Effect of maceration alloys on the performances of PDC drill bit matrix

-

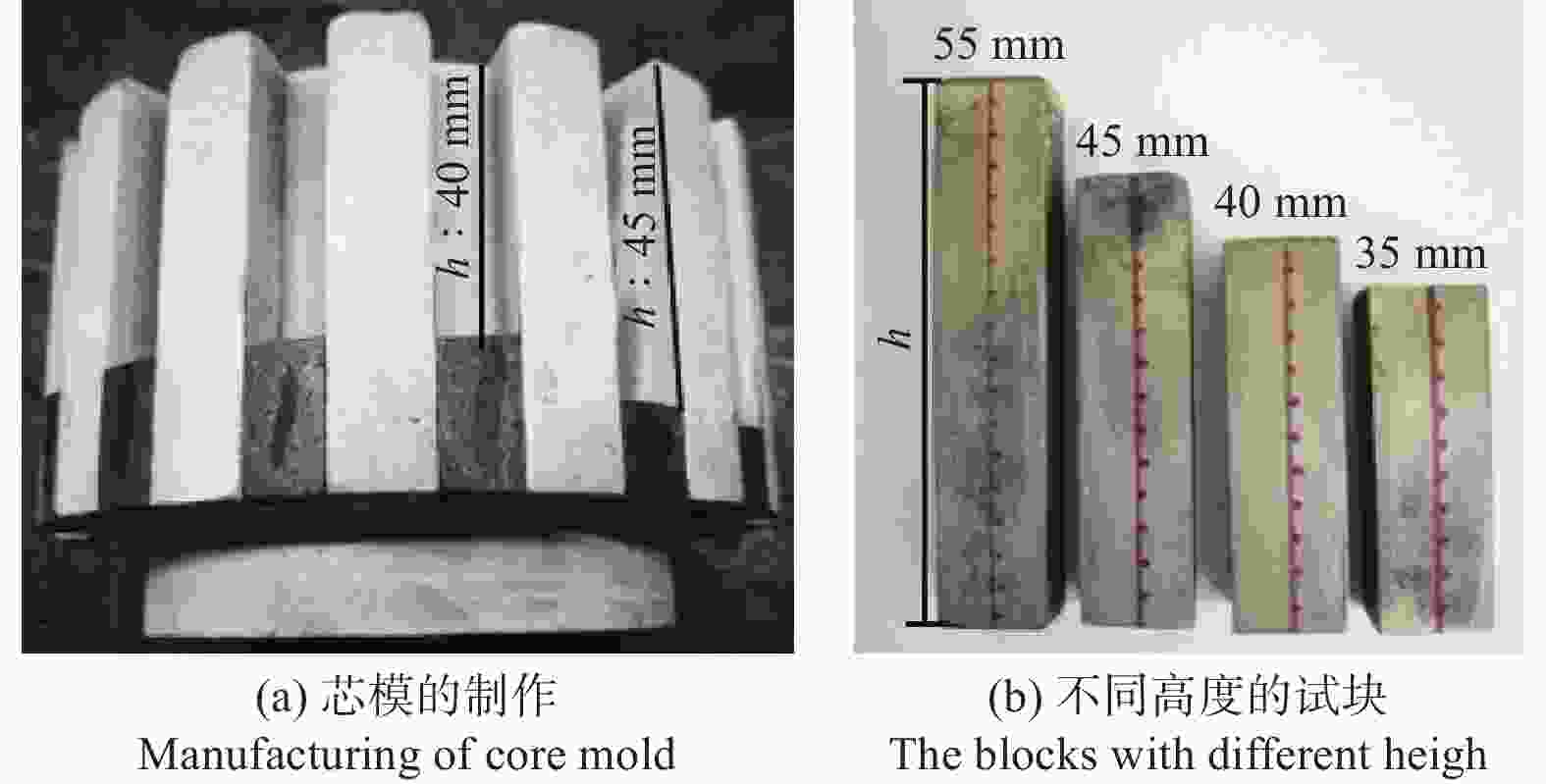

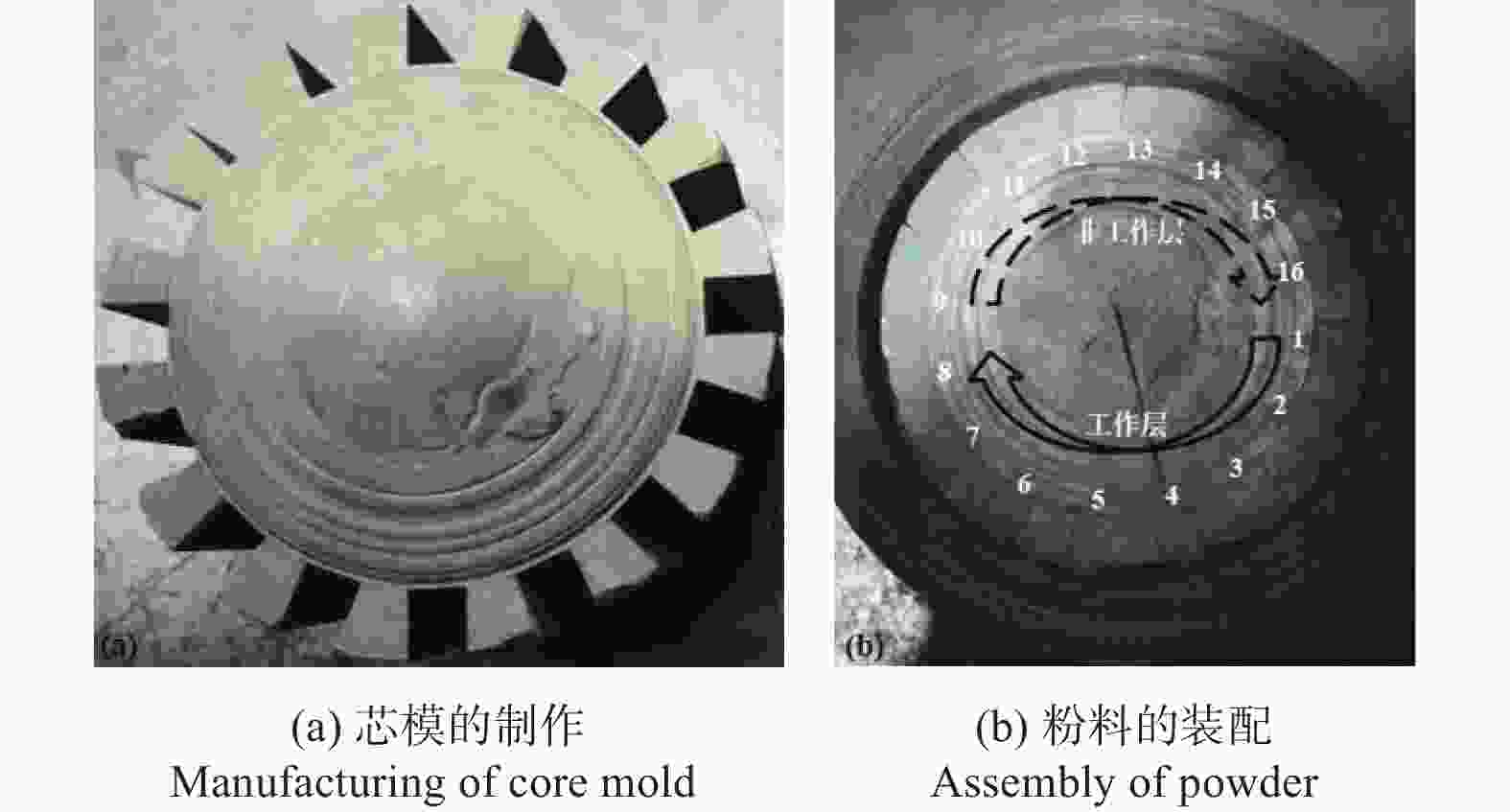

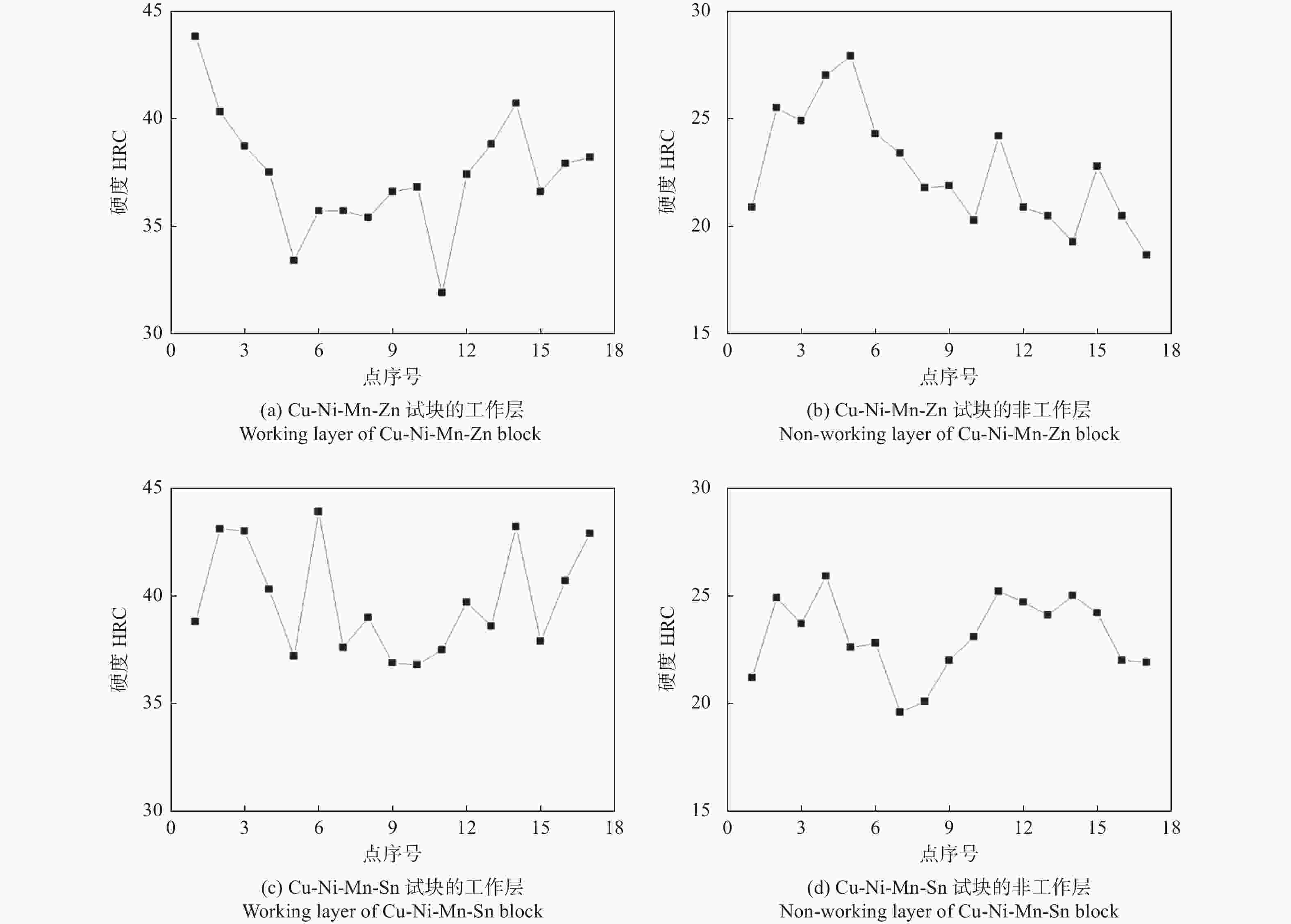

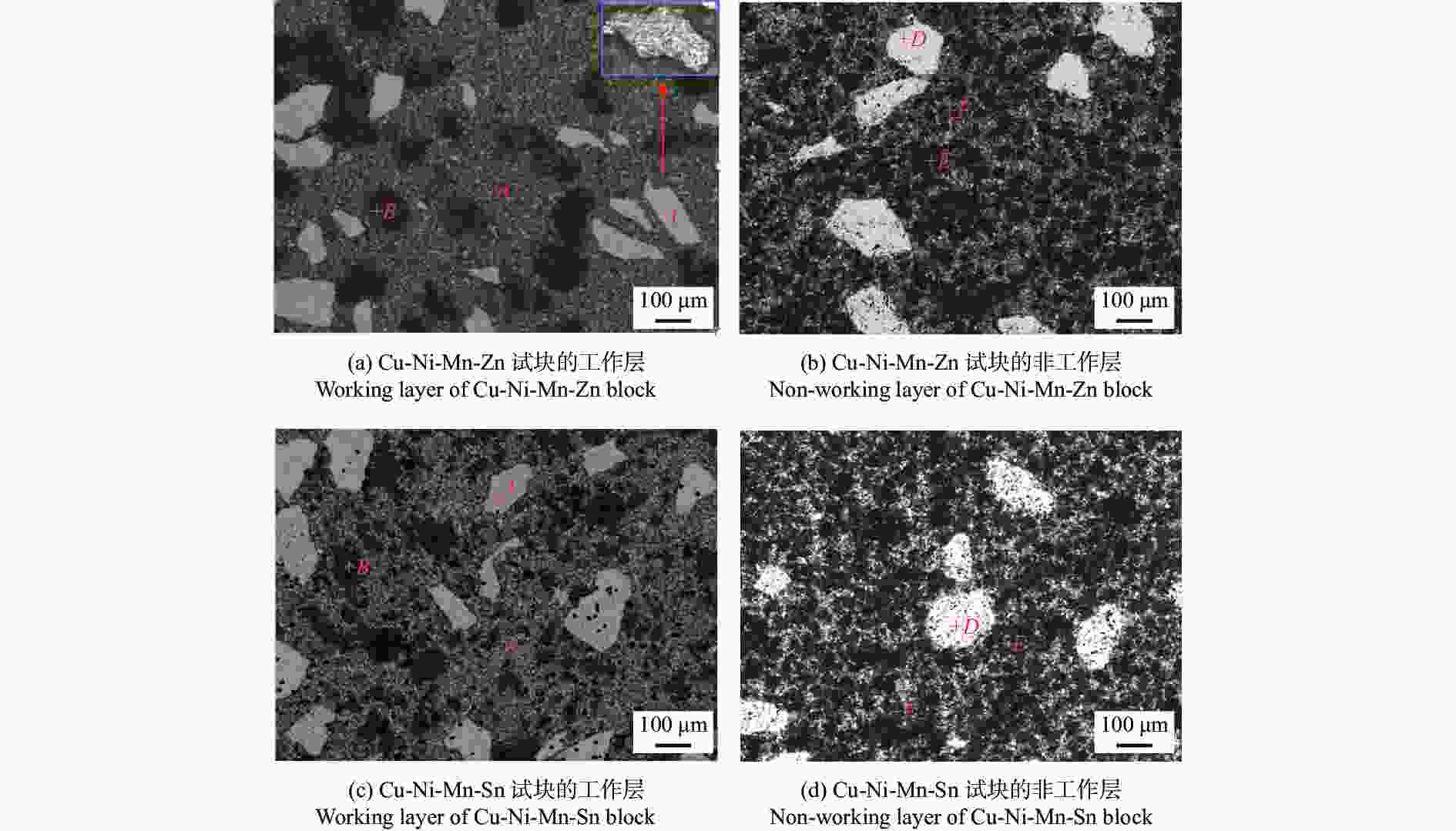

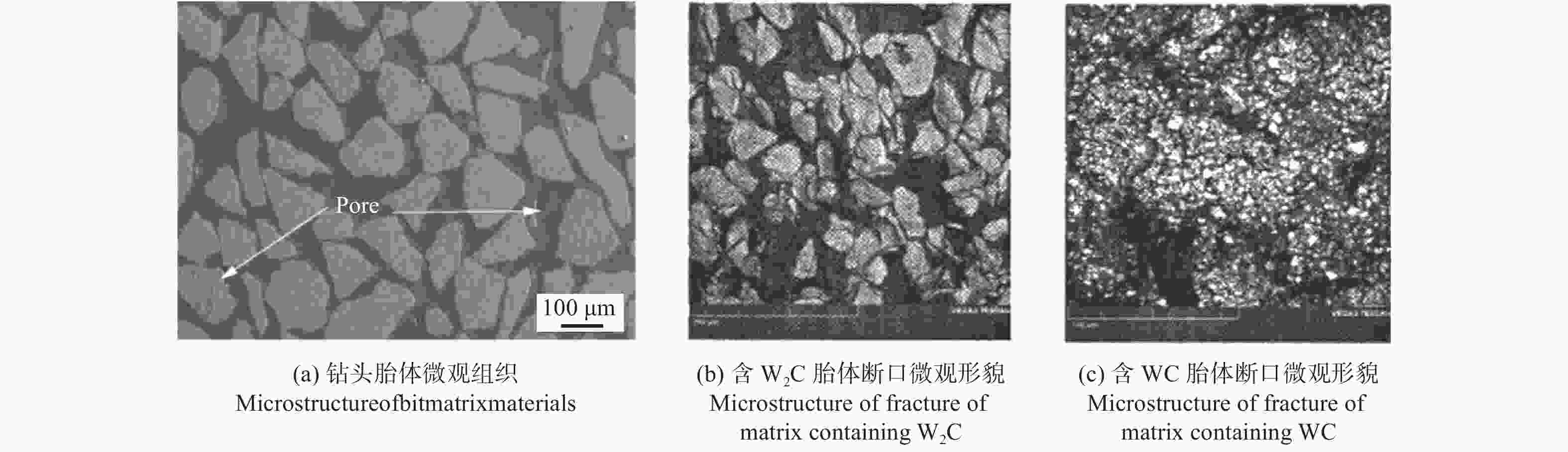

摘要: PDC钻头胎体的浸润比对其力学性能和微观形貌的影响较大,为了探究浸渍合金对胎体性能的影响规律,采用Cu-Ni-Mn-Zn和Cu-Ni-Mn-Sn 2种浸渍合金制作不同高度的工作层和非工作层试块,得出不同浸渍合金下钻头胎体工作层和非工作层的浸润比及力学性能差异,同时利用扫描电镜对试块的微观形貌和元素含量进行分析。结果表明:试块的浸润比为定值;胎体钻头工作层的浸润比小于非工作层的,微观形貌上表现为工作层中浸渍合金的岛状组织大而分散,非工作层的岛状组织小而致密;对于同种类型的试块,通常浸润比越大密度越大;采用Cu-Ni-Mn-Sn得到的试块硬度均大于Cu-Ni-Mn-Zn试块的,但其抗弯强度和冲击韧性远低于Cu-Ni-Mn-Zn试块的。Abstract: The wetting ratio of PDC drill bit matrix has a great influence on its mechanical properties and microstructure. To explore the influences of maceration alloys on the performance of PDC drill bit matrix, two kinds of maceration alloys, Cu-Ni-Mn-Zn and Cu-Ni-Mn-Sn, were used to make the working layer and the non-working layer test blocks with different heights. The differences in wetting ratio and mechanical properties between the working layer and the non-working layer of the matrix bit under different maceration alloys were obtained. At the same time, scanning electron microscopy was used to analyze the microstructure and the element content of the blocks. The results show that the wetting ratio of the test block is a constant value. The wetting ratio of the working layer of the bit matrix is smaller than that of the non-working layer. The microstructures show that the island structure of the maceration alloy in the working layer is large and dispersed, while the island structure in the non-working layer is small and dense. For the same type of test block, the higher the wetting ratio, the higher the density. The hardness of the test block obtained by Cu-Ni-Mn-Sn is higher than that of Cu-Ni-Mn-Zn, but its bending strength and impact toughness are much lower than that of Cu-Ni-Mn-Zn.

-

Key words:

- PDC drill bit matrix /

- maceration alloys /

- wetting ratio /

- mechanical properties /

- microstructure

-

表 1 浸渍合金的主要成分

Table 1. Main components of maceration alloys

浸渍合金 质量分数 ω1 / % Cu Ni Mn Zn Sn Cu-Ni-Mn-Zn 余量 0~5 5~10 20~25 Cu-Ni-Mn-Sn 余量 10~15 0~5 0~5 表 2 工作层试块的浸润比

Table 2. Wetting ratios of working layer blocks with different heights

试块高度 h / mm $ {m}_{粉} $/ g $ {m}_{块} $/ g 浸润比 i 55 47.488 59.138 0.25 45 36.832 46.822 0.27 40 32.126 40.910 0.27 35 29.010 36.290 0.25 表 3 不同浸渍合金试块的浸润比、密度及力学性能

Table 3. Wetting ratios, density and mechanical properties of different maceration alloy blocks

试块性能 浸渍合金 Cu-Ni-Mn-Zn Cu-Ni-Mn-Sn 工作层 非工作层 工作层 非工作层 浸润比 i 0.26 0.49 0.34 0.44 密度 ρ / (g·cm−3) 12.205 10.190 12.330 10.079 硬度 HRC 37.4 22.6 39.8 23.1 抗弯强度 σ / MPa 1 050.581 893.413 828.541 756.561 冲击韧性 KIC / (kJ·m−2) 33.76 54.72 31.02 47.42 表 4 试块的能谱分析结果

Table 4. Results of energy spectrum analysis of blocks

元素 浸渍合金 Cu-Ni-Mn-Zn Cu-Ni-Mn-Sn 工作层元素质量分数 ω2 / % 非工作层元素质量分数 ω3 / % 工作层元素质量分数 ω2 / % 非工作层元素质量分数 ω3 / % A B C D E F A B C D E F Mn 2.98 2.25 1.20 6.10 4.05 Fe 32.31 6.11 19.87 2.97 10.63 Ni 19.66 8.59 12.39 7.69 17.64 9.31 Cu 40.12 18.38 34.43 23.38 58.12 40.52 72.59 40.24 Zn 24.89 15.31 18.62 15.64 Sn 3.09 2.44 1.76 W 100.00 12.35 57.72 100.00 47.18 100.00 3.17 47.31 100.00 0.98 58.00 -

[1] 李俊萍, 胡立, 唐治建, 等. 超细FeCoCu粉末在金刚石钻头中的试验研究 [J]. 探矿工程(岩土钻掘工程),2018,45(8):19-22.LI Junping, HU Li, TANG Zhijian. Experimental study on ultrafine pre-alloy powder FeCoCu used in diamond bits [J]. Exploration Engineering (Rock & Soil Drilling and Tunneling),2018,45(8):19-22. [2] 谢焕文, 刘辛, 胡可, 等. 碳化钨粉末对 PDC 钻头胎体组织与力学性能的影响 [J]. 复合材料学报,2019,36(5):1235-1243.XIE Huanwen, LIU Xin, HU Ke, et al. Effect of cast tungsten carbide powders on microstructure and mechanical properties of polycrystalline diamond compact bit matrix [J]. Acta Materiae Compositae Sinica,2019,36(5):1235-1243. [3] 王帅, 吕智, 林峰, 等. WC含量对金刚石钻头胎体性能的影响研究 [J]. 金刚石与磨料磨具工程,2014,34(6):16-21.WANG Shuai, LV Zhi, LIN Feng, et al. Effect of WC content on the properties of impregnated diamond bit matrix [J]. Diamond & Abrasives Engineering,2014,34(6):16-21. [4] 杨展. 预合金粉胎体钻头性能的研究 [J]. 青岛科技大学学报(自然科学版),2013,34(1):71-75.YANG Zhan. Performance of diamond bit matrix fabricated by pre-alloyed powder materials [J]. Journal of Qingdao University of Science and Technology (Natural Science Edition),2013,34(1):71-75. [5] 常思. 金刚石钻头胎体材料力学性能的多元纳米强化研究 [D]. 吉林: 吉林大学, 2022.CHANG Si. Investigation of hybrid nano-strengthening on mechanical properties of diamond drill bit matrix [D]. Jilin: Jilin University, 2022. [6] ZHANG K, WANG D G, WANG Z Q, et al. Effect of Ni content and maceration metal on the microstructure and properties of WC based diamond composites [J]. International Journal of Refractory Metals & Hard Materials,2020(88):105196. [7] 高雅, 纠永涛, 于新泉, 等. 合金元素对Fe基金刚石节块胎体组织及性能的影响 [J]. 粉末冶金技术,2019,37(2):104-111.GAO Ya, JIU Yongtao, YU Xinquan, et al. Effect of alloy elements on microstructures and properties of Fe-based matrixes for diamond segment [J]. Power Metallurgy Technology,2019,37(2):104-111. [8] 卢安军, 秦海青, 雷晓旭, 等. Ni对自由烧结金刚石工具胎体性能的影响 [J]. 超硬材料工程,2014,26(2):35-38. doi: 10.3969/j.issn.1673-1433.2014.02.010LU Anjun, QIN Haiqing, LEI Xiaoxu, et al. Influence of Ni on the performance of free sintering diamond tool matrix [J]. Superhard Material Engineering,2014,26(2):35-38. doi: 10.3969/j.issn.1673-1433.2014.02.010 [9] HU H X, CHEN W, DENG C, et al. Effect of Fe prealloyed powder and the sintering process on the matrix properties of impregnated diamond bits [J]. Journal of Materials Research and Technology,2021(12):150-158. doi: 10.1016/j.jmrt.2021.02.070 [10] 潘建军, 齐建钊, 龙伟民. PDC钻头用浸渍钎料性能研究 [J]. 金刚石与磨料磨具工程,2013,33(3):60-62.PAN Jianjun, QI Jianzhao, LONG Weimin. Performance of dipped brazing filler metal used in PDC bit [J]. Diamond & Abrasives Engineering,2013,33(3):60-62. [11] 潘建军, 齐建钊, 龙伟民, 等. 金刚石钻头用浸渍钎料的性能分析 [J]. 焊接,2013(2):67-69. doi: 10.3969/j.issn.1001-1382.2013.02.016PAN Jianjun, QI Jianzhao, LONG Weimin, et al. Performance analysis of dipped brazing filler metal for diamond bit [J]. Welding & Joining,2013(2):67-69. doi: 10.3969/j.issn.1001-1382.2013.02.016 [12] 窦晓玥. 新型低造价高性能PDC钻头浸渍合金的研究 [D]. 天津: 河北工业大学, 2008.DOU Xiaoyue. Study on a new type of maceration alloys with low-cost and high-property used in PDC bits [D]. Tianjin: Hebei University of Technology, 2008. [13] 黄俊兰, 龙伟民, 潘建军. 金刚石钻头用钎料的研究 [J]. 焊接,2016(3):26-28. doi: 10.3969/j.issn.1001-1382.2016.03.007HUANG Junlan, LONG Weimin, PAN Jianjun. Study on brazing filler metal for diamond bit [J]. Welding & Joining,2016(3):26-28. doi: 10.3969/j.issn.1001-1382.2016.03.007 [14] 覃怀鹏. Cu和Ni的化合物对金刚石钻头胎体性能的影响 [J]. 超硬材料工程,2016,28(5):1-6. doi: 10.3969/j.issn.1673-1433.2016.05.001QIN Huaipeng. Influence of Cu&Ni compound on the matrix performance of diamond drill bit [J]. Superhard Material Engineering,2016,28(5):1-6. doi: 10.3969/j.issn.1673-1433.2016.05.001 [15] 袁德林, 张金祥, 张帆, 等. 掺杂稀土的高速钢预合金粉对 WC 基钢结硬质合金组织和性能影响 [J]. 中国钨业,2020,35(2):67-70. doi: 10.3969/j.issn.1009-0622.2020.02.012YUAN Delin, ZHANG Jinxiang, ZHANG Fan, et al. Effect of rare earth doped high speed steel pre-alloyed powder on the microstructure and properties of WC-based steel bonded cemented carbide [J]. China Tungsten Industry,2020,35(2):67-70. doi: 10.3969/j.issn.1009-0622.2020.02.012 [16] 幸雪松, 张会增, 胡正惠, 等. 球形铸造碳化钨对PDC钻头喷焊层冲蚀性能的影响 [J]. 机械科学与技术, 2023(2): 294-300.XING Xuesong, ZHANG Huizeng, HU Zhenghui, et al. Influence of spherica cast tungsten carbide on erosion resistance of spray welding coating of PDC drill bit [J]. Mechanical Science and Technology for Aerospace Engineering, 2023(2): 294-300. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS