| [1] |

柴津萩, 王光祖. PDC的主要特性与应用 [J]. 超硬材料工程,2007,19(5):36-42. doi: 10.3969/j.issn.1673-1433.2007.05.011CHAI Jinqiu, WANG Guangzu. Main characteristics and application of PDC [J]. Superhard Material Engineering,2007,19(5):36-42. doi: 10.3969/j.issn.1673-1433.2007.05.011

|

| [2] |

WANG Y G, LIU B, SONG G Y, et al. Study on the wear mechanism of PCD tools in high-speed milling of Al-Si alloy [J]. Advanced Materials Research, 2012,1557:16-19.

|

| [3] |

YAHIAOUI M, GERBAUD L, PARIS J Y, et al. A study on PDC drill bits quality [J]. Wear,2013,298/299:32-41. doi: 10.1016/j.wear.2012.12.026

|

| [4] |

王照智. 仿生耦合孕镶金刚石钻头耐磨增效机理研究 [D]. 长春: 吉林大学, 2017.WANG Zhaozhi. Study on the mechanism of wear resistance and efficiency increase of bionic coupling impregnated diamond bit[D]. Changchun: Jilin University, 2017.

|

| [5] |

POLIAKOV V P, SKURY A L, ERMOLAEV A A, et al. The influence of refractory particles (Al2O3, TiN) on the mechanical strength of carbonado type synthesized polycrystalline diamonds [J]. Diamond & Related Materials,1998,7(2):422-426.

|

| [6] |

POLIAKOV V P, ERMOLAEV A A, LAPTEV A I, et al. The influence of boron compounds’ particles (TiB2, BN3) on the thermal stability and the mechanical strength of synthesized carbonado after heating [J]. Diamond & Related Materials,2001,10(11):2024-2029.

|

| [7] |

DE AZEVEDO M G, POTEMKIN A, SKURY A L D, et al. The high temperature-high pressure sintering of diamond–Cu–Si–B composite [J]. Diamond & Related Materials,2001,10(9):1607-1611.

|

| [8] |

姜涛, 余大斌, 施文. 非钴基氧化物热电材料研究进展 [J]. 材料科学与工程学报,2009,27(1):107-111.JIANG Tao, YU Dabin, SHI Wen. Researches of non-cobalt-based oxide thermoelectric materials [J]. Journal of Materials Science and Engineering,2009,27(1):107-111.

|

| [9] |

WALMSLEY J C. The microstructure of ultrahard material compacts studied by transmission electron microscopy [J]. Materials Science and Engineering A,1988,105/106:549-553. doi: 10.1016/0025-5416(88)90742-2

|

| [10] |

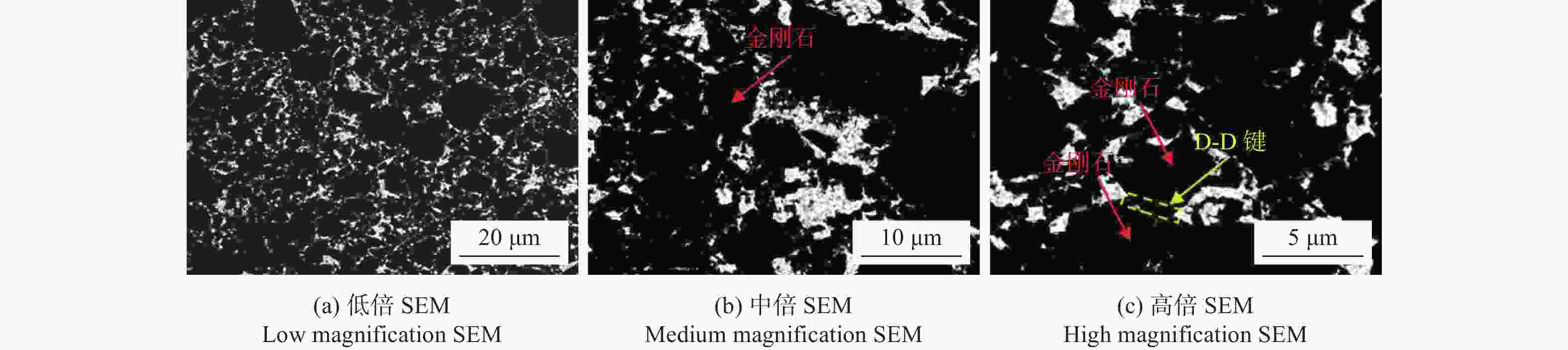

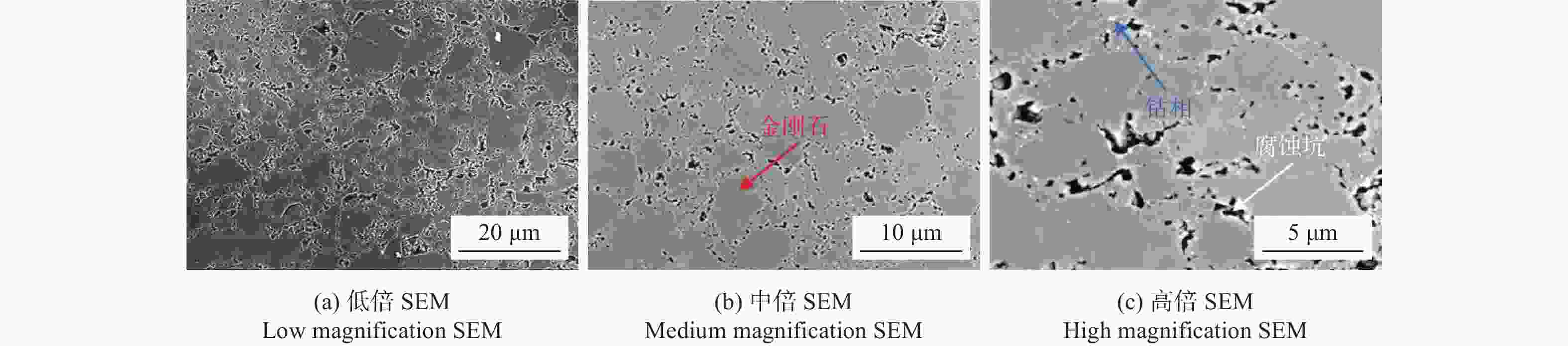

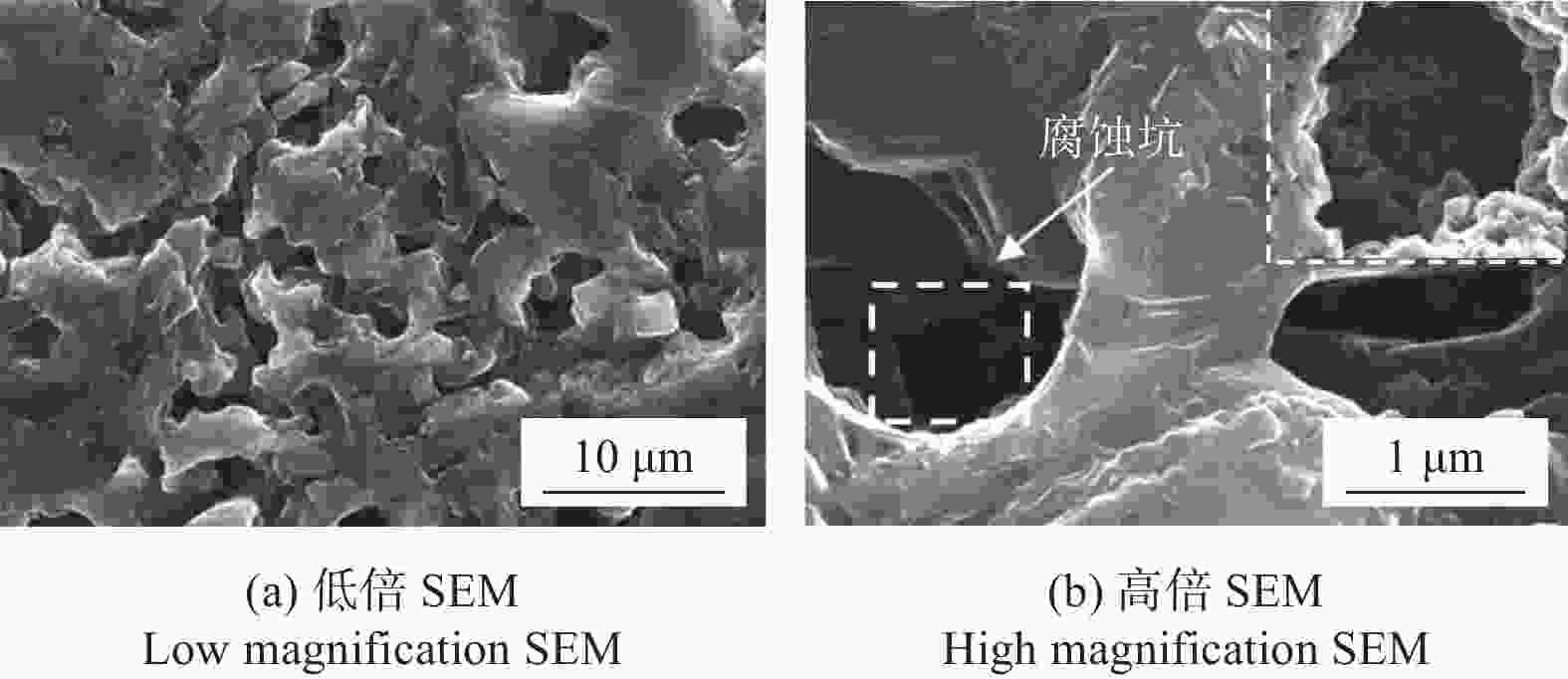

LIU C L, KOU Z L, HE D W, et al. Effect of removing internal residual metallic phases on wear resistance of polycrystalline diamond compacts [J]. International Journal of Refractory Metals and Hard Materials,2012,31:187-191. doi: 10.1016/j.ijrmhm.2011.10.014

|

| [11] |

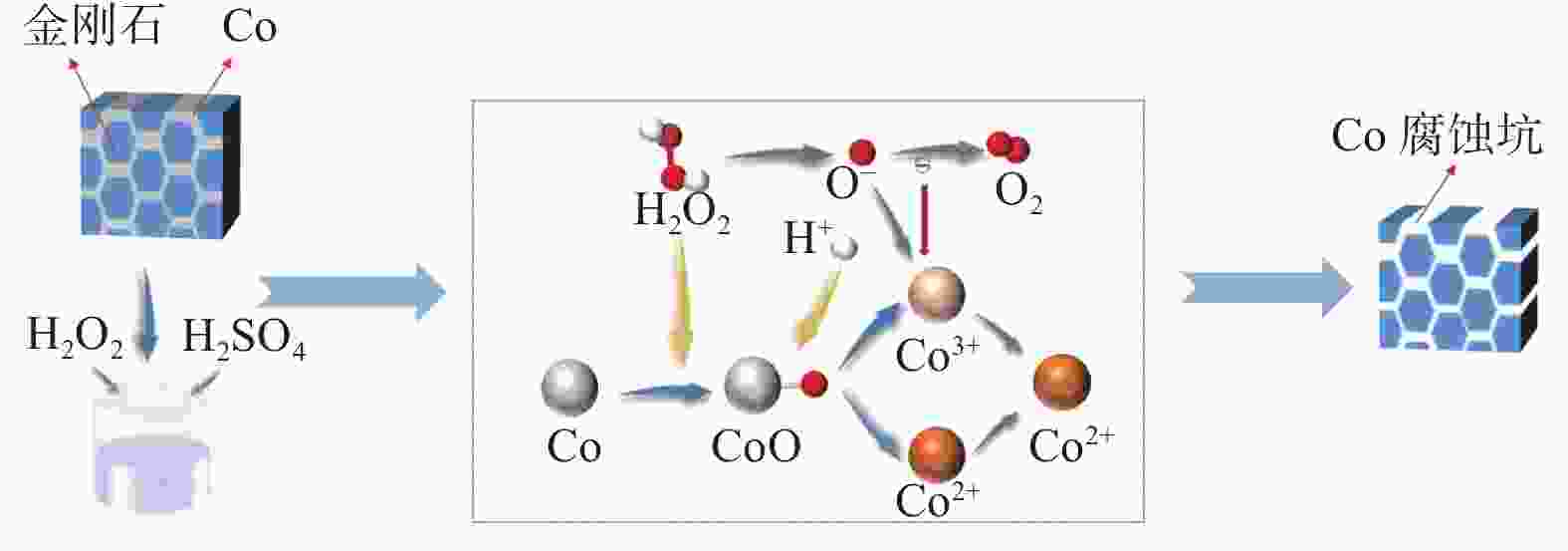

DENG F M, HAO C, DENG W L, et al. Effect of different acid corrosion reagents on de-cobalt effect and performance of PDC at room temperature [J]. Diamond & Related Materials,2020,106:107702-107709.

|

| [12] |

范萍, 薛屺, 易诚, 等. 脱钴对聚晶金刚石热稳定性能的影响 [J]. 材料科学与工程学报,2017,35(1):87-90, 118.FAN Ping, XUE Qi, YI Cheng, et al. Effect of cobalt removal on thermal stability of polycrystalline diamond [J]. Journal of Materials Science and Engineering,2017,35(1):87-90, 118.

|

| [13] |

邵华丽. D-D键合型聚晶金刚石的制备及脱钴技术研究[D]. 郑州: 河南工业大学, 2016SHAO Huali. Preparation of D-D bonded polycrystalline diamond and its cobalt removal technology [D]. Zhengzhou: Henan University of Technology, 2016.

|

| [14] |

CHAKRAVARTHY G V, CHANDRAN M, BHATTACHARYA S S, et al. A comparative study on wear behavior of TiN and diamond coated WC–Co substrates against hypereutectic Al–Si alloys [J]. Applied Surface Science,2012,261:520-527. doi: 10.1016/j.apsusc.2012.08.049

|

| [15] |

杨雄文, 冯枭, 王旭, 等. 金刚石复合片合成材料和工艺研究进展[J]. 超硬材料工程, 2021, 33(6): 34-41.YANG Xiongwen, FENG Xiao, WANG Xu, et al. Research progress in synthetic materials and processes of diamond composite sheets [J] Superhard Materials Engineering, 2021, 33 (6): 34-41.

|

| [16] |

田帅. 立方氮化硼/纳米金刚石多层复合涂层制备及机械性能研究[D]. 南京: 南京航空航天大学, 2020.TIAN Shuai. Preparation and mechanical properties of cubic boron nitride/nano diamond multilayer composite coatings [D] Nanjing: Nanjing University of Aeronautics and Astronautics, 2020.

|

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS