Design and simulation of magnetorheological polishing excitation device based on permanent magnet

-

摘要:

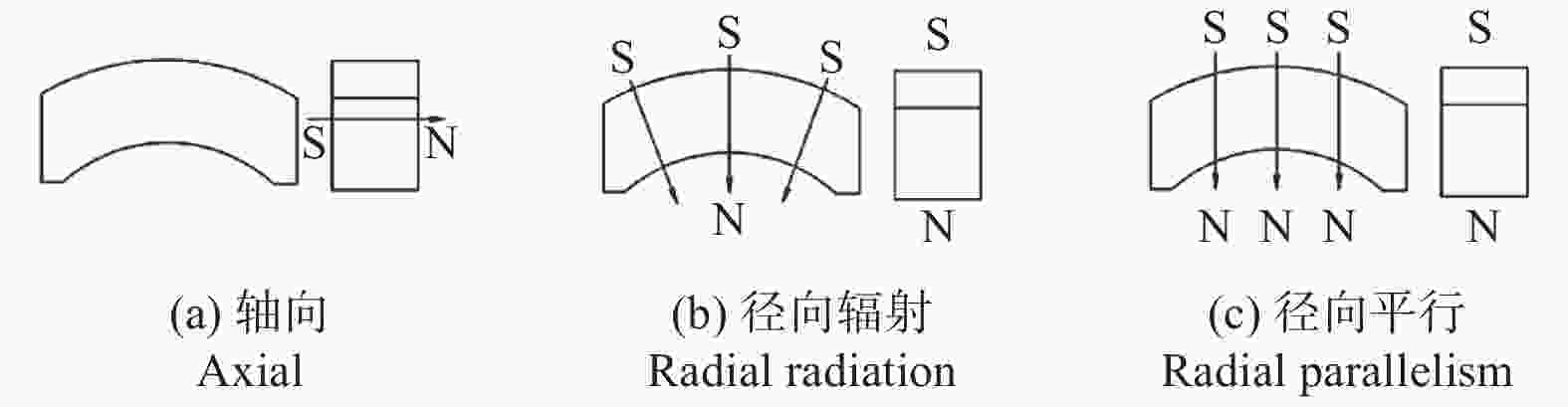

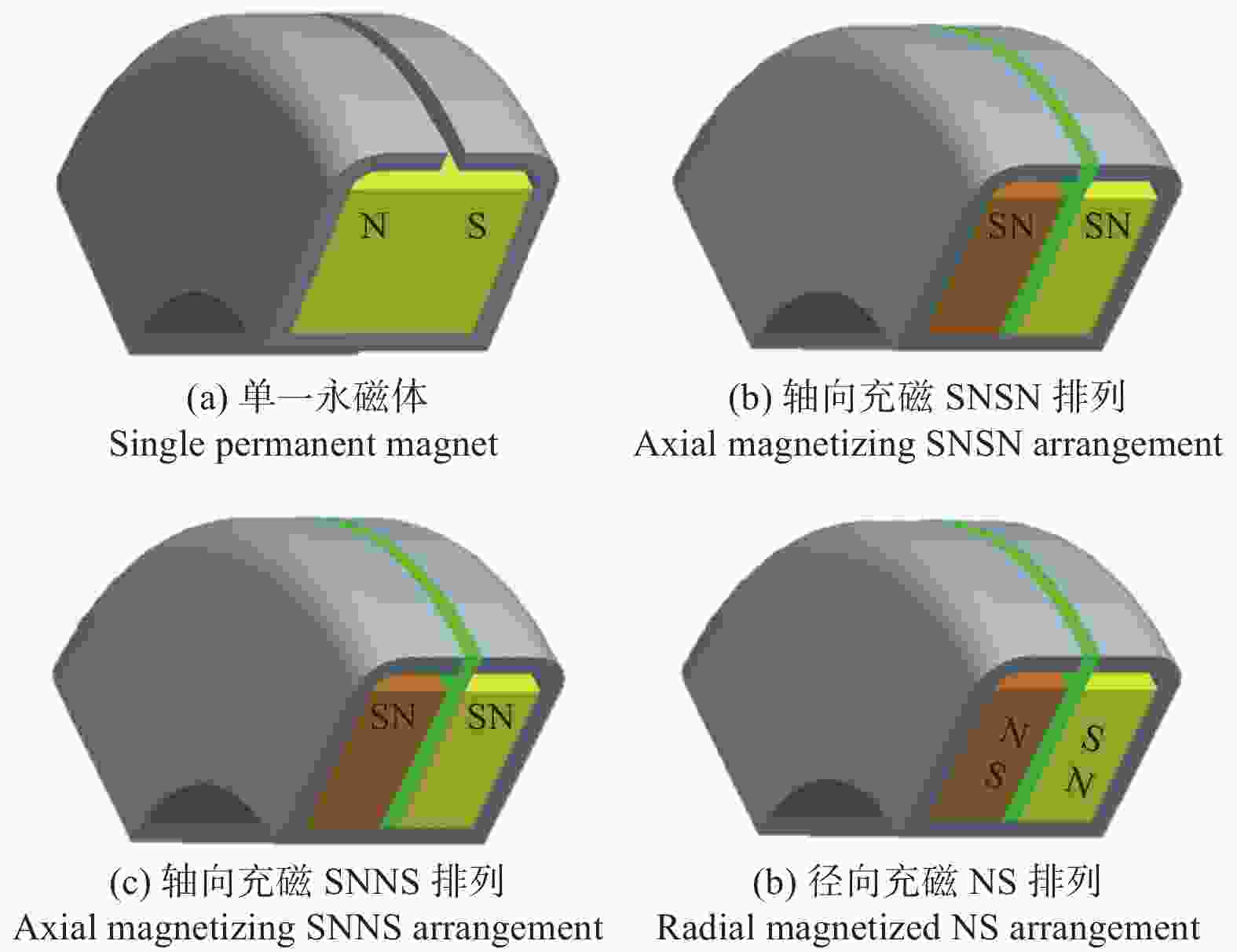

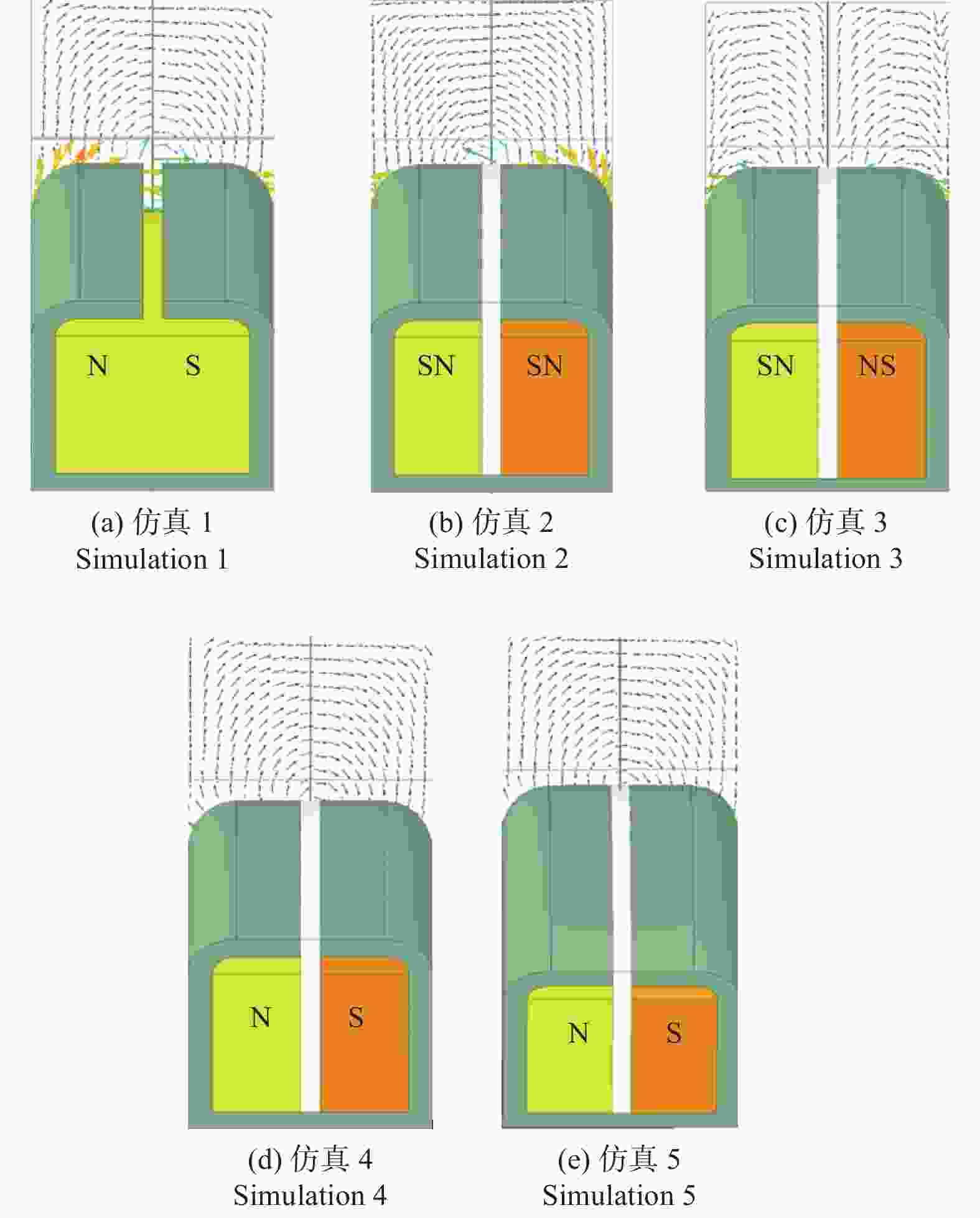

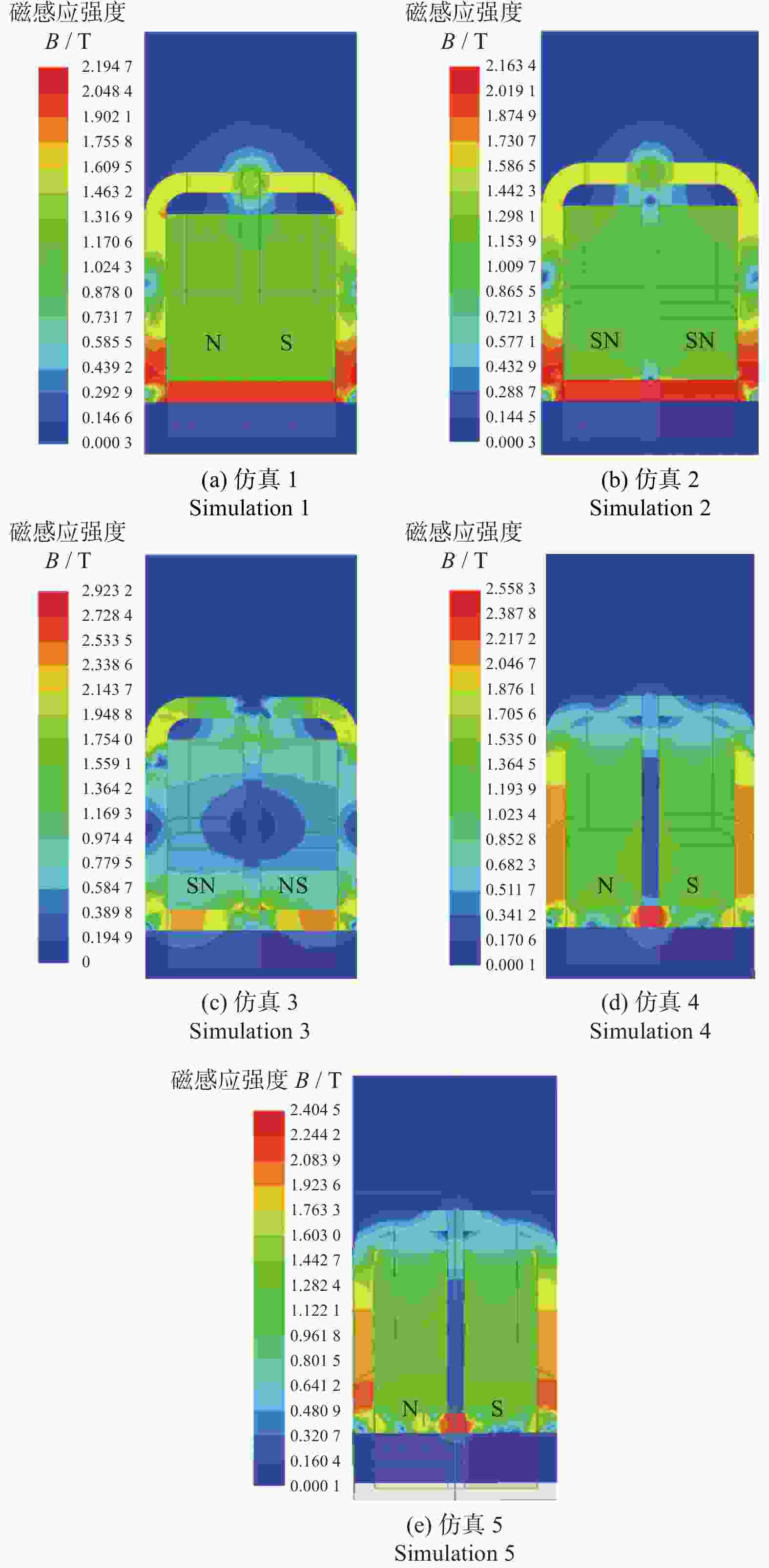

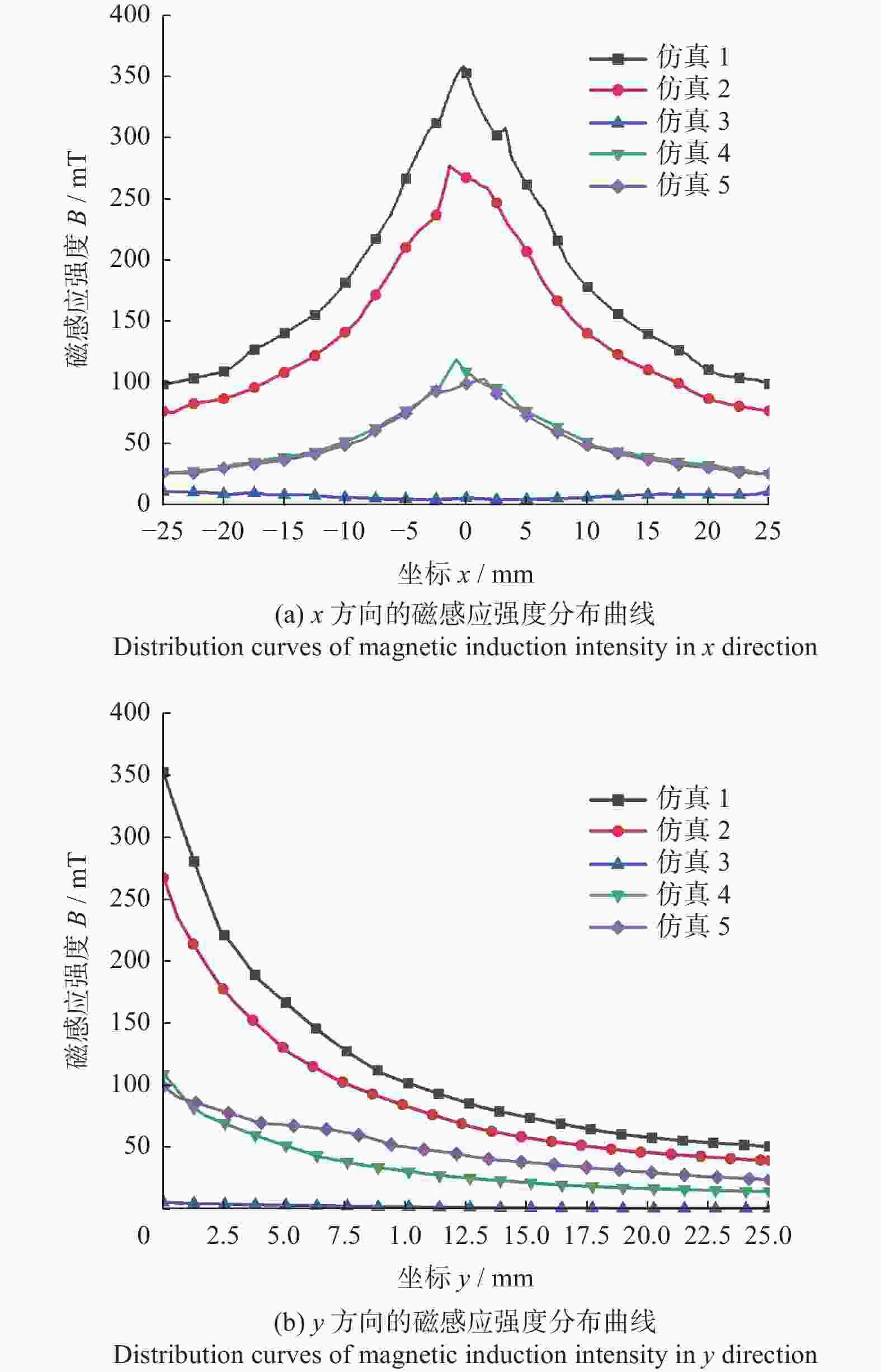

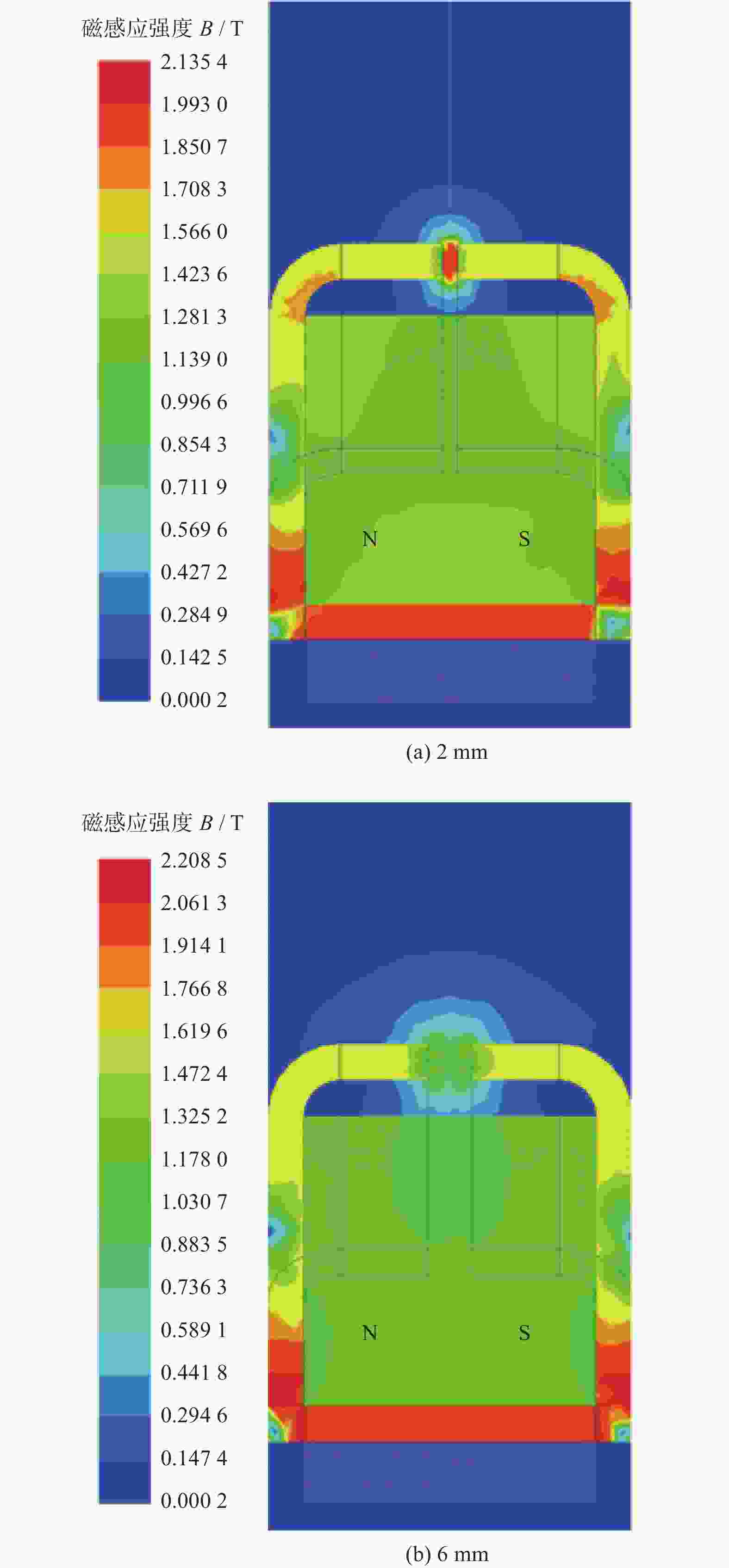

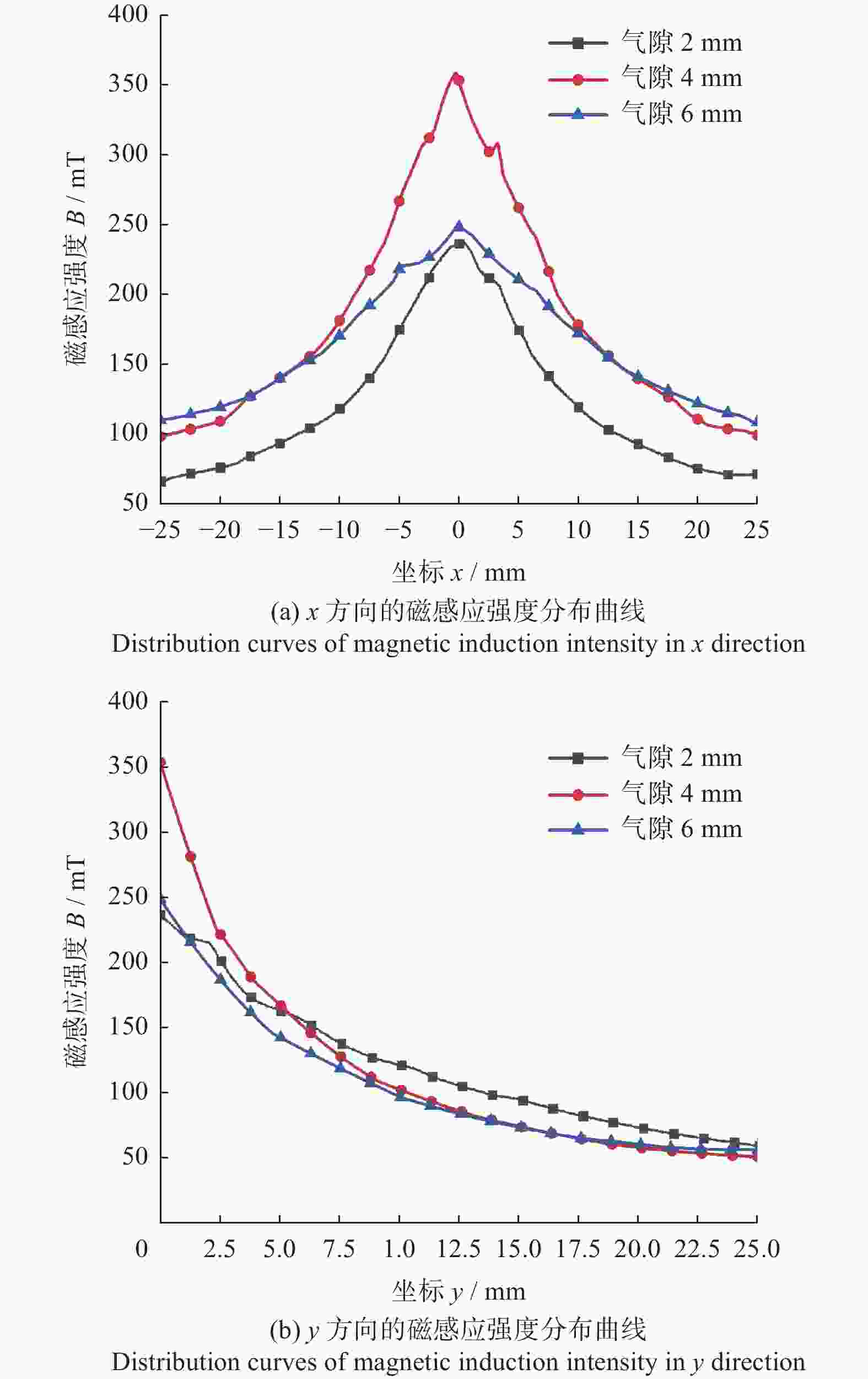

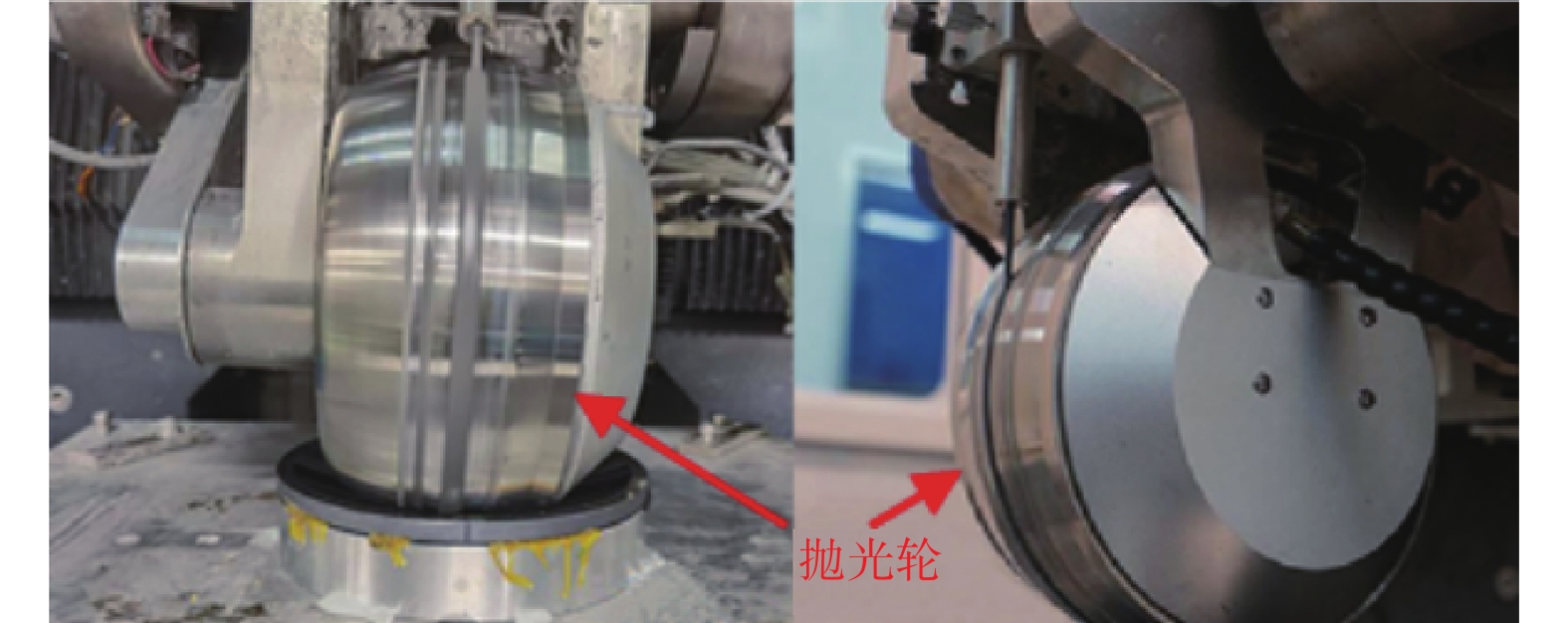

励磁装置作为磁流变抛光设备的核心部件,其能否产生稳定均匀的高梯度磁场,是决定磁流变抛光成功的关键因素。采用扇形永磁体设计磁流变抛光轮励磁装置,并运用ANSYS Electronics Desktop等软件从永磁体数量、充磁方式、排布方式、气隙宽度等方面对励磁装置进行仿真分析,得到不同工况下的磁感应线及磁感应强度分布。结果表明:当气隙宽度为4 mm时,采用单一永磁体轴向充磁产生的磁感应强度最大,可达358.4 mT,理论上可在抛光轮表面形成宽为26 mm、高为6.0 mm的抛光缎带。

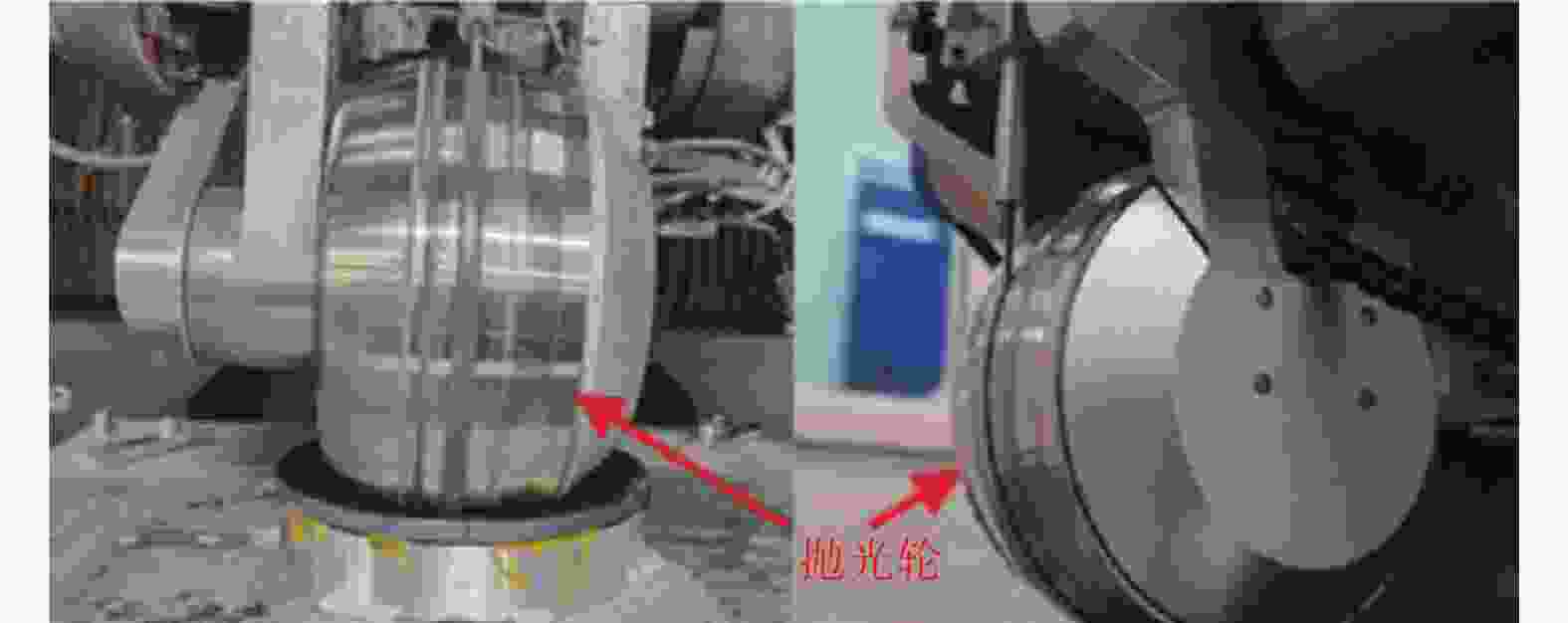

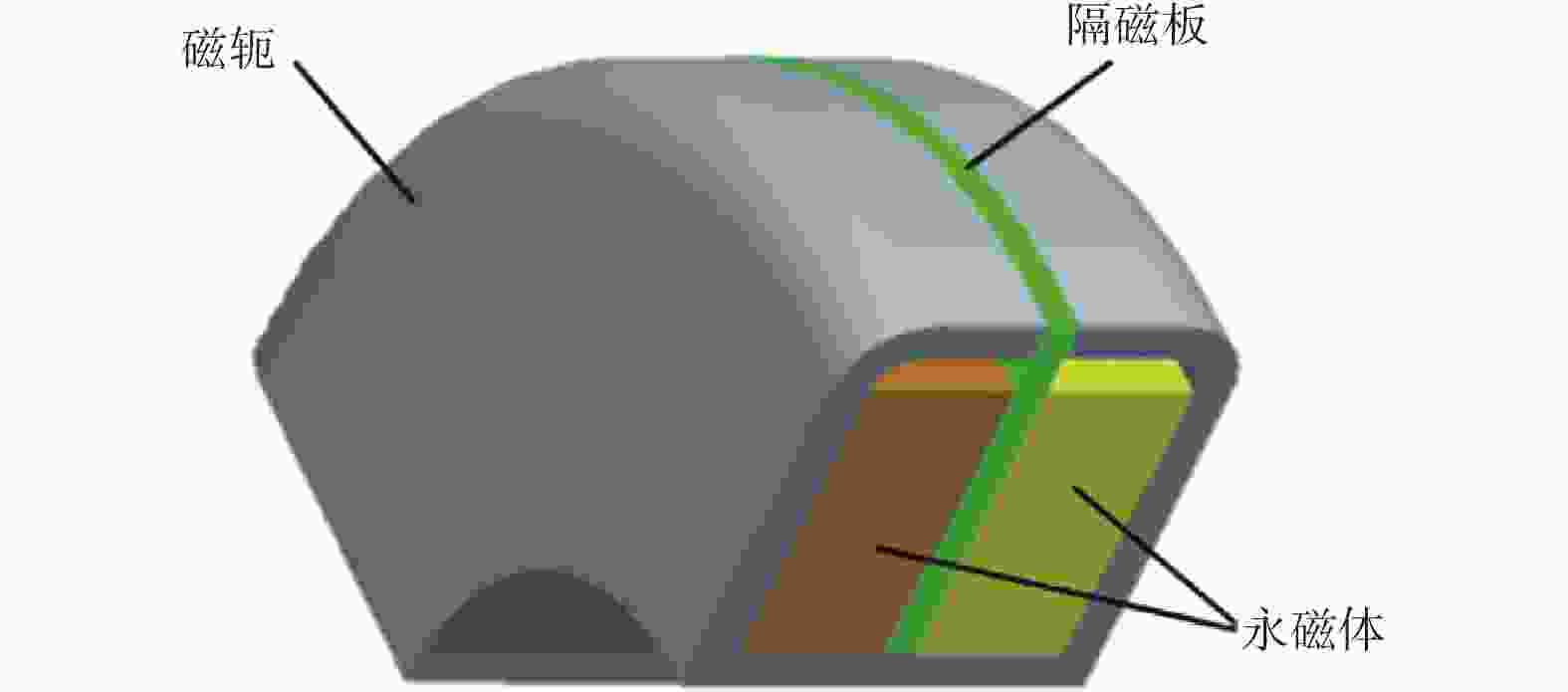

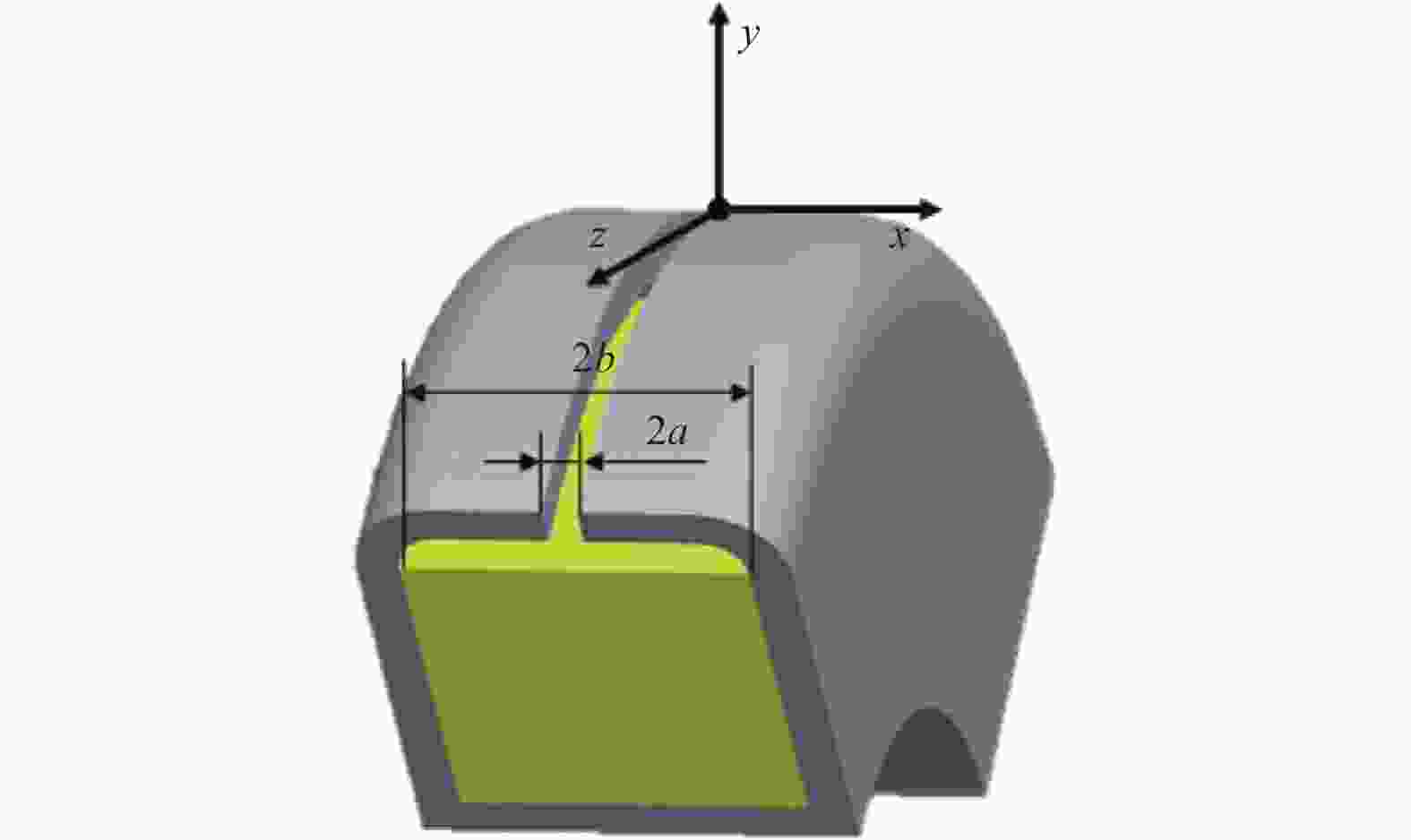

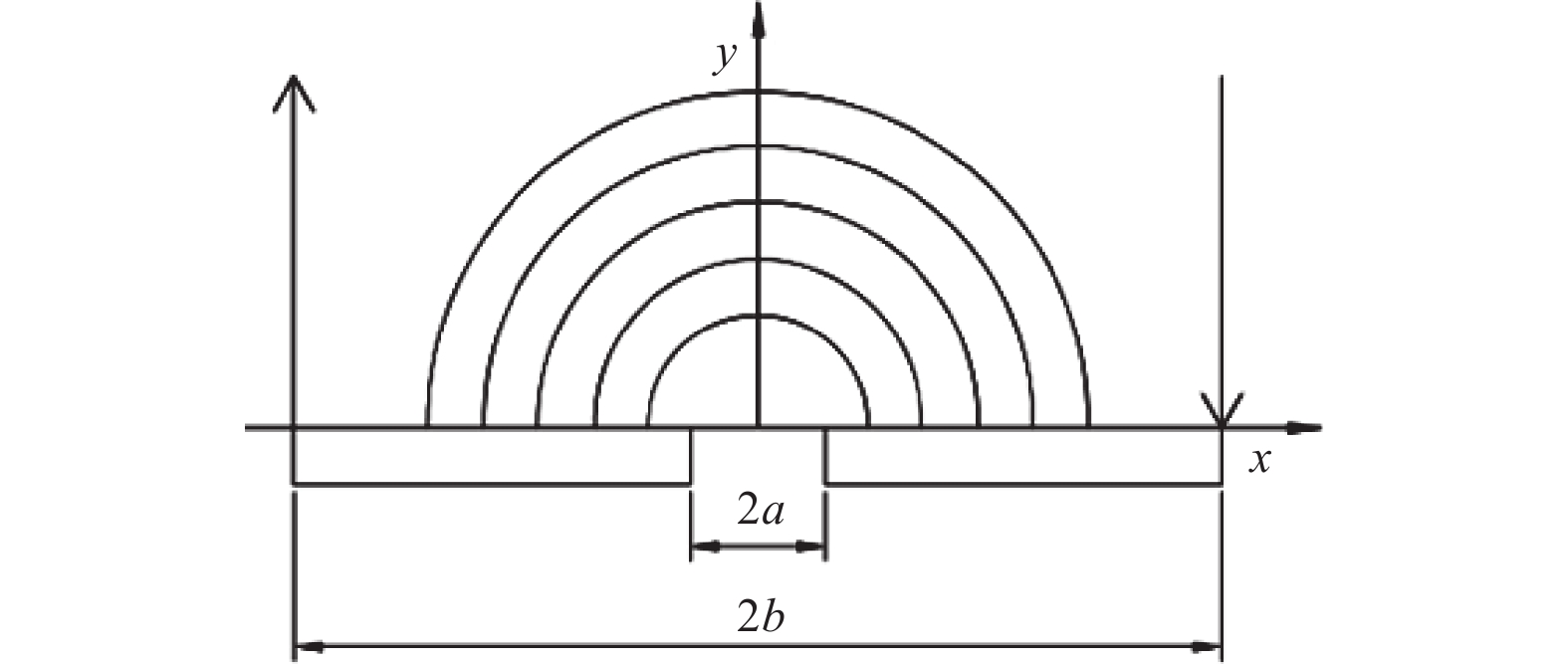

Abstract:As the core component of magnetorheological polishing equipment, the key factor determining the success of magnetorheological polishing is whether the excitation device can generate a stable and uniform high gradient magnetic field. The sector permanent magnet was used to design the excitation device of the magnetorheological polishing wheel. The ANSYS Electronics Desktop and other softwares were used to simulate and analyze the excitation device various aspects, including the number of permanent magnets, magnetization modes, arrangement modes, and air gap widths. The magnetic induction lines and magnetic induction intensity distribution under different working conditions were obtained. The results show that when the air gap width is 4 mm, the magnetic induction intensity produced by axial magnetization of a single permanent magnet is the largest, reaching 358.4 mT. Theoretically, a polishing ribbon with a width of 26 mm and a height of 6.0 mm can be formed on the surface of the polishing wheel.

-

Key words:

- permanent magnets /

- magnetorheological polishing /

- excitation device /

- magnetic field

-

表 1 钕铁硼N50的性能参数

Table 1. Performance parameters of NdFeB N50

参数 数值 剩磁感应强度 Br / T 1.41~1.45 矫顽力 Hcb / (kA·m−1) 828~907 内禀矫顽力 Hcj / (kA·m−1) ≥876 最大磁能积 (BH)max / (kJ·m−3) 382~398 最高工作温度 Tw / ℃ ≤70 表 2 仿真方案

Table 2. Simulation schemes

仿真编号 磁体数量 n / 个 充磁方式 磁极排列分布 1 1 轴向充磁 NS 2 2 轴向充磁 SNSN 3 2 轴向充磁 SNNS 4 2 径向辐射 NS 5 2 径向平行 NS 表 3 仿真结果汇总

Table 3. Simulation results summary

仿真编号 最大磁感应强度

Bmax / mT能否形成抛光头 1 358.4 形成宽为26 mm,峰值高度为

6.0 mm的抛光头2 276.8 形成宽为18 mm,峰值高度为

4.0 mm的抛光头3 11.0 无抛光头形成 4 112.5 无抛光头形成 5 102.7 无抛光头形成 -

[1] 肖强, 王嘉琪, 靳龙平. 磁流变抛光关键技术及工艺研究进展 [J]. 材料导报,2022,36(7):1-24.XIAO Qiang, WANG Jiaqi, JIN Longping. Research progress of key technology and process of magnetorheological polishing [J]. Materials Reports,2022,36(7):1-24. [2] 王嘉琪, 肖强. 磁流变抛光技术的研究进展 [J]. 表面技术,2019,48(10):317-328. doi: 10.16490/j.cnki.issn.1001-3660.2019.10.039WANG Jiaqi, XIAO Qiang. Research progress of magnetorheological polishing technology [J]. Surface Technology,2019,48(10):317-328. doi: 10.16490/j.cnki.issn.1001-3660.2019.10.039 [3] 范娜, 陈传东, 张忠义. 硬脆材料超精密抛光技术研究进展 [J]. 稀土,2022,43(2):20-31.FAN Na, CHEN Chuandong, ZHANG Zhongyi. Research progress on ultra-precision polishing technology of hard and brittle substrate materials [J]. Chinese Rare Earths,2022,43(2):20-31. [4] 周琴琴, 彭可, 陈永福, 等. 磁流变抛光加工中磁场发生装置的设计与实验 [J]. 表面技术,2020,49(6):337-344.ZHOU Qinqin, PENG Ke, CHEN Yongfu. et al. Design and experiment of magnetic field generator in magnetorheological polishing process [J]. Surface Technology,2020,49(6):337-344. [5] 傅茂辉. 半导体晶片磁流变抛光的磁场发生装置设计 [D]. 北京: 北京交通大学, 2018.FU Maohui. Design of magnetic field generator for magnetorheological-finishing of semiconductor wafers [D]. Beijing: Beijing Jiaotong University, 2018. [6] 程灏波. 流体辅助微纳抛光原理与技术 [M]. 北京: 科学出版社, 2014.CHENG Haobo. The principle and technology of fluid assisted micro nano polishing [M]. Beijing: Science Press, 2014. [7] 李士煦. 磁流变抛光去除机理分析与性能优化 [D]. 青岛: 山东科技大学, 2019.LI Shixu. Removal mechanism analysis and performance optimization on magnetorheological finishing [D]. Qingdao: Shandong University of Science and Technology, 2019. [8] 彭小强. 确定性磁流变抛光的关键技术研究 [D]. 长沙: 国防科学技术大学, 2004.PENG Xiaoqiang. Study on the key techniques of deterministic magnetorheological finishing [D]. Changsha: National University of Defense Science and Technology, 2004. [9] 陆敬予. 倒置式磁流变抛光装置研究 [D]. 哈尔滨: 哈尔滨工业大学, 2008.LU Jingyu. Research on inverted device for magnetorheological finishing [D]. Harbin: Harbin Institute of Technology, 2008. [10] 王永强, 尹韶辉, 魏长青, 等. 高效磁流变平整加工中的励磁装置优化及试验研究 [J]. 机械工程学报,2015,51(17):184-193. doi: 10.3901/JME.2015.17.184WANG Yongqiang, YIN Shaohui, WEI Changqing, et al. Optimization of magnetic excitation unit in high efficiency magnetorheological planarization and experimental study [J]. Journal of Mechanical Engineering,2015,51(17):184-193. doi: 10.3901/JME.2015.17.184 [11] 郭隐彪, 郭江, 沈芸松. 磁流变抛光轮结构设计与磁场分析 [J]. 厦门大学学报(自然科学版),2008(4):528-531.GUO Yinbiao, GUO Jiang, SHEN Yunsong. Structural design and magnetic field analysis of magnetorheological polishing wheels [J]. Journal of Xiamen University (Natural Science Edition),2008(4):528-531. [12] 薛阳韩江. 基于永磁体的平面磁流变抛光技术的研究 [D]. 西安: 西安工业大学, 2021.XUE Yanghanjiang. Research on planar magnetorheological polishing technology based on permanent magnet [D]. Xi′an: Xi′an Technological University, 2021. [13] 倪剑锋, 陈月强. 稀土永磁铁磁场特性分析及有限元仿真分析 [J]. 河北能源职业技术学院学报,2020,20(1):82-85. doi: 10.3969/j.issn.1671-3974.2020.01.024NI Jianfeng, CHEN Yueqiang. Analysis of magnetic field characteristics of rare earth permanent magnets and finite element simulation analysis [J]. Journal of Hebei Energy Institute of Vocation and Technology,2020,20(1):82-85. doi: 10.3969/j.issn.1671-3974.2020.01.024 [14] 陈希, 马忠鑫, 程新龙. 基于永磁体的抗磁性材料磁流变抛光装置研究 [J]. 机电工程,2019,36(3):311-315. doi: 10.3969/j.issn.1001-4551.2019.03.017CHEN Xi, MA Zhongxin, CHENG Xinlong. Magnetorheological polishing apparatus for diamagnetic material based on permanent magnets [J]. Journal of Mechanical & Electrical Engineering,2019,36(3):311-315. doi: 10.3969/j.issn.1001-4551.2019.03.017 [15] 宋万里, 马晋涛, 胡志超, 等. 往复式磁流变抛光装置的设计与仿真研究 [J]. 机械设计与制造,2019(2):104-106. doi: 10.3969/j.issn.1001-3997.2019.02.026SONG Wanli, MA Jintao, HU Zhichao, et al. Design and simulation of reciprocating magnetorheological polishing device [J]. Machinery Design & Manufacture,2019(2):104-106. doi: 10.3969/j.issn.1001-3997.2019.02.026 [16] 董国正. 小口径磁流变抛光装置设计与关键技术研究 [D]. 长沙: 国防科技大学, 2015.DONG Guozheng. Design of small-aperture magnetorheological finishing device and the key technology research [D]. Changsha: National University of Defense Technology, 2015. [17] 董国正, 胡皓, 李圣怡, 等. 基于永磁体的小口径磁流变抛光装置设计与优化 [J]. 纳米技术与精密工程,2015,13(4):251-257.DONG Guozheng, HU Hao, LI Shengyi, et al. Design and optimization of small bore magnetorheological finishing device for permanent magnet [J]. Nanotechnology and Precision Engineering,2015,13(4):251-257. [18] 邓高建. 方形永久磁石励磁的高效磁流变抛光工艺研究 [D]. 长沙: 湖南大学, 2014.DENG Gaojian. Research on high efficiency magnetorheological polishing-process with block-shape permanent magnet excitation [D]. Changsha: Hunan University, 2014. [19] 张峰, 邓伟杰. 碳化硅表面硅改性层的磁介质辅助抛光 [J]. 光学学报,2012,32(11):194-199.ZHANG Feng, DENG Weijie. Magnetic-medium assistant polishing of silicon modification layer on silicon carbide surface [J]. Acta Optica Sinica,2012,32(11):194-199. [20] 孙百万. 磁流变抛光试验台结构优化与工作性能分析 [D]. 沈阳: 东北大学, 2017.SUN Baiwan. Structural optimization and working performance analysis of magnetorheological polishing prototype [D]. Shenyang: Northeastern University, 2017. [21] 周虎, 杨建国, 李蓓智. 磁流变抛光装置中的磁路和磁屏蔽设计 [J]. 机械制造,2008(11):32-33. doi: 10.3969/j.issn.1000-4998.2008.11.011ZHOU Hu, YANG Jianguo, LI Beizhi. Design of magnetic circuit and magnetic shielding in magnetorheological polishing equipment [J]. Mechanical Manufacturing,2008(11):32-33. doi: 10.3969/j.issn.1000-4998.2008.11.011 [22] 严密, 彭晓领. 磁学基础与磁性材料 [M]. 杭州: 浙江大学出版社, 2019.YAN Mi, PENG Xiaoling. Fundamentals of magnetism and magnetic materials [M]. Hangzhou: Zhejiang University Press, 2019. [23] 宾水明. 多磨头磁流变抛光装置设计及实验研究 [D]. 广州: 广东工业大学, 2019.BIN Shuiming. Device design and experimental research of magnetorheological finishing with multiple polishing heads [D]. Guangzhou: Guangdong University of Technology, 2019. [24] 路家斌, 宾水明, 阎秋生, 等. 磁场分布对多磨头磁流变抛光材料去除的影响 [J]. 润滑与密封,2020,45(4):20-26. doi: 10.3969/j.issn.0254-0150.2020.04.004LU Jiabin, BIN Shuiming, YAN Qiusheng, et al. Effect of magnetic field distribution on material removal in magnetorheological finishing with multiple polishing heads [J]. Lubrication Engineering,2020,45(4):20-26. doi: 10.3969/j.issn.0254-0150.2020.04.004 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS