The influence of precision polishing parameters on surface roughness of resin-rich layer on antenna reflective surface

-

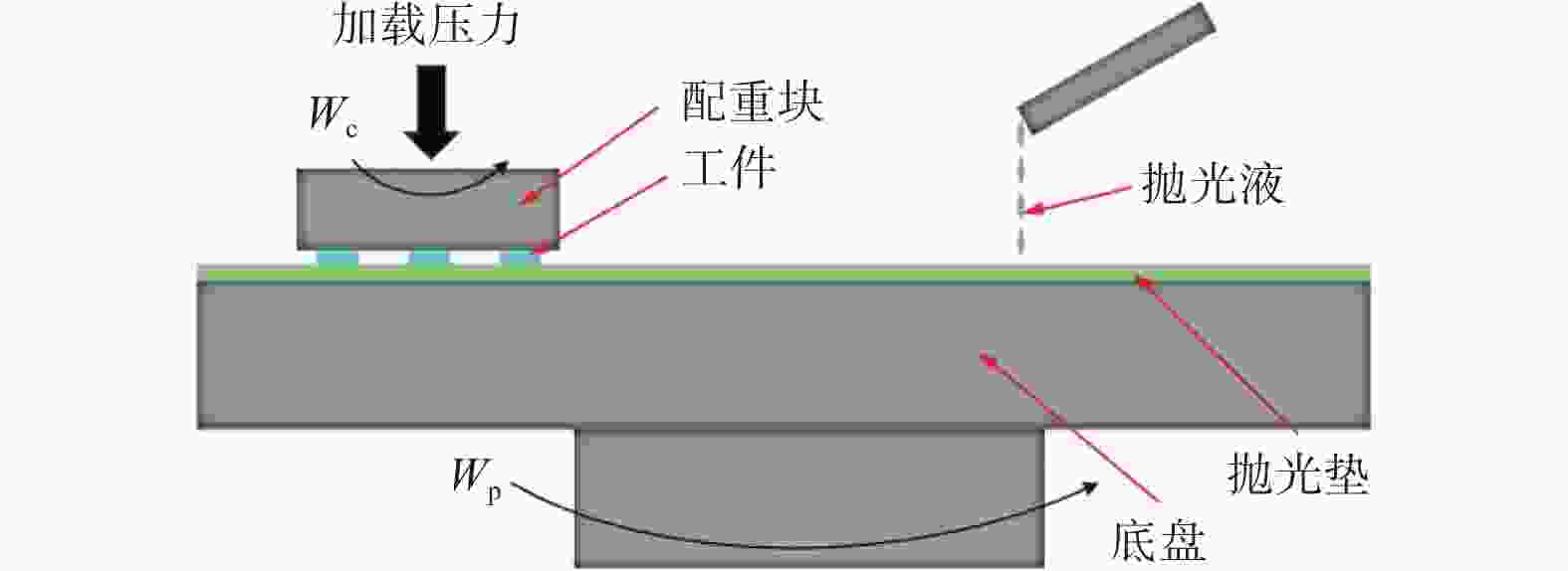

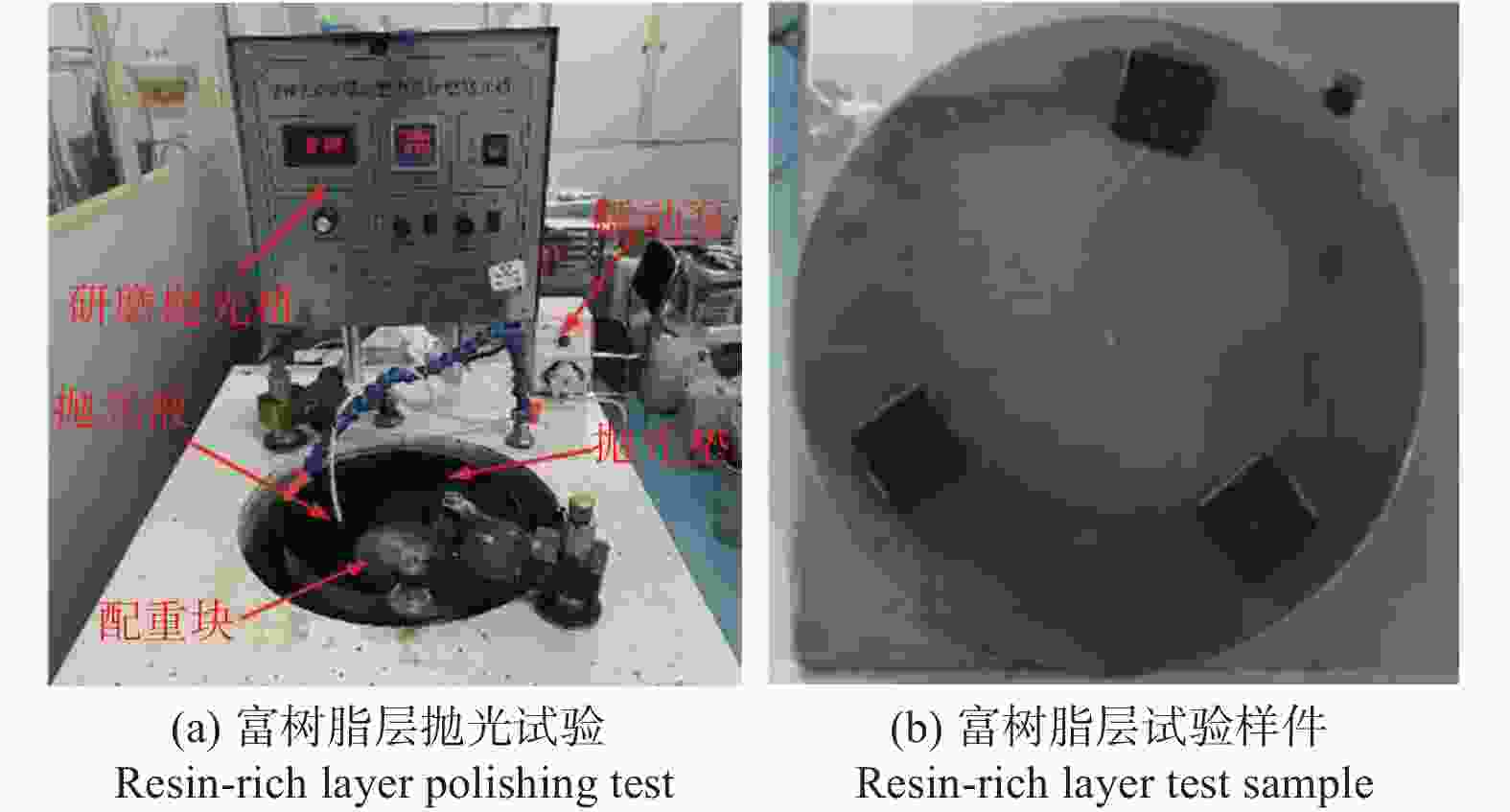

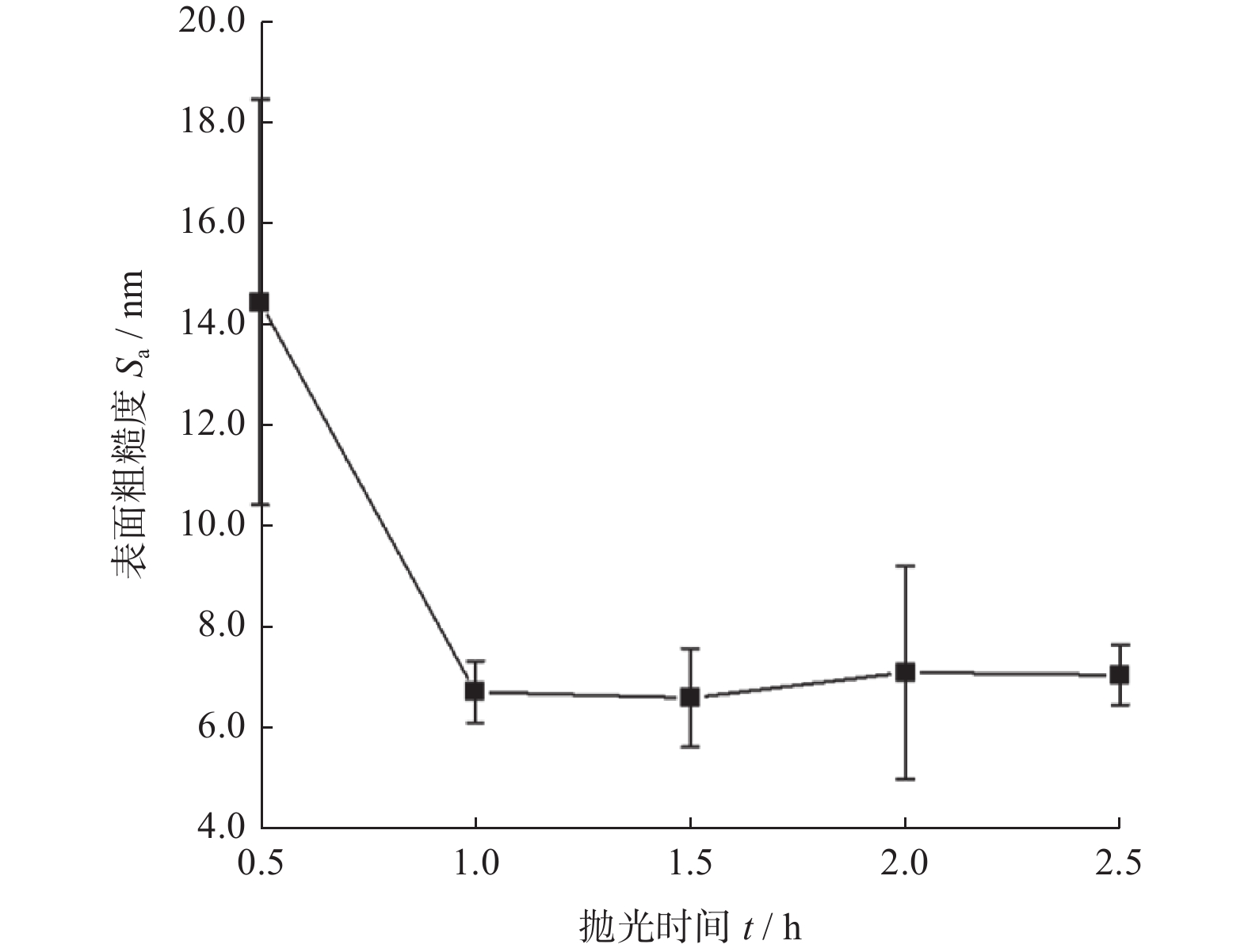

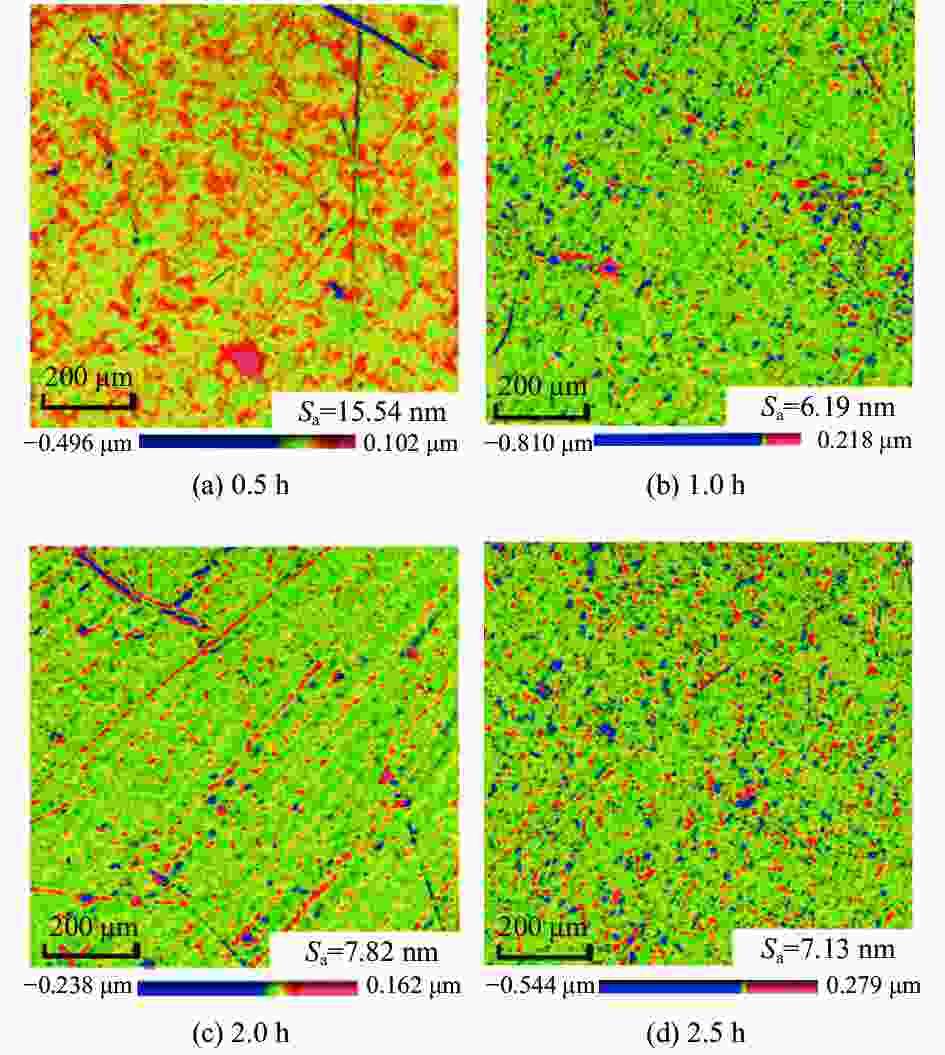

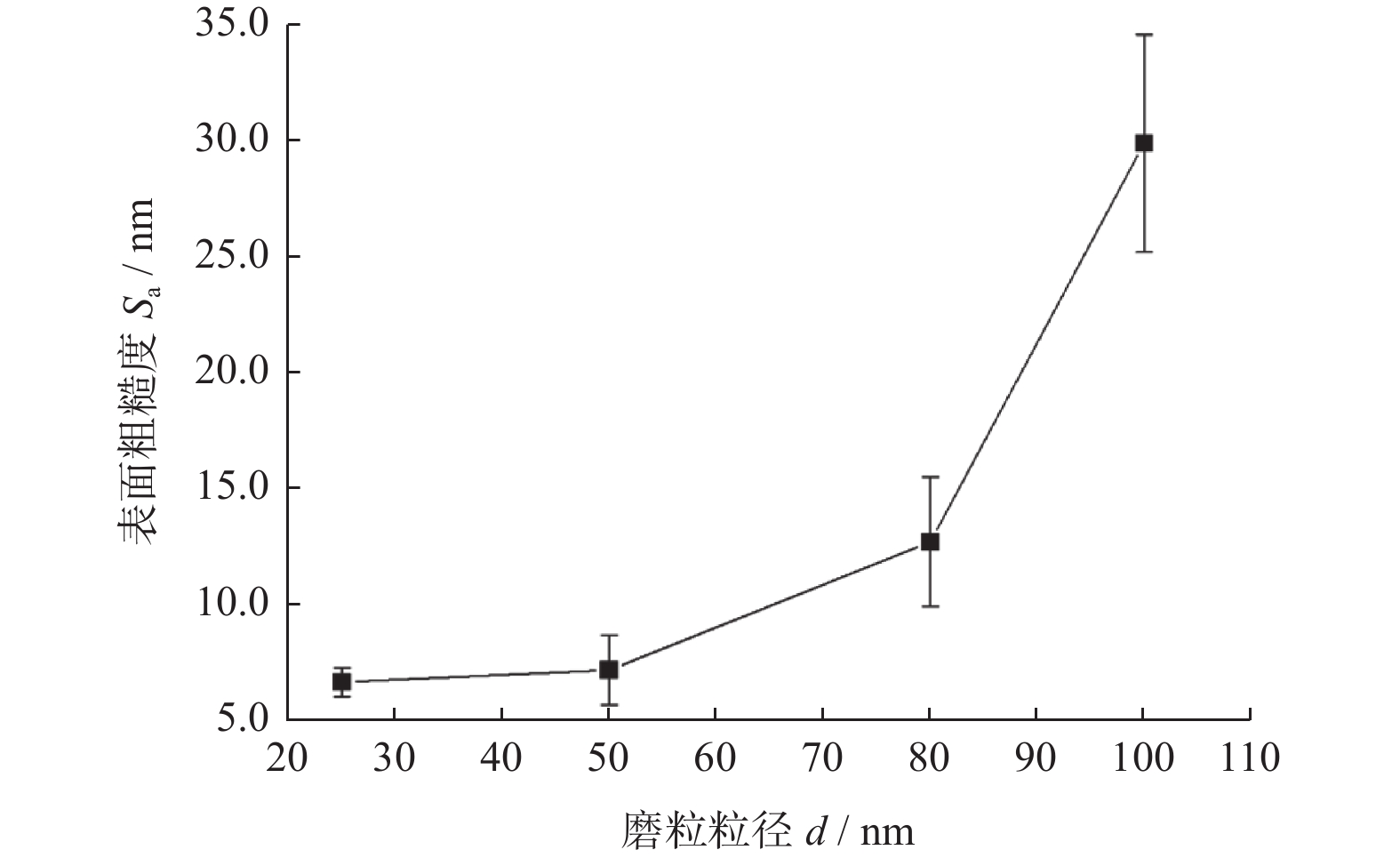

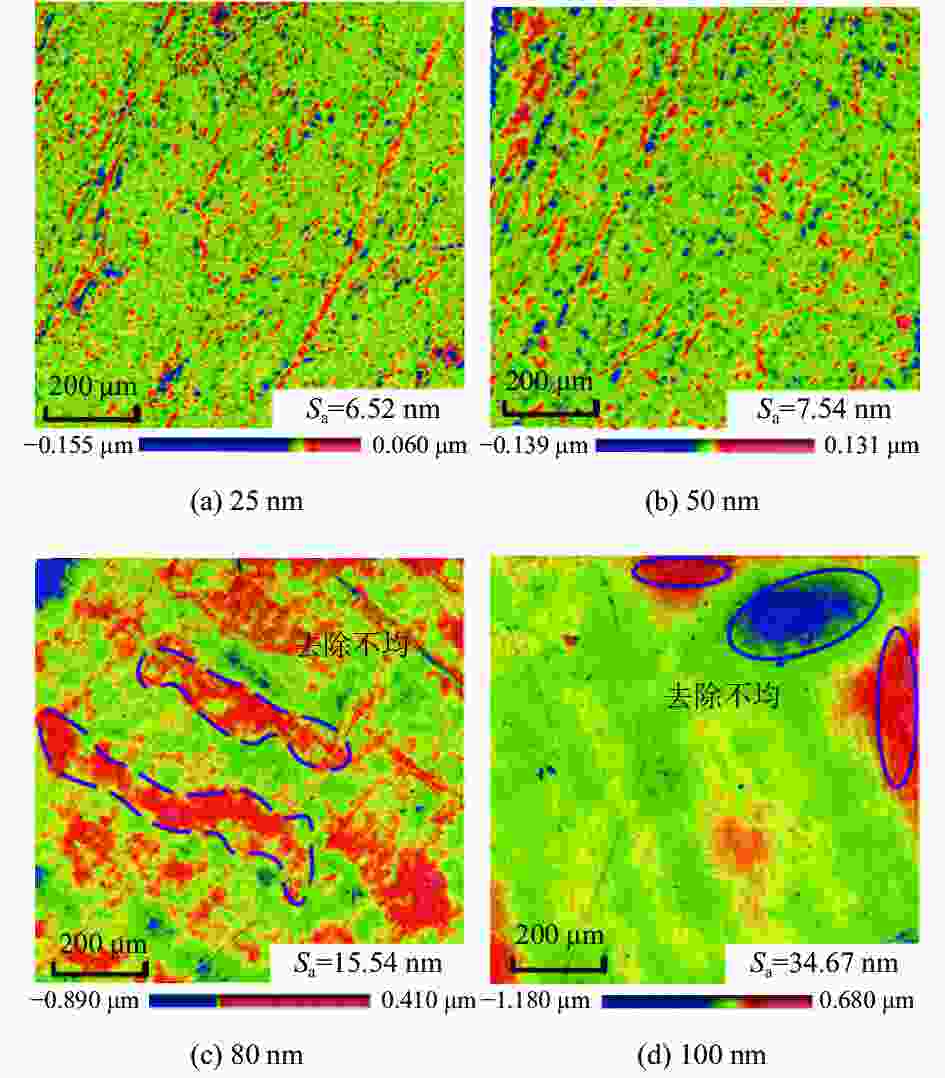

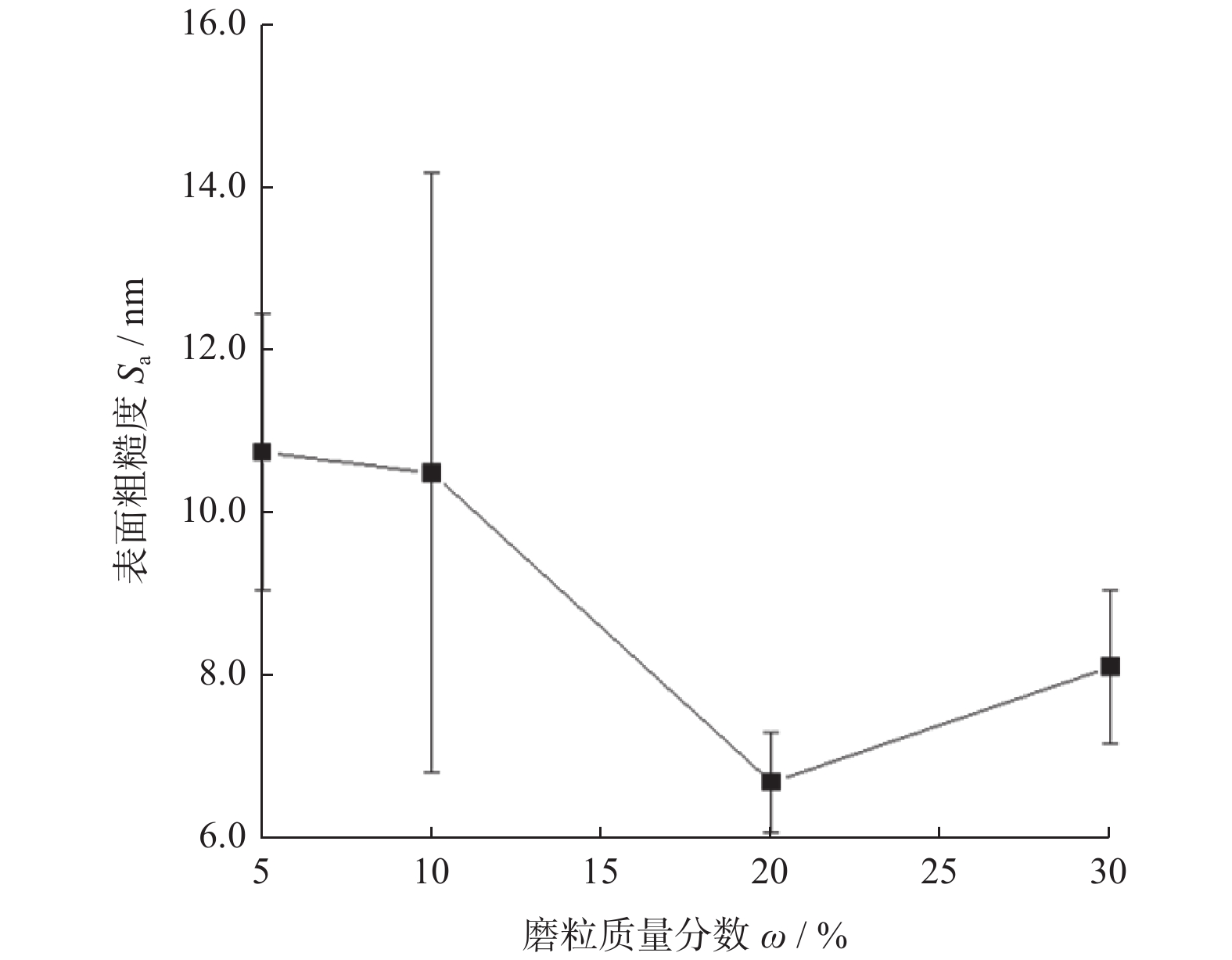

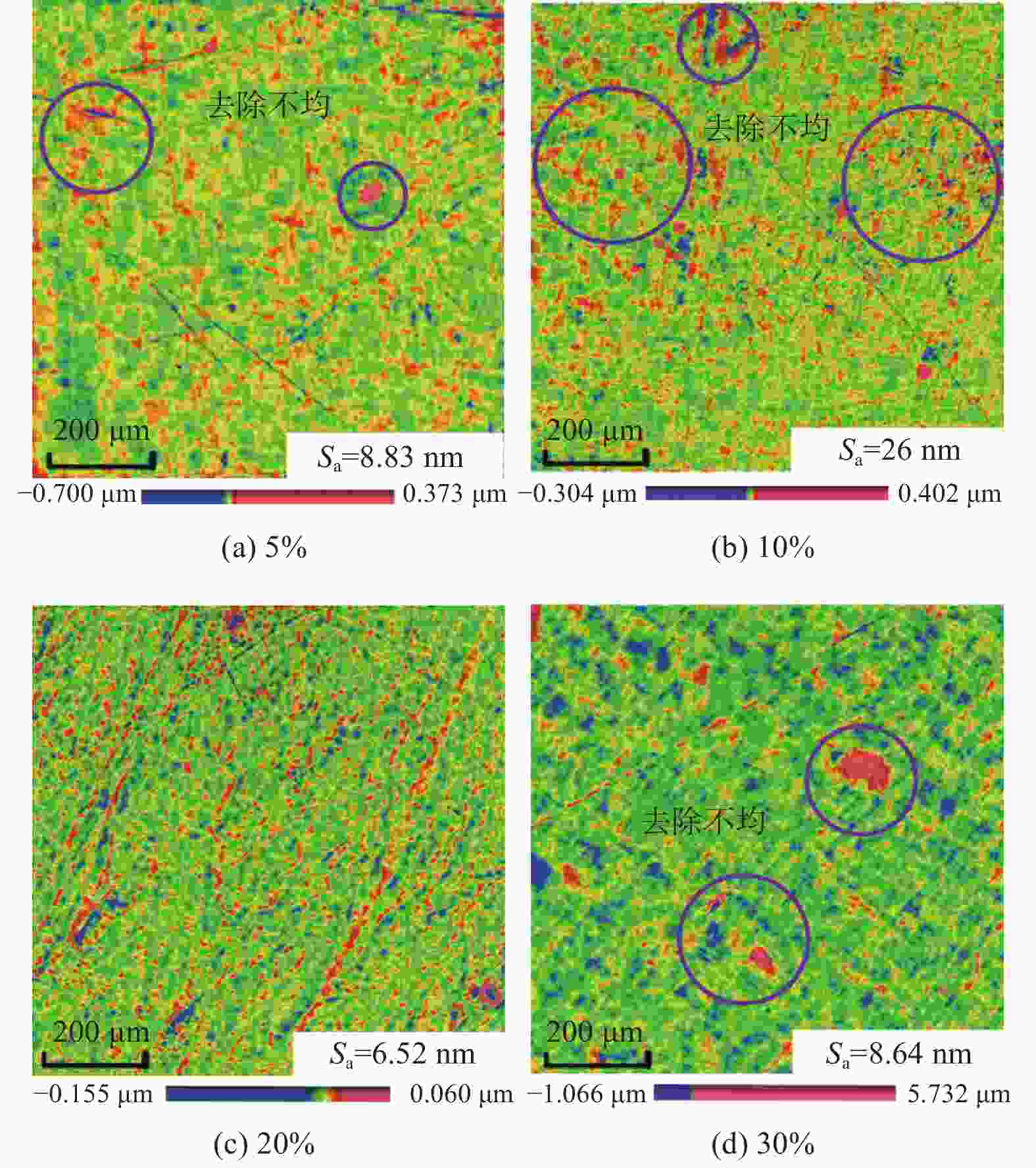

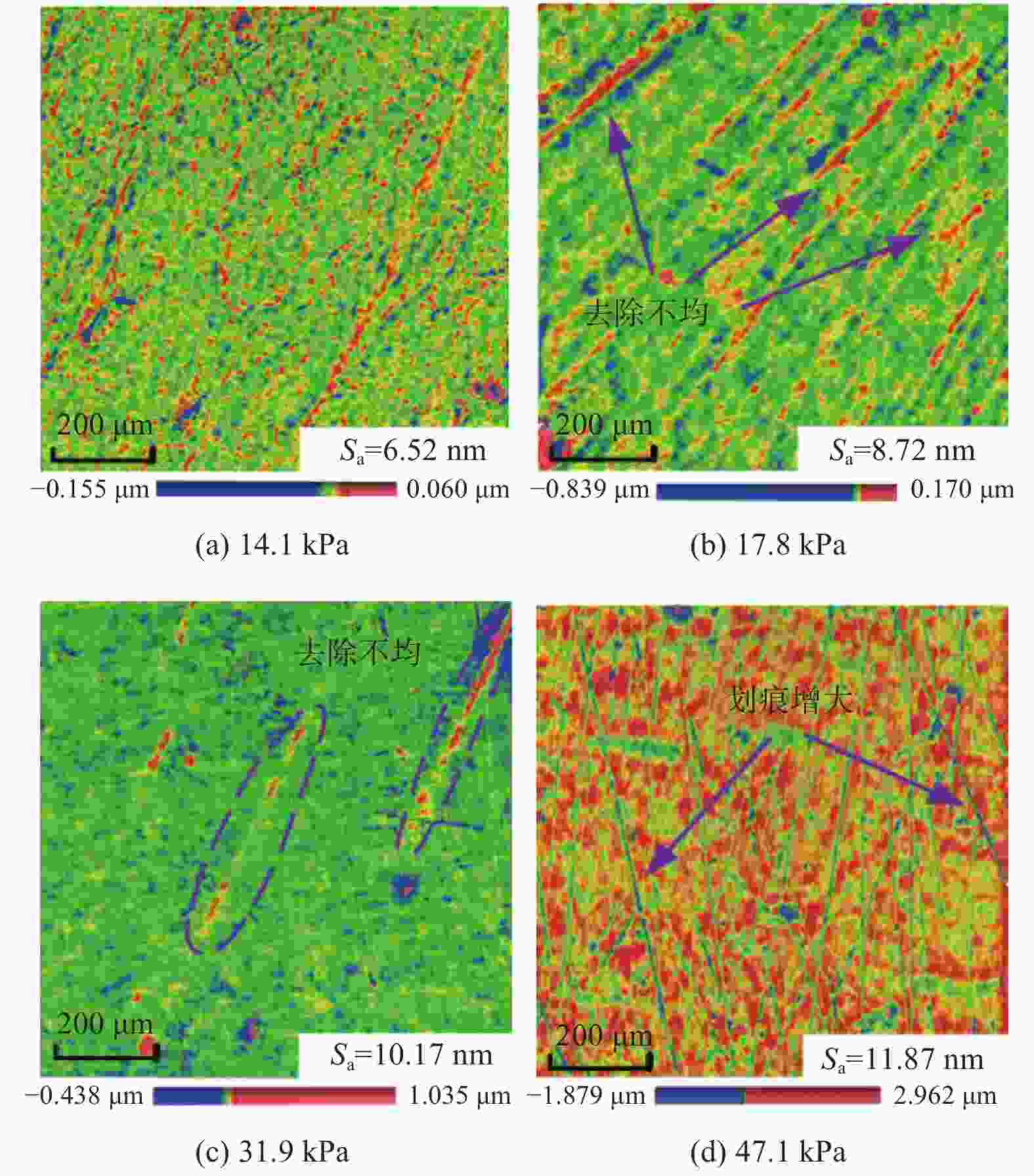

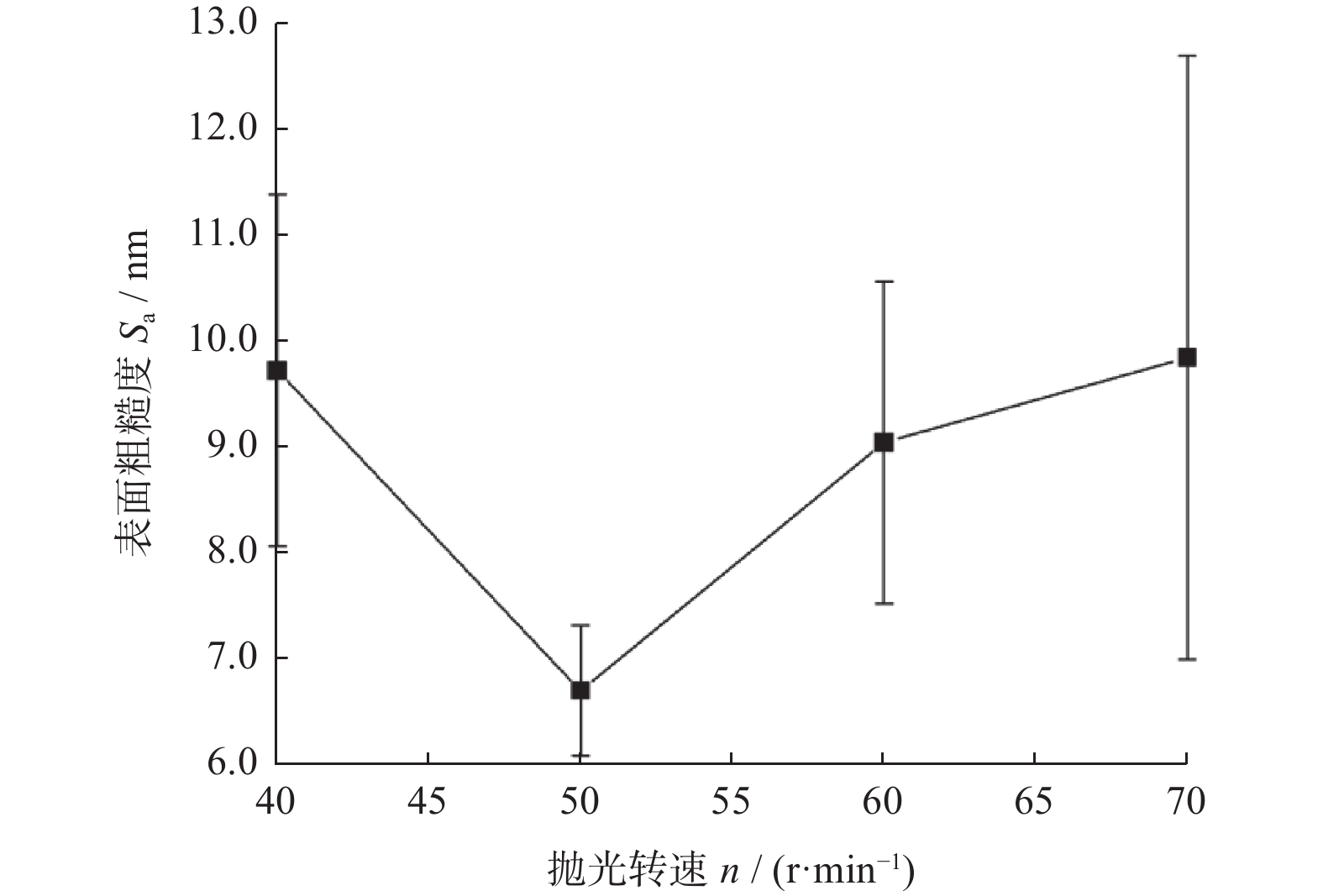

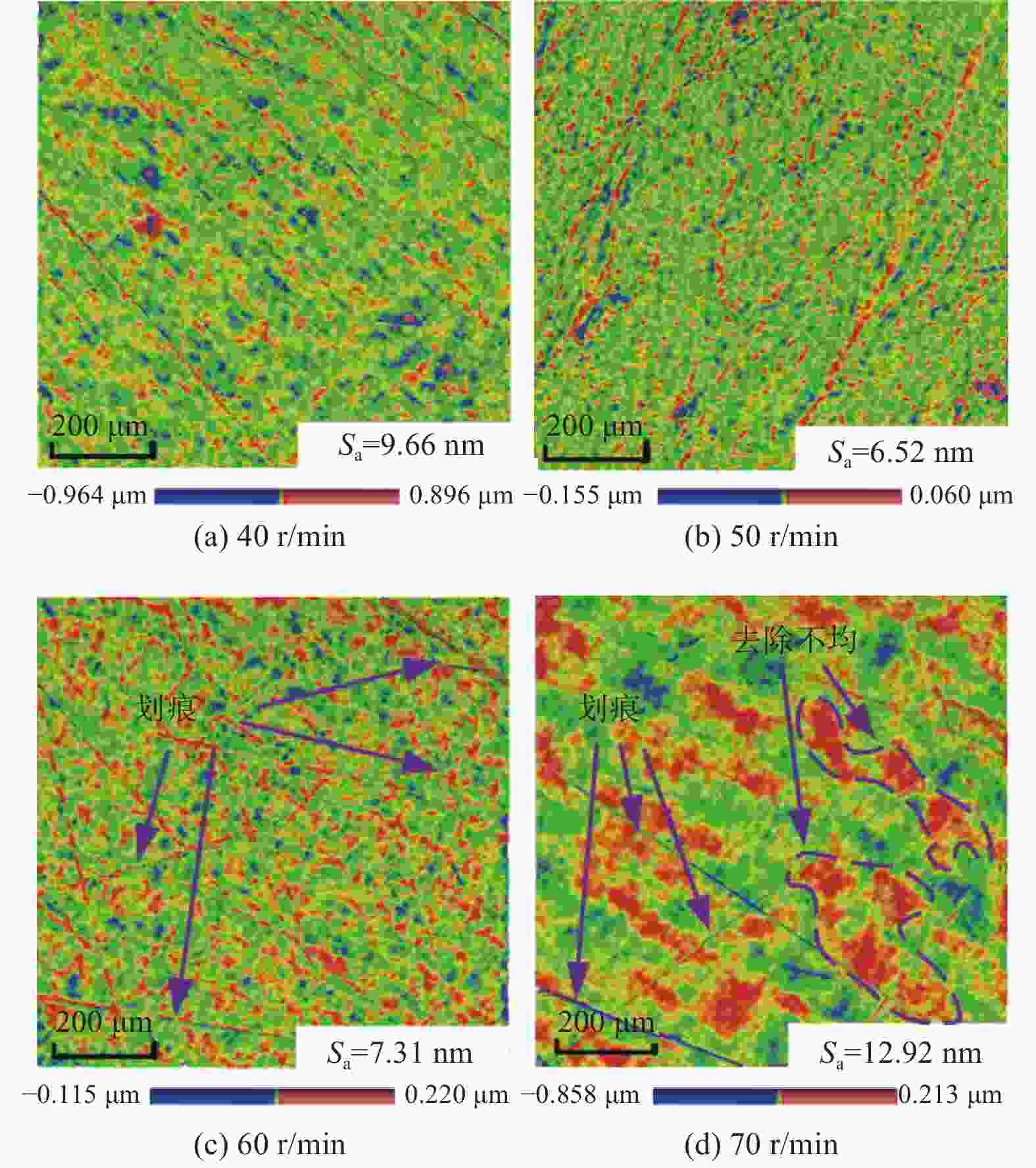

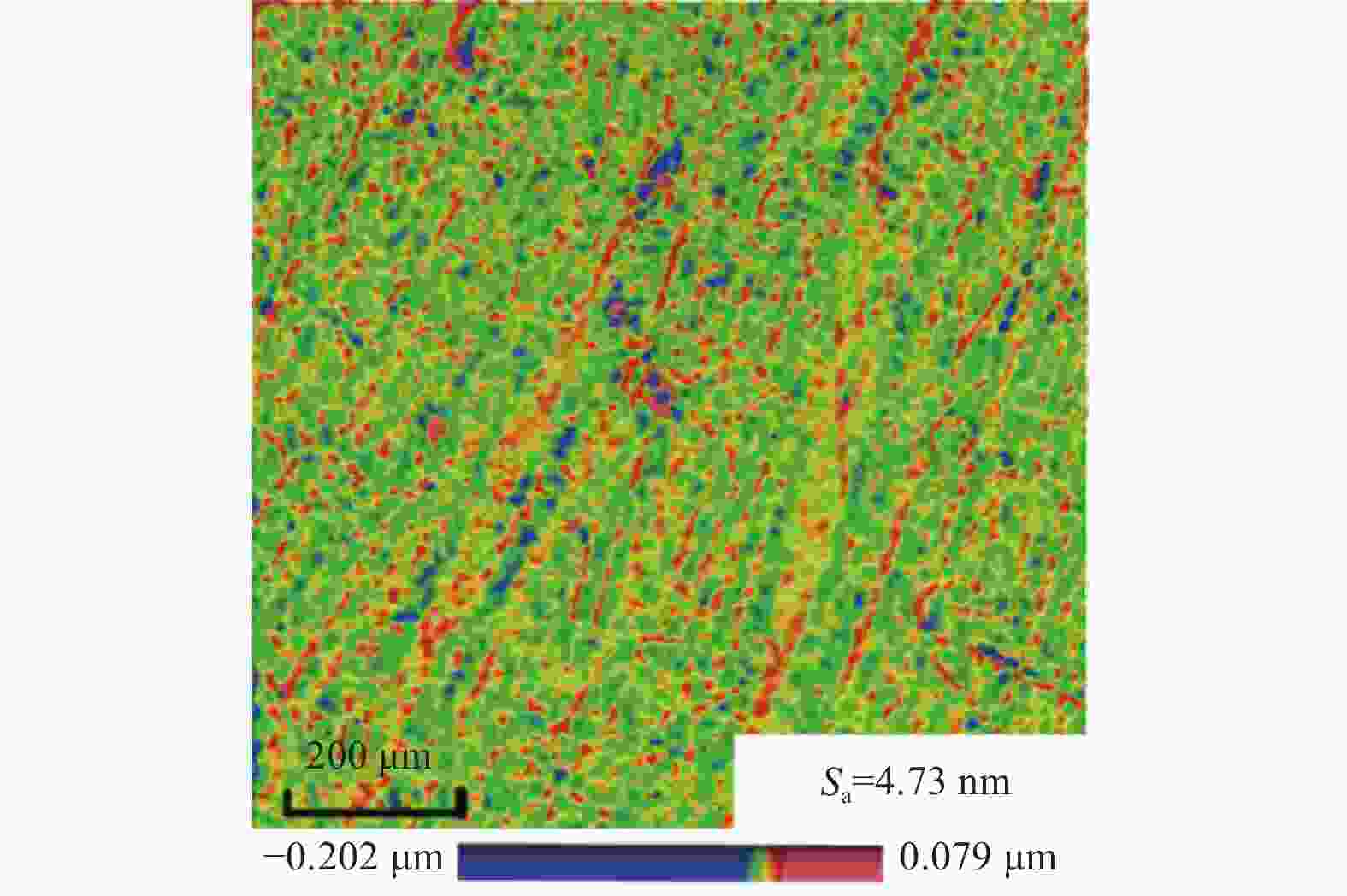

摘要: 针对新一代全碳纤维复合材料天线对反射面表面富树脂层的高质量加工需求,开展富树脂层抛光工艺试验,研究抛光时间、磨粒粒径、磨粒质量分数、加载压力以及抛光转速对富树脂层表面粗糙度的影响规律。结果表明:在当前试验条件下,表面粗糙度随抛光时间的延长先减小后趋于稳定,随着磨粒粒径或加载压力的增大而增大,随磨粒质量分数的升高或抛光转速的增大先减小后增大。在此基础上形成优化工艺参数组合是磨粒粒径为25 nm,磨粒质量分数为20%,加载压力为14.1 kPa,抛光转速为50 r/min,抛光时间为1.0 h,抛光液流量为10 mL/min,用该参数组合加工可获得表面粗糙度Sa为4.73 nm的高质量富树脂层抛光表面。Abstract: The new generation antenna has high-quality processing requirements on the resin-rich layer of the reflecting surface. A polishing experiment on the resin-rich layer was carried out to study the parameters affecting the surface roughness of the layer, namely polishing time, abrasive particle size, abrasive particle mass fraction, loading pressure and polishing speed. The results show that under the current conditions, the surface roughness first decreases and then tends to be stable with the increase of polishing time. It increases with the increase of the abrasive particle size or the loading pressure, and first decreases and then increases with the increase of the abrasive particle mass fraction or the polishing speed. On this basis, an optimized process parameter combination is formed, which includes an abrasive size of 25 nm, an abrasive particle mass fraction of 20%, a loading pressure of 14.1 kPa, a polishing speed of 50 r/min, a polishing time of 1.0 hours, and a slurry flow rate of 10 mL/min. A high-quality resin rich layer polished surface with a surface roughness Sa of 4.73 nm can be obtained by machining with this parameter combination.

-

Key words:

- epoxy resin /

- polishing /

- surface roughness /

- process parameters

-

表 1 富树脂层抛光试验工艺参数

Table 1. Process parameters of resin-rich layer polishing test

试验因素 数值 抛光磨粒粒径 d / nm 25, 50, 80, 100 磨粒质量分数 ω / % 5, 10, 20, 30 抛光液流量 l / (mL·min−1) 10 加载压力 p / kPa 14.1, 17.8, 31.9, 47.1 抛光转速 n / (r·min−1) 40, 50, 60, 70 抛光时间 t / h 0.5, 1.0, 1.5, 2.0, 2.5 -

[1] 杨智勇, 张博明, 解永杰, 等. 碳纤维复合材料空间反射镜制造技术研究进展 [J]. 复合材料学报,2017,34(1):1-11.YANG Zhiyong, ZHANG Boming, XIE Yongjie, et al. Research progress on fabrication technology of space mirror using carbon fiber composite [J]. Acta Materiae Compositae Sinica,2017,34(1):1-11. [2] OHASHI T. Development of CFRP mirrors for low-temperature application of satellite telescopes [J]. Physica Status Solidi, 2012, 201(1): 21-30. [3] 吴楠, 郝旭峰, 史耀辉, 等. 高精度碳纤维增强树脂复合材料夹层天线面板热变形影响参数仿真与实验 [J]. 复合材料学报,2020,37(7):1619-1628.WU Nan, HAO Xufeng, SHI Yaohui, et al. Simulation and experiment on thermal deformation influence parameters of high accuracy carbon fiber reinforced plastic sandwiched antenna panels [J]. Acta Materiae Compositae Sinica,2020,37(7):1619-1628. [4] QIAN Y, HAO X, SHI Y, et al. Deformation behavior of high accuracy carbon fiber-reinforced plastics sandwiched panels at low temperature [J]. Journal of Astronomical Telescopes, Instruments, and Systems,2019,5(3):1. doi: 10.1117/1.JATIS.5.3.034003 [5] 郜广磊. 碳纤维复合材料超声辅助钻削分层损伤研究 [D]. 武汉: 武汉理工大学, 2019.GAO Guanglei. Study on delamination damage of fiber-reinforced plastics by ultrasonic-assisted drilling [D]. Wuhan: Wuhan University of Technology, 2019. [6] 林晨, 许永超. 单晶蓝宝石衬底磨粒抛光技术研究现状 [J]. 福建工程学院学报,2021,19(3):216-222. doi: 10.3969/j.issn.1672-4348.2021.03.003LIN Chen, XU Yongchao. Research status of abrasive polishing technology for single crystal sapphire substrate [J]. Journal of Fujian University of Technology,2021,19(3):216-222. doi: 10.3969/j.issn.1672-4348.2021.03.003 [7] NAIR V S, SAINUDEEN S, PADMANABHAN P, et al. Three-dimensional evaluation of surface roughness of resin composites after finishing and polishing [J]. Journal of Conservative Dentistry,2016,19(1):91-95. doi: 10.4103/0972-0707.173208 [8] 王丹凤, 庄少敏. 3种抛光方法对树脂表面粗糙度影响的比较 [J]. 口腔疾病防治,2014,22(3):134-138.WANG Danfeng, ZHUANG Shaomin. Effects of three polishing methods on surface roughness of composite resin [J]. Journal of Prevention and Treatment for Stomatological Diseases,2014,22(3):134-138. [9] 刘亚男, 王立凯, 刘思思, 等. 3种抛光系统对可切削复合树脂抛光效果的比较 [J]. 口腔疾病防治,2019,27(7):441-445.LIU Yanan, WANG Likai, LIU Sisi, et al. Comparison of polishing effects of three polishing systems on machinable composite resins [J]. Journal of Prevention and Treatment for Stomatological Diseases,2019,27(7):441-445. [10] HALIM N F, SOARES D M T F, DRUMOND N H, et al. Surface roughness of composite resins after finishing and polishing [J]. Brazilian Dental Journal, 2003, 14(1): 37-41. [11] 郭剑苓, 徐莹, 牛玉梅, 等. 不同砂粒粒径抛光碟对复合树脂抛光效果的影响 [J]. 口腔医学,2017,37(4):311-314.GUO Jianling, XU Ying, NIU Yumei, et al. Effect of different particle sizes of polishing disc on surface roughness and bacterial adherence of composite resin [J]. Stomatology,2017,37(4):311-314. [12] 刘锋伟, 吴永前, 陈强, 等. 大口径光学非球面镜先进制造技术概述 [J]. 光电工程,2020,47(10):65-87.LIU Fengwei, WU Yongqian, CNEN Qiang, et al. Overview of advanced manufacturing technology of large-aperture aspheric mirror [J]. Opto-Electronic Engineering,2020,47(10):65-87. [13] 宋月贤, 李胜蓝, 黎清健, 等. 圆光栅玻璃的游离磨料研磨抛光加工工艺 [J]. 金刚石与磨料磨具工程,2014,34(3):52-56.SONG Yuexian, LI Shenglan, LI Qingjian, et al. Lapping and polishing of circular grating glass with free abrasive [J]. Diamond & Abrasives Engineering,2014,34(3):52-56. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS