Microstructure and properties of polycrystalline diamond composites for drilling

-

摘要:

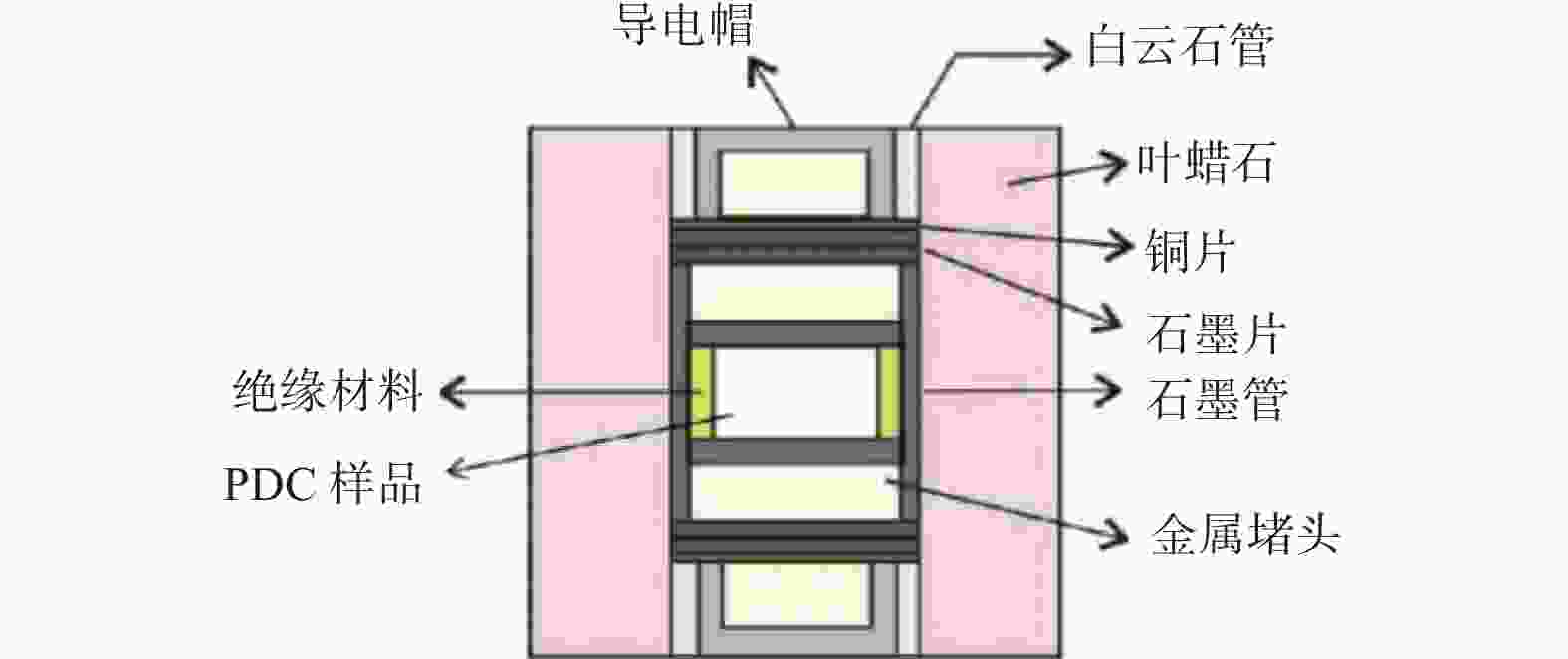

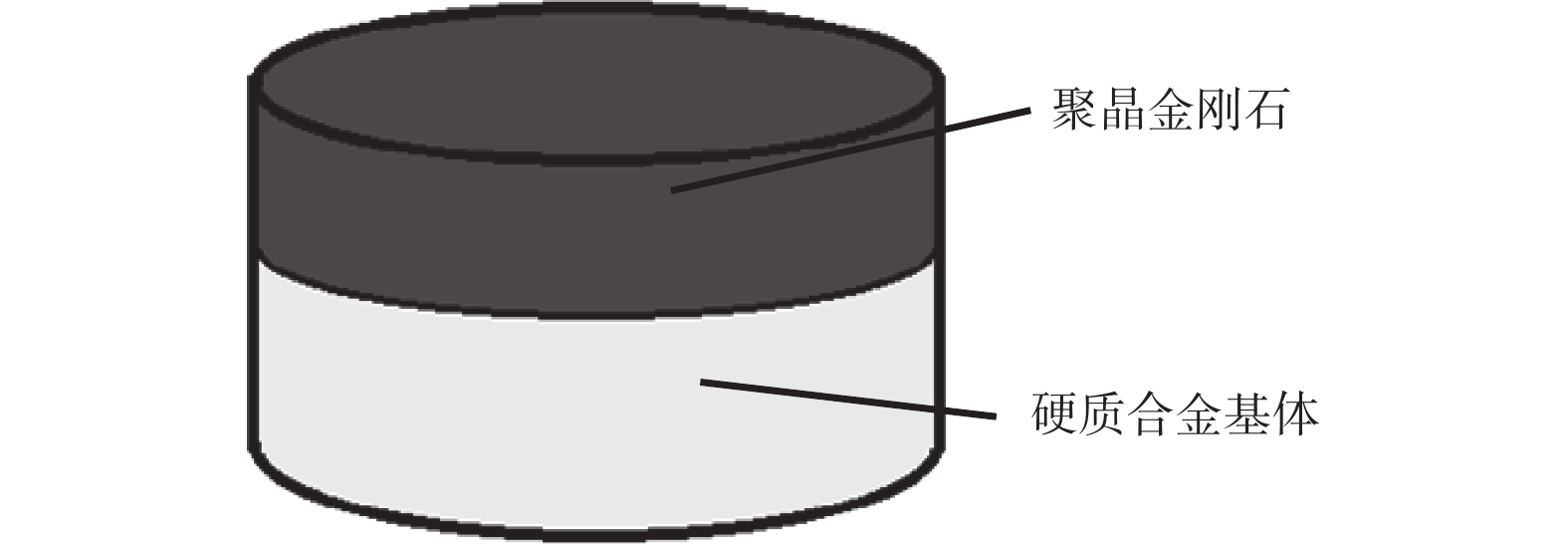

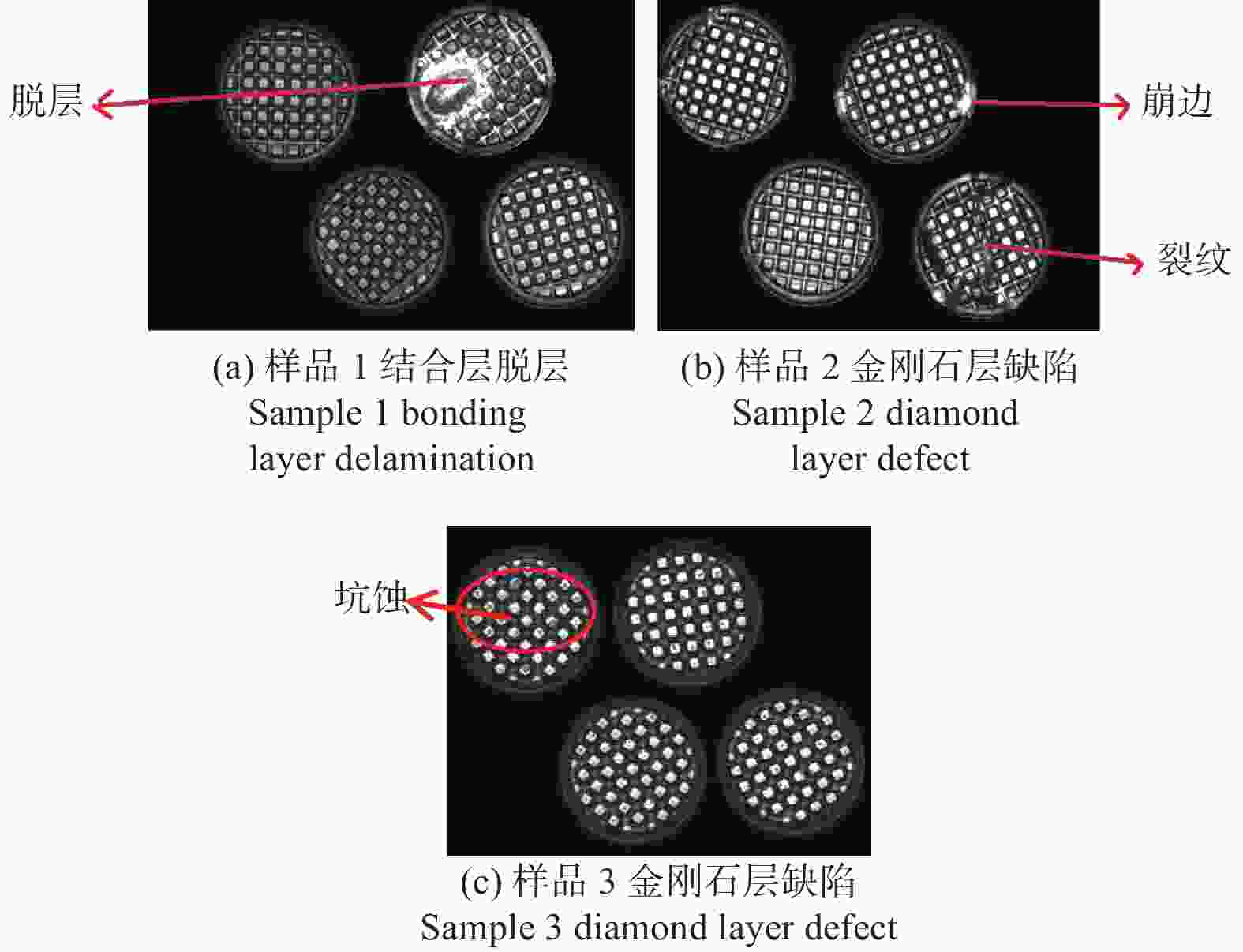

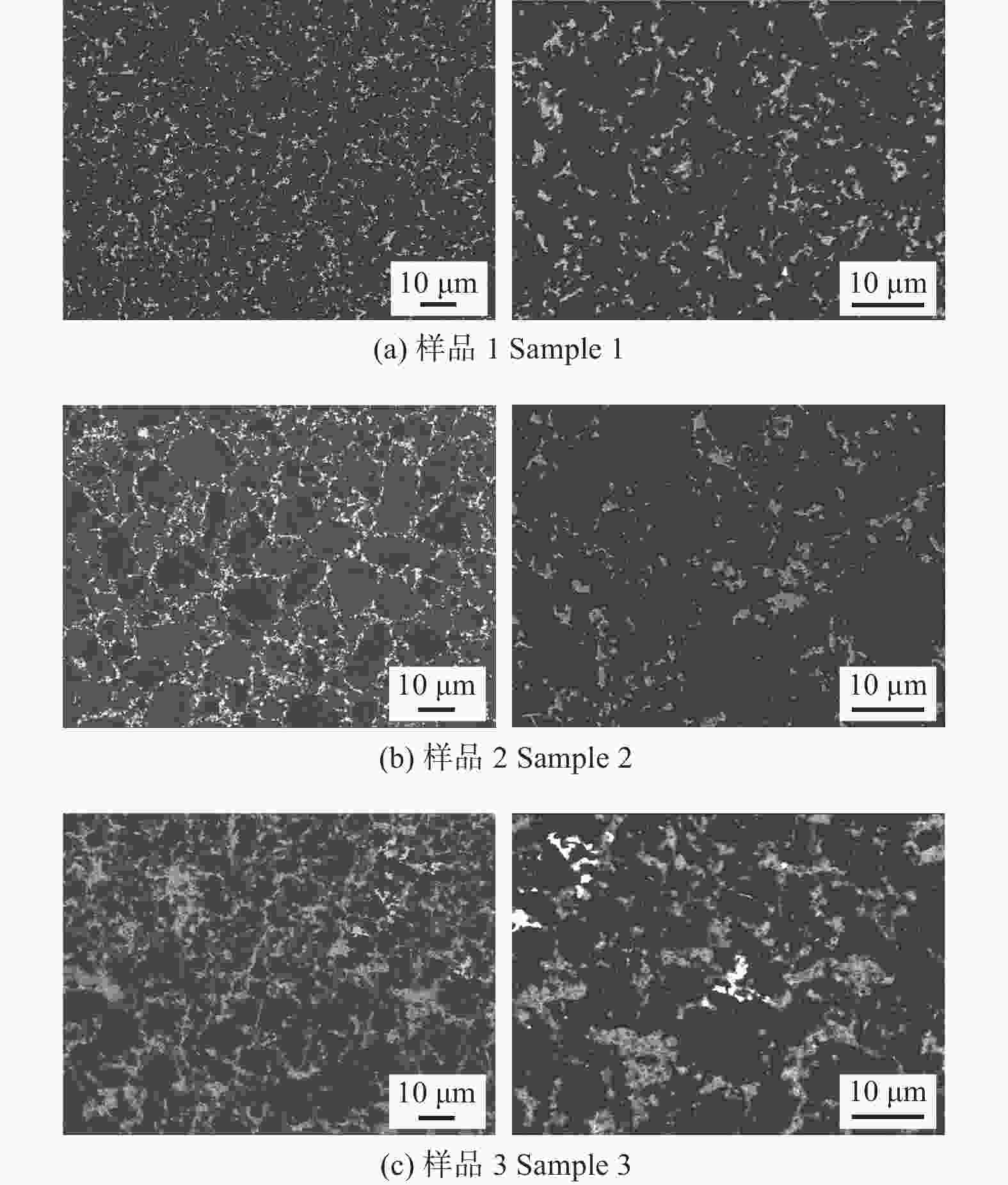

采用上层为细粒度金刚石、下层与硬质合金接触的为粗细度金刚石的分层设计理念,制备钻探用多金刚石层的聚晶金刚石复合片(PDC),对比不同粒度的单层金刚石PDC与多层金刚石PDC的显微组织与性能的差异。利用超声波扫描、扫描电子显微镜(SEM)表征每种PDC的内部缺陷和表面形貌等,并分别对PDC的耐热性、抗冲击性和耐磨性进行测试。结果表明:多层金刚石PDC的综合性能良好,其表层耐磨,下层更耐冲击,且其具有更加均衡的耐热性、抗冲击性和耐磨性。细粒度金刚石层PDC的耐磨性更高,但耐热性和抗冲击性较低,而粗粒度金刚石层PDC的耐热性和抗冲击性能更好,但耐磨性较差。

Abstract:Using the layered design concept of fine-grained diamond in the upper layer and the coarse-fine diamond in contact with the cemented carbide layer in the lower layer, the polycrystalline diamond compact (PDC) with multiple diamond layers for drilling was prepared. The differences in microstructure and performance between the single-layer diamond PDC and the multi-layer diamond PDC with different particle sizes were compared. The internal defects and surface morphology of the PDC were characterized using ultrasonic scanning and scanning electron microscopy (SEM), and the heat resistance, impact resistance and wear resistance of the PDC were tested, respectively. The results show that the comprehensive performance of the multi-layer diamond PDC is good. The surface layer is wear-resistant, while the lower layer is more impact-resistant. The PDC exhibits a more balanced combination of heat resistance, impact resistance and wear resistance. Specifically, the fine-grained diamond layer PDC demonstrates higher wear resistance but lower heat and impact resistance; while the coarse-grained diamond layer PDC exhibits better heat and impact resistance, but poor wear resistance.

-

表 1 3种样品在不同温度下对应的完整片数

Table 1. Number of complete pieces corresponding to three samples at different temperatures

编号 总数量 完整片数 880 ℃ 900 ℃ 910 ℃ 930 ℃ 样品1 4 4 3 2 0 样品2 4 4 4 4 2 样品3 4 4 4 3 2 -

[1] WANG Y, LUI B, SONG J, et al. Study on the wear mechanising of PDC tools in high-milling of Al-Si alloy [J]. Advanced Materials Research,2012,381:16-19. [2] BELLIN F, DOURFAYE A, KING W, et al. The current state of PDC bit part technology [J]. World Oil,2010,231(11):67-71. [3] YAHIAOUI M, GERBAUD L, PARIS J Y, et al. A study on PDC drill bits quality [J]. Wear,2013,298-299:32. doi: 10.1016/j.wear.2012.12.026 [4] 郑安, 梅炳初, 朱教群. 细晶粒金刚石−硬质合金刀具复合片的试制 [J]. 武汉理工大学学报,2004,24(3):9-11. doi: 10.3321/j.issn:1671-4431.2004.03.003ZHENG An, MEI Bingchu, ZHU Jiaoqun. Trial production of fine grain diamond-cemented carbide tool composite sheet [J]. Journal of Wuhan University of Technology,2004,24(3):9-11. doi: 10.3321/j.issn:1671-4431.2004.03.003 [5] 贾洪声, 李彦涛, 王琰弟, 等. 金刚石初始粒径对金刚石聚晶层形貌及表面残余应力的影响 [J]. 超硬材料工程,2010,22(4):67-70. doi: 10.3969/j.issn.1673-1433.2010.04.006JIA Hongsheng, LI Yantao, WANG Yandi, et al. Effect of initial diamond particle size on the morphology and surface residual stress of diamond polycrystalline layer [J]. Superhard Materials Engineering,2010,22(4):67-70. doi: 10.3969/j.issn.1673-1433.2010.04.006 [6] 程斯磊. PDC抗冲击性及耐磨性的测试与研究 [J]. 金刚石与磨料磨具工程,2002(5):41-44. doi: 10.3969/j.issn.1006-852X.2002.05.012CHENG Silei. Test and analysis on the impact toughness and wear-resistance of PCD [J]. Diamond & Abrasives Engineering,2002(5):41-44. doi: 10.3969/j.issn.1006-852X.2002.05.012 [7] 罗德. 聚晶金刚石复合片及其钻头的应用研究 [D]. 武汉: 武汉理工大学, 2010.LUO De. Study on the application of polycrystalline diamond composite and its bit [D]. Wuhan: Wuhan University of Technology, 2010. [8] 王红波, 舒尚文, 孙起昱, 等. 硬岩地层PDC钻头不良工况原因分析与改善措施 [J]. 金刚石与磨料磨具工程,2012,32(189):41-45. doi: 10.13394/j.cnki.jgszz.2012.03.001WANG Hongbo, SHU Shangwen, SUN Qiyu, et al. Cause analysis and improvement measures of poor working conditions of PDC drill bits in hard rock formations [J]. Diamond & Abrasives Engineering,2012,32(189):41-45. doi: 10.13394/j.cnki.jgszz.2012.03.001 [9] 陈晶晶, 孙振亚, 范端, 等. 聚晶金刚石复合片功能的微结构调控研究 [J]. 超硬材料工程,2009,21(6):13-16. doi: 10.3969/j.issn.1673-1433.2009.06.004CHEN Jingjing, SUN Zhenya, FAN Duan, et al. Microstructure regulation of polycrystalline diamond composite sheet function [J]. Superhard Materials Engineering,2009,21(6):13-16. doi: 10.3969/j.issn.1673-1433.2009.06.004 [10] BOVENKERK H P, GLBLER G M. Diamond and cubic boron nitride abrasive compacts using size selective abrasive particles layers: US 4311490 [P]. 1991-02-26. [11] 张健琼, 沈翔, 罗锡裕. 金刚石复合片的微观分析研究 [J]. 金刚石磨料与磨具工程,2011,30(1):100-104.ZHANG Jianqiong, SHEN Xiang, LUO Xiyu. Microscopic analysis of diamond compacts [J]. Diamond & Abrasives Engineering,2011,30(1):100-104. [12] 邵丽华, 王海阔, 徐三魁, 等. 聚晶金刚石的热稳定性研究进展 [J]. 材料导报,2015,29(8):81-84.SHAO Lihua, WANG Haikuo, XU Sankui, et al. Research progress on thermal stability of polycrystalline diamond [J]. Materials Review,2015,29(8):81-84. [13] 黎明发, 张力, 吴永桥, 等. 金刚石复合片的性能检测及发展趋势 [J]. 武汉理工大学学报,2007,29(6):1-4. doi: 10.3321/j.issn:1671-4431.2007.06.001LI Mingfa, ZHANG Li, WU Yongqiao, et al. Performance testing and development trend of diamond compacts [J]. Journal of Wuhan University of Technology,2007,29(6):1-4. doi: 10.3321/j.issn:1671-4431.2007.06.001 [14] DENG J X, ZHANG H, WU Z, et al. Friction and wear behavior of polycrystalline diamond at temperatures up to 700 ℃ [J]. International Journal of Refractory Metals and Hard Materials,2011,29(5):631-638. doi: 10.1016/j.ijrmhm.2011.04.011 [15] 柴津萩, 王光祖. PDC主要特性与应用 [J]. 超硬材料工程,2007,19(5):36-42. doi: 10.3969/j.issn.1673-1433.2007.05.011CHAI Jinqiu, WANG Guangzu. Main characteristics and applications of PDC [J]. Superhard Material Engineering,2007,19(5):36-42. doi: 10.3969/j.issn.1673-1433.2007.05.011 [16] 赵东鹏, 马姗姗, 牛同健, 等. 硬质岩层钻探用曲面聚晶金刚石复合片的性能表征 [J]. 金刚石与磨料磨具工程,2016,36(6):154-160. doi: 10.13394/j.cnki.jgszz.2016.6.0018ZHAO Dongpeng, MA Shanshan, NIU Tongjian, et al. Performance characterization of curved polycrystalline diamond compacts for drilling hard rock formations [J]. Diamond & Abrasives Engineering,2016,36(6):154-160. doi: 10.13394/j.cnki.jgszz.2016.6.0018 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS