Cold compaction and crushing of diamond powders during the sintering of polycrystalline diamond

-

摘要:

为提升聚晶金刚石的致密度,研究在初装、冷等静压后以及六面顶压机内等不同压力条件下,不同金刚石粉体粒径和配比在加压前后的粉体密度、粒径分布及重排微观结构变化,发现金刚石粉体的变化规律。合成过程包括初装料的无序排列到220 MPa等静压后的细颗粒填充孔隙与重排,再到超高压力下大颗粒被挤压破碎,孔隙被逐步填充。由于细颗粒的缓冲效应,大颗粒G20~30在双粒径配方G2~4和G20~30中比在单一粒径G20~30配方中破碎更少,更有利于提升金刚石粉体堆积密度。

-

关键词:

- 聚晶金刚石(PCD) /

- 粉体密度 /

- 粒径分布 /

- 冷压 /

- 破碎

Abstract:[Objectives] Polycrystalline diamond (PCDs) compacts are extensively used in industries such as oil drilling, geological exploration, and high-speed machining tools. To further enhance the density of PCDs and thus improve their performance, this research investigates the powder density, particle size distribution, and changes in their microstructure under different pressures for diamond micro-powders with varying particle sizes and proportions. The objective is to understand the fragmentation behavior and obtain diamond formulations with higher density.

[Methods] A set amount of diamond micro-powders was placed in a fixed-size niobium cup, shaken and compacted before sealing. The cup was then positioned in a synthetic pyrophyllite block, layered with metal plugs, molybdenum, carbon, zirconia, magnesia, and sodium chloride, replicating the structure used in synthesizing PCD tools. A cold isostatic press and a cubic press were employed to apply different pressure gradients. At 220 MPa, the sealed niobium cups underwent liquid pressurization in the cold isostatic press, while the cubic press facilitated pressures of 20, 30, and 40 MPa. After compression, the samples’ mass and volume were measured to calculate their density. Scanning electron microscopy (SEM) was used to observe the morphology of the internal powders, and a laser particle size analyzer was used to observe particle size distribution. The crushing conditions and patterns of diamond micro-powders were then summarized.

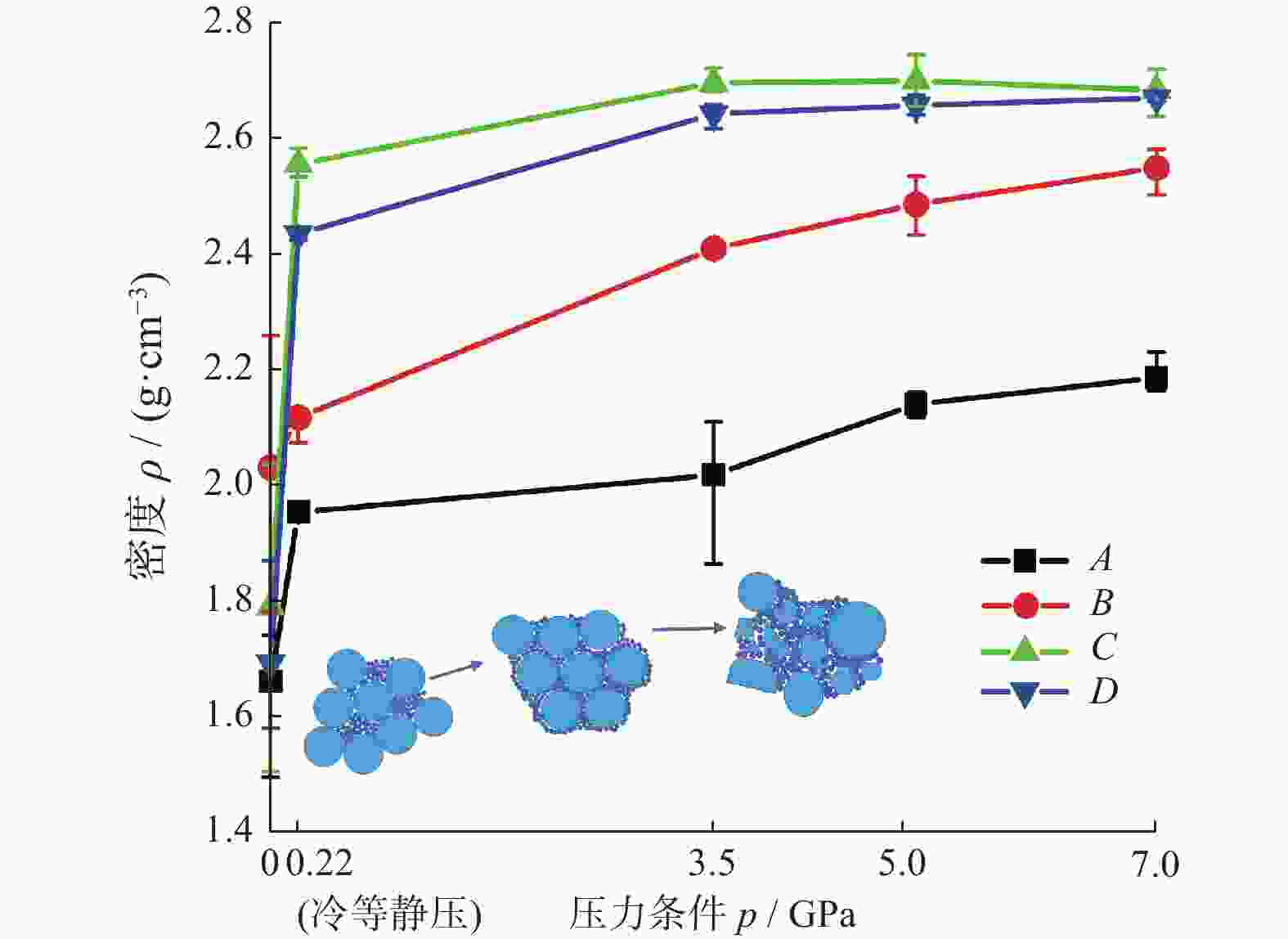

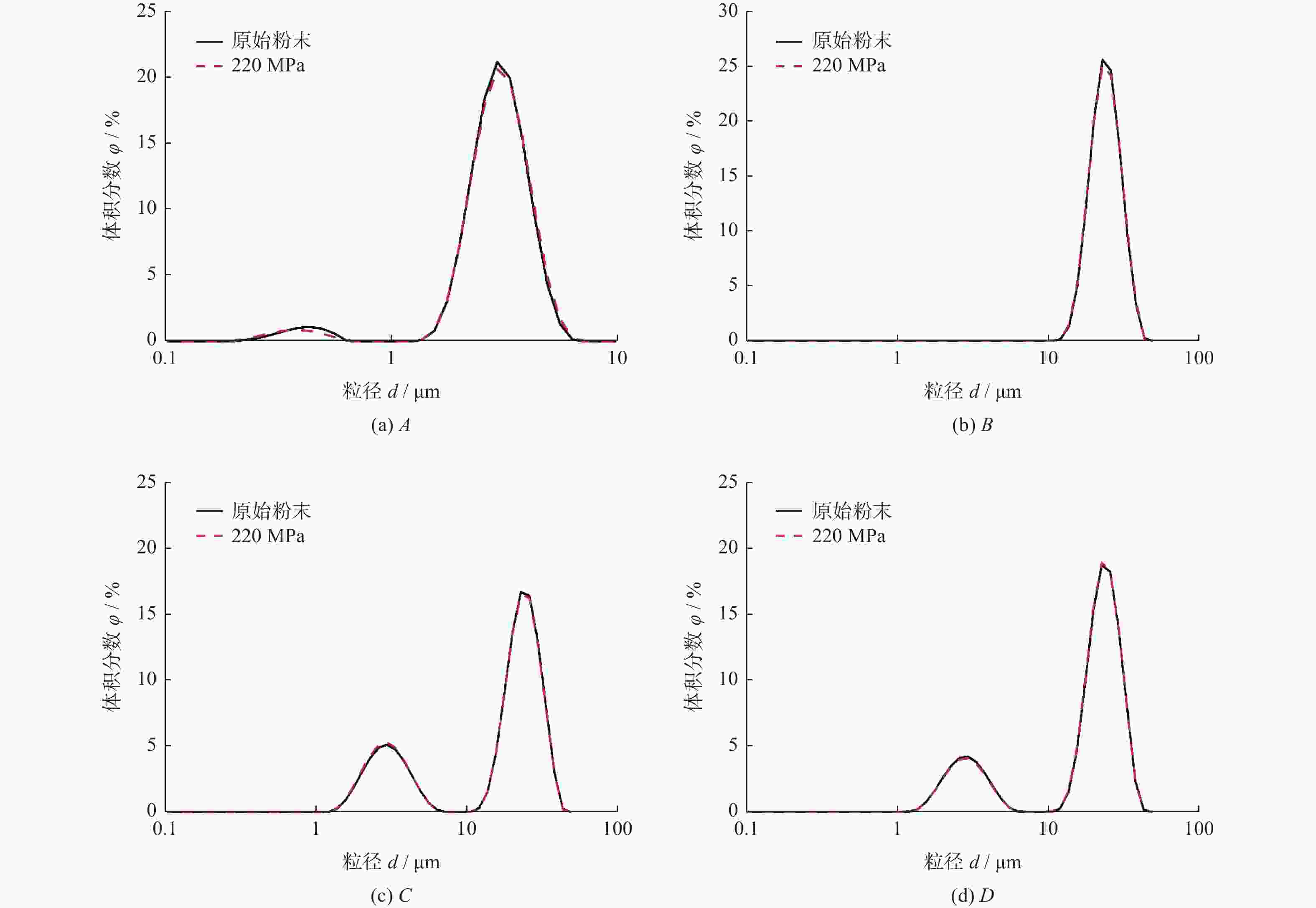

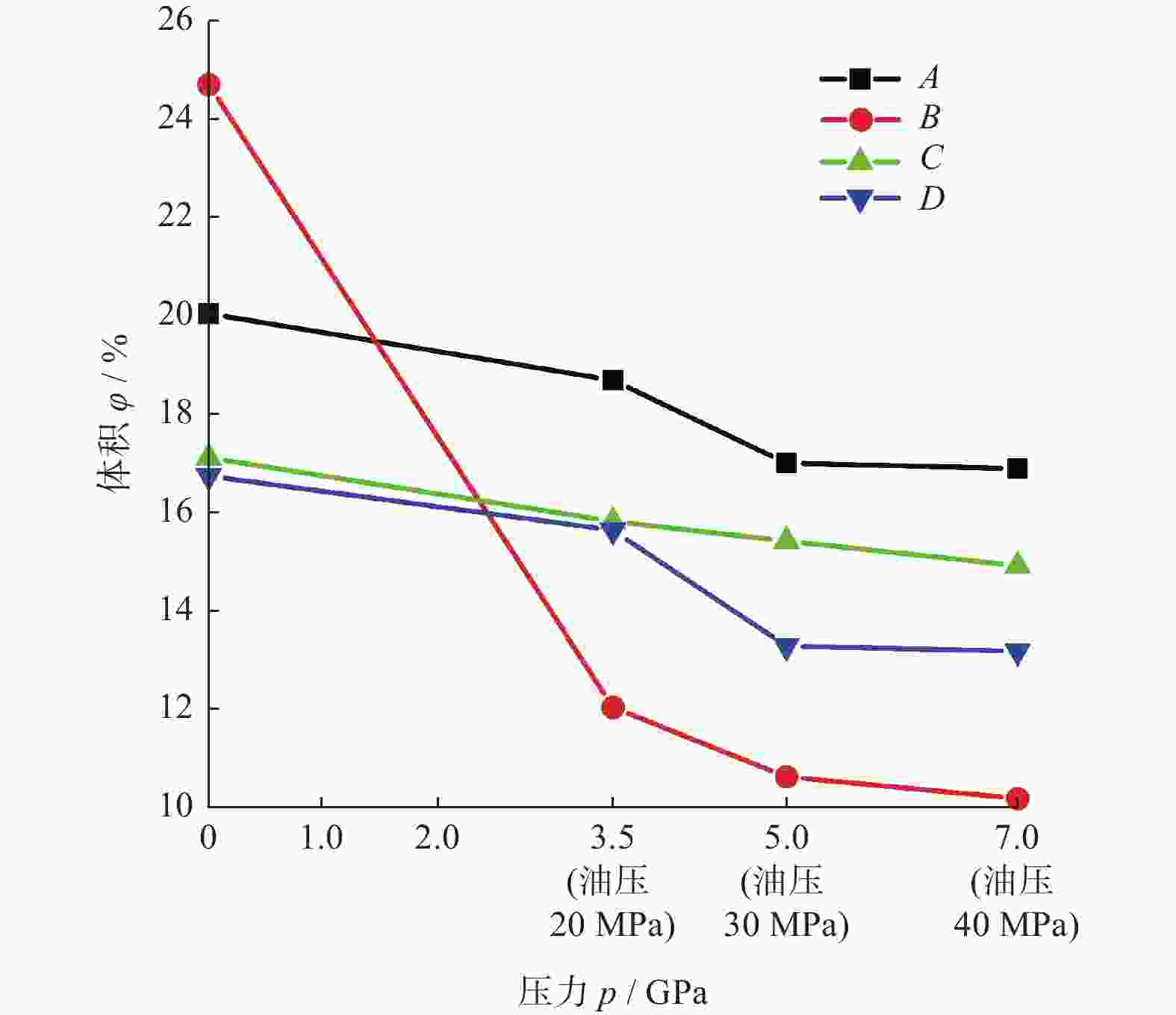

[Results] In summary, the density of diamond micro-powders increased with pressure. After compaction, density distribution ranges from 1.5 to 2.1 g/cm3. For samples of the same volume, coarser particles exhibited higher densities than finer ones, with mixed powder samples showing intermediate densities. This indicated that in the compacted state, there was a larger void ratio between fine particles, and in mixed powders, fine particles were not effectively dispersed among large particles. After cold isostatic pressing at 0.22 GPa, there was a significant increase in sample density, with the density of mixed powders increasing by nearly half, indicating a compact particle arrangement without crushing. Under pressure, particles re-arranged, reducing voids and allowing fine particles to fill the gaps between larger ones. High-pressure treatment in cubic pressing at 20, 30, and 40 MPa resulted in internal pressures of approximately 3.5, 5.0, and 7.0 GPa respectively. Diamond micro-powders underwent fragmentation under high external pressure, and sample densities continued to change, increasing with pressure. Particle size analysis of the crushed powders revealed significant changes in particle size distribution of large particles under high pressure, indicating severe crushing. The density of the mixed powder samples also increased. However, the addition of small diamond micro-powders significantly reduced the crushing of larger particles, with less changes in particle size distribution, which helped maintain the original formulation. SEM observation showed clear crushing of larger particles and validated the stacking model of different particle sizes in the mixed powders. Small particles were evenly distributed among the larger particles, acting as a buffer to increase contact points and reduce stress concentration, thus significantly reducing the occurrence of crushing and rapidly increasing density.

[Conclusions] During the cold pressing stage of synthesis process for PCD compacts, diamond micro-powders of all types undergo varying degrees of crushing, with single-component large particles being most notably affected, while the inclusion of small diamond micro-powders significantly reduces this effect. Mixing large and small diamond particles effectively alleviates the crushing of diamond micro-powders and allows for higher density under the same pressure, resulting in PCDs with higher density and improved performance.

-

Key words:

- polycrystalline diamond (PCD) /

- powder density /

- particle size distribution /

- cold pressing /

- crushing

-

表 1 主峰中位径D50的体积分数及变化

Table 1. Volume percentage variation of the main peak’s D50

样品 体积分数φ/% 初始 系统油压20 MPa Δ 系统油压30 MPa Δ 系统油压40 MPa Δ A 20.0 18.7 6.5 17.0 15 16.9 15.5 B 24.7 12.1 51 10.7 56.7 10.2 58.7 C 17.1 15.8 7.6 15.4 9.9 15.0 12.3 D 16.8 15.7 6.5 13.3 20.8 13.2 21.4 -

[1] YANG X, DENG F. Synthesis and characterisation of ϕ62 mm polycrystalline diamond compact [J]. Diamond & Related Materials,2019,100:107594. [2] MINORU A, SHINOBU Y, FUMIHIRO U, et al. Synthesis of polycrystalline diamond compact with magnesium carbonate and its physical properties [J]. Diamond & Related Materials,1996,5:2-7. [3] JOHAN E W, NATALIA D, JAN H, et al. Thermally stable polycrystalline diamond sintered with calcium carbonate [J]. Diamond & Related Materials,2007,16(11):1929-1935. [4] 邹芹, 向刚强, 王瑶, 等. 聚晶金刚石的研究进展与展望 [J]. 金刚石与磨料磨具工程,2021,41(3):23-32.ZOU Qin, XIANG Gangqiang, WANG Yao, et al. Research progress and prospect of polycrystalline diamond [J]. Diamond & Abrasives Engineering,2021,41(3):23-32. [5] 白清顺, 姚英学, ZHANG Grace, 等. 聚晶金刚石(PCD)刀具发展综述 [J]. 工具技术,2002(3):7-10.BAI Qingshun, YAO Yingxue, ZHANG Grace, et al. Summary of development of polycrystalline diamond (PCD) cutting tools [J]. Tool Engineering,2002(3):7-10. [6] 张勤俭, 曹凤国, 王先逵. 聚晶金刚石的应用现状和发展趋势 [J]. 金刚石与磨料磨具工程,2006(1):71-74.ZHANG Qinjian, CAO Fengguo, WANG Xiankui. Application status and development trends of polycrystalline diamond [J]. Diamond & Abrasives Engineering,2006(1):71-74. [7] 方啸虎, 崔祥仁, 谢德龙. 近年来钻探用超硬材料的发展与展望 [J]. 探矿工程, 2021, 48(S1): 18-24.FANG Xiaohu, CUI Xiangren, XIE Delong. Development and prospect of the super hard materials applied to the drilling industry in recent years[J].Exploration Engineering (Drilling &Tunneling), 2021, 48(S1): 18-24. [8] 贾洪声, 李彦涛, 王琰弟, 等. 金刚石初始粒径对金刚石聚晶层形貌及表面残余应力的影响 [J]. 超硬材料工程,2010,22(4):21-23.JIA Hongsheng, LI Yantao, WANG Yandi, et al. Effect of original size of diamond on morphology and surface residual stress in polucrystalline diamond (PCD) [J]. Superhard Material Engineering,2010,22(4):21-23. [9] 邓福铭, 陆绍悌, 王强, 等. 不同粒度金刚石微粉对PCD微结构与性能的影响 [J]. 超硬材料工程,2012,24(6):15-20. doi: 10.3969/j.issn.1673-1433.2012.06.004DENG Fuming, LU Zhaoti, WANG Qiang, et al. Effects of particle size of diamond powder in the microstructure and properties of PCD [J]. Superhard Material Engineering,2012,24(6):15-20. doi: 10.3969/j.issn.1673-1433.2012.06.004 [10] LAMMER A. Mechanical properties of polycrystalline diamonds [J]. Materials Science and Technology,1988,4(11):949-955. doi: 10.1179/mst.1988.4.11.949 [11] MIESS D, RAI G. Frature toughness and thermal resistance of polycrystalline diamond compacts [J]. Materials Science and Engineering A, 1996(209): 270-276 [12] MCNAMARA D, ALVEEN P, CAROLAN D, et al. Fracture toughness evaluation of polycrystalline diamond as a function of microstructure [J]. Engineering Fracture Mechanics,2015,143:1-16. doi: 10.1016/j.engfracmech.2015.06.008 [13] THOMAS A S. The influence of microstructure on the mechanical properties of polycrystalline diamond: A literature review [J]. Advances in Applied Ceramics,2018,117(3):161-176. doi: 10.1080/17436753.2017.1389462 [14] 王海阔, 任瑛, 贺端威, 等. 六面顶压机立方压腔内压强的定量及受力分析 [J]. 物理学报,2017,66(9):68-75.WANG Haikuo, REN Ying, HE Duanwei, et al. Force analysis and pressure quantitative measurement for the high pressure cubic cell [J]. Acta Physics Sinica,2017,66(9):68-75. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS