Effect of metal coated FeCuNi powder on properties of diamond tool matrix

-

摘要: 为解决Co基金刚石工具成本高,Fe基金刚石工具烧结温度高、把持力弱、胎体易烧死等问题,通过化学法将Cu、Sn、Bi等金属分别包覆于FeCuNi合金粉末表面,制备成金属包覆FeCuNi合金粉末。结果表明:配方中添加金属包覆FeCuNi合金粉末后,三点抗弯强度提高近20%;金属包覆FeCuNi合金粉末烧结过程中,FeCuNi颗粒表面的Sn、Bi率先熔化,与Cu反应形成的Cu-Sn、Cu-Bi等液相能够形成连续的网络状结构,将FeCuNi、Fe、Ni等颗粒包裹和黏结,使得金刚石工具胎体的成分和组织结构分布更加均匀、更加致密,避免了成分偏析的发生。通过以上试验得到初步结论,金属包覆FeCuNi合金粉末可等效替代贵重金属Co,极大地降低金刚石工具生产成本,具有显著的经济效益。

-

关键词:

- 金刚石工具 /

- 金属包覆FeCuNi合金粉末 /

- 胎体

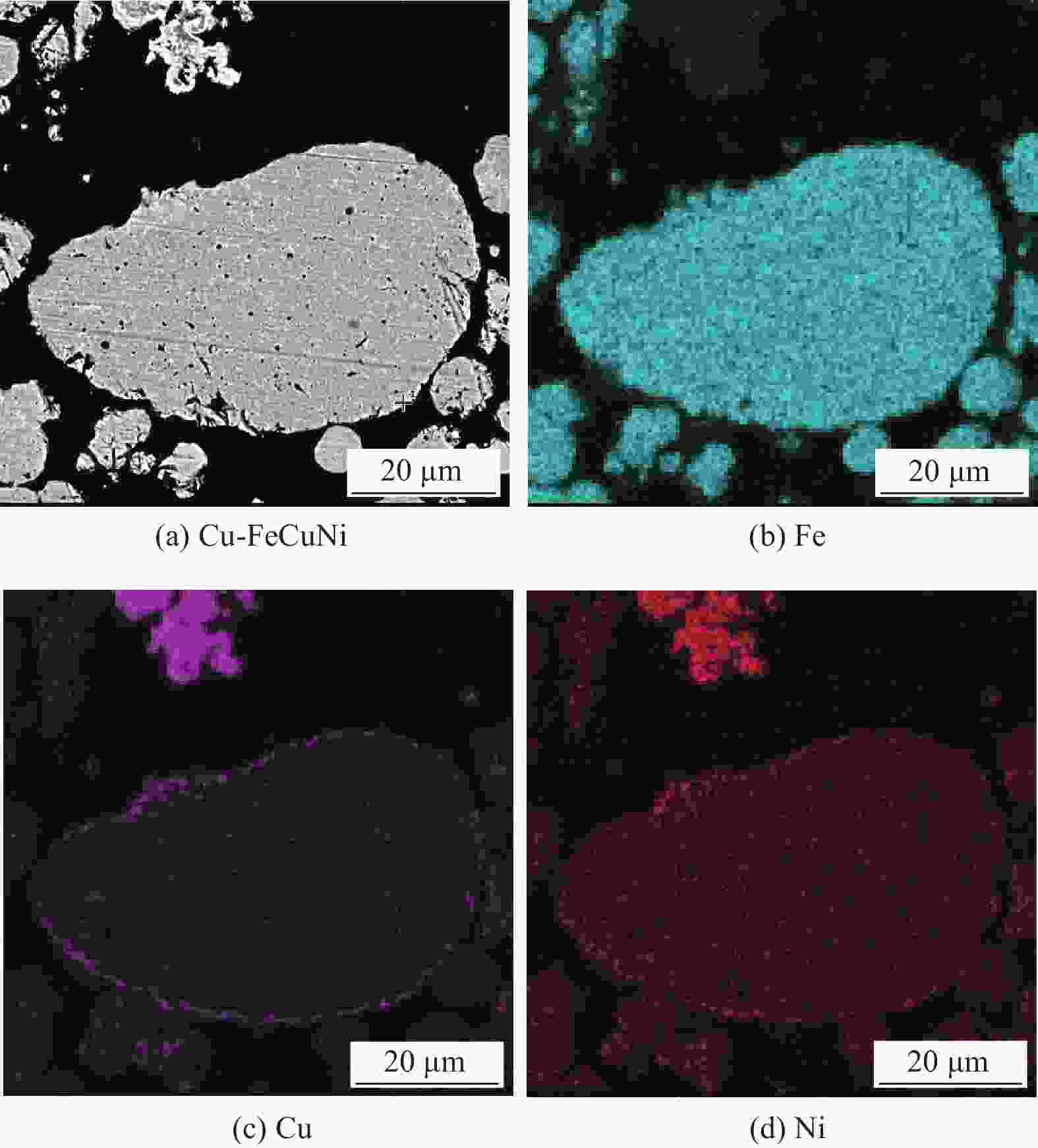

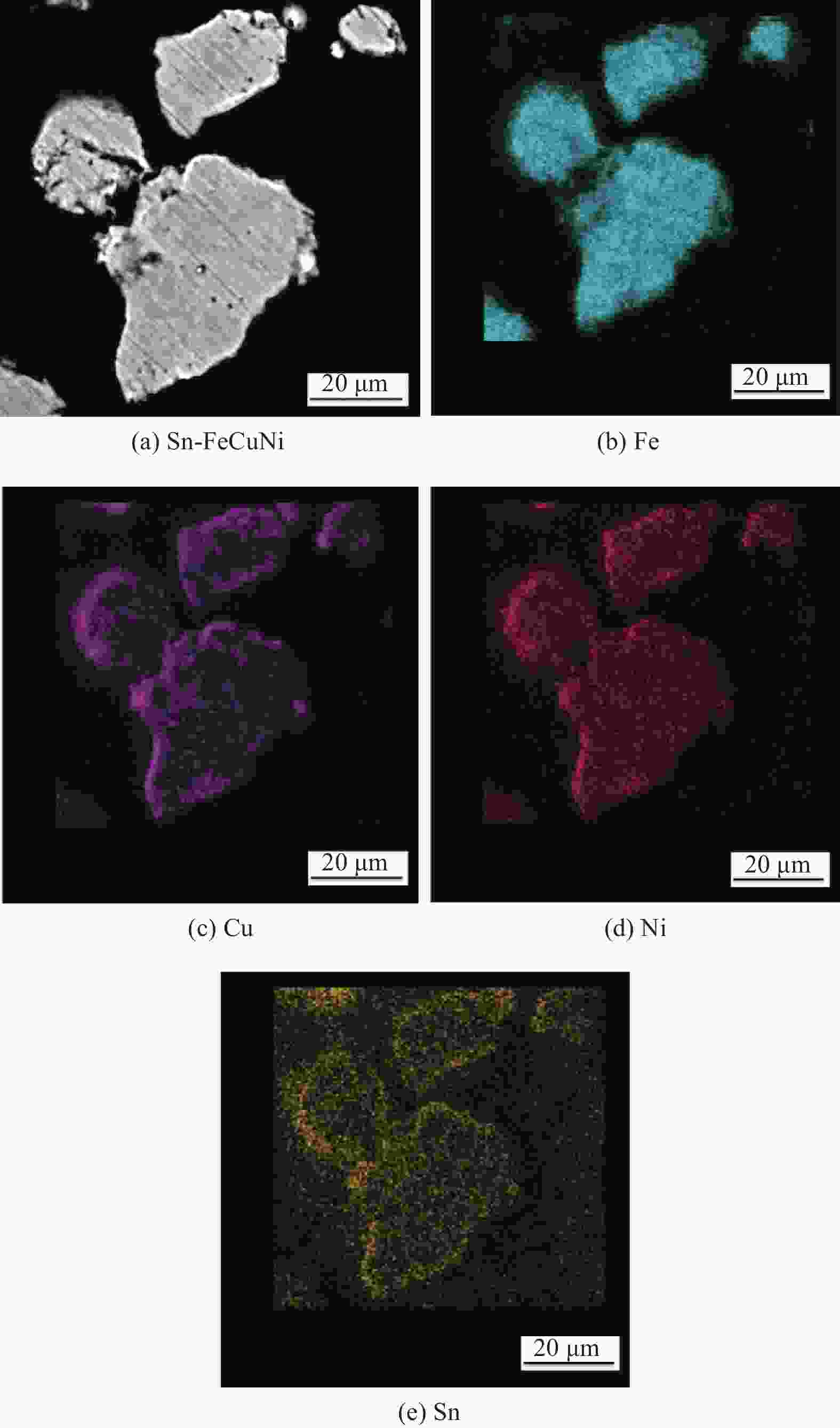

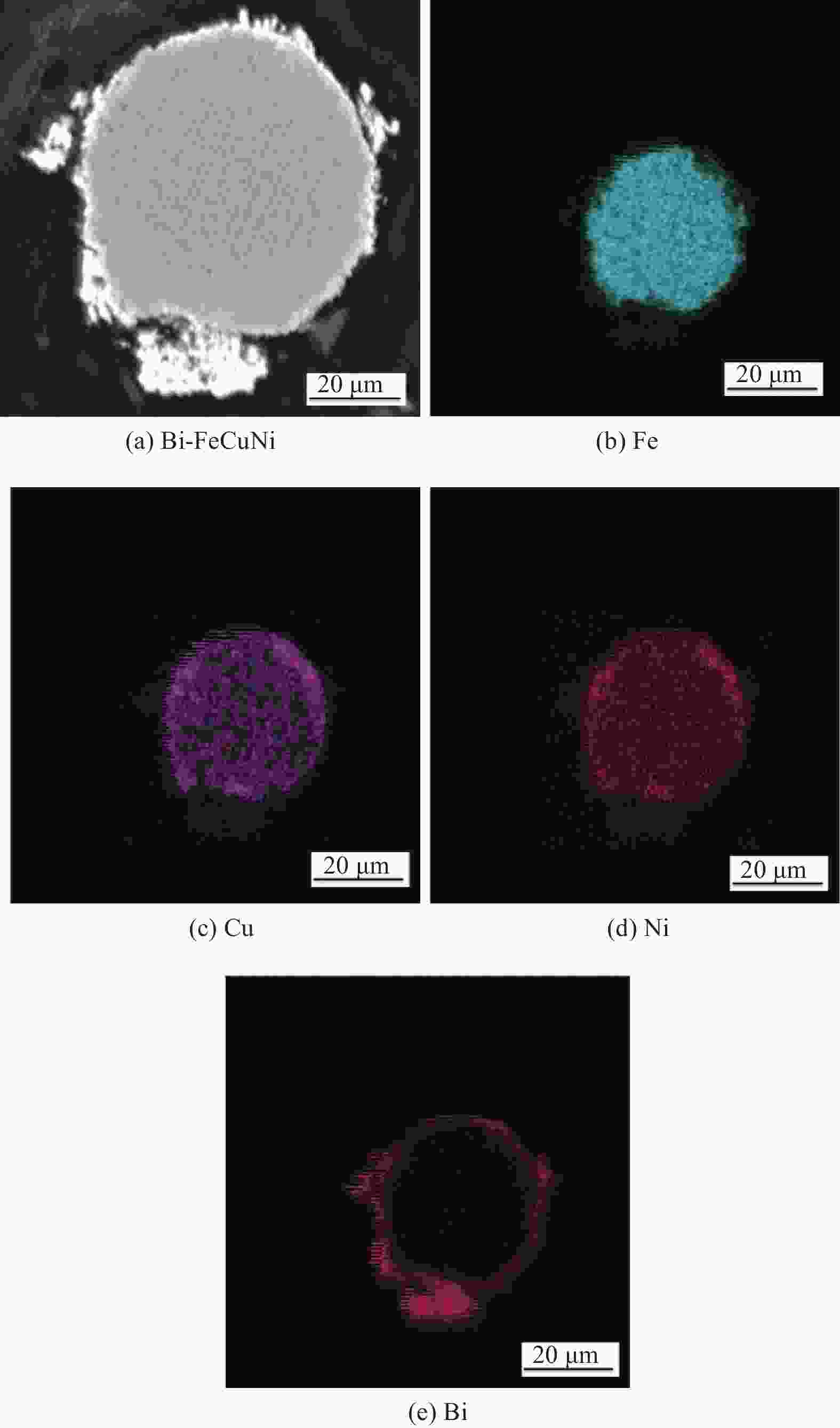

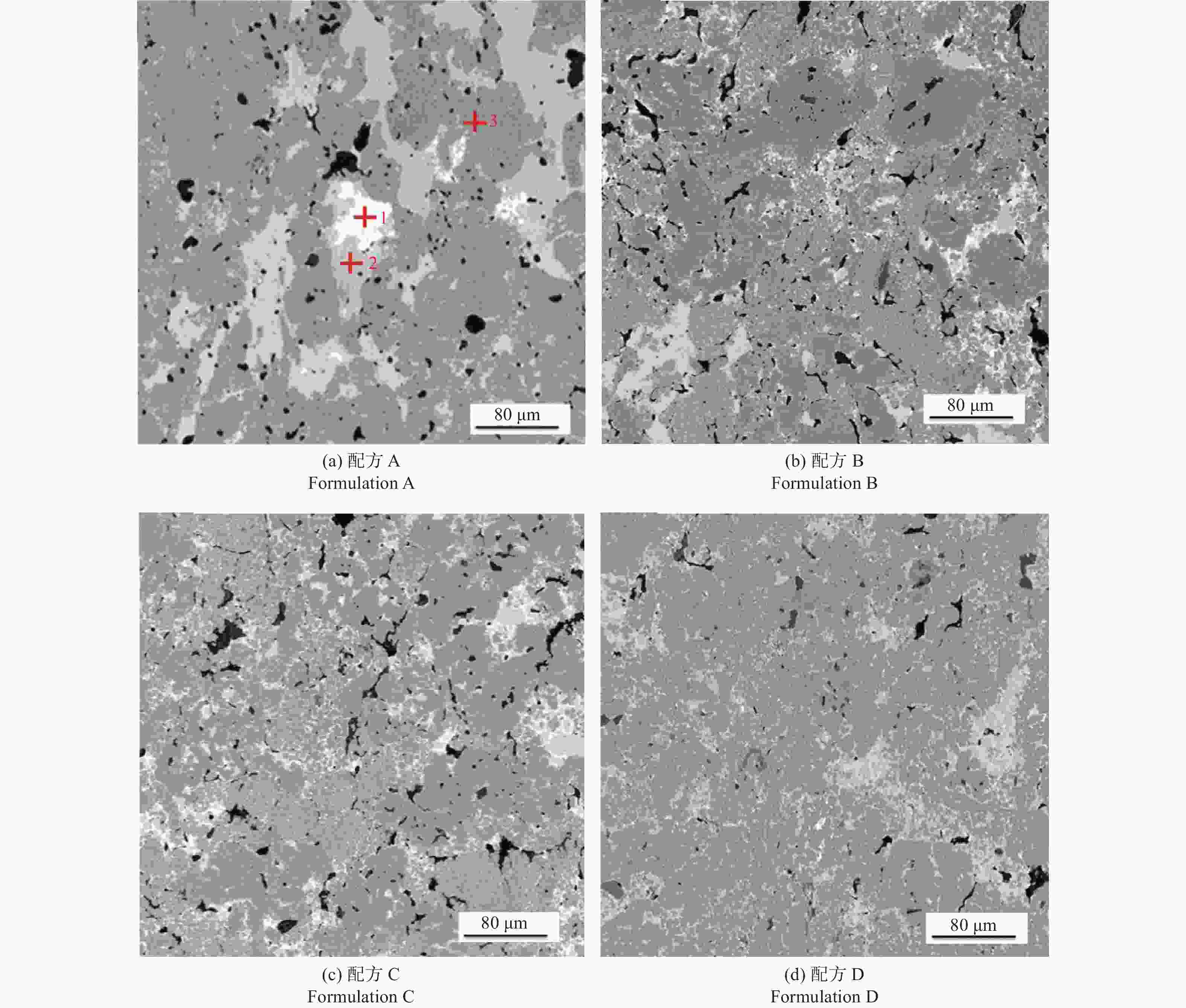

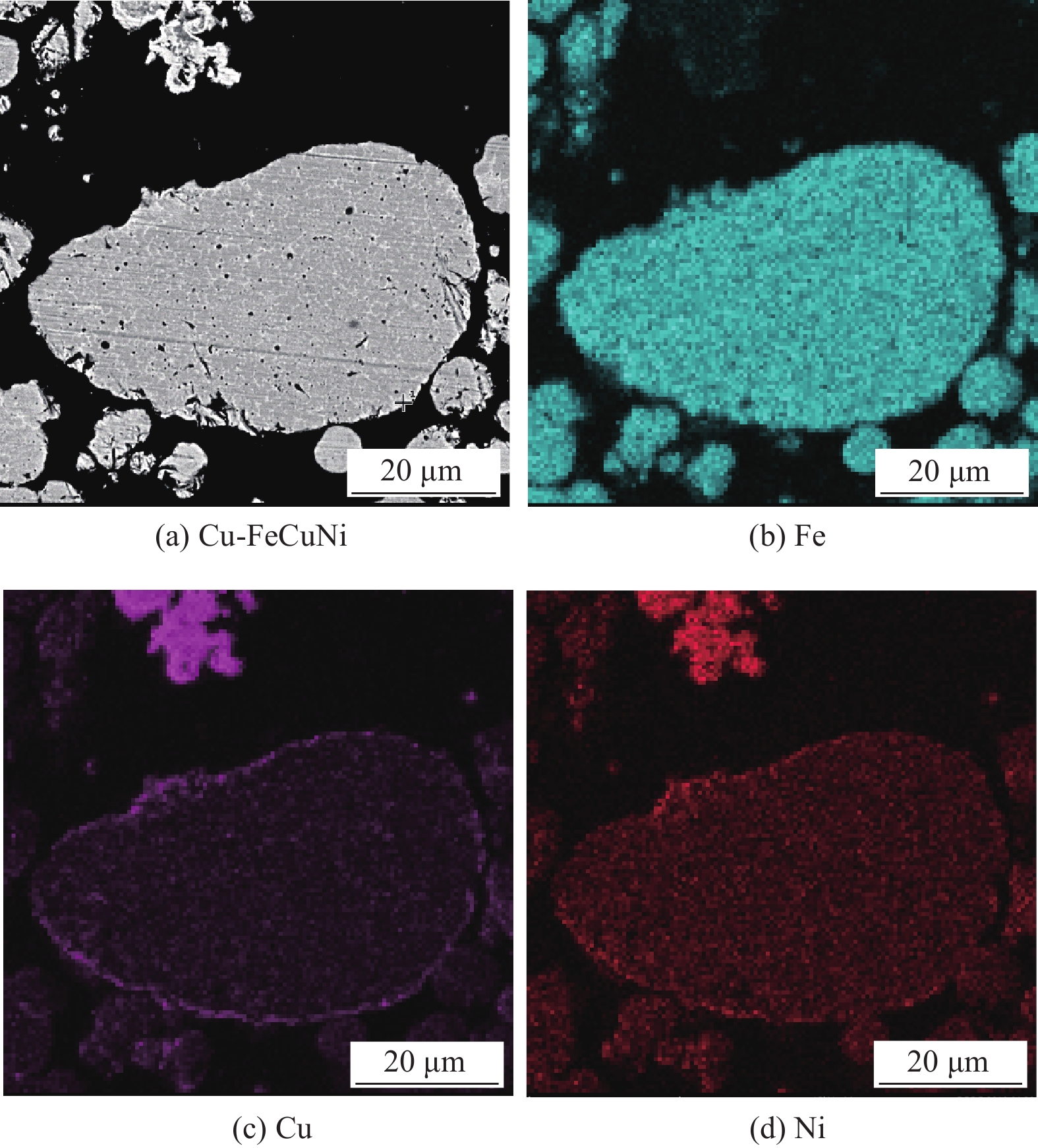

Abstract: Objectives: Diamond tools are widely used in fields such as oil drilling, geological exploration, and stone processing, among which sintered metal bond diamond tools have become the most representative due to their wide applicability and strong durability. Cobalt (Co) has become the preferred material for preparing diamond tools due to its excellent physical properties, but its price is relatively expensive. As market competition gradually intensifies, the application range of Co is becoming limited. It has been found that Fe-based pre-alloy powder has similar properties to Co and can be used as an important way to reduce costs. However, Fe-based diamond tools face problems such as high sintering temperature, narrow controllable process range, easy erosion of diamond, weak holding force, and the tendency for the matrix to burn during production. Additionally, the Sn element is prone to segregation and loss during long-term sintering in the furnace, resulting in unstable performance of diamond tools. This article describes the preparation of FeCuNi-Cu/Sn/Bi alloy powder using a multi-layer coating process to improve the densification of diamond matrix sintering and reduce component segregation. Methods: Co powder, Cu powder, Fe powder, Sn powder, Ni powder, and FeCuNi alloy powder were selected, and Cu, Sn, and Bi were respectively plated onto the surface of FeCuNi alloy powder by chemical methods, forming a uniform coating on the surface. Metal powder and diamond were mixed using a three-dimensional mixer for 2 hours. After mixing, the required weight of uniform powder was weighed, and sample blocks with dimensions of 4 mm × 8 mm × 40 mm were prepared using a hot press sintering machine. The mold material was graphite, and 4 sample blocks were prepared for each group. The experiment was repeated twice. For the tested materials, Rockwell hardness was measured, as well as the three-point bending strength. The microstructure and energy spectrum were analyzed using an electron microscope, and the changes in composition, structure, and mechanical properties of the tire body with fewer joints under different processes were compared and analyzed. Four formulations of sintered diamond tool bodies were designed, and their physical properties were tested. Eight samples were prepared for each formulation. After removing the maximum and minimum values, the average value of the data was calculated for analysis. Results: The hardness of the coated alloy powder formulation body decreased from 110 HRB to 106 HRB, but the decrease was less than 4%, indicating that the hardness remained similar. After adding the coated alloy powder, the flexural strength of the tire body increased by more than 10%. Specifically, for the formulation containing FeCuNi-Bi powder, the flexural strength increased from 945 MPa to 1,120 MPa, an increase of nearly 20%. The improvement was due to the even distribution of low-melting point elements coated on the surface of the alloy powder, which reduced the porosity of the matrix during the sintering process, thereby improving the bending strength of the matrix. Analysis of the microstructure of the four sintered tire bodies revealed that Sn in the original formula reacted with metal elements such as Cu in the tire body, gradually forming CuSn alloy. The distribution of Sn was uneven, and segregation was severe. As the sintering temperature increased, some CuSn alloys with higher Sn content began to melt. However, the wettability between the liquid CuSn alloy and Co or Fe particles was poor, and the distribution in the tire body was discontinuous. The vast majority of the CuSn liquid phase could not penetrate the Co and Fe skeleton phases to form a network connection. Under the interaction of sintering temperature and pressure, a strong and dense bond could not be formed, resulting in an uneven microstructure of the tire body and negatively affecting the performance and application of diamond tools. After adding FeCuNi-Cu/Sn/Bi alloy powder to the formula, the distribution of the coated alloy powder was relatively uniform. During sintering, Sn and Bi on the surface of FeCuNi alloy powder particles melted first, reacting with Cu to form liquid phases such as Cu-Sn and Cu-Bi. These phases gradually diffused along the FeCuNi alloy powder particles from the outside to the inside, entering the gaps between Fe, Ni, FeCuNi and other particles. Ultimately, Cu-Sn and Cu-Bi alloys formed a continuous network structure, encapsulating and bonding particles such as FeCuNi, Fe, and Ni, making the composition and microstructure distribution of the diamond tool bodies more uniform and dense, thus avoiding component segregation. Conclusions: FeCuNi-Cu/Sn/Bi alloy powder was prepared by chemically plating Cu, Sn, and Bi onto the surface of FeCuNi alloy powder. After adding the metal-coated alloy powder to the formula, the microstructure of the matrix was refined, and both hardness and strength were improved. The FeCuNi-Cu/Sn/Bi alloy powder, using coating technology, was sintered to obtain a denser matrix with higher diamond holding force and better mechanical properties.-

Key words:

- diamond tools /

- metal coated FeCuNi alloy powder /

- matrix

-

表 1 FeCuNi合金粉末基本性能

Table 1. Properties of FeCuNi alloy powder

合金粉末 Fe质量分数

ω1 / %Cu质量分数

ω2 / %Ni质量分数

ω3 / %理论密度

ρ / (g·cm−3)FeCuNi 64.50 28.50 7.00 8.08 表 2 金刚石工具胎体配方

Table 2. Formulation of diamond tool matrix

配方 质量分数 ω / % Co Fe Cu Sn Ni 合金粉末 配方A 30.00 36.00 26.00 8.00 — — 配方B — 40.70 17.50 8.00 3.80 30.00(FeCuNi-Cu) 配方C — 40.70 17.50 8.00 3.80 30.00(FeCuNi-Sn) 配方D — 40.70 17.50 8.00 3.80 30.00(FeCuNi-Bi) 表 3 不同配方金刚石工具胎体性能

Table 3. Performance of diamond tool matrix with different formulations

配方 硬度 H /HRB 抗弯强度 σ /MPa 配方A 110 945 配方B 106 1080 配方C 107 1067 配方D 106 1120 表 4 配方A烧结胎体能谱分析

Table 4. Energy spectrum analysis of sintered matrix of formula A

序号 Cu质量分数

ω1' / %Sn质量分数

ω2' / %Ni质量分数

ω3' / %Fe质量分数

ω4' / %相点1 54.36 32.26 11.77 1.61 相点2 78.82 14.41 3.47 3.30 相点3 15.10 — 5.59 79.31 表 5 添加金刚石胎体抗弯强度

Table 5. Bending strength of adding diamond matrix

配方 抗弯强度

(未添加金刚石)

$ {\sigma }_{1} $ / MPa抗弯强度

(添加金刚石)

$ {\sigma }_{2} $ / MPa抗弯强度损失率

η / %配方A 945 718 24 配方B 1080 885 18 配方C 1067 886 17 配方D 1120 930 17 -

[1] 谢北萍, 段隆臣, 孟大维. 金刚石工具胎体材料机械性能的概述 [J]. 超硬材料工程,2008,20(4):21-24. doi: 10.3969/j.issn.1673-1433.2008.04.007XIE Beiping, DUAN Longchen, MENG Dawei. Study on the mechanical properties of the matrix for diamond tools [J]. Superhard Material Engineering,2008,20(4):21-24. doi: 10.3969/j.issn.1673-1433.2008.04.007 [2] 韩娟, 姚炯斌, 刘一波, 等. 磷铁含量对高铁基胎体性能的影响 [J]. 金刚石与磨料磨具工程,2010,30(3):49-54. doi: 10.3969/j.issn.1006-852X.2010.03.011HAN Juan, YAO Jiongbin, LIU Yibo, et al. Effect of addition of ferrophosphorus on the performances of high iron-based bond [J]. Diamond & Abrasives Engineering,2010,30(3):49-54. doi: 10.3969/j.issn.1006-852X.2010.03.011 [3] 吕智, 郑超, 莫时雄, 等. 超硬材料工具设计与制造 [M]. 北京: 冶金工业出版社, 2010: 37-39.LV Zhi, ZHENG Chao, MO Shixiong, et al. Design and manufacturing of superhard material tools [M]. Beijing: Metallurgical Industry Press, 2010: 37-39. [4] 孙毓超, 刘一波, 王秦生. 金刚石工具与金属学基础 [M]. 北京: 中国建材工业出版社, 1999.SUN Yuchao, LIU Yibo, WANG Qinsheng. Fundamentals of diamond tools and metallurgy [M]. Beijing: China Building Industry Press, 1999. [5] 刘一波, 徐强, 徐良. 金刚石工具用金属粉末的特性、现状分析和发展趋势 [J]. 粉末冶金工业,2017,27(4):1-6. doi: 10.13228/j.boyuan.issn1006-6543.20170070LIU Yibo, XU Qiang, XU Liang. Characteristics, status analysis and development trend of metal powders for diamond tools [J]. Powder Metallurgy Industry,2017,27(4):1-6. doi: 10.13228/j.boyuan.issn1006-6543.20170070 [6] 董晓, 许洪祥, 陆娜. 一种金刚石制品用预合金粉末的制备方法: CN106180744A [P]. 2016-12-07.DONG Xiao, XU Hongxiang, LU Na. A preparation method of pre-alloyed powder for diamond products: CN201610721874.5[P]. 2016-12-07. [7] 杨栋, 武玺旺, 张世峰, 等. 预合金粉在金刚石工具中的应用 [J]. 超硬材料工程,2020,32(3):37-40. doi: 10.3969/j.issn.1673-1433.2020.03.009YANG Dong, WU Xiwang, ZHANG Shifeng, et al. Application of pre-alloy powder in diamond tools [J]. Superhard Material Engineering,2020,32(3):37-40. doi: 10.3969/j.issn.1673-1433.2020.03.009 [8] 孙双双. 金刚石绳锯用铁基水雾化预合金粉末的特性与应用研究[D]. 长春: 吉林大学, 2019.SUN Shuangshuang. Study on characteristics and application of iron-based water atomized prealloyed powder for diamond wire saw [D]. Changchun: Jilin University, 2019. [9] 肖俊玲, 胡国程, 丘定辉. 金刚石工具铁基结合剂的应用及展望 [J]. 湖南有色金属,2002,18(1):29-31. doi: 10.3969/j.issn.1003-5540.2002.01.010XIAO Junling, HU Guocheng, QIU Dinghui. The history, current development and divination on iron-based matrix of diamond tool [J]. Hunan Nonferrous Metals,2002,18(1):29-31. doi: 10.3969/j.issn.1003-5540.2002.01.010 [10] 郑日升, 宋冬冬, 夏学胜, 等. 添加组分对LFP全预合金粉末性能的影响 [J]. 超硬材料工程,2012,24(5):30-34. doi: 10.3969/j.issn.1673-1433.2012.05.009ZHENG Risheng, SONG Dongdong, XIA Xuesheng, et al. Influence of addition component on the properties of LFP pre-alloy powder [J]. Superhard Material Engineering,2012,24(5):30-34. doi: 10.3969/j.issn.1673-1433.2012.05.009 [11] 薛弘宇, 于新泉, 纠永涛, 等. P元素加入形式对铁基金刚石工具胎体组织性能的影响 [J]. 焊接学报,2018,39(11):69-72, 107, 132. doi: 10.12073/j.hjxb.2018390275XUE Hongyu, YU Xinquan, JIU Yongtao, et al. Effects of different kinds of phosphorus-containing prealloyed powder on the microstructures and properties of Fe-based sintered matrix [J]. Transactions of the China Welding Institution,2018,39(11):69-72, 107, 132. doi: 10.12073/j.hjxb.2018390275 [12] 张凤林, 周玉梅, 王成勇. 金刚石工具中金刚石与金属结合剂之间的界面 [J]. 工具技术,2007,41(7):20-24. doi: 10.3969/j.issn.1000-7008.2007.07.005ZHANG Fenglin, ZHOU Yumei, WANG Chengyong. Interfacial microstructure between diamond and metal bonds in metal matrix diamond tools [J]. Tool Engineering,2007,41(7):20-24. doi: 10.3969/j.issn.1000-7008.2007.07.005 [13] 黄希祜. 钢铁冶金原理 [M]. 北京: 冶金工业出版社, 1986: 297.HUANG Xihu. Principles of iron and steel metallurgy [M]. Beijing: Metallurgical Industry Press, 1986: 297. [14] 司卫征, 袁慧, 张凤林, 等. 金属基金刚石工具结合剂中添加合金元素的研究进展 [J]. 超硬材料工程,2007,19(1):31-33. doi: 10.3969/j.issn.1673-1433.2007.01.009SI Weizheng, YUAN Hui, ZHANG Fenglin, et al. Research advances of adding alloying elements in the bond of metal matrix diamond tools [J]. Superhard Material Engineering,2007,19(1):31-33. doi: 10.3969/j.issn.1673-1433.2007.01.009 [15] 李鹏旭. 金刚石工具用铁基水雾化预合金粉末的性能测试及改性应用[D]. 长春: 吉林大学, 2020.LI Pengxu. Performance test and modification application of iron-based water atomized prealloyed powder for diamond tools [D]. Changchun: Jilin University, 2020. [16] 张冠星, 张雷, 刘晓芳, 等. 低熔包覆合金粉末及其制备方法和铁基金刚石胎体:CN202010662465.9 [P]. 2020-07-10.ZHANG Guanxing, ZHANG Lei, LIU Xiaofang, et al. Low-melting clad alloy powder, its preparation method and iron-based diamond carcass: CN202010662465.9 [P]. 2020-07-10. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS