Research progress of vitrified bond CBN grinding wheel

-

摘要:

陶瓷CBN砂轮在成形加工和精密加工等领域广泛应用,对其进行研究在提高工件加工质量和加工效率方面具有重要意义。分别从CBN磨粒、改性剂的添加、陶瓷CBN砂轮的制备和磨削性能方面,综述近些年陶瓷CBN砂轮的研究进展,并对其未来发展前景进行展望。在CBN磨粒方面,论述了CBN单晶的合成,介绍了CBN磨粒表面处理和加入强磁场时的处理方式;对于改性剂,分别论述了成孔剂、氧化物、金属物质、纳米材料的添加对陶瓷CBN砂轮性能的改善;在陶瓷CBN砂轮制备方面,介绍了其成形和烧结的方法。此外,还介绍了陶瓷CBN砂轮在钢类材料、镍基合金、钛合金等难加工材料上的磨削加工应用,并提出影响其磨削性能的因素。

Abstract:The ceramic CBN grinding wheels are widely used in the fields of forming and precision machining, and the research on them is of great significance in improving the machining quality and efficiency of workpieces. The research progress of ceramic CBN grinding wheels in recent years is summarized from various aspects, including CBN abrasive grains, modifier addition, preparation and grinding performances. Additionally, the future development prospects are also discussed. Regarding CBN abrasive grains, the synthesis of CBN single crystal is explored, and the surface treatment of CBN abrasive grains, as well as the treatment methods when adding a strong magnetic field, are introduced. Concerning modifier, the influences of adding pore forming agents, oxides, metal materials and nano-materials on the performances of ceramic CBN grinding wheels are discussed. In the preparation of ceramic CBN grinding wheels, the methods of forming and sintering are described. Moreover, the grinding applications of ceramic CBN grinding wheels on difficult-to-machine materials such as steel, nickel base alloy and titanium alloy are introduced, and the factors affecting the grinding performances of CBN grinding wheels are proposed.

-

Key words:

- ceramic CBN grinding wheel /

- abrasive grains /

- modifier /

- vitrified bond /

- grinding performance

-

-

[1] LI Z, DING W F, LIU C J, et al. Prediction of grinding temperature of PTMCs based on the varied coefficients of friction in conventional-speed and high-speed surface grinding [J]. The International Journal of Advanced Manufacturing Technology,2017,90:2335-2344. doi: 10.1007/s00170-016-9578-0 [2] 李征, 刘莹, 丁文峰. 不同CBN砂轮高速加工PTMCs的磨削性能对比 [J]. 金刚石与磨料磨具工程,2020,40(5):5-10.LI Zheng, LIU Ying, DING Wenfeng. Comparing performance of CBN grinding wheels in high-speed grinding [J]. Diamond & Abrasives Engineering,2020,40(5):5-10. [3] 刘明耀, 李克华, 赵兴昊. 中国CBN磨具的研发历程与技术发展趋势 [J]. 金刚石与磨料磨具工程,2017,37(1):1-6. doi: 10.13394/j.cnki.jgszz.2017.1.0001LIU Mingyao, LI Kehua, ZHAO Xinghao. Course and technology development trend of CBN grinding tools in China [J]. Diamond & Abrasives Engineering,2017,37(1):1-6. doi: 10.13394/j.cnki.jgszz.2017.1.0001 [4] 丁文锋, 奚欣欣, 占京华, 等. 航空发动机钛材料磨削技术研究现状及展望 [J]. 航空学报,2019,40(6):1-36. doi: 10.7527/S1000-6893.2019.22763DING Wenfeng, XI Xinxin, ZHAN Jinghua, et al. Research status and future development of grinding technology of titanium materials for aero-engines [J]. Acta Aeronautica et Astronautica Sinica,2019,40(6):1-36. doi: 10.7527/S1000-6893.2019.22763 [5] 师超钰, 朱建辉, 孙鹏辉, 等. 低浓度陶瓷CBN砂轮有效磨粒统计及磨削性能研究 [J]. 现代制造工程,2018,12:119-123. doi: 10.16731/j.cnki.1671-3133.2018.12.020SHI Chaoyu, ZHU Jianhui, SUN Penghui, et al. Research on effective grains statistics and grinding performance of vitrified CBN grinding wheel in low concentration [J]. Modern Manufacturing Engineering,2018,12:119-123. doi: 10.16731/j.cnki.1671-3133.2018.12.020 [6] BHOWMIK S, NAIK R. Selection of abrasive materials for manufacturing grinding wheels [J]. Materials Today,2018,5(1):2860-2864. [7] ZHAO Y, YU T, CHEN L, et al. Microstructure and wear resistance behavior of Ti-C-B4C-reinforced composite coating [J]. Ceramics International,2020,46(16A):25136-25148. doi: 10.1016/j.ceramint.2020.06.300 [8] SUN Y, JIN L, GONG Y, et al. Experimental evaluation of surface generation and force time-varying characteristics of curvilinear grooved micro end mills fabricated by EDM [J]. Journal of Manufacturing Processes,2022,73:799-814. doi: 10.1016/j.jmapro.2021.11.049 [9] 吕智, 谢志刚, 林峰, 等. 超硬材料在精密加工中的应用现状与展望 [J]. 超硬材料工程,2018,30(6):43-46. doi: 10.3969/j.issn.1673-1433.2018.06.015LU Zhi, XIE Zhigang, LIN Feng, et al. Application and development of superhard materials on precision machining [J]. Superhard Material Engineering,2018,30(6):43-46. doi: 10.3969/j.issn.1673-1433.2018.06.015 [10] 孙金阶, 王伟. 中外陶瓷磨具技术比较分析 [J]. 世界制造技术与装备市场,2009,3:92-96. doi: 10.3969/j.issn.1015-4809.2009.03.028SUN Jinjie, WANG Wei. Comparative & analysis on domestic and foreign ceramic abrasive technology [J]. The Manufacturing Technology and Equipment Market,2009,3:92-96. doi: 10.3969/j.issn.1015-4809.2009.03.028 [11] 孙会冰, 赵玉成, 王明智, 等. 立方氮化硼砂轮的研究与发展 [J]. 金刚石与磨料磨具工程,2017,37(5):79-85. doi: 10.13394/j.cnki.jgszz.2017.5.0016SUN Huibing, ZHAO Yucheng, WANG Mingzhi, et al. Research and development of cubic boron nitride grinding wheel [J]. Diamond & Abrasives Engineering,2017,37(5):79-85. doi: 10.13394/j.cnki.jgszz.2017.5.0016 [12] 耿红生, 张国权, 陈远方. 陶瓷砂轮自动加工线的设计与研究 [J]. 成组技术与生产现代化,2021,38(4):50-54. doi: 10.3969/j.issn.1006-3269.2021.04.008GENG Hongsheng, ZHANG Guoquan, CHEN Yuanfang. Design and research on automatic machining line of ceramic grinding wheel [J]. Group Technology & Production Modernization,2021,38(4):50-54. doi: 10.3969/j.issn.1006-3269.2021.04.008 [13] HARRIS T K, BROOKES E J, TAYLOR C J. The effect of temperature on the hardness of polycrystalline cubic boron nitride cutting tool materials [J]. International Journal of Refractory Metals Hard Materials,2004,22(2/3):105-110. doi: 10.1016/j.ijrmhm.2004.01.004 [14] 王光祖. 在不同触媒-hBN体系中cBN的合成 [J]. 超硬材料工程,2005(6):44-47.WANG Guangzu. Synthesis of cBN with various catalyst and hBN system [J]. Superhard Material Engineering,2005(6):44-47. [15] WENTORF R H. Cubic form of boron nitride [J]. The Journal of Chemical Physics,1957,26(4):952-956. [16] FUKUNAGA O, NAKANO S, TANIGUCHI T. Nucleation and growth of cubic boron nitride using a Ca-B-N solvent [J]. Diamond and Related Materials,2004,13(9):1709-1713. doi: 10.1016/j.diamond.2004.02.013 [17] YANG D, JI X, LIU H, et al. The influence of Li-based catalysts/additives on CBN crystal morphologies synthesized under HPHT [J]. Diamond and Related Materials,2011,20(2):174-177. doi: 10.1016/j.diamond.2010.11.023 [18] GUO W, SHI Y, YANG P, et al. Characterization of boron nitride phase transformations in the Li-B-N system under high pressure and high temperature [J]. Journal of Alloys and Compounds,2015,644:888-892. doi: 10.1016/j.jallcom.2015.05.094 [19] LV M, XU B, CAI L, et al. Analysis of transition mechanism of cubic boron nitride single crystals under high pressure-high temperature with valence electron structure calculation [J]. Chinese Physics Letters,2019,36(1):013101. doi: 10.1088/0256-307X/36/1/013101 [20] LV M, XU B, GUO X, et al. Electron energy loss spectroscopy analysis for cubic boron nitride single crystals transition mechanism in Li3N-BN system [J]. Materials Letters,2019,242:75-78. doi: 10.1016/j.matlet.2019.01.058 [21] 温振兴, 许斌, 蔡立超, 等. Li3N触媒粒度对立方氮化硼单晶合成效果的影响 [J]. 人工晶体学报,2014,43(2):285-288. doi: 10.3969/j.issn.1000-985X.2014.02.005WEN Zhenxing, XU Bin, CAI Lichao, et al. Influence of particle size of Li3N catalyst on synthetic effect of cubic boron nitride single crystal [J]. Journal of Synthetic Crystals,2014,43(2):285-288. doi: 10.3969/j.issn.1000-985X.2014.02.005 [22] 王功振, 许斌, 时永鹏, 等. CBN单晶合成效果与合成后Li基触媒组织结构的相关性研究 [J]. 人工晶体学报,2016,45(12):2752-2757. doi: 10.3969/j.issn.1000-985X.2016.12.003WANG Gongzhen, XU Bin, SHI Yongpeng, et al. Study on correlation between synthetic quality of CBN crystals and microstructure of the lithium-based catalyst [J]. Journal of Synthetic Crystals,2016,45(12):2752-2757. doi: 10.3969/j.issn.1000-985X.2016.12.003 [23] 王功振, 贾凤, 时永鹏, 等. 合成后的触媒组织结构对立方氮化硼单晶合成效果的影响 [J]. 超硬材料工程,2017,29(5):12-16. doi: 10.3969/j.issn.1673-1433.2017.05.004WANG Gongzhen, JIA Feng, SHI Yongpeng, et al. Effects of the structure of synthesized lithium-based catalyst on synthetic quality of CBN single crystal [J]. Superhard Material Engineering,2017,29(5):12-16. doi: 10.3969/j.issn.1673-1433.2017.05.004 [24] CAI L, FAN X, SU H, et al. Process optimization of large-sized cubic boron nitride single crystal synthesis with Li3N as catalyst [J]. Ferroelectrics,2020,566(1):145-152. doi: 10.1080/00150193.2020.1762438 [25] 于丽娟. 关于合成立方氮化硼触媒材料的研究 [J]. 西安建筑科技大学学报(自然科学版),1998,30(1):86-88.YU Lijuan. Research on synthesizing cubic boron-nitride catalytic material [J]. Journal of Xi′an University of Architecture & Technology (Natural Science Edition),1998,30(1):86-88. [26] 李启泉, 孙湘东, 刘书锋, 等. 镁基触媒合成立方氮化硼的研究 [J]. 中原工学院学报,2021,32(3):22-26. doi: 10.3969/j.issn.1671-6906.2021.03.005LI Qiquan, SUN Xiangdong, LIU Shufeng, et al. Study on the synthesis of CBN using magnesium-based catalyst [J]. Journal of Zhongyuan University of Technology,2021,32(3):22-26. doi: 10.3969/j.issn.1671-6906.2021.03.005 [27] SINGHAL S K, DER GONNA J V, NOVER G, et al. Synthesis of cubic boron nitride at reduced pressures in the presence of Co[(NH3)6]Cl3 and NH4F [J]. Diamond and Related Materials,2005,14(8):1389-1394. doi: 10.1016/j.diamond.2005.02.007 [28] MA K. Synthesis of cubic boron nitride under relatively lower pressure and lower temperature via chemical reaction [J]. Glass Physics and Chemistry,2020,46(2):181-185. [29] 刘彩云, 高伟, 殷红. 立方氮化硼的研究进展 [J]. 人工晶体学报,2022,51(5):781-800. doi: 10.3969/j.issn.1000-985X.2022.05.004LIU Caiyun, GAO Wei, YIN Hong. Research progress of cubic boron nitride [J]. Journal of Synthetic Crystals,2022,51(5):781-800. doi: 10.3969/j.issn.1000-985X.2022.05.004 [30] MISHMA O, YAMAOKA S, FUKUMAGA O. Crystal growth of cubic boron nitride by temperature difference method at~55 kbar and~1 800 ℃ [J]. Journal of Applied Physics,1987,61(8):2822-2825. doi: 10.1063/1.337874 [31] TANIGUCHI T, YAMAOKA S. Spontaneous nucleation of cubic boron nitride single crystal by temperature gradient method under high pressure [J]. Journal of Crystal Growth,2001,222(3):549-557. doi: 10.1016/S0022-0248(00)00907-6 [32] 张铁臣, 杜永慧, 苏作鹏. 控制自发成核生长大颗粒立方氮化硼晶体 [J]. 金刚石与磨料磨具工程,2003,136(4):23-25.ZHANG Tiechen, DU Yonghui, SU Zuopeng. Growth of large cubic boron nitride crystal by controlling spontaneous nucleation [J]. Diamond & Abrasives Engineering,2003,136(4):23-25. [33] 苏海通, 许斌, 蔡立超, 等. 添加籽晶对合成立方氮化硼单晶的影响 [J]. 人工晶体学报,2015,44(10):2679-2684. doi: 10.3969/j.issn.1000-985X.2015.10.009SU Haitong, XU Bin, CAI Lichao, et al. Influence of adding seed crystals on synthesis of cubic boron nitride single crystal [J]. Journal of Synthetic Crystals,2015,44(10):2679-2684. doi: 10.3969/j.issn.1000-985X.2015.10.009 [34] LI Z C, ZHANG A J, LI Z, et al. Surface treatment of cubic boron nitride grains applied to vitrified bond grinding tools [J]. Materials Science Forum,2011(675/676/677):167-170. [35] YANG X, BAI J, JING W, et al. Strengthening of low-temperature sintered vitrified bond CBN grinding wheels by pre-oxidation of CBN abrasives [J]. Ceramics International,2016,42(7):9283-9286. doi: 10.1016/j.ceramint.2016.02.070 [36] 鲍崇高, 宋奕侨, 侯书增, 等. 磨料表面微氧化对CBN磨具磨削性能的影响 [J]. 西安交通大学学报,2015,49(2):124-129.BAO Chonggao, SONG Yiqiao, HOU Shuzeng, et al. Effect of the CBN grit surface oxidation on grinding performance of the vitrified CBN tool [J]. Journal of Xi′an Jiaotong University,2015,49(2):124-129. [37] 王艳辉, 王明智, 温熙宇, 等. 镀Ti立方氮化硼与玻化 SiO2-Na2O-B2O3结合剂的作用 [J]. 无机材料学报,1995,10(3):351-355.WANG Yanhui, WANG Mingzhi, WEN Xiyu, et al. Reaction between Ti-coated CBN and SiO2-Na2O-B2O3 glass bond [J]. Journal of Inorganic Materials,1995,10(3):351-355. [38] 王艳辉, 王明智, 臧建兵. Cr镀层对立方氮化硼-玻化陶瓷复合材料界面成分、结构的作用 [J]. 复合材料学报,1996,13(1):50-54.WANG Yanhui, WANG Mingzhi, ZANG Jianbin. The influence of Cr-clading on interface structure and composition of CBN-borosilicate glass composite materials [J]. Acta Materiae Compositae Sinica,1996,13(1):50-54. [39] 张明, 臧建兵, 王明智, 等. Mo涂层的立方氮化硼(CBN)与玻化陶瓷复合烧结体的研究 [J]. 人工晶体学报,1996,25(1):23-28.ZHANG Ming, ZANG Jianbing, WANG Mingzhi, et al. Study on composite materials sintered by Mo clad CBN and vitrified ceramics [J]. Journal of Synthetic Crystals,1996,25(1):23-28. [40] 赵玉成, 臧建兵, 王明智, 等. 刚玉涂覆的超硬磨料 [J]. 金刚石与磨料磨具工程,1999(5):6-7.ZHAO Yucheng, ZANG Jianbing, WANG Mingzhi, et al. Superhard abrasive with corundum coating [J]. Diamond & Abrasives Engineering,1999(5):6-7. [41] 张林森, 桂阳海, 闫莉, 等. 氮化硼微粒化学镀镍-磷合金工艺研究 [J]. 电镀与精饰,2009,31(3):38-40. doi: 10.3969/j.issn.1001-3849.2009.03.011ZHANG Linsen, GUI Yanghai, YAN Li, et al. Study of Ni-P alloy electroless plating on boron nitride particles [J]. Plating and Finishing,2009,31(3):38-40. doi: 10.3969/j.issn.1001-3849.2009.03.011 [42] 李建壮, 刘晓玲, 庞子瑞, 等. 镀钛CBN磨料对超高速陶瓷砂轮强度的影响 [J]. 金刚石与磨料磨具工程,2010,30(4):77-80.LI Jianzhuang, LIU Xiaoling, PANG Zirui, et al. Effect of Ti coating on CBN grains upon the bending strength of ultra high speed vitrified cBN wheel [J]. Diamond & Abrasives Engineering,2010,30(4):77-80. [43] 梁宝岩, 韩丹辉, 张旺玺, 等. 微波-熔盐热处理在CBN表面形成TiN类石墨烯晶体 [J]. 金刚石与磨料磨具工程,2018,38(1):37-40.LIANG Baoyan, HAN Danhui, ZHANG Wangxi, et al. TiN graphene crystals on the surface of CBN by microwave-salt molten treatment [J]. Diamond & Abrasives Engineering,2018,38(1):37-40. [44] 陈东风, 曹志强, 杨淼, 等. 强磁场在材料科学中的应用现状及理论分析 [J]. 钢铁研究. 2007, 35(3): 58-62.CHEN Dongfeng, CAO Zhiqiang, YANG Miao, et al. Application situation and theoretical analysis of high magnetic field in material science [J]. Research on Iron and Steel, 2007, 35(3): 58-62. [45] YU T, MA Z, WANG X, et al. Effects of Ni addition on properties of vitrified bond CBN composites in strong magnetic field [J]. Ceramics International,2018,44(8):9312-9317. doi: 10.1016/j.ceramint.2018.02.143 [46] WANG X, SUN X, MA Z, et al. Effects of sintering in a high magnetic field on properties of vitrified bond and vitrified CBN composites [J]. Ceramics International,2018,44(18):22301-22307. doi: 10.1016/j.ceramint.2018.08.355 [47] 石莹, 王学智, 于天彪, 等. 强磁场陶瓷结合剂CBN砂轮制备及磨削性能 [J]. 东北大学学报,2020,41(12):1721-1726.SHI Ying, WANG Xuezhi, YU Tianbiao, et al. Preparation and grinding performance of high magnetic field vitrified bond CBN grinding wheel [J]. Journal of Northeastern University (Natural Science),2020,41(12):1721-1726. [48] WANG X, MING C, ZHENG Y, et al. Study on grinding nickel-based superalloy GH4169 with ceramic bond CBN wheel controlling abrasive orientation by magnetic field [J]. International Journal of Advanced Manufacturing Technology,2022,121:6635-6645. doi: 10.1007/s00170-022-09764-2 [49] HERMAN D, KRZOS J. Influence of vitrified bond structure on radial wear of CBN grinding wheels [J]. Journal of Materials Processing Technology,2009,209(14):5377-5386. doi: 10.1016/j.jmatprotec.2009.03.013 [50] 张习敏, 王明智, 王艳辉. 不同造孔剂对陶瓷结合剂性能的影响 [J]. 金刚石与磨料磨具工程,2002,131(5):19-22. doi: 10.3969/j.issn.1006-852X.2002.05.005ZHANG Ximin, WANG Mingzhi, WANG Yanhui. Effects of different pore forming agents on the properties of ceramic binder [J]. Diamond & Abrasives Engineering,2002,131(5):19-22. doi: 10.3969/j.issn.1006-852X.2002.05.005 [51] 刘一波, 刘伟, 杨德涛, 等. 不同无机铵盐对陶瓷结合剂CBN砂轮造孔的应用研究 [J]. 金刚石与磨料磨具工程,2009,174(6):15-18. doi: 10.3969/j.issn.1006-852X.2009.06.004LIU Yibo, LIU Wei, YANG Detao, et al. Pore-forming effect of different inorganic ammonium salts applied on vitrified bond CBN wheels [J]. Diamond & Abrasives Engineering,2009,174(6):15-18. doi: 10.3969/j.issn.1006-852X.2009.06.004 [52] LV X, LI Z, ZHU Y, et al. Effect of PMMA pore former on microstructure and mechanical properties of vitrified bond CBN grinding wheels [J]. Ceramics International,2013,39(2):1893-1899. doi: 10.1016/j.ceramint.2012.08.038 [53] DING W F, XU J H, CHEN Z Z, et al. Fabrication and performance of porous metal-bonded CBN grinding wheels using alumina bubble particles as pore-forming agents [J]. The International Journal of Advanced Manufacturing Technology,2013,67:1309-1315. doi: 10.1007/s00170-012-4567-4 [54] WANG C C, ZHANG F L, PAN J S, et al. An experimental study on preparation of vitrified bond diamond grinding wheel with hollow spherical corundum granules as pore former [J]. The International Journal of Advanced Manufacturing Technology,2017,93:595-603. doi: 10.1007/s00170-017-0475-y [55] 王超超, 张凤林, 李伟雄, 等. 空心玻璃微珠对陶瓷结合剂金刚石砂轮微观结构和力学性能的影响 [J]. 工具技术,2017,51(10):36-39. doi: 10.3969/j.issn.1000-7008.2017.10.009WANG Chaochao, ZHANG Fenglin, LI Weixiong, et al. Effect of glass bubble as pore former on micro-structure and mechanical properties of vitrified bond diamond grinding wheels [J]. Tool Engineering,2017,51(10):36-39. doi: 10.3969/j.issn.1000-7008.2017.10.009 [56] 轩闯, 王超超, 白福厚, 等. 基于空心氧化铝微球造孔的陶瓷结合剂金刚石砂轮 [J]. 金刚石与磨料磨具工程, 2022, 42(4): 442-448.XUAN Chuang, WANG Chaochao, BAI Fuhou, et al. Vitrified bond diamond grinding wheel based on hollow corundum microspheres [J]. Diamond & Abrasives Engineering, 2022, 42(4): 442-448. [57] 陈卫东, 涂俊群. 不同的造孔剂对陶瓷结合剂CBN砂轮性能的影响 [J]. 超硬材料工程,2014,26(3):1-5.CHEN Weidong, TU Junqun. Influence of different type of pore former on the mechanical property of vitrified bond CBN Grinding Wheel [J]. Superhard Material Engineering,2014,26(3):1-5. [58] 侯永改, 路继红, 张明岩, 等. 成孔剂对陶瓷结合剂CBN磨具结构与性能影响的研究 [J]. 金刚石与磨料磨具工程,2014,34(1):48-52. doi: 10.13394/j.cnki.jgszz.2014.1.0011HOU Yonggai, LU Jihong, ZHANG Mingyan, et al. Study on the influence of pore former to the structure and performance of vitrified bond CBN abrasive tools [J]. Diamond & Abrasives Engineering,2014,34(1):48-52. doi: 10.13394/j.cnki.jgszz.2014.1.0011 [59] 樊雪琴, 侯永改, 路继红, 等. V2O5对低温陶瓷结合剂性能与结构的影响 [J]. 中国陶瓷,2014,50(7):61-63.FAN Xueqin, HOU Yonggai, LU Jihong, et al. Effect of V2O5 on properties and structure of low temperature vitrified bond [J]. China Ceramics,2014,50(7):61-63. [60] REN Q, LIU C X, ZHANG Q, et al. Effects of B2O3 substitution for Al2O3 on the crystallization and properties of translucent mica glass-ceramics [J]. Journal of the European Ceramic Society,2021,41(16):334-341. doi: 10.1016/j.jeurceramsoc.2021.09.048 [61] 王照, 徐三魁, 黄威, 等. B2O3含量对 SiO2-B2O3-Al2O3-Na2O系陶瓷结合剂结构与性能的影响 [J]. 金刚石与磨料磨具工程 [J]. 2022, 42(5): 552-558.WANG Zhao, XU Sankui, HUANG Wei, et al. Effect of B2O3 content on the structure and properties of SiO2-B2O3-Al2O3-Na2O system ceramic binder [J]. Diamond & Abrasives Engineering, 2022, 42(5): 552-558. [62] WANG P F, LI Z H, LI J, et al. Effect of ZnO on the interfacial bonding between Na2O-B2O3-SiO2 vitrified bond and diamond [J]. Solid State Sciences,2009,11(8):1427-1432. doi: 10.1016/j.solidstatesciences.2009.04.026 [63] LUTPI H A, MOHAMAD H, ABDULLAH T K, et al. Effect of ZnO on the structural, physio-mechanical properties and thermal shock resistance of Li2O-Al2O3-SiO2 glass-ceramics [J]. Ceramics International,2022,48(6):7677-7686. doi: 10.1016/j.ceramint.2021.11.315 [64] 赵婧. PbO对陶瓷结合剂性能的影响研究 [J]. 陶瓷,2018,9:23-28. doi: 10.3969/j.issn.1002-2872.2018.06.004ZHAO Jing. Study on the effect of PbO on the properties of ceramic binder [J]. Ceramics,2018,9:23-28. doi: 10.3969/j.issn.1002-2872.2018.06.004 [65] 陈建立, 刘一波, 王雄飞, 等. Al2O3/SiO2比对陶瓷结合剂性能的影响研究 [J]. 超硬材料工程,2022,34(2):25-28. doi: 10.3969/j.issn.1673-1433.2022.02.005CHEN Jianli, LIU Yibo, WANG Xiongfei, et al. Study on the influence of Al2O3/SiO2 ratio on the ceramic bond property [J]. Superhard Material Engineering,2022,34(2):25-28. doi: 10.3969/j.issn.1673-1433.2022.02.005 [66] WU H F, LIN C C, SHEN P Y. Structure and dissolution of CaO-ZrO2-TiO2-Al2O3-B2O3-SiO2 glass (Ⅱ) [J]. Journal of Non-Crystalline Solids,1997,209(1-2):76-78. doi: 10.1016/S0022-3093(96)00553-4 [67] LI B, DUAN D, LONG Q. Influences of ZrO2 on microstructures and properties of Li2O–Al2O3–SiO2 glass–ceramics for LTCC applications [J]. Journal of Materials Science: Materials in Electronics,2016,27:134-139. [68] 侯永改, 张明岩, 田久根, 等. ZrO2对CBN用低温陶瓷结合剂及磨具性能的影响 [J]. 硅酸盐通报,2013,32(8):1592-1596.HOU Yonggai, ZHANG Mingyan, TIAN Jiugen, et al. Effect of ZrO2 on properties of low temperature vitrified bond and abrasive tools with CBN [J]. Bulletin of the Chinese Ceramic Society,2013,32(8):1592-1596. [69] 李启泉, 王新玲, 王永, 等. ZrO2对陶瓷结合剂CBN磨具性能的影响 [J]. 工具技术, 2020, 54(2): 25-28.LI Qiquan, WANG Xinlin, WANG Yong, et al. Effect of ZrO2 on properties of ceramic bond CBN grinding tool [J]. Tool Engineering, 2020, 54(2): 25-28. [70] 田久根, 侯永改. ZrSiO4对陶瓷结合剂预熔玻璃料结构与性能的影响 [J]. 金刚石与磨料磨具工程,2019,39(6):48-52.TIAN Jiugen, HOU Yonggai. Effect of ZrSiO4 on properties and structures of low temperature vitrified bond [J]. Diamond & Abrasives Engineering,2019,39(6):48-52. [71] SHAN D, LI Z, ZHU Y, et al. Influence of TiO2 on the physical properties of low-temperature ceramic vitrified bond and mechanical properties of CBN composites [J]. Ceramics International,2012,38(6):4573-4578. doi: 10.1016/j.ceramint.2012.02.035 [72] SUN X, YU T, WANG X, et al. Effect of TiO2 addition and high magnetic field sintering on properties of vitrified bond CBN composites [J]. Ceramics International,2018,44(14):16307-16313. doi: 10.1016/j.ceramint.2018.06.030 [73] ZHOU R C, LIU X P, WAN L, et al. Influence of TiO2 amount on the interfacial wettability and relevant properties of vitrified bond CBN composites [J]. Journal of European Ceramic Society,2021,41(1):300-309. doi: 10.1016/j.jeurceramsoc.2020.08.016 [74] 肖攀, 张松, 刘旭辉. 氧化钛对陶瓷结合剂金刚石磨具性能及结构的影响 [J]. 超硬材料工程,2019,31(3):19-22. doi: 10.3969/j.issn.1673-1433.2019.03.005XIAO Pan, ZHANG Song, LIU Xuhui. Effect of titanium oxide on the properties and structures of vitrified bond diamond tools [J]. Superhard Material Engineering,2019,31(3):19-22. doi: 10.3969/j.issn.1673-1433.2019.03.005 [75] ZHU W, ZHOU L, TANG M, et al. Effect of TiO2 on the crystallization, thermal expansion and wetting behavior of Nd2O3-Al2O3-SiO2 glass ceramic filler [J]. Journal of European Ceramic Society,2021,41(16):351-357. doi: 10.1016/j.jeurceramsoc.2021.09.030 [76] 李志宏, 朱玉梅, 董庆年. 含CaO陶瓷结合剂强度的研究 [J]. 金刚石与磨料磨具工程,1995(1):22-23.LI Zhihong, ZHU Yumei, DONG Qingnian. Study on the strength of ceramic binder containing CaO [J]. Diamond & Abrasives Engineering,1995(1):22-23. [77] 钟彦征, 张明岩, 侯永改, 等. BaO对低温陶瓷结合剂性能与结构的影响 [J]. 金刚石与磨料磨具工程,2013,33(4):61-64. doi: 10.13394/j.cnki.jgszz.2013.04.009ZHONG Yanzheng, ZHANG Mingyan, HOU Yonggai, et al. Effect of BaO on properties and structure of low temperature vitrified bond [J]. Diamond & Abrasives Engineering,2013,33(4):61-64. doi: 10.13394/j.cnki.jgszz.2013.04.009 [78] 赵仕敬, 王海龙, 李剑, 等. Na2O含量对金刚石砂轮用Na2O-SiO2-Al2O3-B2O3系陶瓷结合剂性能的影响 [J]. 机械工程材料,2018,42(4):1-6. doi: 10.11973/jxgccl201804001ZHAO Shijing, WANG Hailong, LI Jian, et al. Effect of Na2O content on properties of on Na2O-SiO2-Al2O3-B2O3 system vitrified bond for diamond grinding wheel [J]. Materials for Mechanical Engineering,2018,42(4):1-6. doi: 10.11973/jxgccl201804001 [79] 梅涛, 黄启忠, 王绍斌, 等. 碱金属氧化物Na2O对陶瓷结合剂金刚石磨具性能的影响 [J]. 硅酸盐通报,2021,40(3):978-983.MEI Tao, HUANG Qizhong, WANG Shaobin, et al. Effect of alkali metal oxide Na2O on performance of vitrified bond diamond abrasive tools [J]. Bulletin of the Chinese Ceramic Society,2021,40(3):978-983. [80] ZHENG W, CHENG J, TANG L, et al. Effect of Y2O3 addition on viscosity and crystallization of the lithium aluminosilicate glasses [J]. Thermochimica Acta,2007,456(1):69-74. doi: 10.1016/j.tca.2007.01.022 [81] ZHENG W H, CHENG J S, LI H, et al. Structure and properties of the lithium aluminosilicate glasses with yttria addition [J]. Journal of Wuhan University of Technology-Materials Science Edition,2007,22:362-366. doi: 10.1007/s11595-005-2362-x [82] 侯永改, 祝聿霏, 张明岩, 等. 氧化钇对高速CBN砂轮用陶瓷结合剂玻璃料性能的影响 [J]. 中国稀土学报,2012,30(3):330-336.HOU Yonggai, ZHU Yufei, ZHANG Mingyan, et al. Effect of Y2O3 on properties of high-speed CBN grinding wheel with vitrified glass materials [J]. Journal of the Chinese Society of Rare Earths,2012,30(3):330-336. [83] FENG D, LI Z, ZHU Y, et al. Synergistic effects of CeO2 and Y2O3 on the properties of glass-diamond composites [J]. Journal of Alloys and Compounds,2017,727:757-762. doi: 10.1016/j.jallcom.2017.08.076 [84] LI Q, LI Z, FENG D, et al. Comparison of rare earth oxides on properties of vitrified diamond composites [J]. Diamond and Related Materials,2017,71:85-89. doi: 10.1016/j.diamond.2016.12.010 [85] WANG X, MA Z, SUN X, et al. Effects of ZrO2 and Y2O3 on physical and mechanical properties of ceramic bond and ceramic CBN composites [J]. International Journal of Refractory Metals and Hard Materials,2018,75:18-24. doi: 10.1016/j.ijrmhm.2018.03.016 [86] WANG M, ZHENG Q, CHEN A, et al. Crystallization, thermal expansion and hardness of Y2O3-Al2O3-SiO2 glass [J]. Ceramics International,2021,47:25059-25066. doi: 10.1016/j.ceramint.2021.05.236 [87] LI X, WANG Y, YANG P, et al. Effect of Y2O3/La2O3 on structure and mechanical properties of Li2O-Al2O3-SiO2 glass [J]. Journal of Non-Crystalline Solids,2022,596:121847. doi: 10.1016/j.jnoncrysol.2022.121847 [88] 张培强, 万隆, 刘小磐, 等. 碱金属氧化物对陶瓷结合剂性能的影响 [J]. 超硬材料工程,2007,19(3):21-23. doi: 10.3969/j.issn.1673-1433.2007.03.006ZHANG Peiqiang, WAN Long, LIU Xiaopan, et al. Influence of alkali metal oxides on properties of CBN vitrified bond [J]. Superhard Material Engineering,2007,19(3):21-23. doi: 10.3969/j.issn.1673-1433.2007.03.006 [89] WANG P F, LI Z H, ZHU Y M. Influences of alkaline-earth metal oxides on the properties of vitrified bond [J]. Key Engineering Materials,2008,368/369/370/371/372:1405-1407. doi: 10.4028/www.scientific.net/KEM.368-372.1405 [90] 王鹏飞, 李志宏, 朱玉梅. 碱金属氧化物对陶瓷结合剂性能的影响 [J]. 稀有金属材料与工程,2007,36(A1):285-287.WANG Pengfei, LI Zhihong, ZHU Yumei. Effects of alkali metal oxides on the properties of vitrified bond [J]. Rare Metal Materials and Engineering,2007,36(A1):285-287. [91] FENG D, WU W, WANG P, et al. Effects of Cu on properties of vitrified bond and vitrified CBN composites [J]. International Journal of Refractory Metals Hard Materials,2015,50:269-273. doi: 10.1016/j.ijrmhm.2015.01.002 [92] 程利霞, 李志宏, 朱玉梅, 等. 金属Al粉对CBN磨具陶瓷结合剂性能的影响 [J]. 金刚石与磨料磨具工程,2008(5):44-47. doi: 10.3969/j.issn.1006-852X.2008.05.010CHEN Lixia, LI Zhihong, ZHU Yumei, et al. Effect of aluminum on the properties of vitrified bond for CBN grinding tool [J]. Diamond & Abrasives Engineering,2008(5):44-47. doi: 10.3969/j.issn.1006-852X.2008.05.010 [93] HE F, ZHANG W, ZHOU Q, et al. Effect of aluminum addition on microstructure and properties of SiO2-B2O3-Al2O3-CaO vitrified bond [J]. Journal of Wuhan University of Technology (Materials Science Edition),2016,31:1267-1271. doi: 10.1007/s11595-016-1524-3 [94] 李君君, 王云峰, 张爱菊, 等. 金属铝粉和纳米Al2O3粉对陶瓷结合剂性能的影响 [J]. 硅酸盐通报,2021,40(11):3777-3783.LI Junjun, WANG Yunfeng, ZHANG Aiju, et al. Effects of metal aluminum powder and nano-Al2O3 powder on properties of vitrified bond [J]. Bulletin of the Chinese Ceramic Society,2021,40(11):3777-3783. [95] XIA P, LI Z, WU W, et al. Effects of AlN on the thermal and mechanical properties of vitrified bond and vitrified CBN composites [J]. Ceramics International,2014,40(8):12759-12764. doi: 10.1016/j.ceramint.2014.04.129 [96] SUN X, YU T, CHEN Y, et al. Effect of cobalt on properties of vitrified bond and vitrified cubic boron nitride composites [J]. Ceramics International,2020,46(4):5337-5343. doi: 10.1016/j.ceramint.2019.10.286 [97] 王志起, 万隆, 刘小磐, 等. 铁族金属对金刚石磨具陶瓷结合剂性能的影响 [J]. 复合材料学报,2012,29(5):94-98. doi: 10.13801/j.cnki.fhclxb.2012.05.033WANG Zhiqi, WAN Long, LIU Xiaopan, et al. Effect of iron group metal on the properties of vitrified bond for diamond grinding tool [J]. Acta Materiae Compositae Sinica,2012,29(5):94-98. doi: 10.13801/j.cnki.fhclxb.2012.05.033 [98] 王志起, 万隆, 胡伟达, 等. Ti对陶瓷结合剂及金刚石磨具性能的影响 [J]. 金刚石与磨料磨具工程,2011,31(2):50-54. doi: 10.3969/j.issn.1006-852X.2011.02.011WANG Zhiqi, WAN Long, HU Weida, et al. Effect of titanium on the properties of vitrified bond and diamond grinding tool [J]. Diamond & Abrasives Engineering,2011,31(2):50-54. doi: 10.3969/j.issn.1006-852X.2011.02.011 [99] 晋凯, 赵志伟, 郑红娟, 等. 纳米TiO2对微波法制备CBN 陶瓷磨具的结构和性能影响 [J]. 人工晶体学报,2018,47(10):2121-2127. doi: 10.3969/j.issn.1000-985X.2018.10.021JIN Kai, ZHAO Zhiwei, ZHEN Hongjuan, et al. Effect of nano TiO2 on structure and properties of CBN grinding tools prepared by microwave method [J]. Journal of Synthetic Crystals,2018,47(10):2121-2127. doi: 10.3969/j.issn.1000-985X.2018.10.021 [100] 侯永改, 田久根, 马加加. 纳米氧化锆对金刚石磨具用陶瓷结合剂结构与性能的影响研究 [J]. 硅酸盐通报,2015,34(2):530-534. doi: 10.16552/j.cnki.issn1001-1625.2015.02.025HOU Yonggai, TIAN Jiugen, MA Jiajia. Effect of Nano-ZrO2 on properties and structure of vitrified bond for diamond grinding tools [J]. Bulletin of the Chinese Ceramic Society,2015,34(2):530-534. doi: 10.16552/j.cnki.issn1001-1625.2015.02.025 [101] CUI E, ZHAO J, WANG X. Effects of nano-ZrO2 content on microstructure and mechanical properties of GNPs/nano-ZrO2 reinforced Al2O3/Ti(C, N) composite ceramics [J]. Journal of the European Ceramic Society,2020,40(4):1532-1538. doi: 10.1016/j.jeurceramsoc.2019.11.039 [102] 赵志伟, 王春华, 关春龙, 等. 纳米氧化物对CBN磨具陶瓷结合剂性能的影响 [J]. 金刚石与磨料磨具工程,2009(5):59-65. doi: 10.3969/j.issn.1006-852X.2009.06.013ZHAO Zhiwei, WANG Chunhua, GUAN Chunlong, et al. Effect of nano-oxides on properties of vitrified bond for CBN abrasive tools [J]. Diamond & Abrasives Engineering,2009(5):59-65. doi: 10.3969/j.issn.1006-852X.2009.06.013 [103] 张景强, 王宛山, 于天彪, 等. 超高速陶瓷CBN砂轮纳米陶瓷结合剂性能实验研究 [J]. 中国机械工程,2014,25(1):82-87. doi: 10.3969/j.issn.1004-132X.2014.01.016ZHANG Jingqiang, WANG Wanshan, YU Tianbiao, et al. Experimental study of nano-ceramic bond based on super high-speed CBN grinding wheel [J]. China Mechanical Engineering,2014,25(1):82-87. doi: 10.3969/j.issn.1004-132X.2014.01.016 [104] 刘鑫鑫, 刘世凯, 张吉祥. 纳米组分优化对陶瓷结合剂强度的影响研究 [J]. 超硬材料工程,2017,29(4):44-47. doi: 10.3969/j.issn.1673-1433.2017.04.010LIU Xinxin, LIU Shikai, ZHANG Jixiang. Study of the influence of nano component optimization on strength of ceramic bond [J]. Superhard Material Engineering,2017,29(4):44-47. doi: 10.3969/j.issn.1673-1433.2017.04.010 [105] ZHAO Z, HU W, ZHENG H, et al. Synthesis of vanadium and chromium carbides (V8C7-Cr3C2) nanocomposite via an in situ precursor method [J]. Rare Metals,2015,34:498-504. doi: 10.1007/s12598-015-0501-x [106] CHEN F, ZHENG H, ZHAO Z, et al. Effect of V8C7-Cr3C2 nanocomposite on microstructure and properties of vitrified bond CBN grinding tools prepared by microwave heating method [J]. Materials Letters,2018,219:41-44. doi: 10.1016/j.matlet.2018.02.063 [107] 侯永改, 张明岩, 祝聿霏. 超高速陶瓷结合剂CBN砂轮制造及应用 [J]. 工具技术,2012,46(4):3-8. doi: 10.3969/j.issn.1000-7008.2012.04.001HOU Yonggai, ZHANG Mingyan, ZHU Yufei. Manufacturing technology and application of ultra-high speed vitrified bond CBN grinding wheel [J]. Tool Engineering,2012,46(4):3-8. doi: 10.3969/j.issn.1000-7008.2012.04.001 [108] 李兴山, 张景强. 超高速陶瓷结合剂CBN砂轮关键制备技术的研究 [J]. 工具技术,2011,45(4):3-7. doi: 10.3969/j.issn.1000-7008.2011.04.001LI Xingshan, ZHANG Jingqiang. Research on key manufacturing technologies for super-high speed vitrified bond CBN grinding wheel [J]. Tool Engineering,2011,45(4):3-7. doi: 10.3969/j.issn.1000-7008.2011.04.001 [109] 徐明坤, 郭丽和, 周宁宁, 等. 等静压成型对多孔聚酰亚胺保持架成孔性能的影响研究 [J]. 机械工程学报,2022,58(16):178-188.XU Mingkun, GUO Lihe, ZHOU Ningning, et al. Influence of isostatic press on the pore properties of porous oil-containing polyimide retainer [J]. Journal of Mechanical Engineering,2022,58(16):178-188. [110] 李青, 尹育航, 刘鸿. 冷等静压成型工艺对陶瓷结合剂金刚石磨具性能的影响 [J]. 硅酸盐通报,2013,32(7):1379-1383. doi: 10.16552/j.cnki.issn1001-1625.2013.07.039LI Qing, YIN Yuhang, LIU Hong. Effect of properties of vitrified bond diamond abrasive tools by cold isostatic pressing [J]. Bulletin of the Chinese Ceramic Society,2013,32(7):1379-1383. doi: 10.16552/j.cnki.issn1001-1625.2013.07.039 [111] 刘晓妍, 李婷, 罗旭东, 等. 制备工艺对La2O3掺杂氧化镁陶瓷性能的影响 [J]. 耐火材料,2022,56(1):34-37. doi: 10.3969/j.issn.1001-1935.2022.01.008LIU Xiaoyan, LI Ting, LUO Xudong, et al. Effects of preparation process on properties of La2O3 doped magnesia ceramics [J]. Refractories,2022,56(1):34-37. doi: 10.3969/j.issn.1001-1935.2022.01.008 [112] 李建伟, 万隆, 常闯, 等. 溶胶-原位凝胶法制备陶瓷结合剂金刚石砂轮的结构与性能 [J]. 超硬材料工程,2018,30(1):7-12. doi: 10.3969/j.issn.1673-1433.2018.01.002LI Jianwei, WAN Long, CHANG Chuang, et al. Synthesis and performance of vitrified bond diamond grinding wheel by in-situ sol-gel method [J]. Superhard Material Engineering,2018,30(1):7-12. doi: 10.3969/j.issn.1673-1433.2018.01.002 [113] 余剑武, 文丞, 黄帅, 等. 热压烧结工艺参数对超硬磨料砂轮节块性能的影响 [J]. 金刚石与磨料磨具工程,2016,36(6):29-34. doi: 10.13394/j.cnki.jgszz.2016.6.0007YU Jianwu, WEN Cheng, HUANG Shuai, et al. Effect of hot-press sintering parameters on properties of super-abrasive wheel segments [J]. Diamond & Abrasives Engineering,2016,36(6):29-34. doi: 10.13394/j.cnki.jgszz.2016.6.0007 [114] 夏朋昭, 许莹, 蔡艳青, 等. 微波烧结工艺对Ti-Mg复合材料组织和性能的影响 [J]. 金属热处理,2022,47(9):18-26.XIA Pengzhao, XU Ying, CAI Yanqing, et al. Effect of microwave sintering process on microstructure and properties of Ti-Mg composites [J]. Heat Treatment of Metals,2022,47(9):18-26. [115] 曹燕, 程寓, 胡晓, 等. 微波烧结陶瓷结合剂金刚石砂轮磨削硅片性能的研究 [J]. 制造技术与机床,2020,6:122-125. doi: 10.19287/j.cnki.1005-2402.2020.06.023CAO Yan, CHENG Yu, HU Xiao, et al. Study on performance of vitrified bond diamond grinding wheels by microwave sintering grinding silicon water [J]. Manufacturing and Machine Tool,2020,6:122-125. doi: 10.19287/j.cnki.1005-2402.2020.06.023 [116] 张於亮, 汪振华, 姜志嵩, 等. 微波烧结陶瓷结合剂金刚石砂轮研究 [J]. 硅酸盐通报,2022,41(10):3675-3679. doi: 10.16552/j.cnki.issn1001-1625.20220909.003ZHANG Yuliang, WANG Zhenhua, JIANG Zhisong, et al. Study on microwave sintering of ceramic bonded diamond grinding wheels [J]. Bulletin of the Chinese Ceramic Society,2022,41(10):3675-3679. doi: 10.16552/j.cnki.issn1001-1625.20220909.003 [117] 瞿晓波, 李艳玲, 鲁涛, 等. 陶瓷结合剂 砂轮在凸轮轴加工中的应用 [J]. 金刚石与磨料磨具工程,2008(4):70-73.QU Xiaobo, LI Yanling, LU Tao, et al. Application of vitrified CBN grinding wheels in cam shaft grinding [J]. Diamond & Abrasives Engineering,2008(4):70-73. [118] 曹坚. 陶瓷CBN砂轮高速磨削凸轮轴的表面粗糙度研究 [J]. 制造业自动化,2011,33(7):49-50. doi: 10.3969/j.issn.1009-0134.2011.4a.16CAO Jian. Research on surface roughness in cam shaft high speed grinding with vitrified bond CBN wheel [J]. Manufacturing Automation,2011,33(7):49-50. doi: 10.3969/j.issn.1009-0134.2011.4a.16 [119] 鲁涛, 杜雄, 李学文, 等. 陶瓷CBN砂轮在船舶曲轴磨削中的应用 [J]. 金刚石与磨料磨具工程,2015,35(6):28-31. doi: 10.13394/j.cnki.jgszz.2015.6.0006LU Tao, DU Xiong, LI Xuewen, et al. Ceramic CBN grinding wheel applied to grind ship crankshaft [J]. Diamond & Abrasives Engineering,2015,35(6):28-31. doi: 10.13394/j.cnki.jgszz.2015.6.0006 [120] 张济洲, 史光远, 穆云超, 等. 陶瓷结合剂CBN砂轮对GCr15轴承钢锭子的磨削研究 [J]. 金刚石与磨料磨具工程,2004(3):57-59. doi: 10.3969/j.issn.1006-852X.2004.03.017ZHANG Jizhou, SHI Guangyuan, MU Yunchao, et al. Research on grinding of GCrl5 bearing steel spindle with CBN grinding wheel [J]. Diamond & Abrasives Engineering,2004(3):57-59. doi: 10.3969/j.issn.1006-852X.2004.03.017 [121] 刘伟, 刘仁通, 邓朝晖, 等. 轴承钢GCr15高速外圆磨削试验研究 [J]. 兵器材料科学与工程,2018,41(5):40-44. doi: 10.14024/j.cnki.1004-244x.20180821.002LIU Wei, LIU Rentong, DENG Zhaohui, et al. High-speed external cylindrical plunge grinding of bearing steel GCr15 [J]. Ordnance Material Science and Engineering,2018,41(5):40-44. doi: 10.14024/j.cnki.1004-244x.20180821.002 [122] 朱建辉, 闫宁, 师超钰, 等. 低浓度陶瓷CBN砂轮磨削性能分析 [J]. 机械设计与研究,2018,34(1):150-153. doi: 10.13952/j.cnki.jofmdr.2018.0034ZHU Jianghui, YAN Ning, SHI Chaoyu, et al. Research on grinding performance of vitrified CBN grinding wheels with low concentration [J]. Machine Design & Research,2018,34(1):150-153. doi: 10.13952/j.cnki.jofmdr.2018.0034 [123] 李克华, 郜永娟, 李献会, 等. 应用陶瓷CBN砂轮的微型轴承套圈内圆磨削方案 [J]. 超硬材料工程,2020,32(1):19-23.LI Kehua, GAO Yongjuan, LI Xianhui, et al. Internal grinding solution of miniature bearing ring with vitrified bond CBN wheels [J]. Superhard Material Engineering,2020,32(1):19-23. [124] 陈涛, 盛晓敏, 宓海青, 等. 45#钢CBN砂轮高速磨削(120m/s)工艺研究 [J]. 湖南大学学报(自然科学版),2006,33(1):47-50.CHEN Tao, SHENG Xiaomin, MI Haiqing, et al. Study on the high speed grinding (120 m/s) process for 45# by CBN grinding wheel [J]. Journal of Hunan University (Natural Sciences),2006,33(1):47-50. [125] ZHANG C, QU S, XI W, et al. Preparation of a novel vitrified bond CBN grinding wheel and study on the grinding performance [J]. Ceramics International,2022,48(11):15565-15575. doi: 10.1016/j.ceramint.2022.02.090 [126] STEPHEN D S, SETHURAMALINGAM P. Effects of grinding α-β titanium with 3% CNTs in CBN grinding wheel: An experimental study [J]. Materials Science Engineering,2020,912:1-10. [127] WU C, LI B, LIU Y, et al. Surface roughness modeling for grinding of silicon carbide ceramics considering co-existence of brittleness and ductility [J]. International Journal Mechanical Sciences,2017,133:167-177. doi: 10.1016/j.ijmecsci.2017.07.061 [128] LOPES J C, FERNANDES L D M, DOMINGUES B B, et al. Effect of CBN grain friability in hardened steel plunge grinding [J]. The International Journal of Advanced Manufacturing Technology,2019,103:1567-1577. doi: 10.1007/s00170-019-03654-w [129] SATO B K, RODRIGUEZ R L, TALON A G, et al. Grinding performance of AISI D6 steel using CBN wheel vitrified and resinoid bonded [J]. The International Journal Advanced Manufacturing Technology,2019,105:2167-2182. doi: 10.1007/s00170-019-04407-5 [130] CAGGIANO A, TETI R. CBN grinding performance improvement in aircraft engine components manufacture [J]. Procedia CIRP,2013,9:109-114. doi: 10.1016/j.procir.2013.06.177 [131] ADIBI H, REZAEI S M, SARHAN A A D. Analytical modeling of grinding wheel loading phenomena [J]. The International Journal of Advanced Manufacturing Technology,2013,68:473-485. doi: 10.1007/s00170-013-4745-z [132] SANDEEP H, PANKAJ C, ARVIND C, et al. Effect of cooling environment on grinding performance of nickel-based superalloy Inconel 718 [J]. Journal of Applied Sciences,2012,12(10):947-954. doi: 10.3923/jas.2012.947.954 [133] YU T, BASTAWROS A F, CHANDRA A. Experimental and modeling characterization of wear and life expectancy of electroplated CBN grinding wheels [J]. The International Journal of Advanced Manufacturing Technology,2017,121:70-80. [134] SHI Y, WANG Z, XU S, et al. Study on the grindability of nano-vitrified bond CBN grinding wheel for nickel-based alloy [J]. The International Journal of Advanced Manufacturing Technology,2019,100:1913-1921. doi: 10.1007/s00170-018-2807-y [135] XU X, YU Y, HUANG H. Mechanisms of abrasive wear in the grinding of titanium (TC4) and nickel (K417) alloys [J]. Wear,2003,255(7/8/9/10/11/12):1421-1426. doi: 10.1016/S0043-1648(03)00163-7 [136] 张小福, 张红霞, 陈燕. 磨削钛合金用陶瓷CBN砂轮的研制 [J]. 新技术新工艺,2006(9):37-41. doi: 10.3969/j.issn.1003-5311.2006.09.013ZHANG Xiaofu, ZHANG Hongxia, CHEN Yan. Development of vitrified CBN grinding wheel for grinding titanium Alloy [J]. New Technology & New Process,2006(9):37-41. doi: 10.3969/j.issn.1003-5311.2006.09.013 [137] 盛晓敏, 唐昆, 余剑武, 等. TC4钛合金超高速磨削工艺试验研究 [J]. 湖南大学学报,2008,35(9):28-32.SHENG Xiaomin, TANG Kun, YU Jianwu, et al. Process test research on TC4 titanium alloy in ultra-high speed grinding [J]. Journal of Hunan University,2008,35(9):28-32. [138] 胥军, 卢文壮, 王晗, 等. 陶瓷结合剂CBN砂轮高速磨削钛合金TC4-DT [J]. 金刚石与磨料磨具工程,2013,33(5):12-21. doi: 10.13394/j.cnki.jgszz.2013.05.016XU Jun, LU Wenzhuang, WANG Han, et al. High speed grinding TC4-DT alloy with vitrified CBN wheel [J]. Diamond & Abrasives Engineering,2013,33(5):12-21. doi: 10.13394/j.cnki.jgszz.2013.05.016 [139] SHI Y, CHEN L, XIN H, et al. Investigation on the grinding properties of high thermal conductivity vitrified bond CBN grinding wheel for titanium alloy [J]. The International Journal of Advanced Manufacturing Technology,2020,107:1539-1549. doi: 10.1007/s00170-020-05134-y -

下载:

下载:

邮件订阅

邮件订阅 RSS

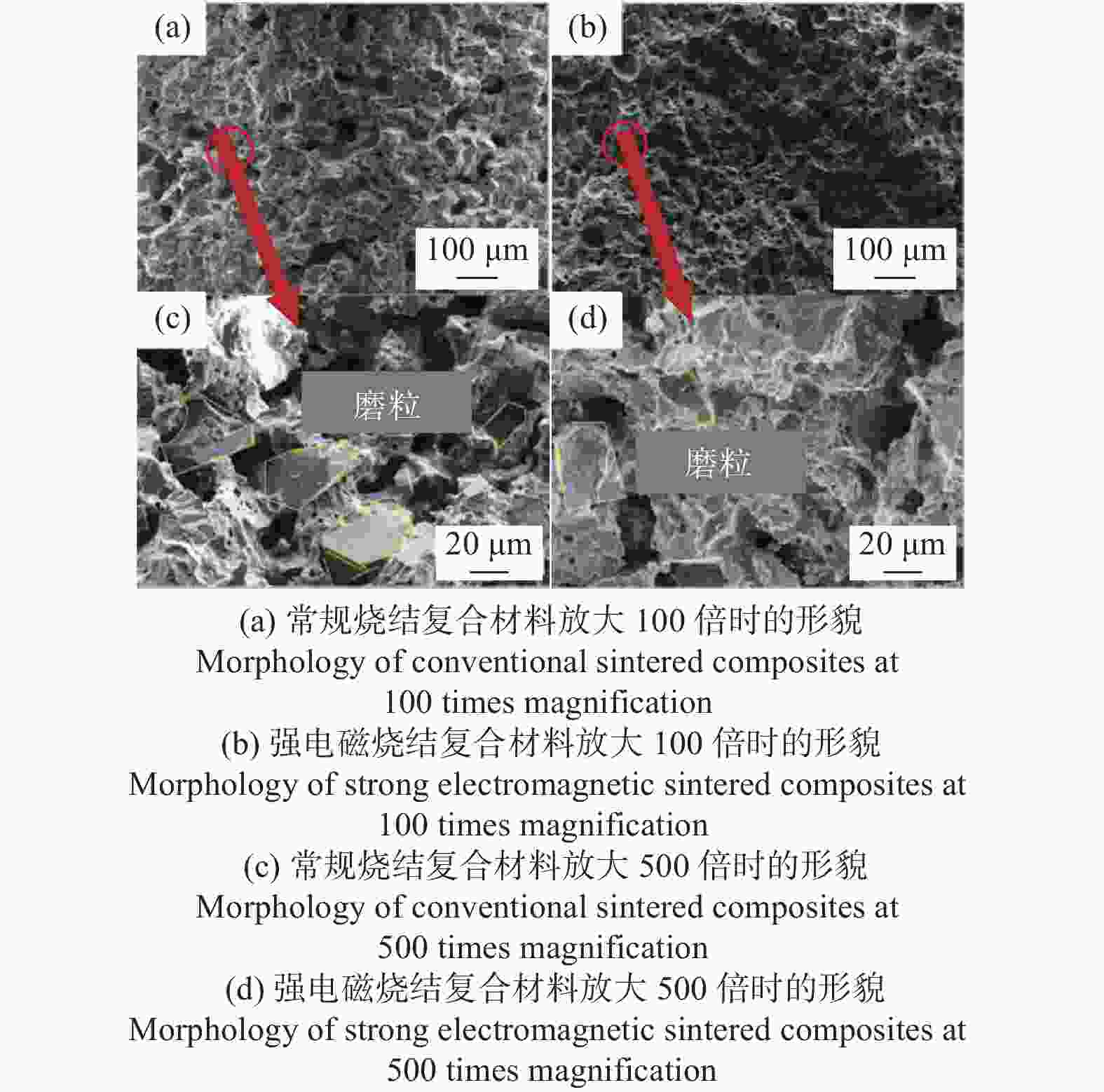

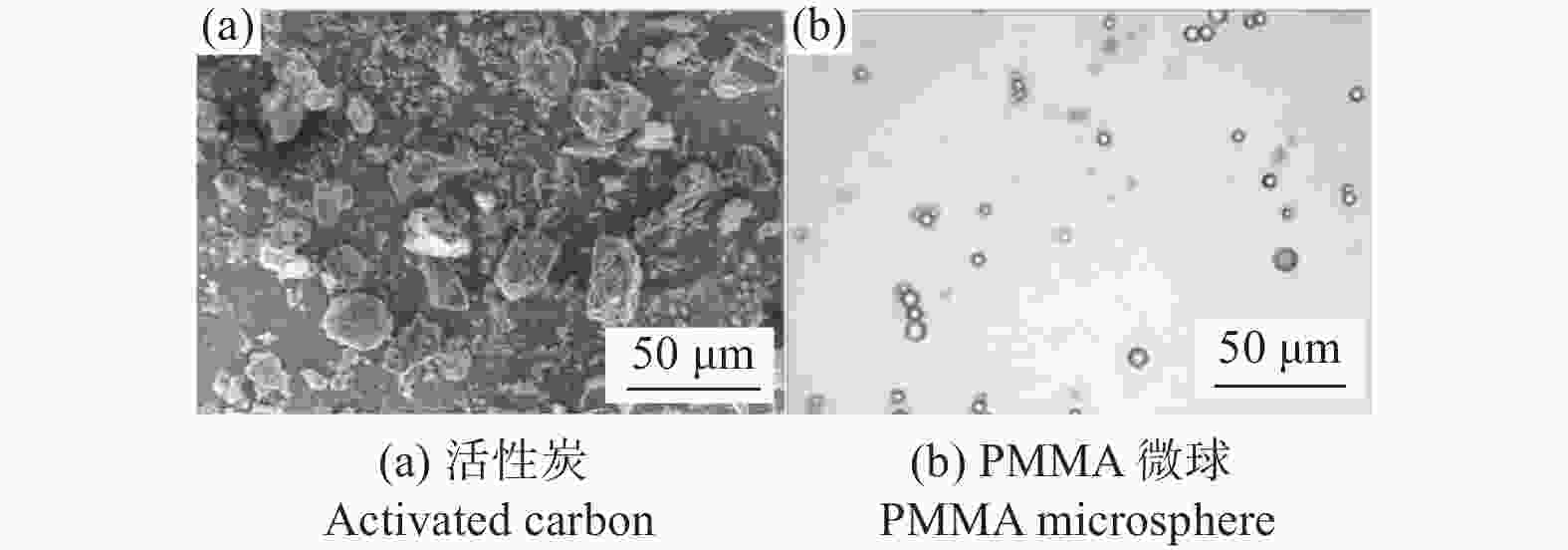

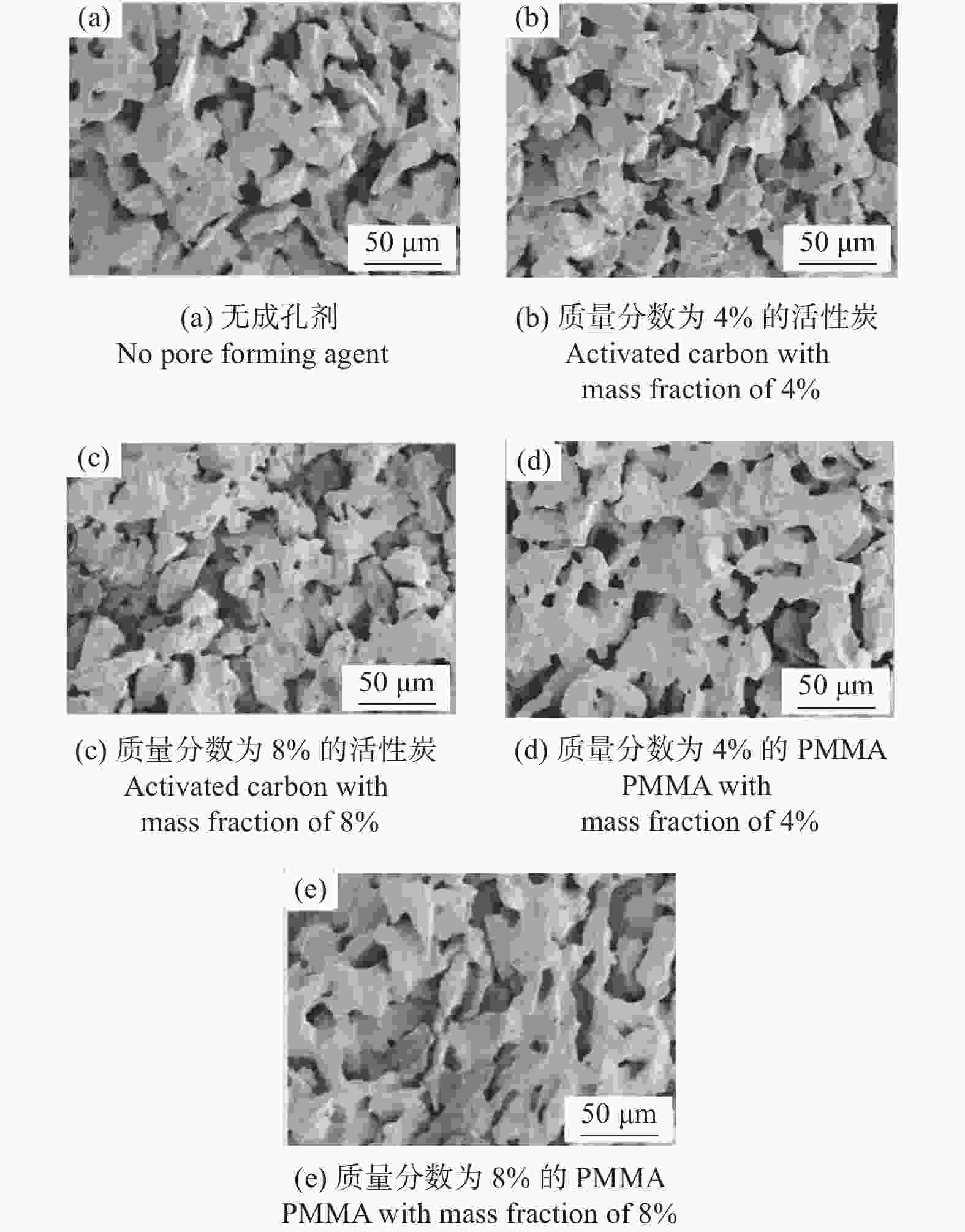

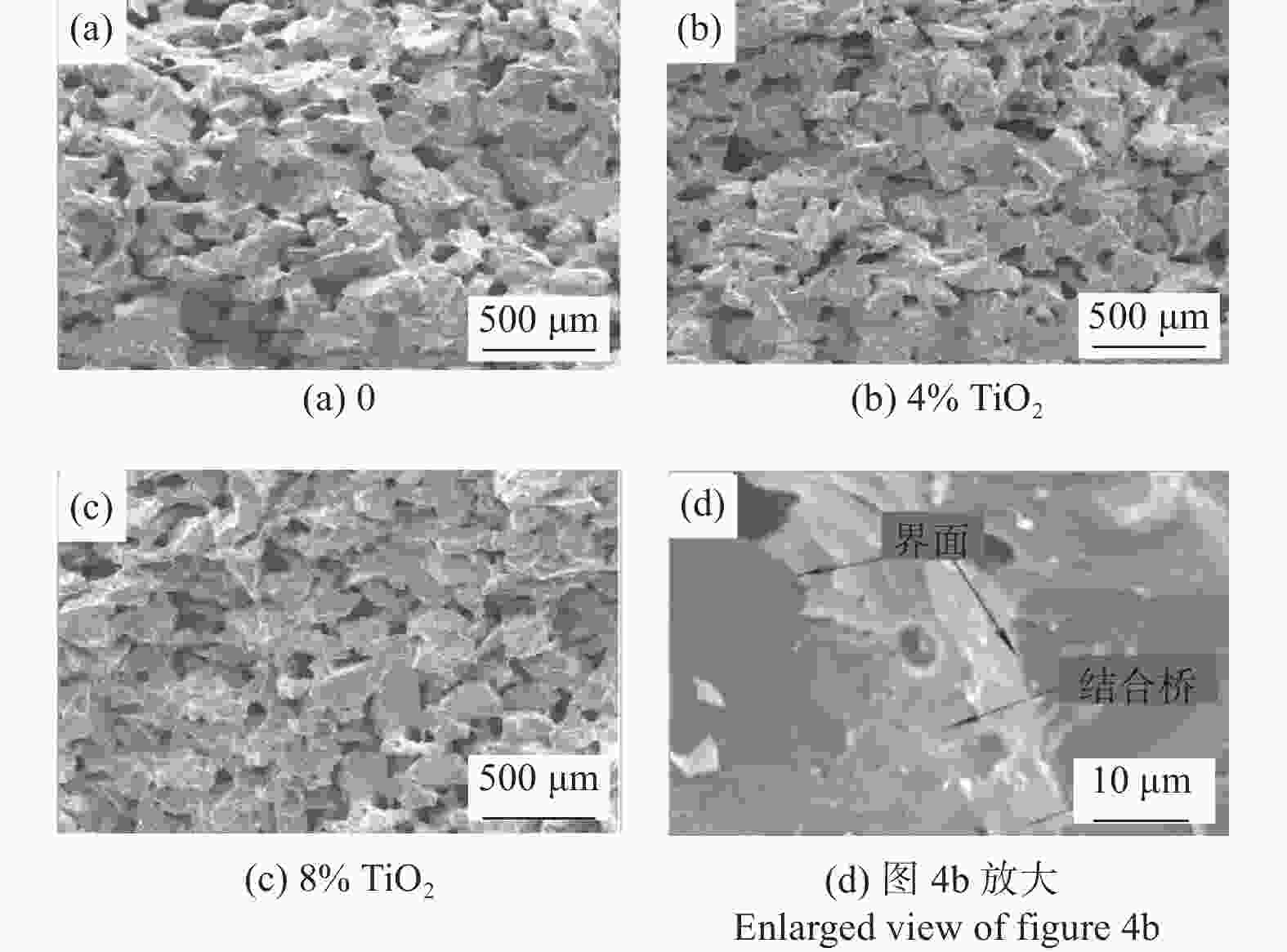

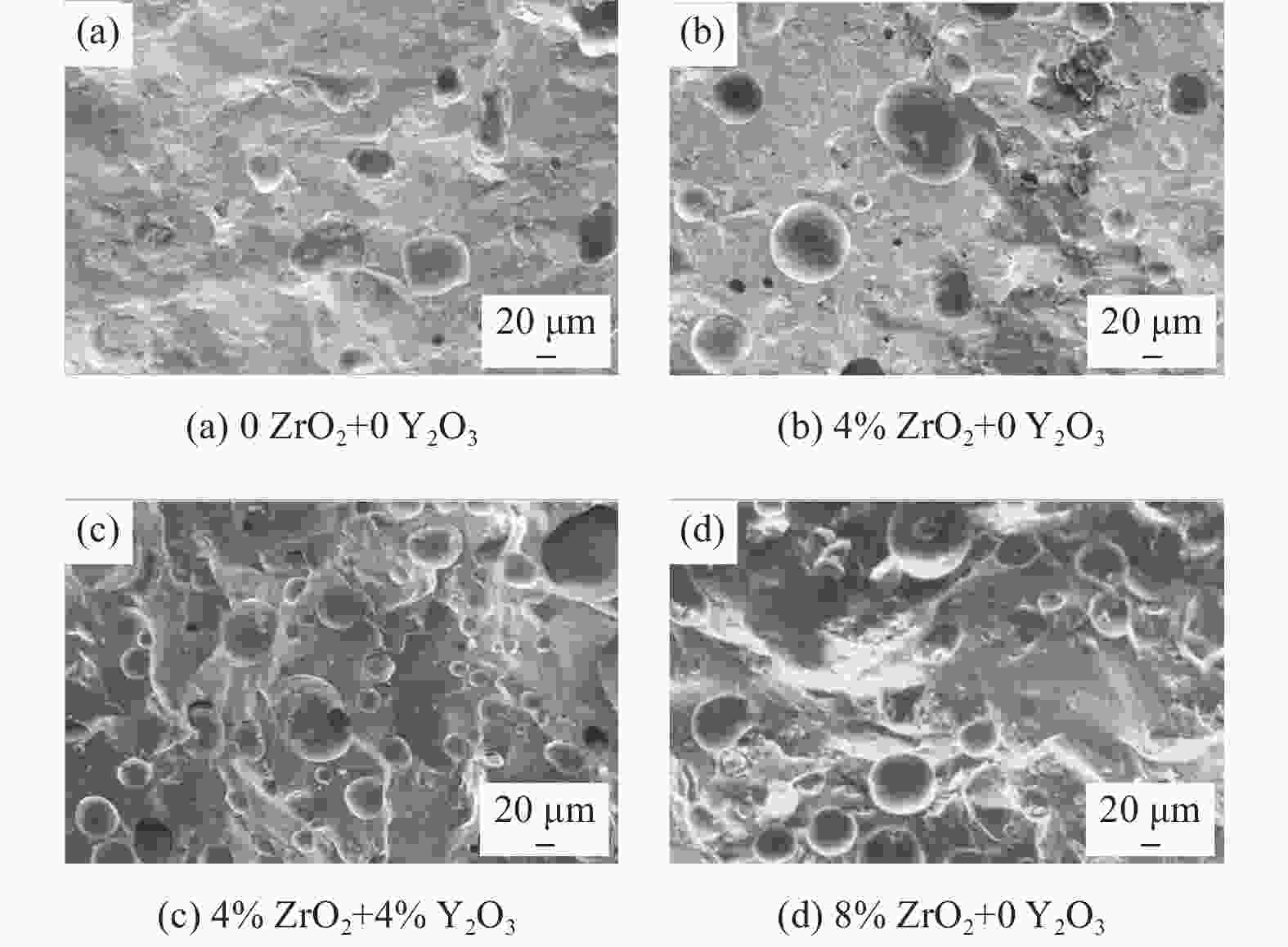

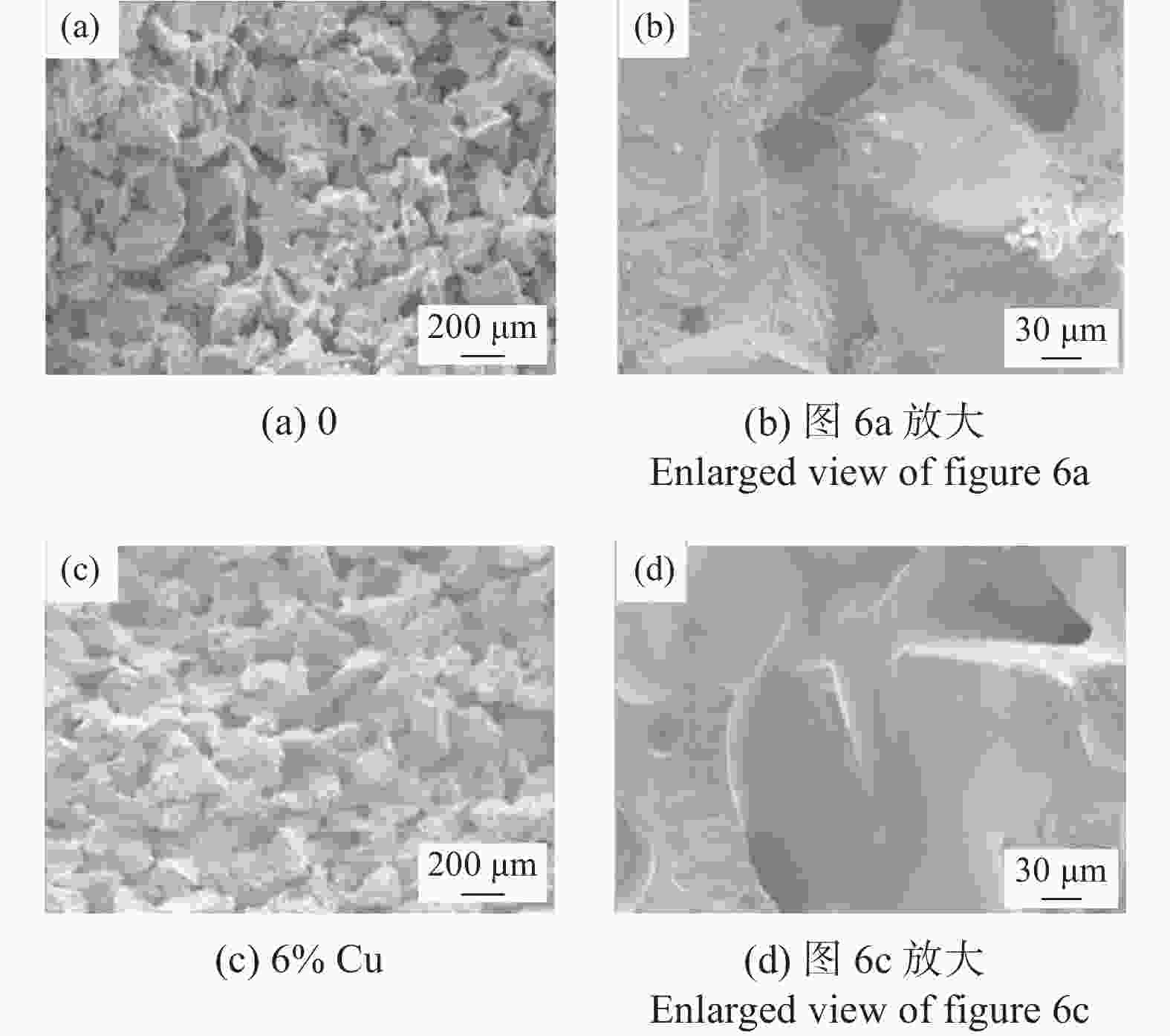

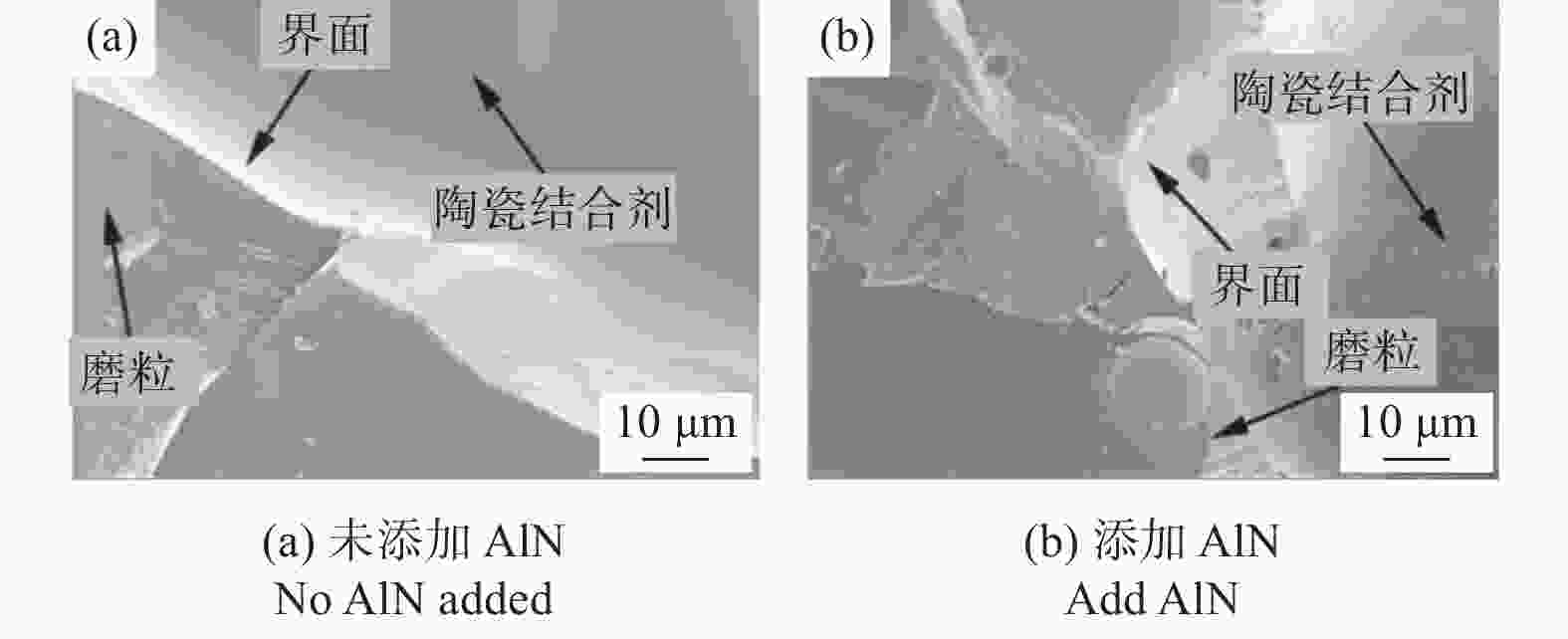

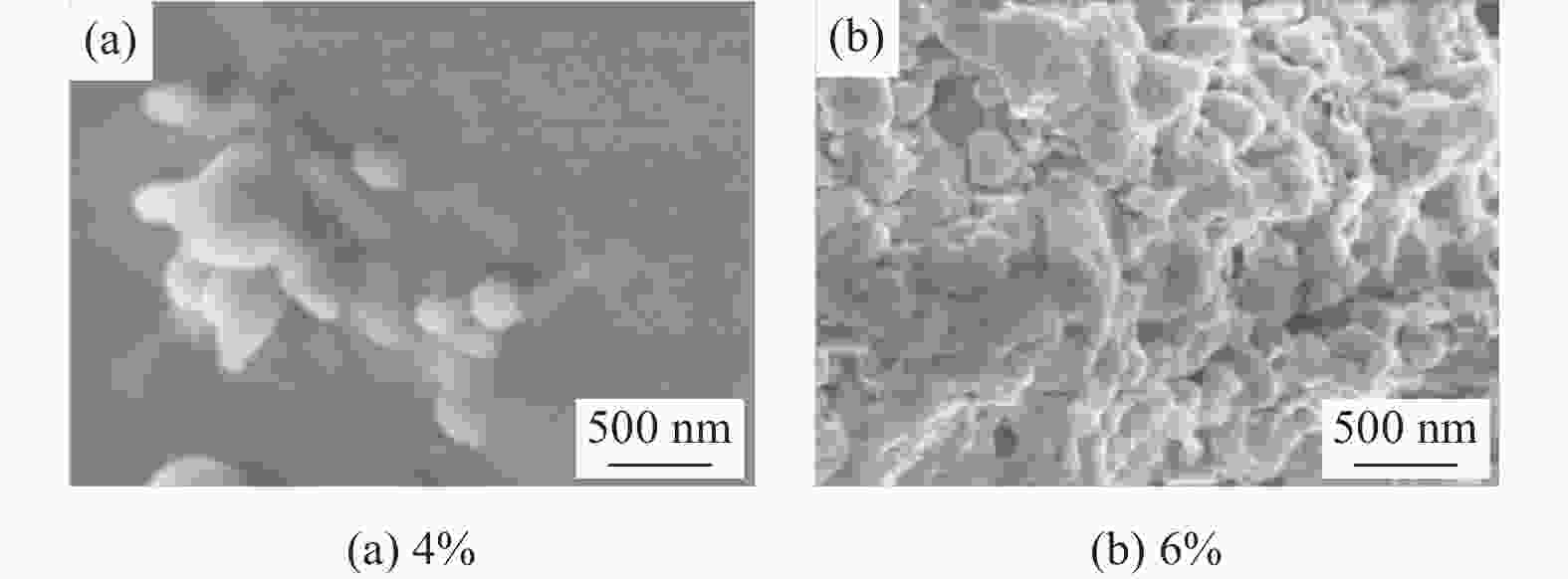

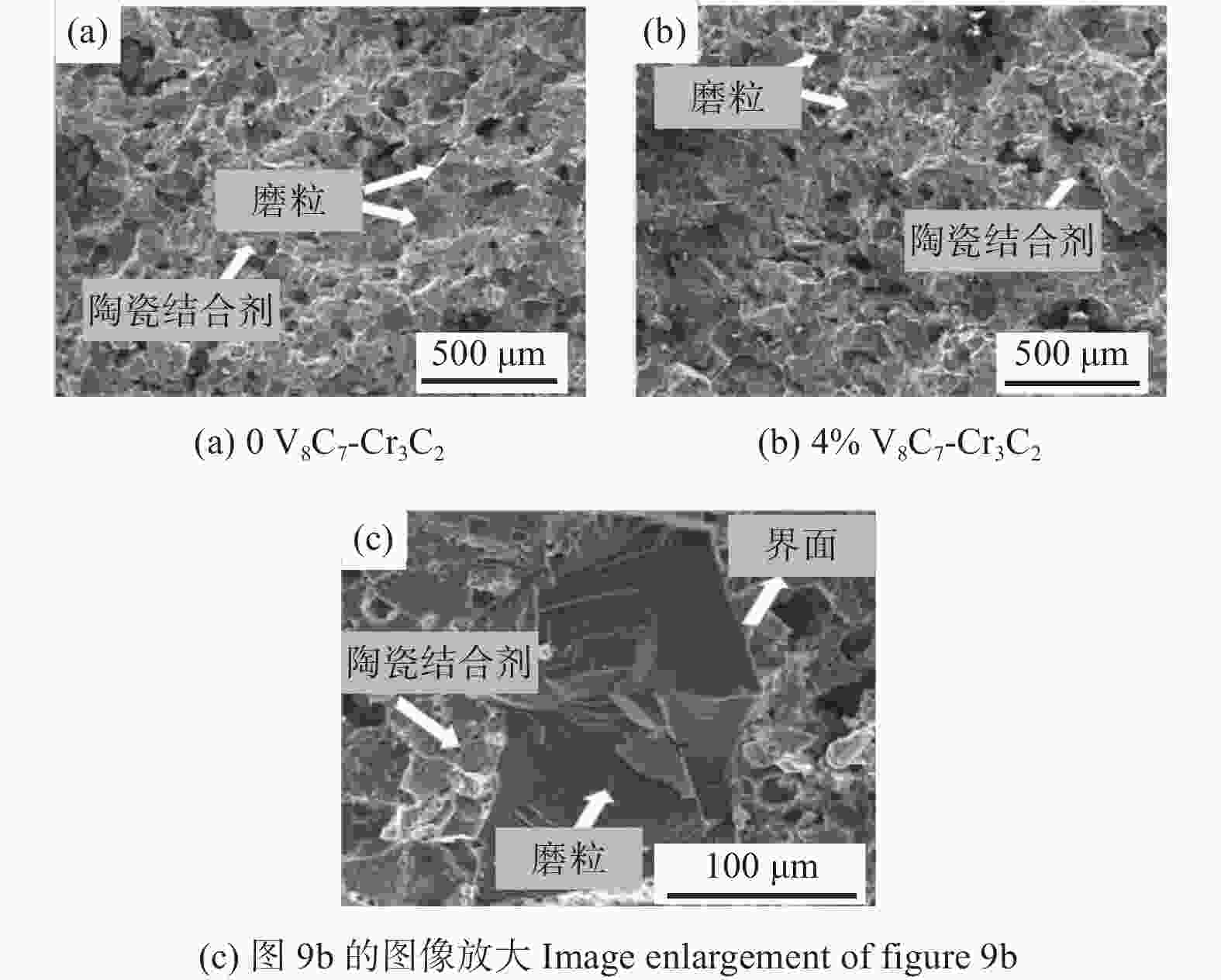

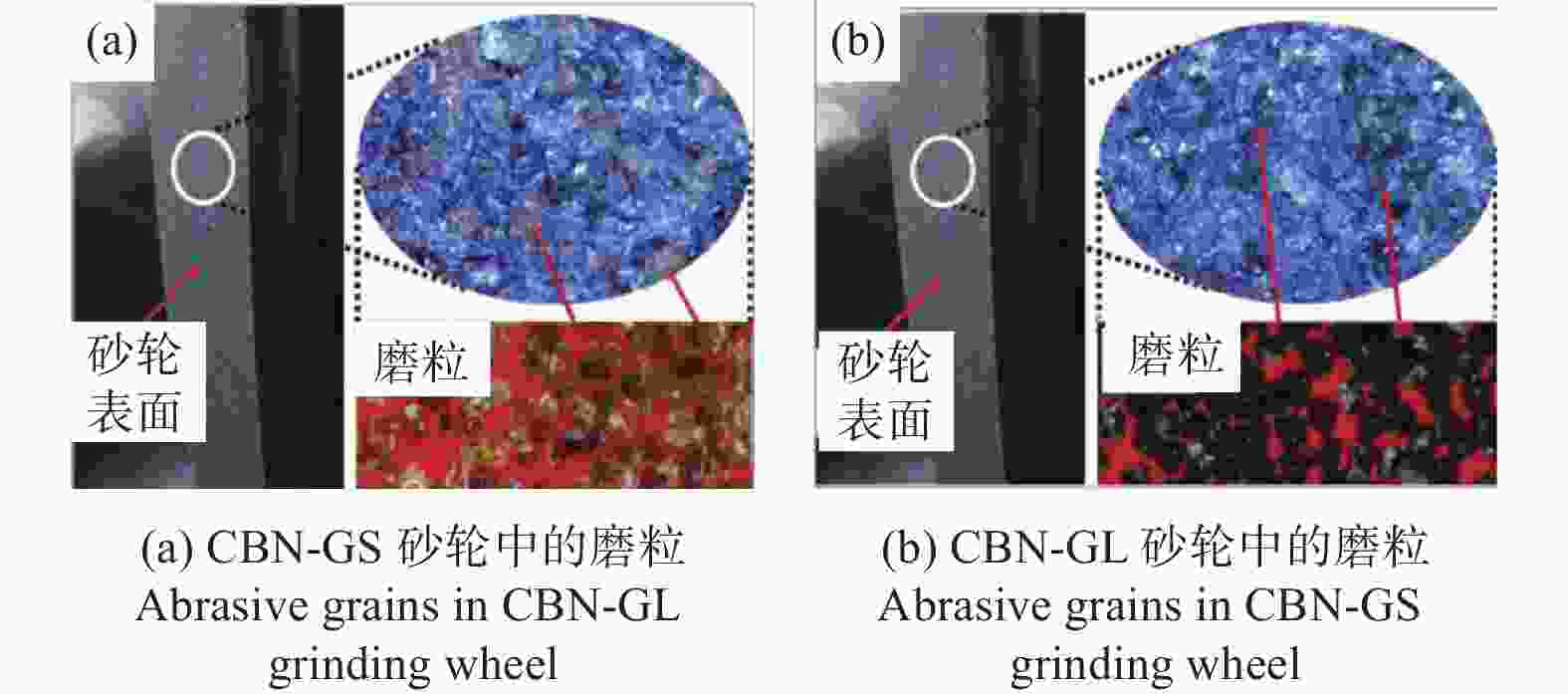

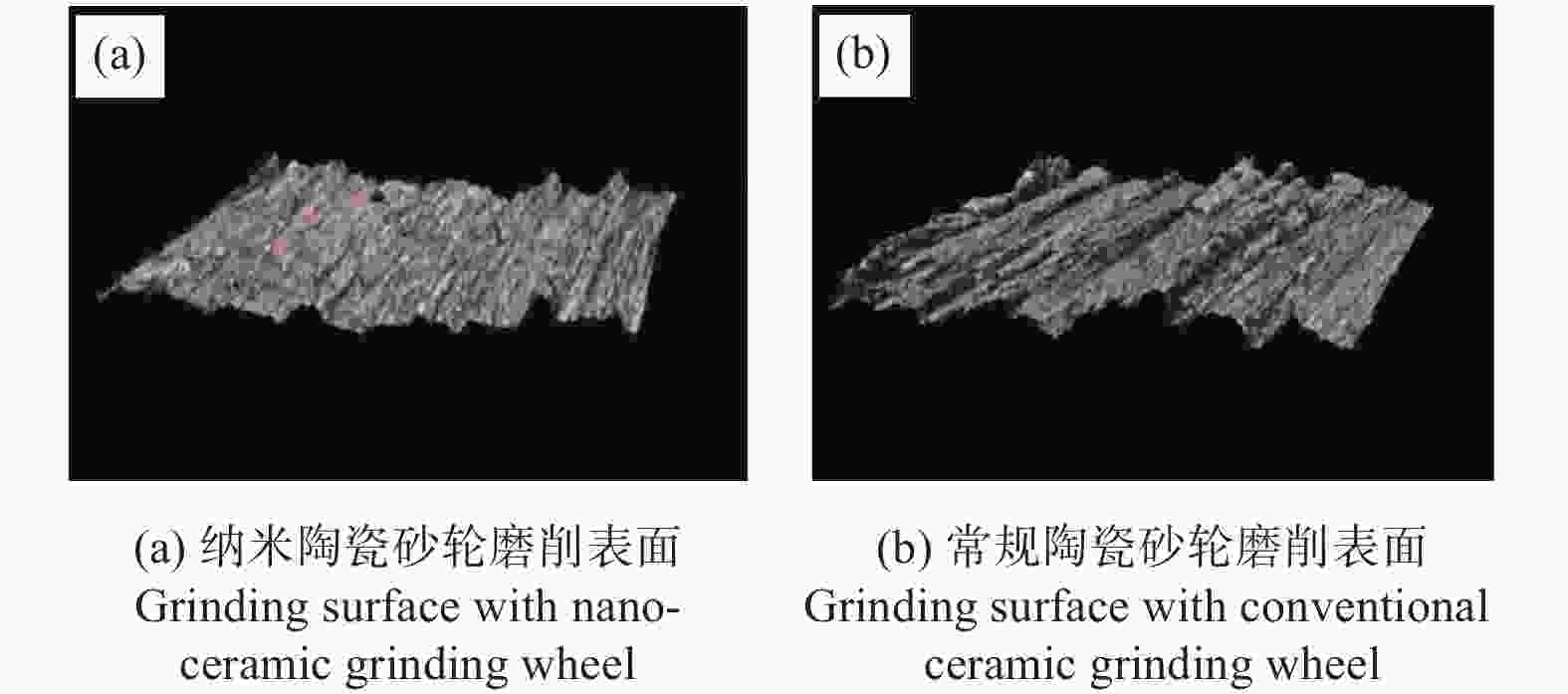

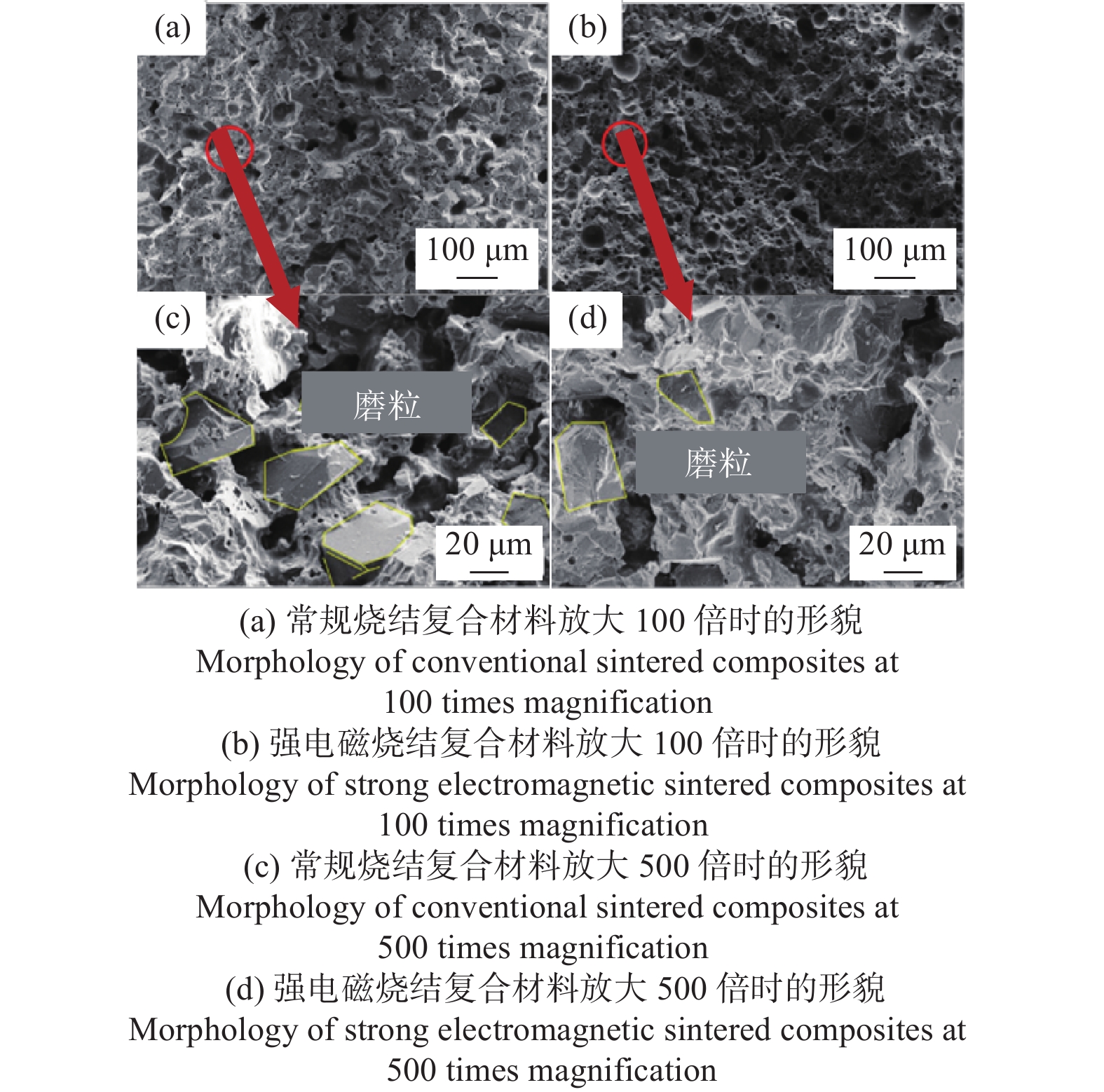

RSS