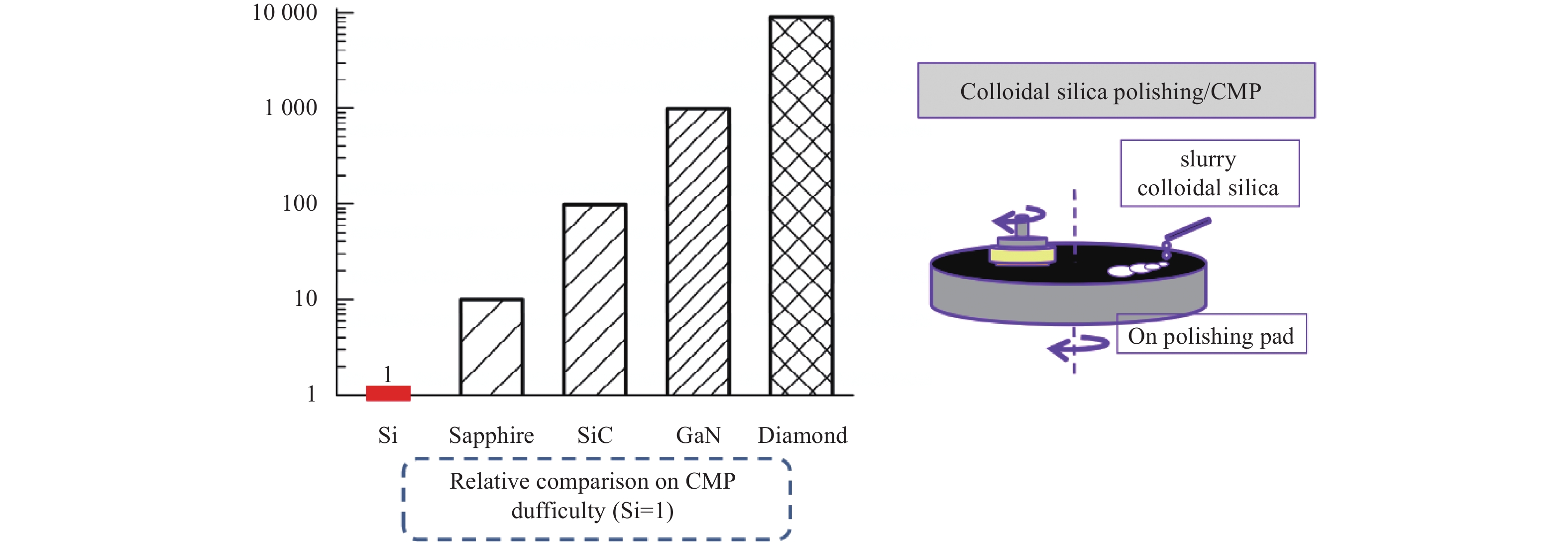

DOI T. Current status and future prospects of GaN substrates for green devices [J]. Sensors and Materials,2013,25(3):141-154. doi: 10.18494/SAM.2013.854

|

| [10] |

DOI T. Next-generation, super-hard-to-process substrates and their high-efficiency machining process technologies used to criate innovative devices [J]. International Journal of Automation Technology,2018,12(2):145-153. doi: 10.20965/ijat.2018.p0145

|

| [11] |

DOI T K, KAGEYAMA T, KASAI T, et al. A new processing technique of GaAs single crystals and its mechanism [J]. International Journal of the Japan Society for Precision Engineering,1996,30(1):16-22.

|

| [12] |

DOI T, MARINESCU I D, KUROKAWA S. Advances in CMP polishing technologies [M]. Amsterdam: Elsevier, 2011.

|

| [13] |

AIDA H, KIM S W, IKEJIRI K, et al. Precise mechanical polishing of brittle materials with free diamond abrasives dispersed in micro-nano-bubble water [J]. Precision Engineering,2014,40:81-86. doi: 10.1016/j.precisioneng.2014.10.008

|

| [14] |

NAKAJIMA K. Tribomicro plasma [J]. Journal of the Japan Society for Abrasive Technology,2007,51(8):453-456.

|

| [15] |

SANO Y, WATANABE M, YAMAMURA K, et al. Polishing characteristics of silicon carbide by plasma chemical vaporization machining [J]. Japanese Journal of Applied Physics, 2006, 45(10s): 8277-8280. Doi 10.1143/JJAP.45.8277

|

| [16] |

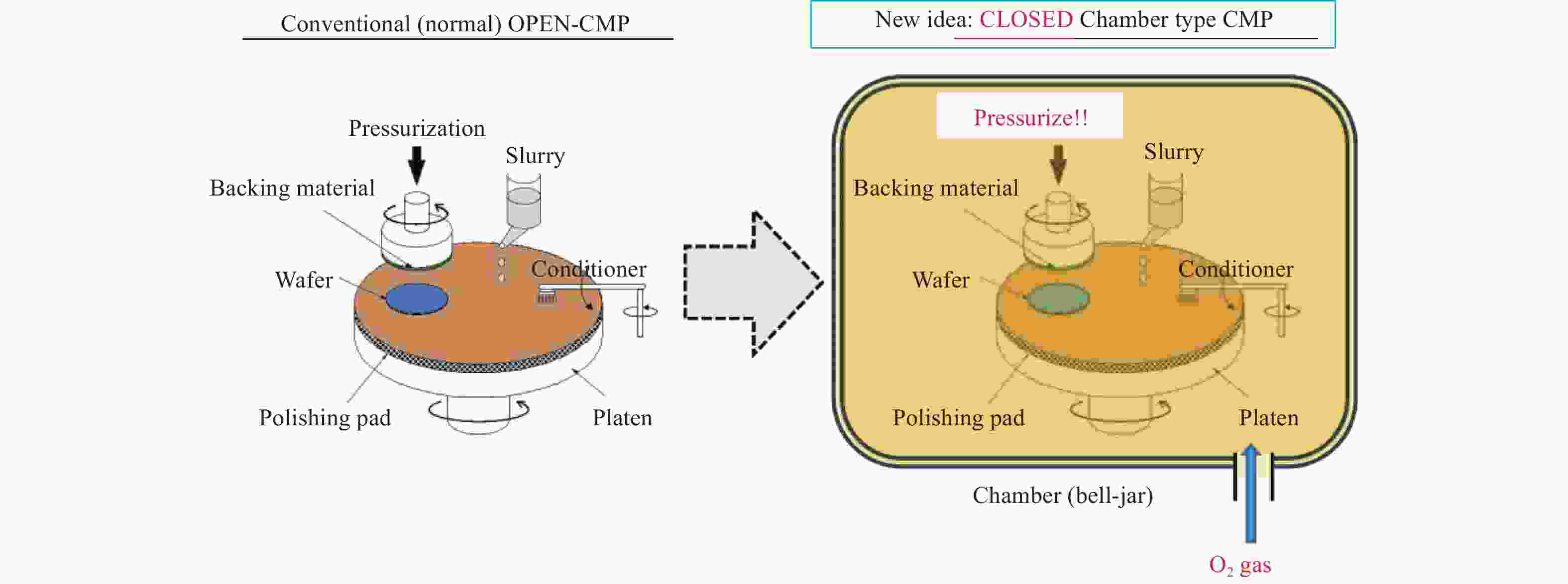

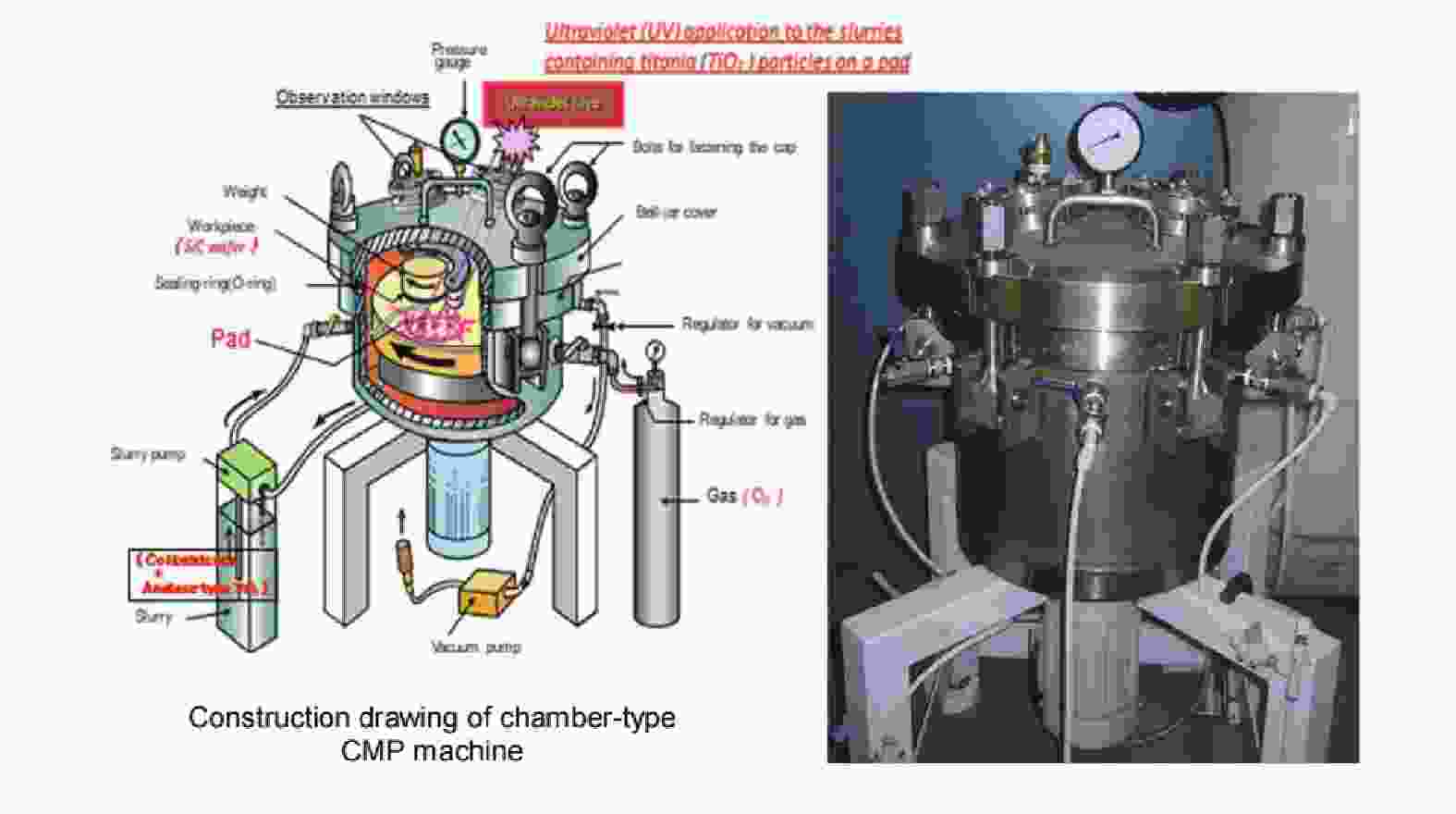

DOY/DOI T K, ICHIKAW K, PHILIPOSSIAN A., A new atmosphere control bell-jar type CMP machine and its characteristics with optoelectronics materials [J]. Proceedings of AUSTCERAM, 2002: 249.

|

| [17] |

DOI T, SANO Y, KUROKAWA S, et al. Study on high efficiency precision machining method of advanced hard working substrate (report 1) [J]. Proceedings of JSPE, Spring Meeting,2013:639-640. doi: 10.11522/pscjspe.2013S.0.639.0

|

| [18] |

DOI T. Impact of novel bell-jar type CMP machine on CMP characteristics of optoelectronics materials [J]. Proceedings of ICM/NFT’06, 2006: 1.

|

| [19] |

SANO Y, DOI T, KUROKAWA S, et al. Study on high efficiency precision machining method of advanced hard working substrate (report 2) [J]. Proceedings of JSPE, Spring Meeting,2013:641-642. doi: 10.11522/pscjspe.2013S.0.641.0

|

| [20] |

DOY/DOI T. Colloidal silica polishing based on micromechanical removal action and its applications [J]. Sensors and Materials,1988,1(3):153-168.

|

| [21] |

KOYAMA K, AIDA H, UNEDA M, et al. Effects of N-face finishing on geometry of double-side polished GaN substrate [J]. International Journal of Automation Technology,2014,8(1):121-127. doi: 10.20965/ijat.2014.p0121

|

| [22] |

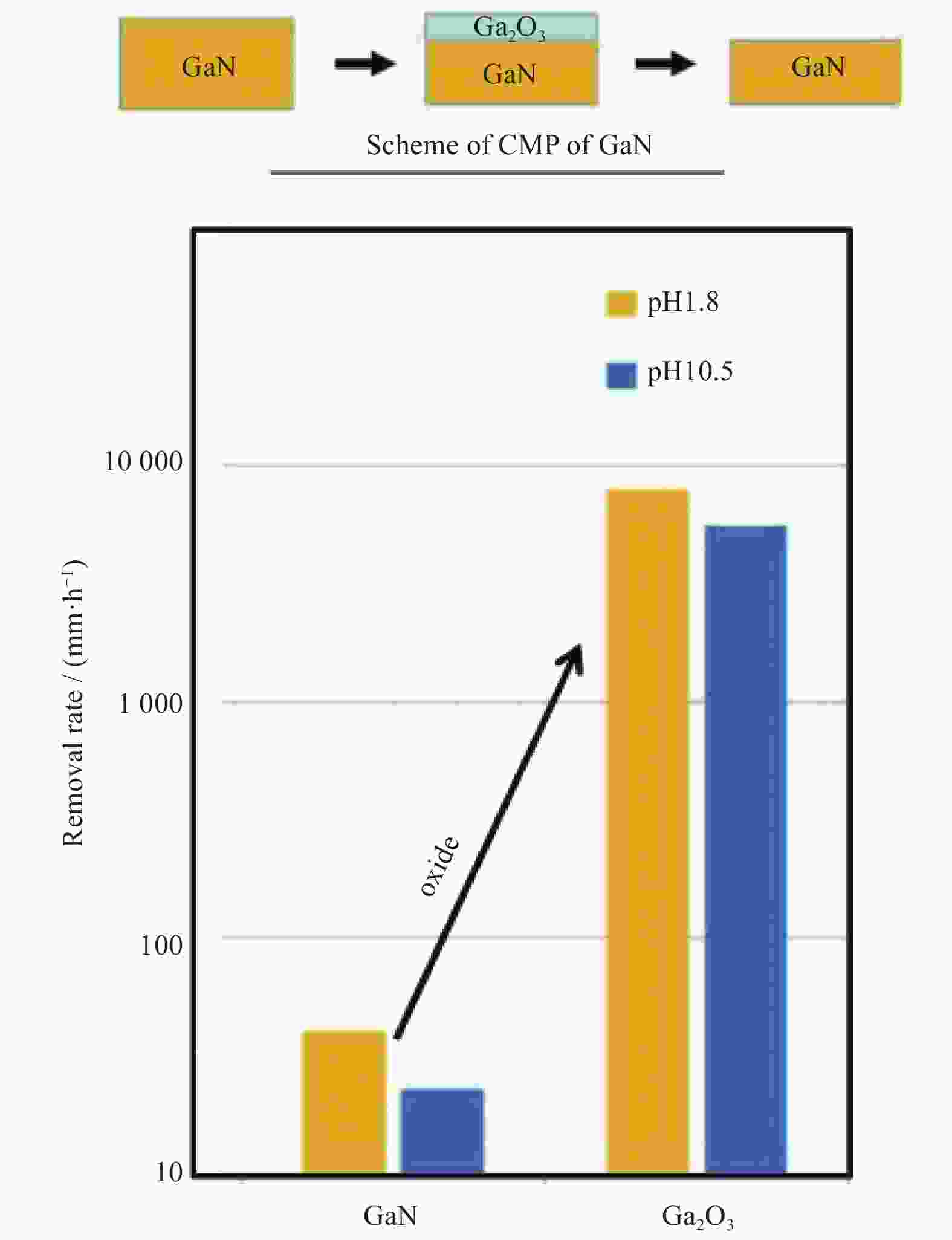

AIDA H, TAKEDA H, DOI T, et al. Chemical mechanical polishing of gallium nitride with colloidal silica [J]. Journal of The Electrochemical Society,2011,158:H1206-H1212. doi: 10.1149/2.024112jes

|

| [23] |

AIDA H, DOI T, YAMAZAKI T, et al. Progress and challenges for chemical mechanical polishing of gallium nitride [J]. Materials Research Society Symposium Proceedings, 2013,1560:875-884. doi: 10.1557/opl.2013.875

|

| [24] |

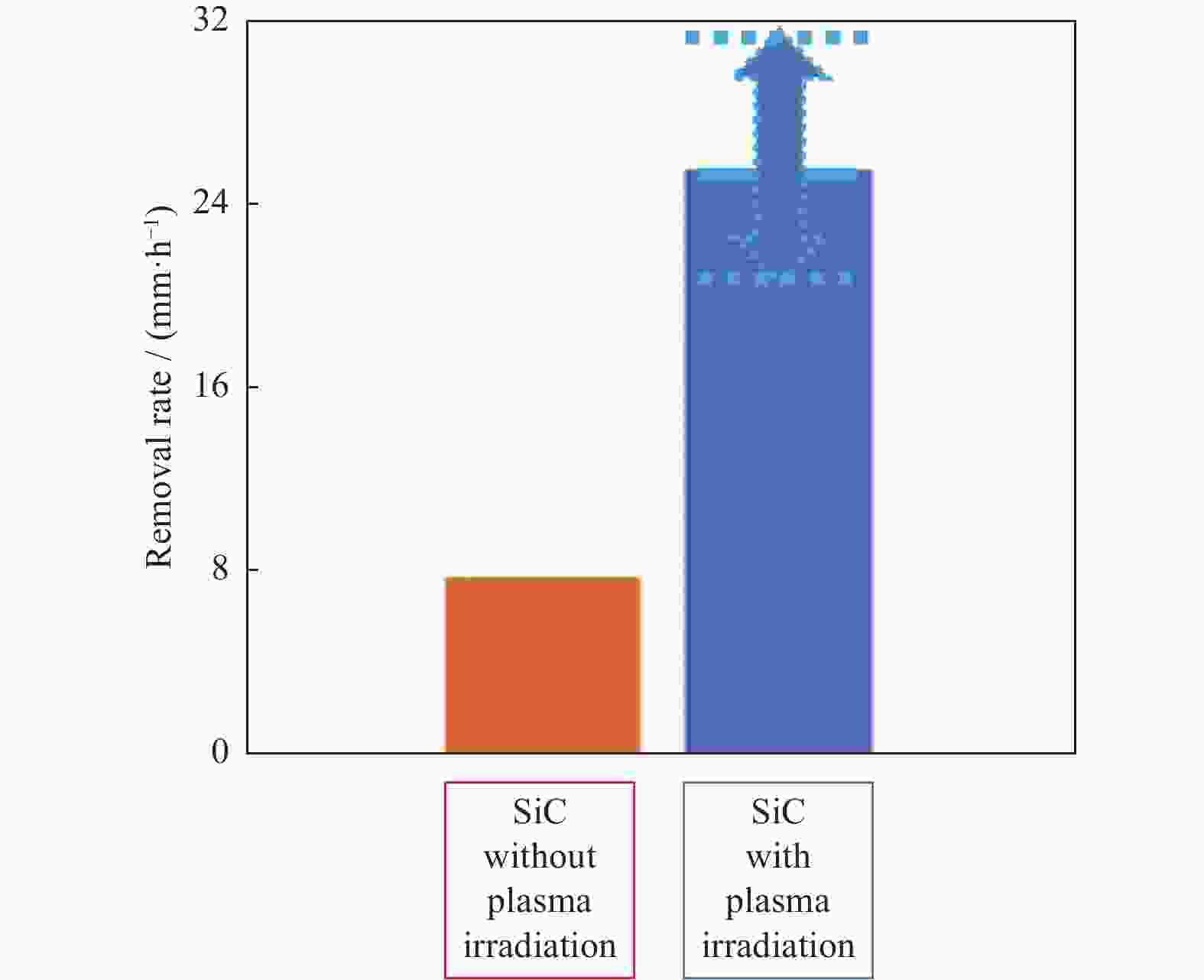

YAMAMURA K, TAKIGUCHI T, UEDA M, et al. Plasma assisted polishing of single crystal SiC for obtaining atomically flat strain-free surface [J]. CIRP Annals - Manufacturing Technology,2011,60:571-574. doi: 10.1016/j.cirp.2011.03.072

|

| [25] |

AIDA H, DOI T, TAKEDA H, et al. Ultraprecision CMP for sapphire, GaN, and SiC for advanced optoelectronics materials [J]. Current Applied Physics,2012,12(Suppl.2):S41-S46. doi: 10.1016/j.cap.2012.02.016

|

| [26] |

De NARDIS D, DOI T, HISKEY B, et al. Modeling copper CMP removal rate dependency on wafer pressure, velocity, and dissolved oxygen concentration [J]. Journal of The Electrochemical Society,2006,153(5):G428-G436. doi: 10.1149/1.2180627

|

| [27] |

MARINESCU I D,DOI T, UHLMANN E. Handbook of ceramics grinding and polishing (2nd edition) [M]. Amsterdam: Elsevier, 2015, 449.

|

| [28] |

DOI T. An innovative processing concept of SiC, GaN and diamond substrates for the next generation semiconductors, and its future perspectives [C]// Production Engineering Institution, The Chinese Mechanical Engineering Society. Proceedings of the 14th China-Japan International Conference on Ultra-Precision Machining Process (CJUMP2018). Harbin: [s.n.], 2018: 23

|

| [29] |

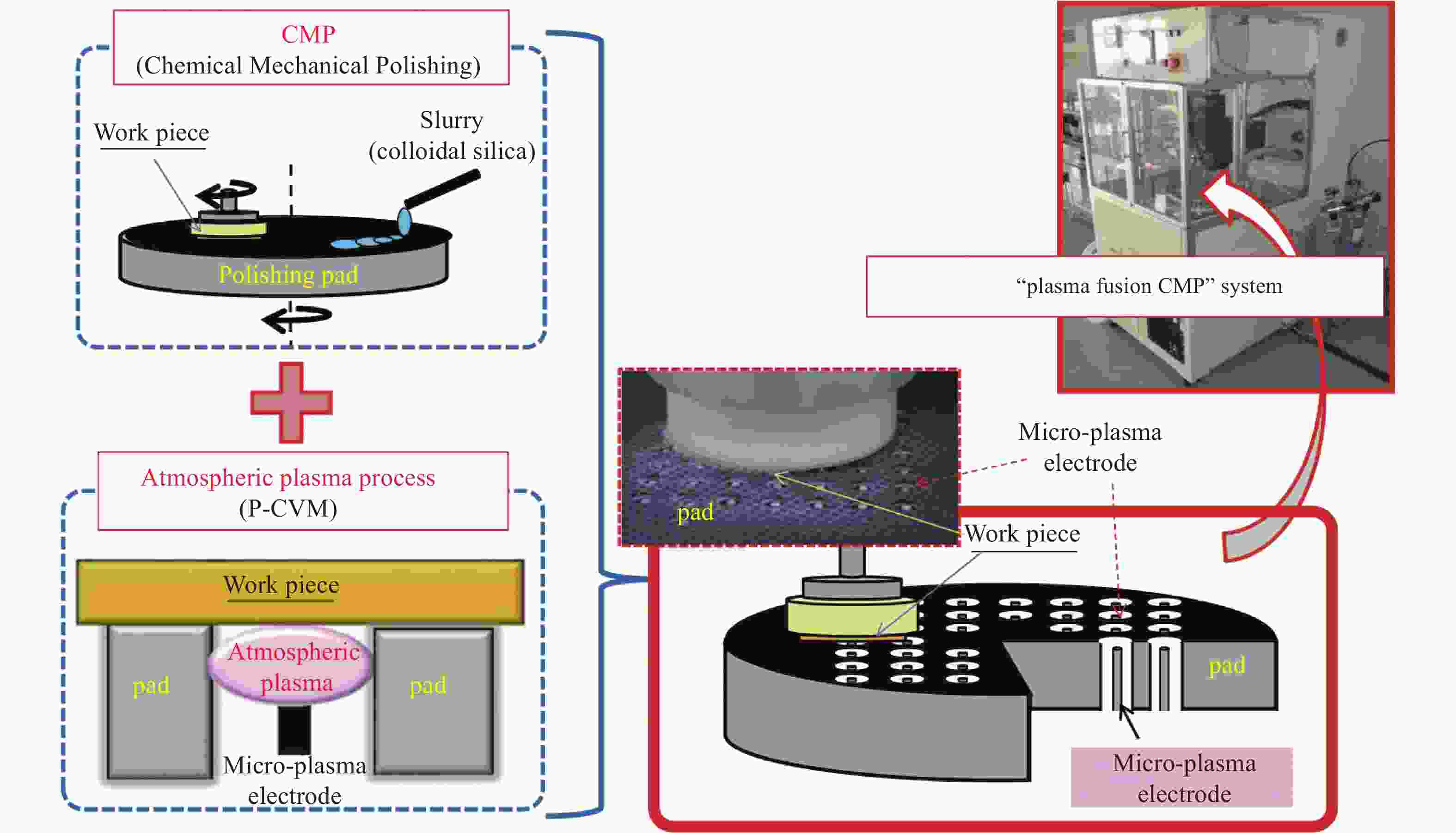

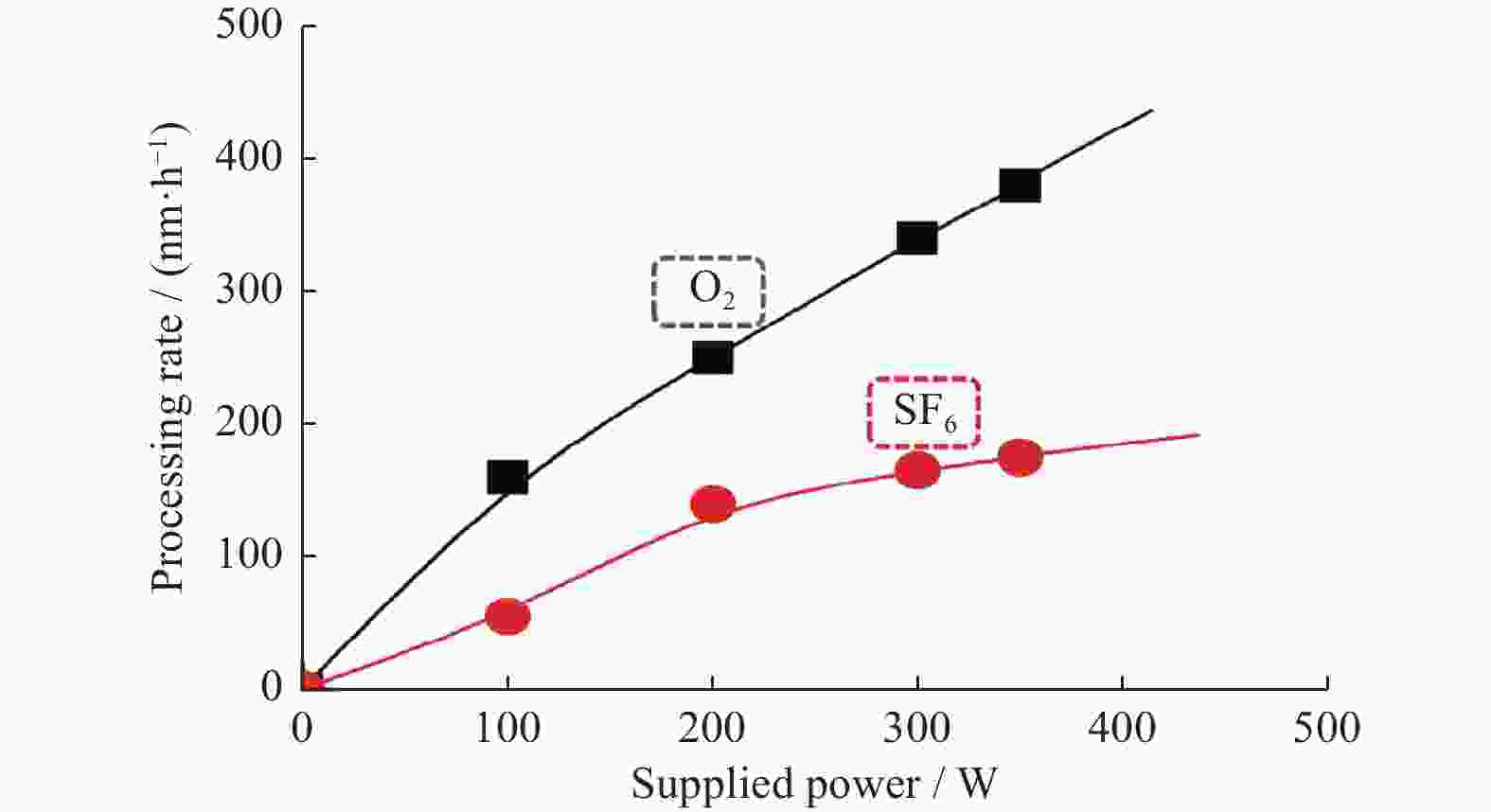

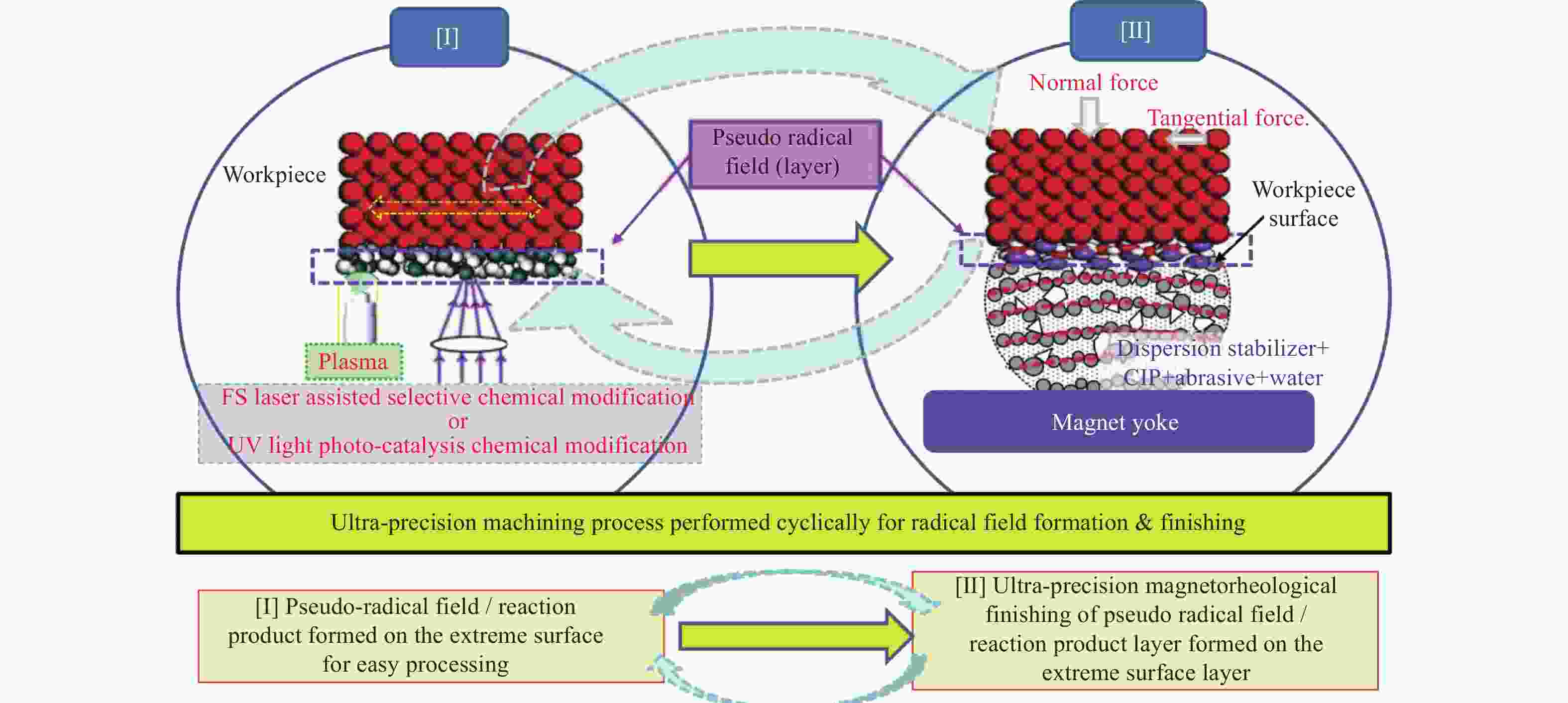

SANO Y, SHIOZAWA K, DOI T, et al. High-efficiency planarization method combining mechanical polishing and atmospheric-pressure plasma etching for hard-to-machine semiconductor substrates [J]. Semconductor Substrates, The Japan Society of Mechanical Engineering (JSME),2016,3(1):1-9.

|

| [30] |

OYAM K, DOI K T. Study on a novel CMP/P-CVM fusion processing system (type-b) and its basic characteristics [C]// The Planarization and CMP Technical Committee, The Japan Society for Precision Engineering. Proceeding of International Conference on Planarization Technology (ICPT2014). Kobe: [s.n.], 2014.

|

| [31] |

NISHIZAWA H, DOI T. Study on a novel CMP/P-CVM fusion processing system (type B) and its basic characteristics [C]// The Planarization and CMP Technical Committee, The Japan Society for Precision Engineering. 2014 Proceedings of Meeting of Planarization CMP Committee. Kobe: [s.n.], 2014.

|

| [32] |

TAKEDA H, DOI T, KIM S W, et al. High efficiency processing and its processing mechanism of large area diamond substrate due to plasma fusion CMP [J]. IEICE Technical Report,2017,117(334):1-6.

|

| [33] |

DOI T. Design and novel processing method “plasma fusion CMP® machine” - Processing characteristics of SiC, GaN & diamond substrates [C]// Southern University of Science and Technology. Proceedings of the Symposium on Ultra-High-Speed Machining and Machining of Hard & Brittle Materials. Shenzhen: [s.n.], 2019.

|

| [34] |

MAUER G, VAßEN R, STÖVER D. Plasma and particle temperature measurements in thermal spray: Approaches and applications [J]. Journal of Thermal Spray Technology,2010,20:391-406. doi: 10.1007/s11666-010-9603-z

|

| [35] |

SANO Y, WATANABE M, KATO T, et al. Temperature dependence of plasma chemical vaporization machining of silicon and silicon carbide [J]. Materials Science Forum,2009,600-603:847-850. doi: 10.4028/www.scientific.net/MSF.600-603.847

|

| [36] |

NISHIZAWA H, DOI T, OYAMA K, et al. Design and test of innovative plasma fusion CMP equipment [J]. Proceedings of JSPE, Spring Meeting,2016:381-382. doi: 10.11522/pscjspe.2016S.0_381

|

| [37] |

SANO Y, DOI T, KUROKAWA S, et al. Dependence of GaN removal rate of plasma chemical vaporization machining on mechanically introduced damage [J]. Sensors and Materials,2014,26(6):429-434.

|

| [38] |

AIDA H, DOI T. Polishing of difficult-to-process single crystals by next-generation processing and its prospects [J]. Shinku / Vacuum Journal,2018,7(11):11-14.

|

| [39] |

REN Y, LI K, LI W, et al. Research on a UV-assisted chemical modification strategy for monocrystalline silicon [J]. Mechanical Science,2021,12(1):133-141. doi: 10.5194/ms-12-133-2021

|

| [40] |

DOI T K, SANO Y, KUROWAKA S, et al. Novel chemical mechanical polishing/plasma-chemical vaporization machining (CMP/P-CVM) combined processing of hard-to-process crystals based on innovative concepts [J]. Sensors and Materials,2014,26(6):403-415. doi: 10.18494/SAM.2014.978

|

| [41] |

LUO H, GUO M, YIN S, et al. An atomic-scale and high efficiency finishing method of zirconia ceramics by using magnetorheological finishing [J]. Applied Surface Science,2018,444:569-577. doi: 10.1016/j.apsusc.2018.03.091

|

| [42] |

REN Y, LI K, LI W, et al. A hybrid chemical modification strategy for monocrystalline silicon microgrinding: Experimental investigation and synergistic mechanism [J]. Chinese Journal of Aeronautics,2022. doi: 10.1016/j.cja.2022.11.004

|

| [43] |

YIN Shaohui, GONG Sheng, HE Bowen, et al. Development on synergistic process and machine tools integrated inclined axis grinding and magnetorheological polishing for small aspheric surface [J]. Journal of Mechanical Engineering,2018,54(21):205-211. doi: 10.3901/JME.2018.21.205

|

| [44] |

ZHANG B, YIN J F. The 'skin effect' of subsurface damage distribution in materials subjected to high-speed machining [J]. International Journal of Extreme Manufacturing,2019,1:012007. doi: 10.1088/2631-7990/ab103b

|

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS